To cite this

this version :

Delmotte, Blaise and Climent, Eric and

Plouraboué, Franck A general formulation of Bead Models applied

to flexible fibers and active filaments at low Reynolds number.

(2015) Journal of Computational Physics, vol. 286 . pp. 14-37. ISSN

0021-9991

O

pen

A

rchive

T

OULOUSE

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID :

13585

To link to this article

:

DOI:10.1016/j.jcp.2015.01.026

http://dx.doi.org/10.1016/j.jcp.2015.01.026

Any correspondance concerning this service should be sent to the repository

administrator:

staff-oatao@listes-diff.inp-toulouse.fr

A

general

formulation

of

Bead

Models

applied

to

flexible

fibers

and

active

filaments

at

low

Reynolds

number

Blaise Delmotte

a,

b,

Eric Climent

a,

b,

Franck Plouraboué

a,

b,

∗

aUniversityofToulouse–INPT-UPS, InstitutdeMécaniquedesFluides,Toulouse,France bIMFT–CNRS,UMR55021,AlléeduProfesseurCamilleSoula,31400Toulouse,France

a

b

s

t

r

a

c

t

Keywords: BeadModels Fibersdynamics Activefilaments Kinematicconstraints StokesflowsThis contribution provides a general framework to use Lagrange multipliers for the simulation of low Reynolds number fiber dynamics based on Bead Models (BM). This formalismprovidesanefficientmethodtoaccountforkinematicconstraints.Weillustrate, with several examples, to which extent the proposed formulation offers aflexible and versatile framework for the quantitative modeling of flexible fibers deformation and rotationinshear flow,the dynamicsofactuatedfilaments and the propulsionofactive swimmers. Furthermore, a new contact model called Gears Model is proposed and successfullytested.Itavoidstheuseofnumericalartificessuchasrepulsiveforcesbetween adjacentbeads,asourceofnumericaldifficultiesinthetemporalintegrationofprevious BeadModels.

1. Introduction

Thedynamicsofsolid–liquid suspensionsisalongstanding topicofresearch whileitcombinesdifficultiesarisingfrom thecouplingofmulti-bodyinteractionsinaviscousfluidwithpossibledeformationsofflexibleobjectssuchasfibers.Avast literatureexists ontheresponse ofsuspensionsofsolid sphericalornon-sphericalparticles duetoits ubiquitousinterest innaturalandindustrial processes.When the objectshavethe abilityto deform manycomplications arise.The coupling between suspended particles will depend on the positions (possibly orientations) but also on the shape of individuals, introducingintricateeffectsofthehistoryofthesuspension.

Whentheaspectratioofdeformableobjectsislarge,thosearegenerallydesignatedasfibers.Manyprevious investiga-tionsoffiberdynamics,havefocusedonthedynamicsofrigidfibersorrods[1,2].Comparedtotheverylarge numberof referencesrelatedtoparticlesuspensions,lower attentionhasbeenpaidtothemorecomplicatedsystemofflexiblefibers inafluid.

Suspension offlexible fibersare encountered inthestudyof polymerdynamics [3,4]whose rheology dependsonthe formationofnetworksandtheoccurrenceofentanglement.Themotionoffibersinaviscous fluidhasa strongeffecton itsbulkviscosity,microstructure,drainagerate,filtrationability,andflocculationproperties.Thedynamicresponseofsuch complexsolutions isstillan open issuewhiletime-dependentstructuralchangesof thedispersedfibers candramatically modifytheoverallprocess(suchasoperationunitsinwoodpulpandpaperindustry,flowmoldingtechniquesofcomposites,

*

Correspondingauthorat:UniversityofToulouse–INPT-UPS,InstitutdeMécaniquedesFluides,Toulouse,France.Tel.:+33534322880. E-mailaddresses:blaise.delmotte@imft.fr(B. Delmotte),eric.climent@imft.fr(E. Climent),franck.plouraboue@imft.fr(F. Plouraboué).waterpurification).BiologicalfiberssuchasDNAoractinfilamentshavealsoattractedmanyresearchestounderstandthe relationbetweenflexibilityandphysiologicalproperties[5].

Flexible fibers do not only passively respondto carrying flow gradients but can also be dynamically activated. Many of singlecell micro-organisms that propel themselves ina fluid utilizea long flagellum tailconnected to the cell body. Spermatozoa(andmoregenerallyone-armedswimmers)swim bypropagatingbendingwavesalongtheirflagellumtailto generatea nettranslationusingcyclicnon-reciprocalstrategyatlow Reynoldsnumber[6].Thesenaturalswimmershave beenmodeledbyartificialswimmers(jointmicrobeads)actuatedbyanoscillatingambientelectricormagneticfieldwhich opensbreakthroughtechnologiesfordrugon-demanddeliveryinthehumanbody[7].

Many numerical methods have been proposed to tackle elasto–hydrodynamiccoupling between a fluid flow and de-formableobjects,i.e.thebalancebetweenviscousdragandelasticstresses.Amongthose,“mesh-oriented”approacheshave theambitionofsolving acompletecontinuum mechanics descriptionofthefluid/solidinteraction,eventhough some ap-proximations are mandatory to describe thoseatthe fluid/solid interface.Without beingall-comprehensive, one cancite immerseboundarymethods(e.g.[8–11]),extendedfiniteelements(e.g.[12]),penaltymethods[13,14],particle-meshEwald methods[15],regularizedStokeslets[16,17],ForceCouplingMethod[18].

InthespecificcontextoflowReynoldsnumberelastohydrodynamics[19],difficultiesarisewhennumericallysolvingthe dynamicsofrigidobjectssincethetimescaleassociatedwithelasticwavespropagationwithinthesolidcanbesimilarto the viscous dissipationtime-scale. In thecontext ofself propelledobjectsthe ratioofthesetime scales iscalled“Sperm number”. When the Sperm numberis smaller orequal to one, the object temporal response is stiff, andrequires small timestepstocapturefastdeformationmodes.Inthisregime,fluid/structureinteractioneffectsaredifficulttocapture. One possible way to circumvent such difficulties is to use the knowledge of hydrodynamic interactions of simple objects in Stokesflow.

This strategy is theone pursued by the Bead Model(BM) whose aim isto describe a complex deformable objectby theflexibleassemblyofsimplerigidones.Suchflexibleassembliesaregenerallycomposedofbeads(spheresorellipsoids) interacting by some elasticandrepulsive forces,aswell aswiththesurrounding fluid.For longelongated structures, al-ternative approaches toBM areindeed possible such asslenderbody approximation [1,20–22] orResistive Force Theory

[23–25].

One important advantage of BM which might explain their use among various communities (polymer Physics [2–5,

26–34], micro-swimmer modeling in bio-fluid mechanics [35–44], flexible fiber in chemical engineering [45–52]), relies

on their parametric versatility, their ubiquitous character andtheir relative easy implementation. We provide a deeper, comparative andcriticaldiscussionabout BM inSection 2.However,we wouldliketo stressthat thepresented modelis moreclearlyorientedtowardmicro-swimmermodelingthanpolymerdynamics.

One shouldalsoadd thatBM canbe coupledto mesh-orientedapproachesinorderto provideaccurate descriptionof hydrodynamic interactions among large collection ofdeformable objects at moderatenumerical cost [43]. Manyauthors onlyconsiderfreedrain,i.e. noHydrodynamicInteractions(noHI),[27,48,49,53]orfarfieldinteractionsassociatedwiththe Rotne–Prager–Yamakawatensor[35,36,40,54].Thisissupportedbythefactthatfar-fieldhydrodynamicinteractionsalready provide accurate predictions for the dynamics ofa single flexible fiber when compared to experimental observations or numericalresults.Inordertoillustratethemethodweuse,forconvenience, theRotne–Prager–Yamakawatensortomodel hydrodynamicinteractions.Wewishtostressherethatthisisnotalimitationofthepresentedmethod,sincethepresented formulationholds foranymobilityproblemformulation. However, itturns out thatforeach configurationwe tested, our model gave very good comparisons with other predictions, including those providing more accurate description of the hydrodynamicinteractions.

Thepaperisorganizedasfollows.First,wegiveadetailedpresentationoftheBeadModelforthesimulationofflexible fibers.In thissection, wepropose ageneralformulationofkinematicconstraintsusingtheframework ofLagrange multi-pliers.This generalformulationis usedto presenta newBeadModel,namely theGears Modelwhich surpassesexisting modelson numericalaspects. Thesecondpartofthepaperisdevotedtocomparisonsandvalidations ofBeadModels for differentconfigurationsofflexiblefibers(experiencingafloworactuatedfilaments).

