Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Institute for Research in

Construction), 1987

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=97032040-c9d7-4340-9dcb-a4978f552cd2 https://publications-cnrc.canada.ca/fra/voir/objet/?id=97032040-c9d7-4340-9dcb-a4978f552cd2

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001413

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

On the equivalent fire exposure

Harmathy, T. Z.

,

Ser

TH1

1N21d

INational Research

Conseil national

I no* c. 1514 21

*

1

Council Can-

de recherches Canada

BLDG

Institute for

lnstitut de

Research in

recherche en

Construction

construction

On

the

Equivalent Fire Exposure

by T.Z. Harmathy

Reprinted from

Fire

and Materials,

Vol.

11,No. 2, 1987

p.

95-104

(IRC

Paper No. 1514)Price

$3.00L'exposition au feu Bquivalente (EFE) est visualide comme une valeur quantitative du potentiel destructif des feux de compartiment reels, exprimBe en fonction de la d u d de rdsistance au feu des 61Bments du bkiment dans des essais au feu normalisBs. L'auteur examine cinq mkthodes de calcul de l'EFE et les compare en se basant sur certaines donnks exphimentales.

FIRE AND MATERIALS, VOL. 11, 95-104 (1987)

On the Equivalent Fire Exposure

T. Z. Harmathy

National Research Council Canada, Institute for Research in Construction, Ottawa, Canada

I

The equivalent fire exposure (EFE) is visualized as a quantifier of the destructive potential of real-world compartment fires in terms of the time to failure of building elements in standard test fires. Five methods of calculating the EFE are b reviewed and compared in the light of some experimental data.

To ensure some basic measure of fire safety it has been a long-standing practice to specify in building regulations minimum levels of fire resistance that compartment boundaries and other structural elements of buildings should possess. The acceptable levels of fire resistance are usually decided on by the writers of building regulations based on experience. Studies over the past twenty years have shown that these decisions, though self-consistent, rarely stand up to theoretical or experimental scrutiny.

To allow a more realistic assessment of fire resistance requirements, the concept of equivalent fire exposure (EFE) was developed. The EFE is visualized as a quanti- fier of the destructive potential of real-world compart- ment fires in terms of fire resistance; in other words, in terms of the time to failure of building elements in standard test fires.

NUMERICAL EXAMPLE

The technique of assessing the EFE has undergone substantial evolution during the years. Five techniques will be examined in this paper. The way these techniques respond to the principal input variables will be first illustrated, by applying them to the calculation of the fire resistance requirements for a hypothetical compartment, characterized by the following information:

Floor area A, = 20.0 m2 Total area of compartment boundaries (including the area of the opening) A, = 85.0 m2 Height of the compartment h, = 2.5 m Area of the ventilation opening A, = 1.8 m2 Height of the ventilation opening h, = 1.2m Thermal absorp- tivity (thermal inertia) of the boundaries ,/(kpc)= 1000Jm-2 s-lt2 K - ' Specific fire load (consisting of cellulosics) L = 30.0kgm-2

Apparently, this compartment is typical of a room in a residential building.

The effect of the specific fire load, L, ventilation factor, A, Jh,, and thermal absorptivity (thermal inertia), ,/(kpc), will be explored by making L, Av and J(kpc) vary, one at a time, within the following ranges:

while keeping all the others constant at values listed above. The lowest value for the thermal absorptivity is somewhat below, and the highest value somewhat above, the range representing customary compartment lining materials.

The results of the study are shown in Figs 1 to 5. In these figures the EFE, assessed according to the five methods to be discussed, is plotted against the selected three variables.

THE CONCEPT O F EQUAL TEMPERATURE-TIME AREAS

Ingbergl was the first to suggest, more than half a century ago, a method for the assessment of the EFE. He regarded the EFE, 7, (h), as solely a function of the specific fire load,

and correlated z, with L by determining the time at which the area under the temperature-time curve in a standard test fire (above a certain base line, somewhere between 150" and 300°C) amounted to the same value as the area under the temperature-time curve in a real-world fire (above the same base line). Ingberg's formula is

with the restriction that L < 146 kgm-2.

