HAL Id: hal-02953322

https://hal.archives-ouvertes.fr/hal-02953322

Submitted on 30 Sep 2020

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Study of translaminar fracture toughness of

unidirectional flax/epoxy composite

Yousef Saadati, Gilbert Lebrun, Christophe Bouvet, Jean-François Chatelain,

Yves Beauchamp

To cite this version:

Yousef Saadati, Gilbert Lebrun, Christophe Bouvet, Jean-François Chatelain, Yves Beauchamp. Study

of translaminar fracture toughness of unidirectional flax/epoxy composite. Composites Part C: Open

Access, Elsevier, 2020, 1, pp.100008. �10.1016/j.jcomc.2020.100008�. �hal-02953322�

an author's

https://oatao.univ-toulouse.fr/26735

https://doi.org/10.1016/j.jcomc.2020.100008

Saadati, Yousef and Lebrun, Gilbert and Bouvet, Christophe and Chatelain, Jean-François and Beauchamp, Yves

Study of translaminar fracture toughness of unidirectional flax/epoxy composite. (2020) Composites Part C: Open

access, 1. ISSN 2666-6820

Study

of

translaminar

fracture

toughness

of

unidirectional

flax/epoxy

composite

Yousef

Saadati

a,∗,

Gilbert

Lebrun

b,

Christophe

Bouvet

c,

Jean-François

Chatelain

a,∗,

Yves

Beauchamp

da Mechanical Engineering Department, École de Technologie Supérieure, 1100 Notre-Dame West, Montreal, QC H3C 1K3, Canada

b Mechanical Engineering Department, Université du Québec à Trois-Rivières (UQTR), 3351 boul. des Forges, Trois-Rivières, QC G9A 5H7, Canada c University of Toulouse; INSA, UPS, Mines Albi, ISAE-SUPAERO, ICA (Institut Clément Ader), 3, rue Caroline Aigle, 31400 Toulouse, France d McGill University, 845 Sherbrooke Street West, Montreal, QC H3A 0G4, Canada

Keywords:

Flax fiber

Translaminar fracture energy Fracture toughness Flax-epoxy composites

Tensile and compressive translaminar fracture Infrared thermography

a

b

s

t

r

a

c

t

Ever growing applications of flax fiber-reinforced composites (FFRCs) and their suitability for structural uses involve implementing the design and failure criteria for these composites. Translaminar fracture is one of the primary failure modes of unidirectional (UD) fiber-reinforced composites, and measuring it is essential for design purposes and in many material failure studies. However, the translaminar fracture parameters have not been evaluated for UD-FFRCs; thus, there is no data available in the literature. Moreover, conventional test methods for this failure mode are complex, and there is no standard method for measuring this value in compression. In this study, the translaminar fracture behavior of a UD flax/epoxy composite has been examined, and its fracture toughness in tension and compression in the fiber direction are determined following existing standard meth- ods as well as using a methodology developed using infrared thermography. Compact tension specimens were adapted and used for this purpose. A fractographic study is conducted to examine the fracture surfaces and better understand the failure mechanisms. For tensile tests, the results of infrared thermography are in good agreement with those of ASTM E1922 and lie in the range of values obtained for similar composites in the literature.

1. Introduction

Overthelasttwo decades,theneed formaterialswithenhanced properties,lowercost,andimprovedsustainabilityhasrenderednatural (cellulosic)fiber-reinforcedpolymercomposites(NFRPCs)anattractive alternativetotheirsyntheticglassfiber(GFRP) counterpartin struc-turalandnon-structuralapplications[1–4].Amongnaturalplantfibers (NFs),flaxisconsideredoneofthemostpromisingforpolymer compos-itesduetoitsuniqueproperties[4–6].Usingcontinuousunidirectional (UD)andoptimallyconfiguredreinforcementsinNFRPCsiscrucialto maximizingtheirload-carryingperformance[7–9].Therefore,UDflax fiber-reinforcedcomposites(FFRPCs)areofprominentimportancefor theindustry.Inadditiontostrengthandstiffness,fracturetoughness isanessentialpropertyoffiber-reinforcedpolymercomposites(FRPCs) formostengineeringapplications[10–12].Nowadays,theengineering desireforanoptimized,efficient,sustainable,cost-effective,and dam-agetolerantproductdesigninconjunctionwiththeever-growing appli-cationsofFFRPCsnecessitatecharacterizingthefracturetoughnessof

∗Corresponding authors.

E-mailaddresses:yousef.saadati.1@ens.etsmtl.ca, yousef.saadati.1@gmail.com(Y. Saadati), gilbert.lebrun@uqtr.ca(G. Lebrun), christophe.bouvet@isae.fr(C. Bouvet), jean-francois.chatelain@etsmtl.ca(J.-F. Chatelain), yves.beauchamp@mcgill.ca(Y. Beauchamp).

thesecomposites.Thefracturetoughnessassociatedwithtranslaminar failuremode(denotedbyGIC,whenexpressedintermsofenergyandby

KICwhenexpressedintermsofstressintensityfactor)isoneofthe

pri-marymechanicalpropertiesofthefiber-reinforcedcomposites(FRCs). Thisisparticularlytruewhenusingthefiniteelementmethod(FEM)to simulatespecificmaterialdamagesoccurringincompositelaminates, likefiberfailure,matrixbreaking,anddelamination[13–17].TheFEM approachrequiresdifferentfractureenergiesasinputvariables,andthe fracturetoughnessindifferentdirectionsandtheircorresponding evalu-ationmethodsareprerequisitesfortheFEMsimulationofFFRPCs.While thesignificanceoftranslaminarfracturetoughness(TFT)measurement wasrecognizedsincethelate’70s,ithasattractedlittleinterest[18]. ThisisbecauseFRCswerenotusedinprimarystructures,wherethis propertyismostlyrequired.Atthesametime,theadvancednumerical simulationmethodsreferringtothispropertywerenotyetdeveloped

[18].ThesituationisnowdifferentasFRCsareusedinstructures,and FEMisacommonlyusednumericalmethod.Withthegrowing appli-cationofNFRPCs,theirTFTisexpectedtoplayanessentialroleinthe

Fig.1. The ECT configuration (a), test speci- men (b), load application configuration (c), and notch (d). (Dimensions in mm).

future.Currently,itisrequiredinmanyresearchfields,suchasthe ma-chiningofcompositematerials,wherenumericalmodelsbasedonFEM areinvolving.

Intheliterature,measuringthetranslaminarfracturetoughnessof NFRPCsislimitedtoafewstudiesthatareallconductedonlyin ten-sion.Hughesetal.[11]studiedtheTFTofsomechoppedNFRPCsand comparedthemtothatofaglass fibermatcomposite.TheGICvalue

ofGFRPwasthree-foldhigherthanthoseofNFRPCs.Theyconcluded thatdifferentmicro-structuraltougheningmechanismswereactivated intheNFRPCscomparedtoGFRP.Silvaetal.[19]reportedanin ten-sionGIC=11.8kJ/m2forwovensisal/polyurethane(PU)composite.

TheyobservedthatGICincreasedwithfibervolumefraction(Vf)and

wasimpairedwiththealkalinetreatmentofthefibers.LiuandHughes

[12]investigatedtheeffectsoftextileyarnlineardensity,weave con-figuration,andstackingsequenceonGICofwovenFFRECs.They mea-suredtheKICofanisotropicwoven-flax/epoxycompositesfollowingBS

7448standard.Accordingtotheirfindings,thefracturebehaviorand

KIC arestronglydependentonthelineardensityof yarnsandthe di-rectionofthetestbutisindependentoftheweavetype.Theauthors reportedKIC valuesin therangeof 3–8.5MPa m1/2 forthe

compos-itesandconcludedthatthefracturetoughnessis moredominatedby thefiberpropertiesandVfratherthanthereinforcementconfiguration.

FollowingASTMD5045,Lietal.[20]studiedthefibersurface treat-menteffectonfracturepropertiesoftextile-sisal/vinyl-estercomposite. TheyobtainedKIC =4.2MPam1/2 fortheuntreatedfibercomposite,

whichincreasedto5.5and6.0MPam1/2,respectively,withSilaneand

KMnO4fibertreatments.Ismailetal.[21]reportedvaluesofKIC≈8.5

andKIC ≈4.5MPam1/2,respectivelyforUD-twistedyarnand

cross-plywovenkenaf/polyestercompositestestedbasedonASTMD5045. ChizyukaandKanyanga[22]investigatedtheeffectsofhydrothermal agingandmoisture absorptionon theKIC of sisal/polyester compos-ites.TheyfollowedtheASTME1922proceduretoevaluatetheKIC of

thecompositesandobtainedKIC≈6.25MPam1/2.Thefractographic

studyrevealedthatthereductionofKICaftermoistureabsorptionwas mainlyduetofiber/matrixdebonding,whichwasthedominant

frac-turemechanisminthecomposite.Manjunathetal.[23]followedASTM E1922andinvestigatedtheKICofjutefabricreinforcedepoxy compos-ites.However,thecriteriaofthestandardwerenotcarefullyrespected, andthereisamismatchbetweentheirreportedtestdataandthe re-portedKIC values.Theirresultisalsooneorderofmagnitudehigher thanthatofAshiketal.[24],KIC =7.71MPam1/2,forananalogous

material.

