Publisher’s version / Version de l'éditeur:

Technical Note (National Research Council of Canada. Division of Building Research), 1970-06-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20359240

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Glass Thickness Requirements for Sealed, Double-Glazed Windows

Under Wind Pressures

Brown, W. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=0f0e6d46-8b2d-437a-b76c-579a6107799c https://publications-cnrc.canada.ca/fra/voir/objet/?id=0f0e6d46-8b2d-437a-b76c-579a6107799c

NATIONAL RESEARCH COUNCIL

OF

CANADA

DIVISION OF BUILDING RESEARC.H

'f

E

C

JHI

N II

C

AIL .

NOTJE

No.

550PREPARED BY

w.

G. Brown CHECKED BY D. G. S.APPROVEDBY N. B. H.

セ June 1970

PREPARED FOR Working Group of the Standing Cormnittee on Residential Standards

SUBJECT GLASS THICKNESS REQUIREMENTS FOR SEALED, DOUBLE-GLAZED WINDOWS UNDER ¥lIND PRESSURES.

PRELIMINARY CONSIDERATIONS

Deflections and Stresses in Single-glazed Windows

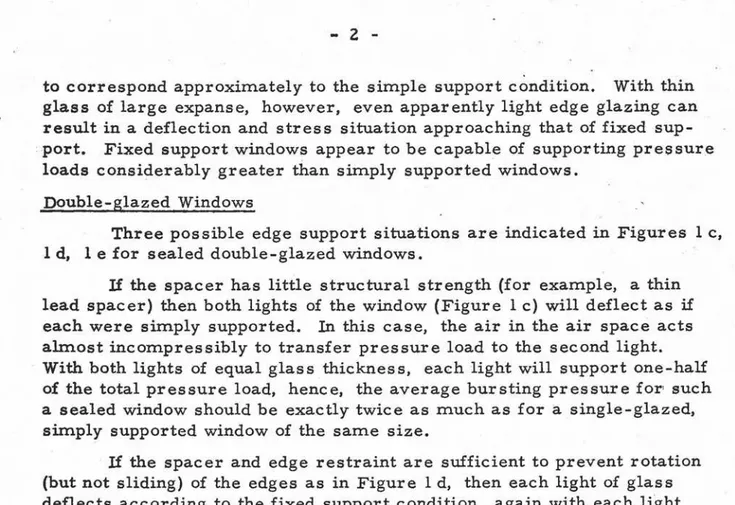

Figures 1 a and 1 b illustrate the two possible extremes of edge

support for single-glazed windows. Simple support (1 a) means that the

edge can rotate freely against t.he support and is also free to slide

in-wards as the window is pressurized. For this situation, the curvature

of the glass and the stress are greatest at the centre and it is here that

most breaks tend to occur. Fixed support (1 b) means that the window

edge cannot rotate, but is neve:rtheless free to slide as a pressure is

applied. In this case, curvature, resulting stress, and breakage are

greatest near the window edge, in contrast to the central location for simple support.

These situations apply only to very long, narrow windows. For most rectangular windows with simple support, the location of maximum stress and the origin of nlOst breaks moves progressively outward along

diagonals as the pressure on the window increases. The fixed support

condition is at present only understood for the condition of fairly small

deflections. As with the long, narrow window, the maximum stress

oc-curs approximately at the edge and at the middle of the larger side of

:e

I2

-to correspond approximately -to the simple support condition. With thin

glass of large expanse, however, even apparently light edge glazing can result in a deflection and stress situation approaching that of fixed

sup-port. Fixed support windows appear to be capable of supporting pressure

loads considerably greater than sirn.ply supported windows. Double-glazed Windows

Three possible edge support situations are indicated in Figures I c, I d, 1 e for sealed double-glazed windows.

If the spacer has little structural strength (for example, a thin

lead spacer) then both lights of the window (Figure I c) will deflect as if

each were simply supported. In this case, the air in the air space acts

almost incompressibly to transfer pressure load to the second light. With both lights of equal glass thickness, each light will support one-half of the total pressure load, hence, the average bursting pressure for' such a sealed window should be exactly twice as much as for a single-glazed, sirn.ply supported window of the same size.

