Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

CANCAM 2003 [Proceedings], pp. 312-313, 2003-06-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=8ce68140-d94b-4983-8a1a-d46cffae49ee https://publications-cnrc.canada.ca/fra/voir/objet/?id=8ce68140-d94b-4983-8a1a-d46cffae49ee

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Grain crushing in sand-structure problems

Grain crushing in sand-structure problems

Zeghal, M.; Edil, T.B.

NRCC-39818

A version of this document is published in / Une version de ce document se trouve dans: CANCAM 2003, Calgary, Alberta, June 1-6, 2003, pp. 312-313

GRAIN CRUSHING IN SAND-STRUCTURE PROBLEMS

Morched Zeghal

1and Tuncer B. Edil

21

Institute for Research in Construction, National Research Council Canada, Ottawa, Ontario, K1A 0R6

2Department of Civil & Environmental Engineering, University of Wisconsin-Madison, USA, 53706

Existence of grain crushing

The results of modified direct shear tests provided by Hoteit (1990) were analyzed to confirm the existence of crushing and to evaluate the extent of its effect. Hoteit conducted an extensive experimental program on both loose and dense Quiou sand from Bretagne, France, at two initial confining pressures, 100 and 350 kPa, at the Institut National Polytechnique de Grenoble. Quiou sand is a uniform (Cu =

9.4) and calcareous sand with a mean grain size of 0.40 mm and an effective grain size of 0.05 mm. Also, he performed tests for constant stress and for constant volume stress paths. Hoteit measured the grain size distribution prior to the test and monitored its change during the shear test. The data were analyzed using the breakage factor defined by Lee and Farhoomand (1967). They evaluated the amount of crushing by defining the ratioD15i/D15f whereD15i is the diameter corresponding to 15% finer before shearing andD15fis the diameter still corresponding to 15% finer but after shearing occurred. The analysis done using bothD10 and D50suggests that using the ratioD50i /D50fis more suitable to describe crushing. Figure 1 shows the variation of the breakage factor as a function of the plastic work (at the end of shear tests) usingD50. The data is more scattered in the case of D10. This is explained by the small quantity, which makes it very sensitive to change.

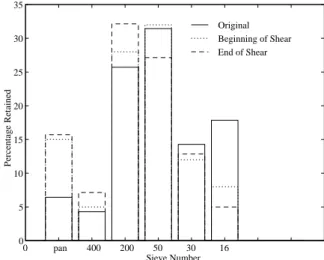

Figure 2, showing the percentage retained by each sieve, clearly supports that the bigger grains are crushing first (reflected in the curve corresponding to the beginning of shear) and crushing the most (curve at the end of shear). Figure 3 shows crushing occurs for loose and dense sand; for both high (350 kPa) and low (100 kPa) confining pressures; and for both stress paths (constant stress and constant volume). This suggests that the amount of crushing can be assumed to be independent of the stress path and initial confining pressure but, it is clearly a function of the plastic work. Of course, plastic work is not solely due to

grain crushing and there are other significant mechanisms that contribute to plastic work; however, it seems that empirical data show that the degree of grain crushing is remarkably well correlated to plastic work (Figure 3). More significantly, the relationship appears to be independent of the direct shear stress path taken, i.e., constant normal stress or constant volume providing a basis for a unified formulation.

Figure 1. Breakage factor for calcareous sand based on D50

versus plastic work at the end of test

Figure 2. Breakage analysis-calcareous sand

2000 3000 4000 5000 6000 7000 8000 1.15 1.2 1.25 1.3 1.35 1.4 1.45 1.5 1.55

Plastic Work [kPa.mm]

Breakage Factor (D50i/D50f)

0 pan 400 200 50 30 16 0 5 10 15 20 25 30 35 Sieve Number Percentage Retained Original Beginning of Shear End of Shear

Figure 3. Breakage factor versus plastic work for calcareous sand (CS: constant stress test and CV: constant volume test)

Coefficient of mobilised friction as a function of plastic work

Figure 4 shows the normalised shear stress as a function of total plastic work (used as an index of grain crushing and other plastic mechanisms) for the experimental data provided by Sengara (1991). It shows that the curve for constant stress and constant volume for the same initial confining pressure coincide even though the constant volume curve continues as a constant function of plastic work beyond the termination of the constant stress curve. The same observations were noted when the analysis was extended for the calcareous sand.

Figure 4. Normalised shear stress versus plastic work for Silica sand (CS: constant stress test and CV: constant volume test).

Experimental evidence from two different sources supports the idea of a changing coefficient of mobilized friction during the interface shear. The idea of changing the coefficient of mobilized friction as a function of the plastic work appears to be reasonable and is backed by the experimental data. The curves showing the change of the coefficient of friction as a function of plastic work appear very similar to the widely used hyperbolic model used in soil mechanics i.e.

where, a and b are two parameters related to the initial slope and the asymptotic limit of the above curves. These parameters can be obtained as the intercept and the slope of a plot of the ratio of plastic work to normalised shear stress versus plastic work.

Conclusions

Analysis of direct shear test data for two different sands (calcareous and Silica) confirmed that grain crushing occurs independently of the direct shear path taken (constant normal stress or constant volume tests). It also revealed a close correlation between mobilized coefficient of friction and plastic work, which can be used as an index of the amount of grain crushing.

References

[1] N. Hoteit: "Contribution à l’Étude du Comportement d' Interface Sable-Inclusion et Application au Frottement Apparent", Doctorate thesis, Institut National Polytechnique de Grenoble, France (1990). [2] K. L. Lee., and I. Farhoomand: "Compressibility and

Crushing of Granular Soils in Anisotropic Triaxial Compression", Canadian Geotechnical Journal, Vol. 4, No. 1, pp 68-100 (1967).

[3] I. W. Sengara: "Finite Element and Experimental Study of Soil-Structure Interfaces", Ph.D. thesis, University of Wisconsin-Madison, Department of Civil and Environmental Engineering (1991).23 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0 100 200 300 400 500 600

Plastic Work [kPa.mm]

Normalized Shear Stress

CV at 35 kPa CV at 69 kPa CV at 138 kPa CS at 35 kPa CS at 69 kPa CS at 138 kPa p p bW a W + = µ 0 1000 2000 3000 4000 5000 6000 7000 8000 9000 1 1.05 1.1 1.15 1.2 1.25 1.3 1.35 1.4 1.45 1.5 CV at 350 kPa (loose) CV at 350 kPa (dense) CV at 100 kPa (loose) CV at 100 kPa (dense) CS at 350 kPa (loose) CS at 350 kPa (dense) CS at 100 kPa (loose) CS at 100 kPa (dense)

Plastic Work [kPa.mm]