Finally,weconcludethepaperbysummarizingtheachievementsweobtainwithourmodelandopennewperspectives tothiswork.

2. TheBeadModel

2.1. DetailedreviewofpreviousBeadModels

The BeadModel(BM) aimsatdiscretizinganyflexibleobjectwithinteractingbeads.Interactionsbetweenbeadsbreak downintothreecategories:hydrodynamicinteractions,elasticandkinematicconstraintforces.Hydrodynamicsofthewhole object resultfrommultibody hydrodynamic interactions betweenbeads. Inthe context oflow Reynoldsnumber, the re-lationship betweenstresses andvelocities islinear.Thus,the velocityoftheassembly dependslinearlyonthe forcesand torques applied on each of its elements. Elastic forces andtorques are prescribed accordingto classical elasticitytheory

[55] offlexible matter.Constraint forcesensurethatthe beadsobeyanyimposed kinematicconstraint, e.g.fixed distance betweenadjacentparticles.Alloftheseinteractionscanbetreatedseparatelyaslongastheyareaddressedinaconsistent

Fig. 1. Spring Model: linear spring to keep constant the inter-particle distance.

Fig. 2. Joint Model: overlapping due to bending if no gap between beads.

Fig. 3. Joint Model: c1is separated by a gapεgfrom the beads.

order. The latteris thecornerstone which differentiates previous works inthe literature fromours. Numerous strategies havebeenemployedtohandlekinematicconstraints.

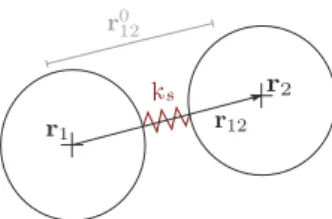

[32,34,35,40]and[50]usedalinearspringtomodeltheresistancetostretchingandcompressionwithoutanyconstraint

onthebeadrotationalmotion(Fig. 1).Theresultingstretchingforcereads:

Fs

= −

ks¡

ri,i+1−

r0i,i+1¢

(1) where•

ksisthespringstiffness,•

ri,i+1=

ri+1−

ri isthedistancevectorbetweentwoadjacentbeads(forsimplicity,equationsandfigureswillbepre-sentedforbeads1 and2 andcaneasilybegeneralizedtobeadsi andi

+

1),•

r01,2isthevectorcorrespondingtoequilibrium.However, regarding the connectivity constraint, the spring model is somehow approximate. A linear spring is prone touncontrolled oscillationsandthe problemmaybecomeunstable. Manyother authors,amongwhich [28–30],thus use non-linear spring models for a better description of polymer physics. Nevertheless, the repulsive force stiffness has an importantnumericalcostintime-steppingaswillbediscussedinSection2.6.3.Furthermore,unconstrainedbeadrotational motionleadstospurioushydrodynamicinteractionsandthuslimitstherangeofapplicationsfortheseBM.

Alternatively, [47–49,53] and [46] constrained the motion of the beads such that the contact point for each pair ci

remainsthesame.Whilemorerepresentativeofaflexibleobject,thisapproachexhibitstwomaindrawbacks: 1. agapbetweenbeadsisnecessarytoallowtheobjecttobend(seeFig. 2),

2. itrequiresan additionalcentertocenterrepulsive force,andthusmoretuningnumericalparameters toprevent over-lappingbetweenadjacentbeads.

Consider two adjacent beads, withradius a, linked by a hinge c1 (typicallycalled ball andsocket joint). The gap

ε

gdefinesthedistancebetweenthespheresurfacesandthejoint(seeFig. 3).Denotepithevectorattachedtobeadi pointing

towardsthenextjoint,i.e.thecontactpointci.

Theconnectivitybetweentwocontiguousbodieswrites:

£

r1

+ (

a+

ε

g)

p1¤ − £

r2− (

a+

ε

g)

p2¤ =

0 (2)anditstimederivative

˙

ri and

ω

i arethe translationalandrotational velocitiesofbeadi. Theconstraintforcesandtorques associatedto (3)areobtainedeitherbysolvingalinearsystemofequationsinvolvingbeadsvelocities[53],orbyinserting(3)intotheequations ofmotionwhenneglectinghydrodynamicinteractions[48,49].

The gap width 2

ε

g controls the maximumcurvatureκ

maxJ allowed without overlapping. From the sine rule, one canderive thesimpleequationrelating

ε

g andκ

maxJκ

maxJ=

q

1− (

a+aε g)

2 a (4)Onceawareoftheselimitations,thegap

ε

g,rangeandstrengthoftherepulsiveforce shouldbe prescribeddependingontheproblemtobeaddressed.

[56] and[43] proposedamoresophisticatedJointModelthan thosehithertocited,usingafulldescriptionofthelinks dynamicsalongthecurvilinearabscissa.Theyderivedasubtleconstraintformulationwhichensuresthatthetangentvector tothecenterlineiscontinuousandthatthelengthoflinksremainsconstant.Thesetwoworksareworthmentioningsince they avoidan empiricaltuning ofrepulsiveforces.Yet, [56]computedthe constraintforcesandtorqueswithan iterative penaltyschemeinsteadofusinganexplicitformulation.

Finally,itisworthmentioningthatthebeadmodelproposedin[31]circumventstheinextensibilitydifficultyby impos-ingconstraintsontherelativevelocitiesofeachsuccessivesegments,sothattheirrelativedistanceiskept constant.Using bendingpotential,[31]permitoverlapbetweenbeadswithrestoringtorque(cf.Fig. 2).ALagrangianmultiplierformulation oftensileforcesis alsousedin[57],whichisequivalentto aprescribed equaldistancebetweensuccessivebeads.Again, inextensibilityconditiondoesnotpreventbeadoverlappingduetobendinginthisformulation.Thecomputationofcontact forceswhichisproposedinthefollowingSection2.2generalizestheLagrangianmultiplierformulationof[31]to general-izedforces.Usingmorecomplexconstraintsinvolvingbothtranslationalandangularvelocities,weshowthatitispossible toaccommodate bothnon-overlappingandinextensibilityconditionswithoutadditionalrepulsiveforces(usingtherolling no-slipcontactwiththegearsmodeldetailedinSection2.3).Thisproposedgeneralformulationisalsowellsuitedforany typeofkinematicboundaryconditionsasillustratedinSection3.4.

2.2. Generalizedforces,virtualworkprincipleandLagrangemultipliers

ThemodelandformalismproposedinthisarticlerelyonearlierworkinAnalyticalMechanicsandRobotics[58,59].The conceptofgeneralizedcoordinatesandconstraintswhichhasproventobeveryusefulinthesecontextsisdescribedhere. Generalizedcoordinates refer toa setofparameters whichuniquely describestheconfigurationofthe systemrelativeto some referenceparameters (positions,angles,. . . ).Fordescribingobjectsofcomplexshape,let usconsiderthepositionri

ofeach beadi

∈ {

1,

Nb}

withassociatedorientation vector pi whichis definedby threeEulerangles p≡ (θ,

φ,

ψ )

. Inthefollowing, anycollectionofvector population

(

r1,

..

ri,

..

rNb)

≡

R willbe capitalized,so that R isa vector inR

3Nb.Hence the collection of orientation vectors pi will be denoted P, which is a vector of length 3Nb, the collection of velocities

dri

dt

= ˙

ri=

vi, will be denoted V, the collection of angular velocity p˙

i≡

ω

i will beÄ

, the collectionof forces fi, F, thecollectionoftorques

γ

i,Γ

.AllV,Ä

,F andΓ

arevectorsinR

3Nb.Let usthen define some generalized coordinateqi foreach bead, which isdefined by qi

≡ (

ri,

pi)

≡ {

r1,i,

r2,i,

r3,i,

θ

i,

φ

i,

ψ

i}

sothatthecollectionofgeneralizedpositions(

q1,

..

qi,

..

qNb)

≡

Q isavectorinR

6Nb.Generalizedvelocitiesarethen definedbyvectorsq

˙

i≡ (

vi,

ω

i)

withassociatedgeneralizedcollectionofvelocitiesQ.˙

Articulated systems aregenerically submitted to constraintswhich areeither holonomic,non-holonomicorboth [33]. Holonomic constraintsdonot dependonanykinematicparameter(i.eanytranslational orangularvelocity)whereas non-holonomicconstraintsdo.

