Publisher’s version / Version de l'éditeur:

Canadian Journal of Civil Engineering, 25, December 6, pp. 975-981, 1998-12-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1139/cjce-25-6-975

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Performance of high strength concrete-filled steel columns exposed to

fire

Kodur, V. K. R.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=b11cb961-5b20-45f6-9070-4c491127f560 https://publications-cnrc.canada.ca/fra/voir/objet/?id=b11cb961-5b20-45f6-9070-4c491127f560Performance of high strength concrete-filled

steel columns exposed to fire

V.K.R. Kodur

Abstract: Results from an experimental program on the behaviour of high strength concrete-filled steel hollow structural section (HSS) columns will be presented for three types of concrete filling. A comparison will be made of the fire-resistance performance of HSS columns filled with normal strength concrete, high strength concrete, and steel-fibre-reinforced high strength concrete. The various factors that influence the structural behaviour of high strength concrete-filled HSS columns under fire conditions are discussed. It is demonstrated that, in many cases, addition of steel fibres into high strength concrete improves the fire resistance and offers an economical solution for fire-safe construction.

Key words: high strength concrete, steel columns, fire-resistance design, high-temperature behaviour, concrete-filled

steel columns.

Résumé : Les résultats d’un programme expérimental sur le comportement de colonnes en acier (HSS) dont la section vide est remplie de béton à haute résistance, sont présentés et ce, pour trois types de béton de remplissage. Une comparaison de la résistance au feu est faite pour des colonnes remplies avec du béton à résistance normale, du béton à haute résistance ou du béton à haute résistance renforcé de fibre. Les différents facteurs qui influencent le

comportement structural des colonnes HSS remplies de béton à haute résistance sous des conditions d’incendie sont discutés. Il est démontré que, dans de nombreux cas, l’ajout de fibres au béton à haute résistance améliore la résistance au feu et offre une solution économique pour obtenir une construction sécuritaire en cas d’incendie.

Mots clés : béton à haute résistance, colonnes en acier, conception de résistance au feu, comportement à haute

température, colonnes en acier remplies de béton. [Traduit par la Rédaction] Kodur 981

Steel hollow structural section (HSS) columns are very ef-ficient structurally in carrying compression loads and mo-ments and are widely used in the construction of framed structures in office and industrial buildings. Often these sec-tions are filled with concrete to enhance the load-bearing ca-pacity. The two components of the composite column complement each other ideally, in that the steel casing con-fines the concrete laterally, allowing it to develop its opti-mum compressive strength, while the concrete, in turn, prevents elastic local buckling in the steel wall.

Another advantage of concrete filling is that it also in-creases the fire resistance of the column without the need for external fire protection for the steel. This increases the us-able space in the building. Properly designed concrete-filled columns can lead economically to the realization of architec-tural and strucarchitec-tural design with visible steel without any re-strictions on fire safety.

In recent years, high strength concrete has become an at-tractive alternative to traditional plain concrete, since it fur-ther increases the load-carrying capacity of HSS columns (Prion and Baraka 1994). However, the behaviour of high strength concrete, at elevated temperatures, is significantly different from that of normal strength concrete (Phan 1996; Kodur and Lie 1995a) and there is little information avail-able in the literature on its performance when exposed to fire.

For a number of years, the National Fire Laboratory, Na-tional Research Council of Canada, has been engaged in re-search studies aimed at developing simplified methods that can be used by the construction industry for evaluating the fire resistance of structural members. Both experimental and numerical studies on the fire resistance of HSS columns filled with concrete have been carried out with the support of the Canadian Steel Construction Council and the Ameri-can Iron and Steel Institute. Studies on HSS columns filled with normal strength concrete have been completed and sim-plified equations for evaluating the fire resistance of these columns have been developed (Kodur and Lie 1995a; Lie and Kodur 1996a; Kodur 1997). Experimental studies on high strength concrete-filled HSS columns have been com-pleted and numerical studies on the fire performance of these columns are at an advanced stage.

In this paper, test results on the fire resistance of HSS col-umns filled with concrete are presented for three types of concrete filling. A comparison is made of the fire resistance

Received November 17, 1997.

Revised manuscript accepted June 8, 1998.

V.K.R. Kodur. Institute for Research in Construction, National Research Council of Canada, Ottawa, ON K1A 0R6, Canada.

