HAL Id: dumas-00523687

https://dumas.ccsd.cnrs.fr/dumas-00523687

Submitted on 6 Oct 2010

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

écoulements gazeux de chambre de combustion de

moteur diesel

Jean-Michel Berals

To cite this version:

Jean-Michel Berals. Validation CFD axisymétrique de modèle zonal des écoulements gazeux de

cham-bre de combustion de moteur diesel. Mécanique des structures [physics.class-ph]. 2010.

�dumas-00523687�

Annexes

Annexe A:

Variables d’entrée du programme Zonal Gas Flow

A-1

Annexe B:

Génération du maillage dans Star-CD

B-1

Annexe C:

Commandes Prostar - Mobilité du maillage

C-1

Annexe D:

Résultats pour les modèles en cycle fermé.

D-1

Partie 1:

Modèle Omega – Maillage fin.

D-2

Partie 2:

Modèle Bloc cylindrique – Maillage fin.

D-11

Partie 3:

Modèle Omega – Maillage large.

D-20

Partie 4:

Modèle Bloc cylindrique – Maillage large.

D-27

Annexe E:

Traitement des couches limites

E-1

Partie 5:

Modèle Omega – Conditions limites de parois avec maillage fin.

E-2

Partie 6:

Modèle Bloc cylindrique - Conditions limites de parois avec maillage fin.

E-4

Partie 7:

Modèle Omega – Conditions limites de parois avec maillage à faible résolution.

E-6

Partie 8:

Modèle Bloc cylindrique - Conditions limites de parois avec maillage à faible résolution.

E-8

Partie 9:

Modèle Bloc cylindrique - Traitement des conditions limites de parois avec malillage à

faible résolution.

E-10

Annexe F:

Modèles avec admission.

F-1

Partie 10:

Comparaisons des profils de vitesses d’admission.

F-2

Partie 11:

Sensibilité de la position de l’ admission.

F-8

Partie 12:

Sensibilité de la résolution du maillage sur les conditions d’admission – Modèles Bloc

cylindriques

F-12

Partie 13:

Conditions d’admission avec les maillages à faible résolution.

F-15

Partie 15:

Modèle Bloc cylindrique avec traitement du maillage près des parois

F-18

Annexe G:

Simulations pour validation.

G-1

Partie 14:

Données de validation CFD en fonction de la position angulaire.

G-2

Partie 16:

Simulation des paramètres thermiques du gaz aux parois.

G-10

Annexe A:

Variables d’entrée du programme Zonal Gas Flow

*Control

########## Dimensions ##########

*Number of grids polar axi

#Number of grids - followed by polar and/or axi to indicate coordinate system

#X, Y, Z

6, 1, 3

*LEN

#grid length (total length)

#Length X, Length Y, Length Z (in meters)

#Z must be stroke + bowl depth + clearance, it's the whole domain!

43e-3, 10e-3, 99.54e-3

*Bowl

#Piston Bowl

#Bowl radius, Bowl Depth (meters), Number of grids in bowl

20e-3, 12.8e-3, 3

*Clearance

#Piston/ Head clearance at TDC

#Piston clearance in meters

0.00074

########## Blockage ##########

*BLOCK

#indicates which grids are blocked and their size

#Bowl radius, ?, Bowl Depth <var: TMP, TMP2, TMP3>

0.020, , 0.005

########## Properties ##########

*RHO

#Gas density in kg/m**3

1.177

*SPEHEA

#Gas specific heat capacity in J/kgK

1.0049e3

*GAMMA

#Diffusion Conductance (viscosity?) in kg/ms

1.846e-5

*UUX

#Initial flow field (m/s)

0, 1047.2, 0

*PHIW (m/s)

1e-12

*PHIE

1e-12

*PHIS

45

*PHIN

45

*PHIB

1e-12

*PHIT

1e-12

#Gas Transport Properties

#*FLUW

#*FLUE

#*FLUS

#*FLUN

#*FLUB

#*FLUT

#Gas flux Properties

########## Source ##########

#*Source

#Gas source terms? <var: TMP, SOURCE>

########## Moving Mesh ##########

*VELPIS

#Piston Velocity in m/s

# shouldn't be necessary anymore, piston velocity

# is now sinusoidal, but I've left it in just in case!

9.66

########## Transient ##########

*Transient no step

#turns on transient run

# can also add "no step" to keyword

#Time step (secs), Total Time (secs)

#Initial conditions for: X, Y, Z at time=0

0.00001, 0.00756

# this seems to be good enough for the compression stroke :)

0.0, 0.0, 0.0

########## Control Parameters ##########

*Cycles

1

*Residuals

#sets the tolerance level for residuals

5.0

#*Wall slip

#turns off wall friction when present

*Cyclic

#turns on cyclic boundary conditions when present

#*Pipe

#turns on pipe flow when present

#can add "dp" to the keyword to perform pressure drop calculations

#*Diffusion

#turnson Diffusion only (implies no wall friction)

#turns on printout in output file

# can add "debug" to keyword for more detail

# useful for results from intermediate steps

#print timestep

# this is the timestep (in secs) between printing out

# velocity information. it's currently set to print

# every 10deg C.A.

42e-5

*End data

*End of file

Annexe B:

Génération du maillage dans Star-CD

•

Mesh file:

! Axi-symmetrical model with Omega bowl shape

!

! Written by J M Berals

!

! 18-2-99

TITLE

Omega bowl - fine model (PUMA) with intake flows

! cylindrical co-ordinate system

csys 2

! Produce main cylinder

ctable 10 FLUID 2 0 1 1 0 AIR1

ctype 10

vc3d 0 0.043 43 0 9 1 0 0.08674 80

! Produce bowl

ctable 12 FLUID 4 0 1 1 0 AIR2

ctype 12

vc3d 0 0.020 20 0 9 1 0.0 -0.0056 5

!produce the interface

v 8001 0.02 0 -0.0056

loca 11 cyli 0.016 0 -0.010337 0 90 0

vgen 13 1 8001 8001 1 0 -15 0 1.0

csys 2

v 8014 0.017 0 -0.0056

v 8015 0.01 0 -0.0056

v 8016 0.0135 0 -0.0118

v 8017 0.018 0 -0.0118

v 8036 0.0021735 0 -0.0056

ctable 16 SHELL 8 0 1 1 0 AIR4

ctype 16

spl 1 vran 8001 8007 1

spls all

spl 2 vran 8007 8013 1

spls all

patc 8013 8016 8017 8007 5 6

patc 8014 8015 8016 8017 6 6

patc 8015 8036 8013 8016 5 6

cset all

cplo

!extrusion

csys 2

ctable 18 FLUID 10 0 1 1 0 AIR5

ctyp 18

vcex 1 1000 cset 3641 3766 local 0.0 9 0.0

!delete shell type cells

cset news shel

cplo

cdel cset

vmer all,,1.0e-8

c

cset none

view 0 -1 0$angl 0$dist 0.013

cent 0.012 0.003 -0.008

! Flip second set of cells to RHS

cset news cran 3441 3540

cset add cran 3727 3792

cflip cset,,righ

! Plot

cset all

plty ehid

cplot

vwrite,,0,all,code,

! choose the boundary conditions

! 1. Cyclic symmetry - identify the two faces in

! the axial-radial plane. one face in set 1 and the other in set2.

! execute the selection step by step

view,-0.0152226,-1,0.379313$angl,5.08036$axis,y$dist,0.0846782

cent,0.0279737,-0.0100088,0.0477568$pltb,on$replot$pltb,off

rdef,1,cyclic,standard

2,all,regular,inte

rdef,2,cyclic,standard

2,all,regular,inte

temp on

pmat,1,fluid

initialize stan 0 0 0 2 0 83046 keps 0 0

dens ideal

turb,ke,0.016

time,tran

wdat,rest,10

! define the boundary conditions for the intake flow

! 3. wall boundaries - identify the faces at the top of the chamber

local,15,cyli,0,0,0,4.5,0,0

csys 15

rinlet,mass_flow,mixl

rdef,3,inlet,standard

79,47,-53,15,0,0.02582,0.1,293,1.205,n

csys 2

Annexe C:

Commandes Prostar - Mobilité du maillage

•

Event file:

