Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Canadian Mineralogy, 24, 2, pp. 323-328, 1986

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=23442f9b-fc8e-4a41-aed1-c930a3a065d6

https://publications-cnrc.canada.ca/fra/voir/objet/?id=23442f9b-fc8e-4a41-aed1-c930a3a065d6

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Influence of physical properties of rock on rate of penetration of a

water-jet drill

Ser

THl

N2Ld

National Research

Conseil national

no.

1388

e.

2

ouncil Canada

de recherches Canada

BIJX:

Institute for

lnstitut de

- --

,

Research in

recherche en

Construction

construction

Influence of Physical Properties

of Rock on Rate of Penetration

of a Water-Jet Drill

by P.E. Grattan-Bellew and M.M. Vijay

ANALYZED

Reprinted from

Canadian Mineralogist

Vol. 24, No. 2, 1986

p. 323

-

328

(IRC Paper No. 1388)

lpCPC

rJgC-

c1-1 I1

?\?G.P.F.F.

\

n_;;7':4 9 Y

11

P5-

fl8-

1

8

1 \,,,:

1 9 r ~ L Q u r

-

.

-.,

35ti.n. C N R C-

lc1sTCana83

6

70

/50/

Price $2.00

NRCC 26053

T h i s p a p e r

i s b e i n g d i s t r i b u t e d i n r e p r i n t

f o r m by

t h e

I n s t i t u t e f o r R e s e a r c h

i n

C o n s t r u c t i o n .

Al i s t of b u i l d i n g p r a c t i c e

and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from

t h e I n s t i t u t e

maybe o b t a i n e d by w r i t i n g t o

t h e P u b l i c a t i o n s Sect'ion,

I n s t i t u t e f o r

R e s e a r c h i n C o n s t r u c t i o n , N a t i o n a l R e s e a r c h

C o u n c i l

of

C a n a d a ,

O t t a w a ,

O n t a r i o ,

Ce

document

e s td i s t r i b u 6 s o u s forme d e

tir--b-part

n31- -1 1 T=-+ 1- - -.

-c o n s

tr u r

d e s put

l e s t e c

d e b a t

p u b l i c :

_

_

--

-

c o n s t i

r e c h e t

K1A

OF

Canadian Mineralogist

Vol. 24, pp. 323-328 (1986)

INFLUENCE OF PHYSICAL PROPERTIES OF ROCK ON RATE OF PENETRATION OF A WATER-JET DRILL PATRICK E. GRATTAN-BELLEW AND MOHAN M. VIJAY

Division of Building Research, Natio a1 Research Council of Canada, Ottawa, Ontario KIA OR6

7

ABSTRACT

5

Drilling experiments show that there is only moderate correlation between rate of drilling by a jet of water and grain size of rock. This probably indicates that the rate of water-jet penetration in rock is influenced by other factors. Fractures induced by a water jet are found to propagate around grain boundaries in most rocks. The exceptions are rocks that contain minerals with a well-developed cleavage, such as calcite and amphibole. Here, fractures tend to fol- low the cleavage planes. The surface area of grains occupy- ing a 1-cm cube (a function of grain size) and the volume of cracks per unit volume of rock are shown to be the main factors determining rate of water-jet penetration.

Keywords: water-jet drill, rocks, penetration, pressure, frac- ture, surface area, cracks, granite, sandstone, quartz diorite, norite.

On montre, par mesures expkrimentales, que la correla- tion entre taux de forage par un jet d'eau et granulomttrie d'une roche n'est que mediocre. D'autres facteurs vien- draient influencer ce taux. Les fissures qui resultent du jet se propagent le long de la bordure des cristaux dans la plupart des cas. Seules sont exceptionnelles a cet egard les roches qui contiennent un mineral a clivage bien dheloppe, comme la calcite ou l'amphibole. Dans ces roches, les fis- sures se propagent le long des clivages. L'aire de la sur- face des grains dans un cube d'un centimttre d'artte (fonc-

r tion de la granulometrie) et le volume des fissures compare

(' au volume de la roche sont les facteurs principaux qui deter-

minent le taux de penetration d'un jet d'eau dans une roche. I

(Traduit par la Redaction)

Mots-clPs: foreuse a jet d'eau, roches, penetration, pres- sion, fissure, aire de la surface des grains, fractures, granite, grts, diorite quartzifkre, norite.

