Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Building Research Note, 1972-05

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=e6f27f51-bcc6-40c9-a77b-57cecec7657a https://publications-cnrc.canada.ca/fra/voir/objet/?id=e6f27f51-bcc6-40c9-a77b-57cecec7657a

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40000622

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Water penetration tests of TTW brick walls

C A N A D A

I

I I I S er THl B92 no.86

c . 2 B U G 1 I 1 '3-3 472

6 1 5 l V I S I O H O F B U I L D I N G R E S E A R C H.

N A T I O N A L R E S E A R C H C O U N C I L-

O T T A W A C A N A D AWATER

PENETRATION TESTSOF

T T W BRICK WALLSby

~ ' J ~ ? D ~ N G RES=s.r,'>

T.

RitchieW A T E R PENETRATION TESTS

OF

T T W BRICK WALLSby

T. Ritchie

T T W (through-the-wall) bricks (nominal dimensions of length = 1 2

in.,

height=

2-1/4 in., and width= 6

or 8 in. ) a r e used exten-sively in single -leaf w a l l s , both as the non -load-bearing enclosing

walls of buildings of conventional structural frame construction, and

as load-bearing walls.. h the latter case buildings as high a s 13 storeys have been canstructed of T T W bricks.

Although the structural properties of T T W w a l l s have been

in-

vestigated in considerable detail, t h e i r weather -r e s i s t i n g character

-

istics, p a r t i c u l a r l y their resistance to rain penetration, have received

less study, The lack of information on these subjects prompted the

Canadian Structural C l a y Association to request the Division of

Building R e s e a r c h to undertake a s t u d y of the w a t e r penetration

of

t e s tw a l l s , the results of which a r e now reported.

TEST W A L L S

The investigation involved the construction and t e s t i n g of 2 2

w a l l s . Five bricks and five mortars w e r e used. One of the bricks

w a s t e s t e d in nominal widths

of

6

and 8 in. ; the other bricks were6

in. wide. W a l l s approximately 5 ft long and 4-1/2 f t high w e r econstructed on concrete foundations at the Divisionts exposure site

in Ottawa, each w a l l being tied to i t s concrete base by means of v e r

-

t i c a l s t e e l rods that projected into the f i r s t three courses of b r i c k s .

The brickwork w a s separated f r o m the concrete by a sbeet of plas

-

t i c flashing. Construction occurred in the period b e t w e e n 2 9 Julyand

9

August 1971. A f t e r construction3 the walls w e r e covered onThe p r o g r a m included t e s t i n g for water leakage, the applica-

tion of various p a r g i n g s to some of the w a l l s which w e r e then r e t e s t e d ,

and the application of a silicone water repellent to a few w a l l s which

were also r e t e s t e d ,

3 RICKS

The five b r i c k s used to construct the t e s t w a l l s and designated

A,

B,

C,

D, and E are believed to be typical of T T W bricks p r o d u c e din Canada. According t o the nomenclature used by the brick industry, a l l are "Modular Norman T T W " bricks, having a f a c e nominally 1 2 in.

long and l a i d to a height of 8 in. in three courses.

Each of the five bricks h a d been farmed by stiff-mud extrusion

and had a textured face. A s shown in Figure 1, various a r r a n g e m e n t s

of core-holes and slots had been provided. Two of the bricks had five

slots, those of Brick A being about 1 in. wide and 2 in. long. those of

B r i c k B slightly longer and narrower and round-ended instead of rec- tangular, Each of these bricks was provided w i t h a jamb-slot on one

end, and B r i c k

B

was also provided with grooves on its back surfacespaced about 1-1/2 in. apart, approximately 1/4 in. deep and'l/2 in.

w i d e , to s e r v e as keys for parging. Bricks

C

and E each contained10 round core-holes, 1-114 in. diameter, arranged in t w o r o w s of

five holes; both w e r e also p r o v i d e d with jamb-slots on one end. In

addition, B r i c k

C

had grooves on its back surface, t h e i r dimensions being the same as those of Brick B. B r i c k D was provided with a com- bination of two s l o t s and six round core-holes; t h e round-ended slotsw e r e approximately

718

in. w i d e by 3 in. long and the holes w e r eapproximately 1 -1 /4 in, in diameter.

