To link to this article: DOI:10.1016/j.compind.2017.01.002

http://dx.doi.org/10.1016/j.compind.2017.01.002

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID:

17506

To cite this version:

Desforges, Xavier and Diévart, Mickaël and Archimède, Bernard A

prognostic function for complex systems to support production and

maintenance co-operative planning based on an extension of object

oriented Bayesian networks. (2017) Computers in Industry, vol. 86. pp.

34-51. ISSN 0166-3615

O

pen

A

rchive

T

oulouse

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

Any correspondence concerning this service should be sent to the repository

administrator:

staff-oatao@listes-diff.inp-toulouse.fr

A

prognostic

function

for

complex

systems

to

support

production

and

maintenance

co-operative

planning

based

on

an

extension

of

object

oriented

Bayesian

networks

Xavier

Desforges

a,*

,

Mickaël

Diévart

b,

Bernard

Archimède

aaUniversitéFédéraleToulouseMidi-Pyrénées,INPT,ENIT,LaboratoireGéniedeProduction,65016Tarbes,France bAéroconseil,31703Blagnac,France

Keywords: Prognostics Complexsystems Availabilityassessment Preventivemaintenance Productionplanning ABSTRACT

Thehighcostsofcomplexsystemsleadcompaniestoimprovetheirefficiency.Thisimprovementcan particularlybeachievedbyreducingtheirdowntimesbecauseoffailuresorformaintenancepurposes. This reduction is the main goal of Condition-Based Maintenance and of Prognostics and Health Management.Boththosemaintenancepoliciesneedtoinstallappropriatesensorsanddataprocessesnot onlytoassessthecurrenthealthoftheircriticalcomponentsbutalsotheirfuturehealth.Thesefuture healthassessments, alsocalled prognostics,produce theRemainingUsefulLifeofthecomponents associated to imprecision quantifications.In thecase of complex systems wherecomponents are numerous,thematteristoassessthehealthofwholesystemsfromtheprognosticsoftheircomponents (thelocalprognostics).Inthispaper,weproposeagenericfunctionthatassessesthefutureavailabilityof complexsystemsfromtheirlocalprognostics(theprognosticsoftheircomponents)byusinginferences rules.Theresultsofthisfunctioncanthenbeusedasdecisionsupportindicatorsforplanningproductive and maintenancetasks. This function exploits aproposed extension forObject Oriented Bayesian Networks(OOBN)usedtomodelthecomplexsysteminordertoassesstheprobabilitiesoffailureof components,functions andsubsystems. Themodelingofthecomplexsystem is requiredanditis presentedaswellasmodelingtransformationstotacklesomeOOBNlimitations.Then,thecomputing inferencerulesusedtodefinethefutureavailabilityofcomplexsystemsarepresented.Theextension addedtoOOBNconsistsinindicatingthecomponentsthatshouldfirstbemaintainedtoimprovethe availabilitiesofthefunctionsandsubsystemsinordertoprovideasecondkindofdecisionsupport indicators for maintenance. A fictitious multi-component system bringing together most of the structuresencounteredincomplexsystemsismodeledandtheresultsobtainedfromtheapplicationof theproposedgenericfunctionarepresentedaswellaswaysthatproductionandmaintenanceplanning canusedthecomputedindicators.Thenweshowhowtheproposedgenericprognosticfunctioncanbe usedtopredictpropagationsoffailuresandtheireffectsonthefunctioningoffunctionsandsubsystems.

1.Introduction

To improve theircompetitiveness inever changingmarkets, companiesneedflexibilityandresponsiveness.Thisleadsthemto implementproductionequipmentofgoodsorservicesevermore flexible, more responsive and thereforemore complexbut also morecostly.Withsuchproductionresources,themajorchallenge istomaintaintheminoperationalconditionwiththehighestlevel of availability for the lowest cost. The implementation of the

Condition-BasedMaintenance(CBM)andofPrognosticandHealth Management (PHM) recommendations usually leads to the improvementoftheequipment availabilityandthereductionof maintenancecosts[18,20,36].Indeed,CBMistheuseofmachinery run-timedatatodeterminethemachinerycondition,whichcanbe used to schedule required repair and maintenance prior to breakdown.PHM,whichrefersspecificallytothephaseinvolved withpredictingfuturebehavior,includingtheRemainingUseful Life(RUL)assessment,intermsofcurrentoperatingstateandwith the scheduling of required maintenance actions to maintain systemhealth,nowenrichesCBM[28,44].Theassessmentofthe RULofcomponentsofa machineryisinfactthemajorissueof PHM.ThatiswhyPHMcanalsobeimplementedtoguaranteethe * Correspondingauthor.

availabilityofassets,whichisatypicaldemandinsome Product-ServiceSystems(PSS)whosebusinesscoreistoprovidemachine capabilityratherthanproductownership.Indeed,PHMenablesto avoidunscheduleddowntimesandcontractpenaltiesinPSS[37]. InthedomainofPHM,manyworkscontributetoassessmore accurately the Remaining Useful Life (RUL) before the failure, whichisalsocalledtimetofailure,ofa criticalcomponentofa system [23,36].This mainlyconsistsin assessing,with a given probability,thedurationofuseofacomponentbeforeitreachesa levelofdegradationbeyondwhichtheriskoffailureistoohigh

[44].ThisisshowninFig.1wheret0isthecurrentdurationofuse. Three main approaches are developed [15]: experience-based prognostics,model-basedprognosticsanddata-drivenprognostics

[4].Theexperience-basedapproachusesdatagatheredfromthe experiencefeedbacktoidentifyreliabilitylaws.Themodel-based approach is based on mathematical models of the physics of degradations of components [16]. The data-driven approach consists in transforming the monitoring data provided by the sensorsinstalledonthesystemintoreliablebehavioralmodelsof degradations [14]. Many works aim at assessing the RULs of componentsoratimprovingtheaccuracyoftheprognosticsfor many kinds of components: ball-bearings [28,43], gear trains

[48,49], train pantographs [17], braking systems [10], batteries

[13,19],etc.,butalsotopredictcrackgrowthinstructures[31,33]. However,only theRULs ofcritical components areassessed becausethey require sensors and data processing resources to detectfailureprecursorsandtoestimatetheremainingdurations ofusebeforethedegradationsreachthefailurethresholdswhich correspondtothelevelsofdegradationbeyondwhichtherisksof failurearetoohigh[34].IntheabsenceoftheRULofacomponent, datasuchasMTTF(MeanTimeToFailure)orMTBF(MeanTime Between Failures) can be used [34]. In this case, the RUL is calculatedbysubtractingtheMTTFortheMTBFfromtheduration ofuse.RULsareestimatesdeterminedfrompredictionsandMTTFs and MTBFs are often obtained statistically. Therefore those quantities are not only scalar and they are so associated to confidenceor imprecisionindicatorslisted in [34].Thatis why mostoftheworksdealing withtheprognosticsofcomponents contributetotheassessmentoftheRULsaswellasthedefinitions oftheirProbabilityDensityFunctions(PDFs)[32].

Althoughthesepreviousworksdealing withprognosticsare componentoriented,theimplementationofCBMand PHMalso requiresthehealthassessment ofthewholesystemsaswellas decisionsupportsformaintenanceplanning[24,45].Mulleretal.in

[29]proposethedeploymentofaprognosisprocesswithinan e-maintenancearchitecture.Thisintegrationintothee-maintenance architectureisdoneelementbyelementandprovidesadecision supportformaintenanceplanningfromthehealthconditionsof thecomponentsbut itdoesnotassesstheoverallabilityof the systemtoperformthefuturetasks.Voisinetal.in[45] definea genericprognosisbusinessprocessbuttheydonotdescribethe processthatcombinestheRULsandtheirimprecisionsinorderto providetheprognosis of thesystem although theymentionits interests. A more integrated approach has been developed in

[26,27].Itconsistsofamethodtomodelboththesystemofinterest and themaintenance system thanks to Probabilistic Relational Models (PRM) that are used to choose the best maintenance strategy thanks to simulations that assesses key performance indicators.

Otherworksalsoconsidertheproductionmanagementsystem suchastheonespresentedin[1,9]thatproposedecisionsupports basedonthehealthassessmentofthesystems.Theyrequiresthe assessmentoftheriskthatthesystemswillfailinfulfilling the operationstheproductionplanningassignstothem.Thisriskof failureis aninputof thedecisionsupportfor maintenanceand production planning. Such decision supports are extended to industrytoperformthemaintenanceactivitiesatthebettertime

[8].Indeed, ifknowing current and futurehealth conditions of componentsisnecessarytoplanmaintenance,knowingtheability ofasystemtoperformfuturetasksisalsonecessaryforproduction schedulinginordertoprovideabettercompromisetosatisfythe respectiveobjectivesofthemaintenancesystemandofproduction management system[5,6,35].Indeed,maintenanceand produc-tioncanplanconflictingactivitiesontheresourcestheyshare:the machineswhileoptimizingtheirownkeyperformanceindicators but may not optimize more global performance indicators [6]. Whereasmaintenancedeterminesthebestpracticestoapplyto componentstosettheproductivetechnicalsystemsatadesired availabilitylevel,productionismoreinterestedintheavailability of functions of these same systems during the fulfillment of productive tasks it plans. Indeed a productive task does not necessary require the availability of all the functions of the productivesystemtobefulfilled.Thusproductivesystemscanbe exploited in a degraded mode (with one or maybe more unavailablefunctions)forsometaskswhilewaitingforthebest momentfortheirmaintenance.Thisistheideaunderstoodby“the capacityofthemachinetoperformtheactivity”mentionedin[6]. Examplesarenumerous:suchasafiveaxismachinetoolthatcan

beusedasa fouraxismachinetooland onlyfordrymachining operationsifitslubricationsystemisalsofailed;atruckwitha failedcoolingsystemcannotcarryfrozenfoodbutitcancarryfood whosetemperaturedoesnotneedtobecontrolled.Inthiscontext, knowing the future availability of functions of the productive technicalsystem accordingtotheproductivetaskstoplanisas important as knowing the future health of its components to organizetheirmaintenance.

