Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

S.P. Shah Symposium on Measuring, Monitoring and Modeling Concrete

Properties [Proceedings], pp. 1-8, 2006

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=f363fd49-12c0-4fda-88de-f1c9b82f0bd6 https://publications-cnrc.canada.ca/fra/voir/objet/?id=f363fd49-12c0-4fda-88de-f1c9b82f0bd6

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Preventing autogenous shrinkage of HPC by internal curing

http://irc.nrc-cnrc.gc.ca

Preventing autogenous shrinkage of high-performance concrete

structures by internal curing

N R C C - 4 8 3 6 8

C u s s o n , D . ; H o o g e v e e n , T .

A version of this document is published in / Une version de ce

document se trouve dans: S.P. Shah Symposium on Measuring,

Monitoring and Modeling Concrete Properties, Alexandroupolis,

Greece, July 3-7, 2006, pp. 1-8

S.P. Shah Symposium on Measuring, Monitoring and Modeling Concrete Properties, 3-7 July 2006, Alexandroupolis, Greece

PREVENTING AUTOGENOUS SHRINKAGE

OF HIGH-PERFORMANCE CONCRETE

STRUCTURES BY INTERNAL CURING

Daniel Cusson and Ted HoogeveenNational Research Council Canada, Ottawa, Canada, K1A 0R6

Abstract: The effect of internal curing on the structural behaviour of large high-performance concrete specimens having different amounts of pre-soaked porous lightweight aggregate was investigated. The results show that the use of lightweight aggregate in high-performance concrete can effectively reduce autogenous shrinkage through improved hydration of cement.

Key words: autogenous shrinkage; high-performance concrete; internal curing; restrained shrinkage; self-desiccation; tensile creep.

1. INTRODUCTION

High-performance concrete (HPC) structures made with low water-cement ratio often exhibits early cracking due to self-desiccation, which may lead to a reduction of their service lives. This paper presents the test results on large prismatic HPC specimens under restrained autogenous shrinkage. Pre-soaked lightweight aggregate (LWA), made of porous expanded shale, was used to provide effective internal curing in order to reduce self-dessication and autogenous shrinkage cracking in the HPC specimens.

Testing systems and methods were developed at NRC (Cusson et al., 2005) for studying restrained shrinkage and creep of large HPC specimens, which present some new features over existing approaches (Kovler, 1994; Bjontegaard et al., 1999). Large size specimens enable the study of the behaviour of concrete made with large coarse aggregate and reinforcing bars. The system can impose a partial (or full) degree of restraint through embedded reinforcement, which is representative of the field conditions. An advantage of using a partial degree of restraint is that restrained shrinkage testing can be conducted without failing high-shrinkage concrete specimens.

2 Daniel Cusson and Ted Hoogeveen

2. EXPERIMENTAL

PROGRAM

The control concrete used ASTM Type 1 cement, had a water-cement ratio of 0.34, and a cement-sand-stone ratio of 1:2:2. Normal density aggregates were used. Three variations of this mix design included 6%, 12% and 20% replacements of normal-weight sand by pre-soaked lightweight aggregate (LWA). For each mix design, all large concrete specimens and small concrete samples were prepared from the same batch and sealed with plastic sheets to prevent external drying during testing. After placing the concrete, the forms were not removed during testing to protect the sensors and prevent thermal shock.

Figure 1 presents the main setup for testing free and restrained shrinkage of large prismatic concrete specimens (200 x 200 x 1000 mm). For the restrained specimen, the axial strain was measured with electrical strain gauges (SG) centered on the four 10-mm reinforcing bars. The test apparatus included a closed loop servo-hydraulic system to control the actuator, using the rebar-mounted strain gauges as the feedback signal. The force, measured by a load cell, was transmitted to the concrete by the steel bars, which have their ends welded to the stiff end plates connected to the rigid test frame.

An unrestrained companion specimen was prepared with no reinforcement. Free shrinkage was measured with LVDTs placed at both ends of the specimen. Two relative humidity (RH) sensors were placed in the specimen to measure the extent of self-desiccation. Thermocouples (TC) were embedded in concrete at the locations shown in Fig. 1.

