Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Institute for Research in Construction), 1993-03

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=9d36bfcf-f5d1-4110-8dae-28e995256fcd https://publications-cnrc.canada.ca/fra/voir/objet/?id=9d36bfcf-f5d1-4110-8dae-28e995256fcd

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20375891

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Fire Resistance of Beam-Slab Specimens: Experimental Studies

Internal Report No. 641 Date of issue: March 1993

National Research Conseil national Council Canada de recherches Canada

Institute for lnstitut de .r-eFtD.rt : ~ t - ~ s t i . i ; u - t c

Research in . recherche en -- B~,., C r e i g h t o t I & r . i i t i i Y S E

Construction construction kHALYVZED

by H.J. Wu, T.T. Lie and J.Y. Hu

This is an internal report of the Institute for Research in Construction. Although not intended for general distribution, it may be cited as a reference in other publications

FIRE RESISTANCE OF BEAM-SLAB SPECIMENS

-

EXPERIMENTAL STUDIESABSTRACT

In this report, the results of tests on three beam-slab specimens, constructed and tested at the T i j i n Fire Research Institute are described. The tests were carried out mainly for the purpose of evaluating the

fue

resistance of beams and slabs constructed of materials commonly used in China The study variables included specimen composition, specimen dimension and materials.FIRE RESISTANCE O F BEAM-SLAB SPECIMENS

-

EXPERIMENTAL STUDIES1 INTRODUCTION

As a part of a joint research project on the "Fire Resistance Evaluation for Housing

(China)" between the Tianjii F i i Research Institute (TEU) of the Fire Bureau of the Public Security hGnktry of China, and the Institute for Research in Construction (IRC), National Research Council of Canada, three tests were canied out on beam-slab specimens at TFRI.

The main purpose of the tests was to provide data for evaluating the lire resistance of beams and slabs constructed of materials commonly used in China.

In this report, the results of the tests on thc three beam-slab specimens are described. The specimens were designed jointly by TFRl and the National

Fire

Laboratmy (NFL) of IRC and were tested atTFRI.-

2 TEST SPECIMENS

In this joint project, three beam-slab specimens, having varying dimensions and materials, were fabricated at TFRI. In order to determine the fire performance of beams and slabs that are

widely used in China, design methods and construction techniques, generally adopted in China, as well as building materials commonly used in China, were selected in the design and fabrication of these test specimens [1,2,3,4].

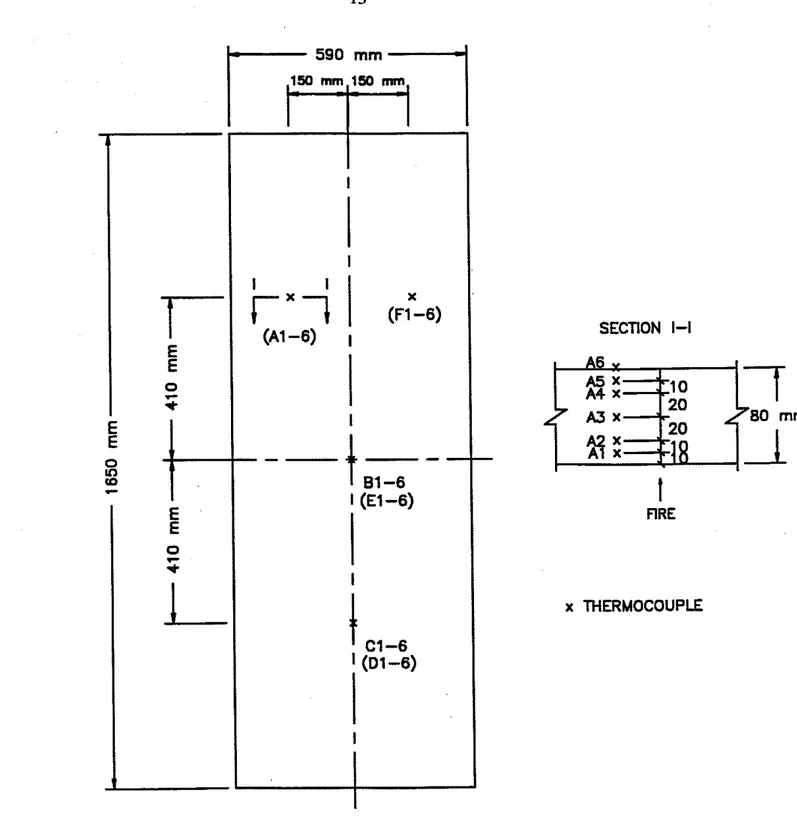

The three beam-slab specimens are described in Table 1 and Figures 1,2,3,4,6,8,9 and 10. Details of the specimens are given below.

2.1 Composition

Two of the beam-slab specimens were composed of one beam and fourteen slabs. The other specimen was composed of one beam and two slabs. The dimensions for the beams were 200 x 400 x 5400 mm. The dimensions of the slabs in the specimens with fourteen slabs were

1650 x 590 x 80 mm and those in the specimen with two slabs were 2950 x 1650 x 120 mm. The beams and slabs were fabricated individually. Before each test, one beam and fourteen slabs (or two slabs) were assembled to form a beam-slab specimen. The joints between the beams and slabs were filled with cast-in-place concrete.

2.2 Materials

The steel bars in the three beam-slab specimens were Type I steel bars. The yield strength of the steel (aJ was 240 MPa and the ultimate strength (ob) was 380 MPa.