However,inthefieldofprognostics,ononehandworksdeal withtheassessments ofRULsof componentsorstructures and withtheassessmentsoftheiraccuraciesorwiththeimprovement of their accuracies. On the other hand, works deal with the planningofmaintenanceactionsandproduction tasksfromthe prognosticsofsystems.However,asfarasweknow,noresearch work deals with the prognostic of complex systems from the prognosticsoftheircomponentsand/ortheirstructurestoprovide thedecisionsupportindicatorsfortheplanningofmaintenance actionsandofproductiontasks.Neverthelesswenoticeworksin which the modeling of the system for its future reliability assessmentisdirectlyusetodefinethebestmaintenancepolicy

[26,27,30].Wealsonoticeoneworkinwhichthesuccessthefuture planned tasks flights is taken into account [9]. The systems (aircrafts) are considered as sets of line replaceable modules (components)forwhichRULsareknown.Anaircraftisconsidered asfailedassoonasoneofitslinereplaceablemodulesfails.Ifthese considerationsareconvenienttotestanoptimizationmethodfor CBM,theyarenotrelevantintermsofhealthassessmentofthe complexsystemthatanaircraftis.

Thatiswhy,this paperpresentsagenericfunctionbasedon ObjectOrientedBayesianNetworks(OOBN)towhichanabilityis added.Thefunctionprovidesdecisionsupportindicatorssatisfying theneedsofmaintenanceandproductionplanning,thankstolocal prognostics andstatisticaldataaboutunmonitoredcomponents suchasTimesToFailure(TTFs)andTimesBetweenFailures(TBFs) andinferences.Toimplementthisfunction,thecomplexsystem mustbemodeled.Thisrequirestheidentificationofthedifferent relationshipsthatcanexistbetweenthecomponentsofcomplex systemsandalsobetweenthecomponentsandthefunctionsthey implement.Then,thepaperpresentsthecomputationrulesbased onBayesiannetworkstowhichweproposeanextension.These rulesareusedtoinfer,atdifferentlevels,theprobabilitiesthatthe components,functions,subsystemsandthecomplexsystemwill fail during the fulfillment of the operations the production planningassigns toit fromthe localprognostics.The proposed extensionconsistsin definingthecomponentsthat shouldfirst undergomaintenanceinordertoreducetheriskoffailureduring the fulfillment of the future operations as the definition of “intelligent prognostics” suggests it in [24]. Modeling trans-formationsarenecessarytoprocesstheproposedfunction;they arepresented.TheyenabletotacklesomeOOBN limitations.To illustrate those rules, a fictitious multi-component system is presented.Itbringstogethermostofthestructuresencounteredin complexsystems.Thisexampleshowresultsfromdifferentvalues oflocalprognosticsandtoshowhowtheindicatorscomputedby theproposedprognosticfunctioncouldbeexploitedby mainte-nance and production planning. An emerging ability of the prognostic function that consists in predicting the impacts of failuresontothewholesystemispresentedtooaswellasawayto use it in the case of consistency-based diagnostics. Finally, conclusionsandprospectsarelisted.

2.Modelingcomplexsystemsfortheirprognoses

Complex systems are multi-component systems in which components may or may not interact with each other, with humanbeingsandwiththeirenvironments[50].Astheaimisthe

prognosticsofcomplexsystemsandasitisverydifficulttopredict futurebehaviorsofhumanbeingsandofthewholeenvironmentof atechnicalsystem,thenotionofcomplexsystemisthuslimitedto multi-componentsystemswithcomplexstructuressuchasthey aredefinedin[30].Theparticularcaseofsystemsofsystemsin whichpropertiescanemergeisnotconsidered.

Systemsengineeringaddressesthedesignofcomplexsystems that meet specified functionsand performances at lowercosts

[22].Thereforetheimplementationofaprognosticfunctionina system must be considered at the design stage [12]. This implementation requires knowledge about the system: the structuralknowledge,thefunctional knowledgeandthe behav-ioral knowledge except the knowledge about the prognostic process [45]. In consistence with the standard ISO 13381-1, discrete models are more adapted for complex systems. More often,thedegradationlevelsarerepresentedwithdifferentstates by using formalisms such as Markov chains and Bayesian networks.Thesestatesaregenerallydefinedbyaphysicalreality whereasthetransitionsbetweenstatesoccurstochastically[16]. Discretemodelsweresuccessfullyimplementedinthedomainof prognostics for RUL assessment [10,19,25,28,43]. However the combination of the possible states for each of the numerous components of the complex systems makes the Markov chain models unmanageable [46]. Hence, we propose a discrete modeling based on Bayesian networks in which transitions betweenstatesofentitiesofthesystemarestochasticandwhose valuesmayimpactthevaluesoftransitionsbetweenthestatesof otherentities.

2.1.Functionalknowledgemodeling

Insystemsengineering,systemsareconsideredfromseveral pointsofview.Oneofthemisthehierarchicalviewwhichbreaks downa system intosubsystems, then intofunctions, then into multiplelevelsofsub-functionstillcomponentsimplementingone ormoresub-functions[22].Knowingtheabilitiesoffunctionsofa complex system to perform future operations or their risks of failing while fulfilling them supports decision making for productionandmaintenanceplanning.Indeed,production plan-ningknowstheoperationsitassignstocomplexsystemsandthus thefunctionsthatwillbesolicitedandhowlongtheirsolicitations willlast.Alloperationsassignedtothesystemdonotnecessarily solicitallitsfunctionsthesamewayandsomemaynotbesolicited atall.So,ifafunctionofasystemisnotabletoperformataskorto fulfillasequenceoftasksatanacceptablelevelofriskaccordingto itsprognostic, productionand maintenance can jointly make a decisionaccordingtoperformanceindicators.Possibledecisions are:thesystemisassignedtoanothertaskthatwillnotsolicitthe “risky”functionor willsolicitit less, thesystemis stoppedfor maintenance,thenumberofoperationsinthesequenceisreduced and the maintenance of components that are likely to fail is planned... Thefunctionalknowledgemodelingaimsat provid-ingthesetsofentitiesthatimplementthefunctionsofthecomplex system.Thoseentitiesareeithercomponentsor functions.This leadstoarecursivedefinitionofafunction.Atthelowerlevelsof thehierarchical breakdown,one orseveral components imple-ment thefunctions. Componentare here consideredas atomic entitiesonwhich themaintenancecanact.Theycanbesimple parts like joints or software modules but also more complex devices like servo-drives. At higher levels of the hierarchical breakdown, functions can be made of components and/or functions.Eventually,atthehighestlevel,thesubsystemsgather functions.Thus,thesystemsengineeringprocessenablestocollect thenecessaryknowledgeforfunctionalmodeling.

Ifanentitybelongingtofunctionfailsor,inamoregeneralway, becomes unable to provide the service for which it has been

designed,thefunctiontowhich itparticipateswillalsobecome unabletoprovideitsservice.Therefore,afunctioncanonlyprovide itsserviceonlyifalltheentitiesbelongingtoitareabletodoso. Suchfunctionsarethencalled“simplefunctions”.Iffunctionsof thesystemareorbecomeunabletoprovidetheirserviceswhereas theirserviceswillnotbesolicitedfortheplannedproductivetasks, the system can be exploited in the degraded mode that correspondstotheunavailabilityofthosefunctions.

Simplefunctionsbecomeweakintermsofreliabilitywhenthey aremadeofmanyentities,sub-entities,etc.Thatiswhy,setsof entitiesthatprovideasameserviceorasamefunctionareoften implementedtomatchthereliabilityorsafetyrequirements[11]. Thesesetsareredundantandcanbemadeofonlyoneentity.In thosesetsifoneentityatleastbecomesunabletoperformitsown service,thewholesetwillnotbeabletoperformthefunctionit wasdesignedfor;buttheothersetscanstillperformthisfunction. However, if there is only one set that is able to perform the function,there is nomoreredundancyand, in manycases,the systemmustnotbeginanewtaskoroperationmainlybecauseof safetyreasons.Thatiswhytwosituationsmustbeconsideredand theirprobabilitiesof occurrence must beassessed: theone for whichnoneofredundantsetsis abletoensureandtheonefor whichonlyonesetisabletoensurethefunction.Forsuchcases, the functional modeling proposal consists in gathering the redundantsetsorentitiesintowhatisthencalleda“redundancy function”inordertoassessboththeprobabilitiesoflossofthe functionandoflossofredundancy.Aredundancyfunctioncanbe solicitedby plannedproductivetasks in a degradedmode that corresponds to sets that are or become unable to providethe serviceiftheprobabilitiesoflossofthefunctionand oflossof redundancy are still acceptable until the fulfilment of the productivetasks.

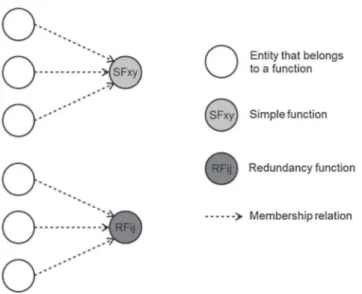

A graphical representation of the functional knowledge is presentedinFig.2.

2.2.Structuralknowledgemodeling

The structural modeling aims at representing the direct interactionsbetweenentities(componentsorfunctions)andtheir failure modes mainly in order to propagate their effects [47]. FailureModesandEffectsAnalysis(FMEA),faulttreesorHAZard andOPerability(HAZOP)studiesenabletocollectthenecessary knowledgeforstructuralmodeling.Indeed,thosestudiesenableto identifywhathappenstoothercomponentsortofunctionswhen

oneorseveralcomponentsfail[7].Modelsusedforsystemdesign can also be exploited such as SADT (Structured Analysis and Designed Technique) diagrams [26], or as SysML (Systems ModelingLanguage)diagramsliketheinternalblocksdiagrams, activitydiagrams,inwhichmaterial,energyanddataflowsthatare used, produced, transformed and exchanged by functions and componentsarerepresented.Therefore,thismodelingconsistsin representing causality relationships between entities of the system that is,nevertheless, consideredas functionalmodeling in[29].