!Axi-symmetrical model with omega bowl shape

!chamber3 model

time,tran

mvgr on event

evfi init

*set rpm 4000

evpa piston rpm 0.043 0.155 0.086 expa 0.086

evpa degre rpm 0

*define noexec

evst i time ib

eddir local 2 3

vset news vran v1 v2

cset news vset all

cset subs flui

edcell add cran cset

evsa i

*end

*set i 1 1

*set ib -100 1

*set v1 1 88

*set v2 176 88

*loop 1 78

*define noexec

evst i degree ia

vset news vran va1 va2

cset news vset all

cset subs flui

eacell add cran cset

evsa i

*end

*set i 80 1

*set ia 0 2.278481

*set va1 6953 -88

*set va2 7128 -88

*loop 1 78

*define noexec

evst i degree id

eddir local 2 3

vset news vran v1 v2

cset news vset all

cset subs flui

edcell add cran cset

evsa i

*end

*set i 160 1

*set id 180 2.278481

*set v1 1 88

*set v2 176 88

*loop 1 78

*define noexec

evst i degree ie

vset news vran ve1 ve2

cset news vset all

cset subs flui

eacell add cran cset

evsa i

*end

*set i 240 1

*set ie 360 2.278481

*set ve1 6953 -88

*set ve2 7128 -88

*loop 1 78

! time 0 event, activate change grid commands

getf 13

movegrid_name

evst 400 time 0

egri read 13

evsa 400

! transient stuff

trfile,initialize,26,10

algo,piso,node,50,0.25,0.8

! step 1: 180-397 degrees

lstep,1,651,cons,60 / rpm / 1080,N,0,3

cpost, Y,Y,Y,Y,Y,Y,Y,Y,Y,N,Y

powall Y N Y

lssave,1

! step 2: 397-570 degrees

lstep,2,519,cons,60 / rpm / 1080,N,0,3

cpost, Y,Y,Y,Y,Y,Y,Y,Y,Y,N,Y

powall Y N Y

rdef 3 wall

nosl

0 0 0

adia

lssave,2

! Only use this command for mesh preview

! rconstant, 4, 1.

! commands to create the subroutine under ufile dir.

!prfi,3422,3426,1,user,n

!system

!ufiles

!usub,save $!POSDAT

geom 8 1.0

pres 1e5 3792

moni 3792

prch,off,off,off

iter 9999

lsra 1 2

prob 10

•

movgrid_name file:

getf 31 code

movegrid_command

rewi 31

ifil 31

close 31

•

movgrid_command file:

!Axi-symmetrical model with omega bowl shape

!inlet16 model

getf 28 post

omega28

evfi conn

! The next lines (below) are necessary in order for Star to

! know which cells are active and non-active

EVFLAG PREP OFF GRID UPARM NEWXYZ

EVLOAD UPTO EVENT EVEX

! put all the vertices in a known position

getf 15

vert_time0

vrea 15 0

! count the number of layers we have in the piston

cset news active

cset subs type 10

*get nlay ncset

*set nlay nlay / 43

*set dist 0.08674

*set dist dist - ypst

*set spac dist / nlay

vset news vran 7041 7128

csys 2

vgen 80 -88 vset,,,0,0,0 - spac

cset news deact

vset news cset

vmod vset f f ypst + spac

vset news vran 43 88

vmod vset f f ypst

! bowl

cset news type 12 18 6

vset news cset

vgen 2 0 vset,,,0,0,ypst

•

Postdata subroutine:

C********************************************************************

SUBROUTINE POSDAT(KEY,VOL,U,V,W,TE,ED,T,P,VIST,DEN,CP,VISM,CON,

* F,ICLMAP,ICTID,RESOR,VF,FORCB,IRN,PREFM,LEVEL)

C Post-process data

C********************************************************************

C---

C STAR RELEASE 3.050 *

C---

INCLUDE 'comdb.inc'

COMMON/USR001/INTFLG(100)

DIMENSION KEY(-NBMAXU:NCTMXU),VOL(NCTMXU),U(3,-NBMAXU:NCMAXU),

* V(3,-NBMAXU:NCMAXU),W(3,-NBMAXU:NCMAXU),

* TE(-NBMAXU:NCMAXU),ED(-NBMAXU:NCMAXU),T(-NBMAXU:NCTMXU,1+NSCU),

* P(-NBMAXU:NCMAXU),VIST(-NBMAXU:NCMAXU),DEN(-NBMAXU:NCTMXU),

* CP(-NBMAXU:NCTMXU),VISM(-NBMXVU:NCMXVU),CON(-NBMXCU:NCMXCU),

* F(3,-NBMAXU:NCMAXU),ICLMAP(NCTMXU),ICTID(NCTMXU),

* RESOR(59,-100:100),VF(NCDMXU),

* FORCB(3,NWLMX),IRN(NWLMX)

DOUBLE PRECISION P

DIMENSION PREFM(100)

INCLUDE 'usrdat.inc'

C---

C This subroutine is called at the end of each iteration/time step

C and enables the user TO OUTPUT DATA.

C Note: File numbers available to the users are from 81 onwards.

C NOTE 2: LEVEL = 1 BEGINING OF ITERATION/TIME STEP

C LEVEL = 2 END OF ITERATION/TIME STEP

C---

C

C coding: To write values of U-velocity component,

C pressure and temperature at 5 specified points

C to a file at each time step (for plotting).

CC---

DIMENSION MONI(5)

DATA MONI/3422,3423,3424,3425,3426/

CC

CC---- (A) ---

IF(INTFLG(1).EQ.0) THEN

CC FIRST ITERATION, SO OPEN FILES

OPEN(81,FILE='MonitU',FORM='FORMATTED', STATUS='UNKNOWN')

OPEN(82,FILE='MonitV',FORM='FORMATTED', STATUS='UNKNOWN')

OPEN(83,FILE='MonitW',FORM='FORMATTED', STATUS='UNKNOWN')

OPEN(84,FILE='MonitP',FORM='FORMATTED', STATUS='UNKNOWN')

OPEN(85,FILE='MonitT',FORM='FORMATTED', STATUS='UNKNOWN')

INTFLG(1)=1

CC ELSE FILES ALREADY OPEN

ENDIF

WRITE(81,800) ITER,(U(1,MONI(I)),I=1,5)

WRITE(82,800) ITER,(V(1,MONI(I)),I=1,5)

WRITE(83,800) ITER,(W(1,MONI(I)),I=1,5)

WRITE(84,800) ITER,(P(MONI(I)),I=1,5)

WRITE(85,800) ITER,(T(MONI(I),1),I=1,5)

800 FORMAT(I8,1P,5E10.3)

CC

CC---- (B) ---

C IF(ITER.EQ.ITERS+ITSTEP) THEN

C TOTMAS=0.

C AVRCON=0.

C DO 200 IP=1,NCELL

C TOTMAS=TOTMAS+DEN(IP)*VOL(IP)

C AVRCON=AVRCON+T(IP,3)*DEN(IP)*VOL(IP)

C 200 CONTINUE

C AVRCON=AVRCON/TOTMAS

C WRITE(60,600) AVRCON

C 600 FORMAT(///,5X,'MASS AVERAGED CONCENTRATION OF SCALAR 2 =',

C * 1PE10.3)

C ENDIF

CC

C---C

RETURN

END

C

•

Static plot file:

!

! This program file produces a static plot

! The command

! store iter 70

! produces the plot at time-step number 70

! To produce the dipslay, run "prol-xm" and

! resume the model called "omega", then type:

! getf 21

! staticplt

! ifile 21

rdef 1 sympl

rdef 2 sympl

cydel all

! To plot in csys2

psys,2

evfi conn

trlo 29

c

! iter number refers to the crank angle position

store iter 1050

evload upto stored

cset subs active

evex on

getc u w

cset all

pltype qhidden

poption vect

view 0 -1 0

angl 0

edge,on

vescale,1.5,prop

clrm,reverse

cplot

TITLE

Omega bowl - fine model (PUMA) with intake flows

SUBTITLE

Crank angle position = 10° BTDC (SOI)

Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

rplo

getv,none,sv

cset all

pltype ehidden

poption cont

edge,on

plme,off

cplot

rplo

! vector plot of inlet boundary tangential velocities

bset,add,bran,7333,7337,1

cset,news,cran,3422,3426,1

cplot

cdis,on,breg

getc,v,none,

popt,vect

plty,qhid

plme,on

vescale,3,prop

view 0 0 1

angl 0

clrm,reverse

cplot

TITLE

Omega bowl - fine model (PUMA) with intake flows

SUBTITLE

Crank angle position = TDC (IVO)

Inlet boundary: u=79m/s,v=47m/s, w=-53m/s

rplo

•

Static reg file:

! This file print registers into files for various cells & vertices data

! The following names are used:

! -regisp_u: stands for register spatial - print u velocity of cells in the bowl

!

Cell nb: 26,3482,3531,3688,3758,3786

! -regiver_dens: stands for register vertices - print the absolute density for

!

the vertices included in the inlet boundary

!

Vertex nb: 7091 7093 7095 7097

!

File 7 register velocity u

!

file 13 register dendity dens

psys,2

evfi conn omega.evn

trlo,,

c

! postprocessing data in files

! cells:

! print to file regisp_u the u velocity

gres $y

cset,news,clis,26,3482,3531,3688,3758,3786

gload,1,cell,cset,0,0,1

gtrans,omega.pstt,getc,2,1,1,all

u,none,

casename

regisp_u

sdata,7,9,1,1,coded

close 7.grf

! 4 vertices at the inlet boundary:

! print to file regiver_dens the density

gres $y

vset news vran 7091 7097 2

gload,1,vertex,vset,0,0,1

gtrans,,getv,2,1,1,iter,0,651

none,dens,

casename

regiver_dens

sdata,13,7,1,1,coded

close 13.grf

casename

omega

Annexe D:

Résultats pour les modèles en cycle fermé.

