HAL Id: hal-01611606

https://hal.archives-ouvertes.fr/hal-01611606

Submitted on 20 Oct 2018

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Carbonated hydroxyapatite starting from calcite and

different orthophosphates under moderate hydrothermal

conditions: Synthesis and surface reactivity in simulated

body fluid

Doan Pham Minh, Ange Nzihou, Patrick Sharrock

To cite this version:

Doan Pham Minh, Ange Nzihou, Patrick Sharrock. Carbonated hydroxyapatite starting from

cal-cite and different orthophosphates under moderate hydrothermal conditions: Synthesis and surface

reactivity in simulated body fluid. Materials Research Bulletin, Elsevier, 2014, 60, p. 292-299.

�10.1016/j.materresbull.2014.08.052�. �hal-01611606�

Carbonated

hydroxyapatite

starting

from

calcite

and

different

orthophosphates

under

moderate

hydrothermal

conditions:

Synthesis

and

surface

reactivity

in

simulated

body

fluid

Doan

Pham

Minh

*

,

Ange

Nzihou,

Patrick

Sharrock

UniversitédeToulouse,MinesAlbi,CNRSUMR5302,CentreRAPSODEE,CampusJarlard,F-81013Albicedex09,France

Keywords: Structuralmaterials Chemicalsynthesis Infraredspectroscopy Surfaceproperties ABSTRACT

Theone-stepsynthesisofcarbonatedhydroxyapatite(CAP)usingcalciteanddifferentorthophosphates was investigatedina closedbatchreactor. Onlyorthophosphoric acidcould leadto thecomplete decompositionofcalciteparticles,whenthereactiontemperaturewassetat80!C.Ontheotherhand,the

reactiontimeandthedilutionof theinitialcalcitesuspensionhadnosignificantinfluenceonthe formationofthesolidproducts.CAPwasformedasthemaincrystallinecalciumphosphatewiththe carbonatecontentintherangeof4.2–4.6wt.%.ThethermaldecarbonationofthesynthesizedCAPstarted at750!Cbutitwasonlysignificantat1000!Cunderairatmosphere.Thisthermaldecarbonationwas

totalat1200!Corabove.AllCAPsamples andproductsfollowingthermaltreatmentswerefound

bioactiveinthetestusingsimulatedbodyfluid(SBF)solution.

1. Introduction

Theinorganicmineralphaseofhumanteethandboneismainly composed of calcium hydroxyapatite (Ca-HA, Ca10(PO4)6(OH)2),

withdifferentsubstitutionssuchassodium,magnesium,chloride, fluoride, carbonate,etc. [1–3].This explainsthe interestin the developmentofCa-HAandsubstitutedCa-HAinthebiomaterials field,duetotheirbiocompatibilityandbioactivity[4,5]. Substitut-ed Ca-HA is formedwhen calcium,phosphate,and/or hydroxyl groups of Ca-HA structure are replaced by other metals and functionalgroups.Thus,bonemineralhasusuallythemolarratio ofcalciumtophosphatevaryingintherangeof1.37–1.87compared withthatof1.67forstoichiometricCa-HA[3].Ingeneral,carbonate isfoundtobethemostabundantsubstitutionanditscontentin bonemineralvariesintherangeof3–8wt.%[6].Carbonategroups caninsertintheapatiticstructurebyreplacingphosphateand/or hydroxyl groups to form carbonated hydroxyapatite (CAP). Conventionally,CAPisA-typeCAPwhencarbonategroupsreplace phosphate groups;B-type CAP when carbonate groups replace hydroxyl groups; and A-B-type CAP when carbonate groups replacesimultaneouslyphosphateandhydroxylgroups.