Written discussion of this article is welcomed and will be received by the Editor until June 30, 1999 (address inside front cover).

of normal strength concrete-filled HSS columns, high strength concrete filled columns, and fibre-reinforced high strength concrete-filled HSS columns.

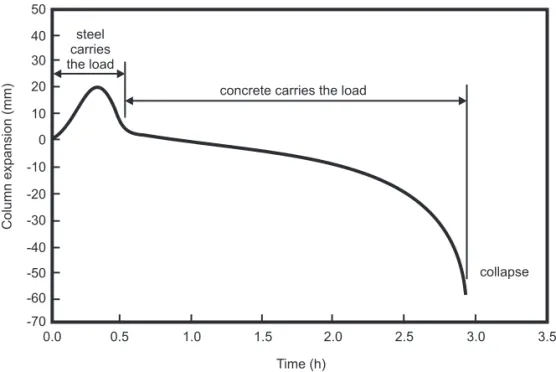

The behaviour of HSS columns filled with concrete, when subjected to fire, depends on the temperature range and the duration of the fire. This is illustrated by the axial deforma-tion versus time plot in Fig. 1 for a typical concrete-filled HSS column (used in buildings) exposed to heat in a fur-nace, specially built for testing loaded columns under fire conditions. During the early stages of fire exposure, the steel column carries most of the load. This is because the steel section expands more rapidly than the concrete core. At in-creased temperatures, the steel section yields because of de-creasing strength and the column suddenly contracts, usually at 20–30 min. This contraction is often accompanied by lo-cal bulging of the steel section. At this stage, the concrete core takes over the load and carries a progressively increas-ing portion of the load with increasincreas-ing temperature. Con-crete, due to its lower thermal conductivity and higher heat capacity, loses strength more slowly than steel and provides fire resistance for the column at these later stages of the test. The strength of the concrete also decreases with time and, ultimately, when the concrete core can no longer support the load, failure occurs either by buckling or by compression. The length of time the concrete is capable of supporting the load can be quite significant, as seen from Fig. 1.

The fire resistance for HSS columns filled with concrete depends on a number of factors, such as the load on the col-umn, cross-sectional dimensions, concrete strength, and the type of concrete filling (Kodur and Lie 1995a). In this paper, the effect of concrete filling and concrete strength on fire re-sistance is investigated using the test results for four HSS columns filled with three types of concrete.

Test specimens

Four HSS columns, namely two columns filled with nor-mal strength concrete (NSC1 and NSC2), a column filled with high strength concrete (HSC1), and a column filled with fibre-reinforced high strength concrete (HFC1), were tested to failure by exposing the columns to fire. The col-umns were of circular cross section. No external fire-proofing protection was provided for the steel.

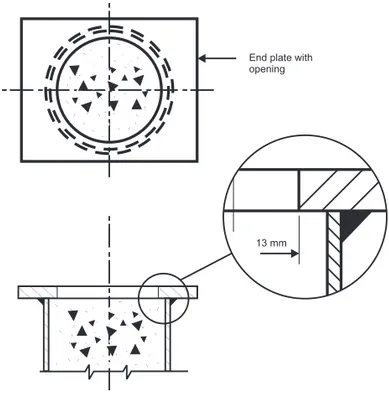

Figure 2 shows elevation and cross-sectional details for the columns. The columns were 3810 mm long, from end plate to end plate. Columns NSC1 and HFC1 were 219.1 mm in diameter and were made from grade 300 steel section with a wall thickness of 4.78 mm. Columns NSC2 and HSC1 were 273.1 mm in diameter and were made from grade 350 steel with a wall thickness of 6.35 mm.

The hollow steel columns were fabricated by cutting the steel sections to appropriate lengths. Steel end plates were then welded to the column extremities, with special attention being given to the centering and perpendicularity of the end plates. A hole, with a diameter 26 mm smaller than the in-side diameter of the hollow steel section, was cut in each plate before welding the plates to the steel section. This con-struction provided a 13 mm lip to transfer the load from the steel plate to the concrete filling, as shown in Fig. 3.

The HSS columns were fabricated by cutting the steel sec-tions to appropriate lengths. Steel end plates were then welded to the column extremities, with special attention be-ing given to the centerbe-ing and perpendicularity of the end plates. A hole, with a diameter 26 mm smaller than the in-side diameter of the hollow steel section, was cut in each plate before welding the plates to the steel section.

