Intégration de la technologie d'électro-activation en

solution comme approche écologique dans le

processus de valorisation du tourteau de soja

Thèse

Natela Gerliani

Doctorat en sols et environnement

Philosophiæ doctor (Ph. D.)

Intégration de la technologie d'électro-activation en

solution comme approche écologique dans le

processus de valorisation du tourteau de soja

Thèse

Natela Gerliani

Sous la direction de :

Mohammed Aider, directeur de recherche

Riadh Hammami, codirecteur de recherche

RÉSUMÉ

Actuellement, la demande pour trouver des sources alternatives de production d’ingrédients alimentaires de valeur tels que les protéines et les extraits riches en nutriments a augmenté de manière hautement significative. Dans ce contexte, le tourteau de soja est une source précieuse de protéines, de glucides et d'autres composés qui peuvent être valorisés et utilisés dans l'alimentation humaine. Cependant, pour extraire des substances ayant une valeur nutritionnelle élevée, on utilise généralement des procédés d’extraction conventionnels basés sur une utilisation accrue des acides forts (HCl, H2SO4) et des bases concentrées (NaOH, KOH). Sur le plan de santé et sécurité au travail, ces produits chimiques hautement dangereux et corrosifs présentent plusieurs inconvénients; notamment la nécessité de disposer de moyens hautement efficaces de protection et de gestion de risque chimique et du personnel qualifié pour leur manutention. En plus, l’utilisation de ces produits chimiques a, à son tour, un impact important sur l’environnement, car leurs effluents sont très dommageables des écosystèmes et nécessitent des moyens d’épuration très coûteux. Conséquemment, la recherche d’autres technologies de substitution partielle ou complète aux procédés d’extraction conventionnels demeure un sujet d’actualité, ce qui amène les entreprises modernes et soucieuses de la protection de l’environnement à s’intéresser au développement de nouvelles technologies durables d'extraction afin de réduire les impacts négatifs de cette industrie. Dans ce contexte, pour résoudre ces problèmes, la technologie d'électro-activation (EA) en solution, qui fait l’objet d’une programmation de recherche de grande envergure de notre équipe, a montré d’excellentes perspectives pour être utilisée comme approche efficace pour l’extraction des matières solubles à partir de résidus issus de pratiques agroalimentaires. Sur le plan environnemental, cette technologie pourrait servir à la réduction des effluents, car, elle ne nécessite que de l'eau, du sel et de l'électricité pour générer des solutions acides (anolytes) et basiques (catholytes) utilisables pour des fins d’extraction. Ainsi, ces solutions pourraient remplacer, partiellement ou totalement, les acides et bases chimiques. Ainsi, ce projet de doctorat en Sols et environnement, divisé en quatre objectifs spécifiques, visait à étudier l’intégration de la technologie d’électro-activation en solution, comme moyen de substitution aux acides et bases chimiques, dans un procédé de valorisation de tourteau de soja à des fins alimentaires humaines, tout en apportant une contribution significative à la protection de l’environnement.

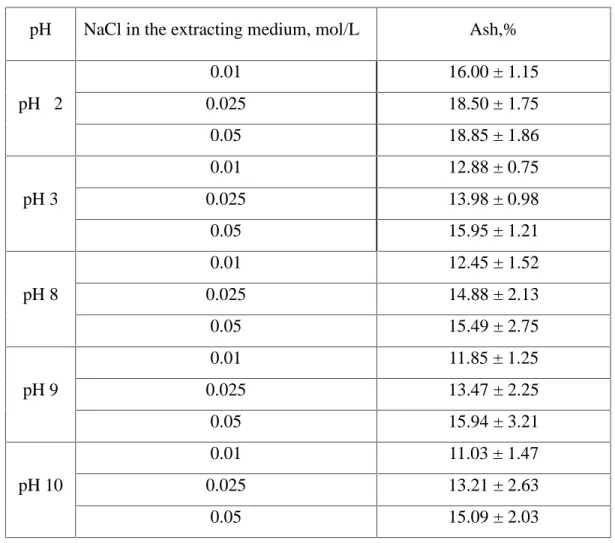

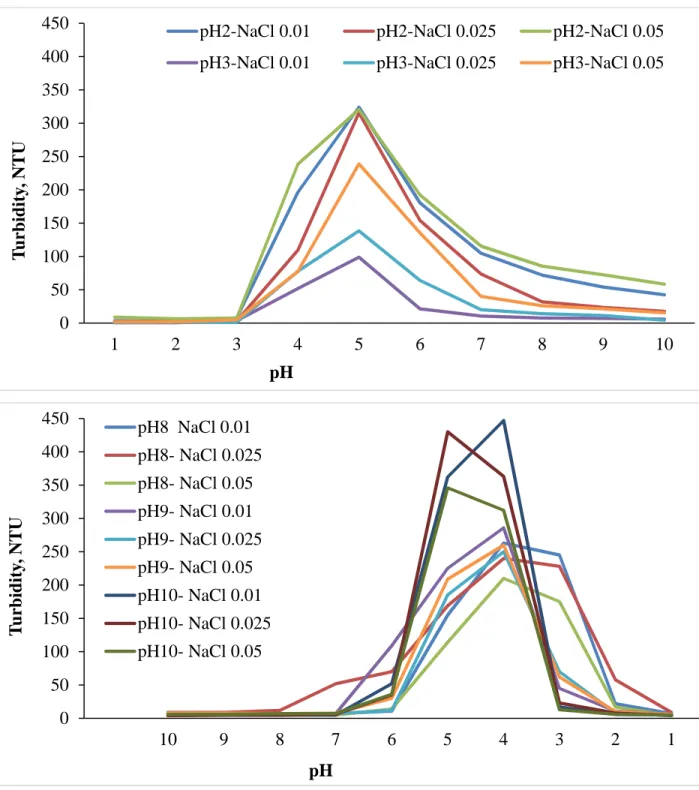

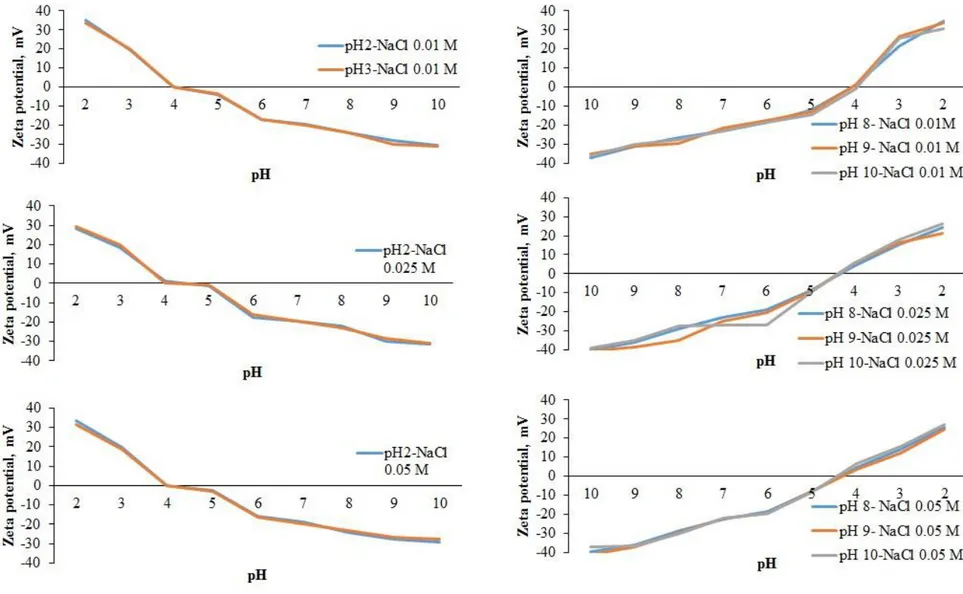

Le premier objectif de ce projet de doctorat visait à étudier et comparer l’extraction acide versus l’extraction basique de la matière sèche soluble à partir de tourteau de soja. Cette matière sèche soluble est composée principalement d’un mélange de protéines, de glucides et de minéraux. L'extraction alcaline a été effectuée à pH 8, 9 et 10 alors que l'extraction acide a été effectuée à pH 2 et 3. Dans les deux modes d'extraction, différentes concentrations de NaCl ont été ajoutées au milieu d’extraction (0.01, 0.025 et 0.05 M). Les résultats obtenus ont montré que les deux méthodes étaient efficaces en termes d'extraction de matière sèche soluble avec des différences qualitatives et quantitatives significatives. L'extraction alcaline était significativement plus efficace en termes de matière sèche totale extraite et de teneur en protéines de l’extrait avec des valeurs moyennes de 39.97 ± 0.23% à 43.35 ± 2.90%, respectivement. Les extraits acides et alcalins étaient caractérisés par une teneur élevée (mg/100 g) en minéraux spécifiques tels que le potassium (334.93 ± 41.93), le calcium (24.73 ± 10.32) et le magnésium (35.34 ± 10.86). Les données obtenues par électrophorèse sur gel (SDS-PAGE) ont confirmé l'efficacité du mode alcalin en termes de teneur en protéines par les bandes plus évidentes. La turbidité la plus élevée a été obtenue à pH 4-5 pour tous les extraits, tandis que le potentiel zêta indiquait un point isoélectrique pHi à pH 4-5 pour les extraits alcalins et un pHi à pH 7-8 pour les extraits acides. Les glucides extraits ont montré un profil pH-dépendant avec un potentiel d’utilisation de l’extrait comme prébiotique. Dans l’ensemble, cette étude a mis en évidence l’efficacité et l’utilisation rationnelle des extractions combinées acide-alcaline pour améliorer la valorisation du tourteau de soja dans les applications alimentaires et réduire les déchets générés par l’industrie de production de l’huile de soja.