1.1. Translaminarfracturetoughnessintension

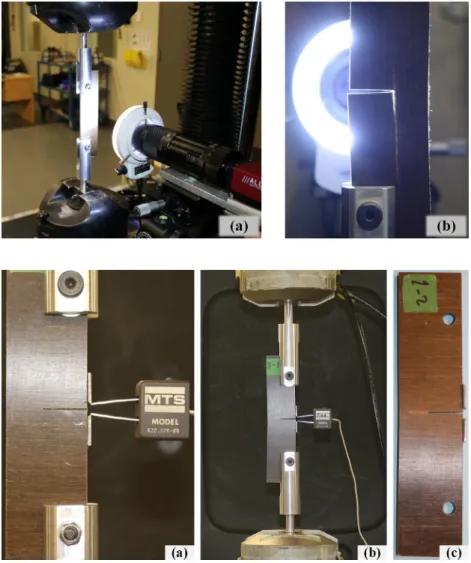

TheASTME1922standard[25]suggeststheextendedcompact ten-sion(ECT)specimenformeasuringthetensileTFTofFRCs.ECT,Fig.1, is an extendedconfiguration of thecompact tension (CT)specimen,

Fig.2(a),whichwasdevelopedtoovercomeundesirablefailuremodes such ascrack growthperpendiculartothepre-notch[26,27]. ASTM E1922wasdevelopedandadaptedtomeasurethefracturetoughness ofFRCsintension,whileanumberofstudieshaveusedCTspecimens, along withASTM E399,D5045,or othermethods[28–33].Without mentioning anyparticularreason,severalresearcherstestedcross-ply laminatesandutilizedarule-of-mixturestypeapproachtomeasurethe fracturetoughnessofUD-FRCs[18].Joseetal.[17]evaluatedthetensile TFTofacarbon/epoxycross-plylaminate[0/90]15aswellasits con-stituentUDlaminates,[0]30and[90]30.Theypresentedananalytical

relationshipbetweentheKICofthelaminateandthoseofitsconstituent

UDsub-laminates.However,someoftheirspecimensfailedimproperly, andtheirderivedequationseemstohaveinconsistentdimensions.Pinho etal.[28]usedasimilarapproachtodeterminetheGICassociatedwith

thetensileandcompressivefailureofUDcarbon/epoxylaminatesusing across-ply[0/90]8Slaminate.TheyusedCTandCCspecimenswiththe

dimensionsandfiberdirectionshownrespectivelyinFig.2(a)and(b) andfollowedtheASTME399procedure.However,theyregenerateda finite-widthcorrectionfactorbasedonFEMtoreplacetheonedefined inASTME399forisotropicmaterials.Theauthorsassumed:(i)thatthe mode-Icriticalenergyreleaserateofthecross-plylaminateisthesum ofenergiesassociatedwiththefiberfractureinthe0° layersandmatrix

Y. Saadati, G. Lebrun and C. Bouvet et al.

Fig.2. The CT (a) and CC (c) configurations and CT (b) and CC (d) test specimens (Dimensions in mm).

crackinginthe90° layers(theythusneglectedotherdamagemodesand interactionbetweenneighboringlayers)and(ii)thatthematrixcracking inthe90° layersoccurredasasinglecrackparalleltothenotch(similar todelaminationmode-I).Withthislastassumption,thecriticalenergy releaserateintensionisquantitativelyequivalenttothatofmode-I de-lamination.Thisassumptionseemsreasonable,asthe0° layersaremuch tougherthanthe90° layers,andisfoundtobeagoodapproximation basedontheirfindingsinapreviouswork[34].Fortheparticular cross-plylay-upstudied,theyderivedanequationusedtocalculatetheGICfor

theUDlaminate.Lateron,Laffanetal.[32]usedthefollowing general-izedformofthederivedequation(withthesameassumptions)tostudy thelay-upeffectsonthefracturetoughnessofcarbon/epoxycomposites intensilefiberfailuremode;

𝐺0 𝐼𝐶=𝑡𝑙𝑎𝑚𝑡 0 𝐺𝑙𝑎𝑚 𝐼𝐶 −𝑡𝑡90 0 𝐺90 𝐼𝐶 (1)

wheretlam,t0 andt90 arethethicknessesofthelaminate,0° and90° layerswithinthelaminate,respectively.𝐺0

𝐼𝐶 isthefractureenergy

as-sociatedwiththefibertensilefailuremode,and𝐺90

𝐼𝐶representsthe

in-tralaminarmode-Imatrixcrackingfractureenergy.Inanotherstudy, Laffanetal.[35]observedthattherewasnointeractionbetweenthe failuremodesoccurringinthe0° and90° plies.Thisresultconfirmstheir approach.Nevertheless,ithasbeenshownthatthelay-upinthe cross-plylaminatescanaffecttheGICmeasuredforthe0° plies[18,32,36,37].

Donadonetal.[38]followedthesameapproachtocalculatethefracture energyinwovencross-plylaminatesalongwithanumericalmethod. Theagreementoftheexperimentalandnumericalresultsconfirmedthe validityofthisapproach.

1.2. Translaminarfracturetoughnessincompression

BycontrasttoTFTintension,thereisnostandardtestmethod avail-abletoevaluatethefracturetoughnessofFRCsincompression.Inafew works[28,30],modifiedCTspecimensareusedincompressionwiththe

testcouponrenamedcompactcompression(CC).Pinhoetal.[28]used thesameapproachexplainedintheprevioussectionfordetermining TFTincompressionofUDlaminates.TheyusedCCspecimenswiththe configurationshowninFig.2(c)and(d)andfollowedtheASTME399 procedure.Theymadethesameassumptionsconsideringthatin com-pressionloading,thematrixcrackinginthe90° layersisclosetowhat happensindelaminationmode-II.Thus,thecriticalenergyreleaserate incompressionisquantitativelyequivalenttothatofmode-II delamina-tion.TheyusedEq.(2)tocalculatetheGICfortheUDlaminateinthe

fiberdirection;

𝐺𝐼𝐶|𝑓𝑖𝑏𝑒𝑟𝑘𝑖𝑛𝑘𝑖𝑛𝑔=2𝐺𝐼𝐶|𝑙𝑎𝑚𝑐𝑜𝑚𝑝−𝐺𝐼𝐼𝐶|𝑚𝑎𝑡𝑟𝑖𝑥𝑖𝑛𝑡𝑟𝑎 (2)

whereGIC|lamcompisthecriticalenergyreleaserateofthelaminate,as

measuredbyaCCtest,GIIC|matrixintraisthemode-IImatrixfailure

in-tralaminarfractureenergy,andGIC|fiberkinkingisthefractureenergy

as-sociatedwithfiber-kinkingfailuremode.Overall,thereisasignificant differencebetweenthefracturetoughnessvaluesreportedbythe au-thorsusingdifferentapproachestomeasurecompressiveTFT[18,33]. Perhapsthisindicatesthatconventionalmechanicaltestsarenot suit-ableforthispurpose.Thecompressivefiberfailuremodeinlaminated compositesisknownasaverycomplexphenomenon,whichisthe re-sultoffibersmicro-bucklingandformationofkink-bandsorcrushing

[28,39,40].So,andunliketension,theauthorsobservedlargedamage zones.Therefore,tomeasurethepureTFTincompression,thedamage mechanismsshouldbeseparated.

1.3. Infraredthermography/Translaminarfracturetoughnessmeasurement

In the past two decades, infrared thermography (IRT) has been broadlyusedtoinvestigatetheenergy-dissipativeprocessesin materi-als,forexample,plasticdeformationinmetals[41]ordamagein poly-mericmaterials[42].Forcompositematerials,Naderietal.[43]used IRTtocharacterizethedamageevolutioninfatigueloading.Theyfound thattheresultswereconsistentwiththoseobtainedbyacoustic

emis-Table1

Configuration and applications of flax/epoxy laminates

Plate Application Test Specimen type Layup Fiber surface density (g/m 2 ) Volume fraction (%) Thickness (mm)

1 E1922 ECT [0] 12 200 41 4.04

2 IRT CT and CC [(0/90) 4 /0] s 200 41 6.06

3 E1922 ECT [(90/0) 4 /90] s 200 41 6.06

sion,whileLisleetal.[44,45]usedittostudydamagedevelopmentin fabric-glass/epoxycomposites.Therelationbetweenfracturetoughness anddissipativeworkhasalreadybeenproved[46],anddependingon thematerial,theratioofthedissipativeworkconvertedintothermal energycanvarybetween10and100%[47,48].Lisleetal.[49]showed thatforacarbon/epoxycomposite,theratioofdissipativework con-vertedtoheatshouldbecloseto100%,butformetallicmaterials,this ratioisusuallylower.TheauthorsusedtheIRTtomeasurethefracture toughnessoftheGFRPintension[45]andthatoftheUD-carbon fiber-reinforcedpolymer(CFRP)compositeincompression[49,50].IRTmade itpossibletoseparatelyassessthedissipatedenergyduetofiberfailure incompressionandeliminatethoseassociatedwithmaterialcrushingat loadingpointsorsecondarycracks.TheyobtainedavalueofGIC=42.5

N/mmincompressionandfoundtheirresultsconsistentwiththoseof Hongkarnjanakuletal.[51](40N/mm)andotherresearchers[28,39]. ThereisnopreviousresearchusingthisapproachtoaddressNFRPCs.

Insummary,nostandardtestmethodshavebeendevelopedfor mea-suringGIC ofNFRPCsandofFRCsincompression,andaverylimited

numberofstudieshaveaddressedthesetopics,whileallNFRPCshave beentestedintension.Theseareessentialpropertiesforengineering de-signpurposesandthemodelingofthesematerialswithnumerical meth-ods,suchasFEM.Moreoverandtoourknowledge,nofractographic andmicrographicanalysisofthissubjecthavebeenperformedfor UD-flaxfiber-reinforcedepoxycomposites (FFRECs).Theworkpresented inthisstudyaimsatevaluatingthefractureenergyassociatedwiththe translaminarfailureoftheUD-FFRECs,usingtwomethodologies,along withaninvestigationofthefracturebehaviorandviabilityofthe stan-dardtestproceduresforFFRECsconsideringthattheseproceduresare usedforsynthetic(glassorcarbon)FRCs.Inthefirstmethod,the com-positewastestedaccordingtotheexistingASTME1922standard.The translaminarfracturewasstudied,andtheGICvalueintensionforcrack

propagatingperpendiculartofiberswasdeterminedandvalidated.In thesecondmethod,employingtheIRT-basedmethodologydeveloped andimplementedforthispurposebyLisleetal.[45,49,50]aswellas ASTMD5045standard,GIC ofUD-FFRECsintensionandcompression

wasdetermined,andthematerialbehaviorwasassessed.

2. Materialsystemandtestspecimens

Unidirectionalflaxfibers,FLAXTAPETM200(fromLINEO– France),

withawidthof400mmandsurfacedensityof200g/m2,wereused

toreinforceMarine820EpoxySystem,mixedwith18wt%Marine824 hardener(fromADTECH® PlasticSystems),topreparetheUD-FFREC laminates.ThecompositelaminatesweremoldedusingtheRTM pro-cess.Thelayersofflaxfiberswerestackedupaccordingtotherequired numberoflayersandorientationoffibers.300mm×300mm compos-iteplatesweremolded,startingwith[0]12and[(0/90)4/0]slaminates, respectivelyforECTandCT/CCspecimens;then,athirdconfiguration, [(90/0)4/90]s,hasbeenusedtoimprovethetranslaminarcrack

propa-gationforECTspecimens,asdetailedinTable1.

