Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-1014, 1981-10

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=10161755-c6cc-4ca7-82df-87087444990c

https://publications-cnrc.canada.ca/fra/voir/objet/?id=10161755-c6cc-4ca7-82df-87087444990c

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001780

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Canadian programs relating to plastics in the built environment - a

summary review

National Research Council of Canada Conseil national de recherches du Canada -.-- -- -\

Ser

TH1

N21d

- 'BLDG

.+.I -. . l l , ; : \CANADIAN PROGRAMS RELATING TO PLASTICS I N

THE BUILT ENVtRONMENT

-

A SUMMARY REVIEW

By

K. Sumi

and

W. Taylor

ANALYZED

Reprinted f r m Journal of FIRE and FLAMMABILITY, Vol. 1 2 (October 1981 )

P. 258265

DBR Paper No. 1014

Division of

Building

Research

Price

$1.25

OTTAWA

N RCC 19849

5/57/60

SOMMAIRE

On donne u n apersu des programme canadiens de recherche sur la

lutte contre les incendies ayant trait a I'emploi des plastiques en

Gtiment. O n ddcrit deux projets (mends grsce

a

une bourse de

I

recherche administrde par la SPI d u Canada e t le Conseil national de

recherche) d'dtude des p r o b l h e s relatifs la propagation d u feu par

les tuyaux de plastique

a

travers de cloisons coupe-feu et

a

la

propagation d u feu dans les murs creux renfermant de la mousse de

plastique. L'apersu fait dgalement mention de I'essai en soufflerie

S t einer de determination de I'inf lammabilitd des plastiques, de

I'dvaluation & la toxicitd des fumdes e t de certaines expdriences

grandeur k l l e pour une nouvelle station sur le terrain.

National Research Council of Canada Division of Building Research Ottawa, Ontario K 1A OR6 Canada

CANADIAN PROGRAMS RELATING TO PLASTICS I N THE

BUILT ENVIRONMENT

-

A SUMMARY REVIEW

Manuscript received May 11, 1981 Manuscript accepted August 20, 1981

ABSTRACT: Fire research programs in Canada relating t o plastics in the built environment are reviewed. The paper describes t w o projects (con- ducted under a Research Fellowship sponsored jointly by SPI o f Canada and the National Research Council) in which the problems concerned with the penetration of fire separations by plastic pipe and the spread of fire in cavity walls containing foam plastics were investigated. I t also deals w i t h the modifications made t o the Steiner Tunnel test when used t o assess flammability o f plastics, evaluation of toxicity o f fire effluents and some full-scale experiments planned for a new field station.

INTRODUCTION

P

LASTICS A R E USED today in a wide range of applications both as construction materials and in building contents such as furniture and furnishings. Because these materials are organic and therefore combustible, their use has been scr~ltinized over the years by regulatory authorities to ensure that an acceptable level of fire safety i s being maintained.One of the results of the increasing use of plastics in the built environment has been the initiation of a Plastics lndustry Fellowship program. This program i s sponsored jointly by The Society of the Plastics lndustry of Canada and the National Research Council of Canada, through i t s Division of Building Research. To date two Fellows have been appointed. The first, P.C. Attwood of Monsanto Canada Ltd., studied the behaviour of plastic pipe under fire collditions during a two-year period beginning in 1977. The second, W. Taylor of Imperial Oil Ltd., i s currently studying the potential for fire spread in concealed spaces of buildings, particularly in cavity walls containing cellular plastics insulation.

Prepared for presentation t o 9 t h Combustibility Symposium Society of the Plastics Industry Coordinating Committee on Consumer Safety, 15 and 18 April 1981, Waslrlngtoh. D. C.

J. Fire & Flammability, Vol. 1 2 (October 1981), p. 258

0022-1 104181 104 0258-08 $04.5010 01981 Technomic Publishing Co., Inc.

Canadian Programs Relating t o Plastics in the Built Environment

The present paper will describe briefly the work carried out to date under the fellowship program, as well as a few other projects that have relevance to the safe use of plastics. The changes made in Canada to the tunnel test (ASTM

E841,

the development of information on toxicity of combustion/pyrolysis products and some of the large-scale 'fire experiments to be conducted in a new field station will be discussed.PLASTICS INDUSTRY FELLOWSHIP PROGRAMS Plastic Pipe Program 111

The use of combustible pipes is permitted, according to the National Building Code of Canada

1980 [2],

in houses and small buildings that do not require fire separations. The Code does not permit the use of combustible pipes where they pass through rated fire separations, or in vertical shafts.A study dealing with the penetration of pipes through fire resistant construction was undertaken to explore the viability of wider use of plastic pipes in buildings, in particular in high-rise apartments. The primary objective was to determine what circumstances or design features would permit plastic pipe to penetrate a fire separation and still maintain the integrity of the separation in the event of a fire.

