An Assessment of Stingless Beeswax as a Pattern Material in Ancient Mesoamerican Lost-Wax Casting

by

Eleni Chrisoula Pitses

Submitted to the

Department of Mechanical Engineering

in Partial Fulfillment of the Requirements for the Degree of Bachelor of Science in Mechanical Engineering

at the

Massachusetts Institute of Technology

June 2018

2018 Eleni Chrisoula Pitses. All rights reserved.

The author hereby grants to MIT permission to reproduce and to distribute publicly paper and electronic copies of this thesis document in whole or in part in any medium now known or

hereafter created.

Signature redacted

Signature of Author:Certified by:

Department of Mechanical Engineering May 11, 2018

Signature redacted

Michael J. Tarkanian Senior Lecturer in Materials Science and Engineering

Signature redacted

Thesis SupervisorMASSACH SETS INSTrrUTE QF TECHNOWGY

SEP 13 2018

Rohit Kamik Professor of Mechanical Engineering Undergraduate Officer 1

An Assessment of Stingless Beeswax as a Pattern Material in Ancient Mesoamerican Lost-Wax Casting

by

Eleni Chrisoula Pitses

Submitted to the Department of Mechanical Engineering on May 11, 2018 in Partial Fulfillment of the

Requirements for the Degree of

Bachelor of Science in Mechanical Engineering

ABSTRACT

Metal objects were of great cultural significance in pre-Columbian Mesoamerica. Historical and archaeological evidence prove that these items were made by the process of investment casting, or "lost wax" casting, by which a wax model of the object is created, and a ceramic mold is built around it. The wax is melted out to allow for the pouring of the molten metal. Considerable research has focused on the alloy composition of these objects, and some research has been done on the ceramic molds, but little is known about the composition, source, and manufacture of the wax itself. This paper builds upon work by Michael Tarkanian and Dr. Elizabeth Paris,

attempting to fill this gap in the literature.

Spanish written accounts of ancient Mesoamerican casting processes mention that wax from stingless bees was mixed with copal, or tree resin, and used to form the models for lost-wax casting. Waxes from Mexican stingless bees Melipona beecheii, Scaptotrigona pectoralis, and Melipona yucatanica were considered in this study, in addition to three copals: Bursera

copallifera, Protium copal, and Pinus contorta. Thermal data from Differential Scanning

Calorimetry revealed no changes in thermal behavior between waxes and their blends with copals, showing that none of the blends considered in this study are miscible. However, hardness testing revealed that the blends of Pinus contorta with Melipona beecheii and with Melipona

yucatanica were harder than their respective waxes. This is in line with a Spanish account of the

casting process, which mentions that copal was added so the wax may "[become firm and] harden well"[ 1]. Including data collected by Tarkanian and Paris, the most favorable material for investment casting would be Friesomelitta nigra wax mixed with Bursera copallifera, according to the criteria considered in this study.

Acknowledgements

I would like to thank Michael Tarkanian for his help and guidance throughout the research,

experimentation, and writing process. His mentorship was invaluable to this work. I would also like to thank Geetha Berera for the time, care, and patience she put into training me on the DSC and helping with data collection. Thanks to her guidance, I can collect and interpret DSC data with confidence. Finally, I would like to thank Elizabeth Paris, Pedro Delgado K6, and Elizabeth Meanwell for providing the wax samples from the Yucatan.

Table of Contents 1. Introduction 2. Mesoamerican Castings 3. Materials 3.1. Beeswax 3.1.1 Bee Species 3.1.2 Maya Beekeeping 3.1.2.1 Religious significance 3.1.2.2 Economic significance 3.2 Copal 3.3 Wax-Copal Blends 4. Experimental 4.1. Materials Tested 4.2. Properties Measured 4.3. Procedure 4.3.1. Sample Preparation 4.3.2. Thermal Testing 4.3.3. Hardness Testing

5. Data and Analysis

5.1. Thermal Properties of Waxes 5.2. Miscibility of Wax-Copal Blends

5.3. Thermal Properties of Wax-Copal Blends

5.4 Hardness of Waxes and Wax-Copal Blends

6. Conclusions 7. Future Work

List of Figures

Figure 2a: Tuyeres excavated from the Bataln Grande region of Peru Figure 2b: Drawing of casting process from Sahagn'n's Florentine Codex Figure 2c: Illustration of bell types identified from excavations at Mayapin Figure 3a: Area inhabited by Melipona yucatanica

Figure 3b: Area inhabited by Melipona beecheii

Figure 3c: Area inhabited by Scaptotrigona pectoralis

Figure 3d: Depictions of bees and bee gods from the Tro-Cortesianus Codex

Figure 3e: DSC data for Apis mellifera, Friesomelitta nigra, and T fulviventris, from Tarkanian and Paris

Figure 3f: DSC data for Bursera copallifera, Pinus contorta, and Protium copal, from Tarkanian and Paris

Figure 3g: DSC data for Apis mellifera and a 50% by weight blend of Apis mellifera with

Bursera copallifera, from Tarkanian and Paris

Figure 3h: DSC data for Frieseomelitta nigra wax and 42%-58% by weight blend of B.

copallifera-F.nigra, from Tarkanian and Paris

Figure 3i: DSC data for Victory Brown foundry wax, and a 42%-58% by weight blend of B. copallifera-F. nigra, from Tarkanian and Paris

Figure 3j: Hardness data collected by Tarkanian and Paris

Figure 3k: ASTM D 1321 hardness of F. nigra-B. copallifera blend as a function of weight % of

B. copalifera, from Tarkanian and Paris

Figure 31: Ash content data from Tarkanian and Paris Figure 4a: Wax samples during first stage of filtration Figure 4b: Wax samples after all filtration

Figure 4c: Copal samples before filtration Figure 4d: Bursera Copallifera after filtration

Figure 4e: Dimensioned drawing of needle for ASTM D I321-16a, "Standard Method for Needle Penetration of Petroleum Waxes"

Figure 4f: Hardness testing apparatus Figure 5a: DSC data for pure waxes

Figure 5b: Table of miscibility of wax-copal blends

Figure 5c: DSC data for M. beecheii and all blends with M. beecheii

Figure 5d: DSC data for M. yucatanica and all blends with M. yucatanica Figure 5e: Hardness data of all waxes and blends

1. Introduction

Metal objects were of great cultural significance in pre-Columbian

Mesoamerica. Historical and archaeological evidence prove that these items were made by the process of investment casting, or "lost wax" casting, by which a wax model of the object is created, and a ceramic mold is built around it. The wax is melted out to allow for the pouring of the molten metal. Considerable research has focused on the alloy composition of these objects, and some research has been done on the ceramic molds, but little is known about the

composition, source, and manufacture of the wax itself.