ThesynthesisofCAPcallsusuallyfortheclassicalwetanddry methods.Inthewetprocess,solublecalciumandphosphatesare

precipitatedinanaqueoussolutioninthepresenceofcarbonate anions[7,8].ThisprocessleadsgenerallytotheformationofB-type CAP [7] but A-B-type CAPmay be also formed[9]. In the dry process,A-typeCAPcouldbegenerated byheatingpureCa-HA underCO2fluxathightemperatureinordertoreplacehydroxyl

groupsbycarbonategroups[10].CAPcouldbealsoobtainedbythe commonmechano-chemicalprocessasdemonstratedby Sucha-neket al.[11],whereinanaqueous suspensionof Ca(OH)2 and

CaCO3(orNa2CO3)and (NH4)2HPO4 aretreatedina

laboratory-scalemill.Butthislastwayrequiresseverereactionconditions. We recently developed a new one-step synthesis process of Ca-HAfromCaCO3andorthophosphoricacid(H3PO4)aseconomical

starting materials at moderate synthesis conditions [12]. The advantageofthisprocesscomparedto classicalCa-HA synthesis pathways remainsin the factthat pure Ca-HA canbeobtained withoutanyfurtherpurificationstep,thankstotheabsenceofall counterionsinthereactionmedium[12].Amodificationofthis processwasthendevelopedfortheone-stepsynthesisofCAPunder moderatehydrothermalconditions[13].CAPcontaining4.2wt.%of carbonatecouldbeobtainedfromthereactionofCaCO3andH3PO4in

aclosebatchreactorunderCO2pressure.CaCO3waschosenbecause

itisthesourceofbothcalciumcationsandcarbonateanionsforthe formationofCAP,andalsobecauseithasconsiderableindustrial importanceandabundantdiversityasabiomineral[14].Inthiswork, we firstlycompared thereaction of calcite with different alkali orthophosphates and orthophosphoric acid in orderto selectthe best orthophosphate.Then,weinvestigatedtheinfluenceofdifferent

* Correspondingauthor.Tel.:+33563493258;fax:+33563493043. E-mailaddress:doan.phamminh@mines-albi.fr(D.PhamMinh).

parameters includingthecontentofwaterintheinitialsuspensionof CaCO3, the reaction temperature and the reaction time, on the

contentofcarbonateinserted inthefinalsolidCAP. Theinvitro biomineralizationactivityofthesolidCAPproductcontainingthe highestcarbonatecontentwasalsoinvestigatedbeforeandafter thermaltreatmentatdifferenttemperatures.

2. Materialsandmethods

Orthophosphoricacid(H3PO4,85wt.%inwater)waspurchased

from Merck. Calcitepowder (CaCO3, d50of 23.6

m

m), and alkaliorthophosphates(NaH2PO4,KH2PO4,NH4H2PO4)ofanalyticalpurity

from Fisher Scientific were used as received without further purification.The reaction of CaCO3 with these orthophosphates

was carried out in a 250mL stainless steel close batchreactor (TopIndustry,France) whichwasequippedwithanelectricalheating jacketandamagneticstirrer.Whenorthophosphoricacidwasused, 10gof calcite powderand45–135gof water were fedintothe reactor. Thereactorwasclosedandthen6.92gH3PO4(85wt.%)wasquickly

injectedintothereactorviaasyringe.Whenalkaliorthophosphates wereused,10gofwaterwassetintothereactor.Thislastonewas closedand135gofanaqueoussolutioncontaining60mmolofan alkaliorthophosphatewasquicklyinjectedintothereactor.Inall

case,themolarratioofcalciumtophosphorusintheinitialreaction mixturewas1.67.Thereactionmixturewaskeptat60or80!Cunder

stirringof800rpmfor48–168hofreaction.Theconditionsforthe synthesisofdifferentCAPweresummarizedinTable1.Duringthe reaction, the pressure in thebatch reactor was measured by a manometer.Whenthereactionreachedthedesiredreactiontime, thereactor was freelycooled down to room temperature.Solid products were separated from liquid phase by filtration using 0.45

m

mfilterpaper.Thentheywereair-driedat50!Cfor48hbeforefurtheranalysesandcharacterizations.

Elemental analysis was carried out by inductively coupled plasma atomic emission spectroscopy (ICP-AES, HORIBA Jobin YvonUltima2apparatus).Infraredspectroscopy(IR)wascarried outusingaShimadzuFTIR8400Sspectrometerinthewavenumber range 4000–500cm"1. X-ray diffraction (XRD) measurements

were carried out using a Phillips Panalytical X’pert Pro MPD diffractometer.Scanningelectronmicroscopy(SEM)observation wasperformedonaPhilipsXL30ESEMapparatus. Thermogravim-etry analysis (TG) was carried out with a SDTQ600 analyzer (TAInstruments)underairflow(100mLmin"1)withtheheating

rateof20!Cmin"1.TheamountofremainingCaCO

3inthefinal

solidwascalculatedcorrespondingtotheobservedweightlossof CO2from610to720!C.

