Publisher’s version / Version de l'éditeur:

Cement and Concrete Research, 13, January 1, pp. 81-88, 1983-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1016/0008-8846(83)90130-8

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fracture toughness of autoclaved portland cement - silica mixtures

Beaudoin, J. J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=822ac7dd-a1f2-477d-b8e2-72e6181f7cc2 https://publications-cnrc.canada.ca/fra/voir/objet/?id=822ac7dd-a1f2-477d-b8e2-72e6181f7cc2no.

1066

c, 2

~tional

Research Council of Canada

I

ma;

lnseil national de reclperches du Canada

I

FRACTURE TOUGHNESS OF

AUTOCLAVED PORTLAND

CEMENTISILICA MIXTURES

by J. J.

Beaudoin

.

ANAhYZECl

Reprinted from

Cement and Concrete Research

Vol. 13, No.

1.

1983

.

.

r.

.

.

.

-

b bBLDG. RES.

L I B R A R Y

83-

02-

2%

B I B L I O T H ~ Q @ €

Rech.

8i:irn.

1

DBR Paper No. 1066

Division of Building Research

This publication is being distributed by the Division of Building Research of the National Research Council of Canada. It should not be reproduced in whole or in part without permis- sion of the original publisher. The Division would be glad to be of assistance in obtaining such permission.

Publications of the Division may be obtained by mailing the appropriate remittance (a Bank, Express, or Post Office Money Order, or a cheque, made payable to the Receiver General of Canada, credit NRC) to the National Research Council of Canada, Ottawa. KIA OR6. Stamps are not acceptable. A list of all publications of the Division is available and may be obtained from the Publications Section. Division of Buildina Re- search, National Research Council of canada, Ottawa. KIA>R~.

CEMENT and CONCRETE RESEARCH. Vol. 13, pp. 81-88, 1983. Printed in the USA.

0008-8846/83/010081-08$03.00/0 Copyright (c) 1982 Pergamon Press, Ltd.

I

FRACTURE TOUGHNESS OF AUTOCLAVED PORTLAND CEMENT/SILICA MIXTURES

J

.

J.

BeaudoinDivision of Building Research, National Research Council of Canada, Ottawa K1A 0R6, Canada

(Communicated by F.H. Wittmann) (Received March 23, 1982)

ABSTRACT

Fracture toughness measurements made at 11% RH on autoclaved cement/silica mixtures having a wide range of silica contents and porosities yielded a series of curves for Kc versus porosity and Kc versus silica content. Those for preparations having low porosity and silica content were unique. Apparently aC2S-hydrate, unreacted silica and pores having specific size distribution can act as crack arrestors. Kc versus hardness curves were similar to those for Kc versus porosity. Simple microhardness tests may be useful in predicting fracture toughness of autoclaved cementitious systems.

I

IntroductionMany industrial products, including concrete block, are formed by

autoclaving portland cement/silica mixtures, variations in the cement/silica ratio producing a variety of cement matrices with different compositions and pore structures. These matrices are multi-component microporous systems.

The reactions that occur when cement/silica mixtures are autoclaved have been the subject of extensive study (1). Depending on initial proportions of cement and silica, the principal products are crystalline aC2S-hydrate, 11 tobermorite, poorly crystallized tobermorite, and sometimes hillebrandite and xonotlite. At low silica contents formation of dense aC2S-hydrate is known to occur. The low strength of autoclaved portland cement paste is attributed to the presence of aC2S-hydrate, although when porosity is significantly reduced, e.g., by sulfur impregnation, these materials have greatly increased strength in proportion to the amount of aC2S-hydrate (2). Mixtures having high silica contents (e.g., 50%) contain significant amounts of unreacted silica. Optimization of silica content for maximum strength has been well documented and the microstructure of the products at optimum silica content has several characteristics similar to those of C-S-H formed during normal hydration of portland cement, e.g., density, crystallinity, etc (3).