The beams were made with carbonate aggregate concrete,with a design strength of 20 MPa. Approximate batch quantities of concrete mix for the beams were:

Concrete Beam Mix:

Cement: 278 kg/m3 Aggregate: 1293 kglrn3 Sand: 673 kg/m3 Water: 175 kg/m3

The slabs were fabricated with two types of concrete, one was carbonate aggregate concrete, the other was ceramsite (expanded clay) aggregate concrete. The concrete design strength was 25 MPa for both concretes. Approximate batch quantities of the carbonate concrete

mix were:

Carbonate Concrete Mix: Cement 314 kg/m3 Aggregate: 1306 kg/m3 Sand: 647 kg/m3 Water: 176 kg/m3

Approximate batch quantities of the ceramsite concrete mix were:

Ceramsite Concrete Mix: Cement: 285 kg/m3 Ceramsite: 650 kg/m3 Sand: 656 kg/m3 Water: 194 kg/m3

Type K chromel-alumel thermocouples were used to measure the temperatures of the beams and slabs. The diameter of the thermocouple wire was 0.8 mm. The exact locations and

numbering of the thermocouples are shown in the Figures 1,5,7,8 and 11. 2.3 Fabrication

All

beams and slabs were cast in forms made of steel plate. The concrete was cured under damp burlap for 7 days at about 20°C. The forms were then stripped and the beams and slabs conditioned in the laboratory.3 TEST APPARATUS

The tests were canied out by exposing the specimens to heat in a furnace specifically built for testing beams, slabs or beam-slab specimens. The test furnace was designed to produce the conditions to which a member might be exposed during a fire; i.e.. temperatures, structural loads and heat transfer. It consisted of a furnace chamber and a loading device. A photograph of the furnace is shown in Figure 12. The characteristics and the instrumentation of the furnace are described below.

3.1 Furnace Chamber

The furnace chamber has a floor area of 3000 x 4000

mm

and is 2100 mm high. The interior faces of the chamber are lined with a ceramic fibre material that efficiently transfers heat to the specimen There are 10 diesel oil burners in the furnace chamber. Each burner can be adjustedindividually, which provides a high degree of temperature uniformity in the furnace chamber. The pressure in the furnace chamber is also adjustable and is set somewhat lower than atmospheric pressure.

3 . 2 Loading Device

Twelve hydraulic iacks were used to load the slabs. Each iack has a loadine head at one end with four loading poiits. The total load was applied on the shbs with 48 loadLg points, producing a uniformly distributed load.

3 . 3 Instrumentation

The furnace tempera- were measured with the aid of eight chromel-alumel

thermocouples. The junction of each thermocouple was located 100 m m from the exposed face of the slabs, at the same height in the furnace chamber. The locations of the junctions and their numbering are shown in Figure 13. The temperatures measured by these eight thermocouples were averaged automatically and the average temperature was used as the criterion for controlling the furnace temperature.

The loads were measured and controlled using hydraulic pressure transducers. The accuracy of measuring and controlling loads was about 4.5 kN.

The deflection of the beam was measured by a transducer

[g.

The deflections of the slabs were measured using electromechanical gauges with an accuracy of 0.01 mm.4 TEST CONDITIONS AND PROCEDURES

4 . 1 Support Conditions

In the

three

tests, the beams were supported by two roller carriages (Figs. 3 and 9) and the slabs were supported by the beam and furnace body (Fig. 2).4 . 2 Loading

All

three beam-slab specimens were tested under a uniform load. The applied loads were calculated and determined according to Refs. 1,2 and 4 and are given in Table 1.The load was applied approximately 30 minutes before the start of each test, until a

condition was reached in which there was little change in the applied load and the deflections of the beams and slabs. This condition was selected as

the

initial condition for the deflections of the beams and slabs. The load was maintained constant throughoutthe

test.4 . 3 Fire Exposure

During the tests, the specimens were exposed to heating controlled in such a way that the average temperature in the furnace followed, as closely as possible, the GB 9978-88 [6] standard temperature-time curve. This curve is given by the following equation:

Tf = 345 loglo (8t

+

1) +To where:Tf =

furnace

temperature ("C) To = ambient temperature ("C)t = time (minutes)

4.4 Failure Criterion

According to the China National Standard GB 9978-88, the beam or slab was considered to have failed when its maximum deflection exceeded U20

("L"

being the clear span of the beam or slab), when the average temperature on the unexposed face of the slab increased to more than 140°C above the initial average temperature or when the temperature at any location on the unexposed face of the slab increased by more than 180°C.In the three tests, the clear span of the beams was 5100 mm, and the maximum permitted deflection was 255 mm; the clear span of the slabs was 1470 mm and the maximum permitted deflection of the slabs was 73.5 mm. The initial temperature was ambient temperature at the beginning of the test

4 . 5 Recording of Results

The furnace, beam and slab temperatures, as well as the deflections of the beams and slabs, were recorded at 1 min intervals.

The results of the tests are summarized in Table 2, in which concrete strengths, test conditions, test time and failure modes are given for each specimen.

The furnace, beam and slab temperatures recorded during the tests, as well as the

deflections, are given in the Tables 3 to 23. A negative deflection value indicates that the bcam or slab moved tow&ds the furnace chamber. The photographs of the beam-slab specimens after the tests are given in Figures 14,15 and 16.

Table 2. Summary of Test Parameters of the Beam-Slab Specimens

*

100x

100 xl00mm

concrete cube strength on test date.Failure Time (hrs) 0:54 0:54 0:54 Failure Mode Excessive Local Temperature Rise of Slab Excessive Defleclion of Slab Excessive Deflection of Slab Specimen No. 1 2 3 Concrete Strength(MPa)

*

Beam 23.1 25.3 27.1 Relative Humidity ( % ) Slab 30.4 33.3 35.7 Beam 85.8 68.1 81.4 Slab 69.4 72.6 75.47

5 DESCRIPTION OF TEST SPECIMENS AND RESULTS

5 . 1 No. 1 Beam-Slab Specimen

Specimen Details

Dimensions of Beam: 200 x 400 x 5400 mm

Dimensions of Slab: 1650 x 590 x 80 mm (Every Slab)

Details of the Beam-Slab Specimen: Figures 1,2 and 3 Details of the Slab: Figure 4

Locations of Thermocouples in the Slab: Figure 5 Details of the Beam: Figure 6

Locations of Thermocouples in the Beam: Figure 7

Concrete Cube Strength: Slab 30.4 MPa, Beam 23.1 MPa Relative Humidity at Test Date: Slab 69.4%, Beam 85.8% Load: 300 kg/m2

Initial Temperature of Unexposed Face of the Slabs: 27OC Test Results

Test Duration: 1 hour 1 minute

Deflections of Beam and Slab: Table 3

Beam Temperatures: Tables 4,5 and 6 Slab Temperam: Tables 7,8 and 9 observations

0:20 Small cracks developed in the slabs.