Spanish written accounts exist, describing the process of lost-wax casting. Bernardino de Sahagd'n was a catholic priest, missionary, and ethnographer who journeyed from Spain to the New World in 1529. The Florentine Codex is a twelve-book ethnographic work written by Sahagan based on his observations of the Maya. In Book 9 of the Florentine Codex, he gives a description of ancient Mesoamerican casting processes. The process would begin with

fabrication of molds.

The craftsmen fashioned [and] designed objects by the use of charcoal [and clay molds] and beeswax [models] to cast gold and silver. With this [step] they made a beginning in their craft[l].

Foundry wax would be surrounded by this mold material, taking the shape of the metal object to be fabricated. Below, Sahagdin describes the fabrication of this wax material.

When the charcoal [core of the mold] had been prepared, designed, carved, then the beeswax melted. It was mixed with white copal, so that it would [become firm and]

harden well. Then it was purified, strained, so that its foreign matter, its dirt, the impure beeswax, could fall[1].

Michael Tarkanian, together with Dr. Elizabeth Paris, originally set out to study thermomechanical properties of mixtures of various species of stingless beeswaxes and copal species to assess their suitability as foundry materials[2]. It was their hypothesis that there may be an ideal mix of beeswax species and copal species, as well as ideal ratio of wax to copal [2]. This thesis expands on their work, testing the thermal and mechanical properties of waxes, copals, and mixtures of the two, in order to try to identify blends that may have been used by the Maya.

2. Mesoamerican Castings

Metallurgy in the New World first emerged in the Andes between 1800 and 2000 BC[3]. The first known instance of Mesoamerican metallurgy was found in western Mexico, dating between 600 and 700 AD[4]. Because of its sudden appearance in the area, and the similarity to practices in South America, some scholars believe that people came by boat from the Andes, bringing with them their metallurgical traditions [4].

Most of Western Mexico is rich in metallic resources, especially copper, silver, and gold. Copper was the predominant resource, and it was used most extensively. Between 650 and

1200/1300 AD, western Mexican metalsmithing was not particularly sophisticated. They appear

to have used almost exclusively either native copper, or easily-smelted copper from oxidized copper ores [5]. However, from about 1300 to the time of the Spanish conquest, Mesoamerican metalworkers appear to have produced multiple copper-based alloys, including copper-arsenic, copper-silver, copper-gold, copper-tin, copper-silver-gold, copper-silver-arsenic, copper-arsenic-antimony, and copper-arsenic-tin[4] [5].

A major challenge towards the development of metallurgy in the New World was the attainment of high enough temperatures to melt metals from ores. While bellows do not seem to have been used in the New World, Andean workers developed the blow tube, which was made from a hollowed-out cane stem, and had a ceramic nozzle known as a tuyere on the furnace end to protect it from burning.[6] [7] .Illustrations by Sahaguin in the Florentine Codex reveal that the same type of blow pipe was used in Mesoamerica (see figure 2b). A simple ceramic furnace was used for smelting metal ingots, as it would be difficult to attain the reducing conditions necessary for alloy creation. Alloys, on the other hand, were made by heating small quantities of components in small earthen pits, lined with a mixture of clay and ash, also using the cane tubes for intensification of the heat. Grinberg analyzed slag samples from Itziparatziko, and

determined that they were formed with a consistent smelting temperature of 1200 C, under oxygen-starved conditions [5]. More specialized furnace technology would have been necessary to reach these parameters, however these technologies have not been recovered in the

archaeological record. Archaeologists are considering that any more sophisticated furnace technology may have been comprised of semi-permanent structures that did not survive in the archaeological record, or that the prevailing strong winds in the area of the site may have aided in increasing the smelting temperature[5].

Figure 2a: Tuyeres excavated from the Batin Grande region of Peru [7].

Figure 2b: Drawing from Book 9 of Sahagfin's Florentine Codex, showing the process of melting and casting gold. The man on the right is using a blow pipe to heat up the fire [1].

Lost-wax casting possibly originated in lower Central America and Colombia around 100 AD, and arrived in Mesoamerica through overland trade during the Classic period [4]. Fray Bernadino de Sahaguin describes the lost-wax casting process as he observed it in the 166* century. He said that the artisan first ground charcoal into powder, and mixed it together with potter's clay, kneading it so the two were fully-incorporated. It was allowed to dry in the sun for two days, and then formed and sculpted into the shape of the desired object. The wax and copal mixture was then rolled out very thin, and was formed to line the clay and charcoal model. The wax/copal-lined model was then covered with more of the clay/charcoal mixture, and it was

allowed to dry in the sun for two days. During the drying process, a tube was inserted to allow for the drainage of molten wax. The model was placed in a crucible to melt out the wax, and the molten metal was poured in through the tube. After the metal dried, the outer clay mold was broken, and the inner portion of the mold was scraped out using a sharp tool[4].

A study by Meanwell, Paris, Alvarado, and Lope, examined small ceramic objects that

may have been associated with metallurgy at the site of Mayapin on the Yucatan. X-Ray fluorescence on the surface of four samples found on the site indicated the presence of copper, arsenic, silver, tin, and gold[8]. Since these compounds are not usually found in clay, the results suggest that these clay artifacts were in contact with molten metal which left behind residue. Using reflected polarized light, researchers found a large copper prill within one of the ceramic pieces[8]. Reflected light microscopy revealed many tiny prills within the fabric of the clay;

these also could have been byproducts of smelting with these ceramic materials. Petrography on the ceramic pieces revealed signs of vitrification, which usually begins at firing temperatures of between 900 and 1100 C. Pure copper melts at 1083 C, which is well within that range, and could have caused vitrification. Researchers compared these ceramic pieces to typical ceramics

from Mayapan, revealing potential differences in their composition and firing. The fabric of this clay was optically active, proving that it had not reached high enough temperatures to vitrify, and therefore it was not in touch with molten metal[8]. The typical Mayapan ceramics also contained large volumes of calcareous inclusions. Calcite breaks down at firing temperatures as low as 650 C, which can cause spalling (or flaking off of clay) during rehydration[8]. The presence of these inclusions is consistent with the geology of the Yucatan peninsula[8]. The absence of these inclusions in the metallurgical ceramics at Mayapan could suggest one of two things. First of all, metallurgical ceramics could have been produced using a different clay source. Alternatively, a

common clay source could have been used for both types of ceramics, but heavily processed for metallurgical uses in order to remove the calcareous deposits that are unstable under high temperatures[8]. Regardless, artisans at Mayapain likely made some effort to make metallurgical ceramics distinct from other ceramics.

