One-Pot Cascade Synthesis of (3S)-Hydroxyketones Catalyzed by

Transketolase via Hydroxypyruvate Generated in Situ from

d-Serine by d-Amino Acid Oxidase

Mélanie L’enfant,

aFelipe Bruna,

aMarion Lorillière,

aNazim Ocal,

aWolf-Dieter Fessner,

bLoredano Pollegioni,

cFranck Charmantray,

a,* and

Laurence Hecquet

a,*

aUniversité Clermont Auvergne CNRS

SIGMA Clermont, Institut de Chimie de Clermont-Ferrand (ICCF) F-63000 Clermont-Ferrand (France)

E-mail: franck.charmantray@uca.fr; laurence.hecquet@uca.fr

b

Institut für Organische Chemie und Biochemie Technische Universität Darmstadt

64287 Darmstadt (Germany)

c

Department of Biotechnology and Life Sciences Università degli Studi dell’Insubria

Varese (Italy)

Manuscript received: January 24, 2019; Revised manuscript received: March 14, 2019;

Version of record online: April 9, 2019

Supporting information for this article is available on the WWW under https://doi.org/10.1002/adsc.201900109

Abstract:

We described an efficient in situ generation of hydroxypyruvate from serine catalyzed by a

d-amino acid oxidase from Rhodotorula gracilis. This strategy revealed an interesting alternative to the

conventional chemical synthesis of hydroxypyruvate starting from toxic bromopyruvate or to the enzymatic

transamination from l-serine requiring an additional substrate as amino acceptor. Hydroxypyruvate thus

produced was used as donor substrate of transketolases from Escherichia coli or from Geobacillus

stearothermophilus catalyzing the stereoselective formation of a carbon carbon bond. The enzymatic cascade

reaction was performed in one-pot in the presence of d-serine and appropriate aldehydes for the synthesis of

valuable (3S)-hydroxyketones, which were obtained with high enantio- and diastereoselectivity and in good

yield. The efficiency of the process was based on the irreversibility of both reactions allowing complete

conversion of d-serine and aldehydes.

Keywords: biocatalysis; transketolase; d-amino acid oxidase; hydroxypyruvate; ketoses; stereoselectivity

Introduction

Hydroxypyruvate (HPA) is a key substrate for several

HPA-dependent enzymes including aldolases

[1]and

transketolases (TK)

[2]used in biocatalysis for the

synthesis of valuable monosaccharides and analogues

by stereoselective carbon carbon bond formation. For

synthetic purposes conducted at gram-scale, the main

problem is the cost of the commercial HPA. This

compound can also be synthetized by hydrolysis of

toxic bromopyruvic acid in the presence lithium

hydroxide.

[3]Enzymatic in situ generation of HPA has

been previously described, in particular from l-serine

using transaminases (TA) (Scheme 1A).

[4–6]The

rever-sibility of the TA-reaction requires the simultaneous

coupling to an irreversible enzyme-catalyzed reaction

to shift the overall equilibrium toward HPA formation

and to avoid its accumulation and degradation,

partic-ularly

at

high

temperature,

and/or

in

buffered

solution.

[5]The irreversible TK-catalyzed

decarboxyla-tion of HPA is a powerful tool for such an approach.

Indeed, TK, a thiamine dependent enzyme, catalyzes

the subsequent transfer of the ketol group of HPA to an

aldehyde acceptor leading to a (3S)-ketose by the

stereoselective formation of the C2 C3 bond.

[1]The

coupling of the TA and the TK reactions in a one pot

has been developed producing the expected ketose

products.

[4–6]The major drawback of this approach is

the requirement of an α-keto acid as an amino group

acceptor, which is a second substrate generating the

corresponding amino acid as an additional by-product

if not recycled. In addition, the equilibrium shift

toward the formation of the product needs an excess of

one of the two TA substrates, i. e., d-serine or α-keto

acid, and in the latter case inhibition of TA was

observed.

[5,6]To circumvent all these limitations, another strategy

consists in using an aminoacid oxidase (AAO) to

catalyze the oxidative deamination of serine into HPA

(Scheme 1B). Substrate specificity studies of AAOs

have shown that the best substrates for lAAOs are

hydrophobic aminoacids

[7]while dAAOs display a

broad aminoacid spectrum including d-serine. Hence,

we have selected the latter enzyme family for the

approach developed in this study.

dAAOs (EC 1.4.3.3) are flavin adenine

dinucleo-tide (FAD)-containing flavoenzymes that catalyze the

deamination of d-amino acids to their imino acid

counterparts with concomitant reduction of FAD which

is subsequently re-oxidized by molecular oxygen with

generation of hydrogen peroxide. The released imino

acid spontaneously hydrolyses to the corresponding

α-keto acid and ammonia (Scheme 2). dAAO activity

has been identified in many organisms, ranging from

fungi to humans.

[8]The well-known pig kidney dAAO

has been first reported for use in biocatalytic

applications,

[9–11]but the enzyme from the yeast

Rhodotorula gracilis (DAAO

Rg) showed much higher

turnover number, better stability under a wide range of

reaction conditions, and a larger active site to

accom-modate various substrates.

[12,13]Due to these properties,

the yeast enzyme has been used in a variety of

biotechnological processes at industrial scale such as

the production of glutaryl-7-aminocephalosporanic

acid from cephalosporin C,

[14]the resolution of racemic

mixtures of amino acids,

[15]and the production of

α-keto acids from natural and synthetic d-amino acids.

[16]DAAO

Rgaccepts the polar amino acid d-serine with

higher specific activity compared to dAAO from pig

kidney.

[9]However, this enzyme has never been

investigated to produce the α-keto acid HPA from

d-serine, especially at preparative scale.

The aim of this work is to study the reaction

catalyzed by DAAO

Rgin the presence of d-serine as

the substrate to evaluate the in situ synthesis of HPA at

preparative scale. It should be noted that d-serine is

commercially available at approximatively the same

price as l-serine and can be produced at industrial

scale by a microbial process.

[17]To validate the

strategy, the DAAO

Rg-catalyzed reaction will be first

studied independently and then coupled with TK,

requiring and consuming HPA as donor substrate. The

irreversibility of TK-catalyzed reaction and the

stereo-selectivity of this enzyme are major advantages. On

this side, wild-type or evolved TKs from mesophilic

[18]or thermophilic

[5,6b,19]sources have been reported as

efficient biocatalysts for the conversion of a wide

range of aldehydes leading to the synthesis of various

(3S)-hydroxyketones. In this study, we have selected

the mesophilic TK from Escherichia coli (TK

eco)

[18d–h]

and the thermostable TK from Geobacillus

stearother-mophilus (TK

gst)

[19,20]to be coupled with DAAO

Rgin a

one-pot two step procedure, starting only from the two

substrates d-serine and an appropriated aldehyde

acceptor for obtaining valuable (3S)-hydroxyketones.