Partie 1:

Modèle Omega – Maillage fin.

Partie 2:

Modèle Bloc cylindrique – Maillage fin.

Partie 3:

Modèle Omega – Maillage large.

STAR PROSTAR 3.05 14-MAY-99 VEL. COMP U W M/S TIME = 0.125000E-02 LOCAL MX= 8.454 LOCAL MN= 0.1419 8.454 7.860 7.266 6.673 6.079 5.485 4.891 4.298 3.704 3.110 2.517 1.923 1.329 0.7356 0.1419 X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 150 BTDC (IVC) swirl ratio 2.5 STAR PROSTAR 3.05 14-MAY-99 COMPONENT V M/S TIME = 0.125000E-02 LOCAL MX= 41.72 LOCAL MN= 0. 41.72 38.74 35.76 32.78 29.80 26.82 23.84 20.86 17.88 14.90 11.92 8.941 5.961 2.980 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 150 BTDC (IVC) swirl ratio 2.5

Figure 1.b: Vitesses axiales – radiales à 150° BTDC.

STAR PROSTAR 3.05 14-MAY-99 COMPONENT V M/S TIME = 0.416667E-02 LOCAL MX= 39.09 LOCAL MN= 0. 39.09 36.30 33.51 30.72 27.92 25.13 22.34 19.55 16.75 13.96 11.17 8.377 5.585 2.792 0. X Y Z

Omega bowl - fine model (PUMA)

Crank angle position = 80 BTDC (compression) swirl ratio 2.5 STAR PROSTAR 3.05 14-MAY-99 VEL. COMP U W M/S TIME = 0.416667E-02 LOCAL MX= 21.65 LOCAL MN= 0.2179 21.65 20.12 18.59 17.06 15.52 13.99 12.46 10.93 9.402 7.871 6.341 4.810 3.279 1.749 0.2179 X Y Z

Omega bowl - fine model (PUMA)

Crank angle position = 80 BTDC (compression) swirl ratio 2.5

Figure 1.d: Vitesses axiales – radiales à 80° BTDC (compression).

STAR PROSTAR 3.05 14-MAY-99 COMPONENT V M/S TIME = 0.708334E-02 LOCAL MX= 69.61 LOCAL MN= 0. 69.61 64.64 59.67 54.69 49.72 44.75 39.78 34.80 29.83 24.86 19.89 14.92 9.944 4.972 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

Figure 1.f: Vitesses axiales – radiales à SOI

Figure 1.g: Vitesses de swirl à SOI.

STAR PROSTAR 3.05 14-MAY-99 VEL. COMP U W M/S TIME = 0.708334E-02 LOCAL MX= 69.64 LOCAL MN= 0.3812 69.64 64.70 59.75 54.80 49.85 44.91 39.96 35.01 30.07 25.12 20.17 15.22 10.28 5.329 0.3812 X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

STAR PROSTAR 3.05 14-MAY-99 VEL. COMP U W M/S TIME = 0.750001E-02 LOCAL MX= 34.52 LOCAL MN= 0.6733 34.52 32.10 29.68 27.26 24.85 22.43 20.01 17.59 15.18 12.76 10.34 7.925 5.508 3.091 0.6733 X Y Z

Omega bowl - fine model (PUMA) Crank angle position = TDC swirl ratio 2.5 STAR PROSTAR 3.05 14-MAY-99 COMPONENT V M/S TIME = 0.750001E-02 LOCAL MX= 75.58 LOCAL MN= 0. 75.58 70.18 64.78 59.38 53.98 48.58 43.19 37.79 32.39 26.99 21.59 16.19 10.80 5.398 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = TDC swirl ratio 2.5

Figure 1.h: Vitesses axiales – radiales à TDC.

Figure 1.j: Vitesses axiales – radiales à 20° ATDC.

Figure 1.k: Vitesses de swirl à 20° ATDC.

STAR PROSTAR 3.05 14-MAY-99 VEL. COMP U W M/S TIME = 0.833334E-02 LOCAL MX= 45.68 LOCAL MN= 0.8562E-01 45.68 42.43 39.17 35.91 32.66 29.40 26.14 22.88 19.63 16.37 13.11 9.857 6.600 3.343 0.8562E-01 X Y Z

Omega bowl - fine model (PUMA) Crank angle position =20 ATDC (expansion) swirl ratio 2.5 STAR PROSTAR 3.05 14-MAY-99 COMPONENT V M/S TIME = 0.833334E-02 LOCAL MX= 48.47 LOCAL MN= 0. 48.47 45.01 41.55 38.09 34.62 31.16 27.70 24.24 20.77 17.31 13.85 10.39 6.925 3.462 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position =20 ATDC (expansion) swirl ratio 2.5

STAR PROSTAR 3.05 14-MAY-99 TURBULENT VISCOSITY PA S TIME = 0.750001E-02 LOCAL MX= 0.1224E-01 LOCAL MN= 0.1810E-14 0.4448E-01 0.4130E-01 0.3813E-01 0.3495E-01 0.3177E-01 0.2859E-01 0.2542E-01 0.2224E-01 0.1906E-01 0.1589E-01 0.1271E-01 0.9531E-02 0.6354E-02 0.3177E-02 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = TDC swirl ratio 2.5

Figure 1.l: Viscosité turbulente à SOI.

Figure 1.m: Viscosité turbulente à TDC.

STAR PROSTAR 3.05 14-MAY-99 TURBULENT VISCOSITY PA S TIME = 0.708334E-02 LOCAL MX= 0.1024E-01 LOCAL MN= 0.1810E-14 0.4448E-01 0.4130E-01 0.3813E-01 0.3495E-01 0.3177E-01 0.2859E-01 0.2542E-01 0.2224E-01 0.1906E-01 0.1589E-01 0.1271E-01 0.9531E-02 0.6354E-02 0.3177E-02 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

Figure 1.n: Energie cinétique de la turbulence à SOI.

STAR

PROSTAR 3.05 14-MAY-99

TURB KINETIC ENERGY M**2/S**2 TIME = 0.708334E-02 LOCAL MX= 38.07 LOCAL MN= 0. 38.07 35.35 32.63 29.91 27.19 24.47 21.75 19.03 16.32 13.60 10.88 8.158 5.438 2.719 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

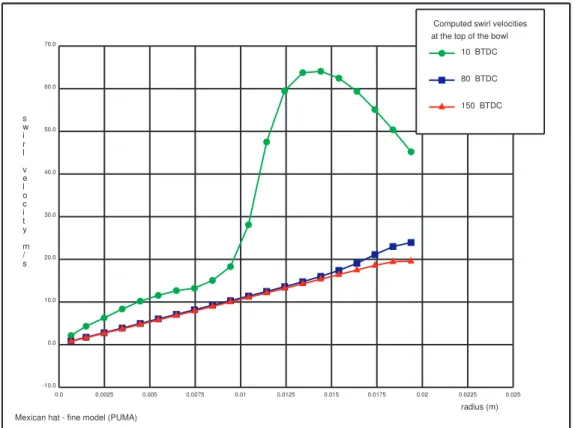

radius (m) s w i r l v e l o c i t y m / s 0.0 0.0025 0.005 0.0075 0.01 0.0125 0.015 0.0175 0.02 0.0225 0.025 -10.0 0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0 80.0

Computed swirl velocities

150 BTDC

80 BTDC

10 BTDC at the top of the bowl

Omega bowl - fine model (PUMA)

Figure 2.a: Maillage.

STAR

X Y Z

Mexican hat bowl - fine model (PUMA) mesh

STAR PROSTAR 3.05 6-MAY-99 COMPONENT V M/S TIME = 0.125000E-02 LOCAL MX= 41.72 LOCAL MN= 0. 41.72 38.74 35.76 32.78 29.80 26.82 23.84 20.86 17.88 14.90 11.92 8.940 5.960 2.980 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 150 BTDC (IVC) Swirl ratio 2.5

Figure 2.b: Vitesses axiales – radiales à 150° BTDC.

Figure 2.c: Vitesses de swirl à 150° BTDC.

STAR PROSTAR 3.05 6-MAY-99 VEL. COMP U W M/S TIME = 0.125000E-02 LOCAL MX= 8.461 LOCAL MN= 0.1439 8.461 7.867 7.273 6.678 6.084 5.490 4.896 4.301 3.707 3.113 2.519 1.925 1.330 0.7361 0.1419 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 150 BTDC (IVC) Swirl ratio 2.5

STAR PROSTAR 3.05 6-MAY-99 COMPONENT V M/S TIME = 0.416667E-02 LOCAL MX= 39.13 LOCAL MN= 0. 39.13 36.33 33.54 30.74 27.95 25.15 22.36 19.56 16.77 13.97 11.18 8.385 5.590 2.795 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 80 BTDC (compression) Swirl ratio 2.5

Figure 2.d: Vitesses axiales – radiales à 80° BTDC (compression).

