Science Arts & Métiers (SAM)

is an open access repository that collects the work of Arts et Métiers Institute of Technology researchers and makes it freely available over the web where possible.

This is an author-deposited version published in: https://sam.ensam.eu Handle ID: .http://hdl.handle.net/10985/11624

To cite this version :

Mamoun FELLAH, Linda AISSANI, Mohamed LABAIZ, Corinne NOUVEAU, Alain IOST, Alex MONTAGNE, Mohamed ABDUL SAMAD, F. LAKMINE - Synthesis, microstructural and tribological characterization of calcined nano-bioceramic - al2o3, sintered at different temperatures - 2016

Any correspondence concerning this service should be sent to the repository Administrator : archiveouverte@ensam.eu

Colloque Indentation 2016 12 – 14 Octobre 2016 Lille

Groupe d’Indentation Multi Echelle Nord Pas-de-Calais

SYNTHESIS, MICROSTRUCTURAL AND TRIBOLOGICAL CHARACTERIZATION OF

CALCINED NANO-BIOCERAMIC Α- AL2O3, SINTERED AT DIFFERENT

TEMPERATURES

FELLAH M1,2, AISSANI L3, LABAIZ M1, NOUVEAU C4, IOST A5, MONTAGN A5, ABDUL SAMAD M6, LAKMINE F3

1.Surface Engineering and Tribology Group, Laboratory of Metallurgy and Engineering Materials, BADJI Mokhtar-Annaba University, P.O. 12, 23000, Algeria E-Mail: mamoun.fellah@yahoo.fr.

2.Mechanical Engineering Department, ABBES Laghrour- Khenchela University P.O 1252, 40004, Algeria.

3.Phusics Department, ABBES Laghrour- Khenchela University P.O 1252, 40004, Algeria

4.Laboratoire Bourguignon des Matériaux et procédées Rue Porte de Paris 71250 CLUNY FRANCE 5.Laboratory of Mechanics Surfaces and processing materials, ARTS ET METIERS ParisTech, 8, Boulevard Louis XIV, 59046 Lille Cedex, France

6. Mechanical Engineering Department, King Fahd University of Petroleum & Minerals. Box 1180, Dhahran – 31261.

Keywords: Sliding friction and wear, Nanobioceramic. Wear testing, Nanotribology,

calcinations, microstructural evolution. Bioceramic

ABSTRACT

The current research was undertaken to study the improvement of the tribological behavior of nanocrystalline bioceramic, α-alumina sample, produced by the calculations of gibbsite at different temperatures (300 to 1200°C), followed by uniaxial pressing, sintering and HIP treatment. The improved friction and wear resistance is attributed to the fine microstructure of the sample calcined at 1400 °C.

1. MATERIALS AND METHODS

The calcined alunminas powders were uniaxially pressed at 150 MPa into discs of 17 mm in diameter and 4 mm thickness. The compaction was carried out at a constant strain rate. After ejecting from the die, the samples were measured and weighed to calculate the density. Green compacts were placed into an alumina crucible with Al2O3 powder and

sintered at different temperatures of 1250, 1300, 1350, 1400 and 1450 °C for 2 h at a heating rate of 30 K min-1 in order to obtain a closed porosity (high density) as observed by M.H. Bocangera [1, 2]. The sintered samples were then introduced into a boron nitride crucible with an alumina powder bed to minimize possible reactions with the graphite heating element and subsequently hot isostatically pressed at 1325 °C and 1350 °C respectively at a heating rate of 30 K.min -1 and at an isostatic pressure of 150 MPa for 35 min.

Colloque Indentation 2016 12 – 14 Octobre 2016 Lille

Groupe d’Indentation Multi Echelle Nord Pas-de-Calais

The temperatures of sintering and hot pressing of the alumina were determined on the basis of our previous published work [1] and of many authors [3, 4 and 5]. This HIP treatment was applied to the powder in order to produce a fine grained material with a final relative density of 98 %.

