Chemical

enterprise

model

and

decision-making

framework

for

sustainable

chemical

product

design

Juliette

Heintz

a,b,1,

Jean-Pierre

Belaud

a,b,

Vincent

Gerbaud

a,b,*

aUniversite´ deToulouse,INP,UPS,LGC(LaboratoiredeGe´nieChimique),4alle´eEmileMonso,F-31432ToulouseCedex04,France bCNRS,LGC(LaboratoiredeGe´nieChimique),F-31432ToulouseCedex04,France

1. Introduction

The chemical manufacturing industry is on the frontline of sustainabledevelopmentasitsproductandprocessactivitiesoften stronglyimpacttheenvironmentandpeople’shealthandsafety. Indeedchemical industries arereconsidering the products that theyuseandproduce,underthepressureofregulationslikeREACH [1]andVOCdirectives[2]orofconsumerswantingeco-labeled products.Theydosofroma‘‘doublygreenchemistry’’perspective: onegreenfortheuseofrenewablerawmaterialsandonegreenfor thereduction oftheirimpacts [3].Themanagement of sustain-abilityduringtheproductdevelopmentcycleisbecomingthenew

paradigm of chemical manufacturing industries [4–6]. It is inducingashiftfromacost-drivendevelopmenttoa sustainabili-ty-drivendevelopment[7].Withinthesustainabilitycontextand driven by the 12 principles of green chemistry and the 12 principlesofgreenengineering[8,9],specificissuesmustbelooked at:theuseofrenewablematerials,theminimizationofenergyand material resources consumption, the evaluation of impacts on environment,theconsiderationofhealthandsafety,theselection of appropriate criteria to assess sustainability [10] and the selection of consistent life cycle methods covering economics, environmentalandsocialissues[11].Howevertheseissuesarea concernforhardscienceengineersthatarenottheonlypeopleto beinvolvedwhendesigninganewproduct.Indeed,thechemical productdevelopmentprocessinvolvesmanystakeholdersacross thechemicalenterprise.Themarketdepartmentwillgetinvolved forcostanalysis,markettrendsanduserneedsassessment.R&D chemists, chemical engineers and process operation engineers bringknowledgeand expertiseinproductproperties,inprocess constraints and in product and process design. The quality

Keywords:

Sustainablechemicalproductdevelopment Collaborativedecision-making

Moleculesubstitution Computeraidedproductdesign Processsystemengineering ICT

ABSTRACT

Thechemicalproductsubstitutionprocessisundertakenbychemicalindustriesforcomplyingwith

regulations,likeREACHinEurope.Initiallydevotedtochemists,chemicalssubstitutionisnowadaysa

complex process involving corporate, business and engineering stakeholders across the chemical

enterprisefororientingthesearch towardasustainablesolution.Weformalizeadecisionmaking

processframework dedicated to thesustainablechemical product design activityinan industrial

context.Theframeworkaimsatimprovingthesharingofinformationandknowledgeandatenablinga

collaborativeworkacrossthechemicalenterprisestakeholdersatthestrategic,tacticalandoperational

levels.Itissupportedbyinformationandcommunicationtechnologies(ICT)andintegratesacomputer

aidedmoleculardesigntool.Duringtheinitialintelligencephase,asystemicanalysisoftheneedsand

usagesenablestodefinetheproductrequirements.Inthedesignphase,theyarecompiledwiththehelp

ofafacilitatortogeneratetheinputfileofacomputeraidedproductdesigntool.Thismultiobjectivetool

isdesignedtofindmixtureswithmolecularfragmentsissuedfromrenewablerawmaterials,andisable

to handle environment-health and safety related properties along with process physicochemical

properties.The finalchoice phase discusses thesolution relevancyand provides feedback,before

launchingtheproductmanufacturing. Theframeworkisillustratedbythesearchofabio-sourced

water–solvent mixture formulation for lithographic blanket wash used in printing industry. The

sustainabilityofthesolutionisassessedbyusingthesustainabilityshadesmethod.

* Corresponding authorat:Universite´ deToulouse,INP,UPS,LGC(Laboratoirede Ge´nieChimique),4alle´eEmileMonso,F-31432ToulouseCedex04,France. Tel.:+33534323651.

E-mailaddress:Vincent.Gerbaud@ensiacet.fr(V.Gerbaud).

1Currentadress:ProsimSA,ImmeubleStrate`geA,51,rueAmpe`re,F-31670 Labe`ge,France.

managementdepartmentisresponsibleforensuringtheproduct quality through norms and means to achieve it. The business processexpertswillbemanagingproductionandchemicalsupply chain; corporate managers.... Hung et al. [12] wrote: ‘Effective product development depends on the integration of a variety of specializedcapabilities,strongfunctionalgroupswith interdisciplin-aryteamsandmultipleprogressivepressures.Newproduct develop-ment [...] involves cross-function integration, a complicated interdisciplinary activity that requires many knowledge inputs to generateasuitableproductsolutionaswellasanappropriateproject plan in the time-competitive environment’. This stresses the importanceofinformationandknowledgemanagementbetween peoplethatarecomingfromdifferentculturesandtheimportance ofbringingthemtoconsiderallthesustainabilityissuestogether. Inthiscontext,wedevelopanICTbaseddecision-makingframe to improve the collaborative participation between all stake-holdersinthedevelopmentofsustainablechemicalproducts.To ourknowledgeitisthefirsttimethatsuchaframeworkiscoupled with a computer aided molecular design for finding chemical product,andthatthiscouplingisspeciallyaimedatsustainable chemicalproductdevelopment.Section2surveysabackgroundon chemicalproductdevelopmentactivityissuesandon enterprise-wideproductengineering.Section3reviewslimitationsofexisting approaches and tools. Itidentifies five challenges and suggests solutions.Section4describesourICTsolutionandcomputer-aided chemicalproductdevelopment.Itissplitintoadescriptionofthe chemicalenterpriseperspectiveandofthedifferentphasesofthe decisionprocess.Itincorporatesadistributedcomputingsolution aimingatfindingchemicalproductssatisfyingpredefined require-mentswithinasustainablecontext.Section5describesadetailed industrial basedcasestudyaimingatfindinganovel ink wash-blanketsolventinaprintingmanufacture.

2. Stateoftheart

2.1. Chemicalproductdevelopment

Hill[5]statedthatchemicalproductdevelopmentcovers‘‘(1) chemical product design and development, and (2) product-orientedprocessdesignand development’’,alsocalledchemical productengineering[4].Werestrictourselvestothefirstissuein thispaper.

2.1.1. Productclassification

Refs. [13,14] classified products in basic, structured and configured-consumer products. Basic/functional chemicals en-compass commodity,intermediate and specialtychemicalsthat aredesignedforachievingonefunction(solvent,reactant)andfor matching only a few key physicochemical properties (solvent power, boilingpoint,etc.).Structuredproducts and configured-consumerproductscombinemanypropertiesandfunctionsina single product, which is often a mixture. Structured products (cream,films,etc.)orindustrialchemicalsareassembliesofbasic chemicals[4,15].Someoftheirpropertiescanbesetbytheproduct manufacturingprocessitself[5,16],whichinducesasimultaneous designoftheproductandprocess.Configured-consumerproducts (drugdeliverypatches,post-itnote,drugpill...)targetthe end-usermarkets and areassemblies of several industrial products withafocus ontheirphysicalconstruction[15].For allproduct classes, the set of requirements is complex. It can include qualitative sensory factors, environment, health, safety (EHS) impact-related properties, stability and flowing considerations along with more traditional physicochemical properties. Costa et al. [4] focused on product perceived quality factors and identified three property classes: product properties, process-relatedpropertiesandusage-relatedpropertiestoencompassall theproducttechnologicalrequirements.

2.1.2. Productdesignsolutions

Fordesigninganewchemicalproduct,thetraditionaltrialand errorbottom-upapproachisintrinsicallyinefficient.Itproceedsas follow: given a raw material, perform chemical, physical or biochemical transformations to make a molecule; then check propertiesandsee aposterioriifthe expectedrequirements are matched.Instead,top-downreverseengineeringapproachesfocus inneedsfirst:theydefineaprioriasetoftargetpropertyvaluesand searchforcomplyingmolecules,eitherintodatabasesorbybuilding themfromapoolofsmallchemicalelements.Reverseengineeringis nicely implemented within computer-aided molecular design (CAMD) tools [17–19]. Those tools rely upon a multi-objective optimization technique to build candidate molecules and upon propertyestimationmodelstoevaluatethecandidateperformance vs.thesetofaprioritargetpropertyvalues.Theuseofaccurate property prediction methodsis recommended to legitimatethe CAMDpredictiveprocess.Nevertheless,experimentalsynthesisand validationcompletestheCAMDprocess.WithintheCAMDtools,the objectivefunctioncanaggregateanytypesofpropertyforwhich existsanestimationmodelbasedonthe molecularandproduct structure.Weidentifygroupcontributionmethods[20–23],QSAR/ QSPRmethods[24],similaritymodelsfortoxicitymodels[25]and arbitraryscalingmethodsforsensorialproperties[26].