Le deuxième objectif consistait à étudier la technologie d'électro-activation permettant d'extraire la matière sèche soluble du tourteau de soja constituée d’un mélange de protéines, de glucides et de minéraux. Les extractions dans des conditions alcalines (catholyte) et acides (anolyte) ont été effectuées avec des solutions électro-activées obtenues à des intensités de courant électrique de 150, 300 et 450 mA pendant 10, 20, 30, 40 et 50 minutes d’électro-activation. Les deux méthodes ont été efficaces pour extraire la matière sèche soluble du tourteau de soja. Le catholyte était le plus efficace pour extraire les protéines avec un rendement maximal de 45.55 ± 2.77 %. De plus, la teneur en protéines augmentait avec le temps de traitement dans les extraits au catholyte, mais diminuait dans les échantillons

extraits par l’anolyte. Les analyses par SDS-PAGE ont confirmé l'efficacité du catholyte à extraire davantage de protéines de meilleure qualité que l'anolyte. Des résultats similaires ont été observés pour les profils d'acides aminés, car les échantillons extraits par le catholyte étant les plus riches en acides aminés essentiels et non essentiels. Bien que l'anolyte ait extrait les quantités les plus élevées des minéraux comme le Mg2+(78 %), Ca2+(37 %) et P3-(37 %) du tourteau de soja, le catholyte s'est avéré plus efficace pour extraire le Zn2+ (65 %), Fe2+ (62 %), et les ions Cu2+ (42 %). Les échantillons obtenus à la fois par l’utilisation des solutions anolytes et catholytes présentaient de bons profils glucidiques contenant certains monosaccharides avec un potentiel de pouvoir prébiotiques. Le profil des glucides variait avec l’intensité du courant électrique utilisé pour la production de solutions électro-activées et le temps de traitement. La teneur en stachyose et en raffinose augmentait avec l’intensité utilisée pour la production des anolytes tout en diminuant dans les échantillons des catholytes. De manière similaire, les teneurs les plus élevées en stachyose et en raffinose ont été observées pour les échantillons obtenus avec la solution catholyte électro-activée pendant 10 min, avec des valeurs respectives allant de 206.64 à 222.49 et de 31.17 à 34.29 mg/g. Les échantillons traités avec l'anolyte électro-activé pendant une plus longue période (30 à 50 min) étaient caractérisés par des teneurs plus élevées en ces sucres.

Le troisième objectif visait à étudier et comparer les propriétés fonctionnelles et l'activité antioxydante de la matière sèche extraite du tourteau de soja de manière conventionnelle et comparées à celles des extraits obtenus par des solutions électro-activées. La capacité d'absorption d'eau (WAC) de l'extrait conventionnel obtenu à pH 8-0.01M NaCl présentait la valeur de WAC la plus élevée (400 ± 7 g/100 g), tandis que la WAC le plus faible (0) était celui des échantillons extraits sous NaCl pH3-0.01M et pH3-0.05M NaCl. L'extrait obtenu avec la solution électro-activée Anolyte_300mA-30min avait une valeur de WAC de 25 ± 1 g/100 g, tandis que la valeur minimale de WAC de 0 g/100 g était observée pour l'extrait obtenu avec de l'anolyte électro-activé Anolyte_450mA-50min et Catholyte_150mA-10min. La capacité d'absorption d'huile (OAC) était la plus élevée pour les échantillons extraits sous des conditions alcalines, quel que soit le mode d'extraction utilisé (conventionnelle ou électro-activation), avec des valeurs comprises entre 5,50 ± 0,54 et 6,85 ± 0,62 mL/g. Les extraits obtenus à pH3-0,05M NaCl et Anolyte_450mA-50min ont des valeurs OAC respectives de 1,85 ± 0,23 et 1,51 ± 0,13 mL/g. Les propriétés moussantes

des extraits classiques étaient supérieures à celles extraites par électro-activation. La valeur maximale de 52% a été observée pour l'échantillon conventionnel obtenu à pH 9-0,025M NaCl, tandis que la capacité de moussage maximale de 28% a été détectée dans l'échantillon électro-activé obtenu avec Anolyte_450mA-50min. Les échantillons électro-activés ont été caractérisés par des propriétés émulsifiantes plus élevées. Les extraits classiques ont montré une activité antioxydante supérieure (92.31 ± 1.5%) à celle obtenue par électro-activation (47.46 ± 0.94%). Les résultats obtenus dans le présent travail mettent en évidence le pouvoir émulsifiant des solutions électro-activées, suggérant sa grande aptitude à être utilisés dans des formulations alimentaires telles que les boissons prêtes à boire et autres produits du type émulsion.

Le quatrième objectif visait à étudier la qualité et le comportement des boissons contenant des extraits obtenus à partir de tourteau de soja par électro-activation. Toutes les boissons produites ont été additionnées d’une poudre de lactosérum pour une teneur final dans le produit de 0.7%. Les boissons de soja ont été codées avec des lettres allant de A à I. Les boissons ayant les codes G, H et I contenaient des particules de protéines plus grosses que les autres échantillons. Ensuite, la viscosité de la majorité des échantillons était faible et les boissons avaient un comportement d’amincissement par cisaillement. Les solutions étaient visuellement stables même si les mesures de turbidité et de potentiel zêta ont montré que le système de produits n'est pas stable dans une plage de pH de 3 à 10. De plus, la solubilité des échantillons était bonne, en particulier pour les échantillons G (97.76 ± 0.04%) et H (97.53 ± 0.18%). De plus, les échantillons I et F ont montré une capacité de moussage très élevée avec une valeur de 98 ± 7.34% et 80 ± 5.25%, respectivement. La boisson ayant le code G présentait une capacité d'absorption d'eau élevée (530 g/100 g). De plus, les valeurs de récupération des protéines de caillé obtenues à partir du coagulum variaient de 56,57 ± 2.17 à 98.57 ± 6.37%.

ABSTRACT

Recently, the demand to find the alternative sources of valuable compounds such as proteins increased. Soybean meal is a valuable source of proteins, carbohydrates and other compounds. These compounds can be valorized from soybean meal and used in human feed. However, to extract valuable substances usually conventional acids and alkalis are used. The use of these chemical solutions, in its turn, has a big impact on the environment as well as other negative consequences. As a result, modern enterprises are more interested in sustainable extraction technologies in order to reduce these negative consequences. To solve these problems the technology of electro-activation (EA) was observed and showed good abilities in extracting of the valuable substances. This technology requires only water, salt and electricity. This work was aimed to study weather this alternative type of extraction is effective for soybean meal valorization.

The first objective was to study conventional extraction and its ability to extract proteins and carbohydrates. Certain parameters of conventional extraction affect the most protein extractability. Thus, from pH, meal to solvent ratio, and salt concentration parameters, the pH of the extracting medium had the most significant effect on protein extractability for conventional extracts. The procedure of extraction was carried out using alkaline (NaOH) and acid (HCl) solutions. As a result, a soluble dry matter composed of proteins, carbohydrates and minerals was extracted from soybean meal. The obtained results showed that the both alkaline and acid methods, that were used, are effective in terms of extraction of soluble dry matter with significant qualitative and quantitative differences. The alkaline extraction was significantly more effective in terms of the total extracted dry matter and protein content in the extracted material with mean values of 39.97 ± 0.23 and 43.35 % ± 2.90, respectively. In fact, this study demonstrated the effectiveness and rational use of the dual acid-alkaline extraction to enhance the soybean meal valorization for food applications and provide reduction of waste generated by the soybean oil industry.

Second objective was to study the influence of electro-activated solutions on proteins extracted from soybean meal and to compare them to the conventional solutions obtained in the first objective. In order to produce electro-activated samples, the optimal parameters of electro-activation for high extraction yield from soybean meal were studied. It was observed that pH changes, right after the electricity is applied, each 10 mins till 60 mins the pH

increased significantly. After the extraction of compounds by electro-activation technique was performed, the comparison of the conventional and electro-activated samples took place. It was found that electro-activation is effective as protein extraction method and for extraction of other compounds with beneficial properties for environment. However, conventional extraction is harmful for the environment, even though the commercial extracts were of higher extraction yield and with the bands of bigger molecular weight. Nonetheless, it was found that when the contact time of electro-activated solution with material is increased, the extraction yield and quality of protein is significantly higher. While for conventional extracts treated by the same time there was no significant difference.