If the spacer and edge restraint are sufficient to prevent rotation (but not sliding) of the edges as in Figure I d, then each light of glass deflects according to the fixed support condition, again with each light

carrying one-half of the pressure load. In this case, the average

burst-ing pressure for the sealed unit would be expected to be exactly twice as much as for a single-glazed, fixed support window of the same size.

It should not be forgotten, however, that this bursting pressure will

always be greater than obtained with simply supported windows.

Figure I e illustrates the situation that apparently occurs with

the majority of sealed, double-glazed windows. The window as a unit

is approxirn.ately sirn.ply supported, but as it deflects under the applied pressure, an additional compressive force is set up in one light and an

equal tensile force occurs in the other light. These forces restrict

rotation of the edges, with the result that for small pressures, the

de-oflections and stresses are similar to those of Figure I d even though

the window unit is not restrained in any way. As pressures are

in-creased, however, the lower glass light supports an increasingly greater

portion of the applied pressure than does the upper light. In these

circumstances, it is not possible at present to calculate the load-bearing capacity of most sealed double-glazed window units from existing data for single light, so it has been necessary to determine some bursting

strengths approximately. The available data are summarized later in

this Note.

Probability of Failure

Analysis of a great many tests on single-glazed windows with as-pect ratios of up to about 3: 1 shows that if windows are designed for a

3

-design pressure of about 0.40 of the average bursting pressure,

approxi-mately 1 per cent of the windows will fail at the design pressure.

Simi-larly, only about 0.1 per cent of the windows will fail for a design

pres-sure of O. ZO times the average bursting prespres-sure. These factors, which

are the ratio of design pressure to average bursting pressure, are

refer-red to as design factors. They can be thought of as reciprocals of safety

factors. It is customary to design windows for failure probabilities

be-tween O. 1 and 1 per cent.

In the case of sealed, double-glazed windows, the available test results are sufficient to yield the average or mean bursting strength but they are not, in themselves, sufficient to determine at what pressures

low levels of failure probability will result. For example, a set of ZO

test results gives no possible information for failure probabilities less

than 5 per cent (i. e., 1 in ZO). In this circumstance, it is necessary

to consider to what extent the design factors already established for 'single-glazing can be expected also to apply for double-'single-glazing.

Accepting that glass fails when stresses reach critical levels, it is apparent that design factors can only differ from those established for single-glazing if the relationship between stress and applied pressure

is different. It is known that for small pressures on all windows and for

all long, narrow windows, the stress varies directly with pressure. For

square single-glazing, however, in the range of pressures at which break-age occurs, it is found that the stress is approximately proportional to

the 0.75 power of pressure. This deviation from linearity which is

maxi-mal for a square plate is due to the fact that the glass acts, in part, as a

membrane. For all windows, then, stress can be expected to be

propor-tional to a power of pressure of between O. 75 and 1. O. (These two

ex-tremes are shown in Figure Z. )