3. Results

3.1.Orthophosphatecomparison

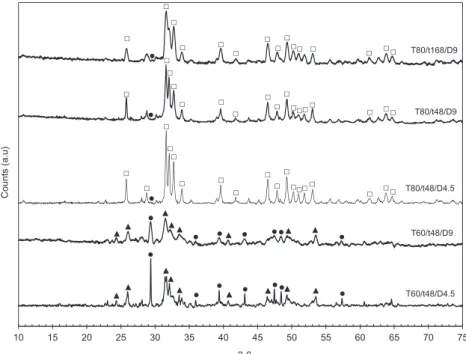

Fig.1presentsXRDresultsofthesolidproductsobtainedfrom thereactionofcalcitewithfourorthophosphatesundersimilar reaction conditions. Inall cases, Ca-HA appeared as the main crystallinecalciumphosphate.Ontheotherhand,the decompo-sitionofcalcite wasdifferent fromeachotherorthophosphate. Under the reaction conditions used, orthophosphoric acid alloweddecomposingcompletelytheintroducedcalcite,because the signal of themain diffractionpeakof calcite at 29.4! was

negligible (CAP–H pattern). For three alkali orthophosphates used,diffractionpeaksofremainingcalcitewereclearlyobserved, which indicates that the reaction of calcite and these

Table1

SynthesisconditionsofCAPfromCaCO3(100mmolor10g),alkaliorthophosphates,

andH3PO4 (66.7mmol);D isthemass ratioofwater tocalciteintheinitial

suspension.Thefinalpressureinthebatchreactorvariedintherangeof9–16bar. Orthophosphate T (!C) t (h) D Water (g) Solidproduct designation Note NaH2PO4 80 48 13.5 135 CAP–Na Comparisonof

orthophosphate KH2PO4 80 48 13.5 135 CAP–K NH4H2PO4 80 48 13.5 135 CAP–N H3PO4 80 48 13.5 135 CAP–H H3PO4 60 48 4.5 45 T60/t48/D4.5 Parametric study H3PO4 60 48 9 90 T60/t48/D9 H3PO4 80 48 4.5 45 T80/t48/D4.5 H3PO4 80 48 9 90 T80/t48/D9 H3PO4 80 168 9 90 T80/t168/D9

orthophosphateswasnotcompleted.Thisresultwasconfirmed byTGanalysis(resultsnotshown).Theremainingcalcitecontent presentinthefinalsolidswas4.4,1.4,0.5and<0.06wt.%forCAP– Na,CAP–K,CAP–NandCAP–H,respectively.Probably, orthophos-phoric acid with higher acidity compared to other alkali orthophosphates was more favorable for the dissolution of calcite particles,which is crucial for the formation of calcium phosphatephases [15].Whencalciteparticleswerecoveredby solid calcium phosphate layers, the contact between these covered calcite particlesandorthophosphatessourcesmust be preventedandsothereactionisstoppedorsloweddown[15,16]. Inadditiontothishigherperformanceforthedecompositionof calcite, nowashingstepwasneededfor thepurificationofthe solidproduct startingfromorthophosphoricacidthanks tothe absenceofcounter-ionssuchasalkalis.Soforthenextparametric

study,CAPsynthesiswasperformedonlywithorthophosphoric acid.