Figure 1 illustrates Ingberg's formula. It also shows that re, according to this rather simplistic concept, is insensitive to the ventilation factor and the thermal absorptivity of the compartment boundaries.

I

0 1987 National Research Council CanadaReceived 5 September 1986 Accepted 16 December 1986

96 T. Z. HARMATHY

VENTILATION FACTOR. A,,$ m 3 I 2 The three techniques to be discussed next were devel-

oped using this procedure.

'

5

1

Law's method L SCALE - I- ZJkpC

AVJhV wI

SCALE < C A I F/

FIRE LOAD, L kg-m-

2 THERMAL A B S O R P T I V I T Y , ~ ~ * r n - ~ s - ' K - ~ Figure 1. Ingberg's method. Dependence of the equivalent fire resistance on L, Av,/hv and J(kpc) (for the selected example).CONCEPTS RELATED TO EQUAL TEMPERATURE RISES

The idea of deriving information on equivalent fire exposures by comparing areas under the temperature- time curves was discarded later as inappropriate. It is now generally held that the attainment of a certain tempera- ture level by some important components of building elements (load-bearing steel components, in general) be regarded as the criterion for deciding on the equivalence of fire exposures.

The commonly employed procedure for formulating the EFE used to be as follows. From room-burn experi- ments (in which some variables having to do with the fire's severity were systematically changed) or from calcu- lations the maximum temperature rise at some locations (usually in a steel component) in the boundaries of the room or in columns placed in the room was determined. Then the course of temperature rise at the same locations in standard fire tests was examined, either by actually subjecting these elements to standard fire tests or by calculations. The EFE was taken as the time at which in the standard tests the temperature reached the level of maxima in the (actual or simulated) room-burn experiments.

Based on an international experimental program,' Law developed the following f ~ r m u l a : ~

where the coefficient, 0.022, may vary slightly with the d

geometry of the solid fuel (cellulosic fire load).

As Eqn (2) and Fig. 2 show, z, is proportional to the specific fire load, and is roughly proportional to A; 'I2 (or,

in terms of the ventilation factor, to (A, Jhv)-'I2). Law's formula does not take account of the thermal absorptivity of the compartment.

Pettersson's method

Pettersson improved on Law's method in two ways:475 by expressing the effect of compartment ventilation in terms of the ventilation factor, Av,/hv, rather than the venti- lation opening, and by taking account of the nature of the compartment boundaries. The latest version of his

VENTILATION FACTOR.

A,,%

m 3 I 2Figure 2. Law's method. Dependence of equivalent fire resistance on L, AVJhv and J(kpc) (for the selected example).

ON THE EQUIVALENT FIRE EXPOSURE 97 VENTILATION FACTOR,

~~q

..

1 . 0 2. 0 3 . 0 4 . 0 VENTILATION FACTOR, lV$ m312 0 10 2 0 30 40-* 5 0 6 0 FIRE LOAD, L kg.m THERMAL A B S O R P T I V I T Y , ~ ~ ~ - m - ~ s - * K - I Figure 3. Pettersson's method. Dependence of the equivalent fireFigure 4. DIN method, Dependence of the equivalent fire re- resistance on f , A,Jh, and J(kpc) (for the selected example).

sistance on L, A,J~, and J(kpc) (for the selected example). formula for cellulosic fire load is6

where C is a factor depending on the thermal absorptivity of the compartment boundaries in the following manner:

For the selected example, the dependence of z, on L, J(kpc) and A, Jh, is shown in Fig. 3.

The DIN method

The German standard DIN 182307s8 gives the following formula for the calculation of the equivalent fire resistance for cellulosic fire load:*

where m is the so-called burning factor (dimensionless) which characterizes the fuel and its geometry, w is the *Equation (4) is a simplified formulation of the DIN method, applicable only to cellulosic fire loads.

heat-dissipation factor (dimensionless) which depends on the ventilation of the fire compartment, and c is a factor (dimensionless) which characterizes the thermal insul- ation of the structural components. The values of m, wand c are tabulated in the standard. In plotting the curves of Fig. 4 the following values have been used:

m = 1 (characteristic of a fire load consisting of wood boards or square sticks) 3.2 0 < Av/AF

<

0.05 2.0 if 0.05<

A,/AF<

0.10 w = 1.5 0.10 < Av/AF<

0.1 5 1.2 0.15 < Av/AF<

0.20Since the values of c are listed in the standard for insulations described in general terms, the ranges for the thermal absorptivity, J(kpc), recommended by Petters- son have been adopted (rightly or wrongly) in selecting appropriate values for c.