PVC and ABS, the two plastics most commonly used in drain, waste and vent pipe systems, were used in the study which utilized specially constructed furnaces to enable the experiments to be carried out under positive pressure. This is a more stringent condition than neutral or negative pressure testing, and one that is particu- larly pertinent to severe Canadian winter conditions.

Various techniques for protecting DWV installations that penetrated either ver- tical or horizontal fire separations were examined in this program. To be considered successful under the test, a building assembly was required to withstand fire condi- tions simulated by the furnace for a minimum of 2 hours and not l e t flames or hot furnace gases escape through the separation via the pipe. The most important finding was that mechanical shut-off devices, comprising guillotine-like slides or blades, are effective in sealing apertures created by melting plastic pipes and main- taining the integrity of the assembly for the required 2 hours.

Cavity Wall Program

The spread of fire in concealed spaces in buildings has presented problems to firefighters. It has been noted as a factor in a number of fires such as the Fairfield Nursing Home fire

(1974)

in England and at one New York Plaza in New York City(1970).

Test data dealing with fire spread in concealed spaces in which cellular plastics insulation has been installed are limited. Lie [3] has found that, in the case of rigid polyurethane sandwiched, without an intervening air space, between two non- combustible materials, propagation of fire through the wall was relatively insignifi- cant, regardless of the flame spread rating of the polyurethane. With an air space,

K.

Sumi

andW.

Taylormore extensive fire spread was noted. As a result, a limitation of 25 for flame spread classification (FSC) as measured by ASTM E 84 was suggested for poly- urethanes used in this configuration. Limited results with polystyrene showed a trend similar to that of polyurethane, i.e., no significant flame spread when there was no air space in the cavity wall. Subsequent work [41 with polystyrene has indicated that under certain circumstances vertical flame propagation could be more significant when there i s no air space in the cavity wall compared with that where an air space i s present.

The need to clarify the situation and develop more data on fire spread in con- cealed spaces containing cellular plastics insulation led to the initiation of the second research project under the DBR Plastics Industry Fellowhsip program. This work, currently under way, deals with the behaviour of foam plastics insulation inside cavity walls in a fire situation.

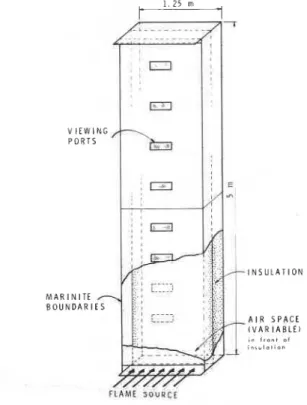

As the objective i s to measure fire spread within the wall cavity and to determine conditions under which fires can be contained within the region of origin, the basic assumption is made that fire will somehow enter the cavity and attention i s focussed on determining the progress of this fire. The flame source in the experi- ments was applied, therefore, via a 25 mm opening in the wall, near the base of the t e s t rig as shown in Figure 1.

Canadian Programs Relating t o Plastics in the Built Environment

Results of tests with polyurethanes indicated that in a cavity wall subject to fire, the flame spread rating of the foam as determined by the ULC-S102-1978 tunnel test [5] is not a significant factor in determining the potential for spread of the fire within the cavity wall. In addition, provided the air space is less than 25 mm, the spread of fire within the cavity will be limited and unlikely to go beyond the region in which the polyurethane i s ignited. With larger air spaces, fire could spread more readily, both horizontally and vertically, and, in the absence of fire stops, could extend to adjacent cavities.

Results of tests with both extruded and bead board polystyrene also showed that significant spread of fire within the cavity wall is unlikely if the air space is less than 25 mm. With larger air spaces the material melts and flows out of the cavity and, in certain situations, can develop as a pool fire.

Further work evaluating other foam plastics insulations in a variety of construc- tions is in progress to develop information concerning their performance in fire situations.

FLAME SPREAD

The principal method used in Canada to determine the flame spread classifica- tion of building materials for regulatory purposes i s based on the Steiner Tunnel Test. Two standards are available, one is similar to ASTM E84 in which materials are mounted on the ceiling of the tunnel (ULC S102) [5], and another in which materials are placed on the floor (ULC S102.2) [6]. The latter i s used for flooring and floor coverings and for materials for which the ceiling mounting i s not con- sidered appropriate, e.g., thermoplastics or loose-fill materials.