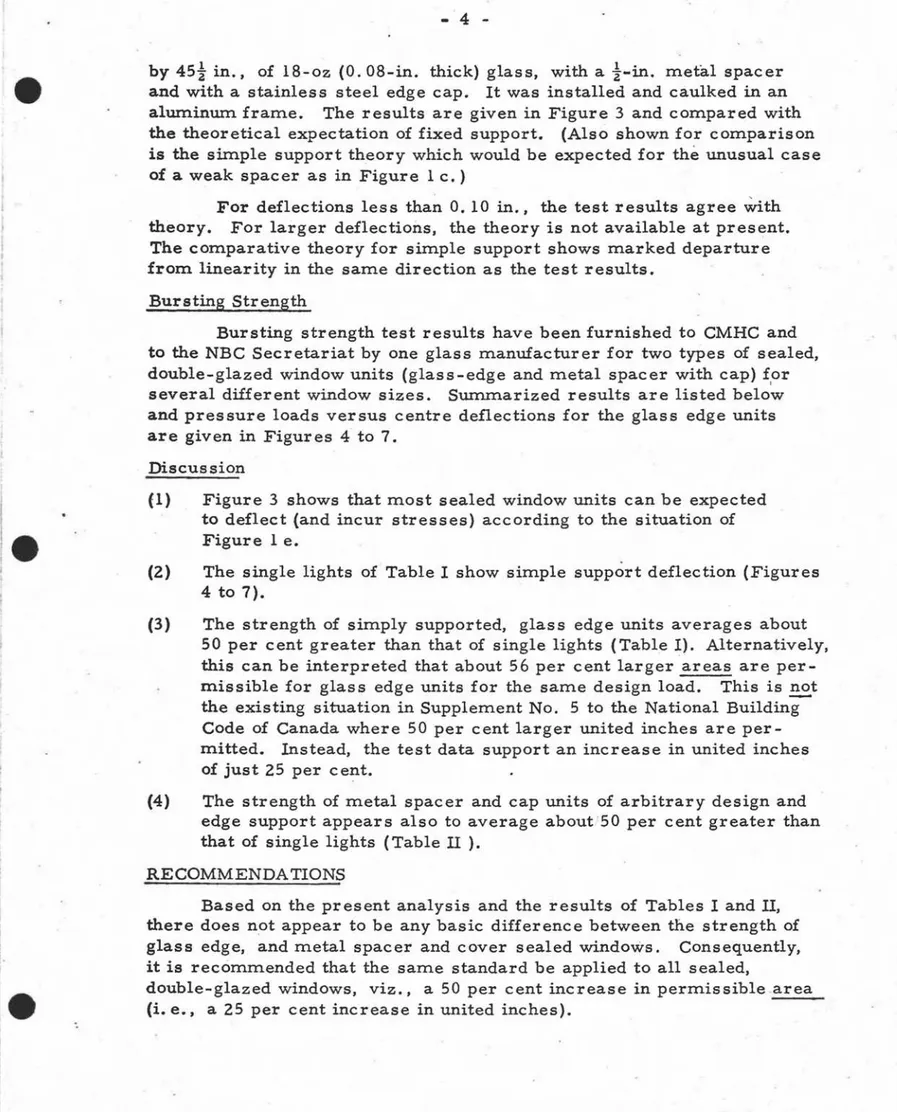

From Figure Z, when stress is proportional to pressure to 0.75 power, the stress corresponding to 1 per cent probability of failure is

approximately 0.5 of the mean failure stress. If the relationship

be-. tween stress and pressure be linear, this 1 per cent probability of fail-ure stress would correspond to 0.5 times the mean bursting pressfail-ure,

so for this case, the design factor would be 0.5 rather than 0.4.

Thus it is safe to assume that the design factors that are appro-, priate for single-glazing will be conservative when used for double-glazing. AVAILABLE TEST DATA