Results and Discussion

Properties of dAAO from R. Gracilis

DAAO

Rgwas overexpressed in E. coli and then

extracted and purified by Ni

2 +chelating affinity

column chromatography as reported earlier.

[10]In order

to use DAAO

Rgunder the best conditions for the

synthesis of HPA in situ from d-serine, we first

determined at analytical scale the stability of the

recombinant flavoenzyme over time at different

tem-peratures and its kinetic parameters using d-serine as

substrate in the presence of oxygen. During turnover

the tightly bound FAD cofactor is reduced by the

d-amino acid to FADH

2and then reoxidized by O

2generating hydrogen peroxide. Since the accumulation

of hydrogen peroxide can lead to an enzyme inhibition,

addition of catalase is required for the dismutation of

hydrogen peroxide to water and oxygen (Scheme 2).

Scheme 1. In situ generation of HPA from TA ordAAO-catalyzed reaction coupled with TK-dAAO-catalyzed reaction.

Scheme 2. Reaction of DAAORg coupled with l-lactate

DAAO

Rgactivity was determined by a coupled

reaction with l-lactate-dehydrogenase (l-LDH)

allow-ing the reduction of HPA in the presence of NADH

(Scheme 2). The disappearance of NADH was

fol-lowed over time by spectrophotometry at 340 nm

(LDH assay).

An optimum DAAO

Rgactivity was previously

described in a 37–45

°C temperature range and a 8.0–

8.5 pH range.

[10]Under those conditions, we observed

that DAAO

Rgfully maintained its activity during

25 hours at 25

°C and at pH 7.5 while at higher

temperature the enzymatic activity decreases

drasti-cally (Figure 1).

The DAAO

Rgkinetic parameters were determined

using the LDH assay described above. The kinetic

parameters toward d-serine were approximatively the

same than those reported in the literature using a

polarographic assay method.

[11]This latter assay has

been used for the determination of kinetic parameters

of other amino acids (Table 1).

DAAO

Rgoffers more substrate flexibility compared

to other dAAOs.

[8,11]Indeed, based on the K

M

values,

the best affinities were apparent for methionine,

d-phenylalanine, d-leucine, and d-alanine. Further amino

acids are also accepted with lower affinities such as

d-serine, d-valine, and d-cysteine. The V

maxobserved for

d-serine is approximately half of the value obtained

with the reference substrate D-alanine. Even if d-serine

is not the best substrate for DAAO

Rg, the K

Mand V

maxvalues are more suitable for biocatalytic applications

compared to those obtained toward l-serine converted

into HPA by TA-catalyzed reaction (K

M22.4 mM; V

max3.3 U. mg

1; V

max/K

M0.14 U. mg

1

. mM

1).

[5]In

addi-tion, the DAAO

Rgcatalyzed reaction is irreversible

offering the possibility to convert d-serine completely

into HPA and making this strategy an efficient

synthetic way for obtaining HPA at preparative scale.

Conversion of d-Serine into HPA Catalyzed by

DAAO

RgFor HPA synthesis from d-serine at preparative scale,

catalase was added dropwise to the reaction mixture,

because addition of a specific quantity of catalase as a

single dose at the beginning of the reaction was found

to be insufficient to ensure the total dismutation of

hydrogen peroxide during the entire reaction period,

thus causing a decrease of dAAO activity. Oxygen was

bubbled into the reactor at a rate of 10 mL. min

1at

atmospheric pressure. The reaction was followed by

quantification of HPA and d-serine over time by

spectrophotometry in aliquots from the reaction

mix-ture. After the completion of the reaction, HPA and

d-serine quantification was performed by in situ

1H

NMR analysis of the reaction mixture.

d-Serine at 50 mM led to almost complete

con-version (90%) in 24 hours while HPA quantification

corresponded to 78% of initial d-serine concentration

(Figure 2). This result may be explained by a slight

HPA degradation over time as previously observed.

[19]In addition, we noted that DAAO

Rgactivity decreased

during the reaction (SI) due to an inhibition by HPA

Figure 1. DAAORgthermostability. DAAORgactivity wasdeter-mined by the LDH assay in the presence of d-serine (50 mM) and O2 at ♦ 25°C, ~ 30°C, * 40°C, & 60°C. 100%

corresponds to initial activity (37.5 U. mg 1 at 25°C and

pH 7.5).

Table 1. Apparent kinetic parameters of DAAORgtoward different d-amino acids (at air saturation).

d-amino acids KM mM Vmax U. mg 1 Vmax/KM U. mg1. mM 1 kcat/KM mM. 1s 1 d-methionine[10] 0.18 115 639 416 d-phenylalanine[10] 0.29 144 497 323 d-leucine[10] 0.50 120 240 156 d-alanine[10] 0.83 140 169 110 d-serine 13.7[10] 61[10] 4.4[10] 3.0

14.0 � 1[a] 48 � 7[a] 3.5 � 0.8[a] 2.3 � 0.5

d-valine[10] 18.9 195 10.3 6.7

d-cysteine[10] 21.4 130 6.1 4.0

already described with 2-oxo-4-methylthiobutyric acid,

the α-keto acid produced from d-methionine

[21a]and

other α-keto acids analogs of amino acids.

[21b]Indeed,

conversion of d-serine into HPA was 66 and 90% at

250 mM and 50 mM, respectively, clearly showing an

inhibition of DAAO

Rgby the ketoacid. To avoid HPA

accumulation and to limit DAAO

Rginhibition, the

DAAO

Rg-catalyzed reaction was therefore coupled

with an irreversible reaction that consumes HPA as

substrate such as a TK-catalyzed reaction.

Hydroxyketone Synthesis from d-Serine and

Vari-ous Aldehydes by DAAO

Rg/TK

gstcoupling

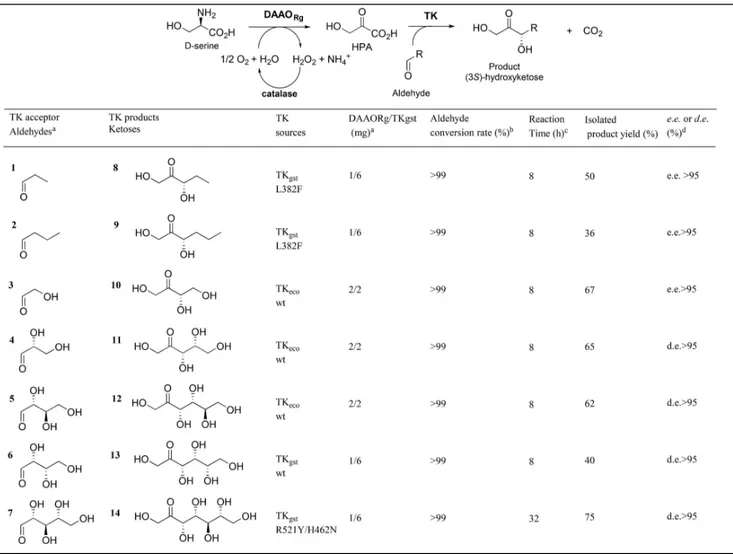

The one-pot, two-step cascade reaction catalyzed by

DAAO

Rgand TK was performed using two substrates:

d-serine and an appropriated aldehyde as TK acceptor

substrate. To validate the strategy, various aldehydes

were chosen, such as non-hydroxylated (1, 2) and

hydroxylated (3–7) aldehydes (Table 2). For better

efficiency, TKs from different sources were used

depending on the aldehyde. Previous substrate

specif-icity studies showed that for wild-type TKs best

substrates are (2R)-configured hydroxylated aldehydes

with hydroxylated short carbon chain length (C

2C

4).