The flame spread classification (FSC) calculated from tunnel test results gives a ranking of materials under the conditions specified by the test method and, for regulatory purposes, it is assumed that the rank order would not be substantially changed under other conditions encountered at fires. Experience with foam plastics, however, indicated a serious discrepancy between results obtained from the tunnel test and those from experimental or real-life fires. The fact that foam plastics do not fit the established flammability merit sequence and can promote fire growth more readily than conventional materials with flame spread ratings many times higher, has resulted in the tunnel test falling into disrepute in the U.S.A.

In Canada, the tunnel standards have been amended in an attempt t o take account of the specific behaviour of foam plastics under the conditions of the t e s t 17, 81. Close observation of these foams in the tunnel revealed that the flame front advances rapidly during the early part of the test, but then slows down and in some cases may fail to advance further or may actually recede during the remainder of the test period. As the initial rapid flame spread was considered t o be of prime importance in the deve' lopment bf a real-life fire, th8"uSe of an equation, which .

gives emphasis to this more important early s ~ r e a d , ot the expense of the sub- sequent relatively static behaviour of the flame front, was introduced into the

K . Sumi and

W.

Taylorcalculation of the FSC. The equation for determining the flame spread of materials that exhibit non-uniform flame propagation i s given in the Canadian Standards by

FSC = 28.2 d/t, where d i s the distance progressed by the flame front before stopping or slowing and t is the time at which this occurs.

Application of this equation to urethane foams with FSC of less than 75, as calculated by the E84 method, resulted in flammability rating increases of between 2 and 10 times while, for other urethanes with higher flame spread or for conven- tional materials, little or no change in the FSC resulted from the amended calcula- tion.

It has been suggested that the new calculation gives a classification for cellular plastics that bears a closer relationship to performance in "real-world" fires. The application of the concept, however, i s not without problems. The accuracy of measurement of the distance "dWat which the flame front slows down or stops, i s

sometimes poor, particularly if the flame propagation distance is small, and calcu- lating an accurate and objective rating may be difficult. In such cases, corner wall testing, using a 4-ft (1.2 m) cubed open corner

[9],

is applied and a tunnel rating i s derived from a correlation between the two methods. This procedure is not entirely satisfactory since the correlation i s only applicable to unfaced thermosetting foams. Aluminum foil faced urethane or polystyrenes cannot be accommodated in this way. Thus there i s still a need for further work to develop a test procedure which can be applied to all situations in which plastic foams are used.TOXICITY OF FIRE EFFLUENTS

In recent years, the toxicity of fire effluents has become recognized as a subject of major importance by the fire safety community. It is an extremely complicated subject; the response of humans to fire effluents adds another dimension to the already complex fire phenomenon.

Two primary approaches are used in developing information on toxicity of fire effluents (combustion/pyrolysis products). One involves evaluation of inhalation toxicity of the combustion atmosphere through response of laboratory animals such as mice and rats (biological approach); the other involves chemical analysis of the effluents. The two approaches complement each other.

Biological Assessment

A great deal of information has been developed, mainly in the past decade, on the response of animals to fire effluents. Studies have included both the specific effects of harmful decomposition products on test animals and simple screening tests to evaluate materials.

I Experimental data show that ranking of materials on the basis of toxicity

af

-

q ~ ~ j n b u s t i ~ n atrnospbre deoerrrls siorri*ioenrlv dmmmpetiitferr~ruCC!dlrrC!S. This isnot surprising since, as is well known, experimental conditions influencii

me

Canadian Programs Relating to Plastics in the Built Environment

ditions, small differences in toxicity results that affect ranking should be disre- garded and attention focussed on materials that produce fire effluents that are significantly more toxic than those produced by conventional materials such as wood. This is, in essence, the position taken by ISOITC 92 (International Organiza- tion for StandardizationITechnical Committee 92 on Fire Tests for Building Materials, Components and Structures). This committee is developing standard test method(s1 "to identify materials which when subjected to thermal decomposition yield products presenting an unusually toxic environment".

Chemical Analysis

Because many organizations have given priority to the biological approach, the development of information by the chemical approach has fallen behind. The authors believe, therefore, that more attention should be given to studies using chemical analysis. The Fire Research Section of DBRINRCC has been investigating this approach to the toxicity problem for about 15 years.

There are many ways by which chemical analysis could be used to develop information on toxicity of fire effluents. Amongthem are:

(a) Evaluation of decomposition procedures used in biological screening tests, (b) Identification and quantitative analysis of toxicants, and

(c) Prediction of toxicity of combustion atmospheres.

The most common method for evaluation of materials based on the propensity for release of harmful products is a biological screening test in which the fire effluents are produced by a specified procedure and t e s t animals then exposed t o them. The information that has been generated is often confusing because as pointed out earlier, the ranking of materials depends significantly on decomposition procedures. Work with chemical analysis i s urgently needed to evaluate the differ- ent decomposition procedures and compare the data with those from experimental fires.