The z, versus L, J(kpc) and A, Jhv curves calculated with the above values are shown in Fig. 4.

98 T. Z. HARMATHY THE NORMALIZED HEAT LOAD CONCEPT

The procedure to be discussed in this section has also been founded on the premise that the attainment of equal temperature levels by important components of building elements is to be regarded as the criterion of the equiva- lence of fire exposures. The difference between this and the previous three procedures of calculating the EFE is the use of the normalized heat load concept which, having been developed on theoretical foundations, allows an insight into the solution of the problem.

The normalized heat load, H(s'I2 K) is defined as9

where q(Wm-') is the heat flux that penetrates the building element, t(s) is time, and z(s) is the fire duration. It has been shown1° that the normalized heat load is the measure of the maximum temperature rise below the surface of a building element at a depth corresponding roughly to a distance where the important load-bearing components (e.g. steel bars) are located. It has also been shown1° that H is practically independent of the tempera- ture history of the medium that imparts heat to the building element. Consequently, the normalized heat load can be looked upon as a measure of the detrimental effect of various fires (real-world fires as well as the standard test fire) on one given type of building element.*

For compartments whose boundary elements are lined with different materials the thermal absorptivity is inter- preted as surface-averaged thermal absorptivity. The theorem of uniformity of normalized heat load states that in a given compartment the normalized heat load is approximately the same for all boundary elements.

The normalized heat load for a real-world fire, H', is generally derived, along with six other process variables, by solving six simultaneous equations by an iterative procedure." However, if H' is the only information of interest, it can be obtained from the following approxi- mate formula, applicable to predominantly cellulosic fire load:'

'

where

6 = J(h"@) whichever is less

1

temperature-time curve, the normalized heat load, H , depends (as a first approximation) on a single variable: the duration of the test fire, r" (h). Curve 1 in Fig. 6 shows the

H"

versus z" correlation for a high-efficiency furnace and Curve 2 for an NRCC test furnace. The following equation is an approximation of Curve 2:13If a specimen of a compartment's boundary element successfully withstands the test fire for a time z", then z" is the fire resistance of that boundary element. Clearly,

r" = T, under the condition that

H'

= H". In other words, the equivalent fire resistance is obtained by substituting H' for H in Eqn (9).In Fig. 5 the dependence of z, on L, J(kpc) and Av Jhv is shown for the chosen example. The full-line curves have been based on calculations using the iterative procedure and the dashed-line curves on approximate calculations using Eqns (6)-(9). Apparently, the approximation is quite satisfactory. Having expressions for H' and z" in explicit form offers the added advantage of greatly simplifying the design of buildings for prescribed levels of fire safety.13

VENTILATION FACTOR,

A,,%

m3"?and 0 (kg s-') is the ventilation parameter defined as

@ = P ~ A V

JG,)

(8) I I I I I1 0 2 0 30 d o 50 60 where ~ , ( k g m - ~ ) is the density of air entering the

FIRE LOAD. L k g * m

-

2 compartment and g(m s - ~ ) is the gravitational constant.For standard test fires, because of the uniqueness of the

I

I I I I I1

500 1000 1500 2000 2500

*A cautionary note: For reasons discussed in Reference 10, the THERMAL ABSORPTIVITY.

6

~ - m - * s - +normalized heat load concept cannot be applied to compartment

boundaries containing important load-bearing components in, or in the Figure 5. The normalized heat load method. Dependence of the

immediate vicinity of, the enclosure surface. For example, it cannot be equivalent fire resistance on L, AVJhv and J (kpc) (for the selected

ON THE EQUIVALENT FIRE EXPOSURE

I I I I

LENGTH OF EXPOSURE T O STANDARD T E S T FIRE, 7" h

Figure 6. Correlations between H and T for standard fire tests.