Traditional methods of studying and characterizing cement and cement/ mineral systems include surface area, microscopy, X-ray diffraction, DTA, TGA, calorimetry and pore structure analysis. By comparison, fracture mechanics

Vol. 1 3 , No. 1 J . J . Beaudoin e q u i l i b r i u m w i t h r e s p e c t t o r e l a t i v e humidity have r e c e i v e d l i t t l e a t t e n t i o n , a l t h o u g h t h e y p r o v i d e a d d i t i o n a l means of c h a r a c t e r i z i n g multicomponent, m o i s t u r e - s e n s i t i v e c e m e n t i t i o u s systems. I d e n t i f i c a t i o n o f m i c r o s t r u c t u r a l f e a t u r e s t h a t a f f e c t t o u g h n e s s c a n assist c o n c r e t e p r o d u c e r s i n d e s i g n i n g t h e b e s t c o n c r e t e mixes f o r v a r i o u s r e q u i r e m e n t s . T h i s i n v e s t i g a t i o n was u n d e r t a k e n t o d e t e r m i n e t h e dependence o f terms c h a r a c t e r i z i n g f r a c t u r e on C-$-H composition and p o r e s t r u c t u r e f o r a v a r i e t y o f calcium s i l i c a t e systems. A second o b j e c t i v e was t o t e s t whether i n c l u s i o n s o f ciC2.S-hydrate and u n r e a c t e d s i l i c a c a n a c t a s c r a c k a r r e s t o r s and toughen t h e m a t r i x m a t e r i a l . Another was t o i n v e s t i g a t e t h e dependence of f r a c t u r e t o u g h n e s s on m i c r o h a r d n e s s f o r t h e s e cement systems i n o r d e r t o e s t a b l i s h whether m i c r o h a r d n e s s t e s t i n g c a n p r o v i d e a s i m p l e method of e s t i m g t i n g f r a c t u r e t ~ u g h n e s s .

Experimental M a t e r i a l s

Type I cement w i t h t h e f o l l o w i n g composition was u s e d : S i 0 2 = 20.78%;

A1203 = 6.20%; Fe203 = 2.22%; CaO = 64.83%; MgO = 1.84%; SO3 = 3.17%;

Na20 = 0.05%; K20 = 0.40%; l o s s on i g n i t i o n = 0.51%. The c a l c u l a t e d Bogue

compound composition was: C4AF = 6 . 7 % ; C3A = 12.7%; C3S = 51.4%; C2S = 20.3%

and CaS04 = 5.4%.

S i l i c a

Ottawa s i l i c a sand was ground and t h e f r a c t i o n p a s s i n g 100-mesh s i e v e was mixed w i t h cement i n t h e f o l l o w i n g amounts: 5 , 10, 20, 30, 50 and 65 p e r c e n t by weight o f s o l i d s .

Sample P r e p a r a t i o n

Samples f o r a u t o c l a v i n g were p r e p a r e d a t w a t e r / s o l i d r a t i o s o f 0 . 2 5 , 0.30, 0.35, 0.40 and 0.45: a t each w a t e r / s o l i d r a t i o , s i x s e t s o f samples, each s e t having a d i f f e r e n t s i l i c a c o n t e n t , f o r a t o t a l o f 30 p r e p a r a t i o n s . Samples were c a s t and m o i s t c u r e d f o r 24 h i n moulds 1.2 x 7 . 5 x 20 cm, t h e n a u t o - c l a v e d a t 216OC (2 MPa) f o r 3 h. T e s t p i e c e s were s l i c e d from t h e a u t o c l a v e d samples, and a t t e m p t s were made t o s l i c e samples made w i t h 0% SiO2, b u t t h e y were s o f r a g i l e t h a t t h e m a j o r i t y f r a c t u r e d d u r i n g c u t t i n g . No t e s t s , t h e r e f o r e , were c a r r i e d o u t w i t h 0% S i 0 2 . T e s t p i e c e s were beams 1 . 2 cm deep x 0.127 cm t h i c k x 7 . 5 cm long w i t h a mid-span n o t c h 0.025 cm wide x 0 . 6 cm deep. The d e t a i l s o f f a b r i c a t i o n have been p u b l i s h e d ( 4 ) . The t e s t p i e c e s were m a i n t a i n e d i n d e s i c c a t o r s a t 11% RH u n t i l t e s t e d t o minimize t h e r i s k o f c a r b o n a t i o n , f u r t h e r h y d r a t i o n , and e x c e s s volume change; t h i s i s a c o n v e n i e n t r e f e r e n c e s t a t e . A minimum o f t h r e e t e s t p i e c e s f o r each

p r e p a r a t i o n were t e s t e d . Techniaues

Microhardness. Microhardness was measured w i t h a L e i t z m i n i l o a d t e s t e r i n a c o n d i t i o n e d box (11% RH) f r e e o f C02 u s i n g a V i c k e r s pyramid i n d e n t o r . F i v e d e t e r m i n a t i o n s were performed on t h e s u r f a c e o f each sample.