Figure 1. Test setup and dimensions of specimens

TC RH RH

LVDT

TC

Elevation of unrestrained specimen (1000x200 mm)

Elevation of restrained specimen (1000x200 mm)

Cross-section (200x200mm) Cross-section (200x200mm) Pinned end connected to actuator Fixed end connected to stiff frame SG and TC at midlength of each rebar 10mm rebars 50mm cover

Preventing autogenous shrinkage of HPC structures by internal curing 3

Additional tests were also conducted in parallel on smaller concrete samples at different times, including the determination of the thermal expansion coefficient, compressive strength, splitting tensile strength, compressive modulus of elasticity and Poisson ratio. The temperature history was measured for each concrete specimen and sample, and maturity was calculated for each size of specimen in order to use consistent sets of results in the calculations. The theoretical background, as well as the strain and stress calculation procedures are presented elsewhere (Cusson et al., 2005).

3. RESULTS

AND

ANALYSES

All specimens were tested under realistic temperature regimes. The concrete temperature reached 45°C at approximately 12 hours after casting and returned to 25°C two days after casting, regardless of the amount of LWA used in the concrete. For the control specimen, the RH reduced from 100% at set time to 94% after 2 days and 91% after 7 days. Due to the added internal curing, the 20%-LWA specimen had reduced drying with the RH reducing to 98% after 2 days and 96% after 7 days. The improved hydration also resulted in an increased 7-day compressive strength going from 50 MPa for the control concrete to 57 MPa for the 20%-LWA concrete.

3.1 Free

shrinkage

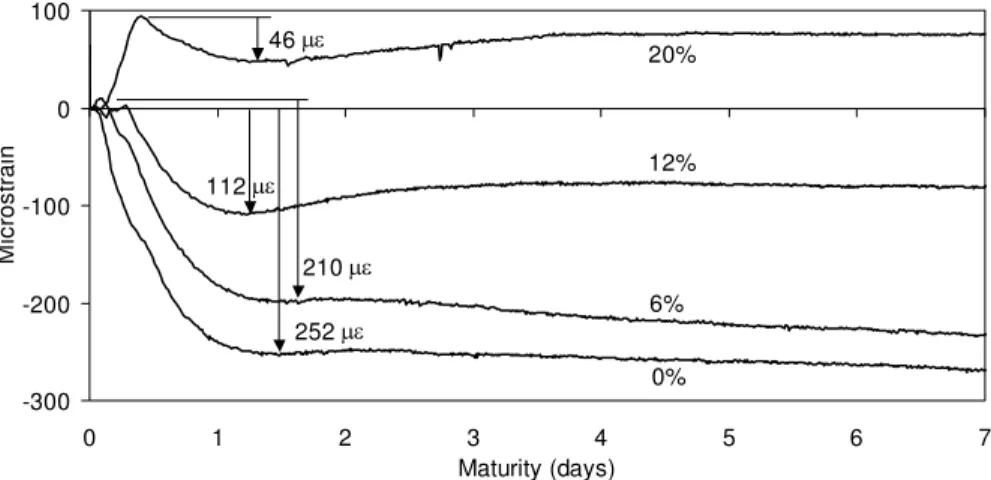

Figure 2 presents the evolution of autogenous shrinkage after removal of the thermal strain from the total strain measured in the unrestrained specimens. Note that the thermal strain curves of the different specimens were very similar. With increased amounts of LWA used in the concrete specimens, autogenous shrinkage reduced considerably, especially for the 12%- and 20%-LWA concrete specimens. The results also show that most of the autogenous shrinkage caused by internal drying developed within one day of setting. This observation suggests that the prevention of excessive self-dessication and autogenous shrinkage cracking in HPC structures should involve techniques that are effective shortly after the setting of concrete.

For each concrete specimen, Figure 2 also indicates the critical autogenous shrinkage strain measured at early age (i.e. between 1 and 2 days) when the rate of shrinkage had reduced considerably. As suggested in the figure, the part of autogenous shrinkage strain that will result in tensile stress should be measured from the peak strain corresponding to the maximum expansion due to swelling, if any. In fact, significant swelling was observed for the 20%-LWA concrete specimen, and was most likely due to the large amount of internal curing water supplied to the cement by the LWA for continuous hydration.

4 Daniel Cusson and Ted Hoogeveen

Figure 2. Autogenous shrinkage strain measured in unrestrained specimens

3.2 Restrained

shrinkage

In order to avoid failing the control and the 6%-LWA specimens during testing, a degree of restraint close to 0.9 was required. For the 20%-LWA specimen, a degree of restraint close to 1.1 was experimented (i.e. the loading system was actually pulling slightly on the specimen). Figure 3 illustrates the tensile stress/strength ratio for each restrained concrete specimen. The ratio is the actual tensile stress measured in concrete (resulting from thermal, autogenous and creep strains) divided by the actual splitting tensile strength measured on 100x200mm concrete cylinders tested at different times. Each stress/strength curve was also normalised by the actual degree of restraint used in the experiment. The results presented in Fig. 3 can be considered equivalent to those obtained under a constant 100% degree of restraint. This normalisation is required in order to allow a comparison between restrained concrete specimens tested under different degrees of restraint.