Metals were believed to have great divine intrinsic value in Mesamerica. According to Sahagd'n, gold was believed to be the excrement of the gods. In Book 11 of the Florentine Codex, Sahaguin says:

The name of this gold, the yellow, the white [silver]-its name comes from teotl [god] and cuitlatl [excrement], because it is wonderful, yellow, good, fine, precious. It is the wealth, the riches, the lot, the possession, the property of the rulers, our lords.[1]

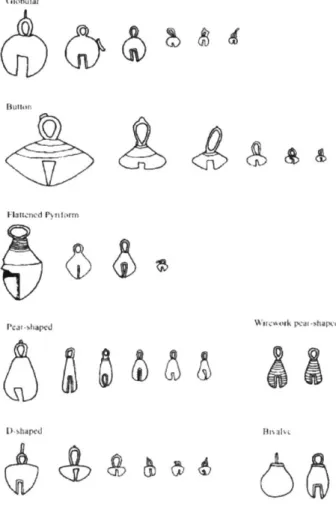

This divine material was not used as an economic commodity; it was used to make objects used in ceremonial contexts. Bells were made using lost-wax casting, and they were produced in larger quantities than any other prehispanic metal object. They make up approximately 60 percent of the artifacts in Western Mexican collections, and they were likely produced in larger quantities than any other metal object[4][5]. In the archaeological record, bells are often found in burial contexts. At the site of Amapa, one burial contains at least 33 bells associated with one individual. Also at that site, bells make up approximately half of 205 metal objects excavated [9].

Mesoamerican bells took on various round shapes, and they all contained a slit at the base, and a loop at the top which would be use to attach them to garments. Most bells contained clappers, which would be inserted through the slit at the bottom, and could be made out of pebbles, ceramic, or metal[4]. Most bells varied in length between about I and 8 centimeters, however a few bells larger than that range have also been found. The pitch of a bell varies with

its size; larger bells had larger resonator cavities and therefore had lower pitches. The great variety in shapes and sizes of bells dated from 600-1300 AD suggests that there may have been some effort to create bells of different pitches so as to create a heterogeneous composition of sounds [4]. In fact, ethnographic studies show that Huastec people still wear bells of varying sizes during traditional dances; they would attach smaller, high-pitched bells to their calves and lower pitched bells to their lower backs[10].

alobula,

Hattened Pnlform

Pucr-shaped

L).sbaped

Figure 2c: Illustration of bell from excavations at Mayapin

W. rudtw pew -shape.d

aLA

types identified 3. Materials 3.1. Beeswax(

(! & d

i5 IThe foundation of Mesoamerican casting wax is stingless beeswax. Beeswax has a very heterogeneous composition. Previous analyses of beeswax showed that samples contained 7% by weight "unidentified materials.[l l]"Beeswax contains mostly hydrocarbons, esters and free acids, whose relative concentrations vary according to bee species. Robert Buchwald, et. al, found a correlation between bee species nesting ecology and the mechanical properties of beeswax, noting that wax from bees whose nests needed to bear more weight had relatively high values for stiffness, resilience, and yield stress, compared to waxes from bees who build their nests in cavities of trees [12].Another study by Buchwald shows that an increase in fatty acid concentration increases the stiffness, yield stress, and proportional limit of stress of

beeswax[ 13].Beeswax is partly crystalline, and several polymorphic transitions in the solid state can be observed prior to the melting point, giving it a generally broad melting profile[ 1].

3.1.1 Bee Species

In antiquity, the Maya were known to be keepers of stingless bees, a tradition that

continues today in indigenous Maya communities. There are 400 stingless bee species around the world, all native to the tropics and subtropics [14][15]. There are 30 species of the genus

Melipona, which is the one most commonly found in Mesoamerica. The two species most

prominent in the Yucatan peninsula are Melipona beecheii and Melipona yucatanica [14].

Melipona beech eii was the most commonly kept by the Maya[16].

Stingless bees and the better known European honeybees are members of different taxonomic families: Meliponidae and Apidae, respectively[ 16]. Stingless bees are similar to honeybees in that both are eusocial, and that both have a high degree of queen-worker

dimorphism[15]. Stingless bees can vary in size from about 2mm long to larger than a honeybee. Those in the Yucatan tend to be in the smaller end of that range. Ethnographic workers who

studied Maya beekeepers of Melipona beecheii in 2004 noted that the bees were less than half an inch long [14]. Diego de Landa, a Catholic Bishop, describes the stingless bees in his account of

pre-Columbian Maya civilization, entitled Relacidn de las cosas de Yucatdin.

There are two kinds of bees and both are very much smaller than ours. The larger kind of these breeds in hives, which are very small. They do not make honeycomb as ours do, but a kind of small blisters like walnuts of wax all joined to one another and full of honey. To cut them away they do nothing more than to open the hives and to break away these blisters with a small stick, and thus the honey runs out and they take the wax when they please. The rest breed in the woods in hollows of trees and of stones and there they search for the wax, in which and in honey this land abounds, and the honey is very good, except that, as the fertility of the nourishment of the bees is great, it sometimes comes out a little watery and it is necessary to give it a boiling on the fire, and when this is done it is very good and keeps very well. The wax is good, except that it is very smoky, and the cause has never been ascertained, and in some provinces it is much more yellow on account of the flowers. These bees do not sting nor do they harm when the honeycombs are cut.[17]

Honey from Melipona beecheii has a lower viscosity than that of Apidae honeybees. It is preferred by the Maya for its unique, somewhat lemony flavor, and it is also believed to have curative properties[ 18]. M. beecheii honey contains high levels of Bacillus, which inhibits pathogenic bacterial growth, and it also has a lower pH than A. mellifera honey[19]. These properties lend themselves well to the medicinal uses of honey among the Maya, including treatment of skin eruptions, tongue sores, and urinary problems[16].