P o r o s i t y . P o r o s i t y d e t e r m i n a t i o n s were made u s i n g helium pycnometric methods ( 5 ) , a n d p o r e s i z e d i s t r i b u t i o n s were determined u s i n g an Aminco Mercury p o r o s i m e t e r c a p a b l e o f i n t r u s i o n p r e s s u r e s up t o 407 MPa.

A b s o l u t e D e n s i t y . D e n s i t i e s o f t h e v a r i o u s p r e p a r a t i o n s were determined by d i v i d i n g sample mass by s o l i d volume, t h e l a t t e r by helium pycnometry.

F r a c t u r e T e s t s

Vol. 13, No. 1 8 3

FRACTURE TOUGHNESS, AUTOCLAVED KIXTURES, MICROHARDNESS

t e s t i n g machine. Notched beam t e s t p i e c e s conditioned t o 11% RH were simply supported i n it and loaded a t t h e mid-point. The mid-span d e f l e c t i o n was measured u s i n g an LVDT with a readout a c c u r a t e t o 0.0001 mm. Cross-head speed was 0.005 mm/min. Load d e f l e c t i o n c u r v e s were o b t a i n e d from t h e I n s t r o n c h a r t r e c o r d s ; t h e maximum l o a d s were g e n e r a l l y l e s s t h a n 1 kg ( t h e s t i f f n e s s o f t h e I n s t r o n machine i s extremely l a r g e i n r e l a t i o n t o t h e f l e x u r a l s t i f f n e s s o f t h e t e s t p i e c e s ) .

C r i t i c a l s t r e s s i n t e n s i t y f a c t o r , Kc, and work o f f r a c t u r e were determined from l o a d - d e f l e c t i o n r e c o r d s , but because t h e d a t a have similar t r e n d s o n l y t h e former i s r e p o r t e d . Kc was determined u s i n g t h e following e x p r e s s i o n f o r mid-point loading o f s i n g l e , edge-notched, f l e x u r a l specimens ( 6 ) :

Kc = Y 3/2 (Pmax t@/(b.d2)

where Y = 1.93

-

3.07 a / d + 14.53 (a/d) 2- 25.11 (a/d13 + 25.8 (a/d14 Pmax = maximum load

R = l e n g t h o f beam a = l e n g t h o f notch b = beam width d = beam depth. Observations Figure 1 i s a p l o t o f Kc v e r s u s s i l i c a c o n t e n t f o r t e s t p i e c e s prepared a t w a t e r / s o l i d r a t i o s ranging from 0.25 t o 0.45. With t h e exception o f curve 1

(w/s = 0.25), Kc v a l u e s g e n e r a l l y i n c r e a s e t o a maximum and t h e n d e c r e a s e with s i l i c a c o n t e n t . Curve 2 (w/s = 0.30) shows a small d e c r e a s e i n Kc between

FIG. 1

C r i t i c a l s t r e s s i n t e n s i t y f a c t o r , Kc, v e r s u s s i l i c a c o n t e n t f o r auto- claved c e m e n t l s i l i c a mixtures pre- pared a t v a r i o u s w a t e r l s o l i d r a t i o s .