Curve 1: high-efficiency furnace; Curve 2: floor test furnace in

IRCINRCC laboratory (estimated).

COMPARISON OF THE FIVE METHODS

For the basic compartment, with the information listed in the section Numerical Example, the following values have

been obtained for 7,:

Ingberg's method 0.62 h

Law's method 1.22 h

Pettersson's method 1.02 h

DIN method 1.04 h

Normalized heat load, approximate method 1.29 h

Note that Ingberg's method is today only of historical significance.

Inspecting Figs 2-5 one will see that, as compared with the method based on the normalized heat load concept: (1) Law's and Pettersson's methods and the DIN method suggest a more significant effect of ventilation on the EFE; and

(2) Pettersson's method and the DIN method indicate a less significant effect of the thermal asborptivity on the EFE. (Law's method does not take account of the effect of thermal absorptivity.)

Equation (6) indicates, however, that, as to their effect on the EFE, ventilation and the thermal absorptivity cannot be considered separately. At relatively small values of the second term in the denominator (which includes the

I ventilation parameter,

a),

the effects of even small changesin the thermal absorptivity, J(kpc) may be quite signifi- cant. Conversely, at small values of the first term (i.e. at

small values of (A, - A,) or J(kpc) or both) changes in the

ventilation will have a more substantial effect. The same conclusion can also be reached on an a priori reasoning by analyzing the role of these two variables in the heat

balance for the burning compartment. It is not justijable,

therefore, to regard the thermal absorptivity and ventilation

as two variables whose eflects can be factored independently into the expression of the EFE (see Eqns(3) and (4)).

THE QUESTION OF ACCURACY

It has so far been seen that the five methods of calculating the EFE will, as a rule, yield different results. Although the claim that the effect of thermal absorptivity and venti- lation cannot be factored independently into the ex- pression of EFE has cast some doubt on at least two of the methods discussed, there has so far been no convincing clue provided concerning the relative accuracy of the five methods.

To prove that the method based on the normalized heat load concept is more reliable that the others, the five methods will now be applied to a series of full-scale compartment burn tests performed at the NRCC. In all these tests the normalized heat load was determined experimentally by measuring the maximum temperature rise in the compartment boundaries at appropriate depths and using Eqn (10) in Reference 15. Clearly, if a satis- factory agreement is found to exist between the experi- mental values of the normalized heat load and those calculated from Eqns (6)-(8), the EFEs calculated from Eqns (6)-(9) should be looked upon as reasonably accu- rate values.

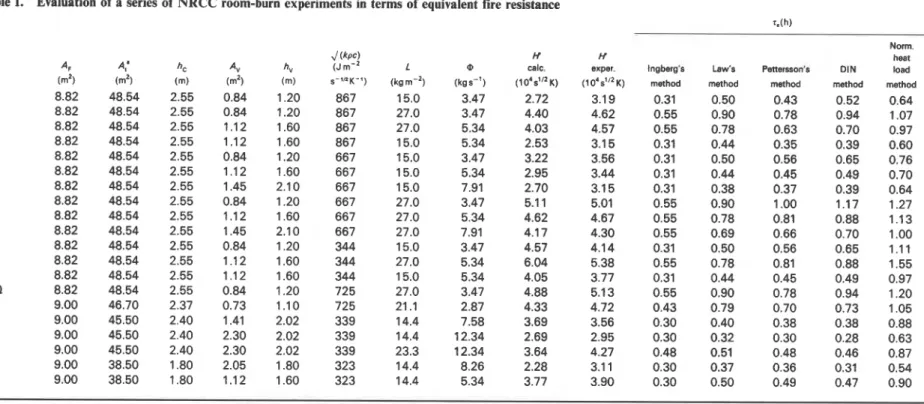

The information listed in the first nine columns in Table 1 summarizes all the important input information, 'such as the geometry of the bum compartment, its ventilation, the thermal absorptivity of the boundaries and the fire load. (The results of Runs Nos A-Q have already been reported;14 those of the last four runs are reported here for the first time.) In most tests the various compartment boundaries were lined with different materials; the thermal absorptivities listed in the table are surface-averaged values.