In thefollowing we considernon-holonomic linearkinematicconstraints associatedwithgeneralized velocitiesofthe form[60]

J

J

J

Q˙

+

B=

0,

(5)such that

J

J

J

is a 6Nb×

Nc matrix andB is avector of Nc components. Nc isthe numberof constraintsacting on theNb beads.B and

J

J

J

mightdepend (even non-linearly)ontime t andgeneralizedpositions Q,butdonotdepend onanyvelocityofvectorQ,

˙

sothatrelation(5)islinearinQ.˙

Insubsequentsections,weprovidespecificexamplesforwhichthis class ofconstraints areuseful. Here we describe,following [58,60] howsuch constraints canbe handled thanksto some generalizedforcethatcanbedefinedfromLagrangemultipliers.Theideaformulatedtoincludeconstraintsinthedynamics of articulatedsystems isto search additional forceswhich could permit to satisfy these constraints.First, one mustrely on generalizedforcesf

i≡ (

fi,

γ

i)

whichincludeforcesandtorques actingoneach bead, whosecollection(f

1,

f

i,

..f

Nb)

is denotedF

.Generalizedforcesaredefinedsuchthatthe totalworkvariationδ

W isthescalarproductbetweenthemand thegeneralizedcoordinatesvariationsδ

Qsothat,ontherighthandside of(6)onealsogetsthetranslationalandtherotationalcomponentsofthework.Then,the ideaofvirtualworkprincipleistosearchsomevirtualdisplacement

δ

Q thatwillgeneratenowork,sothatF · δ

Q=

0. (7)Atthesametime,byrewriting(5)indifferentialform

J

J

J

dQ+

Bdt=

0,

(8)admissiblevirtualdisplacements,i.e. thosesatisfyingconstraints(8),shouldsatisfy

J

J

J

δ

Q=

0.

(9)Combiningthe Nc constraints(9)with(7)ispossibleusinganylinearcombinationoftheseconstraints.Suchlinear

com-binationinvolves Nc parameters,theso-calledLagrangemultiplierswhicharethe componentsofa vector

λ

inR

Nc.Thenfromthedifferencebetween(7)andthe Nc linearcombinationof(9)onegets

(F − λ ·

J

J

J

) · δ

Q=

0. (10)Prescribinganadequateconstraintforce

F

c= λ ·

J

J

J

,

(11)permitstosatisfy therequiredequalityforanyvirtualdisplacement.Hence,theconstraintscanbehandledbyforcing the dynamicswithadditionalforces,theamplitudeofwhicharegivenbyLagrangemultipliers,yettobefound.Notealso,that thisfirst result impliesthat both translational forcesand rotationaltorques associatedwith the Nc constraints are both

associatedwiththesameLagrangemultipliers.

ThisformalismisparticularlysuitableforlowReynoldsnumberflowsforwhichtranslationalandangularvelocitiesare linearlyrelatedtoforcesandtorquesactingonbeadsbythemobilitymatrixM

µ

VÄ

¶

=

Mµ

FΓ

¶

+

µ

V∞Ä

∞¶

+

C:

E∞.

(12) V∞= (

v∞1,

. . . ,

v∞Nb)

andÄ

∞= (

ω

∞1

,

. . . ,

ω

∞Nb)

correspondtothe ambientflowevaluated atthecentersof massri. E∞ is

therateofstrain3

×

3 tensoroftheambientflow.C isathirdranktensorcalledthesheardisturbancetensor,itrelatesthe particlesvelocitiesandrotationstoE∞ [54].MatrixM (andtensorC)canalsobere-organizedintoageneralizedmobility matrixM

M

M

(generalizedtensorC

C

C

resp.)inorderto define thelinearrelation betweenthepreviously definedgeneralized velocityandgeneralizedforce˙

Q

=

M

M

M

F +

V

V

V

∞+

C

C

C

:

E∞,

(13)where

V

V

V

∞= (

v∞1

,

ω

∞1,

. . . ,

v∞Nb,

ω

∞

Nb

)

.TheexplicitcorrespondencebetweentheclassicalmatrixM andtheherebyproposed generalized coordinate formulationM

M

M

is given in Appendix A. Hence, as opposed to the Euler–Lagrange formalism of classical mechanics,the dynamics oflow Reynolds numberflows doesnot involve anyinertialcontribution, andprovide a simple linear relationship between forces and motion. In this framework, it is then easy to handle constraints with generalizedforces,becausethetotalforce willbethe sumoftheknownhydrodynamic forcesF

h,elasticforcesF

e,innerforces associated to active fibers

F

a and the hereby discussed and yet unknown contact forcesF

c to verify kinematicconstraints

F = F

′+ F

c

,

with (14)F

′= F

h

+ F

e+ F

a.

(15)Hence,ifoneisabletocomputetheLagrangemultipliers

λ

,thecontactforceswillprovidethetotalforcebylinear su-perposition(14),whichgivesthegeneralizedvelocitieswith(13).Now,letusshowhowtocomputetheLagrangemultiplier vector.Sincethegeneralizedforce isdecomposedintoknownforcesF

′ andunknowncontactforcesF

c= λ ·

J

J

J

,relations(14)and(13)canbepooledtogetheryielding

M

M

M

F

c=

M

M

M

λ

J

J

J

= ˙

Q−

M

M

M

F

′−

V

V

V

∞−

C

C

C

:

E∞.

(16) Sothat,using(5),J

J

J M

M

M J

J

J

Tλ = −

B−

J

J

J

¡

M

M

M

F

′+

V

V

V

∞+

C

C

C

:

E∞¢,

(17)Fig. 4. Gears Model: contact velocity must be the same for each bead (no-slip condition).

2.3. TheGearsModel

TheEuler–Lagrangeformalismcanbereadilyappliedtoanytypeofnon-holonomicconstraintsuchas(3).Inthe follow-ing,weproposeanalternativemodelbasedonno-slipconditionbetweenthebeads:theGearsModel.Thisconstraint,first introducedinaBeadModel(BM)by[27],convenientlyavoidnumericaltrickssuchasartificialgapsandrepulsiveforces.

However, [27] and [61] relied on to an iterative procedure to meet requirements. Here, we use the Euler–Lagrange formalismtohandlethekinematicconstraintsassociatedtotheGearsModel.

Consideringtwoadjacentbeads(Fig. 4),thevelocityvc1 atthecontactpointmustbethesameforeachsphere:

v1c1

−

v2c1=

0.

(18)vLc1 andvRc1 are respectively therigid body velocity atthe contactpoint onbead1 andbead2. Denote

σ

1 the vectorialno-slipconstraint.(18)becomes

σ

1(˙

r1,

ω

1, ˙

r2,

ω

2) =

0,

(19)i.e.

[˙

r1−

ae12×

ω

1] − [˙

r2−

ae21×

ω

2] =

0,

(20)where e12 isthe unitvector connectingthe centerofbead1,locatedatr1,to thecenterofbead2,located atr2 (e12

=

e2

−

e1).Theorientationpi vectorattachedtobeadi,isnotnecessarytodescribethesystem.Hence,from(20)onerealizesthat

σ

1 islinearintranslationalandrotationalvelocities.ThereforeEq.(19)canbereformulatedasσ

1( ˙

Q) =

J1Q˙

=

0,

(21)where,Q is

˙

thecollectionvectorofgeneralizedvelocitiesofthetwo-beadassembly˙

Q

= [˙

r1,

ω

1, ˙

r2,

ω

2]

T,

(22)J1 istheJacobianmatrixof

σ

1:Jkl1

=

∂

σ

1 k∂

Ql,

k=

1, . . . ,3,l=

1, . . . ,12, (23) J1=

£

J11 J12¤ = £

I3−

ae×12−

I3 ae×21¤ ,

(24) and e×=

0−

e3 e2 e3 0−

e1−

e2 e1 0

.

(25)ForanassemblyofNbbeads,Nb

−

1 no-slipvectorialconstraintsmustbesatisfied.TheGearsModel(GM)totalJacobianmatrix

J

GMisblockbi-diagonalandreadsJ

GM=

J11 J12 J22 J23. .

.

. .

.

JNb−1 Nb−1 J Nb−1 Nb

(26)whereJαβ isthe3

×

6 Jacobianmatrixofthevectorialconstraintα

forthebeadβ

. ThekinematicconstraintsforthewholeassemblythenreadJ

GMQ˙

=

0.

(27)Fig. 5. Beamdiscretizationandbendingtorquescomputationofbeads1,3and5.Remainingtorquesareaccordinglyobtained:γb

2=m(s3)andγb4=

−m(s3).

2.4.Elasticforcesandtorques

Weareconsideringelastohydrodynamics ofhomogeneousflexibleandinextensiblefibers.Theseobjectsexperience bend-ing torques and elastic forces to recover their equilibrium shape. Bending moments derivation and discretization are provided.Then, the role ofbending moments andconstraintforces isaddressed inthe force andtorque balance forthe assembly.