84 Vol. 1 3 , No. 1 J . J . Beaudoin P O R O S I T Y . % M I C R O H A R D N E S S x 1 0 - l ~ M P a FIG. 2 FIG. 3 C r i t i c a l s t r e s s i n t e n s i t y f a c t o r , Kc, C r i t i c a l s t r e s s i n t e n s i t y f a c t o r v e r s u s p o r o s i t y f o r a u t o c l a v e d cement/ v e r s i s m i c r o h a r d n e s s f o r a u t o c l a v e d s i l i c a m i x t u r e s c o n t a i n i n g v a r y i n g c e m e n t l s i l i c a m i x t u r e s . p r o p o r t i o n s of s i l i c a . 5 and 10% s i l i c a c o n t e n t , b u t t h e s h a p e o f t h e c u r v e g e n e r a l l y conforms t o t h a t o f t h e o t h e r s . H i g h e s t v a l u e s o f Kc f o r w / s = 0.25 o c c u r a t 5 and 10% s i l i c a c o n t e n t . T h i s i s f o l l o w e d by a d e c r e a s e i n Kc t o a minimum a t 30% s i l i c a c o n t e n t , a f u r t h e r i n c r e a s e t o a maximum a t 50% s i l i c a c o n t e n t and subsequent d e c r e a s e . F i g u r e 2 i s a p l o t o f Kc v e r s u s p o r o s i t y f o r p r e p a r a t i o n s c o n t a i n i n g v a r y i n g amounts o f s i l i c a ( 5 - 6 5 % ) . Curves f o r 5 and 10% s i l i c a have h i g h v a l u e s o f Kc f o r low p o r o s i t y p r e p a r a t i o n s . The Kc v a l u e s d e c r e a s e t o a minimum a t a b o u t 34% p o r o s i t y and t h e n i n c r e a s e t o a maximum (39 and 42% p o r o s i t y ) , f o l l o w e d by f u r t h e r d e c r e a s e . Kc v a l u e s f o r 20 and 30% s i l i c a c u r v e s i n c r e a s e t o a maximum ( a t 3 2 . 5 and 26% p o r o s i t y , r e s p e c t i v e l y , ) and t h e n d e c r e a s e a s p o r o s i t y i n c r e a s e s . Kc v a l u e s f o r 50 and 65% s i l i c a c u r v e s d e c r e a s e i n a p p r o x i m a t e l y l i n e a r f a s h i o n a s p o r o s i t y i n c r e a s e s . F i g u r e 3 i s a p l o t o f Kc v e r s u s m i c r o h a r d n e s s . The t r e n d s f o r t h e c u r v e s a r e s i m i l a r t o t h e Kc v e r s u s p o r o s i t y c u r v e s ( F i g . 2 ) , c o n s i d e r i n g t h a t m i c r o h a r d n e s s d e c r e a s e s a s p o r o s i t y i n c r e a s e s ( 7 ) . F i g u r e 4 i s a p l o t of m i c r o h a r d n e s s v e r s u s s i l i c a c o n t e n t . Microhardness i n c r e a s e s t o a inaximum and t h e n d e c r e a s e s a s S i 0 2 c o n t e n t i n c r e a s e s . S i m i l a r r e s u l t s f o r compressive s t r e n g t h v e r s u s S i 0 2 c o n t e n t have been r e p o r t e d (3,7).

I t was t h o u g h t t h a t n e i t h e r m a t r i x e f f e c t s a l o n e n o r t o t a l p o r o s i t y c o u l d e x p l a i n t h e d i f f e r e n c e s between t h e b e h a v i o u r of p r o d u c t s formed a t w / s = 0.25 and t h o s e formed a t h i g h e r w/s r a t i o s . P o r o s i m e t r y s t u d i e s were t h e r e f o r e

Vol. 13, No. 1 85 FRACTURE TOUGHNESS, AUTOCLAVED MIXTURES, MICROHARDNESS

80 FIG. 4 I I I r I I Microhardness v e r s u s s i l i c a c o n t e n t f o r a u t o c l a v e d c e m e n t / s i l i c a m i x t u r e s . c a r r i e d o u t . Pore s i z e d i s t r i b u t i o n d a t a were used t o c a l c u l a t e t h e r a t i o t h a t would be an i n d i c a t o r o f t h e r e l a t i v e amounts o f s m a l l and l a r g e p o r e s i n t h e v a r i o u s p r e p a r a t i o n s . An a r b i t r a r y p o r e d i a m e t e r 2 - 0 . 3 0

was chosen ( 0 . 1 pm) and 3 - 0.35

4 - 0 . 4 0 t h e r e l a t i v e p r o p o r t i o n s 5 - 0 . 4 5 o f s m a l l t o l a r g e p o r e s o I I I I I I ( i n terms o f t h e i r t o t a l o 10 20 30 40 50 6 0 YO volume) determined w i t h S I L I C A . 8 r e s p e c t t o t h i s diameter. Values a r e g i v e n i n T a b l e 1. TABLE 1

R a t i o o f Pore Volume Having P o r e s Less t h a n 0.1 pm t o Pore Volume Having P o r e s G r e a t e r t h a n 0 . 1 pm.