3.2.CAPfromcalciteandorthophosphoricacid–XRD characterization

Fig.2presentsXRDpatternsofthesolidproductsobtainedat different synthesis conditions. Both productsobtained at 60!C

(T60/t48/D4.5andT60/t48/D9)containedoctocalciumphosphate (OCP, Ca8(HPO4)2(PO4)4

#

5H2O) as the main crystalline calciumphosphate, and high contents of remaining calcite. So the temperatureof60!Cwasnotenoughforthecompletedissolution

ofcalciteparticles.Probablythistemperatureledtotheformation ofcore–shellparticlesinwhichcalcitecorewascoveredbysolid calciumphosphatelayers(shell)[17].Thisstructurepreventedthe

Fig.2.XRDpatternsofthesolidproductsobtainedatdifferentsynthesisconditions;(&)Ca-HA(JCPDSstandardNo.01-072-1243);(~)OCP(JCPDSstandardNo. 00-026-1056);(*)calcite(JCPDSstandardNo.00-047-1743).

500 1000 1500 2000 2500 3000 3500 4000 Tr ansm ittance, a. u Wavenumber, cm-1 T80/t168/D9 T80/t48/D9 T80/t48/D4.5 T60/t48/D9 T60/t48/D4.5 OH Phosphate CO32 Phosphate CO32

contact of remaining calcite core with phosphate species and sloweddownor stopped thereaction at this temperature. The increaseofthedilutionofcalcitesuspensiondidnotimprovethe dissolutionofcalciteat60!C.

Onthe other hand, whenthe reaction temperature rose to 80!C,calcitecouldbecompletelydissolvedasindicateditsvery

weak signal of the principal XRD peak at 29.4!. At this

temperatureandforthesamereactiontimeof48h,thedilution ofCaCO3suspensionhadnoremarkableinfluenceontheformed

product.Themaincrystallinecalciumphosphatephaseidentified fortheproductssynthesizedat80!CwasCa-HA.However,CAP

(JCPDS standard No. 96-900-3550, 96-900-3551, 96-900-3552) mightbealsopresentintheseproductsbuttheirXRDdiffractions areusuallysuperposedonthoseofCa-HA.SothepresenceofCAP needstobeconfirmedbyotheranalyses.

3.3.CAPfromcalciteandorthophosphoricacid–IRcharacterization IRspectraofallthesolidproductsarepresentedinFig.3.Inall cases,characteristicpeaksofphosphategroupscouldbefoundin thewavelengthrangesof650–550cm"1and1300–910cm"1[13].

Fortwosolidsobtainedat60!C,nosignalofcarbonategroupswas

observed, despite remarkable contents of remaining calcite as shown by XRD analysis (Fig. 2). As mentioned above, calcite remnants must be covered by calcium phosphate layers and thereforecouldnotbedetectedbydiffusereflectanceIRanalysis, whichrecordsonlysurfaceinformationforsolidsamples.

For the solids synthesized at 80!C, absorption bands of

carbonategroupscouldbeclearlyobservedat1545,1450,1415, 880,and870cm"1.Alltheseabsorptionbandscouldbeattributed

tocarbonate groups inserted in theapatite structure of Ca-HA

80

85

90

95

100

105

0

500

1000

1500

TG

(w

t.

%

)

Temperature,

oC

T60/t48/D4.5

T60/t48/D9

(A)

0

0

500

100

0

150

0

DT

G

(w

t.

%

/

oC),

a

u

Temperature,

oC

T60/t48/D4.5

T60/t48/D9

(B)

Fig.4.TGanalysisofthesolidproductssynthesizedat60!C.

80

85

90

95

100

105

0

500

100

0

150

0

TG

(w

t.

%

)

Temperature,

oC

T80/t168/D9

T80/t48/D4.5

T80/t48/D9

(A)

0

0

500

100

0

150

0

DT

G

(w

t.

%

/

oC),

a

u

Temperature,

oC

T80/t168/D9

T80/t48/D4.5

T80/t48/D9

(B)

[18–20].Carbonategroupsreplacedbothphosphateandhydroxyl groupstoformA-B-typeCAP,asillustratedbytheircharacteristic absorption bands at 1545 and 880cm"1 (A-type) and 1450,

1415and870cm"1(B-type)[18,19].

Theelementalanalysisofthreesolidproductsobtainedat80!C

showedthatthemolarratioofcalciumtophosphorusvariedin 1.83–1.90 range, which was higher than the value of the stoichiometricCa-HA. Thiscanbeexplainedbytheinsertion of carbonategroupsatthepositionofphosphategroups.