2.4.1. Bendingmoments

Thebendingmomentofanelasticbeamisprovidedbytheconstitutivelaw[55,62] m

(

s) =

Kbt×

dtds

,

(28)whereKb

(

s)

isthebendingrigidity,t isthetangentvectoralongthebeamcenterlineands isthecurvilinearabscissa.UsingtheFrenet–Serretformula

dt

ds

=

κ

n,

(29)thebendingmomentwrites

m

(

s) =

Kbκ

b,

(30)where

κ

(

s)

definesthelocalcurvature,n(

s)

andb(

s)

arethenormalandbinormalvectorsoftheFrenet–Serretframe.When thelinkconsideredisnotstraightatrest,withanequilibriumcurvatureκ

eq(

s)

,(30)ismodifiedintom

(

s) =

Kb¡

κ

−

κ

eq¢

b

.

(31)Here,thebeamisdiscretizedintoNb

−

1 rigidrodsoflengthl=

2a (cf.Fig. 5).Inextensiblerodsaremadeupoftwobondbeadsandlinked together bya flexible jointwithbendingrigidity Kb.Bendingmoments are evaluatedatjointlocations si

= (

i−

1)

l fori=

2,

. . . ,

Nb−

1,wheresicorrespondtothecurvilinearabscissaofthemasscenteroftheithbead.Thebendingtorqueonbeadi isthengivenby

γ

bi=

m(

si+1) −

m(

si−1),

(32)withm

(

si)

=

Kbκ

(

si)

b(

si)

.SeeFig. 5forthetorquecomputationonabeamdiscretizedwithfourrods.Thelocalcurvature

κ

(

si)

isapproximatedusingthesinerule[42]κ

(

si) =

1 ar

1+

ei−1,i.

ei,i+1 2 (33)whereei−1,i istheunitvectorconnectingthecenterofmassofbeadi

−

1 tothecenterofmassofbeadi.Thiselementarygeometriclawprovidestheradiusofcurvature R

(

si)

=

1/

κ

(

si)

ofthecirclecircumscribingneighboring beadcentersri−1,riandri+1.

Amore generalversion of thediscrete curvature proposed in[63] canalso be used inthe caseofthree dimensional motion.Inthatcase,thecurvatureofthefiberisdiscretizedasin[63]

κ

(

si) =

ei−1,i

×

ei,i+1where, again, ei−1,i is the unit vector connectingthe centerof massof beadi

−

1 to thecenter ofmass ofbead i.Thebendingmomentreads

m

(

si) =

Kbκ

(

si).

(35)Toincludetheeffectoftorsionaltwistingabout theaxisofthefiber,one wouldhaveto computethe relativeorientation between the framesof reference attachedto the beads using Euler angles [56] (see Section 2.2) or unit quaternions as in [53].This wouldprovidethe rateof changeofthe twistanglealong thefiber centerlineandthus thetwisting torque actingoneachbead.Inthefollowing,onlybendingeffectsareconsidered.

2.4.2. Forceandmomentactingoneachbead

TheGearsModelproposedinthispaperdoesnotneedtoconsidergapstoallowbending.

F

c alsoensurestheconnectiv-ityconditionandcircumventtheuseofrepulsiveforcesasdistancesbetweenadjacentbeadsurfacesremainconstant.More specifically, thetangential componentsof theforce Fc,whichis onlyone partofthegeneralized force

F

c,actsastensileforce.

Foreachbeadi,contactforcesappliedfrombeadi tobeadi

+

1 atcontactpointcibetweenbeadi andi+

1 (Fig. 4fortwobeads)isdenotedfci.FromNewtonthirdlawatcontactpointci,thecontactforceappliedtobeadi frombeadi

+

1 is obviously−

fci.Totalforceactingonbeadi fromcontact,andhydrodynamicforcesfh i reads

fi

=

fci−1−

fci+

fh

i (36)

Similarly,thecontactforcefci atpointci producesamomentmci

=

ati×

fci associatedwithlocaltangentvectorti=

ei,i+1 anddistancea to the neutralfiberatpoint ci.Totalmomentacting onbeadi from contactpoints moments, elasticandhydrodynamictorquesarethen

γ

i=

mci−1−

mci+

γ

b

i

+

γ

hi.

(37)The contributionofcontactforceandcontactmomentactingonbeadi exactly equalsthecontributionofthegeneralized contactforce.Indeed,usingthekinematicconstraintsJacobian(26)in(11),andcomputingtheforceandtorque contribu-tions, one exactlyrecovers thefirst andthesecond contributions oftheright-hand-sideof(36) and(37). InAppendix B, wealsoshowthatthismodelisconsistentwithclassicalformulationforslenderbodyforceandmomentbalancewhenthe beadradiustendstozero.

2.5. Hydrodynamiccoupling

Movingobjects(rigidorflexiblefibers)inaviscousfluidexperiencehydrodynamicforcing.Theinteractionsaremediated bythefluidflowperturbationswhichcanalterthemotionandthedeformationofthefibersinamoderatelyconcentrated suspension. Theexistenceofhydrodynamicinteractions hasalsoan effectona singlefiberdynamicswhiledifferentparts ofthefibercanrespondtotheambientflowbutalsotolocalflowperturbationsrelatedtothefiberdeformation.Resistive ForceTheory(RFT)canbeusedtoestimatethefiberresponsetoagivenflowassumingthatthefiberismodeledbyalarge seriesofslenderobjects[23,64].Slenderbodytheoryhasalsobeenused[20,65]torelatelocalbalanceofdrag forceswith the filamentforcesupon thefluid resultingina dynamicalsystemto modelthedeformation ofthefibercenterline.This modelprovidedinterestingresultsonthestretch-coiltransitionoffibersinvorticalflows.

Inourbeadsmodel,thefiberiscomposedofsphericalparticlestoaccountforthefinitewidthofitscross-section.The hydrodynamic interactions areprovidedthrough thesolutionofthemobilityproblemwhichrelatesforces,torquesto the translational and rotationalvelocities ofthe beads.Thismany-body problemisnon-linear in theinstantaneous positions of all particles ofthe system. Approximate solutions of thiscomplex mathematicalproblem canbe achieved by limiting the mobility matricesto their leading order. The simplest model iscalled free drain as themobility matrix is assumed to be diagonalneglecting the HIwith neighboring spheres.Pairwise interactions are requiredto account foranisotropic drag effects within the beadscomposing thefiber. The Rotne–Prager–Yamakawa(RPY) approximation is one ofthe most commonlyusedmethodsofincludinghydrodynamicinteractions.Thiswidelyusedapproachhasbeenrecentlyupdatedby Wajnrybetal.[54]fortheRPYtranslationalandrotationaldegreesoffreedom,aswellasforthesheardisturbancetensor C whichgivestheresponseoftheparticlestoanexternalshearflow(12).

2.6. Numericalimplementation 2.6.1. Integrationschemeandalgorithm

The kinematicsofthe constrainedsystemresultsfromthesuperpositionofindividual beadmotions.Positionsare ob-tainedfromthetemporalintegrationoftheequationofmotionwithathirdorderAdams–Bashforthscheme

dri

dt

=

vi,

(38)Thetimestep

1

t usedtointegrate(38)isfixedbythecharacteristicbendingtime[46]1

t<

µ

(2a)

4

Kb

,

(39)where

µ

isthesuspendingfluidviscosity.Theevaluationofbeadinteractionsmustfollowaspecificorder.Elasticandactiveforcescanbecomputedinanyorder. Constraintforcesandtorquesmustbeestimatedafterwardsastheydependon

F

′.Thenvelocitiesandrotationsareobtained fromthemobilityrelation.Andfinally,beadpositionsareupdated.•

Initialization:positionsri(

0)

,•

TimeLoop1. Evaluatemobilitymatrix

M (

Q)

andC :

E∞(seeSection2.5),2. Calculatelocalcurvatures(33)andbendingtorques

γ

bi (32)toget

F

e,3. Addactiveforcing

F

aandambientvelocityV

∞ ifany,4. ComputetheJacobianmatrixassociatedwithnon-holonomicconstraints

J (

Q)

, 5. Solve(17)togettheconstraintforcesF

c= λ

J

,6. Sumalltheforcingterms

F

= F

e+ F

a+ F

c,7. Applymobilityrelation(13)toobtainthebeadvelocitiesQ,

˙

8. Integrate(38)togetthenewbeadpositions.2.6.2. ImplementationoftheJointModel

Toprovideacomprehensivecomparisonwithpreviousworks,weexploittheflexibilityoftheEuler–Lagrangeformalism toimplementtheJointModelasdescribedin[49] supplementedwithhydrodynamicinteractions. Thejointconstraintfor twoneighboring beadsreads

£˙

ri− (

a+

ε

g)

pi×

ω

i¤ − £˙

ri+1+ (

a+

ε

g)

pi+1×

ω

i+1¤ =

0.