Water/Solid R a t i o S i 0 2 , % 0.25 0.30 0.35 0.40 0.45

*

m means no p o r e s g r e a t e r t h a n 0.1 pm d e t e c t e d T h i s p o r e s i z e r a t i o f o r p r e p a r a t i o n s a t each w / s r a t i o g e n e r a l l y i n c r e a s e s t o a maximum and t h e n d e c r e a s e s a s S i 0 2 c o n t e n t i n c r e a s e s . A t w / s r a t i o s = 0.45 t h e maximum v a l u e of t h e r a t i o i s a t 30% S i 0 2 . For o t h e r w / s r a t i o s t h e maximum v a l u e o f t h e p o r e s i z e r a t i o o c c u r s a t S i 0 2 c o n t e n t s g r e a t e r t h a n 30%. A t c o n s t a n t S i 0 2 c o n t e n t t h e p o r e s i z e r a t i o d e c r e a s e s t o a minimum a s w / s r a t i o i n c r e a s e s t o 0.35 - 0.40. A t S i 0 2 c o n t e n t s o f 50 and 65%, t h e minimum v a l u e of t h e r a t i o o c c u r s a t w / s = 0.45. A b s o l u t e d e n s i t i e s o f t h e v a r i o u s p r e p a r a t i o n s a r e g i v e n i n T a b l e 2. For p r e p a r a t i o n s a t each w / s r a t i o t h e y g e n e r a l l y d e c r e a s e a s S i 0 2 c o n t e n t i n c r e a s e s . The a b s o l u t e d e n s i t y v a l u e s , however, i n c r e a s e a s S i 0 2 i n c r e a s e s from 50 t o 65%. A t c o n s t a n t s i l i c a c o n t e n t t h e l a r g e s t changes i n a b s o l u t e d e n s i t y w i t h r e s p e c t t o t h e v a l u e a t w / s = 0.25 a r e 1 . 8 , 3 . 3 , 2.5, 1 0 . 0 , 5 . 7 and 3.8% f o r S i 0 2 c o n t e n t s o f 5 , 1 0 , 20, 30, 50 and 65%, r e s p e c t i v e l y . With t h e e x c e p t i o n o f p r e p a r a t i o n s w i t h 30% S i 0 2 c o n t e n t t h e d i f f e r e n c e i n a b s o l u t e d e n s i t y f o r t h e v a r i o u s w a t e r / s o l i d r a t i o s a r e a l l l e s s t h a n 6% andVol. 13, No. 1 J . J . Beaudoin

TABLE 2

Absolute D e n s i t i e s of Autoclaved Cement/Silica P r e p a r a t i o n s (g/cc) Water/Solid R a t i o S i 0 2 , % 0.25 0.30 0.35 0.40 0.45 t h e d i f f e r e n c e s i n a b s o l u t e d e n s i t y f o r t h e 5 , 10 and 20% Si02 p r e p a r a t i o n s a r e (3.3%.

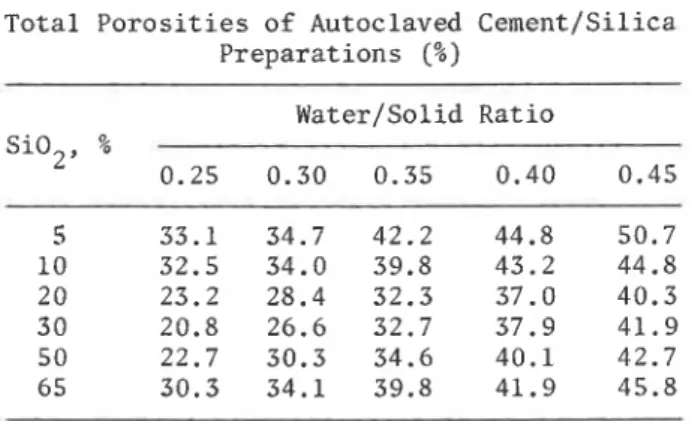

T o t a l p o r o s i t i e s f o r t h e v a r i o u s p r e p a r a t i o n s a r e given i n Table 3 . That