Thenumberoflayersandthicknessoflaminateswereprecisely cal-culated,accordingtotheASTMD3171procedure,andcontrolledwith spacersduringmoldingtoresultinaconstantVf=41%forallcomposite

plateswhileattainingtherequiredthicknessforthetestspecimens. ECTspecimenswerepreparedaccordingtoASTME1922for evaluat-ingtheTFTintension.Fig.1showstheconfigurationandphotographof atypicalspecimen.TheCTandCCspecimensusedforTFTmeasurement

incombinationwithIRTwerepreparedaccordingtoin-plane dimen-sionsspecifiedinPinhoetal.study[28].Theconfigurationsand pho-tographsoftypicalspecimensareshowninFig.2.ThesametypeofCT specimenwasalsousedin[31,32,35].PujolsGonzalezetal.[52]used CTandCCspecimenstoevaluateintensionandcompressionTFTof CFRPcompositesusingIRT-basedmethodology,respectively.Asimilar methodologyisadaptedandemployedinthisstudy.Rectangular speci-menswerecutbya10-inch/90-tooth,DIABLO’scuttingsawblade,with high-densitycarbidetooltips.Then,theloading-pinholesweredrilled withthehelpofsacrificedplatestoavoiddamagestothespecimens.A Protostar® minicornerradiussolidcarbideshoulder/slotmillingcutter (Protostar®-Waltertools)wasusedtocutthenotchinECTspecimens. AscanbeseeninFig.1(d),despitethelowmachinabilityofNFRPCsin termsofsurfacequality,averyneatnotchiscutwithoutdamagingthe composite.The4mm-notchontheCTandCCspecimenswerecutusing amillingcutter;thenotchmouthontheCCwaswidened,andthefinal notch(pre-crack)onCTwascutusingawiresaw.Twocleviseswere alsodesignedandmanufacturedtoeccentricallyintroducetheloadto thespecimens(Fig.1(c)).

3. Translaminarfracturetestsanddatareductionmethods

3.1. StandardtensiontestingofECTspecimens

ASTM E1922 standard involves tension testing of single-edge-notchspecimens todeterminethetensile TFTofvariouscarbon and glass/polymercomposites.However,itcanbeappliedtootherFRPCs, providedthatthespecimendimensionsandthetestresultssatisfythe requirementsofthestandard[25].Followingtheguidelinesofthis stan-dardandaimingatmeasuringthefracturetoughnessoftheUD-FFRECs inthecurrentstudy,ECTspecimens(Fig.1(b))werecutfromthe UD-FFREClaminatewithanominalthicknessof4mm(plate1inTable1). Here,thelowstiffnessoftheECTspecimensmadeitimpossibleto in-stalltheconventionalextensometers,usingknifeedges,atthe notch-mouthtomeasurethenotchmouthopeningdisplacement(NMOD). Al-ternatively,adigitalimagecorrelation(DIC)setup,synchronizedwith loadapplication,wasusedforthispurpose,asshowninFig.3(a). How-ever, noneof thefiveECTspecimenstested withsuchsetup experi-enceda self-similar(paralleltothepre-notch)crack growthanddid notresultineffectivetranslaminarcrackgrowthofconcerninthistest method.Indeed,thecrackpropagatedperpendiculartothenotchand inthefiberdirection,whichinvalidatedthetests,asshowninFig.3(b). Totheauthors’knowledge,noECTspecimensofsyntheticornatural UD-FRCshavebeentestedintheliterature,thereportedECTtestsare mostlyfornatural/syntheticfabricorcross-plyreinforcement architec-tures[18,22,23,53],andafewwerefrompultrudedcomposites[14]; therefore, no benchmark studywas possible,and these experiments wereunavoidable.

Toovercomethisdifficulty,cross-plylaminateswereusedtoavoid thelargedifferenceinstrengthbetweenthelongitudinalandtransverse directionofthetestspecimen,suchthateach0° layerisbackedbya90° layertoinhibitcrackpropagationperpendiculartothenotch,similarto theapproachin[28,32].Eq.(1)isusedtocalculatethetranslaminar fractureenergyofUDpliesusingthatofacross-plylaminateandthe ModeIandModeIIinterlaminarfractureenergiesoftheUDlaminate. Forthispurpose, asecondlaminatewasfabricated(plate3withthe laminationsequenceof[(90/0)4/90]sandnominalthicknessof6mm),

Y. Saadati, G. Lebrun and C. Bouvet et al.

Fig.3. Test setup with DIC used to measure NMOD (a) and failed ECT UD specimen (b).

Fig.4. ECT specimen; knife edges and installed extensometer (a) test setup (b), and failed sample (c).

andECTspecimens(Fig.1(a))werecutandprepared.Thesethickand stiff enoughspecimensmadepossibletheinstallationofan extensome-tertomeasurethemouthopening.Therefore,preciselymachinedknife edgeswerebondedtothespecimens’edgeonbothsidesofthenotch mouth,Fig.4,andtheextensometerMTS(632.02F-20)wasinstalled tomeasurethenotch-mouth-openingdisplacement(NMOD).Thetests wereconductedwitha0.7mm/mincrossheaddisplacementrateonan MTS(858MiniBionix-II)machine,withamounted15kNload-cell.The testsetupandspecimenareshowninFig.4(a)and(b).Thetests contin-ueduntiltheappliedforcedroppedtoamagnitudeoflessthan50%of thepeakload.Thespecimenexhibitedatranslaminarself-similarcrack growth,asexpected,Fig.4(c).

DatareductionwasperformedaccordingtoASTME1922,andthe TFTwascalculatedthroughthestressintensityfactorapproach,as;

𝐾 𝐼𝑐 = [ 𝑃 𝑚𝑎𝑥 𝐵 𝑊 1∕2 ] 𝛼1∕2 [ 1 . 4 + 𝛼] [3 . 97 − 10 . 88 𝛼 + 26 . 25 𝛼2 − 38 . 9 𝛼3 + 30 . 15 𝛼4 − 9 . 27 𝛼5 ] [ 1 − 𝛼] 3∕2 (3)

whereKIcisthecriticalstressintensityfactor(MPam1/2),Pmaxisthe

maximumappliedorfractureload(MN),𝛼 =𝑎∕𝑊 isadimensionless parameter,whileaisthenotchlength,Bisspecimenthickness,andW

isspecimenwidth(a,BandWareinmeter).Accordingtothestandard,

KIcprovides avalidmeasure ofTFT,whenthedamage zoneis

rela-tivelysmall.ThiscriterionisdefinedbasedonNMODvaluesat maxi-mumloadasΔVn/Vn−0≤0.3,forΔVnandVn−0showninFig.6.For

orthotropicplatesunderplanestress(withapre-cracksubjectedto in-planeloading),thefractureenergyGIC canbecalculatedfromKIcas

Table2

Mechanical and thermal properties of UD-FFREC ply [56]

Longitudinal elastic modulus, E 11 22.69 ∗GPa

Transverse elastic modulus, E 22 4.34 ∗GPa

Shear modulus, G 12 1.92 GPa

Poisson’s ratio, 𝜐12 0.4 ∗

Density, 𝜌 1280 kg/m 3

Specific heat, C 665 J/kg/K

Thermal conductivity in normal (z) direction, k 33 0.115 W/m/K

∗Average of the values in tension and compression.

Table3

Elastic properties of [(90/0) 4/90] slaminate

Exx (GPa) Eyy (GPa) Gxy (GPa) 𝜐xy

14.74 12.68 1.92 0.14 follow[17,28,39,54,55] 𝐺𝑙𝑎𝑚 𝐼𝑐 = 𝐾2 𝐼𝑐 √ 2𝐸𝑥𝑥𝐸𝑦𝑦 [( 𝐸𝑥𝑥 𝐸𝑦𝑦 )1∕2 + 𝐸𝑥𝑥 2𝐺𝑥𝑦 −𝜐𝑥𝑦 ]1∕2 (4) whereExx,Eyyarethelaminateelasticmodulirespectivelyinthexandy

directions(showninFigs.1(a),2(a),and(c)),Gxyisthelaminateshear

modulus,and𝜐𝑥𝑦isthePoisson’sratio.Forthe[(90/0)4/90]slaminate,

theseproperties,presentedinTable3,arecalculatedfromthoseofthe UDlaminategiveninTable2,publishedinapreviouswork[56],by usingtheclassicallaminatetheory[57].

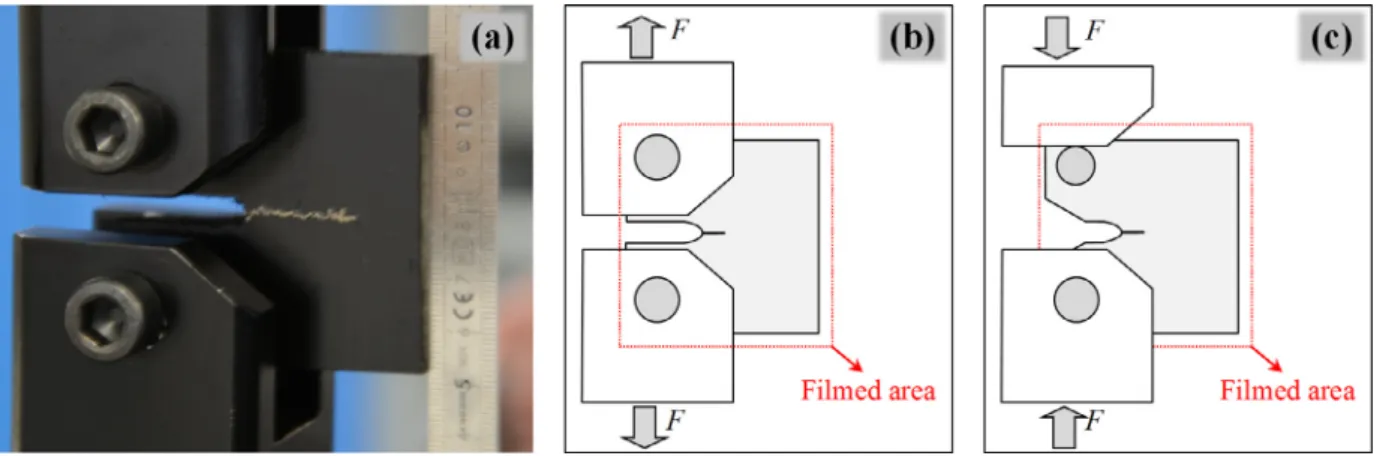

Fig.5. Experimental setup for IRT methodology (a), test specimen and thermal investigation area for CT (b) and CC (c).