0 5 4 The temperature rise on the unexposed face of the slab at the E-6 location of exceeded 180°C.

0:57 The deflection of Slab No. 2 exceeded 73.5 mm.

1:01 The average temperature

rise

on the unexposed face of the slabs exceeded 140°C and the test was terminated.5 . 2 No. 2 Beam-Slab Specimen

Dimensions of Beam: 200 x 400 x 5400 mm

Dimensions of Slab: 1650 x 590 x 80 mm (Every Slab)

Details of the Beam-Slab Specimen: Figures 1,2 and 3 Details of the Slab: Figure 4

Locations of Thermocouples in the Slab: Figure 5 Details of the Beam: Figure 6

Locations of Thermocouples in the Beam: Figure 7 Concrete Cube Strength: Slab 33.3 MPa, Beam 25.3 MPa Relative Humidity at Test Date: Slab 72.6%, Beam 68.1% Actual Loading: 300 kg/m2

Initial Temperature of Unexposed Face of the Slabs: 30°C Test Results

Test Duration: 1 hour 23 minutes Deflections of Beam and Slab: Table 10 Beam Temperatures: Tables 11,12 and 13 Slab Temperatures: Tables 14,15 and 16 observations

0:24 Small cracks developed in the slabs.

0:54 The deflection of Slab No. 1 exceeded 73.5 mm. 1:14 The deflection of Slab No. 2 exceeded 73.5

mm.

1:23 The temperature rise on the unexposed face of the slab at the F-6 location of exceeded 180°C and the test was terminated.

SLAB NO.

x THERMOCOUPLE

B

NOT TO SCALE

Figure 1. Beam and Slabs of Specimens No. 1 and No. 2 and Locations of Thermocouples

SLABS

FURNACE

I

I

-

-

-

I

-

I.

-

a .J A

4 06 MAIN BARS 6 04 DISlRIBUTED BARS 15 mm COVER TO AT 170 rnm SPACING AT 300 mm SPACING MAIN BARS

SECTION A-A

1

590 rnmt

Figure 4. Cross

Section

ofSlabs (1650

x590

x80

mm) for SpecimensNo.

1 andNo.

2I

L1:j

I

(Fl -6) X El

1

I E 0 LO (D-

--I,---

I (El-6)I

I ( 3 - 6'

(Dl -6)I

I SECTION 1-1 x THERMOCOUPLEFigure 5. Locations of Thermocouples in Slabs (1650 x 590

x

80 mm) for Specimens No. 1 and No. 22 *10 F W E BARS 25 mm COVER

1 114 WJN BAR 2 112 NUN WtS

Figure 6. Cross Section of Beams (200 x 400 x 5400 mm ) for Specimens No. 1, No. 2 and No. 3

15 B A

1

3 0 m4

,

I

2700 rnm SECTION 8-8 I SECTION A-AFigure 7.

Locations

of Thermocouples inBeams

(200x

400x

5400 mm) forSpecimens No.

1,No.

2

andNo.

3Table 3. Deflections of Beam and Slabs : No.1 Beam-Slab Specimen

*

Specimen failed earlier (54 min) because of excessive temperature rise at unexposedsirface -

**

The locations of the slabs are shown in Figure 1Time* (min) 0 5 10 15 20 25 30 35 40 45 50 55 6 0 61 Deflection of Slab No. 1 (mm)

**

0.00 -9.90 -17.56 -23.45 -29.92 -36.69 -42.88 -51.80 -54.90 -55.98 -61.41 -64.19 -67.40 -68.02 Deflection of Beam (mm) 0.00 -4.70 -9.85 -13.26 -18.02 -24.00 -29.38 -41.57 -44.51 -45.06 -53.46 -57.47 -62.37 -63.52 Deflection of Slab No. 2 (mm)**

0.00 -9.26 -17.83 -26.20 -33.51 -41.54 -48.03 -57.67 -60.89 -61.83 -68.68 -71.93 -75.86 -76.60Table 4. Beam Temperatures : No.1 Beam-Slab Specimen Time (min) 0 5 10 15 20 25 30 3 5 40 45 50 5 5 6 0 61

Temperatures (OC) Measured at Thermocouple No. :

1 2 3 4 5 6 7 8 9 10 2 7 2 7 2 7 2 7 2 7 27 27 27 27 2 7 30 2 7 33 91 165 29 2 7 33 98 164 5 0 28 66 145 265 4 4 28 62 151 258 82 4 0 95 195 332 71 35 97 206 329 105 53 107 217 236 104 49 108 258 398 109 71 109 218 282 110 82 115 301 450 117 100 116 293 457 114 104 125 338 491 128 109 134 350 525 119 108 141 373 531 147 107 152 393 568 130 108 163 407 565 170 107 181 430 604 150 107 186 439 596 194 104 205 462 633 173 106 210 470 624 216 104 228 490 658 195 105 233 497 648 237 104 250 514 680 215 106 255 522 669 241 105 254 519 684 219 106 259 526 673 Furnace Temperature (OC) 3 8 533 627 702 766 819 863 870 889 905 922 937 949 948

Table 5. Beam Temperatures : No. 1 Beam-Slab Specimen Furnace Temperature (OC) 38 533 627 702 766 819 863 870 889 905 922 937 949 948 Time (min) 0 5 10 15 20 25 3 0 3 5 40 45 50 55 6 0 6 1

Temperatures (OC) Measured at Thermocouple No. :

11 12 13 14 15 16 17 18 19 20 2 6 29 29 27 27 2 7 2 7 27 27 2 7 31 2 9 28 56 8 3 5 6 6 4 4 3 41 8 7 56 3 0 15 104 122 116 127 9 7 94 136 94