Hence, for hydroxylated aldehydes 3–5 and 6, we

employed wild-type TK

eco[2]and wild-type TK

gst,[19]respectively, reported as the best TK sources for these

substrates, respectively. For non-hydroxylated

alde-hydes 1/2 and for long-chain hydroxylated aldehyde 7,

the reactions were performed using previously

identi-fied, specially designed TK

gstvariants L382F

[20b]and

R521Y/H462N,

[22]respectively.

To study the influence of different concentrations of

both enzymes and substrate, the reaction mixtures were

monitored by in situ

1H NMR of the reaction mixture

for the determination of aldehyde conversion rate and

by enzymatic analysis from aliquots for HPA detection

using the LDH assay described above.

For all reactions, the same concentration (50 mM)

of both substrates d-serine and aldehyde was used. The

ratio DAAO

Rg/TK was adjusted to obtain a total

conversion of d-serine considering that a minimum

amount of both enzymes was used and that HPA was

gradually consumed by TK-catalyzed reaction. As an

example, Figure 2 shows the simultaneous

quantifica-tions of d-serine and HPA in the reaction mixture

containing both DAAO

Rgand TK

ecoenzymes in the

presence of glycolaldehyde 3 as TK

ecoacceptor

substrate. The conversion of d-serine into HPA was

achieved in 8 hours. In parallel, a complete

disappear-ance of glycolaldehyde 3 was observed by in situ

1H

NMR. Hence, the bi-enzymatic cascade avoids HPA

accumulation and DAAO

Rginhibition as shown by the

very rapid conversion of d-serine and 3 (8 hours) as

compared to the longer reaction time required for

d-serine conversion (24 hours) when DAAO

Rgwas not

coupled with TK. This procedure also allowed a rapid

and total conversion (8 hours) of other hydroxylated

(4–6) aldehydes as well as non hydroxylated (1, 2)

aldehydes using the appropriate TKs (Table 2).

All the ketose products 8–13 were purified and

characterized as the only products arising with high

enantio- and diastereoselectivity (> 95%).

Enantiomer-ic excess of products 8, 9, 10 were determined by

chiral GC after peracetylation.

[20c]Moreover, the

absolute configurations of these compounds have been

confirmed by comparison with reference samples as

previously described.

[20c]These results show that DAAO

Rg/TK coupling

allows greatly increasing the d-serine conversion rate

as compared to the dAAO

Rgalone, avoiding the

inhibition of HPA by its gradual consumption in the

TK-catalyzed reaction.

The conversion of aldehyde 7 into product 14 was

performed with the ad hoc designed TK

gstvariant

R521Y/H462N.

[22]We showed that this synthesis must

be carried out at 60

°C for improved conversion rate of

aldehyde 7.

[22]Since DAAO

Rgis not stable at this

temperature for longer times, the reaction was first

performed at 25

°C for HPA synthesis from d-serine

(8 hours) and then TK and aldehyde 7 were added with

increasing the temperature to 60

°C for 24 hours. This

procedure allowed to obtain ketose product 13 in

reasonable reaction time (32 hours) with good isolated

yield (72%) and excellent diastereoselectivity (> 95%).

Conclusions

We developed the first application of DAAO

Rgfor

rapid in situ generation of HPA from d-serine. For

improvement of the HPA synthesis, the DAAO

Rgreaction was coupled with TK

gstin a one-pot, two-step

cascade sequence for ketose synthesis from two

substrates, d-serine and an appropriate aldehyde. The

aldehyde was used as TK acceptor substrate and it was

Figure 2. Comparison of d-serine conversion and HPAforma-tion overtime obtained with DAAORgalone (& d-serine and ♦

HPA) or with DAAORg and TKgst in the presence of

introduced in the reaction mixture at the same

concentration as D-serine. dAAO and TK-catalyzed

reactions were performed simultaneously and applied

to the synthesis of ketose products 8–13 from

aldehydes 1–6 with complete conversion of all

sub-strates in 8 hours. All the targeted compounds were

recovered with high enantio- and diastereoselectivity.

For the conversion of long carbon chain aldehyde 7,

TK-catalyzed reaction requiring elevated temperature

(60

°C) and longer reaction time (32 hours), the two

steps were performed sequentially. The produced

polyhydroxylated products 10–14 are valuable

com-pounds in various fields: l-erythrulose 10 is used in

self-tanning formula,

[23]d-xylulose 11 is an important

intermediate for d-xylose fermentation to ethanol,

[24]d-fructose 12 is a well-known sweetener,

[25]l-sorbose

13 is a precursor of ascorbic acid

[26]and

d-altro-heptulose 14 is a marker of sugar metabolism disorders

such as cystinose.

[27]This environmentally friendly procedure represents

an interesting alternative to the conventional chemical

synthesis of HPA from toxic bromopyruvate and to the

in situ generation of HPA by reversible enzymatic

TA-catalyzed reaction from l-serine requiring an

addi-tional α-keto acid as an amino acceptor and excess of

one substrate to shift the equilibrium. This

straightfor-ward approach could be applied to other aldehydes

using wild-type or variants TK

gstand could be used in

additional cascade reactions involving further

HPA-dependent enzymes such as aldolases.

Table 2. Reaction conditions of the one-pot multi-enzymatic cascade synthesis of ketose products.

[a]Reactions were carried out with DAAO

Rg(1 or 2 mg) and TKgst(2 or 6 mg), ThDP (0.1 mM), MgCl2(1 mM), aldose (50 mM),

D-serine (50 mM) at pH 7 and 25°C.

[b]Aldose acceptor conversion determined by in situIH NMR analysis. [c] 1H NMR of reaction mixture (SI).

