Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Institute for Research in

Construction); no. IRC-P-1359, 1985-08

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=3e5e3b4a-0194-42b6-9c43-e5a930af3bde https://publications-cnrc.canada.ca/fra/voir/objet/?id=3e5e3b4a-0194-42b6-9c43-e5a930af3bde

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001796

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Investigating the unexposed surface temperature criteria of standard

ASTM E119

TH1 I National Research Conseil national

N21d Council Canada de recherches Canada no* 1359

*

institute for lnstitut deResearch in recherche en

Bm

1

Construction constructionInvestigating the Unexposed

Surface Temperature Criteria of

Standard ASTM

E l 19

by K.J. Schwartz and T.T. Lie

Reprinted from Fire Technology Val. 21, No, 3, 1985 Price $2.00 NRCC 25544 NRC

-

ClSYl BL3G. RES.L I B R A R Y

On a rassembl6 des renseignements pour 6valuer les critsres de temperature de surfaces non exposees contenus dans la norme ASTM E119. Les recherches ont port6 sur : (1) 1'6tude des publications en vue de trouver des donnees sur l'elaboration de la norme ASTM El19 et les criteres d'augmentation de la temperature de surfaces non expos6es, (2) la realisation d'essais au feu pour obtenir des donnees sur la tempsrature des dalles avec differents mat6riaux placds sur la surface non expos6e et (3) la r6alisation d'essais d'inflammation sur ces

matdriaux pour obtenir leur temperature approximative d'inflammation. Ces renseignements ont permis de d e u x comprendre la relation entre les criteres d'augmentation de la temperature de surfaces non expos6es contenus dans la norme ASTM El19 et la temperature d'inflammation des matdriaux

combusttbles courants. - -

Investigating the Unexposed Surface Temperature Criteria of

Standard ASTM E l 19

by Kenneth J. Schwartz and T. T. Lie

Reprinted from FIRE TECHNOLOGY Volume 21, Number 3

August 1985 Pages 169- 180

Winner of the

1985

Harry C. Bigglestone Award for

Excellence in Written Communication of Fire Pro-

tection Concepts.

KENNETH J. SCHWARTZ

Rolf Jensen 8 Associates, Inc.

and

T . T. LIE

National Research Council of Canada

(Manuscript received November 1984, accepted February 1985)

Information and data were obtained to evaluate the unexposed sur-

face temperature criteria of standard ASTM E l 19. The investigation consisted of: (1) reviewing literature to obtain information on the development of ASTM El19 and the unexposed surface temperature rise criteria, (2) conducting fire tests to obtain temperature data on slabs with various materials placed on the unexposed surface and (3) conducting ignition tests on these materials to obtain their approx- imate temperature a t ignition. The information and data increased the knowledge concerning the relationship between the unexposed surface temperature rise criteria of ASTM El19 and the ignition tem- perature of common combustible materials.

INTRODUCTION

T

WO ISSUES must be addressed when investigating the unexposed sur- face temperature criteria of the standard fire resistance test. First, what is the relative importance of limiting the unexposed surface tempera- tures of fire resistive assemblies in preventing the spread of fire? Second, what is the relationship between the temperature rise criteria and actual ig- nition temperature of combustibles?Failure of a fire resistive assembly is assumed to occur by one of three mechanisms:

1. Structural collapse of the assembly,

Reference: Kenneth J. Schwartz and T. T. Lie, "Investigating the Unexposed Surface Tem- perature Criteria of Standard ASTM E119." Fire Technology. Vol. 21, No. 3. August 1985, p. 169.

Key Words: Surface temperature, temperature rise, ignition temperature, fire resistance, fire spread, structural integnty.

' 170 Fire Technology

2. Openings in the assembly which allow flames and hot gases to pass through, or

3. Excessive heat transfer through the assembly, resulting in high tem- peratures on the unexposed surface sufficient to ignite materials in contact or in close proximity with the barrier.