Third objective aimed to study the comparison of functional properties and antioxidant activity of soybean meal extracts obtained by conventional extraction and using electro-activated solutions. The commercial samples were characterized by superior water absorption and foaming capacity. In contrast, electro-activated samples were characterized by superior emulsification properties. Therefore, conventional samples showed higher antioxidant activity (92.31±1.5%) than electro-activated ones (47.46±0.94%). Overall, this study demonstrated favorable functional and antioxidant properties of samples made by electro-activation method.

The fourth objective was to evaluate the behaviour of functional beverage by using protein-carbohydrate extract obtained from soybean meal produced by electro-activation technology. The results showed that the particle size value was ≤ 0.2 μm for majority of the samples. However, with an increasing of the flow the particle size also increased due to large protein particles formed as complexes of a definite size. Furthermore, the behaviour of systems had Newtonian nature and shear-thinning behavior with the low viscosity which is good for such products as beverages. In addition, the turbidity and z-potential measurements showed that the system of products is not stable in pH range 3-10. Moreover, solubility of samples was quite good, especially for certain samples, it was 97.76±0.04 % and 97.53±0.18%. To conclude, these beverages are high in protein and can serve as nutritional beverages. Regarding the result of this work it can be claimed that electro-activated solutions as extracting agents are quite powerful. Also, additional and very important advantage of electro-activation is option of rejection from conventional chemicals which is an important point for sustainable development.

TABLE OF CONTENTS

RÉSUMÉ ... iii

ABSTRACT ... vii

TABLE OF CONTENTS ... ix

LISTE OF TABLES...xv

LIST OF FIGURES... xvi

LIST OF ABREVIATIONS... xviii

DEDICATIONS... xix

ACKNOWLEDGEMENTS ... xx

FOREWORD ... xxi

INTRODCUTION... 1

CHAPTER 1: LITERATURE REVIEW ... 4

1.1 Soybean information... 4

1.1.1 Soybean history... 4

1.1.2 Production of soybeans... 4

1.2 Soybean oil... 5

1.3 Soybean meal review... 6

1.4 Treatment of plant by-products in food production... 7

1.5 Protein content of soybean meal... 9

1.6 Protein size distribution... 11

1.7 Functional properties of soybean proteins... 12

1.7.1 Solubility... 12

1.7.2 Oil binding capacity... 12

1.7.3 Emulsifying Properties... 13

1.7.4 Foaming Properties... 13

1.8 Carbohydrates content in soybean meal... 13

1.9 Prebiotics... 15

1.9.1 Mechanism of prebiotics... 15

1.9.2 Immunomodulation by prebiotics... 16

1.10 Mineral content... 16

1.10.1 Vitamins and fatty acids... 17

1.11 Antioxidants and phenolic compounds of soybean... 19

1.12.1 Phytic acid... 20

1.12.2 Trypsin inhibitors... 21

1.12.3 Lectins in soybeans... 22

1.12.4 Saponins compounds in the soy... 23

1.13 Conventional extraction of protein... 23

1.13.1 Alkaline extraction... 23

1.13.2 Acid extraction... 24

1.13.3 Trichloroacetic acid (TCA)/acetone precipitation... 24

1.13.4 Phenol extraction and methanol precipitation... 24

1.14 Soy protein utilization... 25

1.14.2 Soy-based drinks... 27

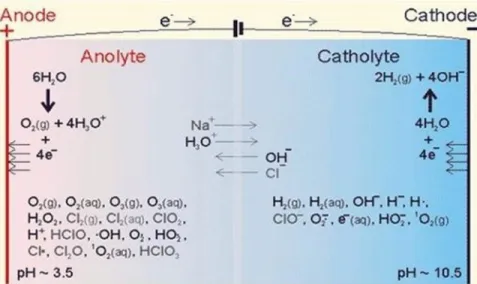

1.15 Electro-activation as sustainable method of protein extraction from soybean meal 27 1.15.1 Environmental impact of conventional chemicals used for protein extraction. 27 1.15.2 Electrochemistry and environment... 30

1.15.3 Electro-activation as a sustainable method of protein extraction... 30

1.15.4 Electro-activation principle... 31

1.15.5 Electrolysis of water... 32

1.15.6 Electro-activation reactions... 33

1.15.8 Types of electro-activation engineering systems... 37

1.15.9 Utilization of EAS... 40

1.15.9.1 EASs used for microorganisms inactivation... 40

1.15.9.2 Swimming-pool water disinfection... 40

1.15.9.3 Purification of drinking water... 40

1.15.9.4 EA as a method of protein extraction... 41

1.16 The advantages of electro-activation technology... 41

CHAPTER 2: RESEARCH PROBLEMATIC, HYPOTHESIS AND OBJECTIVES ... 42

2.1. Research problematic... 42

2.2. Hypothesis ... 42

2.3. General objective... 43

2.4. Specific objectives... 43

CHAPTER 3: ASSESSMENT OF THE EXTRACTABILITY OF PROTEIN-CARBOHYDRATE CONCENTRATE FROM SOYBEAN MEAL UNDER ACIDIC AND ALKALINE CONDITIONS ... 44

RÉSUMÉ ... 45

ABSTRACT ... 46

3.1. INTRODUCTION... 47

3.2. MATERIALS AND METHODS ... 49

3.2.1. Materials... 49

3.2.2. Extraction procedure... 50

3.2.3. Analyses... 50

3.2.3.1. Total dry matter extractability... 50

3.2.3.2. Ash content and specific minerals profile ... 50

3.2.3.3. Total protein content ... 51

3.2.3.4. SDS-PAGE electrophoresis ... 51

3.2.3.5. Turbidity and Zeta potential analyses... 52

3.2.3.6. Carbohydrate content... 52

3.2.4. Statistical analysis... 52

3.3. RESULTS AND DISCUSSION ... 53

3.3.1. Total dry matter extractability... 53

3.3.2. Ash content and specific minerals profile... 56

3.3.3. Total protein content and SDS-PAGE analysis... 58

3.3.4. Turbidity and zeta potential... 63

3.3.5. Carbohydrates content... 67

3.4. Conclusion ... 69

3.5. Acknowledgments... 69

3.6. References... 70

CHAPTER 4: ELECTRO-ACTIVATION TECHNOLOGY AS A GREEN AND SUSTAINABLE ALTERNATIVE TO CONVENTIONAL CHEMICAL TECHNOLOGY FOR PROTEINS-CARBOHYDRATES EXTRACTION FROM SOYBEAN MEAL... 75

RÉSUMÉ ... 76

ABSTRACT ... 77

4.1. INTRODUCTION... 78

4.2. MATERIALS AND METHODS ... 80

4.2.1. Materials... 80

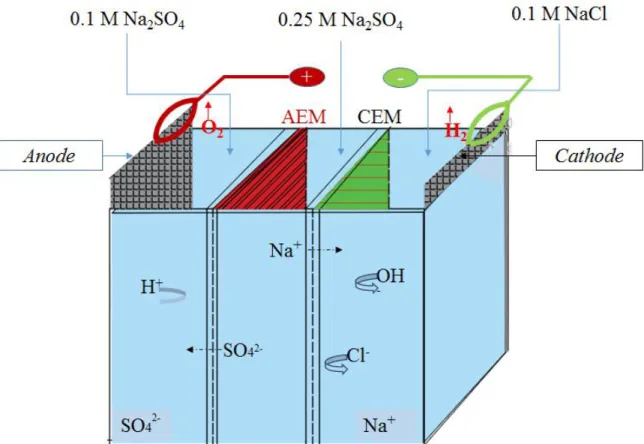

4.2.2. Protocol of the electro-activation... 80

4.2.3. Extraction procedure of the soybean meal by electro-activated solutions... 80

4.2.4.1. Alkalinity, acidity, and pH of the EA solutions ... 81

4.2.4.2. Extractability of the total dry matter ... 82

4.2.4.3. Ash content and specific minerals... 82

4.2.4.4. Protein content and SDS-PAGE electrophoresis... 83

4.2.4.5. Amino-acid profile ... 83

4.2.4.6. Simple carbohydrates content... 83

4.2.4.7. Turbidity and zeta potential ... 84

4.3. Statistical analysis ... 84

4.3. RESULTS AND DISCUSSION ... 85

4.3.1. Alkalinity, acidity, and pH of the EA solutions... 85

4.3.2. Total dry matter extraction yield... 87

4.3.3. Ash content and specific minerals profile... 88

4.3.4. Total protein content and SDS-PAGE analysis... 91

4.3.5. Amino-acid content... 95

4.3.6. Turbidity and Zeta potential... 96

4.3.7. Carbohydrates content... 99

4.4. Conclusion ... 101

4.5. Acknowledgments... 101

4.6. References... 102

CHAPTER 5: A COMPARATIVE STUDY ON THE FUNCTIONAL PROPERTIES AND ANTIOXIDANT ACTIVITY OF SOYBEAN MEAL EXTRACTS OBTAINED USING CONVENTIONAL EXTRACTION AND ELECTRO-ACTIVATED SOLUTIONS ... 105