Table 1. Evaluation of a series of NRCC room-burn experiments in terms of equivalent fire resistance 7.(h) Run No. A B C D E F G H I J K L M N-Q R W Y

z

AB AC Norm. H H heatcalc. exper. Ingberg's Law's Pettersson's DIN load ( 1 0 ~ s " ~ K) ( 1 0 ~ s ' " ~ ) method method method method method

2.72 3.1 9 0.31 0.50 0.43 0.52 0.64 4.40 4.62 0.55 0.90 0.78 0.94 1.07 4.03 4.57 0.55 0.78 0.63 0.70 0.97 2.53 3.1 5 0.31 0.44 0.35 0.39 0.60 3.22 3.56 0.31 0.50 0.56 0.65 0.76 2.95 3.44 0.31 0.44 0.45 0.49 0.70 2.70 3.1 5 0.31 0.38 0.37 0.39 0.64 5.1 1 5.01 0.55 0.90 1 .OO 1.17 1.27 4.62 4.67 0.55 0.78 0.81 0.88 1.13 4.1 7 4.30 0.55 0.69 0.66 0.70 1.00 4.57 4.1 4 0.31 0.50 0.56 0.65 1.1 1 6.04 5.38 0.55 0.78 0.81 0.88 1.55 4.05 3.77 0.31 0.44 0.45 0.49 0.97 4.88 5.1 3 0.55 0.90 0.78 0.94 1.20 4.33 4.72 0.43 0.79 0.70 0.73 1.05 3.69 3.56 0.30 0.40 0.38 0.38 0.88 2.69 2.95 0.30 0.32 0.30 0.28 0.63 3.64 4.27 0.48 0.51 0.48 0.46 0.87 2.28 3.1 1 0.30 0.37 0.36 0.31 0.54 3.77 3.90 0.30 0.50 0.49 0.47 0.90

O N THE EQUIVALENT FIRE EXPOSURE o L A W ' S TECHNIQUE /' A PETTERSSON'S TECHNIQUE 0 0 n 1.5

t

0 DIN TECHNIQUE /' Z a,

0' Z1

aT, ACCORDING TO THE NORMALIZED HEAT LOAD CONCEPT, h

r-"

Figure 7. Evaluation of the NRCC room-burn experiments in terms of the equivalent fire resistance. The Law, Pettersson and DIN methods compared with the technique using the normalized heat load concept. 0 LAW'STECHNIQUE 0

,

0 A PETTERSSON'S TECHNIQUE,,'

1 . 5-

0 DIN TECHNIQUE,

/,

,

-

0 0 o '8, ' 0 / 1 . 0-

0 8-

0 0B

0/ g

0,

0 Q,""

0 . 5 -8

'

-

0' co,,&

0 0 0 r' I I I 0 0. 5 1 . 0 1 . 5 2 . 0 ACCORDING TO THE NORMALIZED HEAT LOAD CONCEPT, h Figure 8. Evaluation of the JFRO room-burn experiments in terms of equivalent fire resistance. The Law, Pettersson and DIN methods compared with the technique using the normalized heat load concept.Table 2. Run No. v A. B G. X H, I. M c, U J. K D E. F, N L 0 P Q R S

Evaluation of a series of JFaO room-bun experiments in terms of equivalent fire resistance

lngberg Law Penersson

method method method

1.23 2.40 1.79 0.15 0.22 0.1 6 0.31 0.43 0.32 0.62 0.86 0.63 1.23 1.73 1.26 0.15 0.16 0.1 1 0.31 0.32 0.22 0.62 0.63 0.45 1.23 1.26 0.89 0.15 0.22 0.20 0.15 0.16 0.1 4 0.62 0.86 0.81 0.62 0.63 0.57 0.31 0.22 0.20 Norm. heat DIN load method method 2.09 2.24 0.16 0.30 0.32 0.45 0.63 0.73 1.25 1.25 0.12 0.23 0.23 0.32 0.47 0.47 0.94 0.72 0.20 0.37 0.1 5 1.27 0.78 0.93 0.59 0.55 0.16 0.33

O N THE EQUIVALENT FIRE EXPOSURE 103

The tenth column gives the normalized heat load on the compartment boundaries, H', as calculated using Eqns (6)-(8), and the eleventh gives H' determined experi- mentally. The next five columns show the EFEs as calculated according to the five methods surveyed.