removing deteriorated concrete from bridge decks (Wallace 1985). Water-jet drilling has also been pro- posed as a method of breaking human gallstones t o facilitate removal (Classen et al. 1984). In some applications a single jet is used; in others, for exam- ple, rock drilling, twin- or multiple-jet systems are usually employed. Water jets may also be used in conjunction with a n abrasive that is fed into the jet (Nakaya et al. 1984) or as a n assist t o tungsten car- bide bits (Lefin & Hurel 1984). Water pressures in the range 35-350 M P a have been used, but in prac- tical applications problems are likely t o be encoun- tered a t higher pressures owing t o failure of seals. It is the purpose of this investigation t o attempt t o define the rock properties that control the rate of penetration of a water jet in hard rock. It was previ- ously hypothesized (Rehbinder 1980) that the resistance of a rock t o erosion should be proportional t o the slenderness ratio of its pores and inversely proportional t o the mean diameter of its grains. The slenderness ratio of the pores should presumably be a function of the permeability of the rock. During the course of the present investigations, permeabil- ity was measured for a number of rocks for which rates of water-jet drilling were also determined. Anal- ysis of the results did not indicate much correlation between the two. This may have been due t o a lack of homogeneity in some of the rocks or to difficulty in obtaining meaningful values for the permeability of some low-porosity rocks. In order t o test the second half of Rehbinder's hypothesis, the mean grain-sizes of the rocks used by the present authors in water-jet drilling experiments were determined and plotted against drilling rates (Fig. 1). The graph shows that drilling rate D increases with increasing grain-size L according t o the equation

INTRODUCTION The correlation of the line fitted t o the points in Figure 1 is, however, relatively poor (R = 0.74). TWO Water-jet drilling is a relatively new technology points representing granite samples with rodghly that is still largely in the developmental stage. Water- similar grain-sizes but drilling rates of 30.3 and 13.4 jet drills can be used for drilling or slotting a wide cm/min indicate that other factors must influence variety of materials; for example, they have been the rate of water-jet penetration in rock.

used for shot holes in mining and quarrying (Lefin ~t was shown previously (Vijay et al. 1982) that & Hurel 1984). Other applications include cutting commonly measured physical properties of rocks, for leather for shoes (Burns & Mohaupt 1984) and example, compressive strength, tensile strength,

324

THE CANADIANG I 1 - GREY BARRE GRANITE

G M - P I N K MUSKOKA GRANITE

0

0 200 400 600 800 1000

G R A I N S I Z E . pm

FIG. 1. Plot of drilling rate versus mean grain-size of rocks.

DIRECTION OF WATER FLOW

e-

FIG. 2. Cross-section of body of drill nozzle of twin-jet sys- tem used in this research. Arrows indicate direction of water flow. Do: 1.321-mm diameter jet, D,: 1.092-mm diameter jet.

FIG. 3 . Optical micrograph of fragment of quartz diorite

recovered from hole drilled by water jet. The fracture path is indicated by the dashed line separating the rock from the plastic mounting medium M. When the frac- ture passing through the feldspar F reached the quartz Q, it detoured around two faces of the subhedral grain rather than cutting across it. This provides evidence that water jets usually penetrate rock by fracture propaga- tion around the grain boundaries.

MINERALOGIST

specific gravity and porosity, do not correlate with rate of water-jet penetration. With some exceptions the drilling rate shows little correlation with miner- alogical composition and no correlation with the hardness of the rock. For example, a soft calcarenite limestone (Carozzi & Textoris 1967) is more resis- tant to water-jet penetration than a granite, which is much harder. Owing to the large requirements for power in water-jet drilling, it is important to 0ptimi.z the energy consumption of the system for a particu lar rock. To do this the physical factors and mechan4 isms of water-jet penetration must be understood.~

I

The drill consists of a generator, a high-pressure pump, and a twin-jet nozzle that rotates at about 200 rpm (Vijay et al. 1984). In the experiments reported here a water pressure of 68 MPa was used, with jet diameters of 1.321 and 1.092 mm for jets Do and D,, respectively (Fig. 2). The following rock sam- ples were used: granites GI1 (medium-grained grey granite from Barre, Vermont) and GM (medium- grained granite from Muskoka, Ontario), calcare- ous Nepean sandstone from Ottawa, Ontario, assorted fine-grained rocks from the Sudbury basin, Ontario (quartz diorite, chloritized amphibolite, altered norite and Ottawa limestone).