These three modes of failure provide the basis for evaluating the fire resistance of assemblies. However, it can be argued that these modes of failure are not of equal importance. For example, structural failure due to fire of a load canying assembly could lead to collapse of an entire structure, . but an excessive rise in temperature on the unexposed surface of a barrier would a t worst spread the fire to an adjacent compartment or room. In addi- tion, fire loss data indicates that a primary avenue for flame spread is from

.

unprotected openings, not from heat conduction through an assembly.Because the standard fire test does not differentiate between failure modes, an assembly which fails structurally a t 2 hours receives the same classification as an assembly that fails the unexposed surface temperature criteria a t 2 hours but remains structurally intact for 3 or 4 hours. The superiority of one assembly over the other is clear, yet it is not recognized by the standard fire test. The justification for changes to the standard fire test and current building code requirements are apparent and need to be ad- dressed.

DEVELOPMENT OF UNEXPOSED SURFACE TEMPERATURE RISE CRITERIA

The history of fire testing in the United States can be traced back to at least 1890. However, the standard fire test as we know it today dates back to 1917 and the formation of ASTM Committee C-5. Committee C-5 prepared a new standard, which was adopted in 1918 as a Method of Fire Tests of Materials and Construction. The standard covered floors and parti- tions, and featured the establishment of a time-temperature curve for con- ducting tests. The curve has remained virtually unchanged to this

The standard test method adopted in 1918 was notable in that it pro- vided a means for classifying assemblies according to their attained fire resistance. Also, "further criteria for the test of partitions was established, requiring that the transmission of heat through the assembly during the test should not be such as to raise the temperature on the unexposed surface of the partition by more than 300" F."l The reason for the choice of 300" F (167" C) rise is not known, but it may be based on the belief that a 300" F -

(167" C) rise could ultimately result in a temperature sufficient to ignite wood or cotton waste.

I t should be noted that during this period fire endurance tests were quite often run for a duration of six to eight hours and in some cases as long as 10 or 12 hours. Since self ignition temperatures are dependent on the period of exposure, these long duration fire tests may account for such low tempera- ture rise criteria.

I

Surf ace Temperature 171

In tests conducted in the 1920s at the National Bureau of Standards on brick and hollow tile walls, it was observed that the unexposed surface tem- peratures continued to rise after the fire in the furnace had been shut down.

1

I I t was thought that even though the temperature rise of the unexposed sur- ! face is limited to 300" F (167" C) during the test, the increasing tempera- tures after the test may be sufficient to ignite cotton waste. "For this

;

reason, the Method of Fire Tests of Building Construction and Materials, proposed in 1926 and finally adopted in 1933, embodied the requirement of a maximum 250" F (139" C) average rise, applying to both floors and parti- t i ~ n s . " ~It has been noted by Gustaferro4 that if this is the reason for the change, it is inconsistent in establishing fire rating classifications since the other criteria do not consider post-fire performance. For example, an assembly which collapses shortly after a 2 hour fire test, can still qualify as a 2 hour fire rated assembly. The rationale for establishing unexposed surface tem- perature rise criteria based on conditions after the test is questionable.

Although there have been refinements and modifications to the Stan- dard since 1933, the basic unexposed surface temperature rise criteria have remained essentially unchanged.

Studies were undertaken to examine the relationship between the tem- perature rise limits specified by ASTM El19 and the temperatures at which self-ignition may occur for various commonly used combustible materials. The main purpose of the studies was to determine the actual ignition tem- peratures of common combustible materials when in contact with the unex- posed surface of a fire resistive assembly.

The Concrete and Masonry Industry Firesafety Committee (CMIFC) established a three part program to investigate the unexposed surface tem- perature criteria of the standard fire test. Conducted by Underwriters Lab- oratories, Inc., this "Fact-Finding In~estigation"~ resulted in the following: 1. Information on the basis for the current unexposed surface tempera-

ture rise criteria,

2. Data on the combustibility of various materials placed on the unex- posed surface of concrete and masonry slabs,

3. Data on the self ignition temperatures of the materials tested. Similar testing, though not sponsored by CMIFC, was also conducted by the National Research Council of Canada (NRCC). Several fire tests were run on small concrete slabs covered by various combustible materials. The NRCC furnace is often used to evaluate the heat transmission character- istics of fire resistive assemblies.