RÉSUMÉ ... 106

ABSTRACT ... 107

5.1. INTRODUCTION... 108

5.2. MATERIALS AND METHODS ... 111

5.2.1. Materials... 111

5.2.2. Functional properties and antioxidant capacity... 111

5.2.2.1. Water absorption capacity (WAC) ... 111

5.2.2.2. Emulsifying properties (EC)... 111

5.2.2.3. Oil absorption capacity (OAC) ... 112

5.2.2.4. Foaming properties... 112

5.2.2.5. Total phenolics content ... 112

5.2.3. Statistical analysis... 113

5.3. RESULTS AND DISCUSSION ... 114

5.3.1. Water absorption capacity (WAC)... 114

5.3.2. Emulsification properties... 116

5.3.3. Oil absorption capacity... 117

5.3.4. Foaming properties... 119

5.3.5. Total phenolics content (TPC)... 121

5.3.6. Antioxidant Activity... 123

5.4. Conclusion... 125

5.5. Acknowledgements ... 125

5.6. References ... 126

CHAPTER 6: DEVELOPMENT OF A READY-TO-DRINK FUNCTIONAL BEVERAGE FORTIFIED BY PROTEIN-CARBOHYDRATE EXTRACT OBTAINED FROM SOYBEAN MEAL BY ELECTRO-ACTIVATION TECHNOLOGY ... 130

RÉSUMÉ ... 131

ABSTRACT ... 132

6.1. INTRODUCTION... 133

6.2. MATERIALS AND METHODS ... 135

6.3. RESULTS AND DISCUSSIONS ... 138

6.3.1. Particle size measurement... 138

6.3.2. Rheological properties... 139

6.3.4. Measurements of solubility and thermal stability... 143

6.3.5. Functional properties of beverages... 145

6.3.6. Thermal coagulation... 147

6.4. Conclusion... 148

6.5. Acknowledgments... 148

6.6. References... 149

CHAPTER 7: TECHNICAL-ECONOMIC COMPARISON BETWEEN CONVENTIONAL AND ELECTRO-ACTIVATION ASSISTED EXTRACTION OF ONE TON DRY MATTER FROM SOYBEAN MEAL... 152

7.1: Conventional processing of soybean meal into soybean meal extract... 152

7.2. Processing of soybean meal into soybean meal extract using electro-activation technology155 7.3. Conclusion... 158

LISTE OF TABLES

Table 1.1: Amino acid composition of soybean meal (Fetuga, Babatunde, & Oyenuga, 1974). ... 10

Table 1.2: Mineral content of soybean (Banaszkiewicz 2011). ... 17

Table 1.3: Vitamins content of soybean (Banaszkiewicz 2011)... 18

Table 1.4: Fatty acids content of soybean (Banaszkiewicz 2011)... 19

Table 3.1: Total ash content in the soybean meal extracts as a function of pH and added NaCl concentration... 57

Table 3.2: Specific minerals profile of the soybean meal extracts, mg/100 g. ... 58

Table 3.3: Carbohydrate profile, expressed as mg/g dry matter, of the extracted dry matter from the used soybean meal as a function of pH and added NaCl concentration. ... 67

Table 4.1: Titratable (total) acidity, alkalinity, and pH of the electro-activated solutions. ... 85

Table 4.2: Extraction yield (Extractability) from the used soybean meal by using anolyte (acid) and catholyte (alkaline) as extracting solutions... 87

Table 4.3: Ash content of the extracts obtained from soybean meal by using anolyte and catholyte as extracting solutions... 89

Table 4.4: Mineral profile of the electro-activated extracts. ... 90

Table 4.5: Total protein content in the extracts obtained by using anolyte (acid) and catholyte (alkaline) as extracting solutions... 92

Table 4.6: Amino acid profile of the initial soybean meal and extracts obtained by using anolyte (acid) and catholyte (alkaline) as extracting solutions. ... 95

Table 4.7: Carbohydrate profile of extracted dry matter from soybean meal by using anolyte (acid) and catholyte (alkaline) as extracting solutions. ... 100

Table 5.1: Emulsifying capacity (EC) of the soybean meal extracts obtained by a conventional (chemical)* and electro-activation** methods... 116

Table 5.2: Oil absorption capacity (OAC) of the soybean meal extracts obtained by a conventional (chemical)* and electro-activation** methods... 118

Table 5.3: Total phenolics contents in the extracted dry matter from the used soybean meal. ... 122

Table 6.1: Solubility and thermal stability of beverages. ... 144

Table 6.2: Foaming capacity and stability of beverages. ... 145

LIST OF FIGURES

Figure 1.1: Illustration of a whole soy bean. ... 5

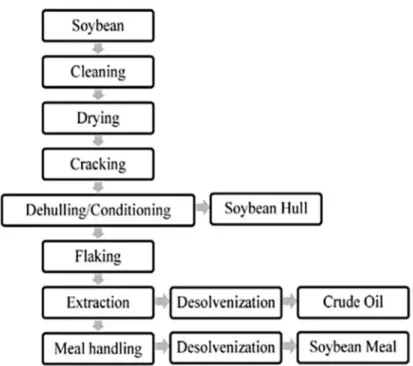

Figure 1.2: Schematic representation of the extraction procedure of oil from soybean. Adapted from (Cheng & Rosentrater, 2017). ... 6

Figure 1.3: Extraction diagram of proteins from waste material... 8

Figure 1.4: D- and L- conformations of amino acids... 9

Figure 1.5: Glycinin and β-conglycinin models of proteins... 11

Figure 1.6: Non-structural carbohydrates of soybean meal. ... 15

Figure 1.7: The structure of phytic acid in a dilute solution. ... 20

Figure 1.8: Kunitz and Bowman-Birk factors (Liener, 1994)... 22

Figure 1.9: Production diagram of soy protein isolates. Adapted from (Lusas and Riaz, 1995). ... 26

Figure 1.10: Production of sodium hydroxide and hydrochloric acid production (L. Thannimalay, S. Yusoff, & N. Zawawi, 2013a)... 29

Figure 1.11: Sealed electrochemical cell. Adapted from (Walsh, 1991)... 32

Figure 1.12: Representation of the electrochemical reactions in an electrolyser. Adapted from (Chaplin, 2016). ... 35

Figure 1.13: Structure of a Nafion membrane (Mikhaylin, 2015). ... 36

Figure 1.14: Electrochemical PEM-1 module. Adapted from (Tomilov, 2002). ... 38

Figure 1.15: Two compartmental electro-activation reactor. Adapted from (Gerzhova, 2016). ... 39

Figure 1.16: Three compartmental electro-activation reactor. Adapted from (Gerzhova, 2016). .... 39

Figure 3.1: Total dry matter extractability from the used soybean meal as a function of the extracting conditions. NaCl: added ionic strength to the extracting medium. Ratio: Solution/soybean meal ratio. ... 54

Figure 3.2: Total protein content in the extracted dry matter from the used soybean meal as a function of the extracting conditions. NaCl: added ionic strength to the extracting medium. Ratio: Solution/soybean meal ratio... 60

Figure 3.3: SDS-PAGE of the extracted proteins from the used soybean meal as a function of the extraction pH and the added ionic strength. ... 62

Figure 3.4: The turbidity of the aqueous solutions obtained by reconstituting the extracted dry matter... 63

Figure 3.5: Zeta potential of the aqueous solutions obtained by reconstituting the extracted dry matter... 66

Figure 4.1: Schematic representation of the used electro-activation reactor for anolyte (acid) and catholyte (alkali) production. ... 81

Figure 4.2: SDS-PAGE gels of the proteins extracted by using catholyte and anolyte. ... 94

Figure 4.3: Turbidity of the extracts obtained by using catholyte and anolyte as extracting agents.97 Figure 4.4: Zeta potential of the extracts obtained by using catholyte and anolyte as extracting agents... 99

Figure 5.1: Water absorption capacity of the conventional and electro-activated samples... 114

Figure 5.2: Foaming stability of the conventional and electro-activated samples. ... 120

Figure 5.3: Antioxidant activity of the conventional and electro-activated samples... 124

Figure 6.1: Particle size measurements in the beverage obtained by dissolving the soybean extract in water together with whey powder. ... 138

Figure 6.2: Rheology of the beverage obtained by dissolving the soybean extract in water together

with whey powder. ... 140

Figure 6.3: Turbidity of the beverage obtained by dissolving the soybean extract in water together

with whey powder. ... 141

Figure 7.1: Representative diagram of the chemical conventional extraction procedure. ... 152 Figure 7.2: Representative diagram of the extraction procedure by using electro-activated solution

LIST OF ABREVIATIONS AEM: Anion exchange membrane CEM: Cation exchange membrane EA: Electro-activation

EAS: Electro-activated solutions

SDS-PAGE: Sodium dodecyl sulfate polyacrylamide gel electrophoresis SB: Soybean

DEDICATIONS

I would like to dedicate this work to my beloved ones. Especially, to my grandfathers Shalva Gerliani and Sergei Sherbina that are passed away long time ago but the memory of them is very important for me.