3.2. Infraredthermographymethod

Inordertoovercometheproblemsexperiencedwithexperimental methodsusedtostudythetranslaminarfractureofcompositematerials, itwasproposed todevelopanapproachallowingestimatingtherate ofenergyreleaseviathetemperaturemeasurementin[43,45,49,50]. CharacterizingthefractureenergyutilizingIRTisanidea conceptual-izedbasedontheprinciplesofirreversiblethermodynamicsand thermo-mechanicallaws.Thecompletedetailsofthemethodology,includingall assumptionsmadeandtheirvalidity,arewelldescribedin45,49,50]for evaluatingthetensileandcompressivefractureenergyofFRCs,andthe readershouldrefertothesedocumentsformoredetails.

Having the dissipated energy evaluated with IRT, the fracture energy,GIC,canbedeterminedusingEq.(5)[45,49].

𝐺𝐼𝐶=𝑑𝑊𝑑𝐴𝑖𝑟𝑟𝑒𝑣= 𝑑𝛽.𝑑𝐴𝑊𝑑𝑖𝑠𝑠 (5)

wheredWirrevdenotesthetotalirreversibleenergy,dWdissistheenergy

dissipatedasheat,dAisthecracksurfacegrowthand𝛽 =𝑑𝑑𝑊𝑊𝑑𝑖𝑠𝑠

𝑖𝑟𝑟𝑒𝑣 isthe

Taylor–Quinneycoefficient(0≤𝛽 ≤1).

Somestudiesofmetallic materialsreported𝛽 ≈ 1forTa[47,49]

and0.5≤𝛽 ≤1forstainlesssteel,dependingontheappliedstrainrate

[49].However,allocatingvalueforthisratioremainsadelicateissuein thisstudy,because,novaluesareavailablefortheflax/epoxy compos-iteunderstudy.Furthermore,themagnitudeofthecoefficientisstrain andstrain-ratedependent[45,48,49].LiandLambros[48]investigated PMMAandPCpolymersintermsofthevalueof𝛽 anditssensitivity tostrainandstrain-rate.Theauthorsfounditimpossibletomeasure𝛽 forPMMA;however,theyreportedvaluesbetween50%forhighstrain and100%forlowstrain,independentofthestrain-rateintheranges oftheinvestigation.Consideringtheavailable𝛽 valuesforpolymersin theliterature,valuesof𝛽 =0.5and𝛽 =0.9werechosenforthisstudy. TheresultsarethencomparedtothoseobtainedfromtheASTME1922 standardtestmethodtoevaluatethevalidityoftheassumptions.

Inthis study,the3Dthermal analysismethodology developedin

[45,49]isutilizedtoevaluatetheheatsourcesinthecompositeusing thethermalpropertiesinTable2,fromwhichthedissipatedenergyand then,usingEq.(5),thecriticalenergyreleaserateorfractureenergyGIC

iscalculated.Forthispurpose,theadaptedCTandCCspecimensfrom

[28],showninFig.2,werecutfrom[(0/90)4/0]slaminate(Plate2in

Table1)andmechanicallyloadedintensionandcompression respec-tively.CTtestswereconductedfollowingASTMD5045standard,and CCtestswereperformedwiththesameprocedurewithacompression loading.Thetemperaturechangeatthesurfaceofthespecimen (outer-most0°-plyofthe[(0/90)4/0]slaminate)wassimultaneouslyrecorded andsynchronizedwiththeloadanddisplacementdata.Thetestsetupis showninFig.5(a).ItcanbenoticedthatfortheCCtests,thegripofthe machinewasonlyputontheaxisofloadintroductioninordertohavea

largerfilmedarea(Fig.5(c)).Thetranslaminarfracturetestswere car-riedoutonanelectromechanicaltractionmachine(INSTRON100kN) atambienttemperature(≈25°C)andaconstantdisplacementrateof2 mm/min.Thethermaldataofthespecimensurfacewasrecordedata frequencyof50Hzusinganinfraredcamera(FLIRSC7000)witha res-olutionof320×256pixels,andathermalresolutionof 0.025Kfor temperaturevariationmeasurement.Thespatialresolution(pixelsize) determinedbythefocaldistanceissetat0.264mm.Thetargetsurface ofthespecimenwaspaintedblackinordertomaximizetheemissivity coefficient,andthenthevalueissupposedtoequal1fordatatreatment. Asexpected,forCTspecimens,thethrough-the-thicknesscrack propa-gatedparalleltothe90° fibersbybreakingthefibersinthe0° layers andcreatedalmostaplanarfracturepath,Fig.5(a).Thefracturepath attheedgeofthespecimenoppositetothenotchedsideshowsthatthe crackpathisalmostplanar.

4. Resultsanddiscussion

4.1. StandardtensiontestingofECTspecimens

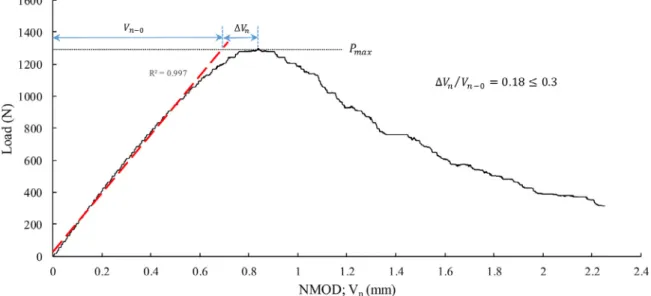

Atypicalloadvs.NMODcurveofacross-ply([(90/0)4/90]s)ECT

specimenisshowninFig.6.Fromthiscurve,itcanbeobservedthat thecompositeexhibitsalinearbehavior(R2=0.997)uptoaround80%

ofthemaximumload.Subsequently,uponinitiatingthedamagezone aheadofthenotchtip,agradualdeviationfromlinearityappearsand continuesuptothepeakload.Afterreachingthepeakvalue,theload decreasesslowlywithnosuddendrops,meaningthatastable translam-inar fractureoccursandpropagates,consistentwiththeobservations duringthetest.Similarbehaviorwasobserved forwoven-flax/epoxy compositestestedusingCCspecimens[12],woven-sisal/polyester com-posites testedusingECT[22],andwoven-sisal/PUcomposites tested byCTspecimens[19].Onamacroscopicscale,thewakeofself-similar crackcanbeseenonafailedspecimeninFig.4(c),satisfyingthe re-quirementoftheASTME1922concerningeffectivetranslaminarcrack growth. Asshown for thetypical specimenin Fig. 6, the additional NMOD duringfracture,ΔVn, fulfillsthecriterionof ASTME1922,in

thiscasewithΔVn/Vn−0=0.18 ≤0.3,andvalidatesthetranslaminar

fracturetoughness(KIC)obtainedusingEq.(3)forallthetests. Substitutingthe𝛼 parametervalueinEq.(3)andusingthemaximum load,theKICofthecross-plyspecimens([(90/0)4/90]s)wascomputed,

andtheresultsaresummarizedinTable4.Thefractureenergy(𝐺𝑙𝑎𝑚𝐼𝐶) wassubsequentlyobtainedfromthedatainTable3andEq.(4)andis alsopresentedinTable4.Asdiscussedearlier,Eq.(1)isusedtocalculate thefractureenergyofthe0° sub-laminates(𝐺0

𝐼𝐶)where𝐺90𝐼𝐶isassumed

tobeequivalentinmagnitudetothemode-Iinterlaminarfractureenergy oftheUD-FFREC,𝐺𝑑𝑒𝑙𝑎𝑚

𝐼𝐶 ,whichwasevaluatedinaseparatestudyas

𝐺𝑑𝑒𝑙𝑎𝑚

𝐼𝐶 =0.691kJ/m2[58]. Accordingly,t0 andt90 wereobtained by

Y. Saadati, G. Lebrun and C. Bouvet et al.

Fig.6. Load vs. Notch-mouth-opening displacement (NMOD) curve.

Table4

Fracture toughness and fracture energy of UD-FFREC

𝐾 𝑙𝑎𝑚

𝐼𝐶 (MPa m 1/2 ) 𝐺 𝑙𝑎𝑚𝐼𝐶 (kJ/m 2 ) 𝐾 𝐼𝐶0 (MPa m 1/2 ) 𝐺 0𝐼𝐶 (kJ/m 2 )

Mean 8.07 7.37 14.27 15.71

STD 0.30 0.55 0.57 1.23

C.O.V. (%) 3.78 7.41 3.99 7.82

pliesinthelaminate,i.e.,8and10plies.Forcomparisonpurposeswith theliteraturedata,𝐾0

𝐼𝐶oftheUD-FFREClaminatewascalculatedback

from𝐺0

𝐼𝐶anditselasticproperties(giveninTable2)usingEq.(4).The

resultsarepresentedinTable4.

Itisdifficulttocomparetheseresultswiththeliteratureconsidering theverylimitedworkspublishedonthemeasurementofTFTin NFR-PCs,particularlyFFRECs.Nevertheless,thevalueobtainedfor𝐾𝐼𝐶𝑙𝑎𝑚is inexcellentagreementwiththeresultspublishedbyLiuetal.[12]for woven-flax/epoxyCTtests,showninTable5.Theypublished𝐾𝑙𝑎𝑚

𝐼𝐶

val-uesintherangeof3to8.5MPam1/2,albeitatlowerV

f(from31%to

35%),thatcoverstheobtainedvalueinthisstudy.The𝐾𝑙𝑎𝑚

𝐼𝐶 =7.2MPa

m1/2mentionedinTable5,withthereinforcementconfigurationmost

consistentwiththecross-plylaminatetestedinthispresentstudybut forafabricinsteadofUDreinforcement inthepresentstudy,should becomparedtothevalueof𝐾𝑙𝑎𝑚

𝐼𝐶 inTable4.Overall,theirresultsare

consistentwiththefindingsofthepresentstudy,consideringtheVfand

different plyarchitecture, andthesetwostudiesconfirm eachother.