Formixtureproducts,eachmixturecomponentcanbedesigned andpropertymodelswithlinearornon-lineardependencyonthe mixture compositionmust beconsidered. Mostcomputeraided productdesign(CAPD)toolsperformasequentialsearchofeach product components individually for example by using CAMD, beforecheckingmixturepropertiesandmixturestability[27–30]or decomposetheoverallproblemintoasubsetofsubproblems[31]. This prompted us to develop in parallel to the present paper Nomenclature

BPMN businessprocessmodelingnotation CAMD computeraidedmoleculardesign CAPD computeraidedproductdesign DSM DesignStructureMatrix EHS Environmental,Health,Safety

ICT InformationCommunicationTechnology LCA LifeCycleAnalysis

LISI levelsofinformationsysteminteroperability LCIM levelofconceptualinteroperabilitymodel MDE modeldrivenengineering

MMI ManMachineInterface OCL ObjectConstraintLanguage

OIM organizationalinteroperabilitymaturity PSE processsystemengineering

QFD QualityFunctionDeployment

QSAR QuantitativeStructureActivityRelationship QSPR QuantitativeStructurePropertyRelationship RED property name expressing the ratio of Hansen

SolubilityRadiusversustheHSPsphereradiusfora givenproduct

RM-ODP ReferenceModelofOpenDistributedProcessing SBVR SemanticsofBusinessVocabularyandRules SME SmallMediumEnterprise

UML UnifiedModelingLanguage VOC VolatileOrganicComponent XML ExtensibleMarkupLanguage

contribution,anewCAPDtoolperformingaglobalmixturesearchby usingageneticalgorithmonaversatilematrixmolecularstructure representation[32].Itenablestobiasthesearchtowardmolecules coming from renewable resources, and toaccount for the poor accuracy of existing property estimation methods for the less studiedrenewablemoleculespoolsusedtobuildthecandidates. 2.1.3. Productrequirements

Thestandarddefinitionofarequirement[33]remainsarguable, sinceitsperceptionbytheuserandbythesolutionprovidercanbe different[34].Asageneraldefinition,westatethatarequirement definesanexpectationexpressedbyoneofthestakeholdersina direct (performance) or indirect (forbidding, limiting) manner. Furthermore, requirementstatementsbetray theculture ofthe stakeholderenouncingit:engineerswillusemathematics,physics, chemistry and numbers to express requirements in terms of property specifications; corporate managers will use words. A classificationofpropertieswaspresentedinthesub-sectionabove aboutproductclassification.

To harmonize the expression of requirements and their understanding, an unambiguous semantic shared by all stake-holdersisneeded:Forrequirementsnotrequiringexplicitmath formulas,thebusiness ruleconcept is wellfitted.Itenables to expressconditionsandrecommendationsintermsofnecessityor obligations[35,87]andallowssomeexternalcontroloftheprocess andprocedurewithintheenterprisestrategy[35].Forhardscience engineering requirements, mathsand numbers can be usedto expressconstraints.Languagecanfurtherbeusedtoexpressthe requirements without ambiguity: the Semantics of Business VocabularyandRules(SBVR)[36]andObjectConstraintLanguage (OCL)[37]applyforbusinessrulesandconstraintsrespectively. 2.1.4. Chemicalproductdesignactivities

The process system engineering (PSE) discipline aims at developing model-based methods and tools for the chemical industries[38].ItinventedtheCAMDapproachwhichhasbecome theleadingtechnique for chemical productdesign [39].Asthe productdesignandmanufacturingprocessesarerelatedtoeach other,amanagementoftheactivityworkflowandtheassociated information is welcomed [40]. In PSE, Varma et al. [41] acknowledgedtheimportanceof‘enterprise-widecross-functional coordination’forthechemicalsupplychainandstressedtheneed for integrating decision-making across the enterprise layers. Indeed, a corporate level decisions about finding a new green non-fossilbasedmolecule willinfluencedecision-makingatthe activity/processlevelwherethenewproductisdeveloped.

Among several frameworks that model chemical product developmentactivities[13,16,28,42].Hill[5] describedaneight steps methodology for basic/functional products design: (i) product definition with an analysis of customer needs; (ii) technicalproductrequirements; (iii)product performance rela-tionshipandderivationofpropertypredictionmodels;(iv)product candidategeneration;(v)productcandidateselection;(vi)process design;(vii)riskanalysis;andfinally(viii)businesscaseanalysis. Formorecomplexproducts,classifiedasstructuredor configured-consumerproducts,nogenericmethodologiesexist.

Underthename‘integrativeproductdesignstrategies’,Smith andIerapepritou[14]reviewedhowconsumer,product-process performanceandbusinessissuesarehandledwithinthechemical productdesignactivitiesof15industryactorsproducingspecialty chemicals,drugs, food, personal careand bulk chemicals.They noticedthatconsumerneedsarealwaystakenintoaccount,and that product-process performance integration is very often implemented in practice although no standardized approach emerges. Regarding business decision variables, they concern project planning and scheduling, resources allocation, product

portfolio management and supply chain management. But the linkagetotheproductdesignactivitiesisnottrivial[14].

Gagnonetal.[43]reviewedbothconventionalandsustainable design processes in the literature and proposed to classify integrated sustainable engineering design process activities in fourstages atfirst;planningandproblemdefinition,conceptual design, preliminary design and detailed design, which are also foundin thestage-gateTM product development process stages [15].Then,theysplitfurtherthefourstagesinto22tasks.Usual steps like design specification, alternative concept generation, alternative concept performance evaluation, are complemented withstepsthatGagnonetal.claimedtobecriticalforachieving sustainability: multidisciplinaryproject team, definitionof sus-tainability(sustainableissues relevantfortheproblem, criteria, assessmentmethods,monitoringindicators,etc.),selectionofan approachformulti-criteriadecisionmaking,performance assess-mentaccordingtothesustainabilitycriteriaorindicators.Finally, theyproposeda methodologytoevaluatetheextentof sustain-ability achieved, by using four degrees of shade over six dimensionsofsustainability.Thesixdimensionscoverthedesign process itself, the indicator relevance, the sustainability issue covered,theanalysistoolaccuracy,thealternativeperformance andthedecision-makingprocessitself.

2.2. Enterprise-wideproductengineering 2.2.1. Decisionmakingprocess

Simon’searlythreephasemodelingdecisionmakingprocess: intelligence,designandchoicephases[44],isoftencompletedby animplementationphase,afeedbackmonitoringphase[45]anda knowledgecapitalizationphase[46].Decisionsaretakenbypeople andcanbehierarchizedinparallelwiththeorganizationofthe enterprise [47,83]. In that case, it is common to distinguish betweenstrategic,management/tacticalandoperationaldecision levels.Amongthenumerousdecisionmakingmethods,wecancite DELPHI[48,49],ELECTRE[50],PROMETHEE [51],multi-attribute utility technique [52], analytic hierarchyprocess [53], analytic networkprocess[54].

Ng [55]sketcheda hierarchicaldecision-making processfor chemical product and process design concerning both process systemengineeringandbusinessprocessengineering.Hematched afourlevelorganization(corporate,businessunit,manufacturing site and R&D laboratories) with a business decision-making framework hierarchized in the order of decreasing time and length scales, from corporate to molecule level. Refs. [10,56] proposed a generic decision-supportframework for sustainable developmentanduseditinthechemicalprocessdesignarea[11]. They identified the stakeholders and their level of interest in economic,environmental and socialissues. Theyalso discussed sustainability indicators choiceand pertinence, and considered severalmultiplecriteriadecisionanalysis(MCDA) techniquesto helpthedecisionmakersinchoosingthemostsustainableoption. The framework was claimed to improve dialog and increase a shared knowledge among decision-makers, to show trade-offs betweenconflictingobjectives.

2.2.2. Productdesignframework

Intendedfortheplanningoftheproductdesignactivity,Hung et al. [12] developed a knowledge-based system by using the Design Structure Matrix framework (DSM) [57] for managing information flowsand forplanningproductand processdesign scheduling and costing. The Quality Function Deployment technique(QFD)[58]wasalsousedbyHungetal.totransform the customer needs and market requirements into technical requirementsandspecifications.Finally,theycoupledtheQFDand DSMcomponentswithaknowledge-basedproductdatabase.The

databaseprovidednecessaryinformationtosupporttheproduct design: customer requirements for elaborating the technical function and for connecting it to the QFD solution principles; engineering requirements;product parts;theproduct architec-ture;thedesignprocesstemplatetogeneratethedurationandcost ofdesignactivitieswithintheDSMframework.

Dekkersetal.[59]usedagenericreferencemodelfordescribing firstly, the product design and product engineering process, secondly, theproduct manufacturing process activities,thirdly, their direct relations and the feedback loops between them. Reviewingtheliterature,theyisolatedfiveresearchthemesinit andisolatedasixththemerequiringmoreeffort,called‘‘Enabling [the interface between thetwo processes] throughInformation andCommunicationTechnology’’.Asidecommenttothattheme wasthenecessity ofbridging themanagementculture andthe engineeringcultureacrosstheenterprise.

2.3. Enterprisemodelingandintegrationconceptsandtools AccordingtoVernadat[60],enterprisemodelingand integra-tionaimsatfacilitatinginformationsharingacrosstheenterprise stakeholdersbyusingmodelsofthestructure,thebehaviorandthe organization of the enterprise. The enterprise organization is usuallymodeledintheaforementionedworks[10,41,55,56]bya hierarchywithstakeholders.Forexample,Nglistedstakeholdersin fourenterpriselevelforachemicalenterprise[55]:CEO,CTO,CFO and board members at the corporationlevel; business VP and marketingmanagersatthebusinessunitlevel;plantmanagersand operatingpersonnelatthemanufacturingsitelevel;R&Ddirectors, chemistsandengineersattheR&Dlaboratorylevel.

Foraconsistentrepresentationoftheenterprisearchitecture,the ISO19440standardrecommendstousefourviews[61]:functional (event-process-activity),organizational(enterprise structure), in-formational(object-data)andresource(resource,capability)[62].Leˆ andWegmann[63]discussedchallengesinenterprisearchitecture and selectedtheRM-ODP(Reference ModelofOpenDistributed Processing)hierarchicalmodelarchitectureforprovidingmultiple view of the enterprise andits environment,such asitsinternal structure, the services provided by the enterprise, the business processes, the data flow between business entities and the informationtechnologycomponentsandtheirinteractions.

Thedegree ofinteroperabilityachievedwithin theenterprise architectureentitiescanbeappreciatedwith thehelpofmodels summarized by Panetto and Molina [64]: the LISI (levels of informationsystem interoperability)model focuseson technical aspectsandcomplexityofinteroperationsbetweensystemsthrough five degrees:isolated, connected, functionaldistributed, domain integratedoruniversalsystems.TheOIM(organizational interoper-abilitymaturity)modeldealswiththeenterpriseenvironmentand organizationalissuesthatcontributetotheinteroperablesystems. Thesystem technicalcoherence–alignment–canbeevaluated throughtheLCIM(levelofconceptualinteroperabilitymodel).