The control and 6%-LWA specimens performed similarly with a predicted failure at about 1.5 days had they been tested under a full restraint. It is clear that adding only 6% LWA in the concrete was not enough to prevent failure. The 12%-LWA concrete specimen performed well and reached a maximum stress/strength ratio of 90% after nearly 3 days. The 20%-LWA specimen experienced compressive stress during the first day (due to thermal expansion and swelling), followed by low tensile stress developing after the cooling period. With a maximum tensile stress/strength ratio of 50% obtained after nearly 3 days, the use of 20% LWA in the concrete proved very effective in reducing the risk of cracking.

-300 00 -100 0 100 0 1 2 3 4 5 6 7 Maturity (days) M ic ros tr ain 0% 6% 20% 12% -2 46 με 112 με 210 με 252 με

Preventing autogenous shrinkage of HPC structures by internal curing 5 0.0 0.2 0.4 0.6 0.8 1.0 1.2 0 1 2 3 4 5 6 7 Maturity (days) S tr e s s /s tr ength r a ti o 0% 6% 20% 12% Predicted failure 0% LWA: 4.1 MPa 6% LWA: 4.8 MPa 12% LWA: 4.5 MPa 20% LWA: 4.2 MPa 7-day splitting tensile strength:

Figure 3. Normalised concrete stress/strength ratio measured in restrained specimens

Figure 4 compares the tensile modulus of elasticity obtained for each specimen. The secant modulus is a best-fit calculation from stress/strain data measured during partial unloading/reloading conducted periodically on the restrained concrete specimens. The effective modulus was obtained from the secant modulus and the time-dependent creep coefficient measured for each specimen (which varied from 1.3 to 2.0 at 7 days). It can be seen that the addition of LWA sand in the concrete had a marginal effect on the effective modulus of elasticity. Some variation in the secant modulus is seen between the different specimens; however, 7-day tests on 100x200mm concrete cylinders for the compressive elastic modulus yielded very similar values such as 31600, 31200, 32000 and 31400 MPa obtained for the 0%-, 6%-, 12%- and 20%-LWA concrete specimens, respectively.

0 10000 20000 30000 40000 0 1 2 3 4 5 6 Maturity (days) E las tic m odulu s ( M P a ) . Secant modulus 0% 6% 20% 7 12% 0-6% 12% 20% Effective modulus

6 Daniel Cusson and Ted Hoogeveen

3.3

Effectiveness of internal curing

Figure 5 illustrates the effectiveness of internal curing on the reduction of both shrinkage and tensile stress in the HPC specimens. As shown in the figure, the critical autogenous shrinkage strain (as defined in Fig. 2) and the stress/strength ratio were reduced considerably with an increased amount of LWA, especially for the 20%-LWA specimen. Both curves indicate that an amount of 25% in this concrete formulation would be required to completely eliminate autogenous shrinkage and tensile stress. An amount higher than 25% is not recommended since excessive swelling might occur.

Note that the water used to pre-soak the LWA was accounted for in the calculation of the water-cement ratio, which was maintained constant for the different concretes. This particular requirement made the evaluation of the internal curing effectiveness more severe than if additional water had been used to pre-soak the LWA.

-300 -250 -200 -150 -100 -50 0 0 5 10 15 20 25

Sand replacement ratio (%)

Mi cr os tr ain 0 20 40 60 80 100 S tr ess /s tr engt h r at io ( % ) Critical strain Stress Strength

Figure 5. Effect of LWA sand replacement ratio on strain and stress reductions

4.

INTERNAL CURING WATER REQUIREMENT

4.1 Theoretical

estimation

The amount of internal curing water required to eliminate self-desiccation can be calculated from chemical shrinkage. Knowing the degree of saturation and absorption capacity of the aggregate, one can estimate the required mass of LWA to introduce in concrete in order to provide adequate internal curing. Researchers, such as Zhutovsky et al. (2004) and Bentz et al. (2005), suggested a similar form of the following equation:

Preventing autogenous shrinkage of HPC structures by internal curing 7 LWA LWA LWA c LWA S CS M M η φ α ⋅ ⋅ ⋅ ⋅ = max with 1 36 . 0 / max = ≤ c w α (1)

where MLWA is the mass of LWA per unit volume of concrete (kg/m3); Mc

is the mass of cement in concrete (kg/m3); CS is the chemical shrinkage (kg of water per kg of hydrated cement); αmax is the maximum expected degree

of hydration; SLWA is the saturation degree of LWA; φLWA is the absorption

capacity of LWA (kg of water per kg of dry LWA); ηLWA is an efficiency factor for the LWA (to be determined in the next section); and w/c is the water-cement ratio of concrete. Note that the equation for αmax suggests that

the lowest w/c that can achieve complete hydration of the cement is 0.36.