[d]Enantiomeric excess (e.e.) determined by chiral GC after peracetylation[20c]and diastereoisomeric excess (d.e.) determined by1H

Experimental Section

General. All chemicals were purchased from Sigma-Aldrich, Alfa-Aesar and CarboSynth. Bradford reagent was from Bio-Rad. Ni-NTA resine was obtained from QIAGEN. Proteins and enzymes were acquired from Sigma-Aldrich. Lyophilisation was carried out with Triad LABCONCO dryer. UV-visible absorbance was measured using a Spark control 10 microplate reader from TECAN and an Agilent Technologies, Cary 300 UV-Vis spectrophotometer enabling Peltier temperature control. MARCHEREY-NAGEL GmbH & Co KG 60/40-63 mesh silica gel for Liquid Flash Chromatography and MARCHEREY-NAGEL GmbH & Co KG 60 F254 silica gel TLC plates with anisaldehyde stain for detection were used. Reaction pH for preparative synthesis was maintained using a TitroLine®7000 autotitrator. NMR spectra were recorded in D2O or DMSO on a

400 MHz Bruker Avance III HD spectrometer. Chemical shifts are referenced to the residual solvent peak. The following multiplicity abbreviations are used: (s) singlet, (d) doublet, (t) triplet, (m) multiplet.

Expression of transketolases (TKecoand TKgst) and d-amino acid oxidase (DAAORg). Escherichia coli strain BL21(DE3) pLysS was used for wild-type TKgst,[19] TKgst L382F,[20c] TKgst

R521Y/H462N[22]and TK eco

[28]overexpression with the plasmid

pET47b and for DAAORg overexpression[11b] with the plasmid

pT7. These strains were stored at 80°C in glycerol (10%). One colony of each recombinant E. coli strain, grown on selective LB agar plates, was transferred into 30 mL liquid LB medium containing ampicillin (100 μg. mL 1) or

kanamy-cin (30 μg. mL 1) and grown at 37°C, 130 rpm for 12 h.

20 mL of the pre-culture was used to inoculate 1 liter of culture medium containing ampicillin (100 μg. mL 1) or

kanamycin (30 μg. mL 1) and grown at 37°C, 200 rpm.

Isopropyl β-D-1-thiogalactopyranoside (IPTG) at 0.5 mM was added when the OD600nm range was 0.7–0.8. The cells

were then grown overnight at 30°C, under stirring at 130 rpm, and harvested by centrifugation at 8000 rpm at 4°C for 15 min. Bacterial pellets were washed twice with phosphate buffer (NaH2PO4· 2H2O, 50 mM), NaCl (300 mM),

pH 8.0) and harvested ( � 5 g/L for TKs and � 2 g/L for DAAORg).

Purification of transketolases (TKeco and TKgst) and D-amino acid oxidase (DAAORg). Harvested recombinant cells from 1 liter of culture were resuspended in 35 mL of phosphate buffer (50 mM) containing NaCl (300 mM) at pH 8.0 for TKs and 14 mL of phosphate buffer (50 mM) containing 2-mercap-toethanol (5 mM) and FAD (0.1 mM) at pH 7.2 for DAAORg.

The cells were disrupted by sonication on ice for 30 min and the insoluble pellets were discarded after centrifugation at 8000 rpm for 15 min at 4°C. Crude extracts were applied to a Ni NTA column equilibrated with phosphate buffer for TKs and with phosphate buffer (50 mM) containing NaCl (1 M), imidazole (20 mM) and glycerol 5% at pH 7.2 for DAAORg.

After washing each column with the same buffer respectively for TKs and DAAORg, the His6-tagged TKs or DAAORg were

finally eluted with phosphate buffer (50 mM) containing NaCl (300 mM) and imidazole (500 mM) at pH 8.0 for TKs and phosphate buffer (50 mM) containing glycerol (5%) imidazole (50 mM) at pH 7.2 for DAAORg. The fractions containing the

eluted proteins were collected and dialyzed against

triethanol-amine buffer (2 mM, pH 7.5) and then against water (pH 7.5) through dialysis tubing (cut-off 14 kDa) at 4°C for TKs and twice against water (pH 7.5) though dialysis tubing at 4°C for DAAORg. Then, these protein solutions were lyophilized.

Protein concentration was determined by the Bradford method and bovine serum albumin (BSA) was used as the standard. The specific activities of lyophilized TKecoTKgst, and DAAORgwere

21 U, 2 U and 37 U per mg of total protein respectively at 25°

C. The purity and molecular mass of these samples were analyzed by SDS-PAGE[29]using Precision Plus Protein™ All

Blue Standards#161-0373 (10–250 kDa, BioRad) as standard. The proteins were revealed with Coomassie Blue G-250. Determination of wild-type TKs (TKeco and TKgst) or variant TKgstactivity.

[5]

One unit of TKgstactivity was defined

as the amount of enzyme that catalyzes the formation of 1 μmol of ketose product per minute at 25°C in glycylglycine buffer (100 mM, pH 7.5). TKgst enzymatic assay was

per-formed in the presence of l-erythrulose and d-ribose-5-phosphate (dR5P) leading to d-sedoheptulose-7-d-ribose-5-phosphate (dS7P) and glycolaldehyde. The glycolaldehyde formed was reduced by yeast alcohol dehydrogenase (ADH) to ethylene glycol in the presence of nicotine adenine dinucleotide reduced form (NADH). l-erythrulose (100 mM), d-R5P (9.1 mM), ThDP (0.1 mM), MgCl2 (0.5 mM), NADH (0.2 mg. mL 1),

5 μL of ADH (25 U. mL 1) and the TK

gst suspension (10 μL)

were added to disposable plastic cuvettes and completed to 1 mL with glycylglycine buffer. The disappearance of NADH was followed by spectrophotometry at 340 nm (value of ɛNADH

at 340 nm is 6220 M. 1cm 1). All measurements were

per-formed in triplicate.

Determination of DAAORg activity. One unit of DAAORg

activity was defined as the amount of enzyme that catalyzes the formation of 1 μmol of hydroxypyruvic acid (HPA) product per minute at 25°C in Tris-HCl buffer (50 mM, pH 7.5). The assay was performed in the presence of d-serine leading to HPA, ammonia and hydrogen peroxide. Catalase, which is essential for the protection of the enzyme, allows dismutation of H2O2

into H2O and O2. The HPA formed was reduced by rabbit

muscle L-lactate dehydrogenase (LDH) to L-lactate in the presence of nicotine adenine dinucleotide reduced form (NADH). d-serine (50 mM), catalase from bovine liver (528– 1320 U. mL 1), LDH (11 U. mL 1), NADH (0.2 mg. mL 1) and

the DAAORg suspension (50 μL) were added to disposable

plastic cuvettes and completed to 1 mL with Tris-HCl buffer. The disappearance of NADH was followed by spectrophotom-etry at 340 nm. All measurements were performed in triplicate. Determination of HPA concentration using LDH assay. The HPA concentration was determined by an enzymatic assay using LDH. A sample of HPA (20 μL) was introduced in a cuvette containing 25 μL of NADH (0.2 mg. mL 1), 20 μL LDH

(187 U. mL 1) and 935 μL of TEA buffer (100 mM) at pH 7.5.