TESTS CONDUCTED BY UNDERWRITERS LABORATORIES

TABLE 1. Description of assemblies tested

Test No. Specimen {in) 1 2 N W Concrete 2 2 N W Concrete 3 2 N W Concrete 4 2 LW Concrete 5 3 NW Concrete 6 3 NW Concrete 7 4 Blmk 8 4 Brick 9 4 Block 10 4 Brick

Northwest Quadrant No. 1

Pol ropylene c

Tt

and fpam padviny

floor tile - o adheslve NewspaperPolvpropylene carpet - No pad ~ o l j . ~ r o ~ y l e n e carpet with adhesive

Y8 in. Plywood

Wood strips - Pine 1 X 2

Wood strips - Pine 1 X 2

Latex paint Latex oain t

Mate&& on Specimen

Southwest Quadrant No. 2

2 X 4 Wood - Pine

X

in. Plywoad Sawdust Cotton waate Cotton waste Polystyrene inaulation Polystyrene insulation Pol styrene insulation w J p a p e r with adhesive Walloa~er with adhesiveSouthsast Q u u d m t No. 3

Nylon carpet and Polyurethane pad h o l e u r n - No adhesive

Cotton waste

Polystyrene insubtion Linoleum with adhesive

Sawdust

Cotton wade Cotton waste

Vinyl trim

Vinyl trim The Northeast Quadrant No. 4 did not have materhh placed on the specimen and was ueed aa a control.

NW - Normal Weight LW - Lightweight

Surf ace Temperature 173

1

I1

0.9 m) slab specimens of concrete, clay brick or concrete masonry block. For I each specimen, the unexposed surface area of the m i m e n was divided into quadrants. A different combustible material was placed in each of three I quadrants and the fourth quadrant, the control, was left bare. Tempera- tures were recorded using thermocouples placed between the slab specimen and the combustible material. For the control a thermocouple was placed under

a

standard 6 X 6 in. (0.1 5 X 0.15 m) felted asbestos &d. The furnace atmosphere temperature was controlled in accordance with the time temper- ature relationship specified by ASTM E119.Table 1 gives a description of each test assembly, the type and thickness of test specimen, and the three materials placed on the specimen. Tests of 2 in. (0.05 m) thick specimens were conducted for two hours, and thicker specimens were tested for four hours in order to achieve sufficiently high un- exposed surface temperatures. Temperatures were also recorded after fire exposure until the unexposed surface temperatures began to decrease. visual observations weremade of the of the materials during and after the tests.

No a t t e m ~ t was made to examine the effect of ventilation or ambient temperature bn ignition temperatures. The testing apparatus did provide some ventilation in order to remove combustion products. I t is likely that ventilation would have an effect on ignition temperatures. Changes in am- bient temperature, on the other hand, would not likely affect ignition tem-

-

Table 2 lists the unexposed surface temperatures upon ignition of the combustible materials. In every case except two (the wood strips) the tem- perature of the control was less than the temperature under the combustible material. This is most likely due to the heat contribution of the combustible materials undergoing pyroiysis and the increased thermal insulation of the materials. In the case of the wood strips, the wood apparently bowed away

TABLE 2. Unexposed surface temperatures at ignition or glowing

On Masonry Surface Under TC Pad On Masonry Surface UnderMaterial

E.t

$

:

Assembly Masonry Tem erature Combustible Tern erature Material [in.) O froc,

MaterialoP*

roc,

1 105 ~ N W concretep 914(490) 2 x 4 in. s t i d 1004 (540) 2 105 2 NW Concrete 972 (522) Plywood 1152 (622) 3 47 2 NW Concrete 615 (324) Sawdust 746 (397) 50 641 (338) Cotton waste 830 (443)

4 60 2 LW Concrete 544 (284) ~ o t t o i baste 776 i413j 5 107 3 NW Concrete 671 (355) Cotton waste 768 (409) 6 102 3 NW Concrete 597 (314) Sawdust 972 (522) 7 114 4 Block 699 (371) Cotton waste 750 (399)

210 913 (489) Wood strips 787 (419)

8 115 4 Brick 560 (293) Cotton waste 569 (298)

190 867 (464) Wood strips 794 (423)

No ignition or glowing occurred in Test Nos. 9 and 10.