Chemical analysis provides a method to assist in identifying compounds responsi- ble for toxic effects. Comprehensive analysis may be necessary for the identifica- tion of extremely toxic compounds following evidence from biological studies that a given material is capable of releasing very harmful products. This information is useful to industry in the development of new products.

Toxicity Index

For many practical applications, detailed chemical analysis, which is extremely time-consuming, is not necessary. Quantitative analysis of a few of the most im- portant known toxicants can often provide a reasonable indication of the toxicity of a mixture of combustion/pyrotysis products. This i s the essence of the toxicity index

~ o - ~ * ~ w ~ ~ ~ t e d h v

T y ~ h j u a aQd_Symi [ 101,I he toxicity of a single product is obtained by decomposingor burning a known amount of material and allowing the products to disperse into a known volume.

K.

Sumi andW.

TaylorThe toxicity index, T, for the toxic compound is given by

where

ce = experimentally determined concentration of a toxic product

cf = concentration of the same toxicant that is fatal or dangerous to man in 30 min.

The toxicity index of a material can be predicted from the sum of the individual indices of the main harmful components, with appropriate factors incorporated where synergistic effects exist. The foregoing equation gives the toxicity of products released from a given weight of material. Assessment based on the rate of release of toxicants has also been considered in subsequent work conducted a t DBR/NRCC.

FULL-SCALE EXPERIMENTS

Most standard fire tests and small scale experiments provide a comparison of the performance of materials only for specified conditions. Often the information ob- tained in this way needs to be complemented by data derived from larger scale, more realistic fires in order t h a t meaningful correlations can be made. An experi- mental facility, in which fire and i t s effects could be studied under controlled conditions on a realistic scale, has not been available in Canada. A major facility has now been built a t a site some 65 km from the Ottawa headquarters of NRCC to meet this need. It comprises a large burn hall, 55 X 30 X 12.5 m (1 80 X 100 X 40 ftl, and a 10-story tower.

The major project planned for the tower structure is a study of the movement of smoke in tall buildings under varying indoor and outdoor conditions and examina- tion of the effectiveness of various methods to control smoke flows during a fire. This work is timely in view of several recent fires, both in Canada and the United States, in which smoke was a major factor contributing to fatalities.

The exterior walls of the tower are composed of removable panels which can be replaced by any desired exterior cladding or facade. This allows for experiments on the influence of the building envelope, including glazing, on the vertical spread of fire.

Other large-scale experiments being planned include those dealing with the effect of lining materials and furnishings on fire development in fully instrumented enclosures, and further studies on plastic pipes and fire spread in cavity walls. The facilities offered by the field station will be of interest to construction-related industries for development work needing large scale fire tests and agencies con- cerned with fire safety.

This paper i s a contribution from the Division of Building Research, National Research Council of Canada and is published with the approval of the Director of the Division.

Canadian Programs Relating t o Plastics in the Built Environment

REFERENCES

1. P. C. Attwood. Fire Technology 16, 37 (February 1980).

2. National Building Code of Canada 1980. National Research Council of Canada, Assoc. Comm. on the National Building Code, NRCC 17303.

3. T. T. Lie. National Research Council of Canada, Division of Building Research, Fire Study No. 29, (1972).

4. M. V. D'Souza. Private communication.

5. Standard method of test for surface burning characteristics of building materials. Under- writers' Laboratories of Canada, ULC-S102-1978.

6. Standard method of test for surface burning characteristics of flooring, floor covering and miscellaneous materials. Underwriters' Laboratories of Canada, ULC-S102.2-1978. 7. M. V. D'Souza and J. H. McGuire. Fire Technology 13,85 (May 19771.

8. M. V. D'Souza. The basis for flammability test methods. Second Symposium on Com- bustibility and Plastics, The Society of the Plastics Industry of Canada, Ottawa, 30 and 31 October, 1979.

9. Standard corner wall method of test for flammability characteristics of nonmelting build- ing materials. Underwriters' Laboratories of Canada, ULCS127-1978.

This publication is being distributed by the Division of Building Research of the National Research Council of Canada. It should not be reproduced in whole or in part without permission of the original publisher. The Division would be glad to be of assistance in obtaining such permission.

Publications of the Division may be obtained by mailing the appropriate remittance (a Bank, Express, or Post Office Money Order, or a cheque, made payable to the Receiver General of Canacta, credit NRC) to the National Research Council of Canada, Ottawa. K I A OR6. Stamps are not acceptable.

A list of all publications of the Division is available and may be obtained from the Publications Section, Division of Building Research, National Research Council of Canada, Ottawa. K I A OR6.