The table shows that there is a fair agreement between the calculated and experimental values of the normalized heat load,

H'

(the measured values are, on average, 5.5%higher than the calculated values). One is led to believe, therefore, that the EFEs calculated according to the normalized heat load concept are of satisfactory accuracy; perhaps a little on the low side. As Table 1 and Fig. 7 show, all the EFE values calculated according to Law's and Pettersson's methods and the DIN method are lower than those calculated according to the normalized heat load concept. The reason is probably the absence of correction (Law) or inadequate correction (Pettersson, DIN) for the thermal absorptivity of the compartment boundaries which, as column 6 in Table 1 shows, was in most tests lower than that for an average residential compartment (700-1000 J m- s- 'Iz K - I

1.

Although experimental values of the normalized heat load are not available for the series, a test series16*17 conducted by the Joint Fire Research Organization (JFRO) has also been analyzed in terms of the EFE. Arranged analogously to Table 1, the important input information for this series and the results of the analysis are listed in Table 2. A comparison with the EFEs is made in Figure 8.

In most tests in this series, the thermal absorptivity of the compartment boundaries was close to the average for residential compartments. Except for three experiments, the ventilation was large enough to bring about fuel- surface-controlled conditions.

As this experimental series was the earliest and one of the most comprehensive it is very likely that its results were used in one way or other in developing all the newer methods of calculating the EFE. It is not surprising, therefore, that the predictions for the EFE by Law's and Pettersson's methods and the DIN method are more evenly matched with those resulting from the application of the normalized heat load concept.

methods and the DIN method (empirical methods based on the concept of equal temperature rises), and a method employing the normalized heat load concept (a theoreti- cally founded method, also based on equal temperature rises), are examined. With the last-mentioned method it is possible to express the equivalent fire resistance by approximate formulas which are continuous for all im- portant variables and thus can be applied to the math- ematical manipulations needed in probabilistic design. It is shown through an analysis of the results of a compart- ment burn-out test series that the method based on the normalized heat load concept is more accurate (especially under non-typical circumstances) than the other four methods.

NOMENCLATURE

A, floor area (m2)

A, total area of compartment boundaries (including the area of openings) (mZ)

Av area of ventilation openings (mZ)

c factor in the DIN formula (dimensionless)

C factor in Pettersson's formula (h m5I4 kg- l) g gravitational constant (m s - ~ )

h, height of compartment (m)

h, height of ventilation opening (m)

H

normalized heat load (s'12 K)H'

normalized heat load for real-world fires (s1I2 K)H"

normalized heat load for test fires (s1I2 K) J(kpc)thermal absorptivity (thermal inertia), k: thermalconductivity, p: density, c: specific heat ( ~ ~ - 2 ~ - 1 / 2 ~ - 1

1

L fire load (kg m-')

rn burning factor in the DIN formula (dimensionless) q heat flux penetrating the compartment boundaries

(W m-2)

t time (s)

w heat dissipation factor in the DIN formula (dimensionless)

Greek Letters

CONCLUSION 6 factor defined by Eqn (7) (dimensionless)

pa density of air entering the compartment on fire Five methods of calculating the equivalent fire resistance, (kg In -

namely Ingberg's method (based on the concept of fire duration (s) temperature-time areas), Law's and Pettersson's methods 7'' duration of test fire (h)

and the DIN method (empirical methods based on the T e equivalent fire duration (h)

equal temperature-time areas), Law's and Pettersson's @ ventilation parameter (kgs-l)

REFERENCES

1. S. H. Ingberg, Tests of severity of building fires. NFPA Quarterly 22, 43 (1 928).

2. P. H. Thomas and A. J. M . Heseldon, CIB International Co- operative Programme on fully-developed fires in single compart- ments, comprehensive analysis of results, JFRO Internal Note

No. 374, 1970.