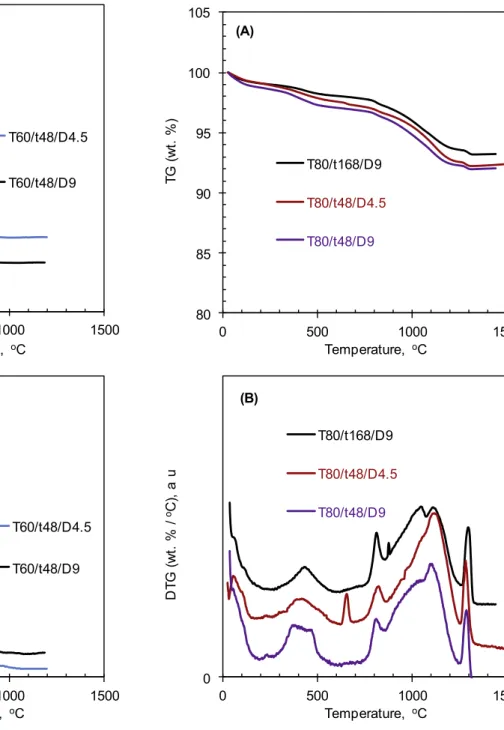

3.4.CAPfromcalciteandorthophosphoricacid–TGcharacterization Fortheuseasbiomaterials,calciumphosphatebasedproducts areusuallytreatedbyasinteringstep[21].Thermalbehaviorofthe preparedsolidswasinvestigatedinlargerangeoftemperatureas showninFigs.4and5.Forthesolidpreparedat60!C(Fig.4),after

thefirstweightlossabout100!Cduetotheremovalofsurface

humidity, different weight losses in the temperature range of 100–600!CwereobservedforthedehydrationofOCP[18,22–25],

which wasthemaincalciumphosphatepresentinthesesolids. Remainingcalciteshowedanintenseweightlossatabout610!C,

followedbythedecarbonationofCAPat750!C.Nofurtherweight

losswasobservedupto1200!Cforthesetwosolids.

For the solids synthesizedat 80!C, afterthedehydration of

surface moisturearound 100!C, thedehydrationof

hydrogeno-phosphate groupstook placein therangeof 100–600!C. These

weightlossesweremuchlowercomparedtothesolidssynthesized at 60!C (Fig. 4). As expected, no notable signal of calcite

decomposition was detectedaround 610!C. On theotherhand,

thedecarbonationofCAPtookplacewithimportantweightlosses. Thisdecarbonationstartedatabout750!Candfinishedatabout

1200!C. The last weight loss around 1250!C was due to the

dehydration of hydroxyl group of apatitic structure to form oxyhydroxyapatite[5].So,whenthesynthesistemperaturewasset at80!C, thereactiontimeand thedilution oftheinitialcalcite

suspensionhadnonotableinfluenceonthefinalCAP.Threesolid productssynthesizedat80!Cseemedalsotohavesimilarthermal

behavior.FromTGanalysis,thecontentofcarbonateinsertedinthe apatiticstructurecouldbecalculated,supposingthatweightloss in thetemperature range of750–1250 was due tothethermal decarbonation. Thus, three solid products synthesized at 80!C

fromcalciteandorthophosphoricacidhadthecarbonatecontent intherangeof4.2–4.6wt.%.

3.5.CAPfromcalciteandorthophosphoricacid–thermaltreatment andbiomineralizationactivityinSBFsolution

For use as biomaterials, hydroxyapatite based products, includingCAP,mayneedstabilizationstepbythermaltreatment. InthecaseofCAP,thethermaltreatmentshouldnotleadtodeep decarbonation, in order tomaintain apatitic carbonate content similartothatofbonemineral[6].Inthissection,thermalstability ofCAPsynthesizedat80!C(T80/t48/D4.5)isdiscussed.Thissolid

T80/t48/D4.5 was chosen because of its lowest content of remainingCaCO3.ThereactivityofsolidproductsinSBFtest,as

the biomineralization activity, is also reported. This test was carriedoutwithT80/t48/D4.5thermallytreatedatthe tempera-turerangeof105–1400!Cunderairatmosphere.