Five bricks of each type w e r e selected for t e s t s of water a b - sorption and compressive strength, one half of each b r i c k f o r each

t e s t . The results given in Table

I

show the range of values f o r thefive samples t e s t e d and the average value,

B r i c k s

C

and E w e r e relatively low in water absorption and initial r a t e of absorption, B r i c k D had relatively high values of these properties, and the other two w e r e intermediate. B r i c k s A andB

w e r e almost equal in initial rate of absorption, but B w a s considerably

higher than A in total absorption. The w a t e r absorption and saturation

coefficient values of all the bricks w e r e we31 below the maximum values permitted S y GSA Standard A82. 1-1965 for Burned Clay Brick;

compressive strength w a s w e l l above t h e minimum value called f o r

in the CSA Standard. According to the classification of bricks

by compressive strength given in the CSA Standard, three of the

bricks (A,

C

andE)

are designated as C l a s sE

{average compressivestrength exceeding 10, 0 0 0 psi); the other two bricks a r e C l a s s

C

( 6 ,

000 to 8 , 000 psi) and C l a s s D [ 8 , 000 to 10, 000 psi).MORTARS

Two mortars containing different proportions of portland

cement and masonry cement and t h r e e m o r t a r s containing various

proportions of portland cement and lime were used. T h e s e m o r t a r s

w e r e Types M, S and N of CSA Standard A179-1967, "Mortar for

U n i t Masonry, " meeting the requirements of the r'Proporticsrr Spsci-

fications" of that s t a n d a r d . The m o r t a r compositions l i s t e d in

Table

I1

show that m o r t a r s M a and S a w e r e c o m p o s e d of portlandcement, masonry cement and sand; mortars M b , Sb and

Nb

were.composed of p o r t l a n d cement, hydrated lime and sand. The m a t e r i a l s

w e r e proportioned by volume in s m a l l batches mixed by hoe in a

m o r t a r tub. The amount of w a t e r u s e d w a s that which p r o v i d e d a

suitable consistency a s judged by the bricklayer. The m o r t a r s are

high-strength mortars normally specified for load-bearing T T W b r i c k

w a l l s . M o r t a r s of l o w e r s t r e n g t h and thus of different composition might result in different performance.

BRICK: MORTAR

COMBINATIONS

The 22 test w a l l s comprised combinations of bricks and m o r

-

t a r s listed in Table 111. Two s e t s of t h r e e w a l l s each w e r e erected f o r the purpose of determining the r e p ~ o d u c i b i l i t y of the leakage

t e s t s . O n e set w a s constructed of B r i c k A and M o r t a r M a ; the second set w a s constructed of t h e same b r i c k and M o r t a r Mb, One w a l l of each of the five bricks w a s constructed with M o r t a r Sa, and one wall

of each of the five bricks w i t h M o r t a r Sb, B r i c k

B

was a l s o used ins i n g l e walls with Mortars Ma, Mb and Nb; Brick A was u s e d with

M o r t a r Nb. Brick A was also u s e d in 8-in. w i d t h with M o r t a r s S a and Sb. A l l bricks w e r e d r y , that is, without wetting before laying. TEST METHOD

W a t e r w a s sprayed on a w a l l by means of five n o z z l e s s p a c e d along a horizontal pipe positioned about a foot f r o m and p a ~ a l l e l t o

the top course of b r i c k s ( F i g u r e 2). The capacity of the nozzles a n d the w a t e r line pressure w a s such that the amount of w a t e r

sprayed on each w a l l w a s about 5 5 gallons per hour, a rate that e s - tablished a film of water over the w a l l surface a f e w minutes a f t e r

the start of spraying.

Provision was made to apply an air pressure d i f f e r e n c e across

the wall during spraying i n order to simulate the effect of wind-

driven rain. A thin, five-sided box about 3 f t aquare and a few inches

deep, of woad with a transparent sheet of plastic f o r m i n g its l a r g e s t

surface, was h e l d tightly against the "inside" (non-sprayed) s u r f a c e of the w a l l with the open s i d e of the box f a c i n g the wall. A l a r g e - diameter flexible duct leading from the box t o an air fan permitted the withdrawal of air from the box, the resulting l o w e r e d air pressure

in the box establishing an a i r - p r e s s u r e difference across the wall,

the amount indicated by means of a manometer and maintained at

2 in. of water. The apparatus (Figure 3) w a s constructed by

J.

R.Sasaki and M.

0.