(40)UsingtheEuler–Lagrangeformalism,(40)isreformulatedwiththeJointModel(JM)Jacobianmatrix

J

JMQ˙

=

0,

(41)where

J

JMhasthesamestructureasin(26)andJi

=

£

Ji1 J2i¤ = £

I3−(

a+

ε

g)

p×i−

I3−(

a+

ε

g)

p×i+1¤ .

(42)Accordingly,thecorrespondingsetofforcesandtorques

F

c areobtainedfromSection 2.2.AsmentionedinSection 2.1,suchformulationdoesnotpreventbeadsfromoverlappingwhenbendingoccurs.ArepulsiveforceFrisaddedaccordingto

[46](theforceprofileproposedby[49]isverystiff,thusveryconstrainingforthetimestep):

Fri j

=

−

F0exp(−di jd+δD 0)

ei j,

di j≤ −δ

D,

−

F0(

12−

2dδi jD)

ei j,

−δ

D<

di j≤ δ

D,

0,

ri j> δ

D.

(43)δ

D isan artificial surface roughness, di j isthe surface to surface distance.di j<

0 indicatesoverlapping betweenbeads iand j.d0 isa numericaldampingdistancewhich hastobe tuned to preventoverlapping. F0 istherepulsive force scale

chosen inorder to avoidnumericalinstabilities. Todeal withthisissue,[46] proposed toevaluate F0 frombending and

viscousstresses.Aslightmodificationoftheirformulaforinertialessparticlesyields

F0

=

C16π µ

L¡

v∞−

v¢ +

C2s

KbEb

L3

,

(44)the bar denotes the average over the constitutive beads or joints where C1 and C2 are adjustable constants. Eb is the

bendingenergy Eb

=

Nb−1X

i=1 Kb¡

κ

(

si) −

κ

eq(

si)

¢

2.

(45)BendingmomentsareevaluatedatthejointlocationssiJ

= (

a+

ε

g)

+ (

i−

1)

×

2(

a+

ε

g)

,i=

1,

. . . ,

Nb−

1.Jointcurvatureisgivenby

κ

¡

siJ¢ =

2 a+

ε

gr

1+

pi.

pi+1 2.

(46)Fig. 6. Dependenceoftheconstraintsǫ¯M/ ˙γL onthetimestepγ˙1t,+:GearsModel,1:JointModel.Inset:ǫ¯M/ ˙γL withtheGearsModelforafixedtime

step given by(39)for different values ofγ˙.

Similarlyto(32),bendingtorqueonbeadi is

γ

bi=

m¡

siJ

¢ −

m¡

siJ−1

¢.

(47)Beadorientationpi isintegratedwithathirdorderAdams–Bashforthscheme

dpi

dt

=

ω

i×

pi.

(48)TheprocedureissimilartotheGearsModel.piareinitializedtogetherwiththepositions.TherepulsiveforceFrisadded

to

F

′andcanbecomputedbetweenstep1and5oftheaforementionedalgorithm.Timeintegrationof(48)isperformed atstep8.2.6.3. Constraintsandnumericalstability

At each time step, the error on kinematic constraints

ǫ

is evaluated, after application of the mobility relation (13), betweenstep7andstep8:ǫ

GM(

t) =

°

°

J

GMQ˙

°

°

2=

Ã

Nb−1X

i=1¡

vLc i−

v R ci¢

2!

1/2 (49)fortheGearsModel,and

ǫ

JM(

t) =

°

°

J

JMQ˙

°

°

2 (50)

fortheJointModel.

ToverifytherobustnessofbothmodelsandLagrangeformulation,anumericalstudyiscarriedoutonastiff configura-tion.

Afiberofaspectratiorp

=

10 withbendingratioBR=

0.

01 isinitiallyalignedwithashearflowofmagnitudeγ

˙

=

5 s−1.Forthisaspectratio,Nb

=

10 beadsareusedtomodelthefiberwiththeGearsModel.JointModelinvolvesadditionalitemstobefixed.Nb

=

9 spheresareseparatedbyagapwidth2ε

g=

0.

25a.Therepulsiveforce isactivated whenthesurface to surfacedistancedi j reachesthe artificialsurfaceroughness

δ

D=

2(

a+

ε

g)/

10.TheremainingcoefficientsaresettoreducenumericalinstabilitieswithoutaffectingthePhysicsofthesystem:d0

= (

a+

ε

g)/

4,C1

=

5 andC2=

0.

5.Fig. 6 showsthe evolution ofthe maximal mean deviation fromthe no-slip/jointconstraint

ǫ

¯

M=

maxtǫ

(

t)/(

Nb−

1)

normalized withthe maximal shear velocity

γ

˙

L dependingon the dimensionless time stepγ

˙

1

t. First, one can observe thatforbothJointandGearsmodels,ǫ

¯

M/ ˙

γ

L weaklydependsonγ

˙

1

t andtheresultingmotionofthebeadscompliesverypreciselywiththesetofconstraints,withinatoleranceclosetounitroundoff(

<

2.

10−16).Secondly,JointModelisunstablefortime steps 100times smallerthan GearsModel.The onset fornumericalinstability indicates that therepulsive force stiffnessdominatesoverbending,thusdictatingandrestrictingthetimestep.

As acomparison, [46] matched connectivityconstraintswithin 1% errorforeach fibersegment.Todoso, theyhadto useaniterativeschemereducingthetimestepby1

/

3 eachiterationtomeetrequirementsandlimitoverlappingbetween adjacentsegments.Forsimilarresults,astiffconfiguration,suchastheshearedfiber,isthereforemoreefficientlysimulated withtheGearsModel.Thirdly,insetofFig. 6showsthat,foragiventime step,theGearsModelconstraints

ǫ

¯

M/ ˙

γ

L aresatisfiedwhatevertheshearmagnitude.Hence,(39)ensuresunconditionallynumericalstabilityasbendingistheonlylimitingeffectfortheGears Model.

Hence,therobustnessoftheEuler–Lagrangeformalismandthenumericalintegrationwechoseprovideastrongsupport totheGearsModelovertheJointModel.

Asa final remarktothissection, itisimportantto mentionthat thenumericalcost oftheproposed methodstrongly dependsonthechoice forthemobilitymatrixcomputation,asusual forbeadmodels.Ifthemobilitymatrixiscomputed takingintoaccountfullhydrodynamicinteractionswithStokesianDynamics,mostofthenumericalcostwillcomefromits evaluationinthiscase.ThislimitationcouldbeovercameusingmoresophisticatedmethodssuchasAcceleratedStokesian Dynamics [66] orForce Coupling Method[18].Moreover, when considering Rotne–Prager–Yamakawa mobilitymatrix, its costonlyrequirestheevaluationof O

((

6Nb)

2)

terms.Furthermore,the mainalgorithmiccomplexityofbeadmodels doesnot comefrom thetime integration ofthe beadpositions which only requiresa matrix–vector multiplication (13)at an O

((

6Nb)

2)

cost.Fast-multipoleformulationofaRotne–Prager–Yamakawamatrixcanevenprovidean O(

6Nb)

costforsuchmatrix–vectormultiplication[67].

Themain numericalcost indeedcomes fromtheinversion ofthecontactforces problem(17). Itis worth notingthat thislinearproblemis Nc

×

Nc whichisslightlydifferentfromNb×

Nb,butofthesameorder.Furthermore,problem(17)givesadirect,singlestepproceduretocomputethecontactforces,asopposedtopreviousotherattempts[27,46,56]which requirediterativeprocedurestomeetforcesrequirements,involvingthemobilitymatrixinversionateachiteration.Thecost fortheinversionof(17)liesin-between O

(

N2c

)

andO(

N3c)

dependingontheinversionmethod. 3. Validations3.1. Jefferyorbitsofrigidfibers

MuchofourcurrentunderstandingofthebehavioroffibersexperiencingashearflowhascomefromtheworkofJeffery

[68]whoderived theequationforthemotionofan ellipsoidalparticleinStokesflow.The sameequation canbeusedfor themotion ofan axisymmetric particle by using an equivalentellipsoidalaspect ratio.Rigid fibers can be approximated byelongated prolateellipsoids.Anisolated fiberinsimpleshearflow rotatesinaperiodicorbitwhilethecenterofmass simplytranslatesintheflow (nomigration acrossstreamlines). Theperiod T (51)is afunctionofthe aspectratioofthe fiberandtheflowshearratewhiletheorbitdependsontheinitialorientationoftheobjectrelativetotheshearplane

T

=

2π

(

re+

1/re)

˙

γ

.