ACKNOWLEDGEMENTS

I am very grateful to my professor Mohammed Aider for the opportunity to be a part of his team, for his support and encouragements. Also, I want to thank him for guidance and ability to turn my work into the right way which helped me a lot in getting results of better quality. Furthermore, I would like to thank my co-director, Dr. Riadh Hammami, for his active participation in reading and correcting my articles. Additionally, I want to thank a lot Diane Gagnon for her great contribution such as helping me thorough all these years spent in the lab. I am also grateful for her kindness, sense of humor and responsiveness. Moreover, I want to thank Pascal Lavoie for the technical support in the laboratory. I want to thank my friends for their participation and their big support in my life. Sergey Mikhaylin, Cheslav Liato, Alina Gerzhova, Sona Amalyan, Valeria Gergiieva, Anna Grigoryan, Gayana Danelyan, Ioanna Burikina, and many others. As well as my family members, my sister Margarita Gerliani-Jones, my father Zurab Gerliani and my mother Helen Gerliani. I am so thankful for their support and the enormous contribution into my life. Certainly, I am grateful to a reader for reading and appreciating my work.

FOREWORD

This thesis consists of seven chapters and results are presented in the form of scientific articles that are submitted or published in the international journals.

The first chapter includes a detailed literature review with the focus on the soybean meal as an alternative source of proteins, its nutritional and technological properties. Also, electro-activation as a sustainable alternative to conventional chemicals (that are used for protein extraction) was reviewed. Finally, soybean protein application in different food systems with the focus on protein-based beverages was reviewed.

The second chapter provides information about the research hypothesis and main objective of this doctoral project, followed by specific objectives which help to achieve the main objective and prove the research hypothesis.

The third chapter is a scientific article that was written to implement the first specific objective, which involved investigation of the pH effect, soybean meal ratio and salt concentration on the protein rate using conventional extraction method (specifically, using NaOH and HCl). This study was performed as a control which further was compared to electro-activation method of protein extraction. This article is published in Food bioscience (Elsevier). Natela Gerliani, Riadh Hammami, Mohammed Aïder (2019). Assessment of the extractability of protein-carbohydrate concentrate from soybean meal under acidic and alkaline conditions. Food bioscience, volume 28, 116-124.

The fourth chapter is a scientific article that was written to implement the second specific objective, which included evaluation of the electro-activation as a green and sustainable alternative to conventional chemical technology and determination of the optimal parameters of the electro-activation for extraction of proteins and carbohydrates from soybean meal. This article is under review in Journal food science and nutrition (Whiley). Natela Gerliani, Riadh Hammami, Mohammed Aïder. Proteins-carbohydrates extraction from soybean meal by electro-activation technology as a green and sustainable alternative to conventional chemical technology, Under review.

The fifth chapter is a scientific article that was written to implement the third specific objective aiming to study functional and antioxidant properties of the conventional and electro-activated extract. This article is under review in International Journal of Food Science and Technology (Wiley). Natela Gerliani, Riadh Hammami, Mohammed Aïder.

Comparison between functional properties and antioxidant activity of soybean meal extracts obtained by conventional extraction and by using electro-activated. International Journal of Food Science and Technology, Under review.

The sixth chapter is a scientific article that was written to implement the fourth specific objective, which aimed to study the behaviour of functional beverage by using protein-carbohydrate extract obtained from soybean meal produced by electro-activation method. This article is under review in journal LWT-Food Science and Technology (Elsevier). Natela Gerliani, Riadh Hammami, Mohammed Aïder. LWT-food science and technology, Under review.

The seventh chapter is a general conclusion and particular recommendations to improve the soybean valorisation results of this work. According to obtained results in each section of this project, it is possible to claim that hypothesis of the work, introduced previously, was proved by all specific objectives that were carried out.

INTRODCUTION

In recent years a demand for protein products has increased for cereals, animal and other products. Nevertheless, there is a big concern about the animal products related to safety, bacterial infections, dioxin contamination, using veterinary drugs and others (Speedy). In turn, it is a well-known fact that there are many legumes such as soybean which contain more protein than poultry and fish. Which means that they are the excellent alternative to replace animal proteins. Moreover, human and animal studies have shown that soy is a perfect protein source. Therefore, in food applications, soy proteins are used in combination with other proteins and effectively improve the nutritional value of the food (Endres 2001). Thus, chemical composition of soybean oilseed (mainly protein) can compensate nutritional deficiency and can be used to balance protein in food. On the other hand, soy oilseeds as protein source has a lot of benefits for health. Specifically, it has been shown in different studies that animal protein, usually casein, is more cholesterolemic and atherogenic than vegetable protein such as soy protein. Moreover, soy oilseeds are the excellent source of dietary fiber which seems to play a great role in controlling blood cholesterol and may have an effect in preventing colon cancer and improving glucose tolerance (Lanou, 2011). So that soy is a perfect material with lots of advantages that should be used in food industry. Frequently, soy oilseeds are used for oil production, during this process a significant amount of soy residue appears (by-product or waste). As a result of the maximizing of the production process related to growing of consumer`s demand humongous number of by-products and wastes are produced which are further underutilized or unutilized. That is, in order to improve environmental performance, minimization of waste should be implied (Chandrasekaran 2012). However, the by-products of soy oil production (soybean meal) are underestimated. Thus, according to the nutritional value, quality and low price, soybean meal is likely to be used as a human feed. In contrast, soybean meals are often used as protein supplements for poultry, ruminants and companion animals (Bernard 2016). Furthermore, various industries, like bakery, dairy and sugar confectionery industry increased the demand for soy derivatives because of their availability, protein quality and affordable price (https://www.mordorintelligence.com/industry-reports/soybean-derivatives-market 2018). That is why the consumption of soybean meal is expected to increase in the period of 2018-2023. Recently, on the global market soybean meal had value

of 81.21 billion USD with major consumers in the world such as China and North America (https://www.mordorintelligence.com/industry-reports/soybean-meal-market 2018).

Regarding the protein quantity and quality, presence of valuable carbohydrates and interesting functional properties, soybean meal is an essential material for food production. However, the most common and affordable way to extract these valuable components is conventional extraction. Nevertheless, modern conventional extraction of proteins and carbohydrates represents the use of sodium hydroxide, hydrochloric acid and other chemicals. Currently, the industries meet a lot of challenges based on environment conscious and demands of consumers (Thannimalay, Yusoff et al. 2013). Due to possible inappropriate chemical management significant risks to human health and to environment are involved, as well as increase of healthcare costs, watersheds, etc. That is, the development and application of alternative sustainable method of extraction is of high interest.

Conventional extraction with the use of sodium hydroxide and subsequent precipitation with hydrochloric acid have a detrimental effect on quality and functionality of proteins (Rodrigues et al., 2012). In addition, it creates a large amount of effluents which need to be further processed. The use of chemical acids and bases cause environmental, safety and health hazards and stimulate researchers to develop alternative “green” methods (Shi et al., 2012). One of the promising techniques for protein extraction implies the energy of electric current in the form of electro-activated (EA) aqueous solutions. The conversion of the electric energy into chemical creates necessary conditions such as pH and alkalinity which can be utilized for proteins extraction (Aider et al., 2012b). No chemical bases are therefore required, which makes the EA an environmentally friendly technology. In the process of electrochemical activation, the transformation of the electric energy into the chemical energy is performed. The uniqueness of EA method lies in the fact that there are specific oxidation-reduction reactions on the electrode caused by the applied electric field. These reactions change physicochemical properties in the near electrode area which promotes the formation of acid and alkaline solutions. Also, highly active metastable compounds with oxidation/reduction capacity are present. These compounds increase properties of anolyte (acid) and catholyte (alkali) solutions (Gerzhova, Mondor, Benali, & Aider, 2015a). This means, that the solutions produced during the electro-activation process can be used in the protein extraction technology in order to replace conventional acid and basic solutions.

Previously, in the work of Gerzhova 2016 these solutions were utilized to extract protein from canola meal (Gerzhova, 2016). And the ability of the solutions (anolyte and catholyte) to extract proteins were confirmed by that investigation.

This project was focused on the determination of the extraction abilities of electrochemically activated solutions. Particularly, extraction of proteins and carbohydrates from soybean meal. Also, the effect of the EA on different characteristics such as quality and quantity of the extracted matter. The current research confirms that EA can be used for soybean meal valorization.

CHAPTER 1: LITERATURE REVIEW 1.1 Soybean information

1.1.1 Soybean history

It was first written about soy (Figure1.1) in list of Chinese plants from 2853 B.C. The reason of soybean and soya food become known in the world, is emigration of Asians to Europe and the United States. In the U.S. the first soybeans were grown in 1829 to further processing of it into the soy sauce. Those days soy sauce was a cheap substitute for coffee. Furthermore, in 1904 soya was demonstrated to be a good source of protein and oil. Afterwards, in 1929 in order to analyse and investigate properties of soy a big variety of soybeans was imported from China to America. This helped in further fast ascension of the U.S. as a world leader in the production of soy. The reason of increased demand of soy consumption was Second World War Thus, due to lack of food production the alternative source of protein such as soybean meal was needed. Harvested fields for soybeans in the United States had become more popular between 1940 and 1955, and the total production of soybeans increased from 78 million up to 374 million bushels. Soybeans continued to grow, the United States began exporting soybeans (meal and oil) to Europe and Asia (Cromwell, 2008).