Pelletier of t h e Division of Building Research.After s p r a y i n g had commenced a record w a s made af the t i m e f o r dampness to appear on the back surface of each w a l l . The ex-

t e n t of the dampness w a s noted at various times, but no rneasure-

ment w a s m a d e of the amount of w a t e r that passed through the wall.

The test l a s t e d f o r

5

hours.A l l w a l l s (22) w e r e t e s t e d initially by w a t e r spraying without

an air pressure difference. This t e s t w a s m a d e on 17 w a l l s 14 days

after construction and on five w a l l s 13 d a y s after construction.

Behaviour in this initial t e s t varied greatly, many of the walls allow- i n g w a t e r to pass t h r o u g h quickly

in

numerous locations; others w e r e much m o r e leakage-resistant, and one wall showed no dampness o nthe back s u r f a c e after the 5-hour period of testing.

T h e performance of all 2 2 w a l l s , on the basis of the extent

of dampness that developed on the back s u r f a c e , expressed as a p e r - centage of a r e a after 5 hours of testing, is shown in Figure 4. R e -

sistance t o leakage d e p e n d e d on the p a r t i c u l a r b r i c k u s e d , on the

m o r t a r , and on the thic'mess of the wall. The influence of each of

REPRODUCIBILITY O F RESULTS

T e s t results given in Table

IV

f o r the t w o s e t s of three w a l l s made of the same brick and t w o mortars, show a reasonable d e g r e e of reproducibility of results. The table indicates the t i m e f r o mstart of t e s t a t which the first, second and t h i r d separate damp spots w e r e seen on the backs of the walls; it a l s o gives an estimate

of the extent of d a m p n e s s that developed.

Both s e t s of w a l s w e r e marked by several damp spots soon after the t e s t s began. The behaviour of the f i r s t s e t w a s quite con-

sistent, not only in the rate of appearance of d a m p spots but a l s o in the eventual extent of dampness, the back surfaces of all three w a l l s

being completely damp after 4 hours of test. The behaviour of the

second s e t was less consistent; but these walls were somewhat m o r e r e s i s t a n t to w a t e r penetration.

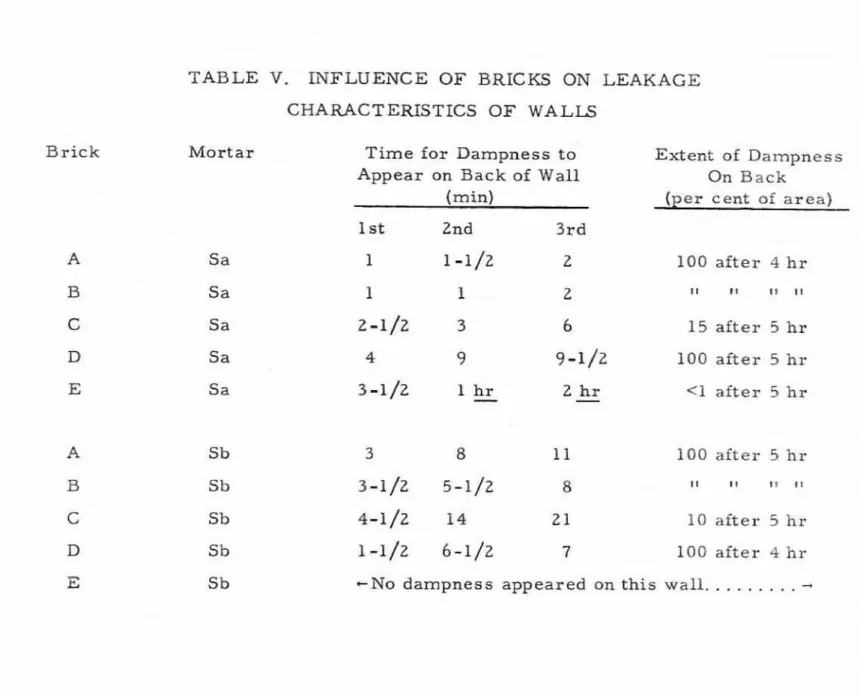

EFFECT O F BRICK ON LEAKAGE

W a l l s constructed of each of the f i v e bricks and two m o r t a r s varied considerably in their resistance to water penetration, as shown by the t e s t results given in Table

V.