Figure 2.e: Vitesses de swirl à 80° BTDC (compression).

STAR PROSTAR 3.05 6-MAY-99 VEL. COMP U W M/S TIME = 0.416667E-02 LOCAL MX= 21.67 LOCAL MN= 0.2269 21.67 20.14 18.61 17.07 15.54 14.01 12.48 10.94 9.412 7.879 6.347 4.815 3.282 1.750 0.2179 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 80 BTDC (compression) Swirl ratio 2.5

STAR PROSTAR 3.05 6-MAY-99 COMPONENT V M/S TIME = 0.708334E-02 LOCAL MX= 71.56 LOCAL MN= 0. 71.56 66.45 61.34 56.23 51.11 46.00 40.89 35.78 30.67 25.56 20.45 15.33 10.22 5.111 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) Swirl ratio 2.5

Figure 2.f: Vitesses axiales – radiales à SOI.

Figure 2.g: Vitesses de swirl à SOI.

STAR PROSTAR 3.05 6-MAY-99 VEL. COMP U W M/S TIME = 0.708334E-02 LOCAL MX= 69.42 LOCAL MN= 0.2285 69.64 64.68 59.73 54.77 49.81 44.86 39.90 34.94 29.99 25.03 20.07 15.12 10.16 5.202 0.2455 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) Swirl ratio 2.5

STAR PROSTAR 3.05 6-MAY-99 VEL. COMP U W M/S TIME = 0.750001E-02 LOCAL MX= 36.37 LOCAL MN= 0.8124 36.37 33.83 31.29 28.75 26.21 23.67 21.13 18.59 16.05 13.51 10.97 8.432 5.892 3.352 0.8124 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = TDC Swirl ratio 2.5 STAR PROSTAR 3.05 6-MAY-99 COMPONENT V M/S TIME = 0.750001E-02 LOCAL MX= 80.08 LOCAL MN= 0. 80.08 74.36 68.64 62.92 57.20 51.48 45.76 40.04 34.32 28.60 22.88 17.16 11.44 5.720 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = TDC Swirl ratio 2.5

Figure 2.h: Vitesses axiales – radiales à TDC.

STAR PROSTAR 3.05 6-MAY-99 COMPONENT V M/S TIME = 0.833334E-02 LOCAL MX= 48.02 LOCAL MN= 0. 48.02 44.59 41.16 37.73 34.30 30.87 27.44 24.01 20.58 17.15 13.72 10.29 6.860 3.430 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 20 ATDC Swirl ratio 2.5

Figure 2.j: Vitesses axiales – radiales à 20° ATDC.

Figure 2.k: Swirl velocities at 20° ATDC.

STAR PROSTAR 3.05 6-MAY-99 VEL. COMP U W M/S TIME = 0.833334E-02 LOCAL MX= 44.74 LOCAL MN= 0.2105 44.74 41.56 38.37 35.19 32.01 28.83 25.65 22.47 19.29 16.11 12.93 9.752 6.571 3.391 0.2105 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 20 ATDC Swirl ratio 2.5

STAR PROSTAR 3.05 6-MAY-99 TURBULENT VISCOSITY PA S TIME = 0.708334E-02 LOCAL MX= 0.9579E-02 LOCAL MN= 0.1810E-14 0.4448E-01 0.4130E-01 0.3813E-01 0.3495E-01 0.3177E-01 0.2859E-01 0.2542E-01 0.2224E-01 0.1906E-01 0.1589E-01 0.1271E-01 0.9531E-02 0.6354E-02 0.3177E-02 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) Swirl ratio 2.5 STAR PROSTAR 3.05 28-JUN-99 TURBULENT VISCOSITY PA S TIME = 0.750001E-02 PSYS= 2 LOCAL MX= 0.1359E-01 LOCAL MN= 0.1810E-14 0.4448E-01 0.4130E-01 0.3813E-01 0.3495E-01 0.3177E-01 0.2859E-01 0.2542E-01 0.2224E-01 0.1906E-01 0.1589E-01 0.1271E-01 0.9531E-02 0.6354E-02 0.3177E-02 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position =TDC swirl 2.5

Figure 2.l: Viscosité turbulente à SOI.

Figure 2.n: Energie cinétique de la turbulence à SOI.

STAR

PROSTAR 3.05 6-MAY-99

TURB KINETIC ENERGY M**2/S**2 TIME = 0.708334E-02 LOCAL MX= 38.08 LOCAL MN= 0. 38.08 35.36 32.64 29.92 27.20 24.48 21.76 19.04 16.32 13.60 10.88 8.160 5.440 2.720 0. X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) Swirl ratio 2.5

radius (m) s w i r l v e l o c i t y m / s 0.0 0.0025 0.005 0.0075 0.01 0.0125 0.015 0.0175 0.02 0.0225 0.025 -10.0 0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0

Computed swirl velocities

10 BTDC

80 BTDC

150 BTDC at the top of the bowl

Mexican hat - fine model (PUMA)

STAR

X Y Z

Omega bowl - coarse model (PUMA) mesh

STAR PROSTAR 3.05 11-JUN-99 VEL. COMP U W M/S TIME = 0.125000E-02 PSYS= 2 LOCAL MX= 7.597 LOCAL MN= 1.339 8.454 7.946 7.438 6.929 6.421 5.913 5.405 4.896 4.388 3.880 3.372 2.863 2.355 1.847 1.339 X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 150 BTDC (IVC) swirl 2.5 STAR PROSTAR 3.05 11-JUN-99 COMPONENT V M/S TIME = 0.125000E-02 PSYS= 2 LOCAL MX= 35.92 LOCAL MN= 0. 41.72 38.74 35.76 32.78 29.80 26.82 23.84 20.86 17.88 14.90 11.92 8.940 5.960 2.980 0. X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 150 BTDC (IVC) swirl 2.5

Figure 3.b: Vitesses axiales – radiales à 150° BTDC.

STAR PROSTAR 3.05 11-JUN-99 COMPONENT V M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 68.60 LOCAL MN= 0. 69.61 64.64 59.67 54.69 49.72 44.75 39.78 34.81 29.83 24.86 19.89 14.92 9.944 4.972 0. X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl 2.5

Figure 3.d: Vitesses axiales – radiales à SOI.

Figure 3.e: Vitesses de swirl à SOI.

STAR PROSTAR 3.05 11-JUN-99 VEL. COMP U W M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 56.59 LOCAL MN= 1.179 69.64 64.68 59.73 54.77 49.81 44.86 39.90 34.94 29.99 25.03 20.07 15.12 10.16 5.202 0.2455 X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl 2.5

STAR PROSTAR 3.05 11-JUN-99 COMPONENT V M/S TIME = 0.750001E-02 PSYS= 2 LOCAL MX= 75.68 LOCAL MN= 0. 77.18 71.67 66.15 60.64 55.13 49.62 44.10 38.59 33.08 27.56 22.05 16.54 11.03 5.513 0. X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = TDC swirl 2.5

Figure 3.f: Vitesses axiales – radiales à TDC.

Figure 3.g: Vitesses de swirl à TDC.

STAR PROSTAR 3.05 11-JUN-99 VEL. COMP U W M/S TIME = 0.750001E-02 PSYS= 2 LOCAL MX= 35.81 LOCAL MN= 0.7180 36.37 33.82 31.27 28.72 26.17 23.62 21.07 18.52 15.97 13.42 10.87 8.323 5.773 3.223 0.6733 X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = TDC swirl 2.5

STAR PROSTAR 3.05 11-JUN-99 COMPONENT V M/S TIME = 0.833334E-02 PSYS= 2 LOCAL MX= 31.29 LOCAL MN= 0. 31.29 29.06 26.82 24.59 22.35 20.12 17.88 15.65 13.41 11.18 8.941 6.706 4.470 2.235 0. X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 20 ATDC swirl ratio 2.5

Figure 3.h: Vitesses axiales – radiales à 20° ATDC.

Figure 3.i: Vitesses de swirl à 20° ATDC.