*

- Glowing**

- Flaming @&ion174 Fire Technology from the slab allowing cooler air to circulate around the exposed thermo- couple.

In all cases of ignition except one, only glowing ignition occurred. In one instance involving newspaper, flaming ignition occurred 12 minutes after glowing was first observed. The cotton waste and sawdust burned with a slow glowing combustion that consumed the material. The plywood, 2

X

4 in. (0.05 X 0.10 m) wood, and wood strips slowly charred with intermittent glowing observed. The other materials tended to distort and slowly decom-I pose by melt or char, however, the materials did not ignite into flames, nor

was glowing observed.

Table 3 lists the temperature increases after the furnace was shut off. The temperature increase of the unexposed surface recorded on the control quadrant ranged between 2" F (lo C) and 43' F (24" C).

Ignition tests were conducted on the combustible materials employed in the small scale fire tests. Small samples of the combustible materials were inserted into a heated chamber and the minimum temperature was recorded a t which glowing or flaming ignition occurred. The data were intended to provide only an indication of the approximate self ignition temperature of the materials placed on the unexposed surface during the fire test.

The ignition temperature tests were conducted using the furnace and equipment as described in standard "Test for Comparative Flammability of Liquids" UL 340. The apparatus consists of a glass combustion chamber surrounded by a molten alloy bath heated by a special electric furnace.

In conducting the tests, varying amounts of the samples were intro- duced into the combustion chamber in successive trials a t progressively lower temperatures. The minimum temperature was recorded at which the vapor, in any proportion with air, would self ignite. The results of these tests are shown in Table 4. In all cases except the wood 2 X 4, the self igni-

TABLE 3. Temperature rise after furnace shut off

Masonry Specimens Material

Test Maximum Maximum

No. Temperature Time, Temperature Time, Increase. OF

loci

min.* T v ~ e Increase. OF 1°C) min.*6 9 i4.9)

7 4 (2.2)

8 29 (15.9)

9 2 (1.1)

10 25 (13.7)

*

Time from gas offFoam pad 71 (39) 25 P l y w d 42 (23) 20 Cotton 53 (29) 2 Carpet 25 (13.7) 15 Linoleum 6 (3.3) 20 Plywood 10 (5.5) 25 Wood strips 9 (4.9) 10 W dstripe 68 (37) 18 Paint 7 (3.8) 4 Trim 36 (19.8) 13

Surface Temperature 175 tion temperatures were higher than the ignition temperature recorded dur- ing the small-scale fire tests. This is expected since self ignition tempera- tures should decrease with an increase in exposure period.

In these tests, concrete slabs, covered by various materials were exposed

in a horizontal position to the heat of a furnace. The concrete slabs were made with siliceous aggegate in three thicknesses. The size of the slab was

31 X 33 in. (0.78 X 0.84 m). In each test, the concrete slab was fully covered by the test material. In addition, tests were carried out on similar concrete slabs with 6 X 6 in. (0.15 X 0.15 m) asbestos pads located at the center of the slab and a t each center of two quadrants along a diagonal of the surface.

During the tests, temperatures were measured at the interface between cover (test material) and concrete slab with the aid of thermocouples. The temperatures measured under the pads are used for comparison with the temperatures measured under the test covers at corresponding locations I and for corresponding slab thickness. The cover materials that were tested, concrete slab thicknesses and the moisture condition of the slabs are specified in Table 5. All test covers were conditioned in an environment of

50% relative humidity at 73O

F

(23" C). The asbestos pads were oven dried prior to the tests.The test furnace chamber had a floor area of 34 X 34 in. (0.86 X 0.86 m) and was 28 in. (0.71 m) high. The area of the opening at the top of the chamber, through which the specimen was exposed to the heat of the fur- nace, was 30 X 30 in. (0.76 X 0.76 m). The temperature in the furnace chamber was controlled in such a way that it followed as closely as possible the ASTM E 119 standard time temperature relation.