Alignmentisanimportantobjectiveofmodeldrivenengineering thatweuseinthiswork.Verticalenterpriseintegrationrefersto decision-makingintegration[60]ortostrategicalignment (Hen-dersonandVenkatraman[86])acrosstheenterpriseorganizational layers like those described by Ng [55]. Horizontal enterprise integrationrefers tophysicaland logicalintegrationofbusiness processes from product demand toproduct shipment (Venadat, 2002)ortocoherencyofinformationacrossthemodelinglayers (metamodels, conceptual models, implementation models). For achieving vertical and horizontal alignment, model-driven engi-neering(MDE)tools,conceptsandlanguagescanbeused[65].With that approach, our process and system analysis relies uponthe integrationofdifferenttechnicalspacescombiningBPMN (business-processmodelingnotation[66,67])andUML2.0(UnifiedModeling

Language,[68])andobject-componentoriented technologiesfor encompassingallfourviewsoftheenterpriserecommendedbythe ISO19440Standard[61].Someinformationdocumentswerealso structuredbyusingaXMLscheme.

3. Limitationsandproposedsolutions

We propose a solution customized for sustainable chemical productdesignbyusingstandardmodelingsemanticsanddecision makingtechniqueswithinan ICTsupported framework.To our knowledgeitisthefirsttimethatsuchaframeworkiscoupledwith a computer aided molecular design tool for finding chemical product,andthatthiscouplingisspeciallyaimedatsustainable chemicalproductdevelopment.Thuswecontributetothebridging ofthemanagementcultureandtheengineeringcultureacrossthe enterpriseasadvocatedbyDekkersetal.[59].

From thestate of the art section, we observe that a newly designed chemical product is ultimately chosen based on the satisfactionofrequirements formulatedbyvariousstakeholders from engineering, business, management cultures across the enterpriselayers.Corporatemanagersmaydecideatthestrategic leveltocopeornotwithREACHregulationandinitiateaproduct substitutionactivity.Atthetacticallevel,business unitexperts, product manager and the marketing office may formulate consumer-related requirements and target a specific crop as a possible renewable material source for the future product molecules.Then attheoperationallevel, engineersmayspecify these high level requirements into property specifications and chemicalstructures.Thosedecisionspropagatedownthroughthe enterpriselayersandaregraduallyrefined.

Therefore,itappearsfromthestateoftheartsectionthatthe designofasustainablechemicalproductsetsfivekeychallenges: (1) decision management and propagation, (2) involvement of many stakeholdersacrossthechemical enterprise,(3) manage-mentoftheinformationandstakeholderknowledge,(4)modeling of the chemical product information (molecular structure, property classes, property models covering both technical and impactissues),(5)ensuringthesustainabilityofthesolution.For eachchallengeweproposesolutions:

1.Fordecisionmanagement,weselectthethreephasesdecision sequenceofSimon[44]anduseitwiththehelpoftheDELPHI method. Although it is not sufficient to handle all business decisionvariablesrecordedby Smithand Ierapepritou[14],it covers reasonablywell the chemicalproduct designactivities beforetheirimplementation[5,43].TheIntelligencephasecovers Hill’ssteps(i)and(ii)aboutproductdefinition,userneedsand requirements.Thedesignphasecoverssteps(iii)aboutproduct performanceandstep(iv)aboutproductcandidategeneration. The choice phase concerns step (v) about product candidate selection.Steps(vi)to(viii)arepartiallycoveredandwouldbe fullyinanextendedversionofSimon’ssequence:processdesign step(vi)belongstoanadditionalimplementationphasebutalso tothedesignphaseinthecaseofso-calledstructuredproducts; steps(vii)aboutriskanalysisbelongstoanmonitoringphasebut is alsorelevantduring the choicephase andstep (viii)about businesscaseanalysis belongstoanknowledgecapitalization phase. In addition, some business variables like resource allocation can still be introduced as requirements in the intelligencephase,asweillustratelaterinthecasestudy.Finally wehierarchizetheintelligencephasedecisionsthroughstrategic, tacticalandoperationallevels.

2.Inparallelwiththathierarchicaldecision-making,wedescribe theenterpriseorganizationwithfourlayers(corporate,business process unit, chemical engineering and chemist) and relate themtostrategic,tacticalandoperationaldecisionlevelsthat

willstructurethedecisionpropagationduringtheintelligence phase.Thisintendstoachieveverticalalignment.

3.Forthemanagementofknowledgeandinformation,weintend todocumenteachdecisionandtheprocessofdecisionrefining. During the intelligence phase, decisions are refined as they propagate through the enterprise organizational layers. We provide access to the documentation produced by other stakeholderssoastoalloweach newdecision tobetakenin awareness of previous decisions. For consistency, we use standard semantics and standard documentation. Besides, consideringthatstakeholdersatthestrategicandtacticallevel might express requirements word semantics whereas opera-tionallevelstakeholdermightusemathsconstraints,wedecide tosplitrequirementsintobusinessrulesandconstrainttypes, expressedwithSBVRand OCLsemantics respectively.Design phaseandchoicephasewillalsobedocumented.Bybringing consistencythroughtheorganizationallayersrelations,theuse of standard semantics participates in achieving horizontal alignmentinitsinformationsense,acrossthemodelinglayers. 4.Fortheproductdesignprocess,weusetheso-calledIBSSCAPD tooldevelopedinaparallelworkandcustomizedspecificallyfor sustainableproductdesign[32].AsanyCAMDapproach,IBSSis performing a need-oriented search, which makes it ready to exploit the requirements tree resulting from the intelligence phase.Itusesadetailedmolecularrepresentationanditisableto copewithalargenumberofpropertyspecificationsexpressing productrequirements.Hence,IBSScanbeusedtofindbothbasic andstructuredproductsasdefined bySmithandIerapepritou [14]beingeithersinglemoleculesormixtures,andtoorientthe search toward bio-sourced molecules. Regarding properties, propertiesdescribedbyCostaas process-relatedpropertycan behandledifwecanfindanalternativeexpressiondecoupled fromthemanufacturingprocessandapplicabletotheproduct designactivity.Forexamplewhensearchingforanewextractive distillationsolvent,wecanrelatedthemanufacturingextractive distillationprocessefficiencytotherelativevolatility thermody-namicpropertywhichiscomputedbyusingonlythechemicals involved,independentlyofthedistillationprocessconfiguration. 5.For ensuring the sustainability of the solution, we first allow requirements to include sustainable issues during the

Intelligencephase.Duringthedesignphase,theIBSSCAPDtool is able to handle environmental, health and safety related propertiesfordescribingthesustainablerequirements.Besides IBSSallows theusertoimposebio-sourcedfragmentsin the candidatemolecules,improvingtheirsustainabilityby satisfy-ing a key principle of green chemistry ‘‘use of renewable materials’’.InadditionweusetheprocedureofGagnonetal. [43]to assess thedegreeof sustainability during thechoice phase.

Overall,accordingtotheLISIscaleforappreciatingthedegreeof interoperability,oursolutionreachesanintermediatedegree,asit isa‘‘functionaldistributed’’solution.

4. AnICTbasedframeforsustainableproductdevelopment 4.1. Chemicalenterprisemodelingframe

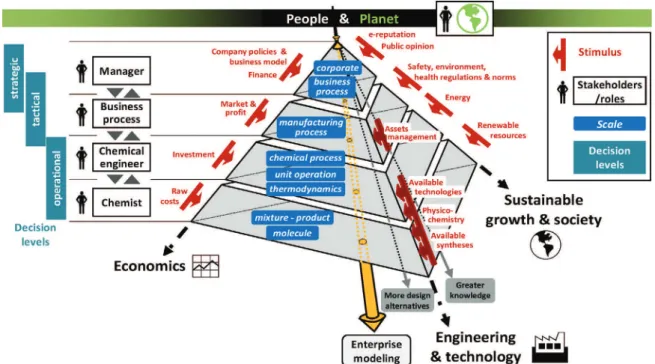

InFig.1,wesketchachemicalenterprisemodelingframewhere decisionlevelsareassignedtoenterpriselayersandsetinparallel withstakeholderrolesandwithamulti-scaledescriptionofthe chemical enterprise from molecules to enterprise-wide issues. Thereby, the frame enforces a vertical alignment through interrelatedlayersdescribingthedecision,theorganizationand thesystem(hereachemicalproduct).

Thepyramidaxes aimatcapturingthepillarsof sustainable engineering principles, society, environment and economy [43] whilekeepingengineeringandtechnologyasthecoreactivityof theenterprise.

Weassumeasimplifiedorganizationoftheenterprisewithfour hierarchicallevelsinspiredbythoseof Ng[55].Ateachlevel,a stakeholderisdefinedasarole,whichcanbeplayedbyateamof people in large companies. Inversely a singleperson can bein chargeofseveralrolesinaSME.Astakeholderfacesstimulialong eachofthethreeaxes(seeexamplesinFig.1)thatwillparticipate inthesettingoftheproductrequirements.Thenthestakeholders areconfrontedtostrategic,tacticaloroperationaldecisionlevels forrespondingtothosestimuli.Strategicandtacticallevelsmay concernseveralstakeholders.Theoperationallevelconcerns hard-scienceandengineeringissues.

Eachlevel is confrontedtooneormoreof theeightsystem scalesfromthecorporatetothemolecularlevel.Fromourproposal ofchemicalenterprisemodel(Fig.1),wemaylist:Corporate<> Businessprocess(portfolioofproducts,financialoperations,etc.) <> Manufacturing process (production plant, biochemical or petroleum-based process,suppliers, storage and transport,etc.) <>Chemicalprocess(production,water&energynetwork,waste treatment, etc.) <> Unit operations (intensified reactor, heat integrateddistillation,filter,crystallizer,etc.)<> Thermodynam-ics (phase transitions,aqueous phases,organic phases,reacting media, etc.)<> Mixture–product (structured product,end-user cream,etc.)<>Molecule(rawmaterial,activeprinciple,etc.).