A graphical representation of the structural knowledge is presentedinFig.3.Inthisrepresentation,thecausalrelationship meansthatthedownstreamentitywillfailorwillbecomeoutof orderiftheupstreamentityfailsorbecomesoutoforder.Thus, only direct causal relationships must be modeled to avoid to consider a same event like several independent ones. Indeed, accordingtothestructuralmodelofFig.3,ifE2failsorbecomesout of order, E5 will fail or will become out of order and then, consequently,E6andE7willfailorwillbecomeoutofordertoo. 2.3.Behavioralknowledgemodeling

Thebehavioralmodelingmainlyaimsatdefiningthedynamical behavior of a system. Behavioral models are used to detect degradationsandtoanalyzetheirtrendsinordertoprognosethe monitoredcomponents.Thetechniquesofdataacquisitionandof dataprocessingimplementedinordertodetectthedegradations andtoanalyzetheirtrendstodefinetheRULs(withconfidenceor uncertaintyindicators)ofthecomponents,arenumerousandthey alsodependonthecomponentstoprognose[36].

The behavioral modeling also requires design knowledgeof components, functions or subsystems. Many stakeholders are involvedinthedesignofcomplexsystems.Theycandesignand providesimplepartsorsubsystems.Thebehavioralmodelingmay need that the supplier of a component provides itsbehavioral model to anotherpartner. This may lead tothe disclosure the know-howofthecomponentsupplier.Therefore,itwouldbemore appropriatethatsuppliersalsoprovidetheprognosticsystemsof theircomponentsfortheirdifferentfailuremodes.Indeed,they knowthebehavioralmodelsandtheycansoimplementthemost relevanttechniques.Inthiscase,asuppliercanprovideeitherone prognostic for each mode of failure of the component or one prognosticforallitsfailuremodesInthislastcase,thecomponent isassumedhavingonlyonefailuremode.Theseprognosticsare hereconsideredaslocalprognosticswhicharetheinputsofthe proposedprognosticfunctionofcomplexsystems.Consequently,a component has one or several local prognostics whatever its complexityis.Thus,localprognosticsareconsideredasattributes ofcomponents.Theseassociationsbetweenlocalprognosticsand componentsconstitutethebehavioralknowledgemodelingforthe prognosticfunction.

A graphical representation of the behavioral knowledge is presentedinFig.4.

Intheparticularcaseofredundancyfunctions,theredundant entitiesorsetsofentitiesachievingthesameservicemustfirstly be gathered in order to create the redundancy function that

implementthisservice.Then,alltheentitiesthatcontributetothe upperlevelservicearegatheredintoasimplefunction.Toillustrate this, we consider the example of the flight control structure presentedin[11].Theflightcontrolprovidesthereferencestothe servo-actuators of the control surfaces of modern commercial aircrafts. In this paper, the flight control service (FCS) is implementedbythreeflightcontrollers(FC),twosticks(ST)one foreachpilotinthecockpit,tworudders(RU)oneforeachpilotin thecockpitandthreeAirDataandInertialReferenceUnits(AD) andwealsoconsiderthatitrequirespowersupply(PS).Forthe proposedgenericfunctionthatprovidesdecisionsupport indica-tors forproductionandmaintenanceplanning,theFCSmustbe modeled as shown in Fig. 5 where the prefix RF stands for redundancyfunction.

Howeverimplementingprognosticsystemsforallthe compo-nentsofcomplexsystemswouldbetoocostly.Thus,datasuchas MTTF or MTBF and theirimprecisions can be used [34] in the absence of the RULs of components as mentioned in the introduction.ThedataobtainedfromtheMTTFsandMTBFsand thedurationsofusearealsoconsideredaslocalprognostics.

The elements of knowledge modeling that are presented in

Figs. 2 and 3show thatthemodeling of a complexsystem for implementing the generic function this paper propose has a directedgraphstructure.ThedirectedgraphGmodelingacomplex systemisanorderedpairG¼ðN;AÞ whereNisthesetofnodesand A isthesetofunweightedarcs.ThesetofarcsAissuch asA¼

Ei;Ej

ð Þ2N2jEi6¼Ej

n o

whereEiistheheadandEjisthetail.Theset Nismadeofthreekindsofnodes:components,simplefunctions andredundancyfunctions.Thosethreetypesofnodesforwhich theirstatesaredifferent,thecomputationoftheprobabilitiesof transitions betweentheirstates arealsodifferentmakesOOBN suitabletooltoimplementtheprognosticfunction.Indeed,OOBNs, thankstotheobjectorientedapproach,enabletoconsiderseveral types (named classes in the object oriented approach) with differentattributesandmethodstocomputethem[3].Concepts, likespecializationandpolymorphism,areveryhelpfultoeasethe implementation of algorithms especially for graph traversal processwithdifferentclassesofnodes.TheOOBNsareextended byPRMsmainlytohandlenon-Bayesianuncertainties.PRMsalso enable toimplement recurrentpatternsbyclassesof objectsof interestsasproposedin[26,27].Astheproposedapproachisless integratedthanin[26,27],theproposedprognosticfunctioncanbe

considered as a service as it is defined in Service Oriented Architecture(SOA)thatleadtodistributedenterprisesapplications

[41].Thisserviceissolicitedbyproductionmanagementwanting to plan productive tasks and it provides decision supports indicatorsusedjointlybyproductionandmaintenance manage-menttovalidateortomodifytheproductiontasksschedulingand toplanmaintenanceinterventions.Therefore,OOBNsaresufficient toolstoimplementit.

Thecomputingrulesusethemodelofthesystemandthelocal prognostics to infer the decision support indicators for joint productionandmaintenanceplanning.Thoserulesaremethods implementedforthedifferentofclassesofnodes.

3.Inferencerules

Theaimofthecomputingrulesistoprovidedecisionsupport indicators for maintenance and production planning from the fusionoflocalprognosticsandthemodelofthecomplexsystem. Thesedecisionsupportindicatorsshallhelpthemaintenanceand productionplanningtomakedecisionaccordingtocriteriasuchas risk,cost,reliabilityandavailability.Riskisoftenconsideredasthe combination of vulnerability and criticality, which can also be consideredas acombinationof probabilityand impact.Usually, impacts can be costs, casualties, damages to environment... Knowingtheimpacts,probabilityorreliabilitycriteriaaremore appropriate for decision supports regarding the assignment of productivetaskstoasystemorregardingitsmaintenance[36].In thiscase,aprognosticshouldbeconsideredastheprobabilityof failureor ofsurvival ina given durationof usewhich includes plannedproductivetasksratherthanastheremainingdurationof useassociatedwithaconfidenceorimprecisionindicator[20,29]. Thatiswhystudiesaimatdefiningdegradationpredictionmodels thatprovideprobabilitydensityfunctionsofthedurationofuse knowingthemaximumdegradationlevellikein[19,49,9]orofthe degradationlevel knowing the durationuse likein [14]. These modelsmayrequiretheexpectedusesofthesystemsthatmaybe introducedthankstoparametersrepresentingtheseverityofthe futuretasks[10].Theexpecteduses,andthustheirseverities,can be anticipated by production planning that assigns tasks to systems.Thusthedefinitionofalwaysmoreaccuratedegradation predictionmodelsisalsooneofthemainissuesinthedomainof prognostics[12].Indeed,accordingtoCBM,componentsandeven structuralpartsmustbemaintainedbeforetheyreachoneoftheir maximum degradation levels. Therefore we assume the local prognostics,whichrunmodelspredictingtheevolvementsofthe degradationsfortheplannedtasksorpredictingtheRULsofthe components, provide the PDFs or the Cumulative Probability DistributionFunctions(CPDFs)ofthosepredictedevolvementsor ofthoseRULs.

Prognostic functions cannot be implemented for all the componentsofacomplexsystemforcostorspacereasons.Thus a complex system is not completely observed in terms of prognostics. Nevertheless, component suppliers can define the PDFsorCPDFsoffailureofcomponentsdependingontheiruses (durationornumberofcycles)thankstostatisticalstudies.These studiesmaycorrespondtothoseaimingatdefiningthe probabili-tiesofelementaryfailures[11],theMeanTimeToFailure(MTTF)of thecomponents.KnowingthePDFortheCPDFoftheTTFortheTBF ofacomponentbasedonitspasseduseandonitsexpecteduse,the probabilityofitsfailurebeforethefulfilmentoftheplannedtasks canbecalculated[44].WethereforeassumethatwehavethePDFs ortheCPDFsoftheTTFsortheTBFsofthecomponentsoreven structureelementswithoutmonitoring.Theprobabilitiesoftheir failures before the fulfilment of the planned tasks, which are determined from their expected uses, are considered as local prognostics.

Fig.4.Elementsofbehavioralknowledgemodeling.

TheFig.6 illustratesPDFsof thepredictionsofRULs, ofthe evolvementofdegradationsandoftheTTFswheret0isthecurrent dateandt1-t0theplanneddurationofusewhichcanalsobecalled thehorizonofuse.LetusnotethePDFsandCPDFscanbegiven relativelytonumberofcyclesandnotrelativelytothedurationof use.Insuchcases,thenumberofcyclesmustbedeterminedforall theplannedtasks.

Oncetheprobabilitiesoffailuresbeforetheendoftheplanned tasks are determined fromthe local prognostics, the proposed

genericfunctioncomputetheprobabilitiesthecomponents,the functions,thesubsystemsandthesystemarenotabletofulfillthe planned tasks according to the complex system model. These probabilitiesarethefirstdecisionsupportindicatorsformaking decisionliketovalidatetheplannedtasks,toreducethenumberof theplannedtasksbeforemaintenance,tomaintainthesystem... Therefore,thegraphthatmodelsacomplexsystem,asdescribedin Section 2, is made of nodes that contain the probabilities the components,thefunctions,thesubsystemsandeventhecomplex Fig.6.PDFsofthepredictionsofRULs,oftheevolvementofdegradationsandoftheTTFs.

systemfailinfulfillingtheplannedproductivetasksiftheysolicit allitsfunctions.Theproposedgenericfunctioncomputes,foreach node,theprobabilitiestoswitchintoundesiredstatesbeforethe fulfillment of these tasks. This computation is donethanks to OOBN ability tocomputethe probabilitiesof random variables knowingtheirconditionaldependencies[21].