OBSERVATIONS

Observations made during the various tests are given in Table 5. Nylon TABLE 4. Ignition temperatures per Standard UL 340.

I nition or Glowin

Sample Amperatwe OF

(OR

Sawdust Glowing 676 (367)

Cotton waste Glowing 700 (371)

News aper

w o o a Glowing 873 (467) Glowing 817 (4361

Paint Glowing 817 (4361

Clear adhesive Glowing 746 (3961

Linoleum paste No ignition or glowing 950 (510)

Pol-wrethane pad Ignition 910 (488)

Polystyrene insulation Ignition 855 (467)

Vinyl tile Ignition 950 (510)

Nylon ca et Ignition 883 (473)

Foam ru#m psd Ignition 770 (410)

Wall aper Ignition 892 (478)

~ i n o i u m Ignition 950 (510)

Polypropylene carpet Ignition 838 (448)

Samples of the wood strips, vin 1 trim and pl ood were not tested.

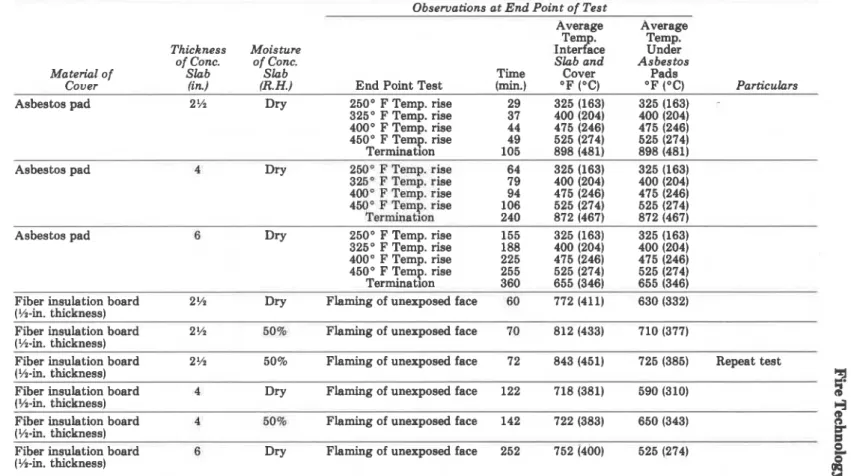

TABLE 5. Details concerning NRCC tests

2

Observations a t End Point of TestThickness Moisture of Conc. of Conc.

Material of Slab Slab

Cover fin.) IR. H.)

Average Average Tem

.

Temp. ~ n t e r z c e Under Slab and AsbestosTime Cover Pads

End Point Test (min.) OF ("C) OF ("C) Particulars Asbestos pad 2 ?h Dry 250" F Temp. rise 29 325 (163) 325 (163) -

325" F Temp. rise 37 400 (204) 400 (204) 400" F Temp. rise 44 475 (246) 475 (246) 450" F Temp. rise 49 525 (274) 525 (274) Terminat~on 105 898 (481) 898 (4811 Asbestos pad 4 Dry 250" F Temp. rise 64 325 (163) 325 (163) 325" F Temp. rise 79 400 (204) 400 (204) 400' F Temp. rise 94 475 (246) 475 (246) 450" F Temp. rise 106 525 (274) 525 (274) Termination 240 872 (467) 872 (467) Asbestos pad 6 Dry 250" F Temp. rise 155 325 (163) 325 (163) 325" F Temp. rise 188 400 (204) 400 (204) 400" F Temp. rise 225 475 (246) 475 (246) 450" F Temp. rise 255 525 (274) 525 (274) Terminat~on 360 655 (346) 655 (346) Fiber insulation board 2% Dry Flaming of unexposed face 60 772 (411) 630 (332) (%-in. thickness)

Fiber insulation board 2% 60% Flaming of unexposed face 70 812 (433) 710 (377) Ilh-in. thickness)

Fiber insulation board 2% 50% Flaming of unexposed face 72 843 (451) 725 (385) Repeat test (%-in. thickness)

Fiber insulation board 4 Dry Flaming of unexposed face 122 718 (381) 590 (310)