Aswegotowardsmallerscales,designalternativesincreases within the decision process and the related knowledge and informationaswell.

4.2. Decisionmakingprocessforsustainablechemicalproductdesign The decision processis triggered by a stimulus thateither conflictswiththebusinesspolicy,likeproductsubstitutionofa

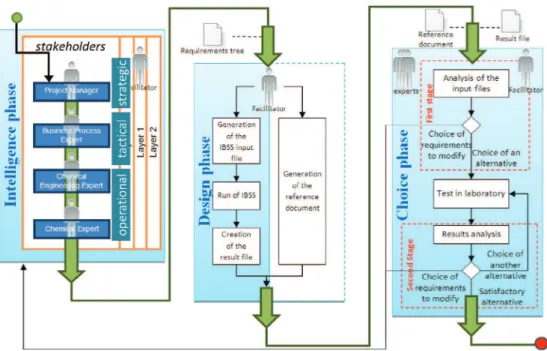

chemicaltocomplywiththeREACHregulation,ormotivatesa changeinthebusinesspolicy,likeaddinggreenersolventstothe productportfolio.Fig.2displaysourdecisionmakingprocessfor sustainable product design,based onSimon’s original process [44].

4.2.1. Theintelligencephase

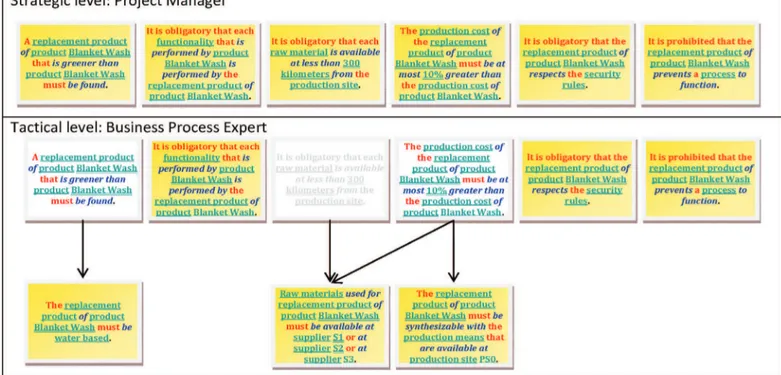

Forchemicalproductdesign,theintelligencephasegoalistoset requirements that meet customer needs and comply with the enterprise strategy. They are usedin thenextdesign phase to constrainthemixturestructureandthepropertiestargetvalues. Fig.3describestheverticalmulti-levelsandhorizontalabstraction layerssupportingtheintelligencephase.

We suppose that the four stakeholders of the enterprise pyramidareinvolvedsequentially,concernedwithdecisionsatthe strategic(manager), tactical(businessprocessexpert) or opera-tional level (chemical engineers and chemists). The tree of requirementsisdefined duringatop-downhierarchicalprocess through the strategic, tactical and operational levels. The propagationofthedecisionensuresastrategicalignmentasthe

Fig.2.Overviewofproductdesigndecisionmakingprocess.

decisionstakenhaveanimpactonthelowerlevels.Thiswaythe businessstrategyisfollowedateachleveloftheenterprise.

Thehorizontalalignmentislimitedtotheuseofasingleunified requirement model for all decision levels (Fig. 3), but a more genericmulti-layerframewaspresentedelsewhere[69].

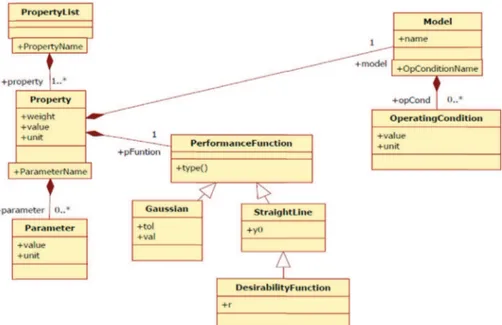

AccordingtoFig.1,eachstakeholderfacesdirectlysomestimuli alongthethree,economy,engineeringand socio-environmental axes.Itallowshimtoaddressspecifictypesofrequirements(layer 0inFig.3).Wedecidethatrequirementsareexpressedasbusiness rulesatthestrategic andtacticallevel,whereastheoperational levelcandirectlyexpressconstraints.Therequirementmodelis displayedasaUML2modelinFig.4.Itshowsthattheconstraints aremodeledbyusingOCLandthelocalrulesareexpressedasSBVR usingstructuredEnglishtoavoidanyambiguousinterpretations andtoimprovecommunication.

In addition,weuseacoloringoftherequirementsisusedto stressthe interest level of therequirement: yellow refersto a ‘‘considerinpriority’’interest,whiterefersto‘‘consideraswell’’ interestandshadedgrayrefersto‘‘ignore’’interest.The‘‘ignore’’ statusmeansthattherequirementiskeptinmindbutisinactive forthecurrentlevel.Itmaybereactivatedalongtheconstructionof therequirements treebyotherstakeholders,asallofthemcan accesstheentiretreedetailsanddocumentation.

Ateachlevel,thededicatedstakeholdersareaskedtoexpress the stimuli they face as requirements within the tree. But as highlightedinthebackgroundsection,collaborativeworkshould bewelcomedtoreachafinalsetofrequirementsthatisconformto theenterprise reality.In additiontoa fullaccesstothetreeof requirements by any stakeholder, we introduce a so-called facilitator, possibly the product design project manager. As a humanfactor easing the overall collaboration, he managesthe differentlayersandskillsneededfortherequirementsmaturity.At thepresent levelofourframeworkdevelopment, hisactivityis supported by a common document oriented tool for handling thetextualandinformalnotesattachedbythedifferentactorsto thedifferentobjectssuchas therequirementobjectsalongthe intelligencephase.Weforeseetwofuturedevelopments.Oneisto use Enterprise Social Software (ESS) tools in support of the facilitatoractivity,whicharebasedon theconceptsofWeb2.0 [70],orSemanticweb[71].Aweb2.0portalisunderconsideration fordevelopingspecificadd-onmodulestoanexistingcollaborative platform.Itscorerequirementsare:profilesmanagement accord-ing to stakeholder, skills and organization level, information

automation, statistics, charts and dashboards, chat, markers of progress,markersofopinion,spaceforsketching,notesandtags management. The second aims at improving the knowledge management based on simple notes by using semantic and ontologicalannotationswhicharenotonlyhumanreadablebut alsosuitedforcomputerprocessing.Forthiswaywehavetodefine aformalvocabularyandmeaningofthedifferentskillsexistingin ourchemicalenterprisecontext.Afurtherperspectivewouldbeto implementtheconceptsofRobinetal.[72]whichallowmodeling ofcollaborativeknowledgeandintegrateitintoadesigncontext enabling an efficient support of the stakeholders during the intelligencephase.

4.2.2. Thedesignphase

Thedesignphasefocusesonthegenerationofchemicalproduct candidates.Fig.2showsthatthefacilitatorsupervisestheselection ofasuitablemethodforgeneratingalternatives.Weuseourown computeraidedproductdesign(CAPD)tool[32],brieflydescribed below.Therequirementstreedatafromtheintelligencephaseare usedasinputandtransformedintoproductspecifications.Some requirements are unsuitable for the CAPD tool, like the cost evaluation, andare putasidetobeconsidered later duringthe choice phase. CAPD tool-specific parameters are added by the facilitator, like those related to the multiobjective search algorithm. In parallel, the facilitator formalizes a reference document understandable by the experts involved in the next decision-making process choicephase. It contains the require-mentssetduringtheintelligencephaseandtheCAPDparameters. Asaresultofthedesignphase,outputcandidatemoleculesor mixtures are listed. Each candidate is ranked according to a performancenoteexpressing itsmatchwiththesetof require-ments. However, since the CAPD tool is based on predictive propertyevaluationmodels,thecandidaterelevancedependson the accuracy of the property evaluation models used. Besides, somemolecularstructuresmaynotbeactuallyfeasibleoreasyto synthesize.Thus,humanexpertiseand laboratoryconsolidation arenecessaryandhandledinthenextchoicephase.

4.2.3. Thechoicephase

Thechoicephaseconsistsinchoosingwhichalternativescanbe implemented.WeselecttheDELPHImethodusedinTavanaetal. [73]forhelpingwiththechoiceofthebestalternative.Afacilitator runs an analysis on the questionnaires’ answers and on the

motivationsoftheseanswers.Ifnoconsensusisreached,asecond roundstartsandtheexpertsanswerthequestionnairesonceagain untilthegroupconvergestowardaconsensusanswer.

Expertsshouldcomefromthedomainsofchemistry,chemical engineering, processsystem engineering,industrial engineering (supplychainissues)andindustrialeconomyandmanagerstaff. Theyalsoshouldnothaveparticipatedinthedesignphasetogive animpartialopinionandbringnewideasifnecessary,andthey shouldbekeptanonymous.TheuseofESSweb-supportedICTtools toeditthepollsandcollecttheanswerscanallowtheexpertsin differentlocationtofillthequestionnairewheneverandwherever theylike,alsosavingtimeandmoney.

Aquestionnaireforchemicalproductdesignisavailableinthe appendixofHeintz[74]andcontainsfourdistinctsetsofquestions, abouttheperformanceofthealternatives(relevanceofproperty choices, of property weighting, of target values, of property estimationmethods,etc.),abouttheproductstructure(synthesis feasibilityofeachcomponentofthemixture,ofthemixtureasa whole, mixture composition, relevance of molecule structure choices,offragmentsbuildingblocksnumberandtype,etc.),about the search algorithm (relevance of the algorithm parameter choices, etc.) and about general issues (overall appreciation of thenumberofalternativestocompare,selectionofthefivebest alternatives, specificrejectioncriteriaand justificationforsome alternatives).Ifexpertsarenotabletoanswerquestionstheycan leavea‘‘noopinion’’answer.