Below are maps of the geographic distribution of three different stingless bee species considered in this study, obtained from Moure's Bee Catalog[20]. They are, from top to bottom:

Figure 3a: Area inhabited by Melipona yucatanica [19].

Figure 3b: Area inhabited by Melipona beecheji [19].

3.1.2. Maya Beekeeping

Beekeeping has been part of life in the Yucatan since the time of the Maya. It has held considerable religious, economic, and cultural significance in the area.

3.1.2.1. Religious Significance

Both historical and archaeological evidence point to the religious significance of beekeeping to the Maya. During the month of Tzoz, according to Diego de Landa, the natives would prepare for a ceremony on behalf of the bees which would take place during the following month, Tzec [21] [22]. In the month Mol, another fiesta was undertaken on behalf of the bees so that the gods may provide an abundance of flowers for the bees[22].

The Tro-Cortesianus, an ancient Maya manuscript, also mentions festivals and gods

related to bees and beekeepers[22]. Images of bees and bee gods from the Tro Cortesianus can be seen in Figure 3d. Temples of the Descending or Diving god, at the sites of Tulum and Coba, contain stone relief depictions of Ah Mucen Kab, the Maya god of beekeepers, bees, and

honey[14].

... . n .x .J4~~ ..

- I Po~y PLATE Im

Figure 3d: Depictions of bees and bee gods from the Tro-Cortesianus Codex, and their accompanying descriptions. From Volume 4 of the Papers of the Peabody Museum of

The belief in the Maya gods has tapered off with time, and the number of shamans knowledgeable in the beekeeping-related ceremonies has dwindled. However, the reverence for bees remains strong in the minds of the beekeepers. Ethnographic researchers studying in the Yucatan in 1981 noted that beekeepers would go to great lengths to keep their bees alive. If one would become covered in honey, the beekeeper would carefully rinse it off and place it back in the hive. If a bee were to die, the beekeepers would wrap it in a leaf and bury it[ 18]. Between

1995 and 2005, there has been a 90% decrease in the number of hives kept in Maya villages [14]

.This has been influenced by multiple factors, including deforestation, pesticide use, competition for food with A. mellifera, and economic and social pressure experienced by the Maya[ 14][19].

3.1.2.2. Economic Significance

Stingless beekeeping was also an important economic activity during Pre-Columbian times. Honey from the Melipona beecheii was used to produce the alcoholic drink, balche, made from water, the bark of the balche tree and honey from Melipona beecheii[ 14] [16]. Balche was prepared and consumed throughout the Yucatan in festival contexts. The demand for this beverage made the economic incentive for beekeeping very strong. Stingless beekeeping

remained an important economic activity during colonial times. Tribute lists from the Yucatan in 1549 showed that 163 out of 173 documented villages paid tribute, in part, with wax or honey of stingless bees[16]. Wax was also among the principal exports of the Yucatan during the colonial era. While stingless beeswax contains many impurities, and was inferior to honey beeswax for candle-making, this trade continued to thrive because honeybee wax had to be imported[16]. The Spaniards may also have blocked the import honeybees so as to maintain the demand for Spanish wax and honey[16].

Honeybees eventually came to Mesoamerica following independence from the Spaniards in the 1820s. Eventually, the production of honeybee beeswax proliferated, leading to the end of trade in stingless beeswax[ 16]. While it never had the same economic significance as it did in the past, meliponaculture has continued into the 2 0h century, mainly in the Maya villages of the Yucatan.

It has been estimated that in 1973, there were between 500 and 1500 stingless beekeepers in the Yucatan, and most were Maya[ 16].

3.2. Copal

Copal is a tree resin from tree species native to Mexico. The term copal derives from the term copalli, which comes from the Aztec word for incense, and today mostly refers to resins

derived from Bursera, Protium, and Pinus pseudostrobus trees [23]. Tree resins usually consist

of a volatile, fragrant fraction, known as an essential oil, and a non-volatile fraction. Fresh resins are translucent liquids, but with time, the essential oil fraction is lost and they turn into brittle solids. In the absence of the volatile essential oil, resins contain 90% by weight di-terpene based acids, with the remaining 10% a blend of esters, alcohols, aldehydes, and hydrocarbons[ 11] .Each acid presents multiple isomers, and rosins are presented to be amorphous as long as no single isomer exceeds 30% by weight. Resins do not clearly present melting points, but rather they have a broad melting profile, usually beginning above 15 C, before they reach a liquid state. It is also worth noting that during heating, resins are susceptible to chemical change, as the acidic fraction is susceptible to isomerization and oxidation reactions [11].

3.3. Wax-Copal Blends

One common way to change the properties of polymers is to blend them with another material or to incorporate other particles[2]. With this in mind, Gaillard, et. al examined thermal and mechanical properties of mixtures of beeswax, rosins, and their blends in order to observe

how they changed when the materials were incorporated in different amounts [24]. Beeswax is a partially crystalline material, with its crystals taking a needle-like form. Microstructural analysis of the blends revealed that the size of these needle-like crystals decreased with the addition of rosin[24]. In mixtures above 90% rosin by weight, the crystalline part of wax formed spherical crystallites that were uniformly distributed throughout the matrix[24]. The study also found that mixtures containing at least 60% resin exhibited superplastic behavior at room temperature[24].

Michael Tarkanian and Dr. Elizabeth Paris investigated multiple properties of wax-copal mixtures in order to determine their suitability as foundry materials. This included examination of their melting profiles, hardness, and ash content.

This study used the wax of Frieseomelitta nigra and Trigonafulviventris, both of which

are native to Mexico, and the wax of Apis mellifera, the European honeybee. Preliminary DSC data of the three individual waxes can be seen in Figure 3e, with Apis mellifera in blue,

Frieseomelitta nigra in green, and Trigonafulviventris in orange. F. nigra and A. mellifera have

similar melting profiles, with melting points at 630 C and 65' C, respectively, and onsets of melting around 42' C[2]. The onset of melting, or "softening point," is the point at which a material begins to undergo an endothermic transformation from a solid to a liquid. T.