The disappearance of NADH was followed by spectrophotom-etry at 340 nm and difference between initial and final absorbance was used to calculate the HPA concentration using the Beer-Lambert law. All measurements were performed in triplicate.

Determination of d-serine concentration using DAAORg/ LDH assay. The d-serine concentration was determined by a coupled enzymatic assay using a combination of DAAORg,

catalase and LDH. In the spectrophotometric continuous assay d-serine is converted into HPA by DAAORgin the presence of

O2 releasing hydrogen peroxide which is then dismutated in

water and O2 by catalase. HPA produced in situ is reduced by

LDH in the presence of NADH. The assay cuvette (1 mL) contained

25 μL of NADH (10 mg. mL 1), 20 μL of LDH (187 U. mL 1),

50 μL of catalase (17000–44000 U. mL 1), 15 μL of DAAO Rg

(40 U. mL 1) in 855 μL of Tris buffer (50 mM) at pH 7.5. The

reaction was initiated with d-serine or an aliquot of the reaction mixture containing d-serine (20 μL). The disappearance of NADH was followed by spectrophotometry at 340 nm and difference between initial and final absorbance gave the d-serine concentration using the Beer-Lambert law. When assaying the d-serine concentration for DAAORg or DAAORg/

TKgst reaction monitoring, two aliquots (containing both

d-serine and HPA) were removed overtime from the mixture. The HPA concentration was determined using LDH assay from the first aliquot. The second aliquot was assayed with DAAORgand

catalase (DAAORg/LDH assay) in order to quantify the total

concentration of d-serine and HPA at once. Indeed d-serine concentration is not directly accessible since at first the enzyme DAAO converts serine to HPA, which is readily assayed by the enzyme LDH. Thus, the d-serine concentration was obtained by substracting HPA concentration (LDH assay) to the total concentration of d-serine and HPA (DAAORg/LDH assay). All

measurements were performed in triplicate.

In situ1

H NMR measurements. Progress of preparative scale enzymatic synthesis were monitored by using quantitative

in situ 1H NMR relative to

3-trimethylsilyl-2,2,3,3-tetradeuter-opropionate (TSP-d4) as internal standard. Aliquots of the

reaction mixture were removed overtime (450 μL) and mixed with 50 μL of TSP-d4(50 mM in D2O).

Procedure of HPA synthesis catalyzed by DAAORg. d-serine (50 mM) was dissolved in H2O and the pH was adjusted to 7

with 0.1 M NaOH. To this stirred solution were added catalase (1 mg, i. e. 1998 U–4995 U/2 h), and DAAORg (2 mg, 86 U)

giving a final volume of 20 mL. Oxygen was bubbled into the reactor (10 mL. min 1 at atmospheric pressure). The reaction

mixture was stirred (100 rpm) at 25°C, and the pH was automatically maintained at 7 by adding HCl (0.1 M) using a pH stat. Oxygen was bubbled into the reactor (10 mL. min 1at

atmospheric pressure). The reaction was monitored by measur-ing HPA appearance usmeasur-ing LDH assay and d-serine consump-tion using dAAORg/LDH assay. The completion of the reaction

was evidenced by in situ1H NMR.

Procedure of simultaneous or sequential cascade synthesis catalyzed by TK and dAAORg. For simultaneous cascade synthesis, ThDP (0.1 mM), MgCl2· 6H2O (1 mM), d-serine

(50 mM) and acceptor aldehyde (50 mM) were dissolved in H2O and the pH was adjusted to 7 with 0.1 M NaOH. To this

stirred solution were added catalase (1 mg/2 h, 1998–4995 U/ 2 h), TKgst (6 mg, 14 U) and dAAORg (2 mg, 86 U) giving a

final volume of 20 mL. Oxygen was bubbled into the reactor (10 mL. min 1 at atmospheric pressure). The reaction mixture

was stirred (100 rpm) at 25°C and the pH was automatically maintained at 7 by adding 0.1 M HCl using a pH stat.

For sequential cascade synthesis, d-serine (50 mM), DAAORg

(2 mg, 86 U) and catalase (1 mg/2 h, 1998–4995 U/2 h) were dissolved in 20 mL H2O and the pH of the solution was adjusted

to 7 with 0.1 M NaOH. The reaction proceeded at 25°C under stirring (100 rpm) until d-serine was totally converted. After-wards, TKgst (6 mg, 14 U) and its cofactors ThDP (0.1 mM),

MgCl2· 6H2O (1 mM) were added to this solution and the

reaction mixture was heated at 60°C under stirring (100 rpm), while the pH was automatically maintained at 7 by adding 0.1 M HCl, using a pH stat. Oxygen was bubbled into the reactor (10 mL. min 1at atmospheric pressure).

Sequential and simultaneous cascades were monitored by measuring d-serine and aldehydes consumption by in situ 1H

NMR and TLC. After total conversion of d-serine and/or aldehydes (8–32 hours), silica was added to the supernatant and the suspension was concentrated to dryness under reduced pressure before dry loading onto a flash silica column. After silica gel chromatography using eluent CH2Cl2/CH3OH (9:1–

8:2) for products 11–14, ethyl acetate/CH3OH (9:1) for product

10 and cyclohexane/ethyl acetate (1:1) for products 8–9, products 8–14 were isolated.

(3S)-1,3-dihydroxypentan-2-one 8. 8 was isolated as colorless

oil (59 mg, 50% yield with TKgstvariant L382F). TLC: Rf 0.38

(cyclohexane/ethyl acetate, 1/1 v:v). NMR data for 8 were identical to those previously described.[20c] 1H NMR (400 MHz,

D2O): 4,57 (d, 1H, J = 19,3 Hz, H1a); 4,48 (d, 1H, J = 19,3 Hz, H1b); 4,33 (dd, 1H, J = 7,7 Hz, J = 4,4 Hz, H3); 1,82 (dqd, 1H, J = 15,0 Hz, J = 7,5 Hz, J = 4,4 Hz, H4a); 1,66 (dq, 1H, J = 14,5 Hz, J = 7,4 Hz, H4b); 0,93 (t, 3H, J = 7,5 Hz, H5). 13C NMR (101 MHz, D2O): 214,2 (C2), 75,80 (C3), 65,04 (C1), 26,25 (C4), 8,47 (C5). m/z HRMS found [M + HCOO] 163.0612, C6H11O5 requires 163.0601 (obtained with TKgst

variant L382F).