---

---

124 173 159 177 120 117 196 110--- ---

155 226 221 255 149 143 253 116---

---

194 273 279 318 189 180 299 123--- ---

230 314 329 369 226 217 349 133--- ---

261 349 371 410 260 251 371 150---

---

292 382 408 445 290 281 389 174--- ---

322 413 440 476 317 308 423 198--- ---

350 444 470 505 342 333 445 221---

---

377 472 498 531 365 356 464 243---

---

403 498 523 556 387 377 481 247--- ---

408 503 528 561 391 381 485Table 6. Beam Temperatures : No. 1 Beam-Slab Specimen Furnace Temperature (OC) 3 8 533 627 702 766 819 863 870 889 905 922 937 949 948

-

Time (min) 0 5 10 15 20 25 3 0 3 5 40 4 5 5 0 55 60 61.

Temperatures (OC) Measured at Thermocouple No. :

21 22 23 24 25 26 27 28 29 30 31 32 26 27 27 27 27 27 27 27 26 26 26 27 93 31 27 29 31 27 30 33 27 30 51 75 148 48 28 40 47 28 47 57 30 50 104 128 217 74 34 57 74 33 67 105 93 104 127 174 287 97 42 69 112 77 84 121 113 115 165 239 344 111 61 82 115 100 108 133 115 117 208 298 388 114 113 103 122 107 116 147 116 119 247 351 419 123 109 115 131 110 115 162 115 124 284 398 447 134 112 113 143 111 124 178 114 137 317 437 473 154 110 117 163 110 135 204 114 155 348 471 496 178 109 122 184 109 150 232 117 176 376 501 516 202 109 132 206 109 170 258 122 205 402 528 535 224 110 154 227 111 191 284 128 231 425 553 539 228 110 159 231 111 195 289 129 236 429 557

Table 7. Slab Temperatures : No.1 Beam-Slab Specimen Time (min) 0 5 10 15 20 25 30 3 5 40 45 50 5 5 6 0 6 1

Temperatures (OC) Measured at Thermocouple No. :

A-1 A-2 A-3 A-4 A-5 A-6 B-1 B-2 B-3 B-4 B-5 B-6

26

-

26-

-

27 27-

27-

-

27 149-

37-

-

27 149-

37-

-

27 230-

85-

-

35 247-

91-

-

34 297-

117-

-

56 323-

120-

-

6 0 360-

142-

-

82 389-

143-

-

9 3 410-

166-

-

99 441-

175-

-

106 450-

192-

-

103 484-

206 --

108 491-

221-

-

105 521-

235-

-

111 529-

251-

-

111 551 - 263-

-

119 563-

280-

-

128 578-

290-

-

138 593-

308 --

149 601-

316-

- 161 617-

334-

-

170 620-

341-

-

182 638-

359-

-

1 8 3 6 3 7-

364 --

199 642-

363-

-

187 640-

368-

-

203 Furnace Temperature (OC) 38 533 627 702 766 819 863 870 889 905 922 937 949 948Table 8. Slab Temperatures : No.1 Beam-Slab Specimen , Furnace Temperature (OC) 3 8 533 627 702 766 819 863 870 889 905 922 937 949 948 Time (min) 0 5 10 15 20 2 5 30 35 4 0 45 5 0 55 60 6 1

Temperatures (OC) Measured at Thermocouple No. :

C-1 C-2 C-3 C-4 C-5 C-6 D-1 D-2 D-3 D-4 D-5 D-6 27

-

, 27-

-

27 27 27 27 27 27 27 123-

36-

-

27 107 67 34 28 27 27 202 - 85-

- 35 183 135 70 38 35 31 272-

113-

-

61 256 147 108 67 57 48 340-

136-

-

96 326 231 135 101 96 79 391-

167-

-

109 375 281 160 115 109 96 435-

198-

-

111 419 324 194 129 119 98 475-

227-

-

115 460 364 226 142 129 99 508-

255-

-

125 496 398 254 158 143 104 537-

282-

-

144 531 430 280 178 159 115 563-

307 , .--

167 560 459 306 201 180 140 586-

331-

-

185 585 485 331 223 201 162 605-

354-

-

202 606 509 353 243 220 180 609-

358-

-

204 610 513 358 247 224 185Table 10. Deflections of Beam and Slabs: No.2 Beam-Slab Specimen

*

Specimen failed at 54 minutes due to excessive deflection of slab No. 1**

The location of the slabs are shown in Figure 1 Time* (min) 0 5 10 15 20 25 30 35 4 0 4 5 5 0 5 5 60 6 5 70 75 8 0 83 Deflection of Beam (mm) 0.00 -10.00 -17.63 -25.96 -37.38 -46.39 -53.36 -58.73 -63.12 -67.15 -71.30 -76.60 -81.66 -87.58 -94.76 -103.50 -114.10 -121.90 Deflection of Slab No. 1 (mm)**

0.00 -11.02 -19.93 -27.73 -37.54 -44.43 -50.27 -55.38 -60.05 -64.59 -68.23 -73.73 -77.18 -77.29 -77.24 -77.27 -77.23 -77.15 Deflection of Slab No.2 (mm)**

0.00 -9.32 -16.84 -23.95 -31.66 -37.07 -41.69 -45.81 -49.62 -53.42 -57.07 -61.43 -65.38 -69.03 -73.86 -79.32 -80.91 -80.87Table 1 1. Beam Temperatures :

No.2

Beam-Slab Specimen Time (min) 0 5 10 15 20 2 5 3 0 35 40 4 5 50 55 6 0 65 7 0 7 5 80 83Temperatures (OC) Measured at Thermocouple No. :