Four small holes were drilled in the steel wall to provide vent holes for water vapour produced during the test. Two pairs of holes, one pair each at the bottom and top ends of the column with a diameter of 12.7 mm, were located with one hole opposite the other 1448 mm from mid-height of the column. Provision of these holes, a mandatory requirement

© 1998 NRC Canada

976 Can. J. Civ. Eng. Vol. 25, 1998

50

concrete carries the load steel carries the load collapse 40 30 20 10 0 -10 -20 -30 -40 -50 -60 -70 0.0 0.5 1.0 1.5 2.0 Time (h) Column expans ion (mm) 2.5 3.0 3.5

for concrete-filled steel columns when used in buildings, is intended to prevent the bursting of the column under steam pressure generated by the heating of entrapped water in the enclosed concrete.

Type K chromel–alumel thermocouples, with a thickness of 0.91 mm, were installed at the mid-height of the column to measure the temperature at different locations in the cross section. The locations of the thermocouples and other instru-mentation details are described in detail in Lie and Chabot (1992) and Kodur and Lie (1995b).

Concrete mix

XOREX steel fibres were used as reinforcement in col-umn HFC1. These fibres are made of mild carbon steel with a tensile strength of approximately 960 MPa. The corrugated shape of these fibres provides a strong mechanical bond to the concrete. The fibres were 50 mm long and 0.9 mm equivalent diameter and had an aspect ratio of 57. The per-centage of steel fibres in the concrete mix was 1.77% by mass.

Four batches of concrete were used for fabricating the col-umns. Concrete in batches 1 and 2 was made with general purpose type 10 Portland cement, whereas batches 3 and 4 had silica fume added as well. All four concrete batches contained carbonate stone and silica-based sand. The mix proportions, per cubic metre of concrete, in the four batches are shown in Table 1.

For the mix with steel fibre, the steel fibres were added to the fresh concrete and mixed for approximately 2 min to provide uniform dispersion of the steel fibres. The concrete was poured into the column through the top opening and vi-brators were used to consolidate the concrete. The 28-day average cylinder strength varied from 35 to 43 MPa for nor-mal strength concrete and was approximately 90 MPa for high strength concrete. The corresponding compressive strength on the test day, which was 6 months or more after

construction, varied from 38 to 42 MPa for normal strength concrete and 82 to 98 MPa for high strength concrete.

The moisture condition at the centre of the column was also measured on the day of the test. The moisture condition of columns HSC1 and HFC1 was approximately equivalent to that in equilibrium with air of 55% and 69% relative hu-midity (RH) at room temperature, whereas for columns NSC1 and NSC2 it was, with air, above 90% RH.

Test apparatus

The tests were carried out by exposing the columns to heat in a furnace specially built for testing loaded columns. The furnace consists of a steel framework supported by four steel columns, with the furnace chamber inside the frame-work. The test furnace was designed to produce conditions, such as temperature, structural loads, and heat transfer, to which a member might be exposed during a fire. The fur-nace has a loading capacity of 1000 t. Full details on the characteristics and instrumentation of the column furnace are provided in Lie (1980).

Test conditions and procedures

The tests were carried out with both ends of the columns fixed, i.e., restrained against rotation and horizontal transla-tion. The columns were subjected to a concentric load. The applied load (C), the factored compressive resistances of the column (Crc), and the concrete core (Cr′) are given in

Ta-ble 2. The factored compressive resistance was computed using an effective length factor (K) of 0.65, for the fixed end condition, as recommended in CSA/CAN-S16.1-M89 of the Canadian Design Code (CSA 1989). The load intensity, de-fined as the ratio of the applied load to the column resis-tance, varied slightly from one column to the other.

The load was applied approximately 45 min before the start of the fire test and was maintained until a condition was reached at which no further increase of the axial defor-mation could be measured. This was selected as the initial

219.1 mm

3810

mm

219.7 mm 273.1 mm 273.1 mm

(a) (b) (c) (d)

Fig. 2. Elevation and cross section of columns (a) NSC1, (b) HFC1, (c) NSC2, and (d) HSC1.