T h e b e s t p e r f o r m a n c e of the 10 w a s that of a w a l l constructed of B r i c k E. This brick w a sa l s o u s e d in the wall that performed second best. The first showed

no damp penetration whatever a f t e r 5 hours of test. T h e s e c o n d d e -

veloped a damp spot on the back after a f e w minutes of test, but the second damp s p o t d i d not appear f o r an hour, and t h e third f o r 2 hours. T h e s e damp spots remained small in area throughout the test, s o that after 5 hours dampness was estimated at l e s s than 1

per cent of the area.

Each

of the w a l l s constructed of B r i c k s A,B

and D w e r e p e n e -trated b y w a t e r within a f e w minutes of the s t a r t of the t e s t . Darnp-

ness on the backs of t h e s e walls continued to extend until no d r y a r e a r e m a i n e d by the time the t e s t w a s completed. Small s t r e a m s of

water could be seen running down the backs of them.

The performance of w a l l s c o n s t r u c t e d of B r i c k C lies between

that of walls of B r i c k E and w a l l s of the other bricks. Although damp-

ness p e n e t r a t e d each of t h e walls constructed of Brick

C

within 5 minof the s t a r t of the t e s t , the e x t e n t of dampness on the back surface r e - mained relatively small, in the w o r s t case amounting to about 1 5 per

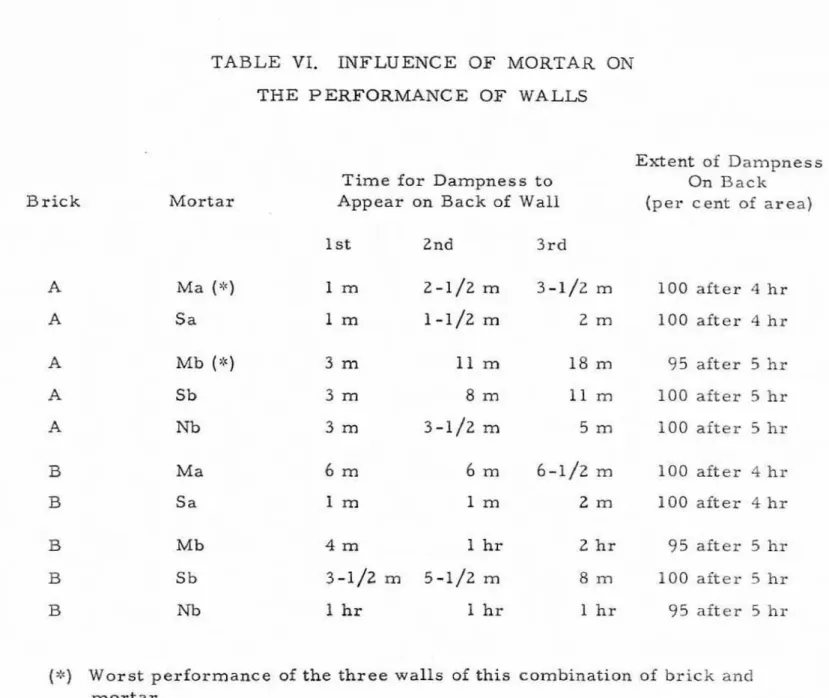

EFFECT O F MORTAR ON LEAKAGE

T e s t s for r e p r o d u c i b i l i t y of results, given

in

TableIV,

also indicate that mortar influenced w a l l performance: it took l o n g e r far dampness to penetrate w a l l s of any b r i c k constructed with M o r t a r Mb than those constructed with M o r t a r Ma; in a d d i - tion, the extent of d a m p n e s s on walls with Mortar M a w a s g r e a t

-

e r,

The influence of th e m o r t a r on the performance of t h e w a l l s is a l s o indicated by the results given in Table V, which indicates that w a l l s of B r i c k s A, B,

C

and E and M o r t a r Sb w e r e m o r e r e -sistant to leakage than the corresponding w a l l s with M o r t a r Sa; the

reverse, however, was t r u e for w a l l s of Brick D,

Additional information on the influence of m o r t a r is shown

in Table VI, which contains information f r o m previous t e s t s . It m a y be seen that walls of Bricks A and B laid in M o r t a r Mb w e r e

t i g h t e r than those l a i d in M o r t a r M a , and that walls laid in M o r t a r

Sb w e r e tighter than those laid in M o r t a r Sa.