1.1.2 Production of soybeans

The first step of the production of soybean seeds is planting them in a period of April 15th- July 15th. Each season it is possible to plant from 6 to 10 different types of soybeans. To grow soybeans, seeds are placed in pods in amount of 1-5 seeds or 2-3 seeds per pod. The period of harvesting depends on the region, planting date and weather conditions. The most active phase of harvesting since October to November. The harvesting procedure usually includes combine machines. Then, seeds are moved from pods and placed into transport truck with following storage process. Generally, different types of storage facilities are used such as farms, elevators, etc. These facilities are utilized to maintain dry conditions before selling and shipping of the soy. After these procedures soybeans are sold to the different processors to crush and refine them into desirable products (Soy).

Figure 1.1: Illustration of a whole soy bean.

1.2 Soybean oil

Currently, the most valuable oilseed on the global market are soybean, rapeseed, sunflower seed, peanut, cottonseed, etc. The manufacturing of the global oilseed production increased approximately 15 % from 2013 to 2017. The primary plant oil in production is palm oil followed by soybean, rapeseed, sunflower and others. China and U.S. are dominant countries that produce soybean oil (Cheng, Dien, & Singh, 2019). Soybean oil is a popular oil source in America. This oil holds 57% of all oil resources produced from plant seeds. Soybean oil contains approximately 88.1% of triglycerides, 9.8% of phospholipids and 0.5% of free fatty acids (Preece, Hooshyar, & Zuidam, 2017). Generally, oil bodies are the main location of the oil. The size of these bodies varies from 0.2–0.5μm (Rosenthal, Pyle, & Niranjan, 1998). The process of soybean oil production shown on the Figure 1.2 includes next steps: preparation of the crop, solvent extraction, degumming followed by desolvenization, and meal processing. During the first step of crop preparation oil seeds should be cleaned, cracked, dehulled then conditioned and flaked. This procedure is applied in order to remove impurities, separate hulls from soybean seeds as well as increase the amount of oil. In this case, heat that involved in conditioning process is used to break down the linkage between proteins and oil. Flaking process is performed in order to improve efficiency of the oil recovery. After the solvent extraction a degumming process should be applied due to its capacity to remove phospholipids. When the phospholipids are removed the action of desolvenization should be applied. After all mentioned procedures oil is

collected, however, soybean meal and hulls are co-produced containing potentially valuable substances (Cheng & Rosentrater, 2017).

Figure 1.2: Schematic representation of the extraction procedure of oil from soybean. Adapted from (Cheng & Rosentrater, 2017).

1.3 Soybean meal review

In recent years, most of the world`s soybean crop is processed into vegetable oil and meal. Soybean meal is the residue obtained after the greater part of the oil has been extracted from an oilseed. Two types of soybean meals exist: conventional soybean meal (43-44% protein) and dehulled soybean meal (47-49% protein). Presently, in processing of soybean plant with an approximate protein concentration of 35 % and oil quantity of 18 %, chemical solvents are used to remove the oil. The residues left after the extraction consist considerable amount of protein, carbohydrates such as oligosaccharides, sucrose and fibres, minerals and vitamins. Due to the rich protein content of the residue, it is used as animal feed, for example, for ruminants and fish. There are different types of oil meals (cakes) depend on seed type such as: sunflower meal (SuM), sesame meal (SM), soybean meal (SBM), coconut meal (CM), mustard meal (MM), palm kernel meal (PKM), groundnut meal (GM), cottonseed meal (CSM), canola meal (CaM), rapeseed meal (RSM) (Ramachandran, Singh, Larroche,

Soccol, & Pandey, 2007a). Thus, there are 17 million tonnes of oil meal production from developing countries like India, Brazil and Argentina of the total 23 million to (Ramachandran, Singh, Larroche, Soccol, & Pandey, 2007a). In this case, soybean meal is the most valuable at the oilseed meal market and represents 55% of the total global production of oilseeds, its production raised from 64% to 66% by 2010. Recently, oil meals are used as substrates in fermentation or as supplements to the production medium. Also, they are reported to be good substrate for enzyme production using fungal species. In some works, SBM has been reported to be a good material for production of clavulanic acid (Higgs, 1979). Due to important nutritional properties of soybean meal such as amounts of usable energy and highly digestible protein (which is composed of a superior blend of amino acids) soybean meal is a perfect source of protein for livestock, poultry and human feed. However, the main part of meal is used for animal feed and only 6% is used for human. In general, the quality of protein in soybean meal is higher than that of cereals (Cromwell, 2008). However, oilseeds proteins contain anti-nutritional factors (ANFs) such as protease inhibitors, lectins, phytoestrogens, lipoxygenase, oligosaccharides and phytin. In turn, the presence of trypsin inhibitors causes inactivation of the pancreatic enzymes’ trypsin and chymotrypsin (Willis, 2003).

1.4 Treatment of plant by-products in food production

In terms of rapid growing of numerous companies in food industry related to population increase there is a wide range of food products that should correspond to the needs and certain requirements of the customers. In fact, food industry generates enormous amounts of by-products and wastes which consist of organic matter which causing environmental pollution and sustainability problems. Also, one of the major problems for the food industry is disposal of by-products of plant food processing (Schieber, Stintzing, Carle, & Technology, 2001). In this case the estimation of the environmental consequences of soybean meal consumption is very important. That is, soy protein potentially have a significant environmental impact as by-product (waste) if not being used at the same time is considered as a promising source due to its nutritional or favourable technological properties (Dalgaard, Schmidt, Halberg, Christensen, Thrane, & Pengue, 2008). Nowadays, valorization of by-products and wastes of food production is the most popular treatment for food industry to be focused on. The valorization of by-products provides a variety of alternatives for their

management other than disposal. In this context, soybean meal should be used in food production in order to avoid harmful impact to environment and profitability for the industry (Anal, 2017).

1.4.1 Under-utilized materials as a potential source of valuable protein

Most of the countries consider protein as the vital nutrient that should be consumed. However, usually the price of proteins is extremely high, and a lot of protein sources do not meet desirable quality criteria. These days, a lot of novel protein sources were discovered. That is, during the plant processing a lot of residues are produced. These residues are by-products and/or waste materials of food production which contain a lot of valuable nutrients. To help resolve the problem of waste disposal these materials can be treated by extraction method in order to obtain protein. The extraction from waste material is shown in Figure 1.3. Consequently, the extracted nutrients can be incorporated into different food products (Mangino).

1.5 Protein content of soybean meal

Organic high-molecular compounds that are constructed from molecules of residues of amino acids linked by peptide bonds are proteins. Soybean meal contains approximately 45-49 % of protein. In fact, proteins of soybean are heterogeneous (Petibskaya, 2012). In turn, soybeans contain a lot of soluble proteins particularly globulins (Petibskaya, 2012).

The most frequently 20 amino acids are presented in nature. There are D or L conformations of amino acids exist (Figure 1.4), but most amino acids found in nature have L conformation. Different types of amino acids exist such as acidic, basic, sulfur containing, hydroxylic, aliphatic, hydrophobic or amidic. In addition, size and net charge can be determined by number and type of amino acids. Indeed, soy proteins provide all the essential amino acids that satisfy human nutritional requirements for growth and maintenance. Soybean meal amino acid profile is shown in Table 1.1. The protein of soybean contains adequate quantities of the essential amino acids such as histidine, isoleucine, leucine, lysine, phenylalanine, threonine, tryptophan, and valine. It should be pointed that soybeans are abundant in lysine quantity. Evidently, lysine is limiting factor in a lot of plants, that is why soy is a great inexpensive source of lysine and can be useful in areas where protein malnutrition is a common problem. Nevertheless, the value of protein is limited by methionine and cysteine content. At the same time, in an adult diet soy protein product supply more than necessary of essential amino acids including methionine. Certain tests with adults showed that the quality of soy protein products is comparable to high-quality animal proteins such as milk and beef (Endres, 2001).

Table 1.1: Amino acid composition of soybean meal (Fetuga, Babatunde, & Oyenuga, 1974).

Amino acids Amino acid composition of crude protein of soybean meal, %(w/w)

Arginin 7.4 Cystein 1.6 Glycine 4.5 Histidine 2.4 Isoleucine 4.6 Leucine 7.8 Lysine 6.1 Methionine 1.4 Phenylalanine 5.5 Threonine 3.8 Tryptophan 1.3 Tyrosine 3.5 Valine 5.2

Indeed, plant seeds contain few groups of proteins that provide storage of amino acids that are involved in the process of the germination and seedling growth. The presence of storage proteins is of great interest as they determine the total protein content and quality of the seeds. The globulin is the most distributed type of storage proteins and can be divided into several groups. These groups are based on the sedimentation coefficients (Shewry, Napier, & Tatham, 1995). Thus, 7S and 11S are the main groups (>80%) present in soy. The 7S group is vicilin-type globulins, 11S legumin-type globulins and also soy contains 2S group of globulins. In this case, for 7S globulins the mature protein is trimeric whereas 11S globulin is hexameric (Shewry, Napier, & Tatham, 1995). The molecular weight of 7S globulins is ~150 to 190 kDa while 11 S consists of six subunit pairs (acidic subunit of 40 kDa and a basic subunit of 20 kDa linked by a disulfide bond). The major fractions of soybean proteins are β-conglycinin and glycinin presented in Figure 1.5. These fractions have differences in

composition, glycinin is richer in methionine and cysteine than β-conglycinin. In the same time, it was found that glycinin is a better gel former when β-conglycinin provides superior emulsifying properties than glycinin (Riblett, Herald, Schmidt, & Tilley, 2001).