?

cb(%-in. thickness)

Fiber insulation board 4 50% Flaming of unexposed face 142 722 (383) 650 (343)

(%-in. thickness)

P

Fiber insulation board 6 Dry Flaming of unexposed face 252 752 (400) 525 (274)

r

(%-in. thickness)

&

Oak (%-in. thickness) 2% 50% Flaming of unexposed face 74 775 (413) 740 (393) Ignition started a t corner

Pine (%-in. thickness) 2 1/n 50% Flaming of unexposed face 112 1017 (547) 950 (510) Ignition started a t

joint in center

.Nylon carpet 2% 50% Test Terminated (No 122 877 (469) 1000 (538) Carpet started to

flaming of unexposed face) melt a t several

locations ~ m . a t 97

Acrylic carpet 2% 50% Test Terminated (No 120 893 (478) 990 (532)

flaming of unexposed face)

Vinyl cushion flooring 2% 50% Test Terminated (No 75 913 (489) 750 (399)

flaming of unexposed face)

Roofing ~ y s t e m of five 2% 50% Flaming of unexposed face 63 618 (326) 660 (349)

la era organic roofing fert

+

bitumen+

%in.volvstvrene foam. Carpet started to melt a t several lvtions at 109 mln. Cushion started to melt a t several locations a t 42 min. Polyst ene a t a r J t t o melt a t 57 min.

Metric Conversions: inches X 0.0254 = meters Temp. (OF

-

32) X % = Temp. OC1

I78 Fire Technology and acrylic carpet, and vinyl cushion flooring melted during the tests, but did not ignite. The lowest average temperature at the interface between cover and concrete slab, measured at the end of the tests, was 877" F(469" C).

Fiber insulation board, oak, pine, and roof felt with bitumen ignited and flamed during the tests. The lowest average temperatures at the interface between cover and concrete slab at which flaming started was 618" F

(325" C).

The lowest average temperature under the asbestos pad a t the time that corresponds to the time a t which flaming occurred was 525" F (274" C). This was observed during the test of a dry 6 in. (0.15 m) concrete slab covered with fiber insulation board, which flamed after 252 minutes of exposure to the standard fire.

In all cases, the presence of moisture in the concrete slab increases the time to flaming, the temperature at which flaming occurred and the cor- responding temperature under the asbestos pads.

CONCLUSIONS

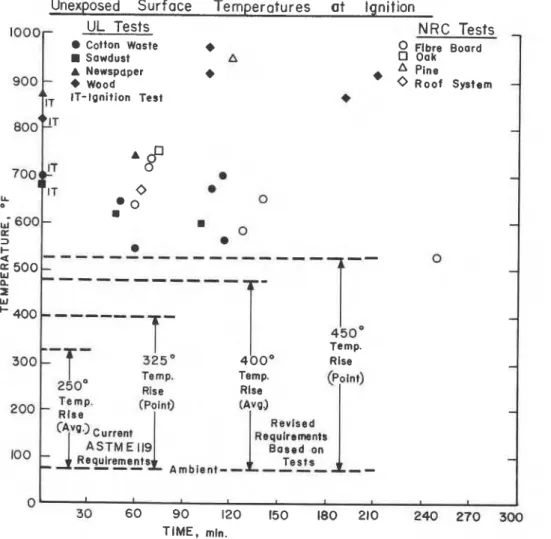

The results of the fire tests and ignition tests, as taken from the Fact- Finding Investigation Report,* have been plotted on the graph shown in Figure 1. The results of the NRCC tests and the current ASTM El19 re- quirements have also been plotted. Based on the results of the fire tests it can be concluded that the self ignition temperatures of ordinary com- bustibles, in contact with the unexposed surface of a fire resistive assembly, are in excess of 520" F (271" C). This suggests that a large factor of safety has been incorporated into the unexposed surface temperature criteria of the ASTM El19 standard, particularly when compared to the other test criteria, which allows for structural collapse or unattended openings to oc- cur any time after the fire endurance period.