KIC =7.71 MPa m1/2 reported byAshik etal. [24]for 50/50wt%

woven-jute/epoxycomposite(Table5) isalsointherangeofthe ob-tainedresults.Thehigherfibercontent,butlowerstrengthofjutefibers couldhavebalancedthetoughnesstobeconsistentwiththeresultofthe presentwork[3,11,59].ChizyukaandKanyanga[22]obtainedKIC=6.5

MPam1/2forfabric-sisal/polyestercompositeswithV

fbetween50%to

55%(Table5).ThelowerKICofthiscompositecanbeattributedtothe lowertensilestrengthofsisalfiberscomparedtoflaxfibers[3,11,59]. Ontheother hand,Silva etal. [19]reportedGIC ≈ 11.5andGIC ≈

7kJ/m2respectivelyforafabricandshortfibersisal/PUcompositewith

Vf≈0.30(Table5).TheGICofshortfibersisal/PUcompositeisinthe

rangeofourresults,butthatofsisal-fabricismuchhigher.Dueto re-portingthetoughnessofsisal-fabric/PUintheformofGIC,itcannotbe

comparedwiththoseofsimilarmaterials;fabric-sisal/polyester compos-itereportedin[22]andtextilesisal/vinyl-esterreportedin[20],both indicatedbyKIC,seeTable5.Theauthorsattributedthehigh

perfor-manceoffabric-reinforcedPUtothebettercompatibilitybetweenNFs

andnaturalresins andtothestructureofthereinforcement.Lietal.

[20]reportedaKIC=4.2MPam1/2foratextilesisal/vinylester

com-posite atVf≈0.32,whichincreasedto6MPa m1/2 afterapplyinga

fibersurfacetreatment.Hughes etal.[11]measuredKIC =5.04and

KIC=5.62MPam1/2respectivelyforjuteandhempnon-wovenfelt

re-inforcedpolyester,Table5.ThereportedKIC≈8.5MPam1/2byIsmail

etal.[21]forUDtwisted-kenaf-yarn/polyestercompositesisalso con-sistentwiththevaluesdeterminedinthisresearch,Table5.Considering thereasonablevariabilityoftheresultsandaftercomparingthemtothe availableliteraturedata,itcanbeconcludedthatthemeasuredvalues arearealisticrepresentationofthefracturetoughnessandfracture en-ergyoftheFFREC.

4.2. FractographyoftheECTspecimens

ThefracturepathsofECTspecimenswhentheloaddroppedtoabout 0.2Pmax,areshowninFigs.4(c)and7(a).Thefailedspecimenisnot sep-aratedintotwopartstoexposethefracturesurface,soitisdifficultto examinethefractureintermsoffailuremechanisms.Ontheotherhand, separatingthetwopartsofthespecimenwouldaltertherupturefaces. Nevertheless,toperformamicrostructuralstudyandexplorethe frac-turemechanisms,oneofthespecimenswasloadeduptofullseparation toexposethefracturesurfacenearthenotchtip.

ThemicrographsareshowninFig.7(a)and(b).Atthesurfaceply, whichisa90° plyorientedparalleltothenotch,matrixcrackingand splitting oftheplyhasoccurred,andthen,withcrackgrowth, fiber-matrixdebondingandfiberbridginghavedeveloped.Inaddition,the crackemanatedfromthecornerofthenotchandpropagatedina self-similarmanner.Forfurtheranalysisofthefailuremechanisms,the frac-turesurfaceisinvestigatedfromthreeviewingdirections,asindicated inFig.8(a).Thenormalviewofthefracturesurface,Fig.8(b),clearly showsthe0° and90° layers.Fiber-matrixdebondingandmatrix crack-ingcanbeobservedin the90° plies,whilefiberfractureoccurredin the0° plies.ThesideviewinFig.8(c)showsahugefiberpull-out,fiber bundlefracture,andfiberbundlesplintering.Thesephenomenaare ac-ceptedasthedominantfailuremodescontributingtofracturetoughness incomposites[19,28,32,35].Thehighvolumeoffiberpull-outisan in-dicationofthepoorfiber-matrixadhesion(duetopoorcompatibilityof hydrophilicNFstowardsthehydrophobicpolymermatrix),resultingin weakinterfacesthathavebeenobservedseveralworks[11,20,56,60]. Althoughfiberpull-outisamechanismthataccountsforsignificant en-ergy absorptioninFRCs [11],poor fiber-matrixadhesionalongwith fiberslippageinsidetheflaxbundleafterfiberfracturecouldeasethe

Table5

Literature data for fracture toughness of NFRPCs

𝐾 𝑙𝑎𝑚

𝐼𝐶 (MPa m 1/2 ) 𝐾 𝐼𝐶𝑙𝑎𝑚 (MPa m 1/2 ) 𝐾 𝐼𝐶𝑙𝑎𝑚 (MPa m 1/2 ) 𝐺 𝑙𝑎𝑚𝐼𝐶 (kJ/m 2 ) 𝐾 𝐼𝐶𝑙𝑎𝑚 (MPa m 1/2 ) 𝐾 𝐼𝐶𝑙𝑎𝑚 (MPa m 1/2 ) 𝐾 𝑙𝑎𝑚𝐼𝐶 (MPa m 1/2 )

Ref. [12] [24] [22] [19] [20] [11] [21]

Material system Woven flax/epoxy Woven jute/epoxy Fabric sisal/polyester

Fabric and short fiber sisal/PU

Fabric sisal/vinyl ester

Jute and hemp mat/polyester

Woven kenaf/polyester Fiber content Vf = 0.31–0.35 50 wt% Vf = 0.50–0.55 Vf ≈ 0.30 Vf ≈ 0.32 Vf ≈ 0.41 No available

Toughness (3–8.5) 7.2 ( V f ≈ 0.33)

7.71 6.5 11.5 and 7 4.2–6 5.04 and 5.62 8.5

Fig.7. Fracture path of cross-ply ECT specimen; (a) whole crack growth after failure, (b) fiber bridging.

fiberpull-outwithoutacorrespondinglargeenergyabsorption.This ef-fectwillcausefiberpull-outtoshareasmallercontributiontofracture toughness.Thereisnoinformationintheliteratureaboutthefracture toughnessofflaxfibers;however,these mightbe some reasonswhy FFRECis offeringlowerTFTcompared toengineeredFRCs.The top view,Fig.8(d),revealsthedepthofthepulled-outfibersandtheseverity ofthisphenomenon.

4.3. Infraredthermographymethod

SubjectingsixCTtotensileloadandsevenCCspecimensto compres-sionload,thetranslaminarfracturetestswereconductedaccordingto themethoddescribedabove.Typicaltemperaturevariationfields mea-suredusingIRTassociatedwiththecrackpropagationarepresentedin

Fig.9.Thetemperatureincreaseobservedduringcrackpropagationis clearlyhigherfortheCTspecimensthanfortheCCones:increasingof about5°CforCTandlessthan2°CforCC.Thisresultconfirmsthe usualconclusionthatthefracturetoughnessoftranslaminarfailureis higherintensionthanincompression[28,30,33,35].Moreover,the ex-tentofwarmingoverthecouponislargerforcompression;thismeans thephenomenonofcompressivefailurecreatesalargerareaofdamage. Thecorrespondingload-displacementcurvesofCTandCCtestsare plottedinFig.10(a)and(b),respectively.ForalltheCTandCCtests,the crackpropagationstartedaboutatmaximumload.TheCTspecimens experiencedaprogressivepropagationofcrackduringtheloaddrop. ThetwofirstCCtests,CC1andCC2,hadtobestoppedat6.5mmof displacementduetoacontactbetweentheedgesofthenotch.Thenthe otherCCtestswerecontinueduntil5.5mmofdisplacementandthe sampleunloadeduntildiminishingoftheload.

Finally,theintrinsicdissipationwasevaluatedusingtheIRTmeasure forCT(Fig.10(c))andCCspecimens(Fig.10(d)).FortheCTspecimens, theintrinsicdissipationissignificant(valuehigherthan4×106J/m3)

andconcentratedatthecrackedges.InFig.10(c),theedgesofthe sam-plearealsoseenduetothemovementofthesampleduringthetest.

Evidently,thevalueof theintrinsicdissipationevaluatedatthe sam-pleedgesshouldnotbeconsidered.FortheCCspecimens,theintrinsic dissipationisrelativelylow(avaluelowerthan0.5 ×106J/m3),and

thecrackpathisbarelydetectable.Moreover,duetothescaleusedin

Fig.10(d),somemeasurednoisesarevisible.Aswillbeexplainedinthe twosubsequentsections,accordingtotheliteraturedataforsynthetic FRCs,GICincompressionislowerthanintension.Therefore,knowing thatthegeneratedheatisproportionaltoGIC,itislogicaltoobtainlower

intrinsicdissipationforCCspecimensthanforCTspecimens.However, fortheauthors,theobtainedresultforCCtestsseemstoolow.Since IRTmeasuresthetemperatureonlyatthesurface,thismightbedueto thedelamination(observedincompressiontestingofFFREC[56])and possiblebucklingoftheouterplies,whichwouldhideasignificantpart ofthecreatedheat.Hence,itwillnotbepossibletoevaluatethereal temperatureinsidethelaminate.