Ln

comparing w a l l s constructed of m a r t a r s of the same m a t - e r i a l s but d i f f e r e n t proportions no consistent influence of m o r t a r composition on w a l l performance w a s evident. Brick A, u s e d with M o r t a r s M a and Sa, f o r example, resulted in w a l l s v e r y s i m i l a r toeach other in terms of leakage characteristics, a s were a l s o w a l l s

of B r i c k A and M o r t a r s Mb, Sb and Nb, B r i c k B used w i t h M o r t a r s

M a and Mb gave waUs of greater resistance to leakage than those of

the s a m e brick with M o r t a r s

Sa

and Sb.In

the three walls of BrickB and M o r t a r s Mb, Sb and Nb, however, t h e best performance w a s that of the l a s t m o r t a r .

Although the t e s t results indicate that m o r t a r influences the

performance of the walls, it is doubtful whether its m a g n i t u d e , f o r

the particular range of mortars used in these t e s t s , would he suffi- cient tr) influence significantly the performance of w a l l s in actual

service.

EFFECT

OF

WALL T H I G K N E ST h e test r e s u l t s for Briclc A, of nominal 6 - and 8-in. w i d t h s , (Table

V I q

show that the thicker w a l l s w e r e significantly m o r e r c -sistant to penetration of dampness. Not only w a s the t i m e t o pene-

dampness an t h e backs of the thicker walls w a s less than that on the

6-in.

w a l l s .EFFECT O F AIR PRESSURE DIFFERENCE

-

A f t e r the initial t e s t of the 2 2 walls, when water w a s s i m p l y

sprayed on the surface, six w a l l s w e r e retested,this t i m e under

conditions that produced a difference in air pressure a c r o s s t h e w a l l {by the method described previously). Two w a l l s of B r i c k E

w e r e retested, one of which had shown no water penetration in t h e

original t e s t and the other a high resistance to w a t e r penetration. The f i r s t w a l l behaved in the s a m e w a y when t e s t e d u n d e r a i r

pressure difSerence and no dampness appeared on t h e back, but the second h a d a slightly increased extent of dampness an its

back surface. The remaining f o u r walls, when tested under

pressure difference, w e r e penetrated by the w a t e r in a much s h o r t e r time than in the original t e s t and dampness spread more rapidly

over the back surfaces,

Following the t e s t under air pressure d i f f e r e n c e , one of t h e w a l l s was t e s t e d again, this t h i r d test being made under the s a m e conditions as the original, that is, without air p r e s s u r e difference. These w a s a s l i g h t reduction in the r a t e of penetration of d a m p n e s s

compared w i t h that of the initial t e s t . PARGING

Nineteen w a l l s w e r e p a r g e d (i. e. back-plastered) a s f o l l n w s :

{a) P a r g i n g of the composition of Mortar A%, t r o w e l l e d on the back

surface to a depth of 112 in, This p a r g i n g w a s applied to 12 w a l l s by

t h e method shown in Figure 5.

(b) P a r g i n g of the composition of M o r t a r Mb, applied a s above t o

four w a l l s .

( c ] P a r g i n s or^ portland cement and sand, applied to t h r e e w a l l s as ' ' ~ u s h - ~ a r g i n g .

"

The freshly-mixed m o r t a r w a s s c r e e d e d t o a depthof 114 in. o v e r a horizontal sheet of rigid foamed plastic insulating material, which w a s then r a i s e d vertically, placed against the back

of the b r i c k wall, a n d pushed against it into position.

h

o r d e r t om a g n i f y t h e possible effect on leakage of the joints between the sheets

of i n s u l a t i o n , s m a l l sheets, 12 in. by 18 in.

,

w e r e u s e d r a t h e r than the much l a r g e r sheets employed in actual construction. The methodsEffect of T r o w e l - P a r g i n g On W a t e r Penetration

The t e s t s w e r e made one week a f t e r parging had been applied

and w e r e somewhat m o r e s e v e r e than the initial t e s t s in that the

walls w e r e sprayed f o r 3 hours without air pressure d i f f e r e n c e ,

then for an additional 2 hours under air pressure d i f f e r e n c e . T h e leakage characteristics of the p a r g e d w a l l s , compared in Table VIII

with those of the corresponding ulaparged w a l l s , w e r e in every c a s e

m a r e favourable, the p a r g e d w a l l s requiring a significant increase

in t i m e f o r dampness to penetrate the wall,

In the group of walls parged with M o r t a r N73 none remained

free of dampness on the back during the test. Two became com-

pletely d a m p on the parged surface in the 5 hours of t e s t , and the

best performance w a s that of a wall which showed a n u m b e r of

i s o l a t e d d a m p s p o t s totalling about 10 per cent of the wall area. The performance of the other walls of this group l a y s o m e w h e r e between t h e s e extremes. An important characteristic of t h e parged w a l l s w a s

that even if they had extensive or complete d a m p n e s s on the back

surface there w a s no water running down them, in contrast with the c o ~ r e s p o n d i n g unparged w a l l s w h i c h frequently h a d small streams

of w a t e r running down the back surface.