3. M . Law, A relationship between fire grading and building design and contents. JFRO Fire Research Note No. 877, 1971. 4. 0. Pettersson, The connection between a real fire exposure and

the heating conditions according to standard fire resistance tests-with special application to steel structures. European

Convention for Constructional Steelwork, CECM-111-74-2 E,

Chapter ll (1 974).

5. Aconceptual approach towards a probability based design guide on structural fire safety. Workshop CIB W14, Chapter 8, Fire

Safety Journal 6, 24 (1 983).

6. Design guide structural fire safety. Workshop CIB W14, Chapter 4, Fire Safety Journal 10, 89 (1 986).

104 T. Z. HARMATHY

7. DIN 18230, Structural Fire Protection in Industrial Building Construction; Part 1: Required Fire Resistance Period; Part 2: Determination of the Burning Factor m; Appendix 1 to Part 1: Calorific Values and m-factors. Draft in manuscript form, March 1978.

8. Concrete for Fire Resistant Construction; A Cembureau Report Prepared with the Assistance of FIP. Chapter 8: Calculations to determine the Required Fire Resistance of Buildings, 1979. 9. T. Z. Harmathy and J. R. Mehaffey, Normalized heat load: a key

parameter in fire safety design. Fire and Materials 6, 27 (1 982). 10. T. Z. Harmathy, The possibility of characterizing the severity of

fires by a single parameter. Fire and Materials 4, 71 (1 980). 11. T. Z. Harmathy, Fire severity: basis of fire safety design. I n Fire

Safety of Concrete Structures (M. S. Abrams (ed.)), Publication SP-80. American Concrete Institute, Detroit (1 983).

12. J. R. Mehaffey and T. Z. Harmathy, Assessment of fire resistance requirements. Fire Technology 17, 221 (1 981 ).

13. T. Z. Harmathy and J. R. Mehaffey, Design of buildings for

prescribed levels of structural fire safety. I n Fire Safety: Science

and Engineering, ASTM STP 882. (T.Z. Harmathy (ed.)),

ASTM, Philadelphia (1 985). p. 160.

14. J. R. Mehaffey and T. 2. Harmathy, Thermal response of corn- partment boundaries to fire. In Fire Safety Science, Proceedings

of the FirstlnternationalSymposium (C. E. Grant and P. J. Pagni (eds)), Hemisphere Publ. Co., Washington (1 986), p. 11 1. 15. T. Z. Harmathy, Postflashover fires-an overview of the research

at the National Research Council of Canada (NRCC) 1970-1 985. Fire Technology 22, 21 0 (1 986).

16. E. G. Butcher, T. B. Chitty and L. A. Ashton, The temperatures attained by steel in building fires, Joint Fire Research Organiz- ation, UK, Fire Research Technical Paper No. 75 (1 966). .

17. E. G. Butcher, G. K. Bedford and P. J. Fardell, Further experi- ments on temperatures reached by steel in buildings. Paper 1,

Proceedings of a Symposium held at Fire Research Station,

January 1967, Joint Fire Research Organization, UK (1968), p.1.

T h i s p a p e r i s b e i n g d i s t r i b u t e d i n r e p r i n t f o r m by t h e I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n . A l i s t of b u i l d i n g p r a c t i c e a n d r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n , N a t i o n a l R e s e a r c h C o u a c i l o f C a n a d a , O t t a w a , O n t a r i o , K1A OR6. Ce document e s t d i s t r i b u 6 s o u s forme d e t i r g - 3 - p a r t p a r l l I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n . O n p e u t o b t e n i r une l i s t e d e s p u b l i c a t i o n s de l ' l n s t i t u t p o r t a n t s u r les t e c h n i q u e s ou l e s r e c h e r c h e s e n r n a t i z r e d e b s t i m e n t e n S c r i v a n t ?i l a S e c t i o n d e s p u b l i c a t i o n s , I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n , C o n s e i l n a t i o n a l d e r e c h e r c h e s du Canada, Ottawa ( O n t a r i o ) , K I A OR6.