4.4. TensiontestingofCTspecimens

Globally,CTspecimensexhibitabrittlebehaviorwitharelatively linearresponseuptoalmostthemaximumload,whichisfollowedby asuddenandthencontinuousforcedrop,indicatingconsistentcrack growthandstiffnessreduction,asshowninFig.10(a).Thesecurvesare verysimilarandareingoodagreementwiththosereportedinthe litera-tureforCTspecimensofcarbon/epoxycomposites[28,31,32,35],which isassuchanindicationofthevalidityofthecurrenttests.Therefore, theyseemtohavesmallenoughdamagezonetousetheASTMD5045 standard,whichisdevelopedforisotropicplasticmaterials,toevaluate thefracturetoughnessforcomparisonpurposes.Thefractureenergyof theUDlaminate(𝐺𝑇 𝑒𝑛

𝐼𝐶)wascalculatedusingthesameapproachapplied

toECTspecimens,andtheresultsaresummarizedinTable6. AsshowninFig.9,forCTspecimens,thedamagezoneisminimal; thiswasalsoobservedbyPinhoetal.[28]usingC-Scan.The propa-gationofthecrackisperceivablefromthethermalimageexposedin

Y. Saadati, G. Lebrun and C. Bouvet et al.

Fig.8. Fracture surface of cross-ply ECT specimen; (a) definition of the viewing directions, (b) normal view to fracture surface, (c) normal view to specimen surface and (d) view parallel to the notch.

polymersintheliterature,twocaseswereinvestigated;firstassuming

𝛽 =0.5andsecond,𝛽 =0.9.Datatreatmentintheselectedzoneswas performedaccordingtothedevelopedandvalidatedmethodologyin

[45,49].TheobtainedfractureenergyvalueispresentedinTable6. Itcanbeseenthatthevalueof𝐺𝑇 𝑒𝑛

𝐼𝐶 obtainedbyASTMD5045,which

wasdevelopedforisotropicplasticmaterials,ismuch(≈49%)higher thanthatdeterminedbyASTME1922,speciallydevelopedforFRCs. Thelaterwasparticularlydevelopedandvalidatedbasedonsynthetic FRCs,though,accordingtothestandard,itisapplicabletoothertypes

ofFRPCsprovidedthatthecriteriaaremet.However,inthisstudy,it was appliedtoNFRPCs,which haveamore complicated microstruc-tureandmaybehavedifferently.ThisisbecauseNFsarecompositeby themselvesthatnormallycomeinbundlescontainingtechnicalfibers thatarecomposedofhelicallyarrangedmicrofibrilsasthemainforce carryingelements.Therefore,theyexhibitmorecomplexfailure behav-iorwithhighvariabilityin thematerialproperties.Thecomplex mi-crostructureoftheNFswillimposeacomplexfiberfractureleadingto different mechanismsofenergyabsorption.Consequently,asa

domi-Fig.9. Temperature variation field observed during the crack propagation of CT, (a) and CC, (b) specimens.

Fig.10. Load–displacement curves for the CT (a) and CC (b) specimens, and intrinsic heat measured by IRT for the CT (c) and CC (d) specimens.

Table6

Fracture toughness and fracture energy of UD-FFREC evaluated by IRT and standard methods

IRT ASTM standards

𝐺 𝑇 𝑒𝑛

𝐼𝐶 (kJ/m 2 ) 𝐺 𝐶𝑜𝑚𝑝𝐼𝐶 (kJ/m 2 ) 𝐺 𝑇 𝑒𝑛𝐼𝐶 (kJ/m 2 ) 𝐺 𝐼𝐶𝑇 𝑒𝑛 (kJ/m 2 ) 𝐺 𝐶𝑜𝑚𝑝𝐼𝐶 (kJ/m 2 ) 𝐺 𝐶𝑜𝑚𝑝𝐼𝐶 (𝐿𝑖𝑛𝑒𝑎𝑟)(kJ/m 2 )

𝛽 = 0.50 𝛽 = 0.90 𝛽 = 0.50 𝛽 = 0.90

E1922 D5045

Max Load Max Linear

Mean 19.88 11.10 1.30 0.77 15.71 23.37 41.29 9.84

STD 2.68 1.49 0.119 0.066 1.23 2.28 3.56 0.39

Y. Saadati, G. Lebrun and C. Bouvet et al.

nantfailuremechanism,thecomplexfractureofNFswillinfluencethe fracturetoughnessofthecompositeandmayrequireadifferent deter-minationmethod.

Nevertheless,thereisnostandardtestmethoddevelopedfortesting NFRPCsandno literaturedataavailabletovalidate theresults. Con-sequently,forthetimebeing,𝐺𝑇 𝑒𝑛

𝐼𝐶determinedbyASTME1922canbe

consideredasthemost reliabletensileTFTvaluefortheunderstudy FFRECs.ThisvalueisplacedbetweenthevaluesobtainedbyIFT analy-sisfor𝛽 =0.90and𝛽 =0.50by±29%difference.Consideringthehigh variabilityofmaterialpropertiesforNFs,thesevaluescouldbe consid-eredconsistentwiththatofthestandardmethod.Ingeneral,eventhe dataavailableforsyntheticFRPCsarescattered,forinstance,CTtests ofauniqueCFRPcompositeshowmorethan15%variation[30,35]. However,assumingtheresultofthestandardmethodastherealvalue, itmaybeconcluded thattherealisticvalueof 𝛽 fortheunderstudy flax/epoxyisbetweenthemargins(0.50and0.90)usedforanalysis,or, technicallyspeaking,theratioofdissipativeworkconvertedintoheat inthiscompositeisbetween50%and90%.ConsideringthatGICisan inverselinearfunctionof𝛽,thisratioforthecompositecanbe calcu-latedbackfromtheresultofthestandardtest(𝛽 =0.69)andbeusedin thefuturecalculationofthefractureenergy,forinstanceincompressive failuremode,presentedinthefollowingsection.Consequently,having apreciseenoughvaluefor𝛽,theemployedmethodbasedonIRTcanbe confidentlyusedtodeterminethefractureenergyofthecomposites.

Naturally,thefailuremodesinCTspecimensarethesameoccurring inECT,asdiscussedintheprevioussection.

4.5. CompressiontestingofCCspecimens

Theload-displacementresponseoftheCCtests(Fig.10(b))ismore difficulttointerpret.Ascanbeobserved,CCspecimensexhibited com-plex,butsimilarbehaviorincompressionloading.Thesimilarityofthe curvesindicatesagood reproducibilityandthecertaintyof thedata recordedforthecompositesunderstudy.Thecompositedisplaysa lin-earbehavioruptoadisplacementofabout1.2mm(1500Nofloading), whereaclearslopereductionhappens.Afterthispoint,arelatively lin-earresponsecontinuesuntiladisplacementof3mmfollowedbya non-linearcurveuptothemaximumload.Forallofthespecimens,thevisual signsoffailureoccurredatthemaximumload,anduponreachingthis point,theloadslowlydroppeduntilthetestwasstopped.The load-displacementresponseoftheseCCspecimensismoreorlessanalogous tothatof carbon/epoxyCCspecimens [28,30]; however,flax/epoxy compositedemonstrates muchhighernonlinearity.TheASTMD5045 standardwasfirstemployedtoevaluatethefracturetoughnessin com-pressionofthecross-plylaminateusingthemaximumload.Then,the fractureenergyof theUDlaminate incompression (𝐺𝐶𝑜𝑚𝑝𝐼𝐶 ) was cal-culatedfollowingtheaforementioned approach usedbyPinho etal.

[28]forCCspecimensandassuming that𝐺90

𝐼𝐶 isequivalentin

mag-nitudetothemode-IIinterlaminarfractureenergyof theUD-FFREC,

𝐺𝑑𝑒𝑙𝑎𝑚

𝐼𝐼𝐶 ,whichwasevaluatedinaseparatestudyas𝐺𝑑𝑒𝑙𝑎𝑚𝐼𝐼𝐶 =0.378kJ/m2,

theresultsaresummarizedinTable6.However,theresultis unreason-ablyhighercomparedto𝐺𝑇 𝑒𝑛𝐼𝐶,whereasitisexpectedtobelowerfor compressiontesting[28,30,33,35].Thisshouldbeduetothe nonlinear-itythatcorrespondstosomedamagesorplasticityinthesampleand meansthatanimportantpartofthedissipatedenergyisnotduetothe crackpropagationbuttoothersecondarydamagephenomena. There-fore,theonsetofdamagemusthavehappenedmuchbeforereaching themaximumloadpoint.Consideringthelowstiffnessofflaxfibersin compressionandthepoorfiber-matrixadhesion,thisfailuremodeisa matrix-drivenfailure.Thus,itisexpectedthattheisotropicepoxy ma-trixexhibitsalinearbehavioruptofailure.Therefore,theoretically,the compositetranslaminarfailureincompressionshouldstartinthe end-pointofthefirstlinearpart,afterwhich,bythedevelopmentofother secondarymaterialdamages,thestiffnessofthesampleandtheslope ofthecurvereduce.Asaresult,theloadatthispointisconsideredas thecompressivetranslaminarfailureloadandisusedtoevaluatethe

𝐺𝐶𝑜𝑚𝑝𝐼𝐶 ofthecomposite,theresultispresentedin Table6.The litera-ture datafor𝐺𝐼𝐶𝐶𝑜𝑚𝑝isvery scattered,forinstance,conducting4-point bendingtests,Laffanetal.[61]measuredvalueof𝐺𝐶𝑜𝑚𝑝𝐼𝐶 =25.9kJ/m2

forIM7/8552CFRP,whileCatalanottietal.[30]reported𝐺𝐶𝑜𝑚𝑝𝐼𝐶 =47.5 kJ/m2 forthesamematerialsystemandPinhoetal.[28]published

𝐺𝐶𝑜𝑚𝑝𝐼𝐶 =79.9kJ/m2foranotherCFRP,bothusingCCspecimens.

There-fore,thevalueinthisrangecanbeagoodrepresentativeofthefracture energyofthecomposite.Nevertheless,thecomplexmicrostructureof theNFcompositeand,consequently,itscomplexbehaviorincreasesthe difficultyofrecognizingtheprecisefailurepointandneedsdeeper anal-ysis.

Fig.9showsthatCCspecimensexperiencemuchbroaderdamage zonecomparedtoCTspecimens,alsoobserved byPinhoetal.[28]. However, theonsetof failureandpropagation ofthe crackcouldn’t berecognizedinthethermalimagesandtheexperimentalheatsource fields.