(3S)-1, 3-dihydroxyhexan-2-one 9. 9 was isolated as colorless

oil (42 mg, 36% yield with TKgstvariant L382F). TLC: Rf 0.36

(cyclohexane/ethyl acetate, 1/1 v:v). NMR data for 9 obtained with either TK were identical to those previously described.[20c] 1H NMR (400 MHz, D 2O): 4,56 (d, 1H, J = 19,3 Hz, H1a); 4,47 (d, 1H, J = 19,3 Hz, H1b); 4,36 (dd, 1H, J = 8,3 Hz, J = 4,1 Hz, H3); 1,80–1,64 (m, 1H, H4a); 1,64–1,51 (m, 1H, H4b); 1,48– 1,30 (m, 2H, H5a/b); 0,90 (t, 3H, J = 7,3 Hz, H6). 13C NMR (101 MHz, DMSO): 213,54 (C2), 74,32(C3), 65,13 (C1), 35,45 (C4), 17,92 (C5), 13,75 (C6). m/z HRMS found [M + HCOO] 177.0768, C7H13O5 requires 177.0760 (obtained with TKgst

variant L382F).

(3S)-1,3,4-trihydroxy-butan-2-one 10. 10 was isolated as colorless oil (81 mg,: 67% yield with wt-TKeco). TLC: Rf 0.37

(ethyl acetate/CH3OH; 9:1). NMR data for 10 obtained with

either TK were identical to those previously described.[20b] 1H

NMR (400 MHz, D2O): δ (ppm) 4.55 (dd, J = 19.4 Hz, 2H,

H1a/b); 4.44 (t, J = 4.1 Hz, 1H, H3); 3.89 (dd, J = 4.1 Hz, J = 2.0 Hz, 2H, H4a/b).13C NMR (101 MHz, D

2O): δ (ppm) 212.24

(C2); 75.8 (C3); 65.77 (C1); 62.81 (C4). m/z HRMS found [M + HCOO] 165.0405, C5H9O6requires 165.0396 (obtained with

wt-TKeco).

(3S, 4R)-1,3,4,5-tetrahydroxy-pentan-2-one 11. 11 was iso-lated as colorless oil (92.8 mg, 62% yield with wt-TKeco). TLC:

either TK were identical to those previously described[30](ratio: β-d-xylulo-2,5-furanose/Acyclic form/α-d-xylulo-2,5-furanose: 62/21/17; lit. Ratio: 62/20/18).[31] 1H NMR (400 MHz, D 2O): δ (ppm) β-d-xylulo-2,5-furanose 4.43–4.37 (m, 1H, H4); 4.21 (dd, J = 9.5 Hz, J = 6.5 Hz, 1H, H5a); 4.07 (d, J = 5.6 Hz, 1H, H3); 3.66 (d, 1H, H5b); 3.65–3.56 (m, 2H, H1a/b); acyclic form 4.71–4.51 (m, 2H, H1a/b); 4.48 (d, J = 2.2 Hz, 1H, H3); 4.10 (d, J = 2.8 Hz, 1H, H4); 3.71 (t, 1H, H5b); 3.68 (m, 1H, H5b); α-d-xylulo-2,5-furanose 4.33–4.28 (m, 1H, H4); 4.26 (m, 1H, H5a); 4.10 (q, 1H, H3); 3.89–3.95 (dd, 1H, J = 9.4 Hz, J = 4.1 Hz, H5b); 3.74 (m, 1H, H1a); 3.68 (m, 1H, H1b).13C NMR (101 MHz, D2O): δ (ppm) β-d-xylulo-2,5-furanose 104.39 (C2); 77.69 (C3); 76.34 (C4); 71.29 (C5); 64.48 (C1), acyclic form 214.4 (C2); 76.76 (C3); 73.42 (C4); 67.49 (C1); 63.33 (C5), α-d-xylulo-2,5-furanose 107.18 (C2); 81.96 (C3); 77.30 (C4); 73.37 (C5); 63.88 (C1). m/z HRMS found [M + Cl] 185.0222, C5H10O5Cl requires 185.0217 (obtained with wt-TKgst);

C5H10O5Cl requires (obtained with wt-TKeco).

(3S, 4R, 5S)-1,3,4,5,6-pentahydroxy-hexan-2-one 12. 12 was isolated as colorless oil (72 mg, 40% yield with wt-TKgst). TLC:

Rf 0.40 (CH2Cl2/CH3OH; 8:2). NMR data for 12 obtained with

either TK were identical to those previously described (ratio: 96/4; lit. Ratio: 98/2).[32] 1H NMR (400 MHz, D 2O): δ (ppm) α-l-sorbo-2,6-pyranose 3.74 (d, J = 4.8 Hz, 1H, H6a); 3.71 (d, J = 11.8 Hz, 1H, H1a) 3.69 (d, J = 1.9 Hz, 1H, H4); 3.65 (d, J = 10.1 Hz, 1H, H6b); 3.64 (m, 1H, H5); 3.52 (d, J = 18 Hz, 1H, H1b); 3.51 (d, J = 2.9 Hz, 1H, H3); α-l-sorbo-2,5-furanose 4.43 (t, J = 6.3 Hz, 1H, H4); 4.31 (tt, J = 6.6 Hz, J = 3.3 Hz, 1H, H5); 4.12 (d, J = 6.1 Hz, 1H, H3); 3.81 (d, J = 3.7 Hz, 1H, H6a); 3.78 (d, J = 4.0 Hz, 1H, H6b); 3.62 (d, J = 3.5 Hz, 1H, H1a); 3.59 (d, 1H, J = 5.3 Hz, H1b). 13C NMR (101 MHz, D2O): δ (ppm) α-l-sorbo-2,6-pyranose 98.48 (C2); 74.59 (C4); 71.12 (C3); 70.16 (C5); 64.23 (C1); 62.52 (C6), α-l-sorbo-2,5-furanose 102.5 (C2); 78.45 (C5); 76.70 (C3); 76.05 (C4); 63.82 (C1); 61.41 (C6). m/z HRMS found [M + Cl] 215.0328, C6H12O6Cl requires 215.0322 (obtained with wt-TKgst).

(3S, 4R, 5R)-1,3 4 5,6-pentahydroxy-hexan-2-one 13. 13 was isolated as colorless oil (118 mg, 65% yield with wt-TKeco).

TLC: Rf 0.19 (CH2Cl2/CH3OH; 8:2). NMR data for 13 obtained

with either TK were identical to those previously described (ratio: 73/22/5; lit. Ratio: 75/21/4).[32,33] 1H NMR (400 MHz,

D2O): δ (ppm) β-d-fructo-2,6-pyranose 4.09–4.04 (m, 1H, H6a); 4.04–4.02 (m, 1H, H5); 3.93 (dd, J = 10.0 Hz, J = 3.5 Hz, 1H, H4); 3.83 (d, J = 10.0 Hz, 1H, H3); 3.76–3.72 (m, 2H, H6b, H1a); 3.60 (d, J = 11.7 Hz, 1H, H1b), β-d-fructo-2,5-furanose 4.17–4.13 (m, 2H, H3, H4); 3.84 (m, 1H, H5); 3.83 (m, 1H, H6a); 3.69 (m, 1H, H6b); 3.63 (d, J = 12.1 Hz, 1H, H1a); 3.58 (d, J = 12.1 Hz, 1H, H1b), α-d-fructo-2,5-furanose 4.17–4.13 (m, 2H, H3, H5); 4.05–4.01 (m, 1H, H4); 3.86–3.82 (m, 1H, H6a); 3.74–3.70 (m, 1H, H6b); 3.72–3.68 (m, 2H,H1a/b). 13C NMR (101 MHz, D2O): δ (ppm) β-d-fructo-2,6-pyranose 99.12 (C2); 70.72 (C4); 70.25 (C5); 68.61 (C3); 64.94 (C1); 64.42 (C6), β-d-fructo-2,5-furanose 102.54 (C2); 81.72 (C5); 76.44 (C3); 75.49 (C4); 63.74 (C1); 63.43 (C6), α-d-fructo-2,5-furanose 105.49 (C2); 83.0 (C3); 82.37 (C5); 77.09 (C4); 63.96 (C1); 62.15 (C6). m/z HRMS found [M + Cl] 215.0328, C6H12O6Cl requires 215.0321 (obtained with wt-TKeco).