ThermaltreatmentofT80/t48/D4.5powderwascarriedoutin the TG–DSC analyzer under air atmosphere. The powder was heatedat10!Cmin"1uptodesiredfinaltemperatureandwaskept

atthis temperaturefor5h.The finaltemperature variedin the range600–1400!C.After,theovenwasfreelycooleddowntoroom

temperature. 500 700 900 1100 1300 1500 1700 Tr an sm itt an ce (a . u .) Wavenumber (cm-1) 105oC 600 oC 800 oC 1000 oC 1545 1450 1415 1200 oC 1400 oC

IR spectrawere rapidlyrecorded onsinteredproducts, and are presented in Fig.6.Althoughthe decarbonationof CAPstarted around750!C(TGanalysis,Fig.5),thethermaltreatmentinthe

temperaturerangeof600–800!Cseemedtohavenoimpactonthe

carbonatecontentofT80/t48/D4.5solid.Thismaybeexplainedby alowkineticdecarbonationofT80/t48/D4.5at600–800!C.When

thesinteringtemperatureroseto1000!C,apartialdecarbonation

couldbeobserved,leadingtoreductionofIRintensityofapatitic carbonategroups.At1200–1400!C,absorptionbandsofcarbonate

groups disappeared, indicating that the decarbonation was complete. Thecalcinationat1200!CledtothecharacteristicIR

spectra ofCa-HA,while thecalcinationat 1400!C decomposed

Ca-HA intotetracalciumphosphate(TTCP)andtricalcium phos-phate(TCP)[18,26].Accordingtopreviousreports[18,19,26],the thermal treatmentunderairatmosphereisexpected toincrease the crystallinities of Ca-HA and CAP, and decrease the apatitic carbonatecontentofCAP,asconfirmedbyIRresults(Fig.6).Butat the very high temperature of 1200–1400!C, Ca-HA and CAP

decomposedintoTCPandTTCP.

Biomineralization activityof sinteredsolids wasinvestigated usingsimulatedbodyfluid(SBF)solution.SyntheticSBFsolution waspreparedaccordingtopreviouswork[27].Forthistest,asolid sinteredataspecifictemperaturewassubmergedintoSBFsolution andtheobtainedsuspensionwasthermostatedat37!Cfor7days.

SEM studywas thenperformedonthepowdersrecoveredafter risingwithwateranddryingatroomtemperature.

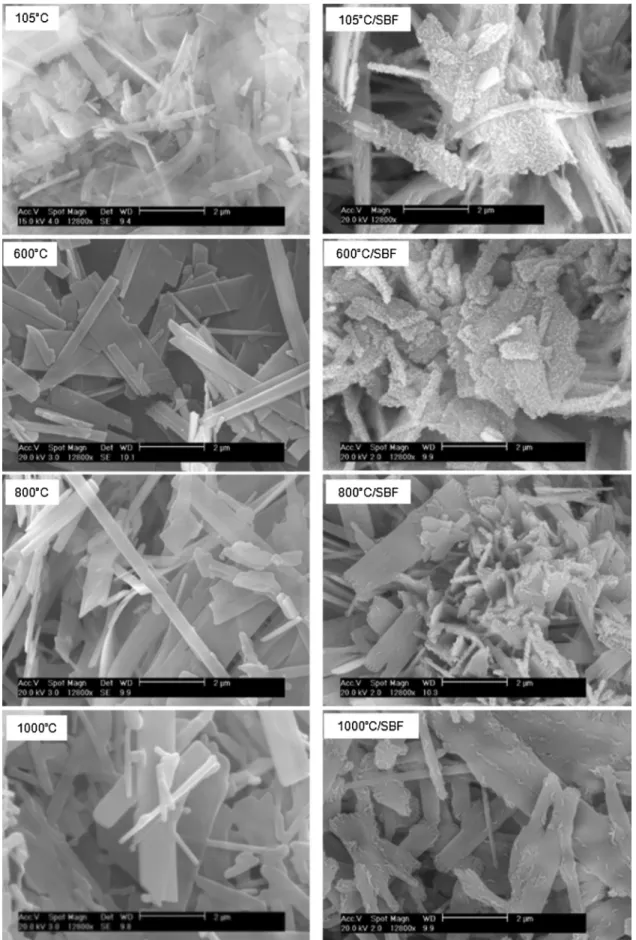

Ontheleft-hand-sideof Fig.7,thesinteringat600–1000!C

hadnosignificantinfluenceontheapparentmorphologyofCAP particles.Particlesofflat-needle-likemorphologydominatedCAP powders, driedat105!Corsintered at600–1000!C.Whenthe

temperature rose to 1200–1400!C (left-hand-side, Fig. 8),

sintering took place with the increase of particle size, true density and the decrease of porosityandspecific surfacearea [28,29].