Figure 1.5: Glycinin and β-conglycinin models of proteins.

It should be emphasized that the molecular structure of proteins is quite complex. The primary structure consists of the linear sequence of the amino acids. The secondary structure is referred to local conserved structures in a form of alpha-helixes, 3,10 -helix, beta sheets, or random coils within a polypeptide stabilized mostly by hydrogen bonds. The tertiary structure comprises several secondary structures are stabilized by different interactions such as van der Waal’s, electro-static, or hydrophobic interactions, hydrogen bonding, or disulfide cross-links. There are some proteins that have quaternary structure with two or more monomers (subunits) that form complex structures stabilized by non-covalent bonds (Riblett, Herald, Schmidt, & Tilley, 2001).

1.6 Protein size distribution

In food manufacturing the distribution of particle size in a colloidal system can significantly affect the stability and quality of the product, especially, in products such as soy beverages and milk. It was determined that large particles were >120 nm while medium particles value varied from 40 to 120 nm and small particles were less than 40 nm. In fact, heat treatment has ability to disrupt these large particles which decreases the particle size diameter. Heat treatment was reported to have significant impact on properties of the colloidal systems. That is, high temperatures are involved in a denaturation and aggregation

processes of proteins (Kitabatake, Tahara, & Doi, 1990). Protein composition of products can be also affected by processing parameters. Moreover, ratio of glycinin and β-conglycinin is important in processing of soy beverages and other soybean derived products (Ji, Cai, & Chang, 1999). In the work of Malaki et al. (2009), it was also demonstrated that subunit composition of proteins impacted the particle size distribution of soymilk (Malaki Nik, Tosh, Woodrow, Poysa, & Corredig, 2009). Thus, it was investigated that the reason playing a role in decreased particle size was solubilizing of the large native proteins.

1.7 Functional properties of soybean proteins

1.7.1 Solubility

Solubility is an important characteristic of proteins in food production because it can significantly affect the other functional properties and provides significant information for processing optimization. In fact, factors that influence protein solubility are composition and ratio of amino acids, protein conformation and molecular size, surface charge and pH, ionic strength and temperature of the solvent. The pH and ionic strength have the most significant impacts on the solubility of soy protein. However, the solubility of proteins can be improved by alkali treatment (pH >10.5). Furthermore, salts, especially sulfite salts, have negative effects on protein solubility. When rising the temperature to 40–50 ˚C the protein solubility increases whereas temperature above 50˚C has opposite effect due to protein denaturation. This process leads to conformational changes where noncovalent bonds are involved in stabilization of secondary and tertiary structures of protein (J. E. Kinsella, 1979).

1.7.2 Oil binding capacity

In the production of cakes, cookies or meat replacers ability of the protein to bind fat is one of the major important characteristics due to certain physical and organoleptic properties. The principle of the oil binding capacity is based on the protein-lipid interactions (J. E. Kinsella, 1979). Thus, this property considered as an amount of added oil to the protein powder which is related to holding this oil certain time. The main factors that affect the oil capacity are type of proteins and its solubility, hydrophobicity and protein concentration. High concentration of the protein increases the oil binding capacity while high solubility has the opposite effect (Gerzhova, 2016).

1.7.3 Emulsifying Properties

The definition of emulsion means immiscible liquid that is dispersion of oil in water or water in oil. The important characteristics for determining emulsifying properties of protein are hydrophobicity and solubility. While emulsion capacity decreases with protein concentration, emulsion stability relatively increases. The method of protein preparation also has influence on formation and stability of emulsions. The pH and temperature affected the emulsifying properties of soy isolate and soy concentrate, having a much greater effect on the former. Emulsifying capacity with increasing pH from 5 to 7 also is increased, but temperature above 50˚C at pH 7 has opposite effect (J. E. Kinsella, 1979).

1.7.4 Foaming Properties

Capacity of proteins to form stable foams with gas by forming impervious protein films is called foaming capacity. It is an important capacity in cakes, soufflés, whipped toppings, fudges, etc. Protein foams are composed of gas droplets encapsulated by a liquid that contain surfactant protein. In order to form the foaming proteins should have ability to concentrate at the interface; to be soluble in the aqueous phase these proteins must be stable, and the component polypeptides must exhibit a balance between their ability to engage in intermolecular cohesion required to form a membrane and the tendency to self-associate excessively which would result in foam instability. Soy isolates have better foaming properties than soy concentrates. An exact balance between flexibility and intermolecular cohesiveness is essential for producing stable foams. Heat treatments at 75–80 ˚C increasing foaming properties (Kinsella 1979).

1.8 Carbohydrates content in soybean meal

The content of carbohydrates in soybean meal is approximately 30–35% on a dry matter basis. Soybeans have low content of assimilable carbohydrates. Soybean meal contains monosaccharides, oligosaccharides and polysaccharides. There are two types of soy carbohydrates: soluble and insoluble. Soluble carbohydrates such as glucose (monosaccharide), fructose (monosaccharide), raffinose (oligosaccharide), stachyose (oligosaccharide) and hydrolysable carbohydrates as starch (polysaccharide), etc. And insoluble structural polysaccharides such as hemicellulose, pectin substances, slimes and other substances that form cell walls (Petibskaya, 2012). Also, carbohydrates can be divided into two other groups: structural (polysaccharides (arabinose, galactose, glucose, mannose,

xylose, etc.) and non-structural (mono- and disaccharides, oligosaccharides, and storage polysaccharides such as starch).The primary non-structural sugars of soybean meal are sucrose, stachyose, raffinose and verbascose (oligosaccharides) shown in Figure1.6. Sucrose quantity in SBM can reach 9.5% (Middelbos & Fahey, 2008). Oligosaccharides are substances that have influenced on decreasing of digestibility of nutrients and hypertrophy of intestines (Salgado, Freire, Mourato, Cabral, Toullec, & Lallès, 2002). However, they deserve specific attention because of their contribution to the growth and colonisation of probiotic bacteria. The soybean stachyose and raffinose are present in soybean seeds and play role of prebiotics. In study of Rastall et al (2002) it was investigated that there was a significant increase of lactobacilli using soygerm powder (Rastall & Maitin, 2002). Thus, the raffinose content of soybean seeds ranges from 0.1 to 0.9g/100g on fresh weight basis and stachyose quantity varies from 1.4 to 4.1g/100g (Hymowitz, Collins et al. 1972). Recently, special attention was given to plant cell wall polysaccharides being considered as novel prebiotics. For example, arabinogalacto-oligosaccharides can be obtained from soybeans by endogalactanases, in turn, this material was tested in pure culture using different intestinal bacteria such as Bifidobacterium sp., Lactobacillus sp, Clostridium sp., Escherichia coli and other. Soy cell oligosaccharides and the polysaccharides were fermented to some extent. Therefore, Bifidobacteria showed good results in fermenting of the arabinogalacto-oligosaccharides (Rastall & Maitin, 2002).

Additionally, non-structural polysaccharides mainly starch play role of the storage polysaccharides. (Middelbos & Fahey, 2008). That is, soybean meal contains 4.66 to 7% of starch and quite a lot of hemicellulose and pectin (Petibskaya, 2012). Pectin is very important anti-nutritional substance (Pusztai, 1991); its components belong to sensitive substances at high temperature. Pectin is involved in agglutination in alimentary tract and mitosis (Banaszkiewicz, 2011)

Figure 1.6: Non-structural carbohydrates of soybean meal. 1.9 Prebiotics

The prebiotics are the food ingredients with beneficial aspects for health that stimulate the growth and activity of certain number of bacteria in the colon. Since the cellulose, pectins and other fibers promote growth of different microorganisms in the gut, other types of prebiotics such as fructo-oligosaccharides and galacto-oligosaccharides stimulate the augmentation of Lactobacillus and Bifidobacterium. To clarify, the best sources of oligosaccharides are seeds of legumes, beans, peas, etc. (Khangwal & Shukla, 2019). There is an alternative definition of prebiotics by Bindel as nondigestible compounds that modulate composition and/or activity of the gut’s microbiota with physiologic benefits for the host. Also, noncarbohydrate compounds may have prebiotic properties such as starch, arabinoxylan, etc. (Quigley, 2019).