However, the knowledge of those probabilities of the dis-abilitiestofulfillofthescheduledtasksisnotsufficientregarding CBM policies and “intelligent prognostics” as defined in [24]. Indeed,maintenanceneedtoknowthecomponentsthatneedto befixedorreplacedtoreducetheprobabilitythatthesystemfails tocompleteitsassignedtasksinordertoshortendowntimesby planninginadvancethemaintenanceactionsandtheirlogistics. Thatiswhytheproposedgenericfunctionalsoprovidedecision supportindicatorsaboutthecomponentsandstructureelements whose maintenance will most increase the abilities of the components, functions, subsystems and system to fulfill the planned tasks. Defining these indicators is the object of the extensionweproposetoOOBN.Thusdecisiontomaintainornotto maintaincomponentscanbemadeaccordingtotheprobabilities offailureoftheentities(components,functions,subsystems...), totheoperational riskassessment, tothecostsof maintenance operations... [9,10,20,30]. In the rest of the paper, structure elementsareconsideredascomponents.

3.1.Forcomponents

According to CBMpolicies, maintenance is done beforethe failureandisconditionedtothehealthstatusofthecomponent.So wecanhereconsiderthatthefailureofacomponentwillnotcause any damage to other components because the failure is not supposedtohappenthankstopreventivemaintenancewhichcan be planned according to the results the proposed prognostic function.In thiscontext,theprobabilitiesof transitionbetween five states canbeconsideredfor each component.These states are:

OK: The component is able to operate within its minimum performances requiredtofulfill theplannedtasks even if its performances are not the best ones because of incipient degradationsorofalittlemoreimportantdegradations. F:Thecomponentisfailed.Thismeansthatthecomponentisnot abletooperatewithinitsminimumperformancesrequiredto fulfill the planned tasks. This state is for failures that have internalorigins. Thecomponent willnot recoveritsspecified performancesifitdoesnotundergomaintenance.

OO: The component is out of order. This means that the component is not able to operate within the minimum performancesrequiredtofulfilltheplaned tasksbut without requiringmaintenance.Thisstatecorrespondstofailureswhose originsarenotinternalbutitistheconsequenceoftheinability ofatleastoneotherentitytoprovideafunctionoraservicethe component needs to operate. To recover its performances required tofulfill theplanned tasks, the maintenance of the componentitselfisuselessbutoneormoreothercomponents havetoundergomaintenance.

FOO: This state is a combination of the F state and the OO state.

KO:Thisstatemeansthatthecomponentisnotabletooperate withinitsminimumperformancesrequiredtofulfilltheplanned tasksbecauseitsstateisF,OOorFOO.KOstandsfor“notOK”. ThegraphofFig.7showstheMarkovmodelofacomponent stateswhere

lF

istheprobabilitythatthecomponentfailsbecause ofatleastonefailurewithinternalorigin,lOO

istheprobability that thecomponentfailsbecauseofexternalreasons,m

F istheprobabilitythatthecomponentrecoversfromtheFstateand

m

OO istheprobabilitythatthecomponentrecoversfromtheFstate.Here,theconsideredcomponentsdonothaveanyself-healing abilities.Thereforemaintenanceisrequiredtobringacomponent backinOKstate.Asoneoftheaimoftheprognosticfunctionisto define if components need maintenance, the

m

F andm

OO transitionsarenotconsidered.OnceacomponentisintheFstate or in the OO state, it is no longer able to operate within its minimum performances required to fulfill the planned tasks withoutmaintenance.So,itisinKOstate.TheconsequencesofKO statesofcomponentsmustbeassessedtodefinetheabilityofthe complexsystem toperformthefuture tasks.Nevertheless,it is interestingtodistinguishtheFstatefromtheOOstatebecauseit makes it possible to guide maintenance intervention to the componentitselfortoothercomponents.Inordertoprovideinformationabouttheabilityofthecomplex systemtoperformthefuturetasksand,also,informationabout componentsthatneedmaintenance,fourfields(namedattributes inobjectorientedapproach)willbecomputedforeachnodethat belongstoacomponentclass:

l

CxF ðtÞ:theprobabilitythatthecomponentCxisintheFstate beforeinstantt,l

CxOOðtÞ:theprobabilitythatthecomponentCxisintheOOstate beforeinstantt,l

CxKOðtÞ:theprobabilitythatthecomponentCxisintheKOstate beforeinstantt;thisprobabilityistheinverseprobabilitythat thecomponentCx isstillintheOKstateuntilinstanttl

CxOKðtÞ andso:l

CxKOðtÞ¼1$l

CxOKðtÞ ð1Þ idCxtðÞ: the identifier of the component that should firstly undergomaintenancetoreduce

l

CxKOðtÞ;itmaybethe compo-nent’sownidentifier.Knowing the proposed generic function provides decision supportindicatorsformaintenanceandproductionplanning,tis thetimeatwhichtheplannedtaskswillbecompleted.

l

CxF ðtÞ is computed from the set local prognostics Px¼ PxiðtÞji¼1;...;n! ofthecomponentCx wherenisthenumber offailuremodesofCx.Theselocalprognosticsaredefinedeither thankstoprognosticfunctionsthatusetheobserveddegradations, thedegradationmodelandtheexpectedusesofthecomponentor thankstostatisticaldatadealing,forexample,withtheTTFsofthe componentbasedonitspassedusesandonitsexpecteduses.A localprognosticPxiðtÞistheprobabilitythatthefailuremodeiof thecomponentCxoccursbeforet.Therefore

l

CxF ðtÞconsistsofthe probabilitythat,atleast,onefailuremodeofCxwilloccurbeforet oroftheinverseprobabilitythatnoneofthefailuremodeswill occurbeforet.l

CxF ðtÞ¼1$Y n i¼1 ð1$Px iðtÞÞ ð2ÞThe

l

CxOOðtÞ computation requires to know the set of the predecessorsofCxinthemodelinggraphG.Thesepredecessorsare entities(componentsorfunctions)notedEi.ThissetisΓ

$1ðCxÞ¼ fEijðEi;CxÞ2AgwhereAisthesetofthearcsofthegraphG.Cxwill beoutoforderbeforetif,atleast,oneEi2Γ

$1ðCxÞwillbecomeKO beforet. Thusl

CxOOðtÞis theinverse probabilitythatnoneofthe Ei2Γ

$1ðCxÞwillbecomeKObeforet.l

CxOOðtÞ¼f1$ Y Ei2Γ$1ðCxÞ # 1$l

EiKOðtÞ $ ;Γ

$1ðCxÞ6¼; 0;Γ

$1ðCxÞ¼; ð3Þl

CxKOðtÞ can so be considered as the inverse probability that neitherCxwillfailnorCxwillbecomeoutoforderbeforet.l

CxKOðtÞ¼1$#1$l

CxF ðtÞ$#1$l

CxOOðtÞ$ ð4ÞidCxðtÞ isdefinedassumingthatifacomponentCyhasjustbeen maintainedthen

l

CyF ðtÞ¼0.Thisassumptionisalsocorrectifeach componentCxofthecomplexsystemhasitsattributel

CxF ðtÞreset to the same very low value (e.g. 1e-10) after they had been maintained. In that case, the component Cy that should firstly undergomaintenanceinordertoreduceatmostthevalueofl

CxKOðtÞ issuchas:l

CyF ðtÞ ¼maxl

CxF ðtÞ; max Ek2A$1Cx ð Þl

EkF ðtÞ # $ ! ð5ÞwhereA$1ðCxÞisthesetofthenodesfromwhichthenodeCxis attainableand Ekis anodethat canbea component,a simple functionoraredundancyfunction.AnentityEkbelongstoA$1ðCxÞ ifitexistsatleastonepathfromEktoCxinthedirectedgraphG. Therule(5)isdemonstratedintheAppendixA.

Fromanimplementationpointofview,idCxðtÞcanbedefined by the following recursive rule: “Whether the

l

CxF ðtÞ of the componentisthemaincontributortol

CxKOðtÞ,andsoidCxðtÞreceives theidentifierCx, orthel

EkF ðtÞof oneof itspredecessors isthe main contributor tol

CxKOðtÞ. If it is thel

EkF ðtÞ of one of its predecessor,thel

EkF ðtÞ ofthispredecessorEkiswhetherthemain contributortol

EkKOðtÞ,andsoidCxðtÞreceivestheidentifierEk,orthel

ElFðtÞofoneofitspredecessorsisthemaincontributortol

EkKOðtÞ.If itis...”.ToavoidtolookforalltheentitiesofA$1ðCxÞandthusto reducethecomplexityofthealgorithm, theattributel

EkFmaxðtÞisintroduced and (5) can be implemented by the following algorithm:

If

l

EkFmaxðtÞ>l

CxF ðtÞ where Ek is such asl

EkFmaxðtÞ¼ maxEi2 Γ$1ðCxÞ #l

EiFmaxðtÞ$then idCxðtÞ idEkðtÞl

CxFmaxðtÞl

EkFmaxðtÞ else idCxðtÞ Cxl

CxFmaxðtÞl

CxF ðtÞend ifwhere, the attribute

l

CxFmaxðtÞ contains the value ofdetermined from (5). This attribute enables to propagate recursivelythevaluethatmaximizes

l

CzKOðtÞofacomponentCz.Thisrulemaynotbe optimalregarding theminimizationof

l

KOCxðtÞ,ifthevalueslF

ðtÞofcomponentsarenotresettoasame valueaftertheyhadbeenmaintainedwhateverthecomponents are. The rule (5) and its implementation (6) consider neither maintenance costs nor notions of risk but just occurrence probabilities.Here,theaimistoimplementa ruletoshowhow theprognosticfunctioncanprovideadecisionsupportindicating the entitythat shouldfirst be maintained. So this rule can be adaptedtomaintenancepoliciesofthecompanythatexploitsthe systemortothestructureofmaintenancecostsforthedifferent componentsasproposedin[30].3.2.Forsimplefunctions

Functionsareimplementedbythemeansofcomponentsand sub-functions.Simplefunctionswillfailorbecomeoutoforder beforet,thetimeatwhichtheplannedtaskwillbecompleted,ifat leastoneoftheirentitiesfailsorbecomesoutoforderbeforet. Consideringthatanentity,whichbelongstoasimplefunction,is maintainedbeforeitsfailureaccordingtoCBMpreventivepolicies andthankstotheindicatorsprovidedbytheproposedfunction, thefailureofthisentitywillnotdamageofotherentitiesbecauseit isnotsupposedtohappen.Thus,twostatescanbeconsideredfor eachsimplefunction:

+OK:Thesimplefunctionisabletooperatewithinitsminimum performancesrequiredtofulfilltheplannedtasks.