RESULTS AND DISCUSSION

I

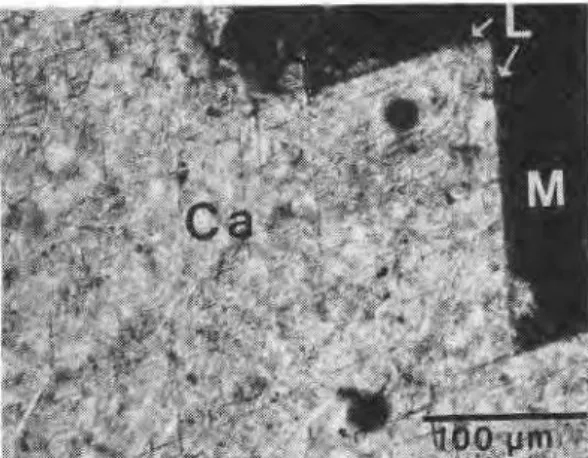

To investigate the mechanism by which a water jet penetrates rock, some chippings recovered from drilling experiments were made into thin sections and examined with the aid of a petrographic microscope. Most of the fragments are multigranular, but par- ticularly in coarse-grained rock such as granite some single-grain particles were observed. The petro- graphic examination showed that fractures generally appear to have propagated along grain boundaries- rather than through the grains. This is illustrated ini Figure 3, which is a photograph of a fragment o f . quartz diorite recovered from a test hole. Examina-4 tion of this micrograph reveals that the fracture passes along the grain boundary of a feldspar crys- tal, then follows around two faces of a subhedral quartz grain before passing along another feldspar grain boundary. Similar'observations were made with other minerals.Exceptions occur in coarsely crystalline limestone, in which fractures frequently traverse the calcite grains by following the cleavage planes, and in coarse-grained amphibolite, in which fractures fol- low amphibole cleavage planes or existing microfrac- tures common in this mineral. Figure 4 is a micro- graph of a fragment of calcite recovered from a drilling experiment on a block of coarse biosparite limestone. In this particle the fracture clearly

RATE OF PENETRATION OF A WATER-JET DRILL

325

propagated along one cleavage plane, then changed direction to an intersecting plane.

Based on these observations, a preliminary

hypothesis was presented to account for the penetra-

tion of a rock by a high-pressure jet of water (Vijay

et al. 1984). The water jet appears to penetrate the

rock by propagating cracks along the grain bound- aries. It is evident that the pressure and hence the

I

energy of a water jet will be reduced by friction as it passes between grain boundaries in penetrating several grain diameters before finally dislodging a5 chip of rock. The frictional forces will be propor-

tional to the surface area Sa of the grains per unit volume. Although the surface area is not a readily measurable parameter, an approximate value per unit volume of rock can be calculated from the mean grain-size by assuming that the rock is composed of uniformly sized, spherical particles having a diameter equal to the mean grain-size (clearly an oversimplifi- cation).

The procedure is as follows. The volume of a sphere of diameter equal to the mean diameter of the grains is calculated and the number of such spheres that can be fitted into a 1-cm3 cube is esti- mated. It can be shown that in a cubic close-packed

array the spheres occupy 73.1 % of the space (Evans

1964), so that the number of spheres per cubic cen- timetre can be obtained by dividing the volume of -one sphere into 0.741 cm3. The surface area of one sphere is calculated, and the resulting value then mul- tiplied by the number of spheres to obtain an esti- mate of the surface area of grains per cubic cen- timetre. In Figure 5 the drilling rate for a number of rock types is plotted against the surface area of the grains per cubic centimetre. The plot reveals that the surface area Sa of the grains is inversely propor- tional to the drilling rate D:

D = 23.37

+

(-0.0753 Sa) (2)FIG. 4. Optical micrograph (crossed polars) of the periph- ery of a calcite drill chipping from biosparite limestone, showing fracture along two cleavage planes in the cal- cite. Ca calcite, L cleavage planes, M plastic mounting medium.

\

E G I 1 - GREY BARRE GRANITE

-

" Ghl - P I N K RlUSKOKA GRANITE , 3 0 - .GI1

-

+ Q Z D - Q U A R T Z DlORlTE 4-

A - CHLORITIZED A \ l P H I B O L I l E-

N -ALTERED W R I T E-

S -CALCAREOUS NEPEAN-

SANDSTONE'

l o --

D -".

- , 0 0 1 0 0 2 0 0 3 0 0 4 0 0 5 0 0FIG. 5. Graph of drilling rate versus surface area of grain boundaries per cubic centimetre of rock.