Deflections

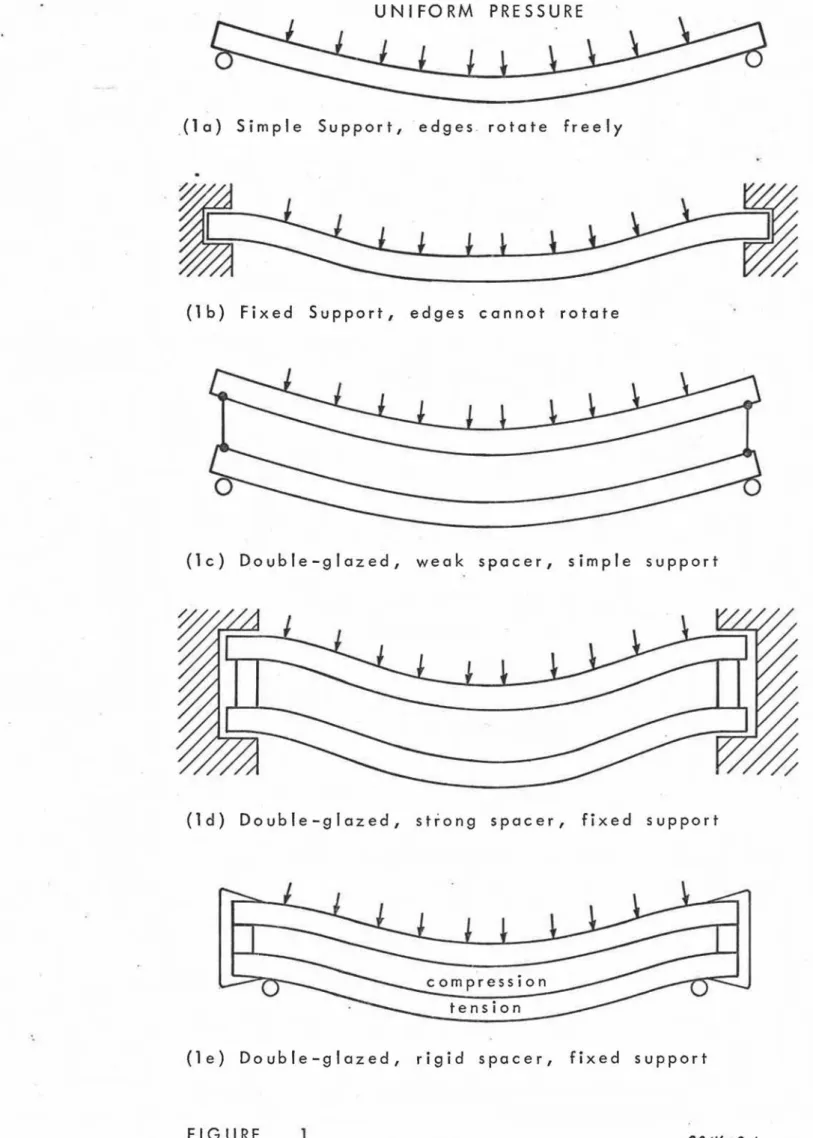

In order to illustrate that most sealed, double-glazed windows will be deflected and stressed as in example (e) of Figure I, some simple centre deflection measurements under uniform pressure were carried out

4

-by 45! in., of 18-oz (0. 08-in. thick) glass, with a i-in. metal spacer

and with a stainless steel edge cap. It was installed and caulked in an

aluminum frame. The results are given in Figure 3 and compared with

the theoretical expectation of fixed support. (Also shown for comparison

is the simple support theory which would be expected for the unusual case of a weak spacer as in Figure 1 c. )

For deflections less than O. 10 in., the test results agree セゥエィ

theory. For larger deflections, the theory is not available at present.

The comparative theory for simple support shows marked departure from linearity in the same direction as the test results.