1 2 3 4 5 6 7 8 9 10 31 31 31 31 31 31 3 1 3 1 31 3 1 34 31 34 101 152 34 3 1 36 92 138 5 6 3 3 55 139 243 5 6 3 2 59 135 231 9 1 4 0 92 196 326 7 5 3 9 79 148 235 108 55 110 253 392 102 55 105 165 268 118 9 7 118 296 441 118 107 123 224 371 122 114 120 337 489 119 114 131 283 433 131 112 127 376 529 127 113 142 332 483 145 108 142 412 563 142 110 156 377 525 164 106 164 443 591 160 109 179 415 558 186 106 187 470 615 181 111 207 447 589 209 110 207 493 637 202 115 234 475 615 230 116 227 515 654 222 121 256 500 637 250 124 246 533 671 241 127 276 521 657 269 136 263 552 688 259 136 294 541 678 287 152 281 570 701 276 149 311 560 691 304 168 298 587 719 292 161 327 578 709 315 179 308 596 728 301 171 336 587 718 Furnace Temperature (OC) 37 580 693 742 784 819 846 870 890 906 925 934 951 968 970 981 994 1002

Table 12. Beam Temperatures : No.2 Beam-Slab Specimen Furnace Temperature (OC) 37 580 693 742 784 819 846 870 890 906 925 934 951 968 970 981 994 1002 Time (min) 0 5 10 15 20 25 30 35 4 0 45 5 0 55 6 0 65 70 75 8 0 8 3

-

Temperatures (OC) Measured at Thermocouple No. :

11 12 13 14 15 16 17 18 19 2 0 3 1 31 31 31 3 1 3 1 31 31 3 1 31 34 31 3 3 75 114 81 8 8 5 3 54 154 7 2 48 66 128 171 119 125 112 113 263 105 75 92 135 152 172 188 126 125 347 111 92 107 144 177 234 254 163 162 410 119 103 117 188 275 290 309 202 201 450 122 112 118 245 351 336 356 237 236 487 128 112 122 299 409 374 394 267 266 509 139 111 133 344 454 406 427 294 293 540 160 113 152 382 491 437 457 319 319 566 186 117 176 414 521 465 485 344 344 589 211 122 203 443 548 491 510 367 368 607 235 132 226 468 571 514 532 389 390 621 258 144 249 490 590 534 552 409 410 634 279 162 270 510 608 554 571 429 430 649 299 181 290 529 623 575 592 449 449 661 319 199 310 546 639 595 612 468 468 676 331 212 322 557 649 608 625 480 480 683

Table 13. Beam Temperatures : No.2 Beam-Slab Specimen

Furnace

Temperature

(OC) 3 7 580 693 742 784 819 846 870 890 906 925 934 951 968 970 981 994 1002Time

(min)

0 5 10 15 20 2 5 30 3 5 40 4 5 50 55 6 0 65 70 7 5 80 83Temperatures

( O C )Measured at Thermocouple No.

:21 22 23 24 25 26 27 28 29 30 31 32 31 31 31 31 31 31 31 31 31 31 31 31 139 33 31 37 37 31 34 34 31 35 64 50 247 50 32 67 60 33 52 56 34 61 117 104 334 73 41 96 94 41 90 96 107 116 141 121 391 89 55 110 117 103 116 120 118 120 190 145 437 109 72 119 122 119 123 123 117 121 239 183 475 120 112 126 130 121 124 125 120 125 286 221 503 118 116 138 142 117 132 133 117 139 331 255 529 128 112 155 169 113 145 146 113 160 373 286 554 142 110 177 199 110 163 169 111 188 411 315 579 161 108 200 224 109 183 196 115 215 446 342 601 182 108 222 247 112 203 222 120 240 477 367 621 208 110 242 267 117 222 246 128 264 506 392 639 222 115 261 286 124 240 269 140 286 530 415 659 241 121 281 305 137 258 290 156 307 552 438 676 259 131 300 323 156 275 312 177 328 575 460 696 277 147 318 340 178 291 333 201 348 596 480 706 288 159 329 351 190 301 345 216 360 608 492

Table 14. Slab Temperatures :

No.2

Beam-Slab Specimen.

Furnace Temperature ( O C ) 3 7 580 693 742 784 819 846 870 890 906 925 934 951 968 970 981 994 1002 Time (min) 0 5 10 15 20 25 3 0 3 5 4 0 45 50 55 6 0 6 5 7 0 7 5 8 0 8 3Temperatures ( O C ) Measured at Thermocouple No. :

A-1 A-2 A-3 A-4 A-5 A-6 B-1 B-2 B-3 B-4 B-5 B-6

29

-

29-

-

29 30-

30-

-

29 119-

33-

-

29 120-

34-

-

2 9 181-

64-

-

29 184-

76-

-

30 255-

106-

-

33 260-

114-

-

3 4 317-

125-

-

45 323-

124-

-

4 7 372-

135-

-

66 377-

138-

-

6 6 417-

151-

-

88 419-

161-

-

83 453-

173-

-

98 453-

184-

-

8 9 483-

196-

-

100 483-

208-

-

8 8 509-

218-

-

100 510-

231-

-

8 8 532-

239-

-

100 535-

253-

-

8 8 553-

259-

-

101 558-

275-

-

90 572-

278-

-

101 580-

295-

-

9 3 591-

297-

-

103 600-

315-

-

9 9 610-

314-

-

106 621-

334-

-

106 627-

331-

-

113 640-

352-

-

116 643-

347-

-

123 659-

370-

-

126 652-

357-

-

130 669-

381-

-

132Table 15. Slab Temperatures :

No.2

Beam-Slab Specimen.