InasimilarapproachtoCTtests,assuming𝛽 =0.50and𝛽 =0.90 thedatawereprocessedtodeterminethetranslaminarfractureenergy incompression(𝐺𝐼𝐶𝐶𝑜𝑚𝑝),andtheobtainedvaluesaregiveninTable6.As expected,thevaluesarelowerthanthoseforCTtests,thoughtheyare obviouslytoolow,indicatingthattheIRTmethodologyis underestimat-ingthefractureenergyincompressionforthesecomposites.Thereisno availableliteraturedatafor𝐺𝐶𝑜𝑚𝑝𝐼𝐶 tobecomparedwiththeobtained val-ues;however,theproportionofthe𝐺𝑇 𝑒𝑛

𝐼𝐶 to𝐺𝐶𝑜𝑚𝑝𝐼𝐶 forothercomposites

evidentlyshowsthatthesethemeasuredvaluesbyIFTdonotrepresent the𝐺𝐶𝑜𝑚𝑝𝐼𝐶 ofthecomposite.Consideringthepresenceofcomplexfailure modesinCCspecimens,whichismorecomplicatedforNFcomposites, itisnottrivialtoperformaroot-cause-analysisforthisissue;however, some hypothesescan bemade.A previousstudyshowsthatthe UD-FFRECexperiencesdelaminationdamageincompressionfailure[56]; thismaybethecaseforthecross-plyCCspecimen.Therefore,the sur-facelayermighthavebeendelaminatedbeforeatranslaminarfailure occursandthenbuckledintheout-of-planedirectionsothatthe gener-atedheatinthesurfaceplyisnotassociatedwithatranslaminarfailure andcouldbetheresultofotherfailuremodes,likebuckling, produc-ingmuchlessheat.Itcouldalsoberelatedtothemicrostructureofthe flaxfiberssothat,undercompressionloading,theirinternalstructure collapses,withthefibersbeingcompressedinthemselvestogenerate re-versibleenergy,ratherthanfailingtoproducethermalenergy.Finally, thepoorfiber-matrixadhesioncouldmakethefibersineffectivein car-ryingthecompressionload;thus,thefractureenergycouldbemostly relatedtomatrixfailureincompression.Thishypothesisissupported byMode-II interlaminarfractureenergyofUD-FFREC, 𝐺𝑑𝑒𝑙𝑎𝑚

𝐼𝐼𝐶 =0.378

kJ/m2,measuredinanotherstudy[58],astheirfailuremodesare

sim-ilar,andthefractureenergyvaluesareclose.

Insummary,usingIRTandcross-plylaminates,validvaluescannot bedeterminedfor𝐺𝐶𝑜𝑚𝑝𝐼𝐶 oftheUD-FFRECs.However,assumingthatthe failurestartsattheendofthefirstlinearpartoftheload-displacement curveandusingtheASTMD5045standard,areasonablevaluecanbe achievedfor𝐺𝐶𝑜𝑚𝑝𝐼𝐶 oftheUD-FFRECs.

5. Conclusions

Thisstudyhasinvestigatedthefracturebehaviorandevaluatedthe fracturetoughnessparametersoftheUD-FFRECsunderquasi-static ten-sile andcompressive loads. Theexisting ASTM E1922 standard test methodwasemployedtoexaminethefracturetoughnessofECT speci-mensintension,andanalreadydevelopedmethodologybasedonIRT, aswellasASTMD5045,wereappliedtostudythefractureenergyin tensionandcompressionrespectivelyusingCTandCCspecimens. Af-terward,combiningthemicrographsandtheload-NMODcurves,the fracturebehaviorandthefracturemechanismsofthecompositewere studied.

ApplyingtheASTME1922standardtestmethodtodeterminethe tensilefracturetoughnessusingUDlaminateswasimpossible,andthe

self-similartranslaminarcrackgrowthofconcernwasnotexhibited.A cross-plylaminatewasinsteadusedtoevaluatethefracturetoughness ofthelaminateandextractthatofUDcompositefollowinganapproach thatwasalreadyusedandprovedvalidinsomeearlierstudies.Although therearenopublishedfracturepropertydataforthesecompositesfor comparison,theobtainedvalues(GIC=15.71kJ/m2andKIC=14.27

MPam1/2)fitverywellintherangeofthoseofthesimilarNFPCs

avail-ableintheliterature.

Experimental testsusing IRTwereconducted,andemployingthe developedprogram, the dataweretreated todeterminethefracture toughnessofthecompositeintensileandcompressiveloadingsusingCT andCCcross-plycompositespecimens,respectively.Anassumptionof

𝛽 =0.5and𝛽 =0.9wasmadefortheTaylor–Quinneycoefficientbased ontheexistingvaluesforsimilarmaterials.Comparedtothestandard testresults,CTspecimensdemonstratedproperadequacyforthis pur-pose;however,theresultsofCCtestsweretoolowandthus unsatisfac-tory.EmployingthismethodologytoCTtests,thevaluesof𝐺𝑇 𝑒𝑛

𝐼𝐶 =19.88

and11.1kJ/m2,respectivelyfor𝛽 =0.5and𝛽 =0.9,wereobtained.

Theresults ofIRT areconsistentwith andarecoveringthose ofthe ASTME1922,showingthattherealvalueof𝛽 isbetweenthetwo as-sumedvalues.Therefore,theapplicationoftheIRTmethodfor evalu-atingtensiletranslaminarfractureenergyofUD-flax/epoxycomposites usingCTtestsisvalidated;however,theaccuracyofIRTfor determin-ingthecompressivetranslaminarfractureenergyusingCCspecimensis notproved.Instead,forCCtestsitwasconcludedthatusingthe max-imumloadoftheinitiallinearload-displacementcurveasthefailure loadandASTMD5045standardleadstoareasonablecompressive frac-tureenergy𝐺𝐶𝑜𝑚𝑝𝐼𝐶 =9.84kJ/m2.Thefractographystudyrevealsthatthe

primarymechanismsactivatedintranslaminarfailurearefiberpull-out, fiberbreakage,andfiber-matrixdebonding.Toconclude,aviewofthe translaminarfracturebehavioroftheUD-FFRECshasbeendrawn,and thetranslaminarfracturetoughnessparametersin thefiberdirection andundertensileandcompressiveloadingsaredetermined.These val-uesarethemostreliabledataeverobtainedtobeusedinengineering designandnumericalsimulationstudies.

DeclarationofCompetingInterest

Theauthorsdeclarethattheyhavenoknowncompetingfinancial interestsorpersonalrelationshipsthatcouldhaveappearedtoinfluence theworkreportedinthispaper.

CRediTauthorshipcontributionstatement

YousefSaadati:Conceptualization,Investigation,Formalanalysis, Datacuration,Validation,Writing-originaldraft.GilbertLebrun: Con-ceptualization,Supervision,Writing-review&editing,Funding acquisi-tion.ChristopheBouvet:Investigation,Methodology,Software,Formal analysis,Writing-review&editing.Jean-FrançoisChatelain: Concep-tualization,Supervision,Writing-review&editing, Funding acquisi-tion.YvesBeauchamp:Conceptualization,Supervision,Writing- re-view&editing,Fundingacquisition.

Acknowledgments

TheauthorssincerelythankMr. DanielPoirierandhiscolleagues fromCDCQ(CentrededéveloppementdescompositesduQuébec),for moldingthecompositeplates,aswellasSergePlamondonand Claude-DanielLegaultwhoprovidedtechnicalassistancethatgreatlyassisted usinthisresearch.ThisworkwassupportedbytheNaturalSciences andEngineeringResearchCouncilofCanada(NSERC)[grantnumber

RGPIN-2017-04305].

Dataavailability

Theraw/processeddatarequiredtoreproducethesefindingscannot besharedatthistimeasthedataalsoformspartofanongoingstudy.

References

[1] T.G. Yashas Gowda , M.R. Sanjay , K. Subrahmanya Bhat , P. Madhu , P. Senthama- raikannan , B. Yogesha , Polymer matrix-natural fiber composites: an overview, Co- gent Eng. 5 (2018) 1446667 .

[2] M. Fuqua , S. Huo , C. Ulven , Natural fiber reinforced composites, Polym. Rev. 52 (2012) 259–320 .

[3] M. Ramesh , K. Palanikumar , K. Reddy , Plant fibre based bio-composites: sustainable and renewable green materials, Renew. Sustain. Energy Rev. 79 (2017) 558–584 .

[4] D.U. Shah , P.J. Schubel , M.J. Clifford , Can flax replace E-glass in structural com- posites? A small wind turbine blade case study, Compos. B: Eng. 52 (2013) 172–181 .

[5] A. Moudood , A. Rahman , A. Öchsner , M. Islam , G. Francucci , Flax fiber and its com- posites: an overview of water and moisture absorption impact on their performance, J. Reinforc. Plast. Compos. 38 (2018) 323–339 .

[6] L. Yan , N. Chouw , K. Jayaraman , Flax fibre and its composites – a review, Compos. B: Eng. 56 (2014) 296–317 .

[7] S. Goutianos , T. Peijs , The optimisation of flax fibre yarns for the development of high-performance natural fibre composites, Adv. Compos. Lett. 12 (2003) 237–241 .

[8] S. Goutianos , T. Peijs , B. Nystrom , M. Skrifvars , Development of flax fibre based textile reinforcements for composite applications, Appl. Compos. Mater. 13 (2006) 199–215 .

[9] H.M. Khanlou , P. Woodfield , J. Summerscales , G. Francucci , B. King , S. Talebian , et al. , Estimation of mechanical property degradation of poly(lactic acid) and flax fibre reinforced poly(lactic acid) bio-composites during thermal processing, Mea- surement 116 (2018) 367–372 .

[10] S. Haldar , M. Herráez , F. Naya , C. González , C.S. Lopes , Relations between intralami- nar micromechanisms and translaminar fracture behavior of unidirectional FRP sup- ported by experimental micromechanics, Compos. B: Eng. 174 (2019) 107000 .

[11] M. Hughes , C. Hill , J. Hague , The fracture toughness of bast fibre reinforced polyester composites Part 1 evaluation and analysis, J. Mater. Sci. 37 (2002) 4669–4676 .

[12] Q. Liu , M. Hughes , The fracture behaviour and toughness of woven flax fibre rein- forced epoxy composites, Compos. A: Appl. Sci. Manuf. 39 (2008) 1644–1652 .

[13] B.G. Falzon , P. Apruzzese , Numerical analysis of intralaminar failure mechanisms in composite structures. Part I: FE implementation, Compos. Struct. 93 (2011) 1039–1046 .

[14] R. El-Hajjar , R. Haj-Ali , Mode-I fracture toughness testing of thick section FRP com- posites using the ESE(T) specimen, Eng. Fract. Mech. 72 (2005) 631–643 .

[15] A. Faggiani , B. Falzon , Predicting low-velocity impact damage on a stiffened com- posite panel, Compos. A: Appl. Sci. Manuf. 41 (2010) 737–749 .

[16] H.A. Israr , S. Rivallant , C. Bouvet , J.J. Barrau , Finite element simulation of 0°/90°CFRP laminated plates subjected to crushing using a free-face-crushing con- cept, Compos. A: Appl. Sci. Manuf. 62 (2014) 16–25 .

[17] S. Jose , R.R. Kumar , M. Jana , G.V. Rao , Intralaminar fracture toughness of a cross– ply laminate and its constituent sub-laminates, Compos. Sci. Technol. 61 (2001) 1115–1122 .