+OO:Thesimplefunctionisoutoforder.Thismeansthatitisnot abletooperatewithinitsminimumperformancesrequiredto fulfilltheplannedtasksbecauseofthefailureof,atleast,oneof itsentitiesorbecause,atleast,oneofitsentitiesisoutoforder. ThisstatealsocorrespondstotheKOstate.

Therefore the probability

l

SFxKOðtÞof a simple function SFx to become KO before t can be related to its probabilityl

SFxOOðtÞto becomeoutoforderandtoitsprobabilityl

SFxOKðtÞofsurvivaluntilt thanksto:l

SFxKOðtÞ¼l

SFxOOðtÞ¼1$l

SFxOKðtÞ ð7Þ Thusonlytwoattributeswillbecomputedforeachnodethat belongstothesimplefunctionclass:+

l

SFxKOðtÞ:theprobabilitythatthesimplefunctionSFxwillbeinthe KOstatebeforet,

+ idSFx t

ðÞ: the identifier of the component that should firstly undergomaintenancetoreduce

l

SFxKOðtÞ.l

SFxKOðtÞiscomputedfromthesetofthepredecessorsofSFxin the modelinggraphG.Thesepredecessors areentities (compo-nents,simplefunctionsorredundancyfunctions)notedEi.Thisset isΓ

"1ðSFxÞ¼fEijðEi;SFxÞ2Ag.SFxwillbeoutoforderbeforetif,at least, one Ei2Γ

"1ðSFxÞ becomes KO before t. Thusl

SFxKOðtÞ andl

SFxOOðtÞaretheinverseprobabilitiesthatnoneoftheEi2Γ

"1ðSFxÞ willbecomeKObeforet.l

SFxKOðtÞ¼l

SFxOOðtÞ¼1" YEi2Γ"1

ðSFxÞ !

1"

l

EiKOðtÞ" ð8ÞTherulethatenablestodetermineidSFxðtÞisderivedfromthe rule (5) knowing that the simple function cannot bethe main contributorto

l

SFxKOðtÞbecauseitdoesnothavel

SFxF ðtÞattributethat alsocorrespondstol

SFxF ðtÞ¼0.ThusthecomponentCythatshould firstlyundergomaintenanceinordertodecreaseatmostthevalue ofl

SFxKOðtÞissuchas:l

CyF ðtÞ¼ max Ek2A"1ðSFxÞl

Ek F ðtÞ ! " ð9Þ WhereanentityEkbelongstoA"1ðSFxÞ thesetofthenodes fromwhichthenodeSFxisattainableifitexists,atleast,onepath fromEktoSFxinthedirectedgraphG.From an implementation point of view, idSFxðtÞ can be determinedby thefollowing algorithmthat isderived from(6) knowingthat

l

SFxF ðtÞ¼0:idSFxðtÞ idEkðtÞ

l

SFxFmaxðtÞl

EkFmaxðtÞ where Ek is such asl

EkFmaxðtÞ¼maxEi2Γ"1ðSFxÞ !

l

EiFmaxðtÞ"where, the attributel

SFxFmaxðtÞcontainsthevaluedeterminedfrom(9).3.3.Forredundancyfunctions

A redundancy function ensures its service until all the redundantentitiesarefailedorbecomeoutoforder.Butifthere isonlyoneentitythatisabletoperformtheservice,thereisno moreredundancyand,inmanycases,thesystemmustnotbegina newtaskmainlybecauseofsafetyreasons[24].Thereforethree statescanbeconsideredforeachredundancyfunction:

) OK: The redundancy function is able to operate within its minimumperformancesitsminimumperformancesrequiredto fulfilltheplannedtasksthankstooneofitsentitiesatleast. ) OO:Theredundancyfunctionisoutoforder.Thisstatemeans

thattheredundancyfunctionisnotabletooperatewithinits minimumperformancesitsminimumperformancesrequiredto fulfilltheplannedtasksandthusthisstatealsocorrespondsto theKOstate.Thisstatealsomeansthatnoneoftheentitiesofthe redundancy function is able to provide the service they implement within the minimum performances its minimum performancesrequiredtofulfilltheplannedtasks.

) LR:Theredundancyislost.Thisstatemeansthatonlyoneentity thatimplementstheredundancyfunctionisabletoprovidethe service within its minimum performances its minimum per-formances required to fulfill the planned tasks. When a redundancy function is in the LR state, the complex system shouldnotbeginanewtaskmainlybecauseofsafetyreason.

Therefore for each node that belongs to the redundancy function class,threeattributeswillbecomputedfort, thetime atwhichtheplannedtaskswillbecompleted:

)

l

RFxKOðtÞ ¼

l

RFxOOðtÞ:theprobabilitythattheredundancyfunction RFxwillbeintheKOstatebeforet,)

l

RFxLR ðtÞ:theprobabilitythattheredundancyfunctionRFxwillbe intheLRstatebeforet,

) idRFxt

ðÞ: the identifier of the component that should firstly undergomaintenancetoreduce

l

RFxKOðtÞandl

RFxLR ðtÞ.l

RFxKOðtÞiscomputedfromthesetofthepredecessorsofRFxin the modeling. These predecessors are entities (components, simple functionsor redundancyfunctions) notedEi.This setisΓ

"1ðRFxÞ¼fEijðEi;RFxÞ2Ag.RFxwillfailbeforetifalltheentities Ei2Γ

"1ðRFxÞwillfailbeforet.Therefore:l

RFxKOðtÞ¼l

RFxOOðtÞ¼ YEi2Γ"1

ðRFxÞ

l

EiKOðtÞ ð11ÞHowever, redundancy will be lost beforet if less than two entitiesEi2

Γ

"1ðRFxÞwillsurviveuntilt.Therefore:l

RFxLR ðtÞ¼l

RFxKOðtÞ þ X Ei2Γ"1 ðRFxÞ f!1"l

EiKOðtÞ": Y Ej2Γ"1 ðRFxÞ;j6¼il

EjKOðtÞg ð12ÞThequantity,ifitwaszero,woulddecreaseatmost

l

RFxKOðtÞ andl

RFxLR ðtÞ isl

EkKOðtÞ¼maxEi2Γ"1ðRFxÞ !

l

EiKOðtÞ". However, the mainte-nance of a component Cy only reduces itsl

CyF ðtÞ. Thus, for a redundantfunctionthatisonlycomposedofcomponentswithout any predecessor, the component that should firstly undergo maintenance is the component Ck that verifiesl

CkF ðtÞ¼maxCi2Γ"1ðRFxÞ !

l

CiFðtÞ".Foraredundancyfunctionthatis composed of components without predecessor and also of componentswithpredecessorsand/orfunctions, the maximiza-tionofl

RFxKOðtÞwillleadtofavorthemaintenanceofcomponents withoutpredecessor.Thisisnotreallyrelevantregardingtothe CBMpolicieswhoseoneaimistomaintaincomponentsjustbefore theirfailures.Thatiswhyweherechoosetheruleadaptedfrom(9) for which the component Cy, which should firstly undergo maintenance, is the one that verifiesl

CyF ðtÞ¼ maxCx2A"1ðRFxÞ

l

Cx F ðtÞ ! "

whereA"1RFx

ð ÞisthesetofthenodesfromwhichthenodeRFxis attainable.Thisruleisnotoptimalforeverycasesregardingthe decreasingof

l

RFxKOðtÞandl

RFxLR ðtÞvaluesifthere arefunctionsor componentswithpredecessorsinRFx;butitiscomplianttothe CBMpolicies.Becauseoftherelationship(11),therules(5)and(9)andtheir respectiveimplementations(6)and(10)donotseemtoberelevant whenaredundantfunctionRFxbelongstothepredecessorsofa simplefunctionorofacomponentEk.Howeverifthe

l

RFxKOðtÞofthe redundantfunctioniscomparedtothel

SFxFmaxðtÞ¼ maxEl2A"1ðEkÞ

l

El FðtÞ ! "

forasimplefunctionSFxortothe

l

CxFmaxdeterminedfrom(5)foracomponent Cx and if

l

RFxKOðtÞ >l

SFxFmax orl

RFxKOðtÞ >l

CxFmax, one can considerthatl

RFxKOðtÞmustbereducedinordertodecreasel

EkKOðtÞ withEk=SFxorEk=Cx.Howeverthisshouldnothappen.Indeed, the components must be maintained beforel

RFxLR ðtÞ reaches a critical threshold in order to keep a minimal safety level and accordingto (12)l

RFxLR ðtÞ>l

RFxKOðtÞ.Consequently, the respective implementationsofrules(5)and(9)mustbemodifiedinsucha waythealgorithm(6)thusbecomes:where Ek is such as

l

EkFmaxðtÞ¼maxEi2 Γ$1ðCxÞfmaxEi=2FRl

Ei FmaxðtÞ ! ; maxEi2FRl

Ei KOðtÞ ! gthen idCxðtÞ idEkðtÞl

CxFmaxðtÞl

EkFmaxðtÞ else idCxðtÞ Cxl

CxFmaxðtÞl

CxF ðtÞendifwhereFRisthesetofnodesthatareredundancyfunctions of the complex system. The algorithm (13) is applied for a componentCx.