ForCAPpowderstreatedat105–1000!C,despitethedecrease

ofcarbonatecontentwhenthecalcinationtemperatureincreased as showed by TGanalysis, CAP particles werecovered by new calcium phosphate layers after contact with SBF solution (Fig. 7, right-hand-side). Previous reports showed that Ca-HA basedmaterialshadappropriatebiomineralizationactivityforthe growthofcalciumphosphatelayersinSBFsolution[27,30,31].SBF solutionwasalsofoundasfavorablemediumfortheprecipitation ofcalcium andphosphate toformCa-HA [32,33].For oursolid synthesizedat80!C,thepresenceoftraceamountof remained

calcitemustnotinfluencethegrowthofCa-HAbecausecalcitehas beenshownasbiomineralanditsgrowthtookplaceinSBFsolution [14,33]. For the solids calcined at 1200–1400!C, although the

thermaldecarbonationwascomplete,thegrowthofnewcalcium phosphatelayersalsotookplace(Fig.8,right-hand-side).Infact, Ca-HA,andnon-apatiticcalciumphosphatesincludingTTCPand TCP, which resulted from thermal treatment of CAP at 1200–1400!C, are also known as active biomineralization

materialsinSBFsolution[26,31,34,35]. 4. Conclusions

The reaction of calcite and different orthophosphates was investigated.Alkaliphosphatesdidnotallowacomplete decom-positionofcalciteat80!Cinaclosebatchreactor.

Ontheotherhand,orthophosphoricacidledtothecomplete decompositionofcalcitepowder,andcarbonatedhydroxyapatite (CAP)wasformed.Thereactiontemperatureof80!Cwasfoundto

be crucial for the total decomposition of calcite and thus the formationofapatiticphase.Thereactiontimeandthedilutionof calcitesuspensionhadnosignificantinfluenceonthereaction.

CAPpowderstartingfromorthophosphoricacidandcalcitewas thermally stable at 600 and 800!C under air atmosphere. At

1000!C for 5h, partial decarbonation was observed. The

decarbonationwastotalat1200orabove.AllCAPanditsthermal decompositionproductswerefoundtobereactiveinSBFsolution, promotingcrystallizationofbiomimeticapatites.

Acknowledgment

Theauthorsgratefullyacknowledgecolleaguesat RAPSODEE Centerfortechnicalhelp.

References

[1]E.D.M.D.Pellegrino,R.M.B.S.Biltz,Medicine44(1965)397–418.

[2]K.J.Quelch,R.A.Melick,P.J.Bingham,S.M.Mercuri,Archs.Oral.Biol.28(1983)

665–674.

[3]J.P.Bilezikian,L.G.Raisz,T.J.Martin,PrinciplesofBoneBiology,3rded.,Elsevier,

2008.

[4]E.S.Thian,Z.Ahmad,J.Huang,M.J.Edirisinghe,S.N.Jayasinghe,D.C.Ireland,R.A.

Brooks,N.Rushton,W.Bonfield,S.M.Best,Biomaterials29(2008)1833–1843.

[5]D.PhamMinh,N.D.Tran,A.Nzihou,P.Sharrock,Mater.Sci.Eng.C33(2013)

2971–2980.

[6]E.Landia,G.Celottia,G.Logroscinob,A.Tampieria,J.Eur.Ceram.Soc.23(2003)

2931–2937.

[7]R.M. Wilson,J.C.Elliott,S.E.P.Dowker,R.I.Smith,Biomaterials25(2004)

2205–2213.