[18] M.J. Laffan , S. Pinho , P. Robinson , A. McMillan , Translaminar fracture toughness testing of composites: a review, Polym. Test. 31 (2012) 481–489 .

[19] R.V. Silva , D. Spinelli , W.W. Bose Filho , S. Claro Neto , G.O. Chierice , J.R. Tarpani , Fracture toughness of natural fibers/castor oil polyurethane composites, Compos. Sci. Technol. 66 (2006) 1328–1335 .

[20] Y. Li , Y-W Mai , L. Ye , Effects of fibre surface treatment on fracture-mechanical prop- erties of sisal-fibre composites, Compos. Interfaces 12 (2005) 141–163 .

[21] A.E. Ismail , S.H. Masran , S. Jamian , K.A. Kamarudin , M.K. Mohd Nor , N.H.M. Nor , et al. , Fracture toughness of woven kenaf fibre reinforced composites, IOP Conf. Ser.: Mater. Sci. Eng. 160 (2016) 012020 .

[22] C. Chizyuka , Effects of hydrothermal ageing on the fracture damage of sisal fibre reinforced polyester composites, Zambian Eng. 46 (2013) 11–19 .

[23] B.M. G , T.N. Vijaykumar , D.B. K N , Jmsse , Optimization of notch parameter on frac- ture toughness of natural fiber reinforced composites using taguchi method, J. Mater. Sci. Surf. Eng. 3 (2015) 244–248 .

[24] K.P. Ashik , R.S. Sharma , N. Raghavendra , Evaluation of tensile, modal and fracture properties of jute/epoxy natural composites with addition of silicon di oxide as filler material, Mater. Today: Proc. 4 (2017) 9586–9591 .

[25] ASTM, Standard Test Method for Translaminar Fracture Toughness of Laminated and Pultruded Polymer Matrix Composite Materials, ASTM International, West Con- shohocken, PA, 2015 .

[26] J. Underwood , M. Kortschot , W. Lloyd , H. Eidinoff, D. Wilson , N. Ashbaugh , Translaminar fracture toughness test methods and results from interlaboratory tests of carbon/epoxy laminates, Fract. Mech. 1256 (1995) 486–508 26th VolumeASTM STP .

[27] R. Piascik , J. Newman , J. Underwood , The extended compact tension specimen, Fatigue Fract. Eng. Mater. Struct. 20 (1997) 559–563 .

[28] S.T. Pinho , P. Robinson , L. Iannucci , Fracture toughness of the tensile and compres- sive fibre failure modes in laminated composites, Compos. Sci. Technol. 66 (2006) 2069–2079 .

[29] L.W.H. Leonard , K.J. Wong , K.O. Low , B.F. Yousif , Fracture behaviour of glass fi- bre-reinforced polyester composite, Proc. Inst. Mech. Eng. L: J. Mater.: Des. Appl. 223 (2009) 83–89 .

[30] G. Catalanotti , P.P. Camanho , J. Xavier , C.G. Dávila , A.T. Marques , Measurement of resistance curves in the longitudinal failure of composites using digital image correlation, Compos. Sci. Technol. 70 (2010) 1986–1993 .

[31] M.J. Laffan , S.T. Pinho , P. Robinson , L. Iannucci , Measurement of the in situ ply fracture toughness associated with mode I fibre tensile failure in FRP. Part I: data reduction, Compos. Sci. Technol. 70 (2010) 606–613 .

Y. Saadati, G. Lebrun and C. Bouvet et al.

[32] M.J. Laffan , S.T. Pinho , P. Robinson , L. Iannucci , Measurement of the in situ ply fracture toughness associated with mode I fibre tensile failure in FRP. Part II: size and lay-up effects, Compos. Sci. Technol. 70 (2010) 614–621 .

[33] H. Liu , B. Falzon , G. Catalanotti , W. Tan , An experimental method to determine the intralaminar fracture toughness of high-strength carbon-fibre reinforced composite aerostructures, Aeronaut. J. 122 (2018) 1352–1370 .

[34] S. Pinho , P. Robinson , L. Iannucci , Developing a four point bend specimen to measure the mode I intralaminar fracture toughness of unidirectional laminated composites, Compos. Sci. Technol. 69 (2009) 1303–1309 .

[35] M.J. Laffan , S.T. Pinho , P. Robinson , A.J. McMillan , Translaminar fracture tough- ness: the critical notch tip radius of 0° plies in CFRP, Compos. Sci. Technol. 72 (2011) 97–102 .

[36] M. Laffan , S. Pinho , P. Robinson , L. Iannucci , Fracture toughness measurement for mode i fibre tensile failure in FRP, in: Proceedings of the International Conference on Composite Materials, 2009 .

[37] R.F. Teixeira , S.T. Pinho , P. Robinson , Thickness-dependence of the translaminar fracture toughness: experimental study using thin-ply composites, Compos. A: Appl. Sci. Manuf. 90 (2016) 33–44 .

[38] M.V. Donadon , B.G. Falzon , L. Iannucci , J.M. Hodgkinson , Intralaminar toughness characterisation of unbalanced hybrid plain weave laminates, Compos. A: Appl. Sci. Manuf. 38 (2007) 1597–1611 .

[39] C. Soutis , P. Curtis , A method for predicting the fracture toughness of CFRP laminates failing by fibre microbuckling, Compos. A: Appl. Sci. Manuf. 31 (2000) 733–740 .

[40] R. Gutkin , S.T. Pinho , P. Robinson , P.T. Curtis , On the transition from shear-driven fibre compressive failure to fibre kinking in notched CFRP laminates under longitu- dinal compression, Compos. Sci. Technol. 70 (2010) 1223–1231 .

[41] S. Dumoulin , H. Louche , O.S. Hopperstad , T. Børvik , Heat sources, energy storage and dissipation in high-strength steels: experiments and modelling, Eur. J. Mech. – A/Solids 29 (2010) 461–474 .

[42] B. Wattrisse , J-M Muracciole , A. Chrysochoos , Thermomechanical effects accom- panying the localized necking of semi-crystalline polymers, Int. J. Therm. Sci. 41 (2002) 422–427 .

[43] M. Naderi , A. Kahirdeh , M.M. Khonsari , Dissipated thermal energy and damage evo- lution of Glass/Epoxy using infrared thermography and acoustic emission, Compos. B: Eng. 43 (2012) 1613–1620 .

[44] T. Lisle , C. Bouvet , M-L Pastor , T. Rouault , P. Margueres , Damage of woven com- posite under tensile and shear stress using infrared thermography and micrographic cuts, J. Mater. Sci. 50 (2015) 6154–6170 .

[45] T. Lisle , C. Bouvet , M.L. Pastor , P. Margueres , R. Prieto Corral , Damage analysis and fracture toughness evaluation in a thin woven composite laminate under static tension using infrared thermography, Compos. A: Appl. Sci. Manuf. 53 (2013) 75–87 .

[46] L.B. Freund , JW. Hutchinson , High strain-rate crack growth in rate-dependent plastic solids, J. Mech. Phys. Solids 33 (1985) 169–191 .

[47] R. Kapoor , S. Nemat-Nasser , Determination of temperature rise during high strain rate deformation, Mech. Mater. 27 (1998) 1–12 .

[48] Z. Li , J. Lambros , Strain rate effects on the thermomechanical behavior of polymers, Int. J. Solids Struct. 38 (2001) 3549–3562 .

[49] T. Lisle , C. Bouvet , N. Hongkarnjanakul , M-L Pastor , S. Rivallant , P. Margueres , Mea- sure of fracture toughness of compressive fiber failure in composite structures using infrared thermography, Compos. Sci. Technol. 112 (2015) 22–33 .

[50] T. Lisle , N. Hongkarnjanakul , C. Bouvet , M-L Pastor , P. Margueres , S. Rivallant , Mea- sure of fracture toughness in composite structures using infrared thermography, in: Proceedings of the ECCM16 – Sixteenth European Conference on Composite Mate- rials, Seville, Spain, 2014 .

[51] N. Hongkarnjanakul , C. Bouvet , S. Rivallant , Validation of low velocity impact mod- elling on different stacking sequences of CFRP laminates and influence of fibre fail- ure, Compos. Struct. 106 (2013) 549–559 .

[52] J.D. Pujols Gonzalez , C. Bouvet , B. Vieille , Translaminar cracking modelling in wo- ven ply composite laminates at high temperature, in: Proceedings of the ECCM19 – Nineteenth European Conference on Composite Materials, Nantes, France, 2020 .

[53] F. Hou , S. Hong , Characterization of R-curve behavior of translaminar crack growth in cross-ply composite laminates using digital image correlation, Eng. Fract. Mech. 117 (2014) 51–70 .

[54] P. Paris , G. Sih , Stress analysis of cracks, in: Fracture Toughness Testing and its Applications Chicago: ASTM-STP 381, 1965, pp. 30–83 .

[55] S.T. Lin , Z. Feng , R.E. Rowlands , Thermoelastic determination of stress intensity factors in orthotropic composites using the J-integral, Eng. Fract. Mech. 56 (1997) 579–592 .

[56] Y. Saadati , G. Lebrun , J.-F. Chatelain , Y. Beauchamp , Experimental investigation of failure mechanisms and evaluation of physical/mechanical properties of unidirec- tional flax–epoxy composites, J. Compos. Mater. (2020) 0021998320902243 .

[57] M.W. Hyer , SR. White , Stress Analysis of Fiber-Reinforced Composite Materials, DEStech Publications, Inc, 2009 .

[58] Y. Saadati , J-F Chatelain , G. Lebrun , Y. Beauchamp , P. Bocher , N. Vanderesse , A study of the interlaminar fracture toughness of unidirectional flax/epoxy composites, J. Compos. Sci. 4 (2020) 66 .

[59] D.K. Rajak , D.D. Pagar , P.L. Menezes , E. Linul , Fiber-reinforced polymer composites: manufacturing, properties, and applications, Polymers 11 (2019) 1667 .

[60] M. Habibi , G. Lebrun , L. Laperrière , Experimental characterization of short flax fiber mat composites: tensile and flexural properties and damage analysis using acoustic emission, J. Mater. Sci. 52 (2017) 6567–6580 .

[61] M. Laffan , S. Pinho , P. Robinson , L. Iannucci , A. McMillan , Measurement of the fracture toughness associated with the longitudinal fibre compressive failure mode of laminated composites, Compos. A: Appl. Sci. Manuf. 43 (2012) 1930–1938 .