(51)˙

γ

is the shearrate ofthe carryingflow. re is theequivalentellipsoidal aspect ratiowhich isrelated to thefiber aspectratio rp (lengthof the fiberover diameterof thecross-section which turns out to rp

=

Nb with Nb beads). The fiberisinitiallyplacedintheplaneofshearandiscomposedonNb beads.NogapsbetweenbeadsisrequiredintheJointModel

becausethefiberisrigidandflexibilitydeformationsarenegligible.Wehavecomparedtheresultswithtworelationsfor re:

Cox[1] re

=

1.24rpp

ln(rp)

,

(52) andLarson[69] re=

0.7rp.

(53)Thisclassic andsimple test case hasbeen successfully validatedin [27,34,49]. Both the Joint andGears models give a correctpredictionof theperiod ofJeffery orbits(Fig. 7). The scaled period

γ

˙

T ofsimulations remains within the two evolutionsbasedonEqs.(52)and(53).Wehavetriedtocompareit withthelinearspringmodelproposed byGaugerand Stark[40](andusedbySlowickaetal.[50] witha moredetailedformulationofhydrodynamic interactions).Inthislatter model,thereisnoconstraintontherotationofbeadsandthesimulationsfailedtoreproduceJefferyorbits(thefiberdoes notflipovertheaxisparalleltotheflow).3.2.Flexiblefiberinashearflow

Themotionofflexiblefibersinashearflowisessentialinpapermakingorcompositeprocessing.Predictionandcontrol offiberorientationsandpositionsare ofparticularinterest inthestudyofflocksdisintegration.Many modelshavebeen designedto predictfiberdynamicsandmuchexperimental workhasbeenconducted.Thewide varietyoffiberbehaviors dependson theratio ofbending stressesover shearstress, which isquantified by a dimensionless number,the bending ratioBR[53,70]

BR

=

E(ln 2r

e−

1.5)µ

γ

˙

2r4p(54)

Fig. 7. TumblingperiodT dependingonfiberaspectratiorp. :theoreticallaw(51)withregivenby(53), :theoreticallaw(51)withre givenby

(52),P: Gears Model,e: Joint Model.

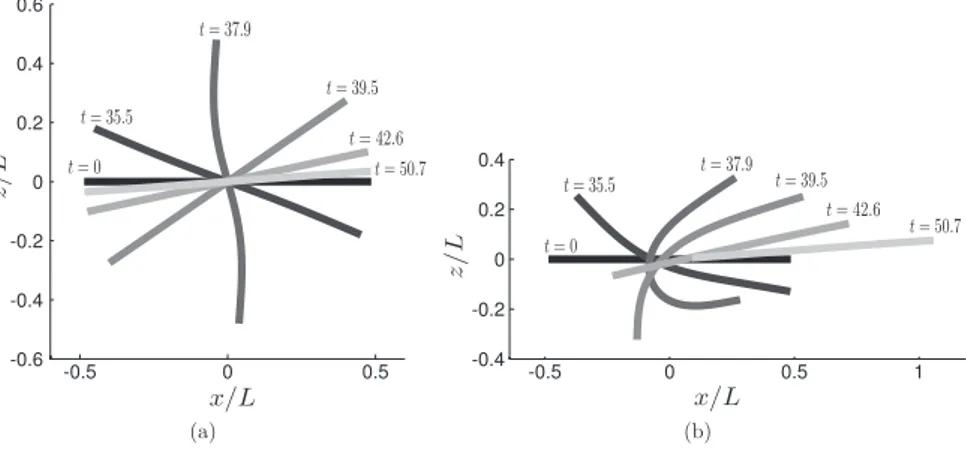

Fig. 8. OrbitofaflexiblefilamentinashearflowwithBR=0.04.Temporalevolutionisshownintheplaneofshearflow.(a) Symmetric“S-shape”ofa straightfilament,κeq=0.(b) Bucklingofapermanentlydeformedrodwithanintrinsiccurvatureκeq=1/(100L).

Inthefollowing,weinvestigatetheresponseoftheGearsModelwithknownresultsonflexiblefiberdynamics. 3.2.1. Effectofpermanentdeformation

[70,71]analyzed the motionofflexiblethreadlikeparticles inashearflow dependingonBR. Theyobservedimportant

driftsfromtheJefferyorbitsandclassifiedthemintocategories.Yet,thegoalofthissectionisnottocarryoutanin-depth studyonthesephenomena.Instead,theobjectiveistoshowthatourmodelcanreproducebasicfeaturescharacteristicof shearedflexiblefilaments.Weanalyzefirsttheinfluenceofintrinsicdeformationonthemotion.

Ifa fiberisstraight atrest,it willsymmetricallydeform ina shearflow. When alignedwiththecompressive axesof the ambient rateof strain E∞, the fiber adoptsthe “S-shape” observed in Fig. 8(a). When aligned withthe extensional axes, tensile forces turn the rod back to its equilibrium shape. This symmetry is broken when the filament is initially slightly deformedor hasa permanent deformation atrest,i.e. a nonzeroequilibrium curvature

κ

eq>

0. An initial smallperturbation of the shape of a straight filament aligned withflow can induce large deformations duringthe orbit. This phenomenonisknownasthebucklinginstabilitywhoseonsetandgrowtharequantifiedwithBR[72,73].Fig. 8(b)illustrates the evolution of a flexible sheared filament with BR

=

0.

04 and a very small intrinsic deformationκ

eq=

1/(

100L)

.Theequilibriumdimensionlessradiusofcurvatureis2Req

/

L=

200.Duringthetumblingmotionitdecreasestoaminimalvalue of2Rmin/

L=

0.

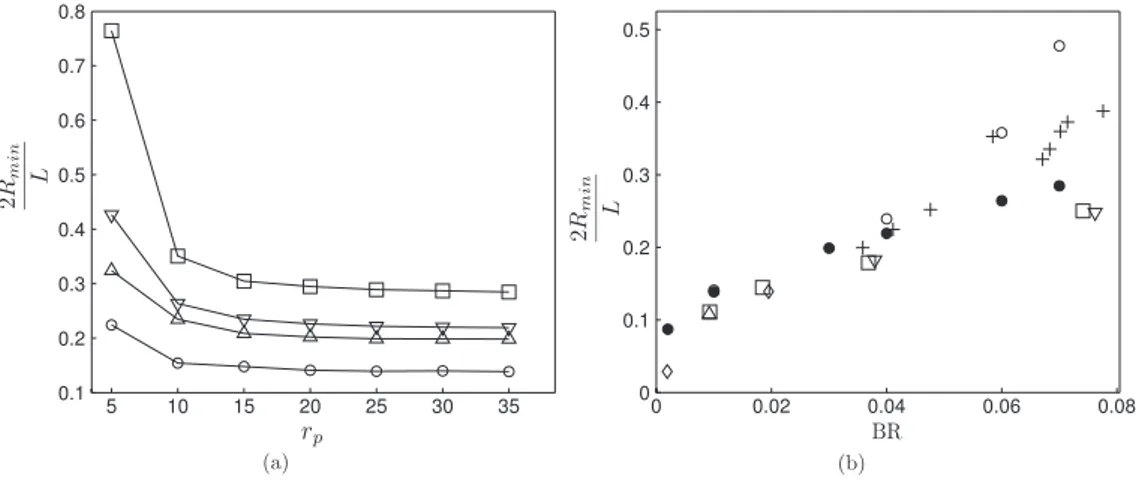

26.Bucklingthusincreasesby770timesthemaximalfibercurvature.3.2.2. Maximalfibercurvature

[74]measuredtheradiusofcurvature R ofshearedfiberforaspectratiosrp rangingfrom283to680.Theyreportedon

theevolutionoftheminimalvalue Rmin,i.e.themaximalcurvature

κ

max,withBR.[53] usedtheJointModelwithprolatespheroidsbutnohydrodynamicinteractionsandcomparedtheirresultswith[74].Bothexperimentalresultsfrom[74]and simulationsfrom[53]areaccuratelyreproducedbytheGearsModel.