4.2

Experimental validation

In practice, elimination of self-dessication and autogenous shrinkage in HPC structures may require more LWA than calculated with Eq. 1 since the water supplied by the LWA for internal curing may not be completely available at an early age. Factors such as the size of pores in the LWA and the porosity of the cement paste around the aggregate particles can significantly influence the effectiveness of internal curing.

The test results of this study can be used to evaluate the prediction accuracy of Eq. 1, or more specifically the efficiency factor of LWA. For instance, Fig. 5 suggests that the use of 25% LWA of total sand content would enable complete elimination of autogenous shrinkage in the HPC specimens of this study. Equation 1 predicts a sand replacement ratio of 20% based on the following data: cement content of 445 kg/m3; chemical shrinkage of 0.07 (measured by XRD analysis); max. hydration degree of 0.94 (Eq. 1); saturation degree of 1.0; absorption capacity of 0.17 at 24 hours (measured by the LWA manufacturer), and total sand content of 890 kg/m3.

For the particular LWA used in the study, the efficiency factor is:

8 . 0 = LWA η (2)

Zhutovsky et al. (2004) reported that efficiency factors as high as 80% had previously been observed. It is therefore suggested to use an efficiency factor no greater than 80% unless new experimental data can demonstrate higher efficiency factors from lightweight aggregates.

It should be noted that other types of LWA included in concretes that are different from those used in this study may require different amounts of LWA for effective internal curing. The effects of supplementary cementing materials (such as silica fume, fly ash and slag) on the effectiveness of internal curing are still unknown and are not accounted for in Eq. 1.

8 Daniel Cusson and Ted Hoogeveen

5.

SUMMARY AND CONCLUSIONS

Restrained shrinkage testing of large high-performance concrete (HPC) specimens was conducted to study the effect of internal curing on the structural performance of concrete specimens made with lightweight aggregate (LWA) sand. The following conclusions are drawn:

1. Autogenous shrinkage, if not controlled, can reach very high values within 24 hours, leading to rapid failure under restrained shrinkage. 2. Tensile stress and cracking due to self-desiccation in HPC specimens

can be completely eliminated through proper internal curing at early age. 3. Wet LWA, in the amount of 20% of total sand, provided enough internal curing water to the hydrating cement in order to eliminate autogenous shrinkage and maintain the tensile stress/strength ratio under 50%. 4. An optimum amount of 25% LWA in the HPC tested in the study was

predicted to completely eliminate tensile stresses due to the simultaneous effects of autogenous, thermal and creep strains.

5. The amounts of LWA used in the concrete specimens (up to 20%) did not adversely affect the strength or elastic modulus of concrete.

ACKNOWLEDGMENTS

The authors would like to thank Mr. John Roberts of Northeast Solite Corporation for providing the lightweight aggregate, as well as Dr. Lyndon Mitchell and Mr. Glendon Pye of NRC for their technical assistance.

REFERENCES

Bentz, D.P., Lura, P., Roberts, J.W., 2005, Mixture proportioning for internal curing, Concrete International, February, 1-6.

Bjontegaard, O., Kanstad, T., Sellevold, E.J., Hammer, T.A., 1999, Stress inducing deformations and mechanical properties of high-performance concrete at very-early-ages, 5th Int. Symposium on Utilization of High-Strength/High-Performance Concrete, Sandefjord, Norway, June 20-24, 1027-1040.

Cusson, D., Hoogeveen, T.J., Mitchell, L.D., 2005, Restrained shrinkage testing of high-performance concrete modified with structural lightweight aggregate, 7th Int. Symposium on Utilization of High-Strength/High Performance Concrete, Washington D.C. USA, June 20-24, ACI SP 228-87, 1:1335-1372.

Kovler, K., 1994, Testing system for determining the mechanical behaviour of early-age concrete under restrained & free uniaxial shrinkage, Materials & Structures, 27:324-330. Zhutovsky, S., Kovler, K., Bentur, A., 2004, Influence of cement paste matrix properties on

autogenous curing of high-performance concrete, Cement & Concrete Composites, 26:499-507.