Dynamics of a three-phase upflow fixed bed catalytic reactor

Texte intégral

Figure

Documents relatifs

A two-dimensional pseudo-homogeneous model has been developed to investigate the influence of tube size on the thermal behavior and performance of packed fixed bed reactor for the

In this study, we performed Euler-Euler two-phase model simulations by using the effective drag force and the effective sub-grid stresses models for gas-solid flow in a 3-D

For validation purpose, the identified Kamal–Sourour model is compared to experimental data in both isothermal and dynamic conditions, using either the specific heat flow _H or

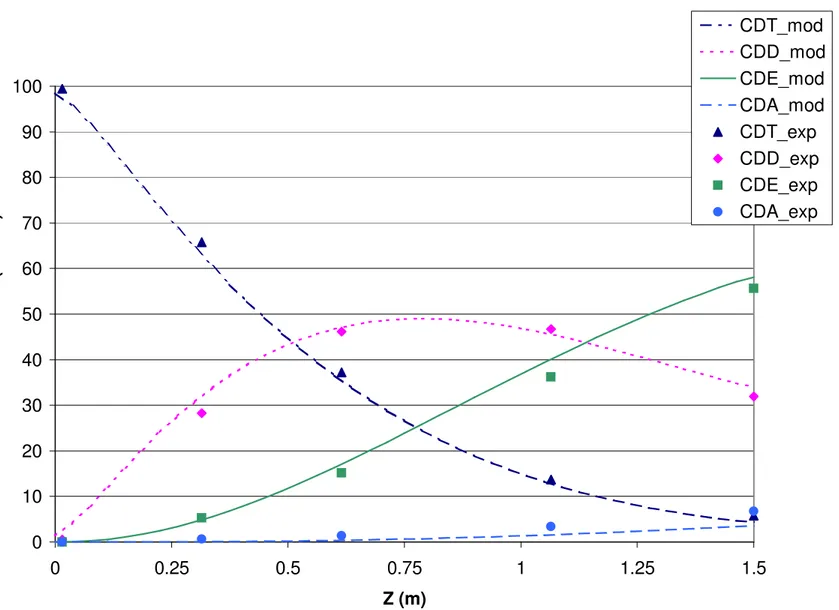

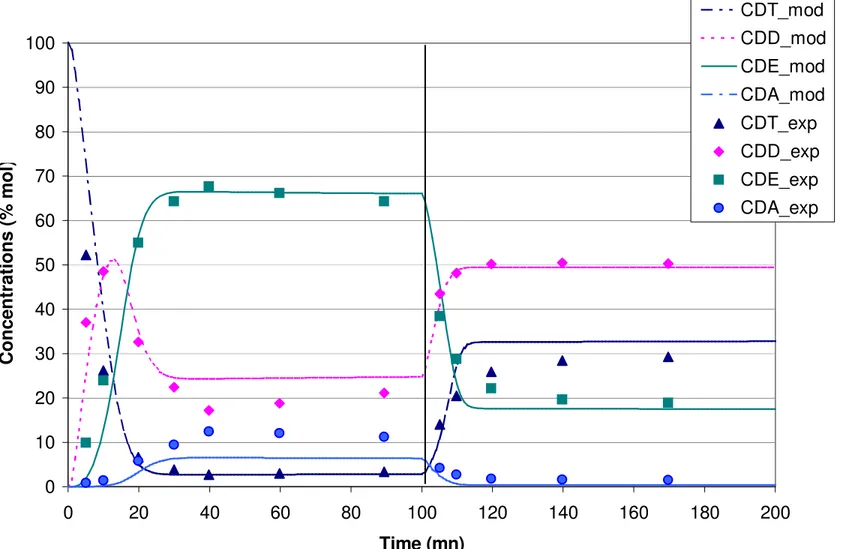

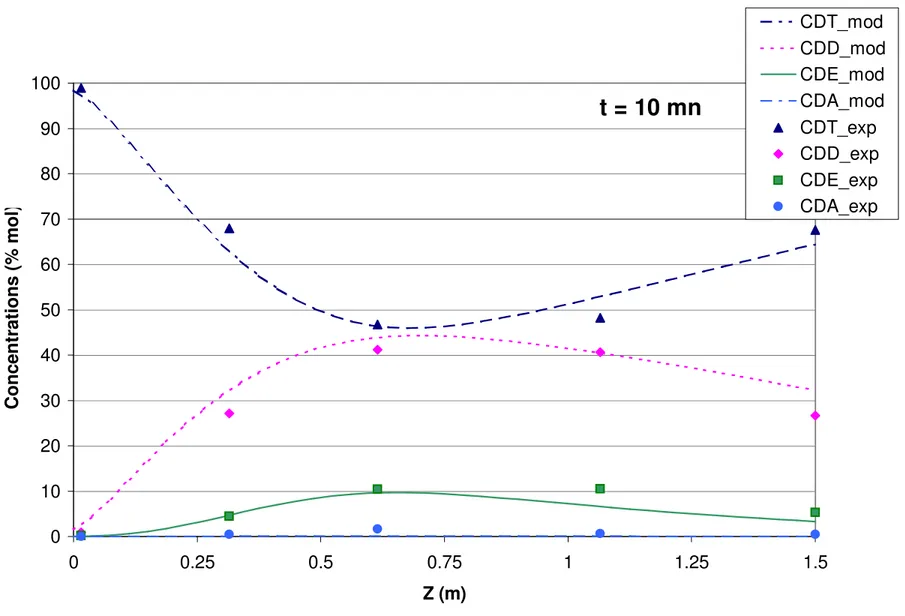

The adequate fitting of the experimental data values for the whole studied 30 range of concentration, and suggest the applicability of the finite solution volume assumption kinetic

Figure 11: Gas Volume in the porous medium as a function of time (left); input and output flow rates at the interface Γ for the gas and liquid phases (right) as a function of time

A two-dimensional pseudo-homogeneous model has been developed to investigate the influence of tube size on the thermal behavior and performance of packed fixed bed reactor for the

In this study, we performed Euler-Euler two-phase model simulations by using the effective drag force and the effective sub-grid stresses models for gas-solid flow in a 3-D

The hydrodynamic model was then compared with the experimental date for the impact of height of the fluidized bed, fluidization gas injection flow rate, and solid circulation flow