(3S,4R,5R,6R)-1,3,4,5,6,7-hexahydroxy-heptan-2-one 14. 14 was isolated as colorless oil (157 mg, yield: 75% with TKgst

variant R521Y/H462N). TLC: Rf 0.22 (CH2Cl2: CH3OH, 80:20

v:v). NMR data for 14 obtained with either TK were identical to those previously described[22] (ratio:

β-D-altro-heptulo-2,5- furanose/α-D-altro-heptulo-2,6-pyranose/α-D-altro-heptulo-2,5-furanose: 67/19/14; lit. ratio: β-D-altro-heptulo-2,5-fura-nose/α-D-altro-heptulo-2,6-pyranose/α-D-altro-heptulo-2,5 fur-anose: 64/20/16.[20d,22] 1H NMR (400 MHz, D 2O): δ (ppm) = (β-D-altro-heptulo-2,5-furanose): 4.30-4.23 (m, 1H, H4), 4.05 (d, J = 7.9 Hz, 1H, H3), 3.80 (d, J = 3.3 Hz, 1H, H6), 3.73–3.72 (m, 1H, H5), 3.63–3.57 (m, 2H, H7a/b), 3.53 (d, J = 12.1 Hz, 1H, H1a), 3.54 (d, J = 12.1 Hz; H1b); (α-D-altro-heptulo-2,6-pyranose): 4.04 (d, J = 7.4 Hz, 1H, H4), 3.98 (m, 1H, H6), 3.91 (d, J = 3.7 Hz, 1H, H3), 3.83 (dd, J = 4.1 Hz, J = 1.9 Hz, 2H, H7a/b), 3.81 (m, 1H, H5), 3.65 (d, J = 11.7 Hz, 1H, H1a), 3.46 (d, J = 11.7 Hz, 1H, H1b); (α-d-altro-heptulo-2,5-furanose): 4.14 (dd, J = 6.1 Hz, J = 4.5 Hz, 1H, H4), 3.94 (d, J = 2.6 Hz, 1H, H3), 3.88–3.84 (m, 2H, H5, H6a), 3.79–3.75 (m, 1H, H6b), 3.69 (d, J = 9.3 Hz, 1H, H1a), 3.51 (d, J = 11.7 Hz, 1H, H1b). 13C NMR (101 MHz, D 2O): δ (ppm) = (β-d-altro-heptulo-2,5-furanose): 101.6 (C-2), 80.1 (C-5), 75.6 (C-3), 75,3 (C-4), 72.6 (C-6), 62.4 (C-1), 62.2 (C-7); (α-d-altro-heptulo-2,6-pyranose): 97.4 (C-2), 70.8 (C-4), 68.7 (C-6), 68.2 (C-3), 64.0 (C-1), 63.4 5), 61.2 7); (α-d-altro-heptulo-2,5-furanose): 104.6 (C-2), 81.7 (C-3), 81.6 (C-5), 76.4 (C-4), 71.5 (C-6), 62.7 (C-1), 62.3 (C-7). m/z HRMS found [M + HCOO] 245.0431, C8H15O9requires 245.0431 (obtained with TKgstvariant R521Y/

H462 N).

Acknowledgements

This work was funded by the Fonds Régional Innovation Laboratoire (grant DOS00494484/00, to L.H.), by the Agence Nationale de la Recherche (grant ANR-09-BLAN-0424-CSD3 to L.H.) and by ERA CoBioTech TRALAMINOL – ID: 64 (grant to W.D.F and L.H.).

References

[1] P. Clapes, W.-D. Fessner, G. Sprenger, A. K. Samland,

Curr. Opin. Chem. Biol. 2010, 14, 154–167.

[2] N. J. Turner, Curr. Opin. Biotechnol. 2000, 11, 527–531. [3] F. Dickens, D. H. Williamson, Biochem. J. 1958, 68, 74–

81.

[4] L. Hecquet, J. Bolte, C. Demuynck, Tetrahedron 1996,

52, 8223–823.

[5] M. Lorillière, M. De Sousa, F. Bruna, E. Heuson, F. Gefflaut, V. de Berardinis, T. Saravanan, D. Yi, W.-D. Fessner, F. Charmantray, L. Hecquet, Green Chem. 2017,

19, 425–435.

[6] a) F. Subrizi, M. Cárdenas-Fernández, G. J. Lye, J. M. Ward, P. A. Dalby, T. D. Sheppard, H. C. Hailes, Green

Chem. 2016, 18, 3158–3165; b) M. Bawn, F. Subrizi,

G. J. Lye, T. D. Sheppard, H. C. Hailes, J. M. Ward,

Enzyme Microb. Technol. 2018, 116, 16–22.

[7] a) L. Pollegioni, G. Molla, S. Sacchi, E. Rosini, R. Verga, M. S. Pilone, Appl. Microbiol. Biotechnol. 2008,

78, 1–16; b) L. Pollegioni, P. Motta, G. Molla, Appl. Microbiol. Biotechnol. 2013, 97, 9323–9341.

[8] L Pollegioni, L Piubelli, S Sacchi, M. S. Pilone, G. Molla, Cell. Mol. Life Sci. 2007, 64, 1373–1394.

[9] a) B. Curti, S. Ronchi, S. M. Pilone, D- and L-amino

acid oxidases, Chemistry and Biochemistry of

Flavoen-zymes, 1991, 3, CRC Press, Boca Raton, pp. 69–96; b) M. S. Pilone, L. Pollegioni, Biocatal. Biotransform.

2002, 20, 145–159.

[10] C. Demuynck, J. Bolte, L. Hecquet, H. Samaki,

Carbohydr. Res. 1990, 206, 79–86.

[11] a) L. Pollegioni, A. Falbo, M. S. Pilone, Biochim.

Biophys. Acta 1992, 120, 1–16; b) S. Fantinato, L.

Pollegioni, S. M. Pilone, Enzyme Microb. Technol. 2001,

29, 407–412.