13 mm End plate with opening

condition for the axial deformation of the column. During the test, the column was exposed to heating controlled in such a way that the average temperature in the furnace fol-lowed, as closely as possible, the CAN/ULC-S101 (ULC 1989) or ASTM E119-88 (ASTM 1990) standard time–tem-perature curve. The load was maintained constant through-out the test. The columns were considered to have failed and the tests were terminated when the hydraulic jack, which has a maximum speed of 76 mm/min, could no longer maintain the load.

Results and discussion

The test data from the four columns, NSC1, NSC2, HSC1, and HFC1, are compared in this section. The load intensity (C/Crc) in columns NSC2 and HSC1 was 0.26 and the corre-sponding values for columns NSC1 and HFC1 were 0.36 and 0.3, respectively. These load levels represent typical loads that are encountered in columns under a fire situation. Although the load intensities for columns NSC1 and HFC1

are not identical, the results can be used to illustrate the comparative behaviour of the three types of concrete filling. The effect of concrete strength on the behaviour of concrete-filled HSS columns is illustrated by comparing the data from columns NSC2 and HSC1, and the effect of steel fibre rein-forcement in high strength concrete is illustrated by compar-ing the test data of columns NSC1 and HFC1.

Behaviour of high strength concrete

The time–temperature curves for the external column sur-face and for depths of 33 and 98 mm in the concrete are plotted in Fig. 4 for columns NSC2 and HSC1. For both col-umns, the temperatures inside the column rise rapidly to about 150°C and then the rate of increase of temperature de-creases. This temperature behaviour is due to the thermally induced migration of moisture toward the centre of the col-umn (Chabot and Lie 1992). The influence of moisture mi-gration is highest at the centre of the column.

The failure of column NSC2 occurred when the tempera-ture at the centre of the concrete core was approximately

© 1998 NRC Canada

978 Can. J. Civ. Eng. Vol. 25, 1998

Cement (kg/m3)

Coarse aggregate (kg/m3) (carbonate)

Fine aggregate (kg/m3)

Steel fibres (kg/m3)

Batch Column 19 mm 12.7 mm 9.5 mm 6.35 mm Total

1 NSC1 439 (type 10) 788 340 1128 621 —

2 NSC2 439 (type 10) 788 340 1128 621 —

3 HSC1 500 (type 30) 440 330 330 1100 700 —

4 HFC1 500 (type 10) 1100 1100 700 45

Table 1. Batch quantities for concrete mix.

Batch Silica fume Fly ash (kg/m3) Water (kg/m3) Water/cement ratio Compressive strength (MPa)

Superplasticizer Retarding admixture 28 day Test day

1 — — 161 0.37 Mighty 150 Master Builders 100 XR 43.0 42.7

2 — — 161 0.37 Mighty 150 Master Builders 100 XR 35.9 38.2

3 30 — 135 0.25 Mighty 150 None 90.5 82.2 4 50 — 140 0.26 Daracem 100 Daratard 17 90.1 98.1 Table 1 (concluded). 1200 1000 800 600 400 200 0 0 20 40 60

Standard Furnace Temperature

column surface 33 mm depth 98 mm depth Column NSC2 Column HSC1 80 100 120 140 160 Time (min) T emperature ( C) o

300°C. The corresponding temperature at the centre of the concrete core for the high strength concrete-filled column, HSC1, was about 100°C. This variation in core temperature at the failure of the columns can be attributed to the differ-ences in mechanical properties of the normal strength and high strength concrete.

For both columns, the reduction in the compressive strength of the concrete with temperature, together with cracking in the concrete core, contributed to failure. How-ever, this reduction in strength with temperature starts only after about 300–350°C for normal strength concrete. In the case of high strength concrete, the reduction in compressive strength with temperature is significant even at temperatures around 200°C and excessive cracking occurs in the concrete core. Hence, the column has a lower fire-resistance rating.

The variation in axial deformation with time for columns NSC2 and HSC1 is shown in Fig. 5. As expected, both col-umns expand, in the initial stages, with the expansion of the steel section and then contract, leading to failure. The defor-mation results from several factors such as load, thermal ex-pansion, water vapour pressure in concrete, and creep. While the effect of load, water vapour pressure, and thermal expan-sion is significant in the early stages, the effect of creep be-comes pronounced in the later stages.