1.9.1 Mechanism of prebiotics

Different mechanisms are involved in the functioning of the prebiotics. For example, antagonism that produces antimicrobial substances where the action of competition for nutrients or for the epithelial surface takes place. In their turn, as a result of substrate fermentation prebiotics can promote barriers for gastrointestinal (GI) pathogens and reduce the intestine pH. Furthermore, Bifidobacteria and Lactobacilli maintain the microbial balance and permeability of the intestine resulting in degradation of carcinogenic enzymes (Kumar, Kumar, Nagpal, Mohania, Behare, Verma, et al., 2010). Due to the capacity to regulate the production of hepatic lipogenic enzymes, prebiotics can promote the growth of beneficial colonic flora. Additionally, prebiotics protect organism from harmful chemical

impact and bacterial pathogens and viruses by modulating the defense system. The β-lymphocytes/leukocytes in peripheral blood and gut-associated lymphoid tissues might be increased by the activation of immune responses of prebiotics (Althubiani, Al-Ghamdi, Samreen, Qais, Khan, Ahmad, et al., 2019).

1.9.2 Immunomodulation by prebiotics

Some prebiotics have ability to increase the number of bacteria that are beneficial for intestine microflora at the same time they reduce the promotion of disease-causing pathogens. For example, in several studies mannose monomers can diminish salmonella infections. Prebiotics change the expression of cytokines in the immune system which have a positive influence on the immunity and directly promote immunity through the interactions with the immune cells. Thus, the therapeutic effects on allergies and reducing abilities towards gastrointestinal symptoms were observed (Tungland, 2018).

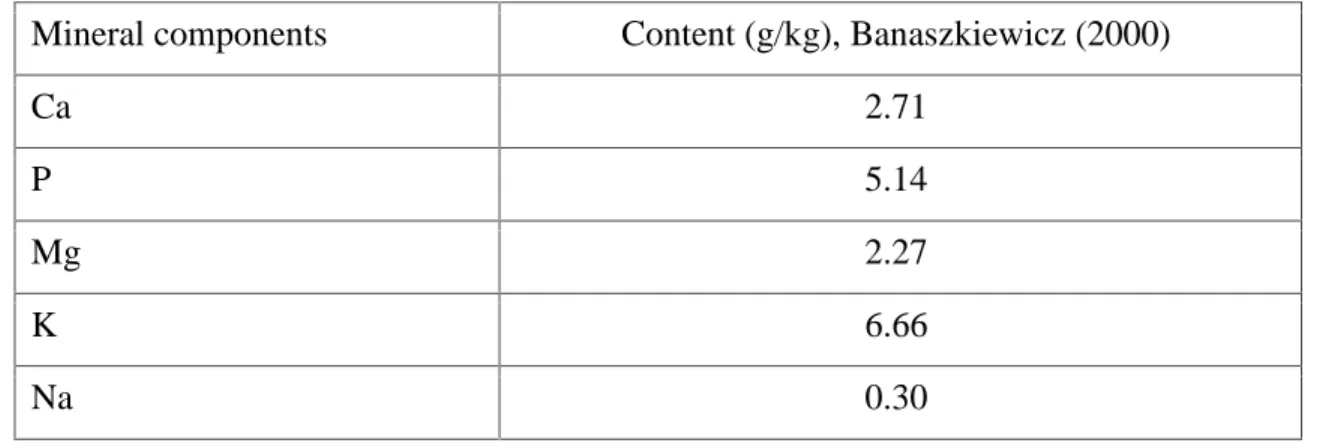

1.10 Mineral content

Minerals are inorganic substances that support normal growth and development of vital functions. These substances are present in all body tissues and fluids and are necessary for a lot of essential physicochemical processes in human organism. Thus, such important substances as vitamins cannot be absorbed without specific minerals. Also, minerals are essential materials for bones and teeth. Plant foods are rich in minerals, almost entire nutrient minerals are performed in plants. The mineral content of soybean is shown in Table 1.2. The products made from soybeans contain the considerable quantities of phosphorus (Banaszkiewicz, 2011). Furthermore, soybean meal contains high concentrations of potassium when the amount of calcium and magnesium is evidently lower. Therefore, soybean meal is low in sodium. Phosphorus is an essential mineral because of its economical and environmental effect. That is why the price of inorganic phosphate have recently increased (Batal, Dale, & Saha, 2010). Phosphorus takes place in production of adenosine triphosphate and assists in functioning of kidneys, and in nerve conduction (Gupta & Gupta, 2014). While potassium is also an important body mineral that is involved in cellular and electrical functions (Haas, 2011). Potassium carries certain amount of electrical charge in blood. Additionally, calcium plays significant role in bones developing, in nervous system and muscle function. Magnesium has many benefits and takes place in relaxation and contraction of muscles and transportation of energy throughout the body.

Table 1.2: Mineral content of soybean (Banaszkiewicz 2011). Mineral components Content (g/kg), Banaszkiewicz (2000)

Ca 2.71

P 5.14

Mg 2.27

K 6.66

Na 0.30

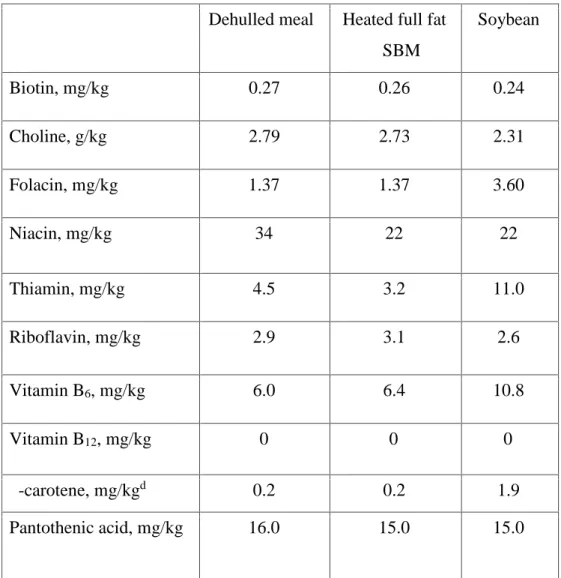

1.10.1 Vitamins and fatty acids

Vitamins are low-molecular substances that are present in the food in low quantity and play major role in many biochemical and physiological processes. Soybeans contain vitamins B, E, K, also A and C with antioxidant properties. Vitamins content of soy is shown in Table 1.3. The bioavailability of beta carotene usually is destroyed by the lipoxygenase that is present in soy. In some studies, the factor of the low carotene absorption was associated with the increasing of the quantity of the residue-bound carotene that passes through intestine. In contrast, soy isolates showed the ability to increase tocopherol amount in poultry (Erdman Jr & Fordyce, 1989).

Table 1.3: Vitamins content of soybean (Banaszkiewicz 2011). Dehulled meal Heated full fat

SBM Soybean Biotin, mg/kg 0.27 0.26 0.24 Choline, g/kg 2.79 2.73 2.31 Folacin, mg/kg 1.37 1.37 3.60 Niacin, mg/kg 34 22 22 Thiamin, mg/kg 4.5 3.2 11.0 Riboflavin, mg/kg 2.9 3.1 2.6 Vitamin B6, mg/kg 6.0 6.4 10.8 Vitamin B12, mg/kg 0 0 0 β-carotene, mg/kgd 0.2 0.2 1.9 Pantothenic acid, mg/kg 16.0 15.0 15.0

There are 99 % of triglycerides in lipid fraction of the soybean seeds. Polyunsaturated fatty acid such as linoleic and linolenic and unsaturated such as oleic exist in soybean seeds. Fatty acids content is about 80%, 50 % of it is the linoleic acid (Banaszkiewicz, 2011). Fatty acids composition in soybean seeds and oil shown in Table 1.4.

Table 1.4: Fatty acids content of soybean (Banaszkiewicz 2011). Fatty acid Soybean seeds, % of DM Soybean oil, %

Palmitic 1.44-2.31 7-12 Stearic 0.54-0.91 2-5 Oleic 3.15-8.82 19-34 Linoleic 6.48-11.6 48-60 Linolenic 0.72-2.16 2-10 Arachidic 0.04-0.7 < 1.0

1.11 Antioxidants and phenolic compounds of soybean

Soybean and soy products possess few phenolic compounds that have shown certain antioxidant properties. In the work of Pratt et al. (1979) it was found that soy proteins have shown lipid antioxidant capacity in aqueous-fat systems. Also, in soybeans and soy flour minimum nine phenolic acids were indicated, including vanillic, caffeic, ferulic, p-hydroxybenzoic, etc. Furthermore, the major flavonoids of soy glycosides, in turn, they are shown to have effective antioxidants. Particularly, the primary isoflavones and cinnamic acid derivatives of soybeans, soy flour and soy protein concentrates are considered as antioxidants. These compounds in combination account all the antioxidant activity of the products. While soy protein isolates have small amounts of flavonoids and cinnamic acids and other compounds that possess antioxidant properties (Pratt & Birac, 1979). The isoflavones can play role of free radical scavengers or metal-chelating agent by inhibiting lipid peroxidation in vitro (Liu, Chang, & Wiesenborn, 2005). In this context, isoflavones can be considered as the major component that can affect the biological activity. The properties of soy antioxidants depend on certain conditions of raw material such as chemical form and concentration of isoflavones as well as storage conditions of material. Soy proteins