a t each S i 0 2 c o n t e n t i n c r e a s e s w i t h w a t e r / s o l i d r a t i o . In g e n e r a l , t h e lowest t o t a l p o r o s i t y a t a given w a t e r / s o l i d r a t i o occurs f o r 20 o r 30% Si02.

A s chemical composition of t h e hydrated p r o d u c t s v a r i e s with s i l i c a c o n t e n t , r e f e r e n c e s i n t h e t e x t t o I1lowr1 o r "high" p o r o s i t y p r e p a r a t i o n s a r e made with r e s p e c t t o a p a r t i c u l a r S i 0 2 c o n t e n t . For t h e purposes of t h i s paper, t h e r e f o r e , low p o r o s i t y r e f e r s t o p r e p a r a t i o n s having t h e lowest p o r o s i t y a t a given S i 0 2 c o n t e n t . A l l occur a t w / s = 0.25. High p o r o s i t y g e n e r a l l y r e f e r s t o p r e p a r a t i o n s having w / s = 0.40 o r 0.45 f o r a given S i 0 2 c o n t e n t . I t i s apparent t h a t t h e terms low and h i g h a r e r e l a t i v e with r e s p e c t t o p o r o s i t y and dependent on t h e p a r t i c u l a r cement system s t u d i e d .

Discussion

The evidence p r e s e n t e d i n t h i s s t u d y i s i n s u f f i c i e n t t o c o r r o b o r a t e any p a r t i c u l a r c r a c k growth mechanism i n autoclaved c e m e n t / s i l i c a systems. The d a t a , however, and information from t h e l i t e r a t u r e t e n d t o i n d i c a t e t h e r e l a t i v e r o l e s of v a r i o u s f a c t o r s t h a t i n f l u e n c e f r a c t u r e toughness.

I n c l u s i o n s ( t h e primary m a t r i x phase i s p o o r l y c r y s t a l l i n e C-S-H) may a c t a s c r a c k a r r e s t o r s i n ceramic and c e m e n t i t i o u s sytems ( 4 , g ) . Of p a r t i c u l a r i n t e r e s t i n autoclaved c e m e n t / s i l i c a systems a r e p a r t i c l e s o f crC2S-hydrate, unreacted S i 0 2 , and p o r o s i t y . I n p r e v i o u s work i t was found t h a t porous

TABLE 3 T o t a l P o r o s i t i e s o f Autoclaved Cement/Silica P r e p a r a t i o n s (%) Water/Solid R a t i o S i 0 2 , % 0.25 0.30 0.35 0.40 0.45

Vol. 1 3 , No. 1 87 FRACTURE TOUGHNESS, AUTOCLAVED MIXTURES, MICROHARDNESS

bodies c o n t a i n i n g dense second-phase i n c l u s i o n s a r e u s u a l l y weak ( e . g . , C3AH6 p a r t i c l e s i n aluminous cement systems), but t h e y can be s t r o n g a t low p o r o s i t y (8). Discussion of t h e d a t a i n Fig. 1 i s d i v i d e d i n t o two p a r t s : p r e p a r a t i o n s having w / s = 0.25, and p r e p a r a t i o n s having w / s > 0.25.

P r e p a r a t i o n s having w / s = 0.25

The h i g h e s t Kc v a l u e s f o r samples obtained with 5 and 10% SiO2 occur a t w / s = 0.25. These samples c o n t a i n s i g n i f i c a n t amounts of dense aC2S-hydrate

( n o t e h i g h s o l i d d e n s i t i e s , Table 2 ) ; t h i s has been v e r i f i e d by X-ray

d i f f r a c t i o n and o t h e r t e c h n i q u e s ( 1 ) . I t has been concluded t h a t formation of dense, second-phase p r o d u c t s i n confined space .enhances t h e "intimacy" of i n t e r p a r t i c l e c o n t a c t , r e s u l t i n g i n formation o f s t r o n g bodies ( 9 : . The p o r o s i t y o f t h e w / s = 0.25 samples w i t h 5 and 10% S i 0 2 (33 and 32%, r e s p e c t i v e l y ) i s n o t low enough t o g i v e h i g h e s t microhardness v a l u e s