STAR PROSTAR 3.05 11-JUN-99 VEL. COMP U W M/S TIME = 0.833334E-02 PSYS= 2 LOCAL MX= 39.95 LOCAL MN= 0.8975 39.95 37.16 34.37 31.58 28.79 26.00 23.21 20.42 17.63 14.85 12.06 9.266 6.477 3.687 0.8975 X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 20 ATDC swirl ratio 2.5

STAR PROSTAR 3.05 11-JUN-99 TURBULENT VISCOSITY PA S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 0.4448E-01 LOCAL MN= 0.1810E-14 0.4734E-01 0.4396E-01 0.4058E-01 0.3720E-01 0.3381E-01 0.3043E-01 0.2705E-01 0.2367E-01 0.2029E-01 0.1691E-01 0.1353E-01 0.1014E-01 0.6763E-02 0.3381E-02 0. X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl 2.5

STAR

PROSTAR 3.05 11-JUN-99

TURB KINETIC ENERGY M**2/S**2 TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 29.47 LOCAL MN= 0. 38.07 35.35 32.63 29.91 27.19 24.47 21.75 19.03 16.32 13.60 10.88 8.158 5.439 2.719 0. X Y Z

Omega bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl 2.5

Figure 3.j: Viscosité turbulente à SOI.

Figure 3.l: Vitesses de swirl calculées au sommet de la cuvette.

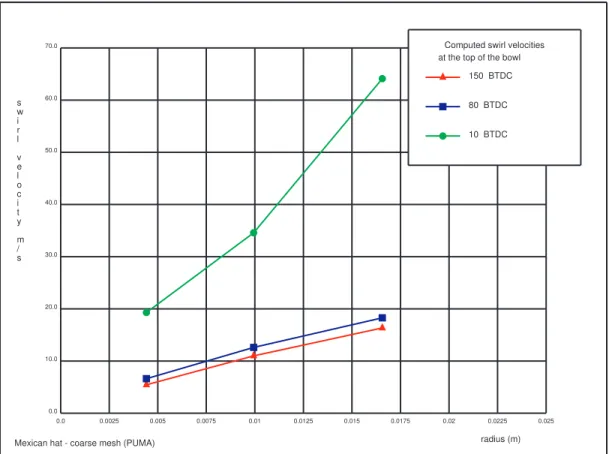

radius (m) s w i r l v e l o c i t y m / s 0.0 0.0025 0.005 0.0075 0.01 0.0125 0.015 0.0175 0.02 0.0225 0.025 0.0 10.0 20.0 30.0 40.0 50.0 60.0 70.0Computed swirl velocities

10 BTDC

80 BTDC

150 BTDC at the top of the bowl

STAR PROSTAR 3.10 31-JUL-99 COMPONENT V M/S TIME = 0.125000E-02 PSYS= 2 LOCAL MX= 35.92 LOCAL MN= 0. 41.72 38.74 35.76 32.78 29.80 26.82 23.84 20.86 17.88 14.90 11.92 8.940 5.960 2.980 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 150 BTDC (IVC) swirl ratio 2.5

Figure 4.b: Vitesses axiales – radiales à 150° BTDC.

Figure 4.c: Vitesses de swirl à 150° BTDC.

STAR PROSTAR 3.10 31-JUL-99 VEL. COMP U W M/S TIME = 0.125000E-02 PSYS= 2 LOCAL MX= 6.516 LOCAL MN= 1.328 8.454 7.860 7.266 6.673 6.079 5.485 4.891 4.297 3.704 3.110 2.516 1.922 1.328 0.7347 0.1409 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 150 BTDC (IVC) swirl ratio 2.5

STAR PROSTAR 3.10 31-JUL-99 COMPONENT V M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 70.19 LOCAL MN= 0. 70.19 65.18 60.16 55.15 50.14 45.12 40.11 35.09 30.08 25.07 20.05 15.04 10.03 5.014 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

Figure 4.d: Vitesses axiales – radiales à SOI.

Figure 4.e: Vitesses de swirl à SOI.

STAR PROSTAR 3.10 31-JUL-99 VEL. COMP U W M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 57.53 LOCAL MN= 1.876 69.64 64.68 59.73 54.77 49.81 44.86 39.90 34.94 29.99 25.03 20.07 15.12 10.16 5.202 0.2455 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

STAR PROSTAR 3.10 31-JUL-99 VEL. COMP U W M/S TIME = 0.750001E-02 PSYS= 2 LOCAL MX= 30.04 LOCAL MN= 0.2465 36.37 33.79 31.21 28.63 26.05 23.47 20.89 18.31 15.73 13.15 10.57 7.987 5.407 2.827 0.2465 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = TDC swirl ratio 2.5 STAR PROSTAR 3.10 31-JUL-99 COMPONENT V M/S TIME = 0.750001E-02 PSYS= 2 LOCAL MX= 76.95 LOCAL MN= 0. 76.95 71.45 65.96 60.46 54.96 49.47 43.97 38.48 32.98 27.48 21.99 16.49 10.99 5.496 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = TDC swirl ratio 2.5

Figure 4.f: Vitesses axiales – radiales à TDC.

STAR PROSTAR 3.10 31-JUL-99 VEL. COMP U W M/S TIME = 0.833334E-02 PSYS= 2 LOCAL MX= 41.83 LOCAL MN= 1.583 41.83 38.95 36.08 33.20 30.33 27.45 24.58 21.70 18.83 15.96 13.08 10.21 7.332 4.458 1.583 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 20 ATDC swirl ratio 2.5 STAR PROSTAR 3.10 31-JUL-99 COMPONENT V M/S TIME = 0.833334E-02 PSYS= 2 LOCAL MX= 42.22 LOCAL MN= 0. 42.22 39.21 36.19 33.17 30.16 27.14 24.13 21.11 18.10 15.08 12.06 9.048 6.032 3.016 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 20 ATDC swirl ratio 2.5

Figure 4.h: Vitesses axiales – radiales à 20° ATDC.

STAR PROSTAR 3.10 31-JUL-99 TURBULENT VISCOSITY PA S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 0.4666E-01 LOCAL MN= 0.1810E-06 0.4666E-01 0.4333E-01 0.4000E-01 0.3666E-01 0.3333E-01 0.3000E-01 0.2666E-01 0.2333E-01 0.2000E-01 0.1667E-01 0.1333E-01 0.9999E-02 0.6666E-02 0.3333E-02 0.1825E-06 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

STAR

PROSTAR 3.10 31-JUL-99

TURB KINETIC ENERGY M**2/S**2 TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 30.73 LOCAL MN= 0. 38.07 35.35 32.63 29.91 27.19 24.47 21.75 19.03 16.32 13.60 10.88 8.158 5.439 2.719 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) swirl ratio 2.5

Figure 4.j: Viscosité turbulente à SOI.

radius (m) s w i r l v e l o c i t y m / s 0.0 0.0025 0.005 0.0075 0.01 0.0125 0.015 0.0175 0.02 0.0225 0.025 0.0 10.0 20.0 30.0 40.0 50.0 60.0

70.0 Computed swirl velocities

150 BTDC 80 BTDC 10 BTDC

Mexican hat - coarse mesh (PUMA)

at the top of the bowl

Annexe E:

Traitement des couches limites

Partie 5:

Modèle Omega – Conditions limites de parois avec maillage fin.

Partie 6:

Modèle Bloc cylindrique - Conditions limites de parois avec

maillage fin.

Partie 7:

Modèle Omega – Conditions limites de parois avec maillage à

faible résolution.

Partie 8:

Modèle Bloc cylindrique - Conditions limites de parois avec

maillage à faible résolution.

Partie 9:

Modèle Bloc cylindrique - Traitement des conditions limites de

parois avec malillage à faible résolution.

STAR PROSTAR 3.05 16-JUN-99 YPLUS PSYS= 2 LOCAL MX= 1449. LOCAL MN= 39.70 1449. 1348. 1247. 1147. 1046. 945.5 844.8 744.2 643.5 542.9 442.3 341.6 241.0 140.3 39.70 X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) wall numbers 38693870 3884 3821 3885 3822 3886 3823 3887 38243825 3888 3826 3889 3827 3878 3828 3879 3829 3880 38303831 3881 3832 3882 38333834 3883 38353836 3872 3837 3873 3838 3871 3877 3874 3868 3839 3876 3875 3867 3866 3840 3865 3793 3841 3794 3842 3795 3843 3796 3844 3797 3845 3798 3846 3799 3847 3800 3848 3801 3849 3802 3850 3803 3851 3804 3852 3805 3853 3806 3854 3807 3855 3808 3856 3809 3857 3810 3858 3811 3859 3812 3860 3813 3861 3814 3862 3815 3863 3816 3817 3818 3819 3820 3864 STAR PROSTAR 3.05 16-JUN-99 YPLUS PSYS= 2 LOCAL MX= 1449. LOCAL MN= 76.50 1449. 1351. 1253. 1155. 1057. 958.6 860.6 762.6 664.6 566.6 468.5 370.5 272.5 174.5 76.50 X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) wall numbers 3887 3880 3828 3873 3833 3876 3868 3838 3866 3794 3799 3846 3803 3851 3808 3855 3861 3816 3818 3820

Figure 5.a: Identification des parois et paramètre y+ à SOI.