Fig.2 showsthat thechoicephaseenables tostart overthe intelligence phase. Four causes were imagined: 1. There is no acceptablealternative.2. Potentiallyinterestingalternativesare not credible, as a result of inappropriate requirements on molecular structure, property estimation models or operating conditions.3.Thebestalternativehasamediumperformance.In thiscase,abettertuningoftheweightingofthepropertytargetsin theglobalobjectivefunctionmustbeencouragedifitstillcomplies with the customer needs priority list. 4. The best predicted alternative is deemed unsuitable for laboratory test, being chemicallynon-feasible,ortoocostlywiththeexistingsynthesis techniques,ortoocostlybecauseofthehighcostofrawmaterials availableatthetimeofthesearch.

Forchoosingthebestalternative,theexpertshaveaccesstothe intelligencephaserequirementstree,therelateddocumentation, and tothedesignphase outputs.Theselatterarethecandidate moleculesormixturesandrelatedpropertyvaluesandallthe tool-related choices (property estimation models,chemical building blockpools,etc.).

Finally, considering that the design phase relies mostly on computerpredictionmethodswhichaccuracymaynotbeoptimal, weimplementatwostageDELPHIprocedureinspiredbythe post-mortem phase of Howardmethod [75](Fig. 2). The first stage selectsthebestpredictedalternative.Thecorrespondingproductis thensynthesizedandformulatedinlaboratory,including experi-mentalpropertymeasurements.Inasecondstage,the experimen-taldatathenreplacethepropertyestimationintheperformance calculationandtheexpertsdecidewhetherthefinalalternativeis stillworthy.Ifnot,anotheralternativeischosenfortesting. 4.3. AnoriginalCAPDsolutionforthedesignphase

Our so-called IBSS CAPD distributed computing tool was developed for findingsustainableproducts. It allowsrunninga multiobjective simultaneous search over theoptimization vari-ableslikethemixturemolecules,themixturecompositionandthe mixtureoperatingconditions.Besidesitcanhandlealargevariety ofpropertyestimationmethods,includingmixtureproperties,and it is able to bias the search toward molecules issued from renewablematerialstocks.TheIBM-RUP(rationalunifiedprocess)

software development method was applied [76]. This iterative processiscenteredonthesoftwarearchitectureandisdrivenby thefunctionalneeds.Inourcase,theyweredefinedthankstothe interviewresultsofthepartnersin theFrenchANRCP2D2009 projectInBioSynSolvaimingatdesigningnewbiosolvents.These partnerscovered theenterprise layers:chemist, chemical engi-neer,productbusinessunit,corporate.

We provide below the core model from the architectural, functional,behavioral and structuralviews intheUML concept understanding[68].AcomplementarydescriptionoftheIBSStool focused on the mixture building and evaluation is published elsewhere[32].

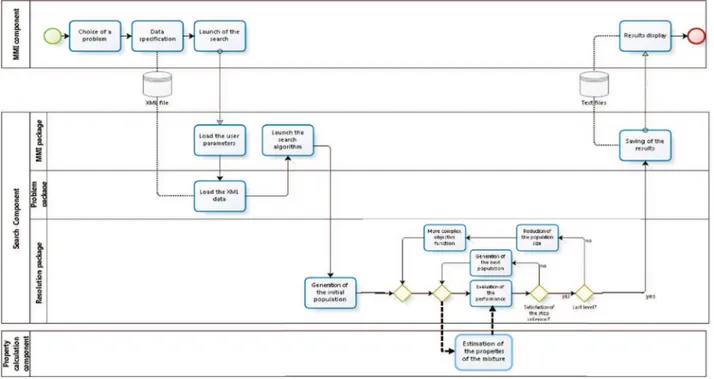

4.3.1. Architecturalview

The CAPD tool architecture is built around three software components, MMI in front office, Searchand P3 in backoffice, whichcan beusedindependently.TogethertheyformtheIBSS application.TheMan-MachineInterface(MMI)isdevelopedinjava forallowingadistributedmulti-platformdeploymentoftheIBSS client. TheSearch component is writtenin C#. Itmanages the search algorithm by generating mixture candidates and by modifyingthemtoinvestigatethesolutionspace.Theevaluation oftheperformance withrespecttothetargetvalues setin the objectivefunctionofallthecandidatesolutionsisdonebyusing the property values returned by the P3 components. The P3 (PropertyPredictionPackage)calculationcomponentisaVB.NET Dynamic-LinkLibrary.Thelistofpropertycalculationmodelscan beupdatedindependentlyoftheothercomponents.

4.3.2. Functionalview

UMLusecaseshavebeenrantodefinefourfunctionalities[74]. Theyare:(i)launchasearch,(ii)defineanXMLproblemfile,(iii) definepropertiesandmodelsusedtoevaluatetheperformanceof the molecule or mixture, (iv) evaluate the properties and performanceofasetofmixtures.

Fortheusecase (ii),assumingthat therequirementstreeis completeandexhaustive,thefacilitatordefinestheXMLproblem file after adding the tool specific parameters, namely search algorithmparameters forIBSS. TheXML fileistheinputof the CAPDtoolandcontainsthreetypesofdata.(i)Themixturedata enabletocustomizethemixturecompositionand structure,by definingthepossiblefixedpartsandthedegreesoffreedomofthe differentvariablepartsandthebuildingblocks.(ii)Theobjective functiondatarefertothepropertiestoevaluate,theirtargetvalues, thepropertyestimationmodelsandtheoperatingconditionsused tocalculatetheseproperties.(iii)Thesearchalgorithmparameters are all the data that can directly influence the speed and the effectivenessofthesearch,namelythepopulation sizeand the elitismpolicy.TheotherfunctionalitiesaredetailedinHeintz[74]. Aspartoftheobjectivefunctiondata,Fig.5showstheUMLClass diagramfortheOCLdescriptionofthecalculablepropertytarget values.Itshowsthatforeachcalculablepropertyonemustchoosea relativeweightinthemultiobjectiveperformancefunction,atarget value,apropertyestimationmodelandpossibleprocessoperating conditions (temperature, pressure, etc.), a performance function describing the evolution of performance with the difference betweenpredictedandtargetvalue,andeventuallysomeparameter valueusefulforthepropertycalculationmodel(ex.thereference valuesofascale-basedrealpropertymodel).

Aspartofthemixturedata,Fig.6showsthemixtureframework enablingtocustomizethesearch.Moleculescanbefixedorfree withinamixture.Fora freemolecule,itispossibletofixornot some fragment which can be constructed from preselected chemicalbuildingblocks.

Fortheusecases(ii)and(iii),theMMIcomponentimplementsa dualloginaccess,forbasicandexpertuser,withdifferentpanel

views.ThedualloginisaimedtocompletemissingXMLdatain casethetreeofrequirementissuedfromtheintelligencephasehas not been refined enough. An expert user can access all functionalities and refine all data whereas a basic user has a limited access. In accordance with our chemical enterprise organizationalstructure(Figs.1and 3),a basicuseris typically acorporatemanager ora businessprocessstakeholder. Abasic usercanproposethenumberofelementsinthemixture,fixsome ofthemixturecompoundsorleavethemfreeforthesearch,select predefinedsourceofbuildingblocks (sugar-based,vegetable-oil based, glycerol derivative based, etc.), define so-called real properties guidelines. The expert user, a chemist or chemical engineerinourorganization,cancustomizethelistsofbuilding blocks, set the molecule structure and fragment data, select calculablepropertiesandtheirestimationmodels,defineproperty targetvalues,definenewsetsofrealproperty,assignthesearch algorithmdata.

Availabletobasicuserafterhavingbeendefinedbyanexpert user, real properties are distinguished from the calculable propertiesdescribedinFig.5classdiagram.Theyarenotlinked topropertyestimationmodelsandaredescribedonascale-based degree:fromlowtohigh.Foreachrealproperty,oneorseveral calculableproperties arepredefined[32].For example,thereal property ‘EHS impact’ is evaluated by computing the ‘acute toxicity’+‘flashpoint’+‘vaporpressure’+‘biodegradability’ prop-erties. Setting a real property degree triggers default values constraintsintheassociatedcalculableproperties.

4.3.3. Behavioralview

Thebehavioralviewpresentsthedifferentprocessesofthetool andisshowninFig.7.

Fig.7highlightsthethreecomponentsandtheir interoperabili-ty. The interoperability between the MMI and the search componentsisasynchronousviaXML andtextfiles.Eventually, the facilitator can directly generate the XML file from the requirements tree data issued from the intelligence phase, completedwithIBSSspecificsearchparameterasrecalledbefore. The interoperabilitybetween thesearchand theP3 calculation componentsissynchronousandwindowslibrarylike.

A multipurpose data structure for describing molecules, fragments,basicandcomplexbuildingblockshasbeendeveloped [32], inspired by earlier works on molecular graph [77,78]. It enablestodescribemolecules,structures,fragments,connections andchemicalbuildingblocksintheXMLinputfileofthesearch component,toprintthemoleculestructureinformationinthetext outputresultfile.Italsoenablestoperformefficientlymolecule structure modifications within the search component, while accounting for the predefined customization of the mixture structure by the user when setting the problem in the MMI component or directly by the facilitator. It is also used to communicate the relevant molecule information between the SearchandP3componentssoastocomputeproperties.

Fig.7showsthatthereexistthreepackageswithinthesearch component.TheMMIandproblempackageshandlethe interop-erabilitywiththeMMIcomponentandassigntheXMLinputfile

Fig.5.ClassdiagramusedfortheOCLdescriptionoftheconstraintsontheproperties.

informationintothedatastructureoftheresolutionpackage.The resolution packagerunsthemultiobjectivegeneticalgorithmto findcandidatemixtures.Threeactivitiesareperformed,firstthe initialpopulation isgenerated, secondtheperformanceof each mixture ofthepopulation is evaluated,thirddependingon the search endingcriteria, a newpopulationis generated,by using modificationoperatorsuponthemixturecomposition,themixture operatingconditionsorthemixturemolecules.