The four w a l l s p a r g e d with M o r t a r M b w e r e much m o r e re-

sistant to w a t e r penetration than those parged with M o r t a r Nb, N o t

only did it take much longer f o r dampness to penetrate them, but the

extent of dampness on the p a r g i n g w a s very small; f o r t h r e e of the f o u r

w a l l s it w a s e s t i m a t e d t o be l e s s than 1 p e r c e n t of the w a l l a r e a and

occurred as isolated spots of dampness. The fourth wall was damp

to the extent of about 2 0 per cent of its area after 5 hours of test. 01 none of these four w a l l s w a s free water s e e n on the p a r g i n g . Effect of Retesting: A P a r ~ e d W a l l

One of the p a r g e d w a l l s , d r i e d b y several d a y s of fine weather a f t e r i t s test, was t e s t e d again. In its second t e s t it w a s much m a r e resistant to w a t e r penetration; the t i m e taken f o r dampness to appear

on the back was doubled a n d the extent of d a m p n e s s w a s much r e d u c e d .

Effect of Push-Pareinrr O n W a t e r P e n e t r a t i o n

T h r e e w a l l s w e r e t e s t e d f o r w a t e r penetration nine days a f t e r

push-parging had been applied. The t e s t consisted of 3 hours ex-

p o s u r e to w a t e r spray, with no air pressure, f o l i o w e d by 2 hours of s p r a y with an air pressure difference maintained across the w a l l . The results of these t e s t s a r e compared i n Table

IX

with the resultsof the initial t e s t s of unparged w a l l s made with no pressure d i f f e r e n c e .

None of the push-parged walls showed dampness on the back of the insulation. O n e w a l l w a s f r e e of d a m p n e s s in the joints between the sheets of insulation during t h e 5 hours of test. The other two w a l l s

were f r e e of dampness until the air p r e s s u r e difference w a s applied;

in one, this resulted in a slow dripping of water f r o m two separate

locations in thejoints, and in the other t h e r e was s i m i l a r behaviour but f r e e r flow of w a t e r from the joints.

SILIGQNE TREATMENT

Two parged w a l l s that had d r i e d during s e v e r a l w a r m , sunny

days following the leakage t e s t w e r e treated w i t h s i l i c o n e on the

brick-faced surface of the w a l l . An unparged w a l l was also t r e a t e d . The silicone solution, a p r o p r i e t a r y composition of the m i n e r a l

spirits type labelled as meeting the requirements of the CGSB s p e c i -

fication f o r silicone water r e ~ e l l e n t f o r masonry, was sprayed over the surface of t h e walls.

Effect of the Silicone T r e a t m e n t on Leakage

The t w o silicone-treated, parged walls w e r e t e s t e d f o r leak-

age eight d a y s after t h e application of the silicone.

The

silicone-treated unparged w a n was tested a f t e r f o u r days. Three hours of

spraying without air pressure were followed by 2 hours of spraying

with an air pressure diEerence across the wal.

The behaviour of the t h r e e walls in t h e s e t e s t s is compared

in Table

X

w i t h their behaviour when tested prior to the application of silicone. It may be s e e n that their p e r f o r m a n c e w a s greatly improved as a result of silicone treatment. Both of the silicone-treated, p a r g e dw a l l s w e r e f r e e of darripness after 5 hours, while the u n p a r g e d w a l l

developed a single d a m p spot i n a horizontal m o r t a r joint a f t e r 3 hours,

2 0 minutes of test. This damp spot subsequently spread s l o w l y along

the joint so that after 5 hours of t e s t it was about 5 in. long.