As determined by the literature review it is believed that the ASTM

El19 requirements for unexposed surface temperatures were first set at a

300" F (167" C) rise because this would be sufficient to ignite wood or cot- ton waste. I t was later reduced to an average rise of 250" F (139" C) because of observations made that the unexposed surface temperature of certain assemblies continued to rise after the furnace fire was extinguished. This revision, which apparently was based on post fire performance, is inconsis- tent with the other test criteria.

Based on the series of tests conducted it is apparent that the current

250" F (139" C) temperature rise is overly conservative. While self ignition temperatures are dependent on the period of exposure, fire ratings in excess of four hours are no longer common. Therefore, it is suggested that a 400" F

*

Re orts of Fact-Finding Investigations pre ared by Underwriters Laboratories Inc. in- clude o s y statements of the facts developed, wit!out statements of conclusion. The complete UL Fact-Findin Re ort is available from the Concrete and Masonry Industry Firesafety Committee, c/o. $ortend Cement Association, Skokie, Illinois.Surf ace Temperature 179

(222" C) average temperature rise, and a maximum 450" F (250" C) temper-

ature rise a t any point be considered in revising the ASTM E l 19 criteria for

unexposed surface temperatures. Experience has shown that fire spread by

heat conduction is rare. Therefore, revised requirements appear to be in

order.

The purpose of a fire resistive assembly serves two functions: 1) to act as

a barrier to the spread of flames and heat, and 2) to perform its structural

function during the period of exposure. Eventually, these two functions need to be separated and each tested accordingly. Economy of construction

and greater reliance on alternative design requirements will force this to

occur.

Unexposed Surface Temperatures at Ignition

1000 UL Tests _NRC Tests

Cotton Waste

+

0 Flbre BoardA 0 Oak

+

'

A Pine O ~ o o f System IT-Ignition Test 800%'-

700-

I T 0*

LL 0 0 8 ; 600 a-

LL a 0 3--- --

mi

0-

I-

450' Temp. 300- 7 -

325' 4 0 0 ° Rlse-

Temp. Temp. 250" Rlse d 100-

-

0 ' I I I - 30 6 0 9 0 120 150 180 210 240 270 300 TIME, min.180 Fire Technology Future fire resistance tests should therefore be run beyond the time the first end point is met andlor until structural failure is imminent. Reporting the order and time when the various end points are reached should also be considered.

Comments are welcomed by the authors.

REFERENCES

"Standard Methods o f Fire Tests o f Building Construction and Materials," - ASTM E119-82.

Shoub. Harry, "Early History of Fire Endurance Testing in the United States." Sym- posium on Fire Testing Methods, ASTM STP 301, American Society of Testing Materials, 196,l. pp. 1-9.

Report of Committee C-6 on Fire Proofing, h e e d i n g % American Society of Testing Materials. 1917, Vol. 17. Part I, pp. 295-300.

" Guataferro. A. H.. "Ternmature Criteria at Failure." Fie Test Pwforrnance. ASTM

STP 464. ~mer;'ean society of Testing Muterinls, 1970, pp. 68-84.

'

Report on Fact Finding Investigation of the Unex osed Surface Temperature Criteria in Standard ASTM E119, for the Concrete and Masonry g d u a t r y Fire Safety Committee, May 27, 1983. Underwriters Laboratories, Inc.T h i s p a p e r i s b e i n g d i s t r i b u t e d i n r e p r i n t form by t h e I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n . A l i s t of b u i l d i n g p r a c t i c e and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n , N a t i o n a l Research C o u n c i l o f C a n a d a , O t t a w a , O n t a r i o , K1A 0R6. Ce document e s t d i s t r i b u 6 s o u s forme de t irC-3-part p a r l l I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n . On peut o h t e n i r m e l i s t e d e s p u b l i c a t i o n s de l l I n s t i t u t p o r t a n t s u r l e s t e c h n i q u e s ou l e s r e c h e r c h e s e n m a t i e r e d e b a t i m e n t e n 6 c r i v a n t 3 La S e c t i o n d e s p u b l i c a t i o n s , I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n , C o n s e i l n a t i o n a l d e r e c h e r c h e s du Canada, Ottawa ( O n t a r i o ) , K1A OR6.