Andthealgorithm(10)becomes: idFxðtÞ idEkðtÞ

l

FxFmaxðtÞl

EkFmaxðtÞ where Ek is such asl

EkFmaxðtÞ¼maxEi2Γ$1ðFxÞfmaxEi=2FR

l

Ei FmaxðtÞ ! ; maxEi2FR

l

Ei KOðtÞ !gwhere FR the setof redundancy functions of thecomplexsystem.Thealgorithm(14)isappliedwhetherfora simplefunctionoraredundancyfunctionFx.

3.4.Algorithmofthegenericfunction

Thegenericfunctionprovidingthedecisionsupportindicators consistsofagraphtraversalinwhichtheattributesofthenodesare computedfromtheattributesofthenodesthatbelongstothesets oftheirpredecessors.Thisfunctionconsistsoffivemainsteps: 1. Themodelinggraphofthecomplexsystemisinstantiated. 2.Theattributes

l

KO,l

F,l

OO,l

LRandl

Fmaxofthenodesaresettozeroandtheattributesidaresettoadefaultvalue.Thisdefault value means that the prognostic function has not been processed.

3.Thelocalprognosesarecomputedfromtheircurrentagesand conditions [36], and the future operations profiles that are transmitted by production planning that assigns tasks to systems,especiallyifthelocalprognosticfunctionsaremodel based [11].Knowing howthefuture productivetasksshould solicitthefunctionsandsubsystemsofthesystem,acceptable levelsofdegradationcouldalsobeadjustedforthecomputation ofthelocalprognosticsunderwhichtheproductivetaskswould befulfilled.

4. Foreachlocalprognostic,theattributes

l

F,l

OO,l

KO,idandl

Fmax oftheinvolvednodeofcomponenttypearecalculatedfrom(2), (3),(4)and(13).4.1. If the attributes

l

KO, id orl

Fmax of the nodehave been modified,foreachsuccessorofthenode,theattributesl

F,l

OO,l

LR,l

KO,l

Fmaxandidarecalculatedfrom(2),(3),(4),(8),(11), (12),(13)and(14)accordingtothetypeofthenode.4.2.Then4.1.

5.Then,foreachnodeandaccordingtoitstype,theattributes

l

F,l

OO,l

KO,l

LRand idaredisplayedorsenttoprovidedecision supportindicatorsforproductionandmaintenanceplanning.Theproposed genericfunctioncanalsobeusedwhena new localprognosisisprovided.Inthatcase,thefunctionbeginsatthe step4whichbecomes“forthenewlocalprognosis,theattributes

l

F,l

OO,l

KO,idandl

Fmaxoftheinvolvedcomponentarecalculated from(2),(3),(4)and(13)”.Inordertovalidatetheproposedprognosticfunctionandthe system modeling, the bridge system and also the Kamat-Riley systemproposedin[38]havebeenmodeledandcomputedbythe proposedprognosticsfunction.Theresultstheprognosticfunction hasproducedhavebeencomparedtotheoneobtainedwithNetica software.TheresultsproducedbyprognosticfunctionandNetica softwarewerethesame.Forthosecomparisons,componentshave had onlyonelocalprognosticeach, redundancyfunctionswere considered as “or” gates and simple functions as “and” gates. However,computationsmade byNetica havenotproduced the intermediateresultsforthe“or”gatesandthe“and”gatesthatthe proposed prognosticfunction canproducefor each attributeof eachnode.

Themodelingofothersystemsmayrequiretransformationsto becomputedbytheproposedfunctionbasedonOOBN.

3.5.Modelinggraphtransformations

Asimplied bythe step4, theproposedgeneric functionfor fusingthelocalprognosesisarecursivegraphtraversal.Therefore, ifthegraphmodelingthecomplexsystemhasgraphcycles,the algorithmmadeofthesteps1to5willneverend.Asthemodeling ofcomplexsystemsandtheproposedgenericfunctionarebased onBayesiannetworksthatareacyclicgraphs[21],graphcyclesof thecomplex system model must besuppressed. Therefore, the graphcyclesmustbeidentifiedasthisisillustratedthroughthe examplepresentedinFig.8(a)wherethehatchedareacorresponds toagraphcycle.Thisidentificationcanbeautomaticallydoneby the Tarjan’s algorithm [42]. Those cycles may appear while modelingthesystemfromdesignmodelssuchasSADTdiagrams ordiagramsproposedinSysMLlikeactivitydiagramsorinternal blockdiagrams.InthosedesignmodelsanentityAcanproducea flowfathatistheinputofanentityBthatproduceaflowfbthatis alsousedbytheentityA.AdirectconsequenceisthatifAdoesnot producefaBwillnotproducefbandifBdoesnotproducefbAwill

Fig.8.Transformationofagraphcycle(a)intoasimplefunctionof interdepen-dence(b).

notproducetheflowfa.Thus,ifoneofboththeentitiescannot operate,thesecondonecannotoperatetoo.ConsideringthatAand Bimplementasimplefunction,thisfunctionwillbeabletooperate onlyifAandBarebothabletooperate.Butcyclesmayinvolve more than two entitiesthat canbefunctionsand components. However,redundancyfunctionsshouldnotbeinvolvedinthose patterns.Indeed,redundantentitiesorsetsofentitiesaremainly designedbecauseofsafetyreasonsandthatiswhytheseentities, which ensure the same function, are very independent as mentioned in [24]. In the cases of graph cycles, like the one described inFig.8(a),theentitiescannotoperatenormallyifat leastoneentityinthecycleisfailedoroutoforder.Agraphcycle canbetransformedbyintroducingasimplefunctionassuggested bytheexamplewithtwoentities.Weherecalltheseintroduced simplefunctions“functionsofinterdependence”.This transforma-tionleadstoreplacecausalrelationshipsbymembershiprelations and viceversa.However, arcs of thecomplex system modeling graphareunweightedandtheyjustdirectthegraphtraversals.So, thisreplacementdoesnotimpactthecomputationofthedifferent attributesofthenodes.Threestepsleadtotransformationofthe complexsystemmodelinggraph:

1.The simple function of interdependence gathers all the componentsincludedinthecycleaswellasthecomponents ofsimplefunctionsincludedinthecycle.

2. Thesimple functionof interdependencebecomestheunique entityofeach functionthatcontainsat leastone component thatbelongstoasimplefunctionincludedinthecycle. 3. Thecomponentsthatwerethetailsofcausalrelationshipswith

components that now belong to the simple function of interdependencearethenconnectedtothesimplefunctionof interdependence,which istheheadofcausalarcs,forwhich thosecomponentsarestillthetails.

TheexampleshowninFig.8illustratesthosemodelinggraph transformationswhereSFidistheintroducedsimplefunctionof interdependence.

Oncegraphcyclesofthemodelinggraphofthecomplexsystem are suppressed, several paths may exist from a given node to anothernode.Thoseseveralpathscanbetheconsequenceofthe design models such as SADT diagrams, activity diagrams or internalblockdiagrams.Intheproposedmodeling,theexistenceof severalpathsfromanodeE1toanodeE2willintroduceseveral times the valueof

l

E1KOðtÞ into thecomputations ofl

E2KOðtÞ andl

E2OOðtÞ,accordingtotheproposedgivenrecursivealgorithmand therelationships (3), (8), (11)and (12) it implements,whereasl

E1KOðtÞ is the probability of a unique event that must so be consideredonlyonce.Toavoidthis,thecomputationoftheattributesofthenodesof themodelingacyclicgraphofthecomplexsystemcanbedoneby generatingseveralgraphsfromthemodelinggraphsuchasthey haveonlyonepathfromonenodetoanotherone.Thegraphthatis obtainedfromdownstreamtoupstreamofthemodelingacyclic graphuntilthereareatleasttwopathsbetweenadownstream nodeEdandanupstreamnodeEu.Inthisfirstgraph,theattributes ofEdwillnotbecomputedbytheproposedfunction.ThenodeEd andthepartofthegraph,whichisdownstream,willbecomputed thankstoasecondgraph.Inthissecondgraph,therelationships betweenthenodeEuandthenodesfromwhichEdcanbereached aresuppressedandEuisdirectlyconnectedtoEd.Thecomputation oftheattributesofthenodesofthisnewgrapharethencomputed butonlytheattributesofthenodesthathavenotbeencomputed forthefirstgrapharestoredordisplayed.Thisnewcomputationis doneuntilthereare,inthisnewgraph,atleasttwopathsbetween twonodes.Athirdgraphmustthenbebuiltaccordingtothesame procedure and so on. Nevertheless there is an exception if an upstreamnodeEdbelongstoaredundancyfunctionRFx,thepath thatgoesthroughtheredundancyfunctionisnotconsideredasa secondpath.Indeedinthiscase,

l

EdKOðtÞdecreasesl

RFxKOðtÞfrom(11) but increasesl

EuKOðtÞof anydownstream nodesExythat canbe reachedbypathsthatdonothaveredundancyfunctionfrom(4) and (8). Indeed, a redundancy function can be assimilated as “or” gates whereas simple functions and components can beassimilated as “and”gates in the modeling based proposed by Simonetal.forthereliabilityofcomplexsystems[38].However, thegenericfunctionweproposecomputesprobabilitiesforthose functions.