Fulviventris, however, has two peaks. The first peak represents the melting of some component of the wax. It melts at a higher temperature than the other two waxes, with an onset of melting of

products remain solid at temperatures up to 2000 C [2]. For this reason, T. fulviventris was deemed unsuitable for foundry applications and was not mixed with copals for further testing.

4,___ 3.5- 3-

2.5--r

U 2 1.5- 1-0.5 0 -0 20 40 60 s0 100 T.mp.u.u..(c) 120 140 160 180 200Figure 3e: DSC data collected by Tarkanian and Paris for the three waxes considered in their study. A. melh/fera is in blue, F. nigra is in green, and T. fulviventris is orange.

1.4 1.2 1 0.8 0.6 0.4 0.2 0 -- -003

Figure 3f: DSC data collected by Tarkanian and Paris for the copal samples considered in their study.

Bursera copalifera is in red, Pinus contorta is in blue and Protium copal is in green. ou100 150 200

Temperature(CQ

After testing the individual samples, they tested blends of waxes and copals. They found that Pinus contorta and Protium copal were not miscible with any of the available wax samples, so the only blends with Bursera copallifera were thermally tested[2]. Tarkanian and Paris hypothesized that the comparatively small copal molecules would disrupt the beeswax crystal

structure, thus increasing the free volume within the polymer system of the blend and decreasing the melting temperature.

As shown in Figure 3g, the addition of B. copallifera to A. mellifera significantly decreased both the melting point and onset of melting. The addition of 50% by weight of B.

copallifera decreased the melting point from 660 C to 570 C, and decreased the onset of melting

from 38' C to 22' C [2]. With this onset of melting, the wax-copal mixture would soften when exposed to body heat, making it easier to roll into sheets and form into bell shapes. The melting profile of F. nigra did not change as dramatically with the addition of B. Copallifera. Figure 3h shows the melting profile of F. Nigra in blue, compared to a mixture of F. Nigra with 42% by weight B. Copallifera, shown in yellow. The wax alone had a melting point of 630 C, while the

mixture had two peaks, at 620 C and 560 C, respectively[2]. The onset of melting decreased more

dramatically, going from 42'C for pure wax to 300 C for the mixture[2]. While this is higher than

the onset of melting for the other mixture, it is 7 degrees lower than the human body temperature, meaning that softening can be expected when it is formed by hand. Figure 3i compares the F. nigra / B. copallifera mixture with Victory Brown, a commercial foundry wax which is meant to be formed by hand. It is clear that these two have similar thermal properties. Victory Brown has an onset of melting at approximately 25'C, compared to 300 for the F.

nigra-B.copallifera mixture[2]. Because of the thermal similarities between the F. nigra-B. copallifera blend and Victory Brown foundry wax, it is reasonable to say that the blend exhibits favorable thermal properties for lost-wax casting.

1.8

0 50 100 150 200

Temperature (C)

Figure 3g: DSC data collected by Tarkanian and Paris of Apils mellifera wax (green) and 50-50 by weight blend of Apis Mellifera and Bursera copallifera (yellow) [2].

Es E 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 250

1.6 1.4 1.2 1 0.8 0.6 0.41 0.2L 0 50 100 150 200 250 -0.2

Figure 3h: DSC data collected by Tarkanian and Paris of Frieseomelitta nigra wax (blue) and a 42%-58% by weight mixture of B. copallifera-F.nigra (yellow) [2].

1.2 1' 0.8 0.6 0.4 0.2 0 50 100 150 200 250

Figure 3i: DSC data collected by Tarkanian and Paris of the 42%-58% blend of B.

The wax samples were also subjected to hardness testing according to a modified version ASTM D1321-16a "Standard Method for Needle Penetration of Petroleum Waxes"[25]. The hardness data can be seen in Figure 3j. For these data, low values indicate hardness, while higher values correspond to a relatively softer material. According to Figure 3j, T. fulviventris was the hardest of all the samples tested; therefore, T. fulviventris is not only thermally, but also mechanically, unsuitable for lost-wax casting. Also in figure 3j, it can be observed that the addition of B. copallifera to A. mellifera causes a minor increase in ASTM D1321 hardness, meaning the material becomes softer. Addition of B. copallifera had a more dramatic effect on F. nigra; there is a significant decrease in the ASTM D1321 hardness value between the pure F. nigra wax and the mixture with 42% by weight B. copallifera [2]. Figure 3k considers additional concentrations of B. copallifera mixed with F. nigra, and shows a clear linear relationship between the amount of B. copallifera added and the hardness of the blend. This trend is in line with Sahag'nn's statement that addition of the copal would allow the blend to "[become firm and] harden well" [1].

T. fulviventris F. nigra-Bursera (42%) Machinable Wax Commercial Apis Casting Wax Apis-Bursera (50%) Victory Brown F. nigra-Bursera (5%) F. nigra 0 5 -I 10 15 20 25 30 35 ASTM D1321 Hardness

Figure 3.j: ASTM D1321 hardness data collected by Tarkanian and Paris [2].

35 30 25 20 15 10 5 0 ' 0 5 10 in 35 40 45

Figure 3k: ASTM D1321 hardness of F. nigra/B. copallifera blend as a function of weight percent of B. copallifera, from Tarkanian and Paris [2]. Recall that a higher ASTM D1321 hardness value corresponds to a softer material.

I

i

'4I

Ash content of waxes, copals, and mixtures, was measured using a modified version of the ASTM D482 "Standard Test Method for Ash from Petroleum Products"[26]. The data from this study is shown in Figure 31. It was found that blends of wax and copal had a lower ash content than either constituent[2]. Both blends considered has a lower ash content than Victory Brown foundry wax, which is formulated specifically for investment casting. From these results, Tarkanian and Paris concluded that blends of F. nigra and B. copallifera are promising

candidates for foundry use[2]. However, they did not have access to wax from Melipona beecheii, which was the bee species most commonly raised by the Maya. This paper expands upon that study by applying some of the same tests to blends with M. beecheii wax, and wax from other species native to Mexico, to see if a blend can be identified that was most-likely used

by the Maya.