Theprinciplesofthemoleculemodificationgeneticoperators aresketchedinFig.8.Inspiredbyliteratureworks[79,80],they were improved with branch insertion and substitution, and completedwithtworoutines.Oneroutineisdedicatedtomaintain thecyclicstructuresvs.non-cycliconesasmodificationmayoften

breakcycle.Theotherroutineismadetoaccountforthepossible fragmentstructureofthemolecules[32].

Inordertobenefitfromtheuseofmoreaccuratebutoftenmore computerdemanding,propertypredictionmethods,thesearchcan berunoveramulti-levelsequence(seetheactivityinFig.7search component).Thepopulationsizeisreducedasthelevelnumber increases[18,26,78].Thisway,thecomputationaltimeforsolving complexmodelsisnotwastedonpoorcandidates.

4.3.4. Structuralview

Thestructural viewpresents themodeling abstractions(the classes and the relationships that exist between them). The property related attributes (Fig. 5) and the mixture-molecule

Fig.7.BPMNdiagramofthethreeIBSScomponentsbehavior.

granularattributes(Fig.6)aretranslatedintotheclassdiagram thatenabledtostructuretheapplicationcodealongwithBPMN activitydiagramswithintheRUPmethodology.Afulldescriptionis availableinHeintz[74].

5. Casestudy:designofanovelinkblanketWASH

Anexampletakenfromliterature[81]isrevisitedandusedto illustrateourframework.

5.1. Sustainabilitycontextandstimulusforblanketwashproduct design

Theremovalofinkresidueanddriedinkfromrubberblankets in theUS lithographicprinting process sector is done with 40 ‘‘blanket wash’’ formulations, 21 of which contain petroleum distillates[81].Inourcase,weconsiderthecaseofablanketwash supplierwillingtoexpanditsportfoliowithgreenerproducts.The processstimulusisthefollowing:pushedbyregulationevolutions, andwishingtoobtaintheISO14001standardcertificationabout designingandimplementinganeffectiveenvironmental manage-ment system, one of theclient requestsa greenersolvent and claimsforadecisionhavetobemade.

A new factis created in thebusiness rulerepository ofthe enterprise following the SBVR standard where red terms are keyword terms for modality, the underlined terms designate standardandspecificobjects,anditalictermsdesignatefactsand verbs:

Inaddition,welistotherfactsandbusinessrulesexistinginthe enterpriserepository:

Fact2describesacustomerneed.BusinessRule1showsthatthe commercial policy of the enterprise is to satisfy thecustomer needs.BusinessRule2ensuresthatsubstitutingproductsachieve the same key functionality (here cleaning ink). BusinessRule3

translatesaspecificpolicyinfavoroflocalsuppliers.BusinessRule4 and BusinessRule5 refer to security and performance require-ments.

The conjunctionof Fact1 and Fact2 violates BusinessRule1. The other BusinessRules are not violated but are cited for considerationsincetheymaybecomeviolatedbythe substitu-tionproduct.

5.2. Blanketwashintelligencephase

Inducedbythebusinessruleviolation,theintelligencephase aimingatdefiningtherequirementstreeisinitiatedbytheproject manager, who takes the role of facilitator. The whole process detailsarefoundinHeintz[74]andanoverviewofthesequential constructionoftherequirementstreeoverthefourorganizational levelsisdisplayedinFigs.9and10.AstheESSBlueKiwiplatform supportingthisphaseisstillunderdevelopment,theprocedureis run here with the help of a facilitator person only and the documents keeping all the construction details are produced manually.

At the strategic level, the project manager translates the enterprisebusinessrules1–5intostrategiclocalbusinessrule1,2, 3,5and6expressedinSVBR(Fig.9).Localbusinessrulesreferto temporaryrules thatapplyonlytothecurrentdecision making process.Asthisistheinitialstageofthedecisionprocess,allrules are assigned a yellow color, meaning a ‘‘consider in priority’’ interest.

TheenterpriseBusinessRule1becomes:

AnewStrategicLocalRule4aboutproductioncostsobjectivesis insertedbythemanager.

A cost increase may be acceptable by the client at the printing facility since using greener product will help him gettingtheISO14001certification,whichmayhelpfindingnew clients:

• Fact1:

Cust

omer C1

wan

ts

a

repl

aceme

nt product

that

is

greener than

prod

uct Blan

ket

Wash

.

• Fact2

:

Each

th

ing

that

is

wan

ted

by a

customer

is

a

custo

mer need

of

that

cust

omer

.

• BusinessRu

le1:

It is o

blig

ato

ry t

hat e

ach

custo

mer need

of

each

custo

mer

satis

is

fied

.

• BusinessRu

le2:

It is ob

ligat

ory that

each

functi

onal

ity

that

is

perfo

rmed

by

a

product

is

perfo

rme

d by

each

repla

cemen

t product

of

that

product

.

• BusinessRu

le3:

It is

ob

ligat

ory that

each

ppli er

su

is loca

ted

at

less than

30

0 ki

lomete

rs

from

the

site

su

pplied

by

this

suppli

er.

• BusinessRu

le4:

It is o

blig

ato

ry t

hat e

ach

product

respects

th

e

security rules

.

• BusinessRu

le5:

It is

proh

ibited that

a

product

prevent

s

a

process

functi

to

on

.

• Strat

egicLocalRule1:

A

repla

cemen

t product

of

product Blanket

Wash

that

is

greener than

product

Blanket

Wash

must

be f

oun

d

.

• Strat

egicLocalRule4:

The

producti

on cost

of

the

rep

lacemen

t product

of

product Blanket

Wash

At thetacticallevel, thebusiness processexpert refinesthe StrategicLocalRule1intoTacticalLocalRule1thatorientsthesearch toward water-based solvents, which bears someadvantages in termsofusabilityandhandling.

Bytakingintoconsiderationssupplychainissues,healsorefines the StrategicLocalRules3 and 4 in TacticalLocalRule2 defining a supplierlistandTacticalLocalRule3definingtheproductionsite.The intereststatuscoloringofeachruleisalsoeventuallychanged:some strategiclevelrulesarekeptinyellowpriorityinterest;newrules arisealsoinyellowstate.StrategicLocalRule3aboutsupplierrangeis giventhegraycolor‘‘ignore’’statussincethenewTacticalLocalRule2 fullysubstitutesit.Ontheotherhand,theStrategicLocalRule4about amaximum10%costincreaseiskeptinthewhitecolor‘‘consideras well’’ statussincethe newTacticalLocalRule2 and TacticalLocal-Rule3donotfullycoveritsmeaning.

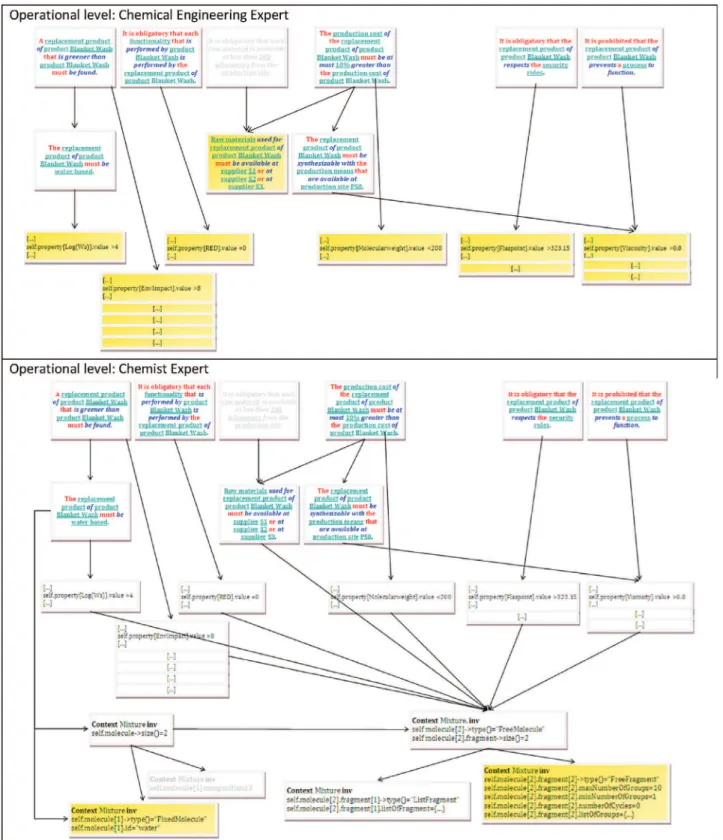

Attheoperationallevel,allyellowandwhitestatusbusiness rules are translated into property target values constraints expressedinOCL(Fig.10).

The chemicalengineering expertis qualified tosetproperty target values.For example,theTacticalLocalRule1about water-based solvent is refined into an OCL constraint on the water solubilitymodellimitvalue(Log(Ws)<4)forallcompoundsofthe replacementproduct:

ContextPropertyListinv self.property[logWS].weight=4 self.property[logWS].value<4 self.property[logWS].unit=’’n/a’’ self.property[logWS].parameter.value=’’n/a’’ self.property[logWS].performanceFunction->type()=’’ Gaussian’’ self.property[logWS].performanceFunction.tol=1 self.property[logWS].performanceFunction.val=0.8

Using Costa’stypologyofproperties[4]we identifyproduct, process-relatedand usage-relatedpropertiesthat areconcerned

byconstraints.Productpropertiesaretheabilitytodissolvethe ink,whichisevaluatedbycomputingsolubilityparametersunder aso-calledREDfunction;themolecularweightMWandthewater solubilitylog(Ws).Process-relatedpropertiesconcerntheprinting

processastheproductisincontactwithaspinningrubberblanket surface,settingspecificvaluesfortheviscosity,thesurfacetension and the density. The other properties are usage-related ones: propertieslikeVOCsareamajorconcerninprintingindustryand areevaluatedbycomputingthevaporpressure.EHSpropertiesare evaluatedusingtheEnvironmentalWaste,EnvironmentalImpact, Health,SafetyandLCAindices[88].Theflashpointisconstrained tosetflammabilitylimits.Molecularweightislimitedtoensure liquidphaseoforganicmolecule.