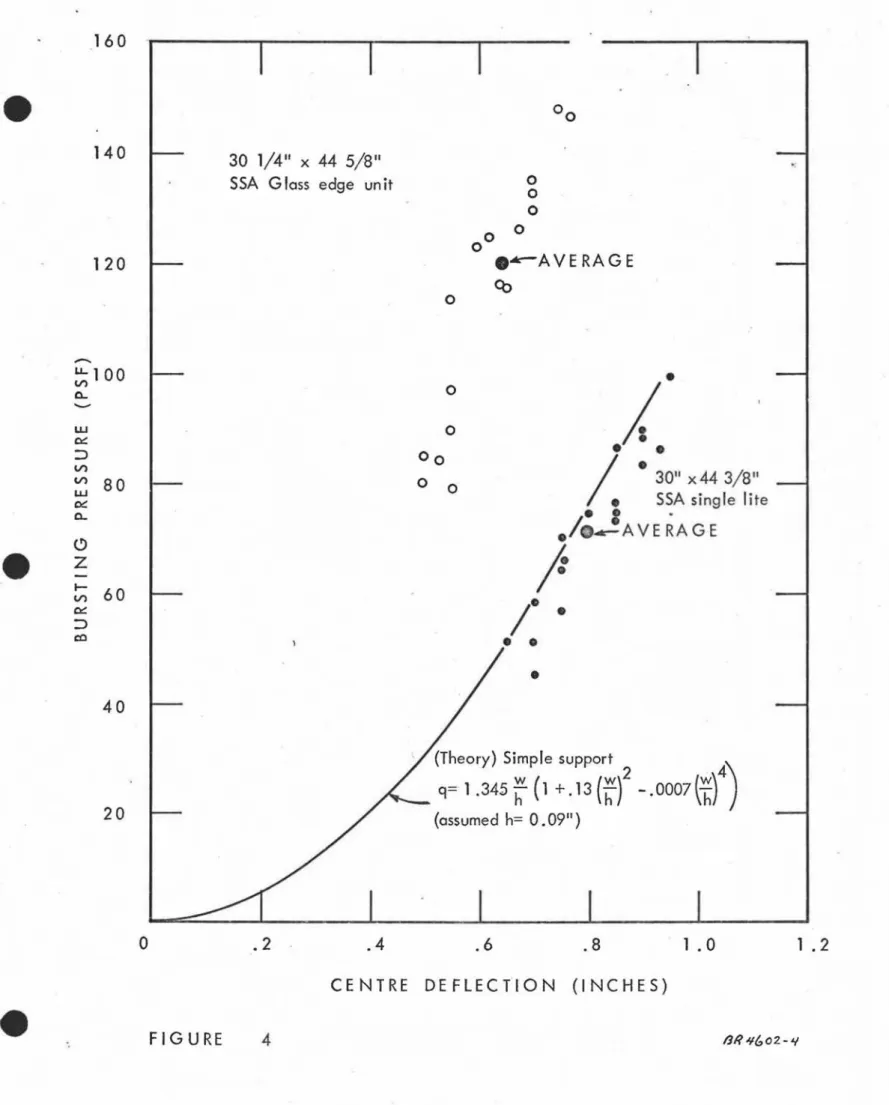

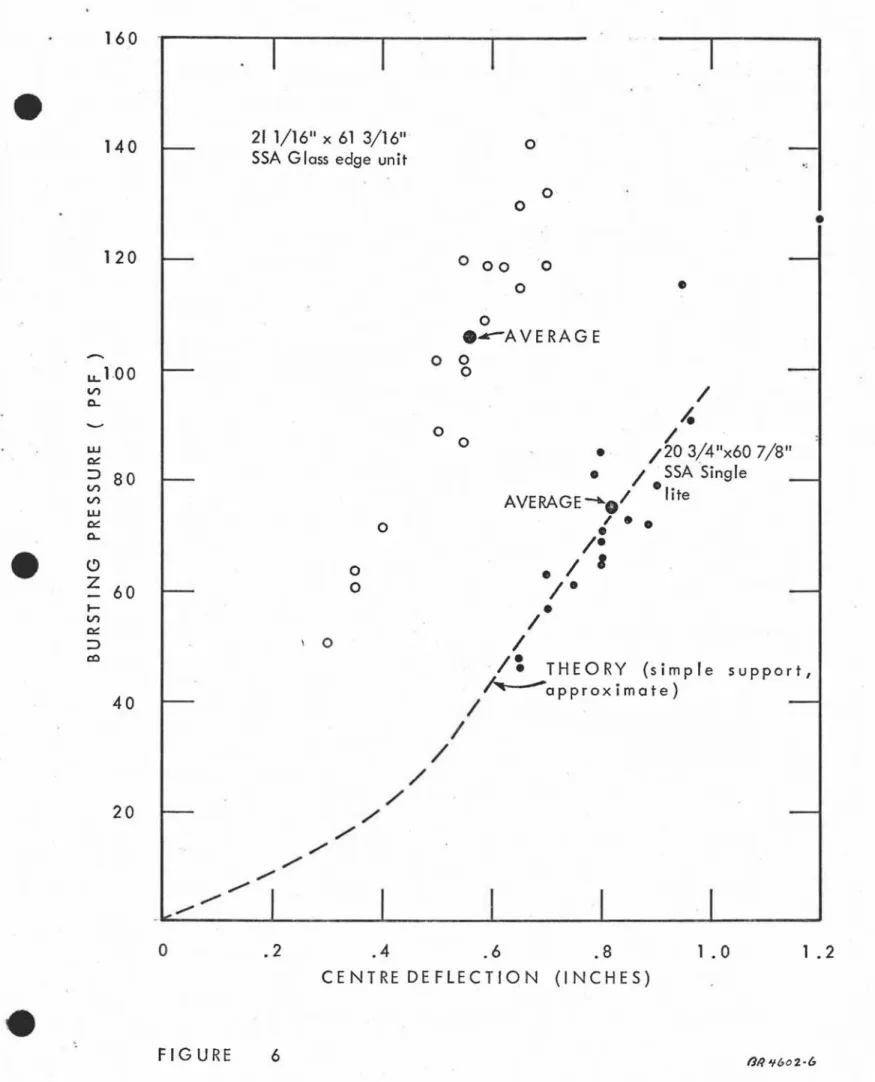

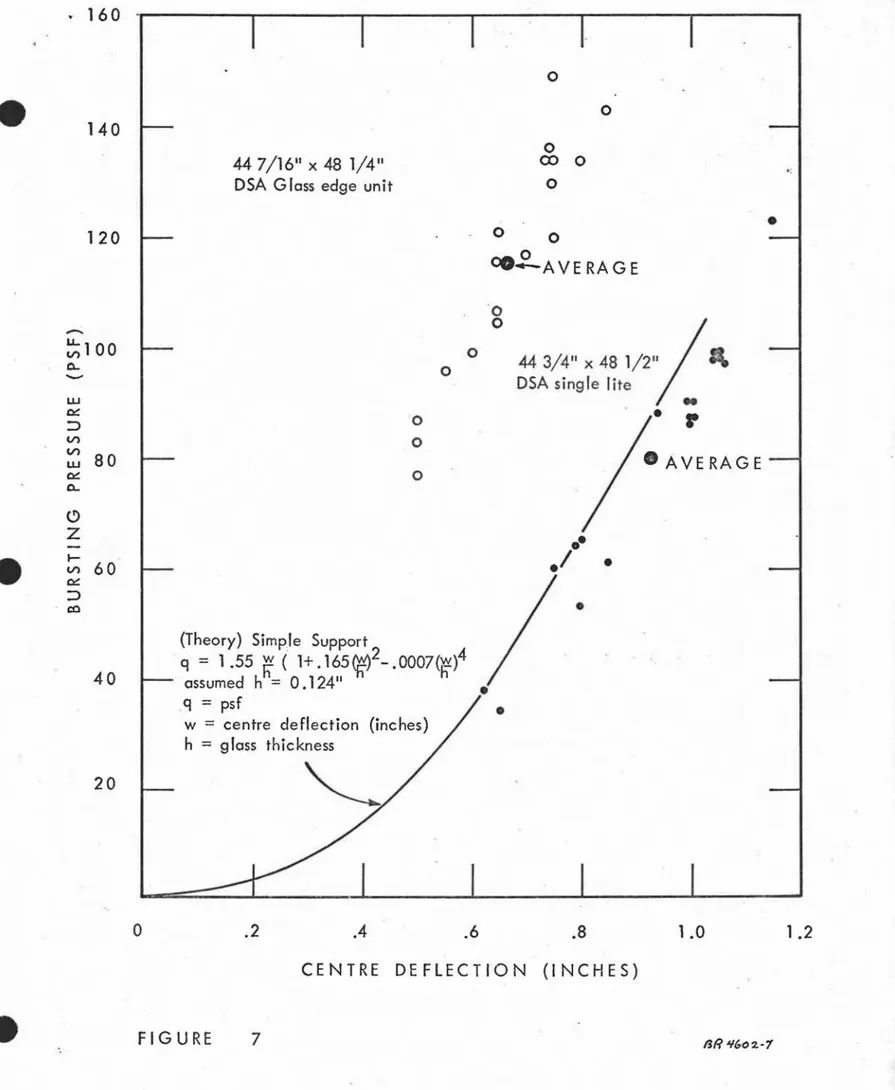

Bursting Strength

Bursting strength test results have been furnished to CMHC and to the NBC Secretariat by one glass manufacturer for two types of sealed, double-glazed window units (glass-edge and metal spacer with cap) f,or

several different window sizes. Summarized results are listed below

and pressure loads versus centre deflections for the glass edge units

are given in Figures 4 to 7.

Discussion

(1)

(2)

Figure 3 shows that most sealed window units can be expected

to deflect (and incur stresses) according to the situation of Figure 1 e.

The single lights of Table I show simple support deflection (Figures

4 to 7).

(3) The strength of simply supported, glass edge units averages about

50 per cent greater than that of single lights (Table I). Alternatively, this can be interpreted that about 56 per cent larger areas are

per-missible for glass edge units for the same design load. This is E2.t

the existing situation in Supplement No. 5 to the National Building Code of Canada where 50 per cent larger united inches are

per-mitted. Instead, the test data support an increase in united inches

of just 25 per 」・セエN

(4) The strength of m.etal spacer and cap units of arbitrary design and

edge support appears also to average about 50 per cent greater than that of single lights (Table 11 ).