Material Average Ash (wt %) Std Dev

(%)

Protium copal 0.03 0.02 Bursera copollifera 1.1 0.4 Pinus contorta 0.17 0.01 Commercial Apis 0.9 0.2 Frieseomelitta nigra 1.4 0.3 Trigonafulviventris 0.9 0.09 Victory Brown 0.1 0.05 Apis-Bursera blend 0 0

F. nigra - Bursera blend 0.03 0.01

4. Experimental

Sahagu'n mentions that copal was added to foundry wax so that it may "become firm." This study aims to determine how the thermal and mechanical properties of wax change when it is mixed with copal. By determining which mixture of wax and copal has the most favorable properties for lost-wax casting, we can determine which combination was most likely used by the Maya 4.1. Materials Tested Waxes: " Melipona beecheii " Melipona yucatanica * Scaptotrigona pectoralis Copals: " Bursera copallifera * Protium copal * Pinus contorta

Waxes were provided from the Yucatin by Elizabeth Paris, Jennifer Meanwell, and Pedro Delgado K6. P. copal was purchased from Govinda, and the other copals were purchased from

the online vendor Scents ofEarth.

4.2. Properties Measured

DSC was used to determine the melting point and onset of melting of each wax, and each

miscible wax-copal mixture. An onset of melting below human body temperature, 370C, would

allow for foundry wax to soften when being handled, making it easier to form.

Hardness was measured using a modified version of the ASTM Dl 321-16a, "Standard Method for Needle Penetration of Petroleum Waxes" [25]. Hardness is a preferred quality for foundry wax used for lost-wax casting, as it would allow for any external designs to stay intact as

4.3. Procedure

4.3.1. Sample Preparation

Each wax sample was rinsed with water in order to remove honey, and then allowed to filter by gravity for 24 hours. The remaining wax for each sample was then melted with a heat gun and passed through a Trimaco medium mesh paper cone strainer in order to remove impurities within the wax, such as pollen or bee parts.

Bursera copallifera was also melted with a heat gun and passed through the same filter

cones. Protium copal and Pinus contorta could not be filtered in this way because they could not

be melted to a point of low enough viscosity to flow through the filter mesh. For these two samples, pieces of copal that appeared pure were used to make blends.

Wax-copal mixtures were made by adding copal to melted wax, as described in the Florentine Codex. Wax was melted in a beaker on a hot plate and copal was added to the liquid wax. A stir bar was added to the beaker, and the wax and copal were left mixing for at least six hours. Mixtures were not made with Scaptotrigona pectoralis wax, as the sample was very high

r

I

?~ ~

Ij

I

Figure 4a: Wax samples during the first stage of filtration. They are, from left to right, Scaptotrigona pectoralis, Melipona beecheii, Melipona

yucatanica

Figure 4b: Wax samples after all filtration. They are, from left to right, Scaptotrigona pectoralis, Melipona

beecheii, and Melipona yucatanica. The yellow spots on the aluminum foil are made up of all the wax that could

be extracted from the Scaptotrigona pectoralis sample. The other two photos show representative samples of the other two waxes, to give a sense for their color. They do not represent all of the wax extracted from their

Figure 4.c: Copal samples before filtration. They are, from left to right, Bursera copalifera, Pinus contorta,

and Protium Copal.

Figure 4.d: Bursera copallifera after filtration.

4.3.2. Thermal Testing

A TA Instruments DSC Q100 V9.9 was used to test thermal properties. A sample of mass

taken for all three waxes individually. Data from the three copals was obtained from Tarkanian and Paris [2]. Mixtures of wax and copal that visibly appeared miscible were subjected to DSC testing to see if their melting properties were altered, which would indicate true miscibility.

Each wax, and wax-copal mixture, was put through two cycles of a constant temperature ramp of 100C per minute, up to I 000C, and back down to 00 C. The first cycle was to clear the

sample's thermal history, and the second cycle generated the data considered in this study. The copal samples, in a study by Tarkanian and Paris, were subjected to a temperature ramp of the same rate, reaching a maximum temperature of 350"C instead of 100 C [2].

4.3.3 Hardness Testing

Each wax, and each wax-copal mixture was subjected to hardness testing using a modified version of ASTM Dl 321-16a, "Standard Method for Needle Penetration of Petroleum Waxes" [25]. A needle in accordance with this test method (see figure 4e for dimensions), as a part of an apparatus weighing a total of 100 grams, was allowed to penetrate each sample for five seconds. The displacement of the needle was then measured in order to obtain a hardness value. Seven measurements were taken for each sample, and the average and standard deviation were calculated. For the hardness measurements, a higher value corresponds to more penetration; a lower value for hardness is indicative of a harder material.

8 055' to

9*025'-3.84 to 4.28 awn dia. 01 o01 mda

Approx. 3.17 mmn dia. 01 o01 mda

Approx. 43 mm

Approx. 58 mm ' Approx. 25.4 mm

Shaft drilled out and length adjusted to give final weight of 2.5 * 0.05 g

Figure 4e: Dimensioned drawing of needle for ASTM D1321-16a, "Standard Method for Needle Penetration of

Figure 4f: Hardness testing apparatus. The test mass has an indentation slightly larger than the outer diameter of the top of the needle, so the mass can be consistently and uniformly applied to the needle. The needle is

constrained to move vertically by the metal bearing.

5. Data and Analysis

5.1. Thermal Properties of Waxes

The melting points and onsets of melting of the three waxes considered were higher than those studied by Tarkanian and Paris. The data for each of the three waxes can be seen in Figure

5a. Scaptotrigona pectoralis has the highest melting point and onset of melting, at 73.81C and

61.30 C, respectively. Melipona beecheii has two melting peaks: one at 66.90 C and one at 700 C. Its onset of melting is at 57.5' C. Melipona yucatanica has a melting point of 65.30 C and an onset of melting of 54.00 C. Since their softening points are above the human body temperature of 370 C, they would not become softer while being formed by hand.

3 2 16 1 0 0 20 40 60

8

Temperature (*C)Figure 5a: DSC data of each of the three waxes considered in this study. Scaptotrigona

pectoralis is in black, Melipona beechefi is in red, and Melipona yucatanica is in blue.