Time(min)

0 5 10 15 2 0 2 5 30 3 5 40 45 5 0 55 60 65 7 0 7 5 80 8 3Temperatures (OC) Measured at Thermocouple No. :

C-1 C-2 C-3 C-4 C-5 C-6 D-1 D-2 D-3 D-4 D-5 D-6 30

-

29-

-

29 30 30 30 30 30 29 163-

35-

-

29 134 81 36 30 30 29 270-

81-

-

30 212 143 72 40 34 30 344-

118-

-

35 296 193 115 76 50 32 407-

134-

-

49 360 247 128 110 98 40 462-

147-

-

73 414 297 144 120 112 55 501-

167-

-

88 457 340 167 125 118 73 510-

188-

-

90 492 376 195 129 120 87 530-

209-

-

89 521 406 222 133 120 90 551-

230-

-

87 546 432 247 147 121 91 573-

251-

-

87 568 456 269 165 128 90 596-

272-

-

88 589 477 289 182 141 91 616-

292-

-

90 608 497 308 199 156 92 636-

312-

-

94 626 516 327 216 172 92 659-

331-

-

104 646 536 346 233 188 94 675-

350-

-

115 664 556 365 249 203 97 697-

368-

-

128 683 575 383 266 218 102 707-

380-

-

135 694 588 394 276 228 106 Furnace Temperature (OC) 3 7 580 693 742 784 819 846 870 890 906 925 934 951 968 970 981 994 1002Table 16. Slab Temperatures : No.2 Beam-Slab Specimen Furnace Temperature ( O C ) 37 580 693 742 784 819 846 870 890 906 925 934 951 968 970 981 994 1002 T i m e

(min)

0 5 10 15 20 25 30 3 5 40 4 5 5 0 5 5 6 0 6 5 7 0 7 5 80 8 3Temperatures ( O C ) Measured at Thermocouple No. :

E-1 E-2 E-3 E-4 E-5 E-6 F-1 F-2 F-3 F-4 F-5 F-6

30 30 30 30 30 29 30 30 30 30 30 30 146 123 35 30 30 29 127 76 34 30 30 30 247 203 79 37 33 30 198 130 67 35 32 30 331 280 119 68 51 33 271 168 105 50 42 35 397 343 128 99 91 45 331 217 119 102 73 49 448 393 142 112 103 63 381 262 135 114 103 74 488 435 167 117 108 76 422 301 154 118 105 101 523 471 197 120 111 83 455 336 181 119 109 113 554 503 226 126 113 86 485 366 207 119 112 121 581 530 252 136 118 86 511 394 232 130 118 124 602 552 275 149 126 87 537 420 256 145 129 126 619 569 295 164 137 88 561 445 279 160 143 127 634 585 314 181 150 89 583 468 301 177 158 132 650 601 332 198 165 91 603 489 322 194 174 142 667 619 350 216 182 94 623 509 341 211 189 159 681 635 360 234 198 101 641 529 360 228 205 179 699 652 385 250 214 113 661 547 378 249 222 199 709 662 396 260 223 125 671 558 389 256 231 210 - - -

5 . 3 No. 3 Beam-Slab Specimen

Specimen Details

Dimensions of Beam: 200 x 400 x 5400 mm

Dimensions of Slab: 2950 x 1650 x 120 mm (Every Slab)

Details of the Beam-Slab Specimen: Figures 8,2, and 9 Details of the Slab: Figure 10

Location.. of Thermocouples in the Slab: Figure 11 Details of the Beam: Figure 6

Locations of Thermocouples in the Beam: Figure 7

Concrete Cube Strength: Slab 35.7 MPa, Beam 27.1 MPa Relative Humidity at Test Date: Slab 75.4% Beam 81.4% Actual Loading: 300 kg/m2

Initial Temperature of Unexposed Face of the Slabs: 30°C Test ResulQ

Test Duration: 1 hour 21 minutes Deflectioas of Beam and Slab: Table 10 Beam Temperatures: Tables 11,12 and 13 Slab Temperatures: Tables 14,15 and 16 observations

0:10 Small cracks appeared in the centre of the two slabs. 0:53 The deflection of Slab No. 1 exceeded 73.5 mm. 1:06 The deflection of Slab No. 2 exceeded 73.5 mm.

1:21 The deflection of the beam exceeded 255 mm, the beam collapsed and the test was terminated.

SLAB

x THERMOCOUPLE NOT TO SCALE

Figure 8 Beam and Slab of Spec* NO. 3 and LDC&OIIS of Thermocouples FILLER CAST AT lFRl NO. 1

-

I I I I I I I I SLAB NO. 2 I ': I I'.

I I I: I I I X I I A I I I I I I : I X I I I B ': '- I : I '::.

I ? I I l I I X I D I I I I I I I I X I A A/

I

--

FURNACE CARRIAGEI

B 1 ' 1 I I I I I I I 1I

I I I C I I I I 1 I I I 1 t E I I I I I I I I I I I I I I I I I I I I I II::

I : I 1 . 1 1 . 1 1 . 1 *. . I I I I I I :I I . I :II

- II

\

I ' I I ' I I 1 II

,L

-

.

-

-

sL A

9 06 DISTRIBUTED &4RS 15 06 MAIN BARS 15 rnm COVER TO

AT 200 mrn SPACING AT 200 mm SPACING MAlN BARS

SECTION A-A

Figure 10. Cross Section of Slabs (2950 x 1650 x 120 mm) for Specimen No. 3

410 rnrn, 410 rnrn

1 - 7

X (Fl-8)i

/

l r c 1 : O ~ l I .t

---

*---

i

5:

3

(El -8)l

i

(Dl-8) I SECTION 1-1t

FIREfigure 11. Locations of Thermocouples in Slabs (2950 x 1650 x 120 mm) for Specimen No. 3

Table 17. Deflections of Beam and Slabs: No.3 Beam-Slab Specimen

*

Specimen failed at 53 minutes due to excessive deflecton of Slab No. 1**

The location of the slabs are shown in figure 8 Time* (min) 0 5 10 15 20 25 3 0 3 5 40 45 5 0 5 5 6 0 65 7 0 7 5 8 0 81 Deflection of Slab No.l(mm)** 0.00 -10.04 -18.36 -29.96 -38.72 -46.81 -58.77 -62.29 -65.62 -69.20 -72.78 -75.99 -80.49 -80.90---