Comparing both the chemical engineer and the chemist decision refining process, we observe that thesupplier related TacticalLocalRule2isnotrelevantforthechemicalengineerbutit isforthechemistsforselectingsuitablemoleculefragmentlists. Thechemistexpertalsoaddsconstraintsonthemixture.Fig.10 showsthatmolecule[1]ofthebinarymixtureisfixedanditthe water molecule,whereas molecule [2] is a free moleculeto be designed.Atfirstaconstraintonmixturecompositionissuggested (morethan 3/10shouldbewater),but as hisgray colorstatus shows,itisignoredduringthedesignphasebecauseoftheability oftheCAPDtooltooptimizeatthesametimemolecularstructures andmixturecompositions.Thus,allthepropertyconstraintssetby thechemical engineer apply tomolecule [2]. The molecule [2] structure is constructed from preselected chemical building blocks.Thosearedecidedin accordancewiththe TacticalLocal-Rule2 listing the suppliers. In our case, the list of fragments selectedistakenfromrenewablerawmaterialspools:vegetable oils,glycerolderivativeandcellulosicderivative.Then,thelistof building blocks is selected among usual chemical functions. It excludeswell-knownpollutingchemicalfunctions:halogenslike chloride,fluorideandaromaticslikebenzenederivative.

Fig.9.Strategicandtacticallevelconstructionoftherequirementstreeforinkblanket-washproduct.

Thewholerequirementstreeprocessconstructionleadstothe definitionof28requirements(Figs.9and10).

5.3. Blanketwashdesignphase

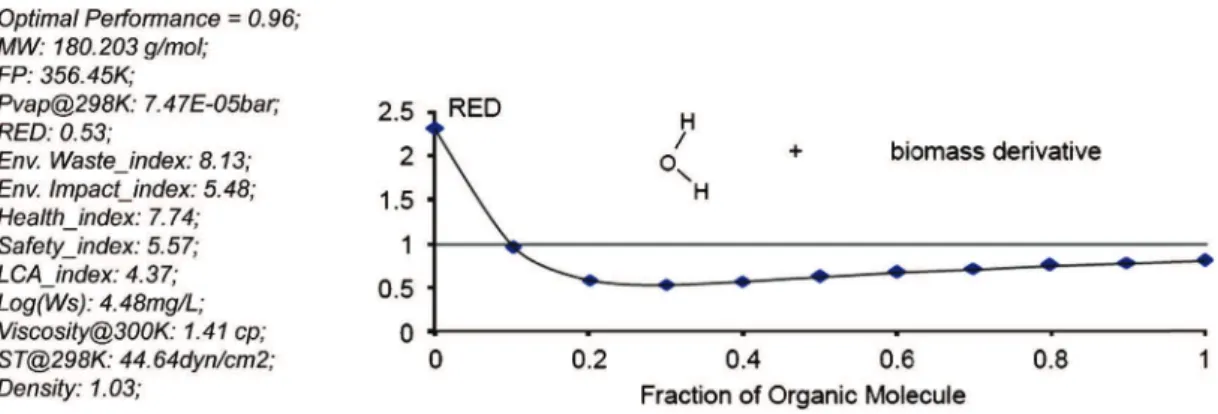

Extracted fromthe requirementstree, the13 property target valueshavebeenset and havetobematched bythe candidate mixturewater–organicsolvent.Theyallcorrespondtocalculable propertieswithspecificpropertyestimationmethods.Detailsabout thepropertyestimationmodelchoicesaregiveninHeintzetal.[82].

Toolspecificparametersareaddedbythefacilitatorbasedon preliminarytests[74].Therelevantinformationiswritteninthe XML fileby thefacilitatorloggedas expertuser.Following the requirements tree, he defines a two componentmixture to be searched.Waterisimposedasthefirstcomponent.Thesecondisa solventwhichcompositionisanoptimizationvariable.Theorganic solvent structure is split into two fragments, one with a core synthontraceable fromthe biomassrenewable material stocks selectedin theIntelligence phase and theotherbuilt fromthe chemicalblocksselectedbythechemist.

Thesearchisranover300generationsandiscompletedinless than 40min.The resultoutputfile displaysa listofa hundred mixturesratedbytheirperformance[82].Analysisoftheresults shows that only 13 different molecules are proposed for the organicsolvent,allincludingbio-sourcedfragments.Furthermore, thebest18mixtures arecomposed ofthesamewater–biomass derivative organic solventwith a variation of the composition. Confidential issues prevent us to display the organic molecule formula.Forthem,theperformancerangesfrom0.94to0.96outof 1.Aunityperformanceisahypotheticalgoalbeingachievedfora nullvalueoftheREDproperty,enablingtoevaluatethecapacityof the mixture todissolve the ink (RED<1).Fig. 11 displaysthe propertyvaluesfortheoptimalsolutionandthevariationofthe REDwiththeorganicsolventcompositionintheaqueousmixture. Itshowsthatthemixturewitha0.3fractionoforganicmolecule showsthebestdissolvingcapacity.

5.4. Blanketwashchoicephase

Consideringthatthe18topalternativescorrespondtothesame binaryaqueousmixture,themixturewiththehighesttheoretical performance, at composition x=0.3 is retained for laboratory validationbytheexperts.Theyalsojudgethatthenumberofgood alternatives is largeenough (45 candidates with a performance higherthan0.9).However,aconsensusisreachedtocarryoutanew designphasebecausethe propertypredictionmodelforthefive indexmethodsusedtopredicttheenvironmental,environmental waste,health,safetyandlifecycleimpactsarenotconsideredtobe accurate enough for the biomass derived solutions. Indeed, a chemicalengineeringexpert recommendsfindingmoreaccurate andversatilepropertyestimationmethods.Hesuggesttosubstitute the health index by a method for evaluating the toxicity, the environmental wasteindexby amethod forevaluatingthe bio-concentration factor, the environmental impact index by a biodegradability factor prediction method together with an increased weighting of the vapor pressure prediction method (vaporpressureisoneoftheVOCevaluationmethod),thesafety indexbyaflashpointpredictionmethod,andtodiscardtheLCA index.Resultsobtainedwiththatnewsetofpropertyestimation methodsarenotdisplayedinthiscontribution.

Thesecondstageofthechoicephaseconsistsindeterminingif, inlightoftheexperimentalresultsfromlaboratory,thealternative testedisstillconsideredsatisfactory,orifanotheralternativefrom thesetshallbetested.Similarlytothefirststage,anotherpossible outcomeistogobacktotheintelligenceandthedesignphasesfor obtaininganewsetofalternatives.

Attheend,themixturedefinedbyitscomposition,molecular structuresandphysicalproperties,isselectedbytheenterprisein ordertoreplacethecurrentchemicalproduct.TheImplementation phasecanstarttheintegrationanalysisofthenewproductwithin theproductionprocess.

A posteriori, we can assess the sustainability degreeof the solutionoversixdimensionsassuggestedbyGagnonetal.[43], withsustainabilityshaderangingfromA(minimal)toD(stateof theart).The‘designprocess’dimensionconsistsincountinghow manytaskswerecoveredamongthe22taskslistedbyGagnonin hisintegratedsustainabledesignprocess.With13tasks,including all tasks listed as critical by Gagnon (see the state of the art section),the‘design-process’dimensionisgraded‘‘B-shade’’.The ‘sustainability issue covered’dimension is graded ‘‘B-shade’’as issues covering partially all three sustainability pillars are considered. The ‘indicator relevance’ dimension should get an excellent‘‘D-shade’’gradesinceasystematicsearchofbio-sourced solventisrun.Butitisdegradedtoapoorgrade‘A-shade’sincethe initialEHSindexmodelswerefoundunsuitable.The‘analysistool accuracy’ dimension is graded a fair ‘C-shade’ because most propertyestimationmodelsbuttheEHSindexmethodsarestateof theartmodels.The‘alternativeperformance’dimensionisgraded ‘C+-shade’becauseanovelaqueous–bio-basedsolventmixture hasbeenfound,dramaticallyreducingtheenvironmentalimpact. The‘decision-making’dimensionisgraded‘C-shade’becauseall sustainabilitypillarsareaddressedandsoinabalancedmanner. Overall with one A, two Bs and three Cs shades, the experts estimate that the product development process is reasonably sustainablebutcanbeimproved.Thusthedecisionistakentorun againtheCAPDtoolbyselectingnewpropertyestimationmethods for the EHS impacts assessment as the ‘indicator relevance’ dimensionisresponsibleforthecurrentworstshade‘‘A’’. 6. Conclusion

We have formalized a three phase decision makingprocess frameworkdedicatedtosustainablechemicalproductdesigninan industrial context where chemical related industries need to complywithnewregulations,likeREACHorseektoexpandtheir portfolioofproductwithalowenvironmentalimpact.Basedon ourproposalofchemicalenterprisemodel,wehavesupportedthe decisionprocesswithinformationandcommunication technolo-gies,distributedsolutionsandstandardmodelingandcomputing languages.Wehavebeencarefultoverticalalignmentbydefining parallel and hierarchical layers of the decision levels, of the enterprise organization,of therequirementsmodelsand of the system itself, the product. We have taken care of horizontal alignment by using consistent semantics for describing the requirementsandaconsistentframeworkfordescribingmolecules andpropertiesintheCAPDtool.Togetherwiththedocumentation gatheredthroughthewholeprocess,ourproposalimproves the sharingofinformationandknowledgeandenablescollaborative workacrossthechemicalenterpriseactorsatthestrategic,tactical and operational levels of decision. Overall we have achieved a ‘‘functionaldistributed’’solution,themediumlevelin interopera-bilityaccordingtotheLISImethod.

Duringtheintelligencephase,amodeldrivensimplified multi-scalemulti-layerapproachinvolvesfourstakeholdersacrossthe enterprisespanningthestrategic,tacticalandoperationaldecision levels. A simplified model of requirements is proposed. Upper enterpriselayerrequirementsatthestrategicandtacticallevels areexpressedthankstolocalrules,inspiredbybusinessrulesand usingSBVRStructuredEnglish.Thelowerlayerrequirementsatthe operationallevelareexpressedasconstraintswrittenwithOCL. Withthehelpofafacilitator,asystemichierarchicalanalysisofthe needs and usages enables the stakeholders to build a tree of requirements for the design phase. Product requirements are refinedfromthegeneralenterpriserulesleveltowardthetechnical constraintslevel,whilethewholeprocessstepsisdocumentedin parallelandavailabletoallpeopleinvolved.