5.2. Miscibility of Wax-Copal Blends

Figure 5b shows results of the miscibility testing from this study and the study by

Tarkanian and Paris. Blends were not made with Scaptotrigona pectoralis because the sample was very high in pollen and not enough wax was extracted to make the blends. The mixture of

M. beecheii and P. copal visibly did not appear miscible; after hours of mixing, the copal pieces

100

' - - ' - -

-rest of the blends showed a decrease in copal piece size during mixing, so their miscibility was determined by their DSC data. Since the DSC data did not show a change between the waxes and their blends, the blends were determined to be immiscible. The DSC data of blends will be discussed in more detail the following section.

Bursera copallifera Protium copal Pinus contorta

Melipona beecheii n n n Melipona yucatanica n n n Scaptotrigona pectoralis ? ? ? Trigonafulviventris ? ?? Frieseomelita nigra yn n Apis mellifera y _ n n

Figure 5b: Table of miscibility of wax/copal blends, combining data from this study with data from Tarkanian and Paris. "y " means that a combination is miscible, and "n " means that a combination is not miscible. Data is not available for combinations with "?"

5.3.Thermal Properties of Wax-Copal Blends

It is clear from 5c that the melting behaviors of the M. beecheii blends are very similar to the

melting behavior of the pure wax. The measured values for softening point and both melting

peaks for each blend are all within less than 2C of their corresponding values for pure M.

beecheii. Similarly, we do not see differences in thermal behavior between M. yucatanica and its

blends. In Figure 5d, the curves for the blends with B. copallifera and P. contorta are nearly indistinguishable, in blue and red, respectively. The pure M. yucatanica curve has the same shape, just shifted upward because of the slightly higher baseline for that data file. The measured values for onset of melting and melting point of the blends are within 0.3C of the measured

3 2-CR 0 -0 20 40 60 80 100 Temperature (*C)

Figure 5c: DSC data for M. beechedi and all blends involving M. beecheii. M. beecheii is in black. M. beechefi mixed with 5% by mass P. contorta is in red. M beecheii mixed with

3 2-CD 0-0 20 40 60 80 100 Temperature (*C)

Figure 5d: DSC data for M. yucatanica and all blends containing M. yucatanica. Pure

M. yucatanica is in black. M. yucatanica mixed with 10% by mass P. contorta is in red.

5.4. Hardness of Waxes and Wax-Copal Blends

Although these blends were not miscible, it is possible that the incorporation of copal particles within the wax matrix may have affected the mechanical properties of the blends. The

Maya may have taken advantage of these immiscible blends for these changes in mechanical properties

Hardness data for this study is displayed in Figure 5e. For both waxes considered, the addition of B. copallifera and P. copal caused a slight increase in the average ASTM D1321 Hardness value, making the material softer. This may not be significant in the case of M. yucatanica, as there is overlap in the uncertainty ranges for the pure wax and both blends. There is also significant overlap between the pure M beecheii data and the data for M beecheii + 10%

B. copalifera. However, the increase in hardness value between pure M beecheii and M beecheii + 5% P. copal is statistically significant, increasing from 17.2 4.1 to 27.1 1.4. This softening of the material may have made it easier to form, making it more suitable for investment casting.

The addition of P. contorta caused a decrease in hardness value for both waxes considered. This was more dramatic in the case of M yucatanica, which saw a decrease from

27.7 2.1 for pure wax to 10.5 2.0 for a blend with 10% by weight P. contorta. There was overlap in the error ranges between M beecheii (17.2 4.1) and its mixture with 5% P. contorta,

which had a hardness of 13.4 2.3. This decrease may have been less pronounced because this

hardening of these waxes upon addition of P. contorta is more in line with Sahagn'n's account, where he writes that copal was added so the wax may "become firm and harden welI"[1].

35 30 25 20 15 10 -5 0

I

1

0 CO CI

0 0 LOI

II

I

~jI

0. 0 (U 0 0. 0l -a 0. C + 2 J2 0i CL 0 U In +e W) 0. 0Figure 5e: Hardness data. Averages were calculated from 7 measurements of each sample, and the error bars

represent standard deviation.

a

C

'0 IV-CM

6. Conclusions

None of the blends examined in this study were miscible. Therefore, in terms of thermal properties, none of them exhibit any benefit over pure wax.

Addition of copal did cause some changes in mechanical properties in the immiscible blends. Most notably, the addition of P. contorta to both M. yucatanica and M. beecheii

decreased their respective ASTM 1321 hardness values; in other words, it made them more firm. This agrees with Sahagin's account that the addition of copal to wax would allow it to "[become firm and] harden well"[1]. However, when considering both thermal and mechanical properties, the mixture of F. nigra and B. copallifera studied by Tarkanian and Paris appears to be the most favorable for lost-wax casting applications. Not only does the addition of copal cause the wax to become firmer, as described by Sahag'nn, but it also decreases the melting point, which would make working by hand easier, and it decreases ash-content which would decrease the likelihood of a casting failure[2]. Because M. beecheii was the bee species most commonly raised by the Maya, it would be worth pursuing further studies involving this wax to see if its blends have

advantages over the F. nigra-B. copallifera blend. 7. Future Work

In the future, it would be worthwhile to test ash content of all the waxes and blends considered in this study so they can be more thoroughly compared to those studied by Tarkanian and Paris. It would also be worth testing additional concentrations of copal with the blends considered in this study to see if any relationship exists between concentration of copal and hardness. When additional materials become available, it would also be worth testing blends

with Scaptotrigona pectoralis wax, and any other waxes of stingless bees native to Mexico. Also, further procedures can be developed to evaluate these materials in more specific contexts of their use. Quantifying the ease with which these waxes can be rolled into sheets, the ease with which they can be formed around core molds, and their ability to hold patterns during the application of clay mold material, can provide valuable data in the search for the Ancient Mesoamerican foundry wax.

References

[1] Dibble, C. E., and Anderson, A. 0., 1959, Florentine Codex: General History of the Things of New Spain. Book 9 - The Merchants, Fray Bernardino Sahagun, The School of

American Research and The University of Utah, Santa Fe.

[2] Tarkanian, M., and Paris, E., 2017, "An Evaluation of Stingless Bee Wax as a Pattern Material in Mesoamerican Investment Casting," Societyfor American Archaeology, Vancouver, BC.