CONCLUSIONS

W a l l s constructed of T T W bricks varied g r e a t l y in resistance

to w a t e r penetration when subjected to 5 hours of w a t e r spraying. Their performance depended on both t h e particular b r i c k used and on t h e

m o r t a r , but their g e n e r a l l y low resistance to leakage indicated that

it i s d e s i r a b l e t o p r o v i d e them with an a d d i t i o n a l b a r r i e r to r a i n pene-

Parging on T T W walls increased their resistance to leakage

significantly; and trowelled-on p a r g i n g of relatively high portland cement content w a s considerably m o r e effective than one

of

l o w e r cement content i n increasing resistance to leakage. A pargingof mortar composed of portland cement and sand and applied by

p ~ h - ~ a r g i n g on r i g i d foamed plastic insulation gave variable r e s u l t s ;

one wall. parged in this way w a s f r e e of dampness, but t w o others had

w a t e r dripping from t h e joints between the plastic sheets.

A silicone solution applied t o the three w a l l s , t w o parged and one unparged, rendered them highly resistant to w a t e r penetration.

The effect of repeating the leakage t e s t s of unparged and

parged w a l l s w a s found to reduce the rate and amount of leakage,

indicating that the weathering of walls should alter their resistance

to water penetration. This aspect of the performance of T T W w a l l s

w i l l be studied further.

As

a part of this additional study, t h r e eof the w a l l s have been made i n t o one w a l l of a heated and insulated structure, so that they will be w e a t h e r e d in a manner similar to that experienced in the f i e l d . These w a l l s and others used in the project w i l l be kept under observation and tested p e r i o d i c a l l y for

-

*-

-T- --+- m o o d e w (Tl r- a G & r j 4-

h A-

A*

-

-

0 U-Y IR Q - N m m m . 2 w k m o P O Q - N m * r - - w s w r - m. -

r - m - . c - m t c m m r - . Y * .. .

- .2

o o o o o o o o a o d d M A n, i .d h-

n . Y --

-

- - 0 m o o E - 4 u l mu's- - -

%

N I - N H 4-

3 u-

. .*

r;-

-

d f. m m a 0 d I \ F r T ,-

m m s P i s P i 2 4-

0 0 A h 0 0 d'TABLE 11. MORTAR COMPOSITION

TABLE 111. COMBINATION!3

OF

BRICKS AND MORTARSU S E D

% M o r t a r

T y p e

Ma ~b S a S b N bTO

CONSTRUCT TEST WALLS Number of W a l l sB r i c k Brick B r i c k B r i c k B r i c k

Mortar A B

C

DE

Proportions by Volume

(>:) one wall of 6 -in. brick; one w a l l of 8 -in. brick

Portland Cement 1 1 1 1 I Hydrated Lim e

-

114-

I 1 2 1 Masonry Cement 1-

2-

-

Sand 6 3 - 3 1 49

4-112 6TABLE

IV.

REPRODUCIBILITY O F TEST RE5ULTST i m e Taken For

Dampness to Appear Extent of D a m p n e s s

On

Back of W a l l O n B a c k of W a l l(min) (*) ( p e r cent of area)

I s t 2 nd 3rd W a l l 1 B r i c k A, M o r t a r Ma 2 2-1 1 2 5 100 a f t e r 4 hs W a l l 2 I I 1 1 1 2 4 2 3 - 1 1 2 100 11 r-~r W a l l 3 I t 1 1 2 - 1 JZ 3 5 100 t t t l 4 7 W a l l 1 B r i c k A, M o r t a r

M b

4-1/2 5 8 99 after 5 hr W a l l 2 I I KI 3 1 1 1 8 95 11 t 1 t l W a l l 3 r t I I 7-112 17 3 6 9 5 11 T I 1 1TABLE

V.

I N F L U E N C EOF

BRICKS OM LEAKAGECHARACTERISTICS

OF

WALLSB r i c k Martar Time f o r Dampness t o

Appear on Back of W a l l

(min)

I s t 2nd 3 r d

Extent of D a m p n e s s

On

Back(per cent of area)

100 after 4 hr II IT !r 1 1 45 after 5 hr 1 0 0 after 5 hr c1 after 5 hr 100 after 5 hr I 1 I 1 t l t I 1 0 a f t e r 5 hr P O 0 a f t e r 4 hr

+ N o

dampness appeared en this w a l l .. . . .

. . . .

-.-ITABLE

VI.