Crank angle position (x 3 time steps)

Y +

-100 0 100 200 300 400 500 600 700 -150.0 0.0 150.0 300.0 450.0 600.0 750.0 900.0 1050.0 1200.0 1350.0 1500.0cylinder head wall

WALL 3828

WALL 3833

WALL 3838

WALL 3846

WALL 3851

WALL 3855

WALL 3861

Omega bowl - fine model (PUMA)

Dimensioless parameter for log-law wall functions

Crank angle position (x 3 time steps)

Y +

-100 0 100 200 300 400 500 600 700 -100.0 0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0 800.0 900.0 1000.0block liner wall

WALL 3816

WALL 3818

WALL 3820

Crank angle position (x3 time steps)

Y +

-100 0 100 200 300 400 500 600 700 -100.0 0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0piston crown wall

WALL 3794

WALL 3799

WALL 3803

WALL 3808

Crank angle position (x3 time steps)

Y +

-100 0 100 200 300 400 500 600 700 -150.0 0.0 150.0 300.0 450.0 600.0 750.0 900.0 1050.0 1200.0 1350.0 1500.0 1650.0piston bowl side wall

WALL 3866

WALL 3868

Crank angle position (x3 time steps)

Y +

-100 0 100 200 300 400 500 600 700 -110.0 0.0 110.0 220.0 330.0 440.0 550.0 660.0 770.0 880.0 990.0 1100.0piston bowl bottom wall

WALL 3873

WALL 3876

WALL 3880

WALL 3887

STAR PROSTAR 3.05 18-JUN-99 YPLUS PSYS= 2 LOCAL MX= 1362. LOCAL MN= 37.92 1362. 1267. 1173. 1078. 983.6 889.1 794.5 699.9 605.4 510.8 416.2 321.6 227.1 132.5 37.92 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) wall numbers 37223723 37243725 3726 3727 3669 3728 3670 3729 3671 3730 3672 3731 3673 3732 3674 3733 3675 3734 3676 3735 3677 3736 3678 3737 3679 3738 3680 3739 3681 3740 3682 3741 3683 3742 3721 3684 3720 3719 3685 3718 3717 3686 3716 3715 3687 3714 3713 3688 3641 3689 3642 3690 3643 3691 3644 3692 3645 3693 3646 3694 3647 3695 3648 3696 3649 3697 3650 3698 3651 3699 3652 3700 3653 3701 3654 3702 3655 3703 3656 3704 3657 3705 3658 3706 3659 3707 3660 3708 3661 3709 3662 3710 3663 3711 3664 3665 3666 3667 3668 3712 STAR PROSTAR 3.05 18-JUN-99 YPLUS PSYS= 2 LOCAL MX= 1362. LOCAL MN= 67.72 1362. 1269. 1177. 1085. 992.2 899.7 807.3 714.8 622.4 529.9 437.5 345.0 252.6 160.2 67.72 X Y Z

Mexican hat bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) wall numbers 3728 3734 3739 3676 3719 3681 3716 3714 3686 3642 3647 3694 3651 3699 3656 3703 3709 3664 3666 3668

Figure 6.a: Identification des parois et paramètre y+ à SOI.

Crank angle position

Y +

0 72 144 216 288 360 432 504 576 648 720 -140.0 0.0 140.0 280.0 420.0 560.0 700.0 840.0 980.0 1120.0 1260.0 1400.0 1540.0cylinder head wall

WALL 3676

WALL 3681

WALL 3686

WALL 3694

WALL 3699

WALL 3703

WALL 3709

Mexican hat - fine model (PUMA)

Dimensionless parameter for log-law wall functions

Crank angle position

Y +

0 72 144 216 288 360 432 504 576 648 720 -100.0 0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0 800.0 900.0 1000.0block liner wall

WALL 3664

WALL 3666

WALL 3668

Crank angle position

Y +

0 72 144 216 288 360 432 504 576 648 720 -100.0 0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0piston crown wall

WALL 3642

WALL 3647

WALL 3651

WALL 3656

Crank angle position

Y +

0 72 144 216 288 360 432 504 576 648 720 -140.0 0.0 140.0 280.0 420.0 560.0 700.0 840.0 980.0 1120.0 1260.0 1400.0 1540.0piston bowl side wall

WALL 3714

WALL 3716

WALL 3719

Crank angle position

Y +

0 72 144 216 288 360 432 504 576 648 720 -400.0 0.0 400.0 800.0 1200.0 1600.0 2000.0 2400.0piston bowl bottom wall

WALL 3728

WALL 3734

WALL 3739

STAR

PROSTAR 3.05

15-JUN-99

YPLUS

PSYS= 2

LOCAL MX= 8691.

LOCAL MN= 217.0

8691.

8085.

7480.

6875.

6270.

5664.

5059.

4454.

3849.

3243.

2638.

2033.

1428.

822.3

217.0

X

Y

Z

Omega bowl - coarse model (PUMA)

Crank angle position = 10 BTDC (SOI)

wall numbers

53 41 54 51 42 52 43 49 50 48 36 44 37 45 38 46 39 40 47

Crank angle position

Y +

0.0 24.0 48.0 72.0 96.0 120.0 144.0 168.0 192.0 216.0 240.0 -200.0 0.0 200.0 400.0 600.0 800.0 1000.0 1200.0 1400.0 1600.0 1800.0cylinder head wall

WALL 41

WALL 42

WALL 43

WALL 44

WALL 45

WALL 46

cylinder head wall

Crank angle position

Y +

0 24 48 72 96 120 144 168 192 216 240 -1000.0 0.0 1000.0 2000.0 3000.0 4000.0 5000.0 6000.0 7000.0 8000.0 9000.0 10000.0 0.1100E+05block liner wall

WALL 39

WALL 40

WALL 47

block liner wall

Crank angle position

Y +

0.0 24.0 48.0 72.0 96.0 120.0 144.0 168.0 192.0 216.0 240.0 -200.0 0.0 200.0 400.0 600.0 800.0 1000.0 1200.0 1400.0 1600.0 1800.0piston crown wall

WALL 36

WALL 37

WALL 38

piston crown wall

Crank angle position

Y +

0.0 24.0 48.0 72.0 96.0 120.0 144.0 168.0 192.0 216.0 240.0 -1200.0 0.0 1200.0 2400.0 3600.0 4800.0 6000.0 7200.0 8400.0 9600.0 0.1080E+05 0.1200E+05piston bowl wall

WALL 48

WALL 49

WALL 50

WALL 51

WALL 52

WALL 53

WALL 54

Dimensionless parameter

piston bowl walls

for log-law wall functions

STAR

PROSTAR 3.05

15-JUN-99

YPLUS

PSYS= 2

LOCAL MX= 8680.

LOCAL MN= 299.5

8680.

8081.

7482.

6884.

6285.

5687.

5088.

4490.

3891.

3292.

2694.

2095.

1497.

898.1

299.5

X

Y

Z

Mexican hat bowl - coarse model (PUMA)

Crank angle position = 10 BTDC (SOI)

wall numbers

42 33 43 34 44 35 45 41 40 28 36 29 37 30 38 31 32 39

Crank angle position

Y +

-40 0 40 80 120 160 200 240 280 320 360 400 -200.0 0.0 200.0 400.0 600.0 800.0 1000.0 1200.0 1400.0 1600.01800.0

cylinder head wall

WALL 33

WALL 34

WALL 35

WALL 36

WALL 37

WALL 38

cylinder head wall

Crank angle position

Y +

-40 0 40 80 120 160 200 240 280 320 360 400 -1000.0 0.0 1000.0 2000.0 3000.0 4000.0 5000.0 6000.0 7000.0 8000.0 9000.0 10000.0block liner wall

WALL 31

WALL 32

WALL 39

block liner wall

Crank angle position

Y +

-40 0 40 80 120 160 200 240 280 320 360 400 -200.0 0.0 200.0 400.0 600.0 800.0 1000.0 1200.0 1400.0 1600.0 1800.0piston crown wall

WALL 28

WALL 29

WALL 30

piston crown wall

Crank angle position

Y +

-40 0 40 80 120 160 200 240 280 320 360 400 -1200.0 0.0 1200.0 2400.0 3600.0 4800.0 6000.0 7200.0 8400.0 9600.0 0.1080E+050.1200E+05

piston bowl wall

WALL 40

WALL 41

WALL 42

WALL 43

WALL 44

WALL 45

Dimensionless parameter

piston bowl wall

for log-law wall functions

STAR

X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = BDC mesh

STAR

X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = BDC

mesh detail of the treatment of the wall boundary

Figure 9.a: Vue du maillage.