[3] Lechtman, H. N., 1980, "The Central Andes: Metallurgy without Iron," The Coming of

Age ofIron, T.A. Wertime, and J.D. Muhly, eds., Yale University Press, pp. 267-334.

[4] Hosler, D., 1994, The Sounds and Colors of Power . The Sacred Metallurgical

Technology ofAncient West Mexico, MIT Press, Cambridge, MA.

[5] Maldonado, B., 2012, "Mesoamerican Metallurgical Technology and Production," The

Oxford Handbook ofMesoamerican Archaeology, D.L. Nichols, and C.A. Pool, eds.,

Oxford University Press, New York, NY, pp. 616-627.

[6] Shimada, I., Epstein, S. M., and Craig, A. K., 1983, "The Metallurgical Process in Ancient

North Peru," Archaeology, 35(5), pp. 38-45.

[7] Shimada, I., and Merkel, J. F., 1991, "Copper-Alloy Metallurgy in Ancient Peru," Sci. Am., 265(1), pp. 80-86.

[8] Meanwell, J. L., Paris, E. H., Cruz Alvarado, W., and Peraza Lope, C., 2013,

"Metallurgical Ceramics from Mayapan, Yucatin, Mexico," J. Archaeol. Sci., 40, pp.

4306-4318.

[9] Pendergast, D. M., 1962, "Metal Artifacts from Amapa, Nayarit, Mexico," Am. Antiq.,

[10] Hosler, D., and Guy, S.-P., 1992, "The Huastec Region: A Second Locus for Production of Bronze Alloys in Ancient Mesoamerica," Am. Assoc. Adv. Sci., 257(5074), pp.

1215-1220.

[11] Gaillard, Y., Mija, A., Burr, A., Darque-Ceretti, E., Felder, E., and Sbirrazzuoli, N., 2011, "Green Material Composites from Renewable Resources: Polymorphic Transitions and Phase Diagram of Beeswax/rosin Resin," Thermochim. Acta.

[12] Buchwald, R., Breed, M. D., Greenberg, A. R., and Otis, G., 2006, "Interspecific

Variation in Beeswax as a Biological Construction Material," J. Exp. Biol., 209(20), pp.

3984-3989.

[13] Buchwald, R., Breed, M. D., Bjostad, L., Hibbard, B. E., and Greenberg, A. R., 2009,

"The Role of Fatty Acids in the Mechanical Properties of Beeswax," Apidologie, 40(5),

pp. 585-594.

[14] Cohn, D., 2005, "Xunan Kab, the Stingless Bees of the Yucatan: Preserving

Meliponiculture in Mayan Communities- Part One of Two Parts," Am. Bee J., 145(8), pp.

656-660.

[15] Wilson, E. 0., 1974, The Insect Societies.

[16] Kent, R. B., 1984, "Mesoamerican Stingless Beekeeping," J. Cult. Geogr., 4(2), pp.

14-28.

[17] Tozzer, A. M., 1941, Landa's Relaci6n de Las Cosas de Yucatan: A Translation. [18] Weaver, N., and Weaver, E. C., 1981, "Beekeeping with the Stingless Bee Melipona

Beecheii, by the Yucatecan Maya," Bee World, 62(1), pp. 7-19.

[19] Ocampo Rosales, G. R., 2013, "Medicinal Uses of Melipona Beecheii Honey, by the

Roubik, eds., Springer Sience+Business Media, New York, NY, pp. 229-240.

[20] Carmargo, J. M. F., and Pedro, S. R. M., 2013, "Meliponini Lepeletier, 1836," Catalogue

of Bees (Hymenoptera, Apoidea) in the Neotropical Region, J.S. Moure, D. Urban, and

G.A.R. Melo, eds., p. online version. Available at http://www.moure.cria.

[21] Landa, D. de, 1941, Landa's Relaci6n de Las Cosas de Yucatdn: A Translation, The Peabody Museum, Cambridge, MA.

[22] Tozzer, A. M., 1910, "Animal Figures in the Maya Codices," Pap. Peabody Museum Archaeol. Ethnol., 4(3), pp. 283-372.

[23] Gigliarelli, G., Becerra, J. X., Curini, M., Marcotullio, M. C., and Forti, L., 2015, "Chemical Composition and Biological Activities of Fragrant Mexican Copal (Bursera Spp.)," Molecules, 20, pp. 22383-22394.

[24] Gaillard, Y., Girard, M., Monge, G., Burr, A., Ceretti, E. D., and Felder, E., 2013,

"Superplastic Behavior of Rosin/beeswax Blends at Room Temperature," J. Appl. Polym. Sci.

[25] ASTM Standard D1321, 2016, "Standard Test Method for Needle Penetration of Petroleum Waxes," ASTM Int. West Conshohoken, PA.

[26] ASTM Standard D482, 2013, "Standard Test Method for Ash from Petroleum Products," ASTM Int. West Conshohoken, PA.

![Figure 2a: Tuyeres excavated from the Batin Grande region of Peru [7].](https://thumb-eu.123doks.com/thumbv2/123doknet/14108882.466344/10.917.267.466.798.1054/figure-a-tuyeres-excavated-batin-grande-region-peru.webp)

![Figure 3a: Area inhabited by Melipona yucatanica [19].](https://thumb-eu.123doks.com/thumbv2/123doknet/14108882.466344/17.917.248.693.123.314/figure-a-area-inhabited-by-melipona-yucatanica.webp)

![Figure 3g: DSC data collected by Tarkanian and Paris of Apils mellifera wax (green) and 50-50 by weight blend of Apis Mellifera and Bursera copallifera (yellow) [2].](https://thumb-eu.123doks.com/thumbv2/123doknet/14108882.466344/24.917.170.738.260.687/figure-collected-tarkanian-paris-mellifera-mellifera-bursera-copallifera.webp)

![Figure 3.j: ASTM D1321 hardness data collected by Tarkanian and Paris [2].](https://thumb-eu.123doks.com/thumbv2/123doknet/14108882.466344/27.917.124.798.114.454/figure-astm-d-hardness-data-collected-tarkanian-paris.webp)

![Figure 3.1: Table of ash content data collected by Tarkanian and Paris [2].](https://thumb-eu.123doks.com/thumbv2/123doknet/14108882.466344/28.918.192.794.553.911/figure-table-ash-content-data-collected-tarkanian-paris.webp)