I N F L U E N C E O F MORTAR O N THE PERFORMANCEOF

WALLSExtent of Dampness T i m e f o r Dampness to On B a c k

B r i c k M o r t a r Appear on Back of W a l l (per cent of area)

A M a (xc) I m 2-1/2 rn 3 - 1 / Z m 100 a f t e r 4 hr A

Sa

1 rn 1-1/2 m 2 m 100 a f t e r 4 h r A h.fb(*I

3 rn I l m 18 rn 95 after 5 hr ASb

3 m 8 m I1 rn l o 0 after 5 hr A Nb 3 m 3 - 1 / 2 rn 5 m 100 a f t e r 5 hr 6 m6

m 6 - l / 2 m 1 0 0 a f t e r 4 h r 1 m 1 rn 2 rn 100 a f t e r 4 hr 4 rn I hr 2 hr 95 a f t e r 5 hr 3-112 m 5-1/2 rn 8 m 100 a f t e r 5 hr 1hr

1 hr 1 hr 95 a f t e r 5 hr(*I

W o r s t performance of the three w a l l s of this combination of b r i c k a n dTABLE VII.

EFFECT OF

WALL THICKNESS O NPERFORMANCE

Extent of Darnpnes s

Time f o r Dampness To O n B a c k

B r i c k Mortar Thickness Appear om Back of W a l l ( p e r cent of area)

A Sa 6 in. I rn 1-1J.Zrn Zrn A S a 8 in. 8 m 12 rn 19 rn A

Sb

6 in. 3 m 8 m l l m A Sb 8in.

4-112 m 7-112 rn 30 rn 100 a f t e r 4 hr 7 5 after 5 hr 100 a f t e r5

hr 2 5 a f t e r 5 hrTABLE VLII. E F F E C T O F TROWEL-PARGING ON WATER P E N E T R A T I O N

P a r g h g

Zornposition B r i c k M o r t a r Time f o r Dampness t o Appear on Back of W a l l Before parging applied T e s t of P a r g e d W a l l

TABLE IX

EFFECT

OF

"PUSH -PARGING1'ON WATER PENETRATION

B r i c k Mortar Condition Time for Dampness to A p p e a r

1 s t 2nd 3 r d - .

A Ma (*) Unparged 1 rn 2 - 1 JZ m 3 - 1 1 2 rn

B Mb Unparged 4 m 1 hr 2 h r

B Mb 'Tush-pargedIt

N o

dampness appearedD Sb Unparged 1-112 m 6 - 1 1 2 m 7 rn

D Sb 'Push-parged" 4 hr 4 hr

5 hr

(+I

W a l lNo. 2 of

s e t of t h r e e w a l l s af this combination of b r i c k and mortar.TABLE

X.

EFFECTO F

A SILICONE TREATMENTON

LEAKAGE CHARACTERISTICSB r i c k ~ M n r t a r Condition Time for Dampness t o A p p e a r

1 st 2 nd 3 r d

(+) A Sa N o Silicone 14-112 m 1 5 - 1 1 2 rn 17 rn

...

...

(::I A Sa Siliconed No Dampness.

C*)

I3 Sa N o Silicone 7 rn 7-112 m 8 m...

. . .

[+) B Sa Siliconed N o Dampness..

(Y;$C) A M b N o Silicone 4117 2 1 rn 28 rn

4 ~ : : )

A M b Siliconed 3 hr-

20 m----

----

(a) W a l l s parged with Mortar Nb

F i g u r e 1. Five bricks u s e d to construct t e s t walls; left to

right, A, B, C, D and

E,

F i g u r e 2. Method of s p r a y i n g w a t e r an the walls; three w a l l s a r e being sprayed simultane~usly; adjacent walls are protected from wetting. * * . i. ; I < I F i g u r e 3 . Method of applying

a difference of air pressure

MORTAR

Mu Ma Mm So 50 Mb Mb Mb Sb Sb N b

WA LL WA LL WALL WALL WALL WALL

1 2 3

-

8 0 A 2 4 0 B R I C K A LL 0 0 FIGURE 4 B R I C K B B R I C K C B R I C K D E X T E N T OF D A M P N E S S O N B A C K S U R F A C E OF W A L L S A F T E R 5 H O U R S OF T E S T 8 4 -931Figure 5. Application of p a r ging,

{a) wetting the waU, and

Figure 6 . Push-parging; (a) screeding m o r t a r over a sheet

of rigid insulation (sheets applied to wall shown in the background), a n d (b) sheet of insulation with parging applied to