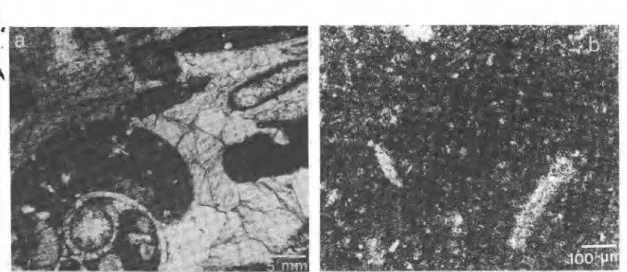

FIG. 6. ,(a) Optical micrograph (Nomarski differential contrast) showing fractures C traversing grain boundaries B in granite GM. (b) SEM micrograph showing open fractures C cutting across grain boundaries B in granite GM.

326

THE CANADIAN MINERALOGISTC

4 4 - -

-

-

G I 1 -GREY BARRE GRANITE -G M - P I N K MUSKOKA GRANITE - CHLORITIZED AMPHlBOLlTE Z

- -

- 2 2 1 0-

- P - D 0 0 8 0 1 2 0 1 6 0 ZOOFIG. 7. Graph of drilling rate D versus volume of cracks per unit volume of rock Vc for a number of rocks.

It may be seen by comparing Figures 1 and 4 that the correlation between drilling rate and surface area of the grains per cubic centimetre is about the same as that between drilling rate and mean grain-size, sug- gesting that drilling rate is affected by other factors. Examination of polished ion-milled sections of granites GM and GI1 by optical microscopy showed that granite GM contains many hematite-filled frac- tures cutting across the grains (Fig. 6a). Further

examination by SEM (Fig. 6b) revealed that many

cracks are open; these would facilitate penetration by a water jet. In contrast, granite GI1 contains few cracks other than those along grain boundaries. From this it was concluded that the differences in drilling rates observed in the two granites are due to the presence of cracks traversing the grains in granite GM. Observation of other rocks in the SEM confirmed that open cracks are largely confined to the grain boundaries. Few defects other than cracks along grain boundaries were observed in the rocks

studied. It may therefore be concluded that per- meability may be largely determined by the volume of cracks Vc per unit volume of rock.

It would, of course, be very difficult to determine accurately the volume of cracks per unit volume of rock. A rough estimate was obtained using the fol- lowing procedure: a point-count method (Hutchin- son 1974) similar to that employed for modal anal- ysis of rocks in thin section with a petrographic

microscope was used in conjunction with the SEM

i

to obtain an estimate of the volume of cracks per unit volume of rock. Considerable error is involved, in this procedure owing to the narrowness of the cracks and the possibility that owing to their length, some cracks may be counted more than once. The volume of cracks Vc is plotted against drilling rate

D for a number of rock types (Fig. 7). The drilling

rate is shown to increase with the volume of cracks

in the rock (equation 3).

It is concluded that the rate of penetration of a water jet in rock is largely controlled by two factors: the calculated surface-area of the grains per cubic centimetre and the volume of cracks per unit volume of rock. Additional drilling experiments should be carried out to verify this hypothesis.

In a few instances the drilling rates calculated for particular rocks (equation 2) were not achieved in practice. This is generally due to inhomogeneities in the rock. For example, in a block of Nepean sand- stone with a mean grain-size of 270 pm, the water

FIG. 8. (a) SEM micrograph of polished ion-milled section of Nepean sandstone showing quartz grains Q with intersti- tial clay minerals. (b) Polished ion-milled section of calcareous zone in sandstone. Q quartz, C calcite.

RATE OF PENETRATION OF A WATER-JET DRILL

327

jet penetrated rapidly for some time, then slowed p R O F 1 L E 0 F D R I L L I N G R A T E , c r n l m i nbefore finally speeding up again. Examination of thin H o L E D R I L L E D

sections taken from beside the hole shows that in I N s A N D S T O N E 0 5 10

I I

>

regions offering most resistance to drill penetration

-

the quartz sandstone contains calcareous zones. Figure 8 presents SEM photographs of polished sec- tions of sandstone: Figure 8a shows a relatively pure quartz sandstone with only minor amounts of inter-

C

stitial clay minerals and calcite; in Figure 8b, calciteis a major constituent of the rock, in some zones comprising about 30% of the rock. The variation in

'I

drilling rate with calcite content of the limestone isillustrated diagrammatically in Figure 9. ,

. -.

.

..

. .

_

...--.

. ., *It was shown previously that, in calcite, cracks induced by a water jet tend to follow cleavage planes rather than propagate along grain boundaries. The

following hypothesis is proposed to account for the

0

Q U A R T Z S A N D S T O N Eslow rate of water-jet penetration in calcareous sand-

stone: assume a crack tip with energy EVgreater than C A L C A R E O U S S A N D S T O N E

the threshold energy required for crack propagation in the sandstone. It moves along the boundary between two quartz grains until it enters an area of calcite, where it splits into a maximum of three cracks; these follow the cleavage planes. The energy at each of the three new crack-tips will be less than the original energy. The process will continue until the energy E V of the original crack-tip is dissipated by subdivision to such an extent that the energy of the individual crack-tips is reduced below the threshold value required for crack propagation along the boundaries of the quartz grains.