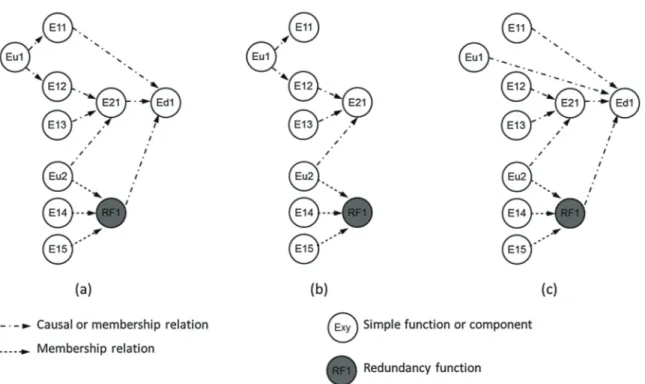

Toillustratetheproceduretogeneratethegraphs,anexampleis presentedinFig.9.InFig.9,thegraph(a)istheoneobtainedafter thetransformationstosuppressgraphcycles.Inthisgraphthere aretwopathsbetweenthenodesEu1andEd1.Therearealsotwo pathsbetweenthenodesEu2andEd1.Thegraph(b)isobtained from (a) by suppressing the node Ed1. The proposed generic function is then computed for the graph (b) and the values obtainedfortheattributesofthenodesof(b)arestored.Thenext stepconsistsinbuildingagraphtocomputetheattributesofEd1 whichisthegraph(c).Inthisgraph,Eu1isdirectlyconnectedto Ed1suchas

l

Eu1KOðtÞisintroducedonlyonceinthecomputationofl

Ed1KOðtÞ.Thegenericfunctionisthencomputedforthegraph(c)but onlythevaluesoftheattributesofEd1arestored.However,there aretwopathsbetweenEu2andEd1ingraph(c)butEu2belongs theredundancyfunctionRF1whichcorrespondstotheexception describedpreviously.3.6.Usingtheattributescomputedforeachnodes

Forproductionplanning,thestoredattributes

l

KOandl

LRare indicatorsthatassesstheprobabilitythatthefunctionsrequiredby theplannedtaskswillfailwhilefulfillingthem.Accordingtothe values of these indicators, production planningmay choose to validatetheassignmentofproductivetasks,toreducethenumber ofassignedtasks,tochangetheassignedtasksand/ortoschedule downtimesformaintenance.Formaintenanceplanning,thestoredattributes

l

KO,l

F,l

OO,l

LR and/oridareindicatorsthataimathelpingmaintenancetochoose the components that should be maintained. The attribute id indicatesthecomponentthatshallfirstundergomaintenanceto better increase the probability that the entity (function or component)survivesuntilthecompletionoftheplannedtasks.Fig.10.Fictitiousmulti-componentsystem.

Ifattributes

l

KO,ofentitiesarebeyondthemaximumacceptable probabilityofinabilitytofulfilltheplannedproductivetasks,the impactofthemaintenanceofthecomponents,whichareindicated bytheattributesidofthosesameentities,canbecheckedapriori. Thisiscanbedonebysetting,forexample,tozero(ortoaverylow value)thevaluesofthelocalprognosesofthecomponentsthatare supposedtoundergomaintenanceandbyrunningtheproposed generic function again with these new values of the local prognostics.Afterward,thefunctionwillprovidethenewvalues of the attributesl

KO,l

F,l

OO,l

LR and idfor thenew proposed repairs if some attributesl

KO still have too high values. The discrepanciesbetweenthevaluesoftheattributesl

KO,l

F,l

OO,l

LR beforeandaftermaintenancewillsoenabletoassesstheefficiency ofthemaintenanceofcomponentsrelativelytotheabilityofthe entities(mainlyfunctions)ofthecomplexsystemtocompletethe plannedtasks.Thanks to the proposed decision indicators, production scheduling andmaintenance managementcanjointly makethe bestdecision accordingtojointperformance indicators[5,6,35]. Thedecisioncanbe,butnotlimitedto,tovalidatetheassignment of productivetasks,toreducethenumber ofassigned tasks,to change the assigned tasks, to schedule downtimes and, for downtimes,tochoosethecomponentstomaintain.

4. Exampleofmulti-componentsystemandexperimental results

Theaimofthispartistopresentthedecisionsupportindicators theproposedgenericfunctionforcomplexsystem providesand

howthisfunctioncouldbeusedbyproductionandmaintenance planning. These results are obtained from a fictitious multi-componentsystemwhose goalistobringtogethermostof the situationsthatmaybeencounteredincomplexsystemsfromthe pointofviewof theproposedprognosticfunctioncomputation. Thefictitious complex system,which is presentedin Fig.10,is madeofthreesubsystemsthatcontainsredundancyfunctionsor simple functions. Several components (Cx) implement the functions.In Fig.10,thearcsarethecausalrelationshipsofthe structuralknowledgemodeling.

Thisfictitiousmulti-componentsystemismodeledaccording tothebehavioral,structuralandfunctionalknowledgemodeling principles described in this paper. The model of this fictitious complexsystemisshowninFig.11whereCxisforthecomponent numberx,PxiisthelocalprognosticsnumberiofthecomponentCx, RFkistheredundancyfunctionnumberk,SFlisthesimplefunction numberl,SFsjisthesubsystemnumberjthatisconsideredasa simplefunctionsandCSisthecomplexsystem.

Transformingthegraphcycles,thatthehatchedareashighlight, ofthemodeled fictitiouscomplexsystem byusingfunctionsof interdependence, the model of the fictitious complex system becomestheonepresentedinFig.12 whereSFimisthesimple function of interdependencenumber m. Thenthree graphsare generatedtoavoidtointroduceseveraltimestheprobabilityofthe KOstateofonenodetothecomputationoftheKOstateofanother oneunlessitbelongstoaredundancyfunction.Thesegraphsare presented in Figs. 13–15 on which the proposed generic is successivelyrun.The resultscomputed forallthenodes ofthe graphofFig.13arestored.ForthegraphofFig.14,onlytheresults

computedforthenodesSFs2andSFs3arestoredand,forthegraph ofFig.15,onlytheresultscomputedforthenodeCSarestored.The stored values of the attributes of nodes are decision support indicatorsforproductionandmaintenancescheduling.

FourscenarioswhoseresultsarepresentedinTable1havebeen computedfromthegraphsofFigs.13–15.Inthosescenarios,we consider that the planned productive tasks will solicit all the functionsofthesystemandthattheirprobabilitytofailbeforethe completionofthosetasksmustnotbebeyond1.5e-2andthatthe only criterion to maintain components is the improvement of reliabilityaccordingtorules(13)and(14).

The scenario 1 consists of a situation where all the local prognostics assess probabilities of failure before the end of scheduledtasksassignedtothecomplexsystemat1e-4.

Thescenario2isbasedonthesamesituationasthescenario1 butthelocalprognosticsP121 andP251 provideassessedprobabilities offailurebeforetheendofscheduledtasksassignedtothesystem at 3e-2and thelocal prognostics P11

2 ,P211 , P341 and P371 provide assessedprobabilitiesoffailurebeforetheendofscheduledtasks assignedtothesystemat1e-2.Thentwodecisionscanbemade

according to the indicators provided by the proposed generic functionandpresentedinTable1:

The productionplanningdefines a newsequence of tasksfor whichthereisnofunctionwhoseprobabilityoffailurebeforethe achievement of this sequence is greater than 1.5e-2, and maintenance planning schedules the necessary actions on componentsC25andC37afterthecompletionofthissequence thankstothevaluesoftheirlocalprognostics.

The production planning decides not to solicit the complex system and maintenance of components C25 and C37 is undertaken.

Thescenario3isbasedonthesamesituationasthescenario2 butthecomponentswhoseidentifiersappearintheattributesidof thefunctionswhoseattributes

l

KOorl

LRaregreaterthan1.5e-2 aremaintained.ThesecomponentsareC25andC37highlightedin darkgreyinTable 1. Tocheckifthemaintenance of thosetwo components is enough to get under the maximum allowed probability that a function of the system fails before the Fig.13. FirstgraphgeneratedtoavoidtointroduceseveraltimestheprobabilityoftheKOstateofonenode.completionoftheplannedtasks,thelocalprognosticsP251 ,P252 and P37

1 aresetto1e-6assumingthemaintenanceofC25andC37is done(butitcouldbeothervaluesmuchlowerthantheonesbefore their maintenance). For this scenario, the proposed generic functionissuccessivelyrunforthethreegraphswiththosenew valuesofP25

1 ,P252 andP371 .Theindicatorsitprovidessuggeststo maintainC34too,ifproductionplanningneedsthatthemaximum allowed probability of the complex system CS before the completionoftheplannedtasksis1.5e-2.Thus,threecomponents shouldundergomaintenancetogetunderthemaximumallowed probability of failure of a function before the end of the tasks planned for the scenario 2. After the maintenance of C34, we supposeP34

1 issetto1e-6too(butitcouldbeanothervaluemuch lowerthantheonebeforeitsmaintenance)andthentheproposed function is processedagain for the three graphs.The provided indicatorsshowthatifC25,C37andC34aremaintained,thereisno morefunctionwhoseprobabilityoffailurebeforethecompletion of the planned tasks is greater than 1.5e-2 (the supposed maximumallowedthreshold).Indeed,inthiscase

l

CSKOishighest valuewhichislowerthan1.09e-2.Thescenario4highlightstheabilityoftheproposedgeneric functiontopredictpropagationsoffailuresandtheireffectsonthe functioningoffunctionsandsubsystems.Inthiscasethesystems must implement a diagnosticmodule.When a localdiagnostic states that a component is failed, at least one of its local prognosticsmustbesettoone(thevalueoftheprognosticmust besaved ina buffertobe recoveredif neededlater).Thenthe prognosticfunctionissuccessivelyrunfromstep4forthethree graphs.Then,eachcomponentorfunctionwhoseattribute

l

KOis equaltoonecanconsequentlybeconsideredoutoforder.These resultscanespeciallybeusedfortheconsistencybaseddiagnosis approachinordertoreducethenumberofcandidatecomponents[2]. Indeed, the second stage of consistency based diagnostic consistsin verifyingthecandidates.Ifcomponentsor functions thatareprognosed“outoforder”consequentlytothefailureofa componentarestilloperatingaccordingtotheirowndiagnostic modules,onecanconsiderthatthecomponentthatistheoriginof these prognostics is not failed and that it was due to a false detectionandsothelocalprognosticthatwassettoonemustbe resettothevaluethatwassavedinthebufferandtheproposed generic function is processed again for the three graphs. The Fig.14.SecondgraphgeneratedtoavoidtointroduceseveraltimestheprobabilityoftheKOstateofonenode.

computedvaluesof

l

KOandl

LRcanalsobeusedbyproduction operatorstomakedecision abouthowtoadapt tothedetected failure. The scenario 4 is based on the scenario 3 but the components C12 and C34 are diagnosed as failed. The conse-quencesarethatfunctionsSF3,SFs3andCSareoutoforderandthe redundancyofRF2islost.5.Conclusion