(Fig. 4 ) . I t i s , however, s u f f i c i e n t l y low t o g i v e r e l a t i v e l y h i g h f r a c t u r e toughness v a l u e s . I t may be seen, f o r w / s = 0.25, t h a t t h e 5 and 10% S i 0 2 samples have t h e lowest small p o r e / l a r g e pore r a t i o (Table 1 ) and t h a t t h e w / s = 0.25 samples i n g e n e r a l have lower t o t a l p o r o s i t y when compared with h i g h e r w / s r a t i o samples. I t i s suggested t h a t f o r t h e s e p r e p a r a t i o n s aC2S-hydrate p a r t i c l e s may a c t a s c r a c k a r r e s t o r s .

A s S i 0 2 c o n t e n t i n c r e a s e s , t h e amount o f aC2S-hydrate d e c r e a s e s and formation o f p o o r l y c r y s t a l l i n e C-S-H i n c r e a s e s . I t i s argued t h a t t h e d e c r e a s e i n

Kc

a s S i 0 2 i n c r e a s e s t o 30% i s due, i n p a r t , t o t h e d e c r e a s e i n amount o f aC2 S-hydrate. The subsequent i n c r e a s e i n Kc with i n c r e a s e i n S i 0 2 c o n t e n t t o 50% may be due t o c r a c k - a r r e s t i n g p r o p e r t i e s o f unreacted Si02 p a r t i c l e s , although t h e r e i s no d i r e c t evidence of t h i s . F u r t h e r d e c r e a s e i n Kc with S i 0 2 c o n t e n t i s probably due t o i n c r e a s e d p o r o s i t y and weaki n t e r p a r t i c l e c o n t a c t s .

P r e p a r a t i o n s having w / s > 0.25

A s shown i n Fig. 1 (curves f o r w / s r a t i o > 0.25), Kc i n c r e a s e s t o a maximum and t h e n d e c r e a s e s a s SiO2 i n c r e a s e s . Kc i s a l s o low a t low S i 0 2 c o n t e n t s , i n s p i t e of t h e f a c t t h a t aC2S-hydrate i s p r e s e n t . T h i s s u g g e s t s t h a t o t h e r f a c t o r s c o n t r o l l i n g toughness predominate. For t h e s e p r e p a r a t i o n s t h e maximum f o r each w / s r a t i o occurs i n t h e g e n e r a l range of s i l i c a c o n t e n t corresponding t o lowest t o t a l p o r o s i t y , and t h e p o o r l y c r y s t a l l i n e C-S-H phase, which i s predominant, may e x e r t a s i g n i f i c a n t i n f l u e n c e on f r a c t u r e behaviour.

The Kc v e r s u s p o r o s i t y curves (Fig. 2) provide a d d i t i o n a l information on t h e f r a c t u r e behavior o f t h e systems s t u d i e d . The 5 and 10% Si02 p r e p a r a t i o n s t h a t c o n t a i n s i g n i f i c a n t amounts of aC2S-hydrate have high v a l u e s a t low p o r o s i t y (w/s = 0.25). The Kc v a l u e s d e c r e a s e a s p o r o s i t y (and w / s r a t i o ) i n c r e a s e s and t h e n i n c r e a s e t o a maximum. T h i s maximum corresponds t o a low v a l u e o f t h e s m a l l / l a r g e pore r a t i o (0.55) r e l a t i v e t o t h e v a l u e f o r t h e w / s = 0.25 p r e p a r a t i o n ( 7 . 2 ) . The Kc v a l u e s f o r t h e 20 and 30% Si02 p r e p a r a t i o n s i n c r e a s e t o a maximum and t h e n d e c r e a s e a s p o r o s i t y i n c r e a s e s . The p o r o s i t y v a l u e s where maximum v a l u e s o f Kc occur correspond t o v a l u e s o f w / s r a t i o given i n Table 3. The v a l u e o f t h e maximum i t s e l f i s a l s o