Forthedesignphase,thetreeofrequirementiscompiledand eventuallycompletedbythefacilitatortogeneratetheinputsofa computeraidedproductdesignCAPDtool.OurinnovativeCAPD toolisbuiltwithsufficientflexibilitytocopewithsustainability contextspecificfeatures.Itenablestofindmixturesassolutions andtosourcecandidatemoleculesfromrenewablerawmaterials. Italso handlesamulti-criterion search abletohandlemultiple propertiesthat coverthe threepillars ofsustainability, society, environmentandeconomyalongwithfunctionalproperties.The CAPDtool implementsa genetic algorithm and uses molecular graphs.Aspects of the functional, architectural, behavioral and structural system views have been presented through class diagramsandactivitydiagrams.

Thechoicephaseisdividedintwostages.ItusestheDELPHI method where the experts first choose the most promising alternative for laboratory testing. Then, once the experimental values are available, the experts validate or invalidate the alternativeforimplementation.Finally,theydiscussthesolution relevancyandprovidefeedback,beforelaunchingthe‘‘greener’’ productmanufacturing.

The originalframeworkis illustratedbythesearchofa bio-sourced aqueous–solvent mixture formulation for lithographic blanketwashforwhichtheintelligence,thedesignandthechoice phasearedescribed.Finally,thesustainabilityofthesolutionis assessedbyusingGagnon’ssustainabilityshadesmethod. Acknowledgement

This scientific work was supported by the French national researchagency(InBioSynSolvANR-CP2D-2009-08)inpartnership withSolvay-RhodiaCompany.

References

[1]REACH,2008.DocumentationavailableatECwebsite: http://ec.europa.eu/en-terprise/sectors/chemicals/reach/index_en.htm.

[2]VOC,VOCSolventsEmissionsDirective(Directive1999/13/EC)amendedthrough article13ofthePaintsDirective(Directive2004/42/EC), 2004.

[3]M.Nieddu,E.Garnier,C.Bliard,Theemergenceofdoublygreenchemistry,a narrativeapproach,EuropeanReviewofIndustrialEconomicsandPolicy(2012/1) (2012).

[4]R.Costa,G.D.Moggridge,P.M.Saraiva,Chemicalproductengineering:an emerg-ingparadigmwithinchemicalengineering,AIChEJournal52(2006)1976–1986.

[5]M.Hill,Chemicalproductengineering—thethirdparadigm,Computers& Chemi-calEngineering33(2009)947–953.

[6]G.Hall,J.Howe,Sustainabilityofthechemicalengineeringmanufacturing indus-try-towardsanewparadigm?EducationforChemicalEngineers5(2010)e100– e107.

[7]L.Patil,L.Srinivas,K.Murthy,D.Dutta,R.Sudarsan,Towardanintegrateddecision supportframeworkforsustainabilityanalysis,NISTIR(2013),http://dx.doi.org/ 10.6028/NIST.IR.7909.

[8]P.T.Anastas,J.Warner,GreenChemistryTheoryandPractice,OxfordUniversity Press,Oxford,1998p.135.

[9]P.T.Anastas,J.B.Zimmerman,Designthroughthe12principlesofgreen engi-neering,EnvironmentalScienceTechnology(2003)94–101.

[10]A.Azapagic,S.Perdan,Anintegratedsustainabilitydecision-supportframework. PartI.Problemstructuring,InternationalJournalofSustainableDevelopment& WorldEcology12(2005)98–111.

[11]A.Azapagic,A.Millington,A.Collett,Amethodologyforintegratingsustainability considerationsintoprocessdesign,ChemicalEngineeringResearchandDesign84 (2006)439–452.

[12]H.F.Hung,H.P.Kao,Y.S.Juang,Anintegratedinformationsystemforproduct designplanning,ExpertSystemswithApplications35(1–2)(2008)338–349.

[13]B.Smith,M.G.Ierapepritou,Frameworkforconsumer-integratedoptimalproduct design,IndustrialandEngineeringChemistryResearch48(18)(2009)8566– 8574.

[14]B.V.Smith,M.G.Ierapepritou,Integrativechemicalproductdesignstrategies: reflectingindustrytrendsandchallenges,Computers&ChemicalEngineering34 (2010)857–865.

[15]W.D.Seider,W.Soemantri,J.D.Seader,D.R.Lewin,Perspectivesonchemical productandprocessdesign,Computers&ChemicalEngine33(2009)930– 935.

[16]M.Hill,Productandprocessdesignforstructuredproducts,AIChEJournal50(8) (2004)1656–1661.

[17]R.Gani,E.A.Brignole,Moleculardesignofsolventsforliquidextractionbasedon UNIFAC,FluidPhaseEquilibria13(1983)331–340.

[18]P.M.Harper,R.Gani,P.Kolar,T.Ishikawa,Computer-aidedmoleculardesignwith combinedmolecularmodelingandgroupcontribution,FluidPhaseEquilibria (1999)158–160,337–347.

[19]L.E.K. Achenie, R.Gani,V.Venkatasubramanian, ComputerAided Molecular Design:TheoryandPractice, Elsevier,Asmterdam,Netherlands,2003.

[20]K.G.Joback,R.C.Reid,Estimationofpure-componentpropertiesform group contributions,ChemicalEngineeringCommunications57(1987)233–243.

[21]L.Constantinou,R.Gani,Newgroupcontributionmethodforestimating proper-tiesofpurecompounds,AIChEJournal40(1994)1697–1710.

[22]J.Marrero,R.Gani,Group-contributionbasedestimationofpurecomponent properties,FluidPhaseEquilibria(2001)183–184,183–208.

[23]A.S.Hukkerikar,B.Sarup,A.T.Kate,J.Abildskov,G.Sin,R.Gani, Group-contribu-tion+(GC+) based estimation ofproperties ofpure components:improved property estimation and uncertainty analysis, Fluid Phase Equilibria 321 (2012)25–43.

[24]M. Karelson,V.S. Lobanov,A.R.Katrinsky, Quantum-chemical descriptorsin QSAR/QSPRstudies,ChemicalReviews96(1996)1027–1043.

[25]S.A.Gallenos,Mini-reviewonchemicalsimilarityandpredictionoftoxicity, CurrentComputer-AidedDrugDesign2(2006)105–122.

[26]M.Korichi,V.Gerbaud,P.Floquet,A.-H.Meniai,S.Nacef,X.Joulia,Computeraided aromadesign.II.Quantitativestructure–odourrelationship,Chemical Engineer-ingandProcessing:ProcessIntensification47(2008)1912–1925.

[27]R.Gani,Chemicalproductdesign:challengesandopportunities,Computersand ChemicalEngineering28(2004)2441–2457.

[28]E.Conte,R.Gani,K.M.Ng,Designofformulatedproducts:asystematic method-ology,AIChEJournal57(2011)2431–2449.

[29]A.I.Papadopoulos,M.Stijepovic,P.Linke,P.Seferlis,S.Voutetakis,Molecular designofworkingfluidmixturesfororganicrankinecycles,ComputerAided ChemicalEngineering32(2013)289–294.

[30]M.Mattei,M.Hill,G.M.Kontogeorgis,R.Gani,Designofanemulsion-based personaldetergentthroughamodel-basedchemicalproductdesign methodolo-gy,ComputerAidedChemicalEngineering32(2013)817–822.

[31]A.T.Karunanithi,L.E.K.Achenie,R.Gani,Anewdecomposition-based computer-aidedmolecular/mixturedesignmethodologyforthedesignofoptimalsolvents andsolventmixtures,IndustrialEngineeringChemicalResearch44(2005)4785– 4797.

[32]J.Heintz,V.Gerbaud,J.-PBelaud,ModelsdrivenconceptionofanComputerAided MixtureDesigntool,in:21stEuropeanSymposiumonComputerAidedProcess Engineering,Elsevier,2011,pp.1608–1612.

[33]IEEE,StandardGlossaryofSoftwareEngineeringTerminology,IEEEStd610, 12-1990, 1990.

[34]K.E.Wiegers,SoftwareRequirements, O’ReillyMedia,Inc.,2009.

[35]R.G.Ross,PrinciplesoftheBusinessRuleApproach, 1sted., AddisonWesley, Boston,USA,2003.

[36]OMG,SemanticsofBusinessVocabularyandBusinessRules(SBVR),v1.0,OMG, Needham, MA, 2008, Available at: http://www.omg.org/spec/SBVR/1.0/PDF/

(WWWDocument).

[37]OMG,ObjectConstraintLanguageOMGAvailableSpecificationVersion2.0,OMG, Needham, MA, 2006, Availableat:http://www.omg.org/spec/OCL/2.3.1/PDF/

(WWWDocument).

[38]K.U.Klatt,W.Marquardt,Perspectivesforprocesssystemengineering.Personal viewsfromacademiaandindustry,Computer&ChemicalEngineering33(2009) 536–550.

[39]K.M.Ng,R.Gani,K.Dam-Johansen,ChemicalProductDesign, Elsevier, Asmter-dam,Netherlands,2007.

[40]W.Marquardt,M.Nagl,Workflowandinformationcenteredsupportofdesign processes.TheIMPROVE perspective,Computer&ChemicalEngineering29 (2004)65–82.

[41]V.A.Varma,G.V.Reklaitis,G.E.Blau,J.F.Pekny,Enterprise-widemodeling& optimization—anoverviewofemergingresearchchallengesandopportunities, Computer&ChemicalEngineering31(2007)692–711.

[42]B.V.Smith,M.G.Ierapepritou,Modelingandoptimizationofproductdesignand portfoliomanagementinterface,Computers&ChemicalEngine35(2011)2579– 2589.