Agenericfunctionprovidingdecisionsupportsforproduction andmaintenancebasedonBayesiannetworkstoinfertheability of complex system to complete planned tasks from local prognosticsandonan extension toidentifycomponentstobe maintained,was presentedinthis paper.Thedecision support indicators it provides help the production planning to assign productive tasks and also to guide maintenance toward the componentsthatshouldfirstlybemaintained.The implementa-tion of this function requires a modeling of the system that consistsofgraphsthatrepresentfunctional,structuralandapart ofthe behavioralknowledge aboutthesystem. Themethodto build those modeling graphs to adapt them to the generic functionrequirementswaspresented.Theinputsofthisfunction are the local prognostics of the components. These local prognostics provide theprobabilities that thecomponents fail accordingtotheirdifferentfailuresmodesbeforetheendofthe tasksthatproductionplanninghasassignedtothesystem.From

theselocalprognostics,thegenericfunctionassessesthevaluesof thetransitionsbetweenthestatesofeachnodeof thecomplex systemmodelandsoitprovides,forallthehierarchicallevels,the ability of functions and subsystems to fulfill the planned productive tasks. These values are the probabilities that the differententitiesofthecomplexsystems(components,functions, subsystems,etc.)failorbecomeoutoforderbeforetheendofthe assignedtasks.Theseprobabilitiesaredecisionsupportindicators used by productionplanning tovalid or not tovalid thetasks schedulingforagivencomplexsystemandtheycanbeusedto definethedowntimesof thisgivencomplexsystem toperform maintenance. The proposed prognostic function also guides maintenance toward the components that need it in order to shortendowntimesbyenablingtoplanthemaintenanceactions and theirlogistics in advance. Therefore the proposedgeneric function contributes to a better compromise between the satisfaction of therespective objectives of the conditionbased maintenance and of the production planning. The proposed prognosticfunctioncanpredictpropagationsoffailuresandtheir effectsonthefunctioningoffunctionsandsubsystemsandthusit can be reused to implement a consistency based diagnostic function dedicated to the system. In this case the diagnostic functionandtheprognosticfunctioncanshareapartofthesystem modeling. Scenarios weredescribedtoshow howtheprovided decision support indicators can be used for production and maintenanceplanningpurposes.

Further developments of this work will deal with the implementation of the prognostic function on a real system. Other developments will aim at making interoperable various uncertainty models usedfor thelocalprognoses. Thiscouldbe broughtintooperation thankstotheDempster-Shaferevidence theoryorofthetransferablebeliefmodelthatincludesacredal leveltorepresentandtocombinetheinformationandapignistic levelfordecisionmaking[13,38–40].

AppendixA.

l

CxKOðtÞ¼1# 1#l

FCxðtÞ! 1#l

CxOOðtÞ!l

CxKOðtÞ¼1# 1#l

CxF ðtÞ! 1# 1#P

Ei2G#1Cx ð Þ 1#l

Ei KOðtÞ ! h i n ol

CxKOðtÞ¼1# 1#l

CxF ðtÞ!:P

Ei2G#1 Cx ð Þ 1#l

Ei KOðtÞ !IfanodeEisasimplefunction,then

l

EFðtÞ ¼0,hence:l

CxKOðtÞ¼1 # 1#l

CxF ðtÞ!:P

Ei2G#1Cx ð Þ 1# 1# 1#l

Ei FðtÞ ! 1#l

EiOOðtÞ! h i n ol

CxKOðtÞ¼1# 1#l

CxF ðtÞ!:P

Ei2G#1 Cx ð Þ 1#l

Ei FðtÞ ! 1#l

EiOOðtÞ! h il

CxKOðtÞ¼1# 1#l

CxF ðtÞ ! :P

Ei2G#1Cx ð Þ 1#l

EiFðtÞ ! 1# 1#P

Ej2G#1Ei ð Þ 1#l

Ej KOðtÞ ! h i h i n ol

CxKOðtÞ¼1# 1#l

CxF ðtÞ!:P

Ei2G#1Cx ð Þ 1#l

EiFðtÞ!:P

Ej2G#1Ei ð Þ 1#l

Ej KOðtÞ ! n o IfwenoteA#1Eð Þthesetofthenodes,fromwhichthenodeEis attainable,wethenrecursivelyobtain:

l

CxKOðtÞ¼1# 1#l

CxF ðtÞ!:P

Ek2A#1ðCxÞ 1#

l

EkF ðtÞ!

Hence,thevalue

l

EmF ðtÞ2%0;1%,ifitwaszero,woulddecreaseat mostl

CxKOðtÞissuchas:l

EmF ðtÞ¼maxl

CxF ðtÞ; max Ek2A#1ðCxÞl

Ek F ðtÞ ! ! References[1]A.Arnaiz,S.Ferreiro,M.Buderath,Newdecisionsupportsystembasedon operationalriskassessmenttoimproveaircraftoperability,Proc.Inst.Mech. Eng.PartOJ.RiskReliab.224(2010)137–147.

[2]J.Biteus,M.Nybergb,E.Friska,Analgorithmforcomputingthediagnoseswith minimalcardinalityinadistributedsystem,Eng.Appl.Artif.Intell.21(2008) 269–276.

[3]M.Blaha,J.Rumbaugh,ObjectOrientedModelingandDesignwithUML,2nd ed.,PearsonPrentice-Hall,Chesterfield,2005.

[4]C.Byington,M.Watson,M.Roemer,T.Galie,Prognosticenhancementstogas turbinediagnosticsystems,ProceedingsoftheIEEEAerospaceConference,Big Sky,USA,2001.

[5]M.Chaouqi,J. Benhra,A. Zakari,Agile approachfor joint schedulingof productionandmaintenanceinflowshop,Int.J.Comput.Appl.59(2012)29– 36.

[6]T.Coudert,B.Grabot, B.Archimède,Production/maintenanceco-operative schedulingusingmulti-agentsandfuzzylogic,Int.J.Prod.Res.40(2002)4611– 4632.

[7]J.Dunjo,V.Fthenakis,J.A.Vilchez,J.Arnaldos,Hazardandoperability(HAZOP) analysis.Aliteraturereview,J.Hazard.Mater.173(2010)19–32.

[8]W. Elghazel, J. Bahi, C. Guyeux, M. Hakem, K. Medjaher, N. Zerhouni, Dependabilityofwirelesssensornetworksforindustrialprognosticsand healthmanagement,Comput.Ind.68(2015)1–15.

Table1

Resultsofthecomputedscenariosforthefictitiousmulti-componentsystem.

Scenario1 Scenario2 Scenario3 Scenario4

Nodeid lLR lKO id lLR lKO id lLR lKO id lLR lKO id

CS 1.40E#03 C23 5.98E#02 C25 2.08E#02 C34 1.00E+00 C34

SFi2 3.00E#04 C22 1.02E#02 C37 2.02E#04 C35 3.01E#04 C35

SFi1 2.00E#04 C21 1.01E#02 C21 1.01E#02 C21 1.01E#02 C21

SFs3 6.00E#04 C35 2.03E#02 C37 1.04E#02 C34 1.00E+00 C34

SFs2 8.00E#04 C23 4.03E#02 C25 1.05E#02 C21 1.05E#02 C21

SFs1 8.00E#12 C13 6.08E#08 C12 6.08E#08 C12 2.02E#06 C12

SF5 3.00E#04 C35 1.02E#02 C37 2.02E#04 C35 3.01E#04 C35

SF4 3.00E#04 C35 1.02E#02 C37 2.02E#04 C35 3.01E#04 C35

SF3 3.00E#04 C32 1.02E#02 C34 1.02E#02 C34 1.00E+00 C34

SF2 5.00E#04 C25 4.00E#02 C25 1.02E#02 C21 1.02E#02 C21

SF1 5.00E#04 C23 1.04E#02 C21 1.04E#02 C21 1.04E#02 C21

RF2 2.00E#04 1.00E#08 C33 1.01E#02 1.00E#06 C34 1.01E#02 1.00E#06 C34 1.00E+00 1.00E#04 C34 RF1 1.20E#07 8.00E#12 C13 3.12E#04 6.08E#08 C12 3.12E#04 6.08E#08 C13 1.03E-02 2.02E#06 C12

C37 1.00E#04 C37 1.00E#02 C37 1.00E#06 C37 1.00E#06 C37

C36 1.00E#04 C36 1.01E#04 C36 1.01E#04 C36 2.00E#04 C36

C35 1.00E#04 C35 1.00E#04 C35 1.00E#04 C35 2.00E#04 C35

C34 1.00E#04 C34 1.00E#02 C34 1.00E#02 C34 1.00E+00 C34

C33 1.00E#04 C33 1.00E#04 C33 1.00E#04 C33 1.00E-04 C33

C32 2.00E#04 C32 1.01E#02 C34 1.01E#02 C34 1.00E+00 C34

C31 1.00E#04 C31 1.00E#04 C31 1.00E#04 C31 1.02E#04 C31

C25 2.00E#04 C25 3.01E#02 C25 2.00E#06 C25 2.00E#06 C25

C24 3.00E#04 C24 1.02E#02 C21 1.02E#02 C21 1.02E#02 C21

C23 3.00E#04 C23 3.00E#04 C23 3.00E#04 C23 3.00E#04 C23

C22 1.00E#04 C22 1.00E#04 C22 1.00E#04 C22 1.00E#04 C22

C21 1.00E#04 C21 1.00E#02 C21 1.00E#02 C21 1.00E#02 C21

C13 2.00E#04 C13 2.00E#04 C13 2.00E#04 C13 2.00E#04 C13

C12 2.00E#04 C12 3.01E#02 C12 3.01E#02 C12 1.00E+00 C12

![Fig. 1. Probability densities associated to RUL [44] .](https://thumb-eu.123doks.com/thumbv2/123doknet/3030584.85273/3.892.190.713.848.1124/fig-probability-densities-associated-rul.webp)