[12] L. Pollegioni, K. Diederichs, G. Molla, S. Umhau, W. Welte, S. Ghisla, M. S. Pilone, J. Mol. Biol. 2002, 324, 535–546.

[13] L Pollegioni, S Iametti, D Fessas, L Caldinelli, L Piubelli, A Barbiroli, M. S. Pilone, F. Bonomi, Protein

Sci. 2003, 12, 1018–1029.

[14] a) T. A. Savidge, Enzymatic conversion used in the

production of penicillins and cephalosporins. In: E. J.

Vandamme (ed.), Biotechnology of industrial antibiotics. Dekker, New York. 1984, 171–224; b) M. S. Pilone, S. Butò, L. Pollegioni, Biotechnol. Lett. 1995, 17, 199–204; c) L. Pollegioni, L. Caldinelli, G. Molla, S. Sacchi, M. S. Pilone, Biotechnol. Prog. 2004, 20, 467–473.

[15] a) T. Tosa, R. Sano, I. Chibata, Agric. Biol. Chem. 1974,

38, 1529–1534; b) A. Caligiuri, P. D’Arrigo, E. Rosini,

D. Tessaro, G. Molla, S. Servi, L. Pollegioni, Adv. Synth.

Catal. 2006, 348, 2183–2190.

[16] a) S. Tu, D. B. McCormick, Sep. Sci. 1972, 7, 403–408; b) L. Pollegioni, G. Molla, Trends Biotechnol. 2011, 29, 276–283.

[17] H. Ikeda, Y. Yonetani, S. I. Hashimoto, Process for producing D-serine, US 7,186,532 B2, Kyowa Hakko Kogyo Co Ltd.

[18] a) C. Wikner, L. Meshalkina, U. Nilsson, M. Nikkola, Y. Lindqvist, M. Sundstrom, G. Schneider, J. Biol. Chem.

1994, 269, 32144–32150; b) F. Charmantray, V. Helaine,

B. Legeret, L. Hecquet, J. Mol. Catal. B: Enzym. 2009,

57, 6–9; c) A. Ranoux, S. K. Karmee J. Jin, A. Bhaduri,

A. Caiazzo, I. W. Arendsand U. Hanefeld,

ChemBio-Chem 2012, 13, 1921–1931; d) G. A. Sprenger, U.

Schörken, G. Sprenger, H. Sahm, Eur. J. Biochem. 1995,

230, 525–532; e) G. R. Hobbs, R. K. Mitra, R. P.

Chauhan, J. M. Woodley, M. D. Lilly, J. Biotechnol.

1996, 45, 173–179; f) T. U. Zimmermann, G. A. Sprenger, W.-D. Fessner, Tetrahedron: Asymmetry 1999,

10, 1643–1646; g) M. E. B. Smith, E. G. Hibbert, A. B.

Jones, P. A. Dalby, H. C. Hailes, Adv. Synth. Catal. 2008,

350, 2631–2638; h) A. Cázares, J. L. Galman, L. G.

Crago, M. E. Smith J. Straford, L. Ríos-Solís, G. L. Lye, P. A. Dalby, H. C. Hailes, Org. Biomol. Chem. 2010, 8, 1301–1130.

[19] J. Abdoul Zabar, I. Sorel, V. Hélaine, F. Charmantray, T. Devamani, D. Yi V. de Berardinis, D. Louis, P. Marlière, W.-D. Fessner, L. Hecquet, Adv. Synth. Catal. 2013, 355, 116–128.

[20] a) J. Abdoul Zabar, M. Lorillière, D. Yi, L. Nauton, F. Charmantray, V. Hélaine, W.-D. Fessner, L. Hecquet,

Adv. Synth. Catal. 2015, 357, 1715–1720; b) K. Benaissi,

V. Hélaine, V. Prévot, C. Forano, L. Hecquet, Adv. Synth.

Catal. 2011, 353, 1497–1509; c) D. Yi, T. Saravanan, T.

Devamani, F. Charmantray, L. Hecquet, W.-D. Fessner,

Chem. Commun. 2015, 51, 480–483; d) T. Saravanan,

M. L. Reif, D. Yi, M. Lorillière, F. Charmantray, L. Hecquet, W.-D. Fessner, Green Chem. 2017, 19, 481– 489; e) T. Saravanan, S. Junker, M. Kickstein, J. Hegen, S. Hein, M. K. Link, S. Witt, M. Lorillière, L. Hecquet, W.-D. Fessner, Angew. Chem. Int. Ed. 2017, 56, 5358– 5362.

[21] a) J. A. Moreno, J. Catalán, M. A. Galán, Biotechnol.

Lett. 1994, 16, 8, 843–848; b) J. A. Moreno, F. J.

Montes, J. Catalán, M. A. Galán, Enzyme Microb.

Technol. 1996, 18, 379–382.

[22] M. Lorillière, R. Dumoulin, M. L’enfant, L. Nauton, A. Rambourdin, V. Thery, W.-D. Fessner, F. Charmantray, L. Hecquet, 2018, submitted.

[23] K. Jung, M. Seifert, T. Herrling, J. Fuchs, Spectrochim.

Acta A Mol Biomol. Spectrosc. 2008, 69, 1423–1428.

[24] K. Karhumaa, R. G. Sanchez, B. Hahn-Hägerdal, M.-F. Gorwa-Grauslund, Microb. Cell. Fact. 2007, 6:5. [25] H. D. Belitz, W. Grosch, P. Schieberle, in Food

Chemistry 2009, 248–270, Heidelberg: Springer-Verlag.

[26] L. L. Gao, G. C. Du, J. W. Zhou, J. Chen, J. Liu,

Biotechnol. Prog. 2013, 29, 1398–1404.

[27] a) M. M. Wamelink, E. A. Struys, E. E. W. Jansen, H. Blom, T. Vilboux, W. A. Gahl, M. Komhoff, C. Jakobs, E. N. Elevtchenko, Mol. Genet. Metab. 2011, 3, 339– 342; b) M. M. C. Wamelink, E. A. Struys, V. Valayanno-poulos, M. Gonzales, J.-M. Saudubray, C. Jakobs,

Prenatal Diagn. 2008, 5, 460–462.

[28] Y. Dong, T. Devamani, J. Abdoul-Zabar, F. Charmantray, V. Helaine, L. Hecquet, W.-D. Fessner, ChemBioChem

2012, 13, 2290–2300.

[29] U. K. Laemmli, Nature 1970, 227, 680–685.

[30] T. Vuorinen, A. S. Serianni, Carbohydr. Res. 1991 209, 13–31.

[31] J. Wu, A. S. Serianni, T. Vuorinen, Carbohydr. Res.

1990, 206, 1–12.

[32] T. Barclay, M. Ginic-Markovic, M. R. Johnston, P. Cooper, N. Petrovsky, Carbohydr. Res. 2012, 347, 136– 141.