a s s o c i a t e d w i t h composition. The r e a c t i o n p r o d u c t s i n autoclaved cement/ s i l i c a mixtures c o n t a i n p r o p o r t i o n a t e l y more p o o r l y c r y s t a l l i n e C-S-H and l e s s aC2S-hydrate a s s i l i c a c o n t e n t i n c r e a s e s . The 20% S i 0 2 p r e p a r a t i o n has t h e h i g h e s t v a l u e o f Kc f o r any of t h e samples, and it appears t h a t t h i s

composition c o n t r i b u t e s t o maximum toughness. For 50 and 65% S i 0 2

p r e p a r a t i o n s t h a t c o n t a i n s i g n i f i c a n t amounts o f unreacted s i l i c a t h e h i g h e s t v a l u e s of Kc occur a t lowest p o r o s i t y . A l l Kc v a l u e s d e c r e a s e a s p o r o s i t y i n c r e a s e s . The s m a l l / l a r g e pore r a t i o d e c r e a s e s a s p o r o s i t y i n c r e a s e s

Vol. 13, No. 1 J.J. Beaudoin

(Table 1). The additional phase (unreacted silica) makes it difficult, however, to draw any conclusion about the effect of pore size distribution on fracture toughness.

The Kc versus microhardness curves (Fig. 3) are similar to the Kc versus porosity curves. Microhardness generally decreases as porosity increases. Fracture toughness, however, increases at intermediate porosities for many of the preparations studied. This behavior, observed for several ceramic, portland and alumina cement systems, has been attributed, in part, to crack- arresting properties of pores (4,8,10).

Silica contents for maximum values of microhardness are the same for every water/solid ratio (20%) except w/s = 0.30 preparations (30%). Silica contents for maximum values of Kc are within the range of 20 to 30% except for low porosity, w/s = 0.25, preparations. An optimum mixture of aC2S-hydrate and C-S-H for maximum Kc and microhardness may exist at these silica contents.

Conclusions

1. Fracture mechanics is a useful tool that complements traditional techniques for studying the effect of microstructural changes on performance and behavior of cement systems.

2. There is an optimum silica content for maximum toughness in the systems studied when water/solid ratio is greater than 0.25. The maximum toughness for each water/solid ratio generally occurs at lowest total porosity.

3. Maximum toughness is dependent on composition. The largest value is obtained for 20% silica preparations that contain mixtures of poorly crystallized C-S-H and aC2S-hydrate.

4. Dependence of critical stress intensity factor on Si02 content and porosity for low water/solid ratio preparations, e.g., w/s = 0.25, are unlike those for high water/solid ratios. The influence of aC2S-hydrate and unreacted Si02 particles on fracture toughness appears to be greater at low waterlsolid ratio.

5. There is a maximum in the dependence of fracture toughness on porosity that depends on silica content.

6 . Porosity and pore size distribution appear to play a role in the resultant fracture toughness of cement/silica systems and may be one of the factors responsible for increases in fracture toughness.

7 . Microhardness measurements can be used to predict fracture toughness of autoclaved cement/silica mixtures.

Acknowledgement

The author wishes to thank J.J. Wood for his assistance with the experimental work. This paper is a contribution from the Division of Building Research, National Research Council of Canada, and is published with the approval of the Director of the Division.

References

--

1. G.L. Kalousek, Proc. V. Int. Symp. Chem. Cem., Tokyo, Part 111, p. 523, 1968. 2. R.F. Feldman and J.J. Beaudoin, Cem. Concr. Res. 7, 19 (1977).

3. C.A. Menzel, Proc. Amer. Concr. Inst.

31,

125 (1975). 4. J.J. Beaudoin, Cem. Conc. Res.12,

289 (1982).5. R.F. Feldman, J. Cem. Technol. 3, 5 (1972). 6. B. Gross and J. Srawley, ASTM S% 410, 13 (1966).

7. J.J. Beaudoin and R.F. Feldman, Cem. Concr. Res.

5,

103 (1975). 8. R. Stevens, Trans. Br. Ceram. Soc.80,

81 (1981).9. V. S. Ramachandran and R.F. Peldman, J. Appl. Chem. Biotech.