STAR PROSTAR 3.05 14-JUN-99 YPLUS PSYS= 2 LOCAL MX= 403.4 LOCAL MN= 136.4 403.4 384.3 365.3 346.2 327.1 308.0 289.0 269.9 250.8 231.7 212.7 193.6 174.5 155.4 136.4 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) wall numbers 77 60 78 61 79 62 8081 76 75 74 69 63 64 70 65 71 66 727357 67 58 59 68

Crank angle position (x 3time steps) Y + 0 110 220 330 440 550 660 770 880 990 1100 -100.0 0.0 100.0 200.0 300.0 400.0 500.0 600.0 WALL 57 WALL 58 WALL 59 WALL 60 WALL 61 WALL 62 WALL 63 WALL 64 WALL 65 WALL 66 WALL 67 WALL 68 WALL 69 WALL 70 WALL 71 WALL 72 WALL 73 WALL 74 WALL 75 WALL 76 WALL 77 WALL 78 WALL 79 WALL 80 WALL 81 Dimensionless parameter for log-law wall functions

Figure 9.c: Identification des parois et paramètre y+ à SOI.

Crank angle position (x 3time steps) Y + 440 462 484 506 528 550 572 594 616 638 660 -100.0 0.0 100.0 200.0 300.0 400.0 500.0 600.0 WALL 57 WALL 58 WALL 59 WALL 60 WALL 61 WALL 62 WALL 63 WALL 64 WALL 65 WALL 66 WALL 67 WALL 68 WALL 69 WALL 70 WALL 71 WALL 72 WALL 73 WALL 74 WALL 75 WALL 76 WALL 77 WALL 78 WALL 79 WALL 80 WALL 81 Dimensionless parameter for log-law wall functions

Crank angle position (x 3time steps) Y + 0 40 80 120 160 200 240 280 320 360 400 0.0 4.0 8.0 12.00 16.00 20.00 24.00 28.00 32.00 36.00 40.00 WALL 57 WALL 58 WALL 59 WALL 60 WALL 61 WALL 62 WALL 63 WALL 64 WALL 65 WALL 66 WALL 67 WALL 68 WALL 69 WALL 70 WALL 71 WALL 72 WALL 73 WALL 74 WALL 75 WALL 76 WALL 77 WALL 78 WALL 79 WALL 80 WALL 81 Dimensionless parameter for log-law wall functions

details near BDC

Figure 9.e: Détail du paramètre y+ vers TDC.

STAR PROSTAR 3.05 17-JUN-99 VEL. COMP U W M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 62.07 LOCAL MN= 0.2673 62.07 57.66 53.24 48.83 44.41 40.00 35.58 31.17 26.75 22.34 17.93 13.51 9.096 4.682 0.2673 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) treatment of wall boundaries

STAR PROSTAR 3.05 17-JUN-99 COMPONENT V M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 66.74 LOCAL MN= 0. 66.74 61.97 57.21 52.44 47.67 42.90 38.14 33.37 28.60 23.84 19.07 14.30 9.534 4.767 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) treatment of wall boundaries

Figure 9.g: Vitesses axiales – radiales à SOI.

STAR PROSTAR 3.05 18-JUN-99 YPLUS PSYS= 2 LOCAL MX= 2196. LOCAL MN= 106.0 2196. 2047. 1898. 1748. 1599. 1450. 1300. 1151. 1002. 852.5 703.2 553.9 404.6 255.3 106.0 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) treatment of wall boundary

77 60 78 61 79 62 80 81 76 75 74 63 69 64 70 65 71 66 727357 67 58 59 68 STAR PROSTAR 3.05 18-JUN-99 VEL. COMP U W M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 66.33 LOCAL MN= 2.072 66.33 61.74 57.15 52.56 47.97 43.38 38.79 34.20 29.61 25.02 20.43 15.84 11.25 6.662 2.072 X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) treatment of wall boundary

Figure 9.i: Identification des parois et paramètre y+ corrigés à SOI.

STAR PROSTAR 3.05 18-JUN-99 COMPONENT V M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 62.33 LOCAL MN= 0. 62.33 57.88 53.43 48.98 44.52 40.07 35.62 31.17 26.71 22.26 17.81 13.36 8.905 4.452 0. X Y Z

Mexican hat bowl - coarse model (PUMA) Crank angle position = 10 BTDC (SOI) treatment of wall boundary

Annexe F:

Modèles avec admission.

Partie 10:

Comparaisons des profils de vitesses d’admission.

Partie 11:

Sensibilité de la position de l’ admission.

Partie 12:

Sensibilité de la résolution du maillage sur les conditions d’admission

– Modèles Bloc cylindriques

Partie 13:

Conditions d’admission avec les maillages à faible résolution.

STAR PROSTAR 3.05 26-MAY-99 VEL. COMP U W M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 65.64 LOCAL MN= 0.4623 65.64 60.98 56.33 51.67 47.02 42.36 37.71 33.05 28.40 23.74 19.08 14.43 9.773 5.118 0.4623 X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) swirl 2.5

Figure 10.a: Vitesses axiales – radiales à SOI.- Référence.

Figure 10.b: Vitesses de swirl à SOI.- Référence.

STAR PROSTAR 3.05 26-MAY-99 COMPONENT V M/S TIME = 0.708334E-02 PSYS= 2 LOCAL MX= 70.93 LOCAL MN= 0. 70.93 65.86 60.80 55.73 50.66 45.60 40.53 35.46 30.40 25.33 20.27 15.20 10.13 5.066 0. X Y Z

Omega bowl - fine model (PUMA) Crank angle position = 10 BTDC (SOI) swirl 2.5

Figure 10.c: Vitesses axiales – radiales à 90° ATDC (processus d’admission)

avec le profil de vitesses (a).

Figure 10.d: Vitesses axiales – radiales à 90° ATDC (processus d’admission)

STAR PROSTAR 3.05 28-MAY-99 VEL. COMP U W M/S TIME = 0.375000E-02 PSYS= 2 LOCAL MX= 123.9 LOCAL MN= 0.2464 123.9 115.1 106.2 97.40 88.57 79.74 70.90 62.07 53.24 44.41 35.58 26.74 17.91 9.079 0.2464 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 90 ATDC (intake)

Inlet boundary: swirl 220 around valve axis, u=91.8m/s, w=-53m/s

STAR PROSTAR 3.05 28-MAY-99 VEL. COMP U W M/S TIME = 0.375000E-02 PSYS= 2 LOCAL MX= 125.1 LOCAL MN= 0.1148 125.1 116.2 107.3 98.34 89.41 80.48 71.55 62.62 53.69 44.76 35.83 26.90 17.97 9.045 0.1148 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 90 ATDC (intake) Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

STAR PROSTAR 3.05 28-MAY-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 119.7 LOCAL MN= -102.6 119.7 103.8 87.91 72.03 56.16 40.28 24.40 8.523 -7.354 -23.23 -39.11 -54.99 -70.86 -86.74 -102.6 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC)

Inlet boundary: swirl 220 around valve axis, u=91.8m/s, w=-53m/s

Figure 10.e: Vitesses de swirl à IVC avec le profil de vitesses d’admission autour de l’axe des

soupapes (a)

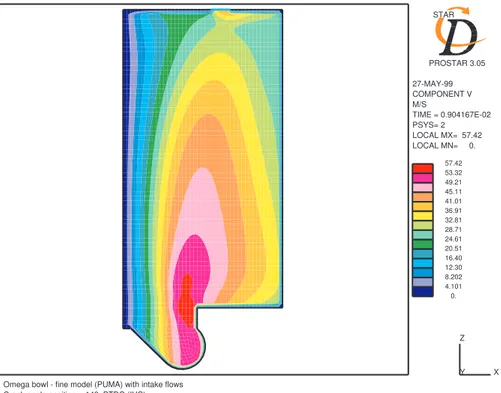

STAR PROSTAR 3.05 27-MAY-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 57.42 LOCAL MN= 0. 57.42 53.32 49.21 45.11 41.01 36.91 32.81 28.71 24.61 20.51 16.40 12.30 8.202 4.101 0. X Y ZOmega bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC)

Inlet boundary: swirl 4.2 around chamber axis, u=91.8m/s, w=-53m/s

Figure 10.f: Vitesses de swirl à IVC avec le profil de vitesses d’admission autour de l’axe de la

chambre (c)

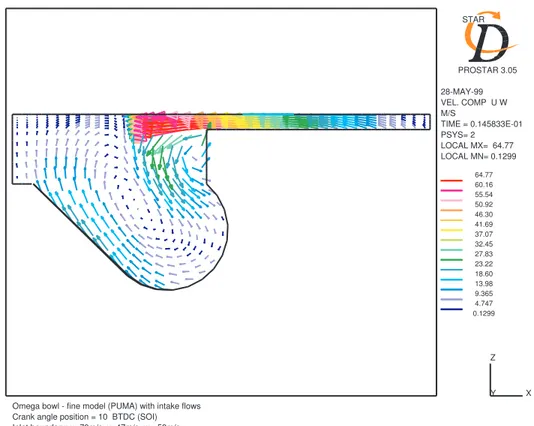

STAR PROSTAR 3.05 28-MAY-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 64.77 LOCAL MN= 0.1299 64.77 60.16 55.54 50.92 46.30 41.69 37.07 32.45 27.83 23.22 18.60 13.98 9.365 4.747 0.1299 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

STAR PROSTAR 3.05 28-MAY-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 72.29 LOCAL MN= 0. 72.29 67.13 61.97 56.80 51.64 46.47 41.31 36.15 30.98 25.82 20.66 15.49 10.33 5.164 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

STAR PROSTAR 3.05 25-MAY-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 85.42 LOCAL MN= 0. 85.42 79.32 73.22 67.12 61.02 54.91 48.81 42.71 36.61 30.51 24.41 18.30 12.20 6.102 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC) Inlet boundary: u=v=92m/s, w=-53m/s

Figure 10.i: Vitesses de swirl à IVC avec le profil de vitesses d’admission (g) – Génération de

swirl plus élevée.