---

---

---

Deflection of Beam (nun) 0.00 -8.32 -14.31 -27.41 -37.62 -47.90 -66 -91 -71.52 -76.14 -81.13 -87.28 -92.26 -99.53 -107.60 -158.50 -183.40 -247.50 -268.60 Deflection of Slab No.2(mm)** 0.00 -6.69 -12.55 -22.85 -30.53 -37.83 -48.28 -51.35 -54.25 -57.34 -60.79 -63.30 -67.42 -71.20 -88.82 -88.78---

---

Table 18. Beam Temperatures :

No.3

Beam-Slab Specimen Time (min) 0 5 10 15 20 2 5 30 3 5 4 0 4 5 5 0 55 60 65 70 7 5 8 0 81Temperatures ( O C ) Measured at Thermocouple No. :

1 2 3 4 5 6 7 8 9 10 35 35 35 34 34 35 35 35 35 35 4 0 3 5 3 9 87 132 4 0 35 39 76 118 6 2 36 59 129 218 57 36 59 117 198 6 4 4 3 96 180 295 8 6 43 92 163 271 106 69 106 232 355 105 58 107 208 327 113 9 1 109 276 403 106 98 110 247 372 124 103 118 315 446 113 102 117 284 414 143 104 134 349 482 127 103 132 317 449 168 104 155 381 514 148 104 153 348 480 193 104 177 409 542 173 104 174 377 509 215 104 199 435 567 199 104 196 403 534 236 105 218 458 586 223 104 217 428 556 255 108 236 477 601 244 107 238 449 575 273 112 252 495 617 264 111 256 469 592 290 119 269 510 628 280 115 273 487 606 306 132 285 524 641 297 122 289 503 619 321 153 301 539 658 314 139 305 518 633 324 156 304 542 661 318 144 309 521 637 Furnace Temperature ( O C ) 53 579 683 745 786 817 848 870 889 904 918 933 946 958 969 979 989 991

Table 19. Beam Temperatures :

No.3

Beam-Slab Specimen Time (min) 0 5 10 15 20 2 5 30 35 40 45 50 5 5 6 0 65 7 0 75 80 8 1Temperatures (OC) Measured at Thermocouple No. :

11 12 13 14 15 16 17 18 19 2 0 3 6 3 6 36 35 35 35 3 5 35 35 3 5 37 3 6 44 108 164 120 105 7 3 76 147 48 3 9 73 176 273 215 165 113 114 262 8 4 65 103 247 357 311 258 157 161 360 96 83 123 302 413 383 332 212 213 430 102 94 137 346 459 440 392 260 260 486 108 102 151 385 501 488 443 300 299 530 116 106 176 420 535 529 486 337 335 566 124 109 200 452 565 562 522 370 367 584 133 112 225 481 592 589 550 398 395 617 141 116 249 508 617 612 575 421 418 636 167 121 273 532 638 632 597 442 438 651 186 128 296 553 656 651 617 461 457 660 205 135 318 572 674 669 636 480 476 680 225 145 338 588 688 690 654 500 495 693 244 161 357 604 703 708 672 521 516 709 263 182 376 619 721 728 688 541 536 728 265 185 381 623 725 732 691 545 540 732 Furnace Temperature (OC) 5 3 579 683 745 786 817 848 870 889 904 918 933 946 958 969 979 989 991

Table 20. Beam Temperatures :

No.3

Beam-Slab Specimen Furnace Temperature (OC) 53 57 9 683 745 786 817 848 870 889 904 918 933 946 958 968 979 989 991 Time ( m i d 0 5 10 15 20 25 30 3 5 40 45 5 0 5 5 6 0 6 5 70 7 5 80 8 1-

Temperatures (OC) Measured at Thermocouple No. :

21 22 23 24 25 26 27 28 29 30 31 32 35 35 35 34 35 35 35 36 36 36 36 35 156 36 35 40 37 35 40 41 36 38 66 88 274 48 35 65 48 36 60 65 38 53 111 127 373 74 40 94 72 41 93 100 62 86 138 194 441 9 8 50 108 96 57 110 113 110 108 182 261 483 109 72 115 110 83 112 115 105 111 225 319 512 114 9 1 124 113 103 118 111 108 113 261 368 542 119 105 140 115 108 137 122 109 119 293 411 564 126 109 165 118 109 161 139 108 127 327 451 583 135 109 193 124 109 185 164 109 142 358 486 588 147 110 218 134 109 209 192 110 162 387 517 611 164 110 241 152 109 232 220 114 186 413 544 625 183 111 263 174 111 254 246 119 210 438 568 637 201 113 284 194 113 274 272 127 233 461 589 652 219 114 304 213 117 292 289 146 253 482 607 669 236 118 323 231 123 308 305 170 273 502 625 691 252 123 340 248 131 323 322 192 292 521 640 696 255 126 344 251 133 326 325 196 296 524 644

Table 21. Slab Temperatures : No.3 Beam-Slab Specimen Furnace Temperature (OC) 5 3 579 683 745 786 817 848 870 889 904 918 933 946 958 968 979 989 991 Time (min) 0 5 1 0 15 20 2 5 30 3 5 4 0 45 5 0 5 5 60 6 5 70 7 5 8 0 8 1 2

Temperatures (OC) Measured at Thermocouple No. :