[8]S.Padilla,I.Izquierdo-Barba,M.Vallet-Regí,Chem.Mater.20(2008)5942–5944.

[9]H.E.Mason,A.Kozlowski,B.L.Phillips,Chem.Mater.20(2008)294–302.

[10]T. Tonegawa,T. Ikoma,Y.Suetsugu,N.Igawa,Y.Matsushita,T. Yoshioka,

N.Hanagata,J.Tanaka,Mater.Sci.Eng.B173(2010)171–175.

[11]W.L.Suchanek,P.Shuk,K.Byrappa,R.E.Riman,K.S.TenHuisen,V.F.Janas,

Biomaterials23(2002)699–710.

[12]D.PhamMinh,N.D.Tran,A.Nzihou,P.Sharrock,Ind.Eng.Chem.Res.52(2013)

1439–1447.

[13]D.PhamMinh,N.D.Tran,A.Nzihou,P.Sharrock,Mater.Res.Bull.51(2014)

236–243.

[14]M.Mozafari,F.Moztarzadeh,Challengesofspontaneousformationofcalcite

duringbioactivityassessmentonbioactivematerialsinterfaces,in:J.Dobrev,P.

Markovic (Eds.), Calcite: Formation, Properties and Applications, NOVA

SciencePubInc.,NewYork,2011,pp.95–122.

[15]D.PhamMinh,N.Lyczko,H.Sebei,A.Nzihou,P.Sharrock,Mater.Sci.Eng.B177

(2012)1080–1089.

[16]C.Verwilghen,M.Chkir,S.Rio,A.Nzihou,P.Sharrock,G.Depelsenaire,Mater.

Sci.Eng.C29(2009)771–773.

[17]D.PhamMinh,H.Sebei,A.Nzihou,P.Sharrock,Chem.Eng.J.198–199(2012)

180–190.

[18]J.C.Elliott,StudiesinInorganicChemistry18:StructureandChemistryofthe

ApatitesandOtherCalciumOrthophosphates,Elsevier,Amsterdam–London–

NewYork–Tokyo,1994.

[19]M.E.Fleet,X.Liu,Biomaterials28(2007)916–926.

[20]M.E.Fleet,Biomaterials30(2009)1473–1481.

[21]M.Jarcho,Clin.Orthop.Relat.Res.157(1981)259–278.

[22]A.I. Mitsionis, T.C. Vaimakis, C.C. Trapalis, Ceram. Int. 36 (2010)

623–634.

[23]H.Monma,Y.Nishimura,T.Okura,Phosph.Res.Bull.18(2005)127–134.

[24]A.Lebugle,E.Zahidi,G.Bonel,React.Solids2(1986)151–161.

[25]A.Bigi,G.Cojazzi,M.Gazzano,A.Ripamonti,N.Roveri,J.Inorg.Biochem.40

(1990)293–299.

[26]C.J.Liao,F.H.Lin,K.S.Chen,J.S.Sun,Biomaterials20(1999)1807–1813.

[27]S.Jalota,S.B.Bhaduri,A.C.Tas,Mater.Sci.Eng.C28(2008)129–140.

[28]S.Bailliez,A.Nzihou,Chem.Eng.J.98(2004)141–152.

[29]D.PhamMinh,M.GaleraMartinez,A.Nzihou,P.Sharrock,J.Therm.Anal.

Calorim.112(2013)1145–1155.

[30]T.Kokubo,S.Ito,M.Shigematsu,S.Sakka,T.Yamamuro,J.Mater.Sci.22(1987)

4067–4070.

[31]T.Kokubo,H.Takadama,Biomaterials27(2006)2907–2915.

[32]A.C.Tas,Biomaterials21(2000)1429–1438.

[33]M.Mozafari, F.Moztarzadeh, M.Tahriri, J. Non-Cryst.Solids 356 (2010)

1470–1478.

[34]K.Kurashina,H.Kurita,M.Hirano,J.M.A.deBlieck,C.P.A.T.Klein,K.deGroot,

J.Mater.Sci.:Mater.Med.6(1995)340–347.

[35]L.A.DosSantos,L.C.DeOliveira,E.C.S.Rigo,R.G.Carrodeguas,A.O.Boschi,