RECOMMENDA TIONS

Based on the present analysis and the results of Tables I and II, there does not appear to be any basic difference between the strength of

glass edge, and metal spacer and cover sealed windows. Consequently,

it is recommended that the same standard be applied to all sealed,

double-glazed windows, viz., a 50 per cent increase in permissible area (i. e., a 25 per cent increase in united inches).

5

-Additional

Glass sizes for single lights given in the Residential Standards

have been reviewed and found to be somewhat conservative.

*

Thus,all things considered, it would appear that there should be little re-maining objection to permitting 50 per cent larger areas for (all) sealed window units.

Testing

It should be appreciated that for purposes of window strength

design, the average bursting pressure of a number of samples is not the

information that is required. What is really required is to know how

many will fail at the design load. To determine the 1 per cent failure

level for a given type of window, for example, with reasonable accuracy, would require that about 1000 samples be loaded to the design figure in

order to break about 10 samples. The results of such testing would not

offer any information about design factors and would not in themselves

permit any generalization for other types and sizes of windows. If all

of the 1000 samples were broken, then the mean bursting pressure and

design factor would be established reasonably well. Itis clear, however,

from. the section on 'probability of failure' that all of this effort would have been carried out only to establish a design factor of perhaps 0.45 in place of an estimated value of 0.4 obtained from previous tests on

single-glazing. The tests would still not allow generalizations for other

window types and sizes.

The strength of glass also depends on load duration, on

temper-ature, and to a small extent on relative humidity. These factors would

require careful attention in testing. It should also be kept in mind that

design wind pressure is a very imprecise figure, generally conservative: in this situation, high quality test results are not of great value.

In view of this, it can be expected that additional tests of the kind summarized in Tables I and II on different types of sealed-glazing

units will show the same general variability as in these Tables. Rather

than undertake any limited number of エセウエウ at this time, it would seem

more reasonable to accept the moderately well established design factors discussed under 'probability of failure' and to assume that Tables I and II are fairly characteristic of sealed double-glazing in comparison with single - glazing.

I

I

,e

TABLE I

Test Results for Glass-Edge Window Units

Average Breaking

Window Type Size, in. Number Bursting Load Ratio

of Pressure, to Single

Samples psf Light

glass-edge 30i x 44 5/8 SSA 20 120 1. 69

single light 30 x 44 SSA 19 71

-glass-edge 21 1/16 x 61 3/16 SSA 19 106 1.42

single light 20 3/4 x 607/8 SSA 18 75

-glass-edge 44 7/17 x 481. DSA4 20 115 1.44

single light 44 3/4 x 48.1 DSAa 20 80

-,

glass-edge 28 7/16 x 66 DSA 20 116 1. 76

single light 287/16 x 66 DSA 0 - 20 66

-•

TABLE II

Test Results for Metal Spacer and Cap Window Units

Average

Window Type - Size, in. Number Bursting Breaking

.

of Pressure, Load Samples psf Ratioi"

air-space 30 x 48 DS 24 144 1.3 single light 30 x 48 DS 24 108-1." air-- s pac e4 . 48 x 48 DS 20 116 2.1 single light 48 x 48 DS 25 56

-.

i"

air-space 72 x 72(i"

plate) 6 137 1.7single light 71i x 72

(i"

plate) 25 82-Notes to Tables I and II

(1) Tests for Table I were carried out in Andersen sash, which appears

to give approximately simple support in all cases. All tests were

Continuation of Notes to Tables 1 and II

(2) Tests for single lights of Table II were not contem.poraneous with

those of the double units. Slight differences in glass .thickness

re-sulting from. m.anufacture tolerance can have an appreciable effect

on bursting pressure. Edge support for the single lights for the

OS glass appears to have been interm.ediate betWeen the sim.ple

and fixed condition. The edge support for 、セオ「ャ・ZBァャ。コ・、

i>s

glassappears also to have been interm.ediate between sim.ple and fixed support, and support for the i-in. plate glass is unspecified.