2. RESULTS AND DISCUSSIONS

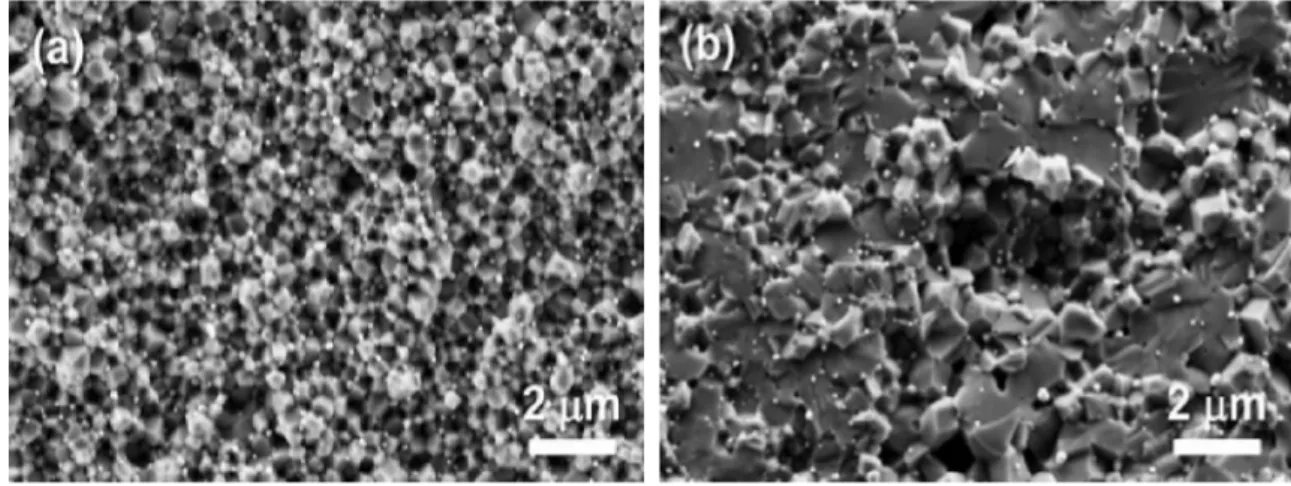

The friction and wear properties, structural evolution, lattice parameters, hardness morphological changes as a function of calcination, sintering temperature and nanocristalinity were reported using XR diffraction, XPS, MEB and Tribometer. The different transition aluminas are formed and may even be present simultaneously. It is observed that the crystallite size of the particles reduced to 8 nm after calcinations at 1250°C. Morphological studies of powder particles indicated that the powder particle size continuously decreases with increasing temperature of calcinations.

The sliding wear rate and wear coefficient of friction were lower in the nanocrystalline samples sintered at 1400 °C at same load (3, 6 or 10N). The improved friction and wear resistance is attributed to the finer microstructure of the sample calcined at 1400°C.

Figure 1: surfaces SEM micrographs corresponding to HIPed Alumina, sintered at: a) 1250 °C and b) 1350°C.

3. References

[1] M.H. Bocanegra-Bernal. Hot isostatic pressing (HIP) of α-Al2O3 submicron ceramics pressure less sintered at different temperatures: Improvement in mechanical properties for use in total hip arthroplasty (THA). Int. Journal of Refractory Metals & Hard Materials 2009; 27: 900-906.

[2] FELLAH Mamoun, ABDUL SAMAD Mohammed, LABAÏZ Mohamed, ASSALA Omar, "Sliding friction and wear performance of the nano-bioceramic α-Al2O3 prepared by high energy milling”. Tribology International, 91 (2015) 151-159.

Colloque Indentation 2016 12 – 14 Octobre 2016 Lille

Groupe d’Indentation Multi Echelle Nord Pas-de-Calais

[3]. Slonaker M, Goswami T. Review of wear mechanisms in hip implants: Paper II–ceramics IG004712, Materials and Design 2004; 25: 395–405.

[4] Chantikul P, Bennison S. J, Lawn B. R. Role of grain size in the strength and R-curve properties of alumina. Jam Ceram Soc, 1990; 73: 241927.

[5] Padture N. P, Bennison S. J, Chan H. M. Flaw-tolerance and crack- resistance proper- ties of alumina aluminum titanate composites with tailored microstructures. J Am Ceram Soc 1993; 76: 231220.