Hydrodynamicinteractionsbetweenfiberelementsplayanimportantroleinthebendingofflexiblefilaments[46,50,74]. AsmentionedinSection2.5theuseofspherestobuildanyarbitraryobjectiswellsuitedtocomputethesehydrodynamic interactions.However,modeling rigidslenderbodiesinastrongshearflowbecomescostlywhenincreasingthefiberaspect ratio.First,the aspectratioofafibermadeup of Nb spheresisrp

=

Nb.Eachtimeiteration requiresthecomputation ofFig. 9. (a)Minimalradiusofcurvaturedependingonfiberlengthforseveralbendingratios. :BR=0.01, :BR=0.03, :BR=0.04, :BR

=0.07.(b) MinimalradiusofcurvaturealongBR.!:currentsimulationswithaspectratiorp=35 andintrinsiccurvatureκeq=0;":currentsimulations

with aspect ratio rp=35 and intrinsic curvatureκeq=1/(10L); simulation results from[53]withκeq=1/(10L): (E: rp=50,P: rp=100,e: rp=150,

1: rp=280);+: experimental measurements from[74], rp=283.

M

andC :

E∞ andtheinversionofalinearsystem(17)correspondingto Nc relationsofconstraintswithNc≥

3(

Nb−

1)

.Secondly,foragivenshearrate

γ

˙

andbendingratioBR,Young’s modulus increasesasr4p.Accordingto(39),thetimestep

becomesverysmallforlarge E. [53] partiallyavoidedthisissueby neglectingpairwise hydrodynamic interactions(

M

is diagonal),andbyassemblingprolatespheroidsofaspectratiosre∼

10.Yet, it is shown in Fig. 9(a) that for a fixed BR, 2Rmin

/

L converges asymptotically to a constant value with rp. Anasymptoticregime(relativevariationlessthan2%)isreachedforrp

≥

25.Choosingrp=

35 thusenablesavalidcomparisonwithpreviousresults.

Oursimulationresultscomparewellwiththeliteraturedata(Fig. 9(b))andbettermatchwithtoexperimentsthan[53]. When BR

≥

0.

04, the Gears Model clearly underestimates measurements forκ

eq=

1/(

10L)

and overestimates them forκ

eq=

0.However,SalinasandPittman[74]indicatedthattheerrorquantificationonparametersandmeasurementsisdiffi-culttoestimateasthefiberswerehand-drawn.Notably,drawingaccuracydecreasesforlargeradiiofcurvature,whichleads totheconclusionthattheherebyobserved discrepancymightnotbe critical.Theydidnotreport thevalueofpermanent deformation

κ

eq forthefibersthey designed,whereas, asevidenced by[71],ithasastrongimpact on Rmin.Anumerical

studyofthisdependenceshouldbeconductedtocomparewith[71,Fig. 7].

[46]usedthesameapproachas[53]withhydrodynamicinteractions torepeatnumericallytheexperimentsfrom[74]; buttheirresults,thoughreliable,weredisplayedsuchthatdirectcomparisonwithpreviousworkisnotpossible.

Toconclude, it should be notedthat, in [53], the aspect ratiodoesnot affect 2Rmin

/

L for a fixed BR, confirmingtheasymptoticbehaviorobservedinFig. 9(a). 3.3.Settlingfiber

ConsiderafibersettlingunderconstantgravityforceF⊥

=

F⊥e⊥ actingperpendicularlytoitsmajoraxis.Thedynamicsofthesystemdependsonthree competingeffects:the elasticstresseswhich tendto returntheobjectto itsequilibrium shape,thegravitationalaccelerationwhichuniformlytranslatestheobjectandthehydrodynamicinteractionswhichcreates localdragalongthefilament.After atransient regime,thefilamentreachessteadystateandsettlesataconstantvelocity withafixedshape(seeFigs. 10(a)and 10(b)).Thissteadystatedependsontheelasto-gravitationalnumber

B

=

F⊥L/

Kb.

(55)[41,75]and[65]examinedthecontributionofeachcompetingeffectbymeasuringthenormaldeflectionA,i.e.thedistance

betweentheuppermostandthelowermostpointofthefilamentalongthedirectionoftheapplied force(Fig. 10(b)); and thenormalfriction coefficient

γ

⊥/

γ

⊥0 asa function of B.γ

0

⊥ isthenormalfriction coefficient ofa rigidrod.To compute

hydrodynamicinteractions[75]usedStokeslet;[41],theForceCouplingMethod(FCM)[18];[65],SlenderBodyTheory. SimilarsimulationswerecarriedoutwithboththeJointModeldescribedinSection2.6.2andtheGearsModel.Fiberof length L

=

68a ismadeout of Nb=

31 beadswithgapwidth 2ε

g=

0.

2a for theJoint Modeland Nb=

34 for theGearsModel.ToavoidbothoverlappingandnumericalinstabilitieswiththeJointModel,thefollowingrepulsiveforcecoefficients wereselected:d0

= (

a+

ε

g)/

4,δ

D= (

a+

ε

g)/

5,C1=

0.

01 and C2=

0.

01.NoadjustableparametersarerequiredforGearsModel.

Fig. 11 showsthat our simulations agreeremarkably well withprevious results exceptslight differenceswith[65] in

the linearregime B

<

100.Using SlenderBody Theory,[65] madethe assumption of a spheroidal filament instead of a cylindricalone,withaspectratiorp=

100,i.e. threetimeslarger thanother simulations,whence suchdiscrepancies. TheFig. 10. Shapeofsettlingfiberfor B=10000 intheframemovingwiththecenterofmass(xc,zc).(a)Metastable“W”shape,t=12L/Vs.(b)Steady

“horseshoe” shape at t=53L/Vs. Vsis the terminal settling velocity once steady state is reached.

Fig. 11. (a)ScaledverticaldeflectionA/L dependingonB. :GearsModel, :JointModel, :FCMresultsfrom[41], :Stokesletsresultsfrom

[75], :Slenderbodytheoryresultsfrom[65].(b)Normalfrictioncoefficientvs. B. :GearsModel, :JointModel, :FCMresultsfrom[41], :Stokesletsresultsfrom[75].

normalfriction coefficient (Fig. 11(b)),resultingfromhydrodynamic interactions, perfectlymatchesthe valueobtainedby

[41] withtheForce CouplingMethod.The FCMis knowntobetter describemultibody hydrodynamicinteractions. Sucha resultthussupportstheuseofthesimpleRotne–Prager–Yamakawatensorforthishydrodynamicsystem.

DifferencesbetweenGearsandJointModelsimplementedherearequantifiedbymeasuringtherelativediscrepancieson theverticaldeflection A

ǫ

A=

AG

−

AJAG

,

(56)andonthenormalfrictioncoefficient

γ

⊥/

γ

⊥0ǫ

γ⊥=

(

γ

⊥/

γ

⊥ 0)

G− (

γ

⊥/

γ

⊥ 0)

J(

γ

⊥/

γ

⊥ 0)

G.

(57)DiscrepanciesbetweenJointandGearsmodelsremainbelow5% exceptatthethresholdofthenon-linearregime(B

≈

100)whereǫ

A reaches15% andǫ

γ⊥≈

7.

5%.Inaccordance with[75], a metastable “W”shape is reachedfor B

>

3000 (Fig. 10(a)) until it convergesto the stable “horseshoe”state(Fig. 10(b)).3.4.Actuatedfilament

Thegoalofthefollowingsectionsistoshowthatthemodelweproposedisnotonlyvalidforpassiveobjectsbutalsofor activeones.Elastohydrodynamics alsoconcernswimmingatlowReynoldsnumber[6].Manytypeofmicro-swimmershave beenstudiedbothfromtheexperimentalandtheoreticalpointofview.Amongthemtwocategoriesaredistinguished: cili-atesandflagellates.Ciliatespropelthemselvesbybeatingarraysofshorthairs(cilia)ontheirsurfaceinasynchronizedway (Opalina,Volvox,Paramecia). Flagellatesundulate and/orrotatetheir externalappendageto push(pull)thefluid fromtheir aft(fore)part(spermatozoa,ChlamydomonasRheinardtii,BacillusSubtilis,EschericiaColi).Recentadvancesinnanotechnologies allowsresearcherstodesignartificialswimmingmicro-devicesinspiredbylowReynoldsnumberfauna[7,76,77].

Inthatscope,thestudyofbendingwavepropagationalongpassiveelasticfilamenthasbeeninvestigatedby[78,79]and

[24,80].

Theexperimentof[79] consistsina flexible filamenttetheredandactuatedatits base.Thebaseanglewas oscillated sinusoidallyinplanewithanamplitude

α

0=

0.