A second rock that appears to give anomalous

results is Ottawa limestone. Again, there was rapid initial penetration, followed by slowing of the drill and subsequent speeding up in a manner similar to that for sandstone. Examination of thin sections taken from beside the hole showed, however, that

FIG. 9. Schematic diagram of section through hole drilled in sandstone, showing dependence of drilling rate on calcite content of sandstone.

variations in the drilling rate were due in this case to changes in the grain size of the rock. Rapid penetration was obtained in coarse-grained biosparite limestone with a mean grain-size of 1000 pm (Fig. lOa), but the rate decreased when the water jet entered layers of fine-grained calcarenite limestone with a mean grain-size of 120 pm (Fig. lob).

The mean grain-size L, its related property, the

surface area Sa of the grains per unit volume of rock,

FIG. 10. Optical micrographs of limestone. Rapid penetration was obtained in (a) biosparite showing coarse grain-size, compared to (b) fine-grained pisolitic calcarenite, with poorly defined grain-boundaries.

328

THE CANADIANand the volume of cracks Vc per unit volume of rock are the major factors determining rate of water-jet penetration of rock. Measured permeabilities d o not correlate well with drilling rates. The lack of corre- lation may be due t o difficulties in making accurate measurements of the permeability of these low- porosity rocks and t o lack of homogeneity in some of the samples.

The authors are indebted to A. Annor of CAN- MET Rock Mechanics Laboratory in Ottawa for measurement of the permeability of some of the rock samples. Thanks are also due t o P. J. Lefebvre and E.G. Quinn for technical assistance and maintenance of the laboratory equipment, and to W.H. Brierley, who carried out many of the drilling experiments. This paper is a contribution from the Division of Building Research, National Research Council of Canada.

BURNS, D.J. & MOHAUPT, U.H. (1984): Computer lay- out and waterjet cutting of shoe components from multilayers of flexible sheets. Proc. 7th Znt. Symp. Jet Cutting Technology (Ottawa), Pap. G5,601-608. CAROZZI, A.V. & TEXTORIS, D.A. (1967): Paleozoic Carbonate Microfacies of the Eastern Stable Interior (U.S.A.). E. J . Brill, Leiden.

CLASSEN, M., LEUSCHNER, U., JESSEN, K., LOUIS, H., HAFERKAMP, H. & SHIKORR. W. (1984): Endoscopic jet cutting of human gallstones. Proc. 7th Znt. Symp. Jet Cutting Technology (Ottawa), Pap. D4,211-220.

MINERALOGIST

EVANS, R.C. (1964): An Introduction to Crystal Chemistry. Cambridge University Press, Cambridge, England.

HUTCHISON, C.S. (1974): Laboratory Handbook of Petrographic Techniques. J. Wiley & Sons, New York.

LEFIN, Y. & HUREL, A. (1984): Rotary drilling assisted by water jets and other recent developments of high pressure water jets for cutting of rocks in France. Proc. 7th Znt. Symp. Jet Cutting Technology (Ottawa), Pap. H3, 439-454.

NAKAYA, M., KITAGAWA, T. & SATAKE, S. (1984): Con- crete cutting with abrasive waterjet. Proc. 7th Znt. Symp. Jet Cutting Technology (Ottawa), Pap. E3, 281-292.

REHBINDER, G. (1980): A theory about cutting rock with a water jet. Rock Mechanics 12, 247-257. VIJAY, M.M., BRIERLEY. W.H. & GRATTAN-BELLEW,

P.E. (1982): Drilling of rocks with rotating high pressure water jets; influence of rock properties. Proc. 6th Znt. Symp. Jet Cutting Technology (Sur- rey, England).

,

GRATTAN-BELLEW, P.E. & BRIERLEY, W.H. (1984): An experimental investigation of drilling and deep slotting of hard rocks with rotating high pres- sure water jets. Proc. 7th Znt. Symp. Jet Cutting Technology (Ottawa), Pap. H2, 419-438. WALLACE, M. (1985): Water blasting robot helps com-plete bridge repair 14 months early. Concrete Con- struction 30(9), 785-786.

Received August 13, 1985, revised manuscript accepted December 12, 1985.