STAR PROSTAR 3.05 25-MAY-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 119.4 LOCAL MN= 0. 119.4 110.8 102.3 93.78 85.25 76.73 68.20 59.68 51.15 42.63 34.10 25.58 17.05 8.525 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=v=92m/s, w=-53m/s

Figure 10.j: Vitesses axiales – radiales à SOI avec le profil de vitesses d’admission (g) –

Génération de swirl plus élevée.

Figure 10.k: Vitesses de swirl à SOI avec le profil de vitesses d’admission (g) – Génération de

swirl plus élevée.

STAR PROSTAR 3.05 25-MAY-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 66.06 LOCAL MN= 0.8919 66.06 61.40 56.75 52.09 47.44 42.78 38.13 33.47 28.82 24.16 19.51 14.86 10.20 5.546 0.8919 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=v=92m/s, w=-53m/s

Figure 11.a: Position de la condition limite d’admission vers l’axe de la chambre.

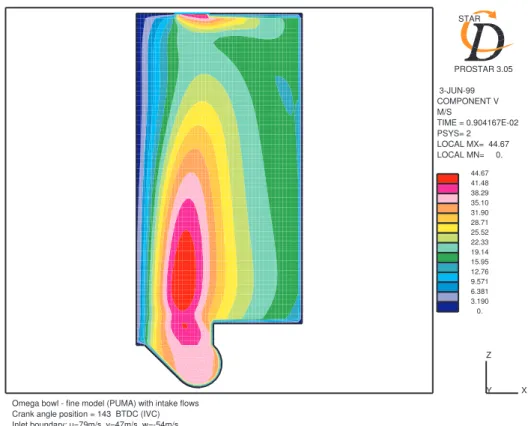

STAR PROSTAR 3.05 3-JUN-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 44.67 LOCAL MN= 0. 44.67 41.48 38.29 35.10 31.90 28.71 25.52 22.33 19.14 15.95 12.76 9.571 6.381 3.190 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC) Inlet boundary: u=79m/s, v=47m/s, w=-54m/s

Figure 11.c: Vitesses de swirl à IVC avec la position de l’admission vers l’axe de la chambre.

STAR PROSTAR 3.05 3-JUN-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 63.98 LOCAL MN= 0. 63.98 59.41 54.84 50.27 45.70 41.13 36.56 31.99 27.42 22.85 18.28 13.71 9.140 4.570 0.3815E-05 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC) Inlet boundary: u=79m/s,v=47m/s, w=-47.5m/s

STAR PROSTAR 3.05 3-JUN-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 64.22 LOCAL MN= 0.3429 64.22 59.66 55.10 50.53 45.97 41.41 36.84 32.28 27.72 23.16 18.59 14.03 9.468 4.906 0.3429 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s, v=47m/s, w=-54m/s

STAR PROSTAR 3.05 3-JUN-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 49.00 LOCAL MN= 0. 49.00 45.50 42.00 38.50 35.00 31.50 28.00 24.50 21.00 17.50 14.00 10.50 7.000 3.500 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s, v=47m/s, w=-54m/s

Figure 11.e: Vitesses axiales – radiales à SOI avec la position de l’admission

vers l’axe de la chambre.

STAR PROSTAR 3.05 3-JUN-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 65.20 LOCAL MN= 0.3804 65.20 60.57 55.94 51.31 46.68 42.05 37.42 32.79 28.16 23.53 18.90 14.27 9.641 5.011 0.3804 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s,v=47m/s, w=-47.5m/s

Figure 11.g: Vitesses axiales – radiales à SOI avec la position de l’admission

vers la paroi du cylindre.

Figure 11.h: Vitesses de swirl à SOI avec la position de l’admission vers la paroi du cylindre.

STAR PROSTAR 3.05 3-JUN-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 91.66 LOCAL MN= 0. 91.66 85.12 78.57 72.02 65.47 58.93 52.38 45.83 39.28 32.74 26.19 19.64 13.09 6.547 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s,v=47m/s, w=-47.5m/s

STAR PROSTAR 3.10 4-AUG-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 64.89 LOCAL MN= 0.2916 64.89 60.27 55.66 51.05 46.43 41.82 37.20 32.59 27.98 23.36 18.75 14.13 9.520 4.906 0.2916 X Y Z

Mexican hat bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI)

Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

Figure 12.a: Vitesses axiales – radiales à SOI avec le profil de vitesses d’admission (g) –

Maillage fin.

Figure 12.b: Vitesses de swirl à SOI avec le profil de vitesses d’admission (g) – Maillage fin.

STAR PROSTAR 3.10 4-AUG-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 74.67 LOCAL MN= 0. 74.67 69.33 64.00 58.67 53.33 48.00 42.67 37.33 32.00 26.67 21.33 16.00 10.67 5.333 0. X Y Z

Mexican hat bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI)

STAR PROSTAR 3.10 4-AUG-99 VEL. COMP U W M/S TIME = 0.375000E-02 PSYS= 2 LOCAL MX= 61.05 LOCAL MN= 1.442 61.05 56.79 52.53 48.28 44.02 39.76 35.50 31.24 26.99 22.73 18.47 14.21 9.957 5.699 1.442 X Y Z

Mexican hat bowl - fine model (PUMA) with intake flows Crank angle position = 90 ATDC (intake)

Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

STAR PROSTAR 3.10 4-AUG-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 42.18 LOCAL MN= 0. 42.18 39.16 36.15 33.14 30.13 27.11 24.10 21.09 18.08 15.06 12.05 9.038 6.025 3.013 0. X Y Z

Mexican hat bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC)

Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

Figure 12.c: Vitesses axiales – radiales à 90° ATDC (processus d’admission)

avec le profil de vitesses (g) – Maillage à faible résolution.

Figure 12.d: Vitesses de swirl à IVC avec le profil de vitesses d’admission (g) –

Maillage à faible résolution.

STAR PROSTAR 3.10 4-AUG-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 58.30 LOCAL MN= 1.185 58.30 54.22 50.14 46.06 41.98 37.90 33.82 29.74 25.66 21.58 17.50 13.42 9.344 5.265 1.185 X Y Z

Mexican hat bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI)

Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

Figure 12.e: Vitesses axiales – radiales à SOI avec le profil de vitesses d’admission (g) –

Maillage à faible résolution.

Figure 12.f: Vitesses de swirl à SOI avec le profil de vitesses d’admission (g) –

Maillage à faible résolution.

STAR PROSTAR 3.10 4-AUG-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 75.85 LOCAL MN= 0. 75.85 70.43 65.01 59.59 54.18 48.76 43.34 37.92 32.51 27.09 21.67 16.25 10.84 5.418 0. X Y Z

Mexican hat bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI)

STAR PROSTAR 3.05 29-MAY-99 COMPONENT V M/S TIME = 0.904167E-02 PSYS= 2 LOCAL MX= 40.66 LOCAL MN= 0. 40.66 37.75 34.85 31.94 29.04 26.14 23.23 20.33 17.42 14.52 11.62 8.712 5.808 2.904 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 143 BTDC (IVC) Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

Figure 13.a: Vitesses de swirl à IVC avec le profil de vitesses d’admission (g) – Modèle

Omega.

STAR PROSTAR 3.05 29-MAY-99 VEL. COMP U W M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 57.52 LOCAL MN= 0.7751 57.52 53.47 49.42 45.36 41.31 37.26 33.20 29.15 25.10 21.04 16.99 12.94 8.882 4.828 0.7751 X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s, v=47m/s, w=-53m/s

Figure 13.b: Vitesses axiales – radiales à SOI avec le profil de vitesses d’admission (g) –

Modèle Omega.

Figure 13.c: Vitesses de swirl à SOI avec le profil de vitesses d’admission (g) – Modèle Omega.

STAR PROSTAR 3.05 29-MAY-99 COMPONENT V M/S TIME = 0.145833E-01 PSYS= 2 LOCAL MX= 79.49 LOCAL MN= 0. 79.49 73.81 68.13 62.46 56.78 51.10 45.42 39.74 34.07 28.39 22.71 17.03 11.36 5.678 0. X Y Z

Omega bowl - fine model (PUMA) with intake flows Crank angle position = 10 BTDC (SOI) Inlet boundary: u=79m/s, v=47m/s, w=-53m/s