435 rad andfrequencyζ

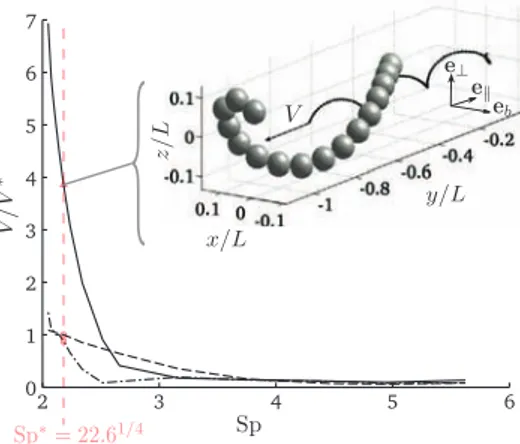

.Deformationsalongthetailresultfromthecompetingeffectsofbendinganddrag forcesactingonit.Adimensionless quantitycalledtheSpermnumbercomparesthecontributionofviscousstressestoelasticresponse[19]

Sp

=

Lµ ζ (

γ

⊥/

L)

Kb¶

1/4=

L lζ.

(58)γ

⊥ is thenormal frictioncoefficient. When usingResistive Force Theory,(

γ

⊥/

L)

ischanged into a drag per unit lengthcoefficient

ξ

⊥. lζ can be seen as the length scale at which bending occurs. Sp.

1 corresponds to a regime at whichbendingdominatesoverviscous friction:thewholefilamentoscillatesrigidlyinareversibleandsymmetricalway.Sp

≫

1 correspondstoaregimeatwhichbendingwavesareimmediatelydampedandthefreeendismotionless[19].Theexperimentof[80]issimilarto[79] exceptfor thattheactuationatthebaseisrotational.Here,thefilament was rotatedatafrequency

ζ

formingabaseangleα

0=

0.

262 rad withtherotationaxis.Inbothcontributions,theresultingfiberdeformationsweremeasuredandcomparedtoResistiveForceTheoryforseveral valuesofSp.Simulationsofsuchexperiments[79,80]wereperformedwiththeGearsModel.

3.4.1. Numericalsetupandboundaryconditionsatthetetheredbaseelement

Corresponding kinematic boundary conditions for BM are prescribed with the constraint formulation of the Euler– Lagrangeformalism.

3.4.1.1.Planaractuation Inthecaseofplanar actuation[79],weconsiderthatthetethered,i.e. thefirst,beadisplacedat theoriginandhasnodegreeoffreedom

½

r˙

c1

=

0,

ω

c1

=

0.

(59)

Denote

α

0 theangleformedbetweenex ande1,2.Thetrajectoryofbead2 mustfollow

rc2

(

t) =

2a cos(α

0sin(ζt))

0 2a sin(α

0sin(ζt))

.

(60)Thetranslationalvelocityofthesecondbeadr

˙

2(

t)

isthusconstrainedbytakingthederivativeof(60)˙

rc2

(

t) =

−2a

α

0ζ

cos(ζt)

sin(α

0sin(ζt))

0

2a

α

0ζ

cos(ζt)

cos(α

0sin(ζt))

3.4.1.2. Helicalactuation Inthecaseofhelicalbeating[24,80],theanchorpointofthefilamentisslightlyoff-centeredwith respecttotherotationaxisex[24]:r

(

0)

= δ

0(cf.Fig. 13,left inset).[24]measuredavalueδ

0=

2 mm withafilamentlengthvaryingfrom L

=

2 cm to10 cm.Herewe takeδ

0= ˜

δ

0sinα

0 withδ

˜

0=

2.

7a andvarythefilamentlength bychangingthenumberofbeadsNbtomatchtheexperimentalrange

δ

0/

L=

0.

1→

0.

02.Thepositionofbead1 mustthenfollowrc1

(

t) =

˜

δ

0cos(α

0sin(ζt))

cos(α

0cos(ζt))

˜

δ

0cos(α

0sin(ζt))

sin(α

0cos(ζt))

˜

δ

0sin(α

0sin(ζt))

.

(62)Thetranslationalvelocityofthefirstbeadr

˙

1(

t)

isthusconstrainedbytakingthederivativeof(62)˙

rc1(

t) =

˜

δ

0α

0ζ [−

cos(ζt)

sin(α

0sin(ζt))

cos(α

0cos(ζt))

+

sin(ζt)

sin(α

0cos(ζt))

cos(α

0sin(ζt))]

˜

δ

0α

0ζ [−

cos(ζt)

sin(α

0sin(ζt))

sin(α

0cos(ζt))

−

sin(ζt)

cos(α

0cos(ζt))

cos(α

0sin(ζt))]

˜

δ

0α

0ζ

cos(ζt)

cos(α

0sin(ζt))

.

(63)Andtherotationalvelocityissettozero

ω

1=

0.Thevelocityofthesecondbead

˙

rc2(

t)

isprescribedinsynchronywithbead1:˙

rc2(

t) =

( ˜δ

0+

2a)α

0ζ [−

cos(ζt)

sin(α

0sin(ζt))

cos(α

0cos(ζt))

+

sin(ζt)

sin(α

0cos(ζt))

cos(α

0sin(ζt))]

( ˜δ

0+

2a)α

0ζ [−

cos(ζt)

sin(α

0sin(ζt))

sin(α

0cos(ζt))

−

sin(ζt)

cos(α

0cos(ζt))

cos(α

0sin(ζt))]

( ˜δ

0+

2a)α

0ζ

cos(ζt)

cos(α

0sin(ζt))

.

(64)The rotationalvelocity

ω

2 isconsistentlyconstrained bythe no-slipcondition.The three-dimensionalcurvatureκ

isdis-cretizedwith(34).

Inbothcases,imposingactuationatthebaseofthefilamentthereforerequirestheadditionofthreevectorialkinematic constraints,(59)and(61),totheno-slipconditions:Nc

=

3(

Nb−

1)

+

3×

3.TheadditionalJacobianmatrixJact writesJact

=

I3 03 03 03· · ·

03 03 03 I3 03 03· · ·

03 03 03 03 I3 03· · ·

03 03

.

(65)Thecorrespondingright-handsideBact containstheimposedvelocities

Bact

=

0 0−˙

rc2

(66)forplanarbeating,and

Bact

=

−˙

rc1 0−˙

rc2

(67)forhelicalbeating.

Jact and Bact are simply appended to

J

J

J

and B respectively; corresponding forces and torquesF

c are computed asexplainedbeforeinSection2.2.

3.4.2. Comparisonwithexperimentsandtheory

The dynamics of the system can be described by balancing elastic stresses (flexion andtension) with viscous drag. Subsequentcouplednon-linearequationscanbe linearizedwiththeapproximationofsmalldeflectionsorsolvedwithan adaptiveintegrationscheme[23,25,81].

3.4.2.1. Planaractuation [79] consideredbothlinearandnon-lineartheoriesandincludedtheeffectofasidewall byusing thecorrectedRFTcoefficientsof[82].

Simulations are in good agreement with experiments, linear and non-linear theories for Sp

=

1.

73,

2.

2,

and 3.

11(Fig. 12). Even though sidewall effects were neglected here, the Gears Model provides a good description ofnon-linear

Fig. 12. Comparisonwithexperimentsandnumericalresultsfrom[79].GearsModelresultsaresuperimposedontheoriginalFig. 3of[79].Snapshotsare shownforfourequallyspacedintervalsduringthecycleforonetailwithα0=0.435 rad. :experiment, :lineartheory, :non-lineartheory,—:

Gears Model, (a)ζ =0.5 rad s−1, Sp=1.73. (b)ζ =1.31 rad s−1, Sp=2.2. (c)ζ =5.24 rad s−1, Sp=3.11.

Fig. 13. Comparisonwithexperimentsfrom[80].(Insets)EvolutionofthefilamentshapewithSp4.Snapshotsareshownfortwentyequallyspacedintervals

duringoneperiodatsteadystate.Graylevelfadesastimeprogresses.Leftinset:δ0/L isthedistanceofthetetheredbeadtotherotationaxis,d/L isthe

distance of the free end to the rotation axis. (Main figure) Distance of the rod free end to the rotation axis normalized by the filament length d/L. E: experiment,":GearsModelwithnoanchoringdistanceδ0/L=0,2:GearsModelwithδ0/L=0.1→0.02 asin[24].

3.4.2.2. Helicalactuation Oncesteadystate was reached, [80] measuredthe distanceofthetip oftherotatedfilament to therotationaxisd

![Fig. 12. Comparison with experiments and numerical results from [79]. Gears Model results are superimposed on the original Fig](https://thumb-eu.123doks.com/thumbv2/123doknet/3180212.90783/18.892.310.592.150.548/comparison-experiments-numerical-results-gears-results-superimposed-original.webp)