A - 1 A-2 A-3 A-4 A-5 A-6 B-1 B-2 B-3 B-4 B-5 B-6

32 32 32 3 1 3 1 30 32 32 32 32 3 1 30 1 0 6 47 33 3 1 3 1 30 1 5 4 59 33 32 3 1 30 1 6 2 1 0 7 44 32 3 1 30 2 5 1 109 48 34 32 30 230 1 1 9 94 37 33 30 3 4 1 137 98 49 34 30 288 1 4 3 1 0 8 63 4 1 3 3 409 172 102 90 8 5 36 339 172 112 85 6 1 43 464 212 107 96 9 1 48 382 2 0 1 1 1 7 1 0 0 80 54 507 247 117 99 9 3 6 1 417 230 1 2 3 1 0 9 96 64 542 279 127 102 9 5 84 448 258 1 3 0 1 1 4 104 74 573 309 1 4 1 1 0 6 97 94 475 283 1 4 1 1 1 6 1 0 8 8 1 599 337 1 6 0 111 98 97 498 306 1 5 4 117 1 1 0 84 6 2 1 362 1 8 1 117 100 93 517 3 2 6 1 7 0 1 1 7 111 85 639 386 202 124 1 0 3 87 535 345 1 8 5 117 112 8 5 655 407 2 2 1 1 3 1 1 0 8 79 549 362 1 9 8 1 1 8 111 8 5 670 427 237 1 3 9 1 1 3 7 8 560 376 2 1 1 1 2 0 1 1 0 84 680 444 252 1 4 9 1 1 8 7 7 5 7 1 388 222 1 2 4 109 85 695 460 267 160 124 78 584 4 0 1 232 1 2 9 1 0 9 86 710 475 2 8 1 1 7 1 1 3 0 8 1 586 404 234 1 3 1 109 8 5 714 478 284 174 132 8 3 - -

Table 22. Slab Temperatures : No.3 Beam-Slab Specimen Time (min)

-

0 5 10 15 2 0 25 30 3 5 4 0 45 5 0 55 60 65 7 0 75 8 0 8 1Temperatures (OC) Measured at Thermocouple No. :

C-1 C-2 C-3 C-4 C-5 C-6 D-1 D-2 D-3 D-4 D-5 D-6 32 32 32 31 31 30 32 32 32 31 31 30 126 54 33 31 31 30 129 61 33 31 31 30 202 102 44 33 31 30 222 110 47 34 32 30 279 134 69 38 34 31 307 132 73 40 34 31 342 160 96 52 41 34 378 173 101 53 41 33 396 195 110 74 58 42 436 215 108 75 54 39 441 232 119 97 77 55 482 254 115 100 77 50 478 265 127 107 94 69 517 287 128 105 103 65 507 294 138 111 103 79 543 315 145 108 106 79 533 321 151 113 105 85 563 338 164 111 108 86 556 344 167 114 106 88 578 358 183 115 108 90 577 366 183 116 107 88 594 377 200 120 108 91 596 387 199 120 107 88 609 395 215 127 108 92 614 405 215 125 108 88 626 413 230 136 111 92 628 422 229 131 110 88 641 430 244 145 115 91 643 438 241 139 114 90 658 446 258 154 119 90 660 453 254 147 120 92 678 462 272 163 126 91 663 456 256 149 121 93 683 465 274 166 128 91 Furnace Temperature I0C) 53 579 683 745 786 817 848 870 889 904 918 933 946 958 968 979 989 991

Table 23. Slab Temperatures : No.3 Beam-Slab Specimen Furnace Temperature ( O c ) 5 3 579 683 7 4 5 7 8 6 817 848 870 889 904 9 1 8 933 946 958 9 6 8 979 989 9 9 1 Time (min) 0 5 1 0 1 5 2 0 2 5 3 0 3 5 4 0 4 5 5 0 5 5 6 0 6 5 7 0 7 5 8 0 8 1

Temperatures ( O C ) Measured at Thermocouple No. :

E-1 E-2 E-3 E-4 E-5 E-6 F-1 F-2 F-3 F-4 F-5 F-6

3 3 3 3 32 32 3 1 30 32 32 32 3 1 3 1 3 0 1 4 2 49 33 32 3 1 30 1 0 2 47 3 3 3 1 3 1 3 0 236 9 2 43 3 3 3 1 3 1 1 6 3 8 3 40 3 3 32 29 330 1 1 8 64 3 8 3 3 3 6 237 1 1 4 59 3 6 34 29 404 1 4 1 93 5 2 4 2 4 0 303 1 3 7 9 0 4 6 3 8 3 1 462 1 7 7 1 0 5 7 4 6 6 90 3 5 8 1 7 0 1 0 4 66 48 3 8 5 0 6 2 1 4 111 9 0 8 0 9 0 400 204 1 0 9 9 1 67 4 8 542 2 4 8 1 1 9 9 9 8 9 9 1 430 234 1 1 5 1 0 3 9 1 57 5 7 1 2 7 8 1 3 0 1 0 4 95 92 450 259 1 2 4 1 0 7 1 0 2 69 596 3 0 4 1 4 6 1 0 6 99 9 1 4 6 5 282 1 3 7 1 0 9 1 0 4 74 617 329 1 6 5 1 0 8 1 0 2 92 480 302 1 5 2 111 1 0 5 84 636 3 5 1 1 8 3 1 1 2 1 0 3 9 2 498 3 2 1 1 6 7 1 1 3 1 0 5 8 8 656 372 2 0 1 1 1 8 1 0 3 9 1 5 1 8 339 1 8 2 1 1 5 1 0 5 89 672 392 217 1 2 6 1 0 5 9 1 539 357 1 9 6 1 1 8 1 0 5 90 686 4 1 1 233 1 3 6 1 0 9 92 559 376 210 1 2 2 1 0 5 9 1 702 428 247 1 4 7 1 1 5 9 1 580 393 223 1 2 8 1 0 4 9 1 7 2 1 444 262 1 5 7 1 2 2 9 1 6 0 0 410 237 1 3 5 1 0 4 9 2 7 2 5 447 265 1 6 0 1 2 3 90 604 414 239 1 3 6 1 0 4 9 1

REFERENCES

1. Reinforced Concrete Structures Design Code (TJ10-74), The China Construction Industry Publishing House, 1974.

2. Reinforced Concrete Structures, Tianjin University, Tongji University, The China Construction Industry Publishing House, 1987.

3. Building Materials, Hunan University, The Chma Construction Indushy Publishing House, 1987.

4. B. N. Lie, China Civil Engineering Handbook, The Shanghai Science and Technology Publishing House, 1989.

5 . T. T. Lie and J. E. Berndt, Remote Measurement of Large Deflections in Fire Tests, Division of Building Research, National Research Council of Canada, 1972.

6. Fire-Resistance Tests-Elements of Building Construction (GB9978-88), National Standard of the People's Republic of China, 1988-10-26.