UNIFORM

PRESSURE

.(10)

Simple Support, edges rotate freely(1

b) Fixed Support, edges cannot rotate(lc) Double-glazed, weak spacer, simple support

(ld) Double-glazed, strong spacer, fixed support

compression tension

(le) Double-glazed, rigid spacer, fixed support

STRESS

.;PRESSURE

Mean Bursting Pressure (MBP)t

OAMBP

O.5MBP

t

t

Mean Failure セ⦅ - - - -Stress Stress for 1%MZMMMMGセ probability af failureFIGURE

2

RE LA T ION S HIP

BET WEE N DES I G N FA C TOR AND

"

•

/

/

/

/

/

セ

.

.,

I

EX PER I MENTAL

II

セO

/

/

/

/

••

/

/

(

/

/ / / / / / / / / / /"

/..

/ /セBB

THEORY (simple support)BLLセ

"

"

" ,",,,,,,,

,..

- - " . . " " . " 151 0

-.. U-V)0

-W セ :::> V) . V) w セ0-5

o

0.10

CENTRE DEFLECTION (INCHES)

- 0.20

FIGURE 3

CENTRE DEFLECTION FOR A 33" x TUセB SEALED, DOUBLE

o

160 MキMMMMNNNNLNNNMMMセMMMMセMMM

140

120

30 1/4" x 44 5/8" SSA G loss edge un it

o

o

oo

o

0 0 e'-AVERAGEco

.;1 .2

1 .0

.8.6

.4

.2

.

o

...

lJ..100•

V) 0j

a.. ... w 0 0:: :J 00! ..

V) V) 80 0 0 30" x44 3/8" w• SSA single lite

0:: a..

•

•.il

-!AVERAGEC>

e

z

j:

I -60 V)Ie

0::•

:J co•

•

•

40(Theory) Simple support

20

アセ

1 .345

セ

(1+

.13HセIR

-

.0007セセエI

(assumed h= 0.09")CENTRE DEFLECTION (INCHES)

160

o

140

28 7/16"

x66"

DSA G lass edge un

ito

.;120

o

o

• ....-AVERAGE

000o

•

28 7/16"

x66"

DSA Single lite

a

o

o

0/

/

,.

•

I ••

/ fI_AVE RAGE

I.

f

/

.

/

/

/

/

Oセ

THEORY (Simple support,

.."""-

.

)/

approximate

/

/'

, / / ' /'"""

----",,,,,

20

40

---セ

1 00 0..-

LU 0:: ::> V) V) LU 80 0:: 0..<.?

Z セ V) 60 0:: ::> coo

. 2.4

.6

.8

1 . 01 . 2

CENTRE

DEFLECTION

(INCHES)

o

160

140

21 1/16" x 61 3/16"

SSA Glass edge unit

o

o

o

-120

o

00 0o

•

o

o

o

Nセaverageo

0o

o

o

o

\ 0/

-'

/

-

/20 3/4"x60 7/8"

_

/ . SSA Single

AVERAGE-....I

-lite

/..

•

I-• I

,

I

-/

I

I:

THEORY

(simple support,

iセ。ーーイック

imate)

/

/

/

/

/

/ '

/ ' . / . / /,....,

,...

/20

-

LL100

V) 0-... W セ ::>80

V) V) w セ 0-C) Z60

セ V) セ ::> co40

o

.2

.4

.6

.8

CENTRE DEFLECTION

(INCHES)

1 .0

1 .2

セ 160

o

o

14044 7/16

11 X48 1/4

11DSA G lass edge unit

o

ex:> 0o

120 0 0CO2-

AVE RA G E•

o·

.1

•

•

•

o

'0o

0 044 3/4"

x481/2

,1

DSA single lite

..

'0 •

r

o

(Theory) Simple Support q

=

1 .55

セ

( 1+ . 165Wl

2-NPPPWHセIT

assumed h

=

0.12411q

=

psfw

=

centre deflection (inches) h=

glass thickness 2040

-..セQ

00

0--

W セ :::> V') V')80

w セ0-0

Ze

.-

V')60

セ :::> a )o

.2

.4

.6

.8

1.0

1.2

CENTRE DEFLECTION (INCHES)