The results shown in Fig. 5 indicate that the deformation behaviour is influenced by the strength of concrete inside the HSS section. For column NSC2, the failure is by gradual contraction, whereas for column HSC1 it is by sudden con-traction. This can be attributed to the brittle nature of high strength concrete.

In Table 2, a comparison of the fire-resistance values for the columns is shown. The fire resistance (48 min) of the high strength concrete-filled steel column (HSC1) is much less than the fire resistance (144 min) of the normal strength concrete-filled column (NSC2).

Behaviour of fibre-reinforced high strength concrete

The fire-resistance behaviour of high strength concrete can be improved by adding steel fibres to the concrete mix. The time–temperature curves for a normal strength concrete-filled steel column (NSC1) and a fibre-reinforced high strength concrete-filled steel column (HFC1) are shown in Fig. 6 at various concrete depths. The temperatures follow similar trends in both concrete cores. However, at the centre of the column, the temperature in column NSC1 is slightly less than that for HFC1.

The failure of column NSC1 occurs when the temperature near the centre reaches about 350°C, whereas the failure in column HFC1 does not occur until the temperature reaches about 600°C. This can be attributed to the superior mechani-cal properties of steel-fibre-reinforced concrete. There is very little information on the properties of fibre-reinforced high strength concrete, however, studies on steel-fibre-reinforced normal strength concrete have shown that the compressive strength increases with temperature up to about 400°C (Lie and Kodur 1996b).

The improved performance in column HFC1 can further be seen in Fig. 7, which shows the axial deformation as a function of time for columns NSC1 and HFC1. The defor-mation behaviour of the fibre-reinforced high strength

con-30 20 Column NSC2 Column HSC1 10 0 0 20 40 60 80 100 120 140 160 180 200 Time (min) Axial deformation (mm) -10 -20 -30 -40 -50

Fig. 5. Axial deformation of columns NSC2 and HSC1 as a function of exposure time.

Size of HSS (mm)

Factored resistance (kN) Test load

C (kN)

Load intensity Fire resistance (min) Column Cr′ Crc C/Cr′ C/Crc NSC1 219.1×4.78 699 1551 560 0.80 0.36 108 NSC2 273.1×6.35 947 2689 712 0.75 0.26 144 HSC1 273.1×6.35 2291 4023 1050 0.46 0.26 48 HFC1 219.1×4.78 1184 2032 600 0.50 0.30 174

© 1998 NRC Canada

980 Can. J. Civ. Eng. Vol. 25, 1998

1200 1000 800 600 400 200 0 0 20 40 60

Standard Furnace Temperature

column surface 26 mm depth 105 mm depth (centre) Column NSC1 Column HFC1 80 100 120 140 160 180 Time (min) T emperature ( C) o

Fig. 6. Temperature at various depths for columns NSC1 and HFC1 as a function of exposure time.

30 20 Column NSC1 Column HFC1 10 0 0 20 40 60 80 100 120 140 160 180 200 Time (min) Axial deformation (mm) -10 -20 -30 -40 -50

Fig. 7. Axial deformation of columns NSC1 and HFC1 as a function of exposure time.

NSC2 NSC1 0 50 100 Time (min) 200 150

High strength concrete Plain concrete

High strength fibre reinforced concrete HSC1

HFC1

crete-filled steel column, HFC1, is similar, during the early stages of the test, to that of the normal strength concrete-filled steel column NSC1. At the later stages, column HFC1 performs better than column NSC1, since the presence of steel fibres enhanced the ductility of column HFC1. Al-though the lower load intensity on column HFC1 contrib-uted to an increased fire resistance to some extent, much of the contribution is from the presence of steel fibres in the high strength concrete.

The fire-resistance values of normal strength, high strength, and high strength fibre-reinforced concrete-filled columns are compared in Fig. 8. The variation in fire resis-tance from one column to another can be attributed to the different types of concrete filling in the columns. The fire resistance of the high strength fibre-reinforced concrete-filled columns is much higher than that of all other columns tested. This indicates that, for high strength concrete appli-cations, adequate fire resistance can be obtained by adding fibre reinforcement to concrete.

By adding fibres, the load-carrying capacity of the mem-ber also increases to a certain degree. The additional cost in the case of fibre-reinforced concrete-filled columns, over the cost of concrete, is the cost of the steel fibres. Since there are no additional fire-protection costs for the steel, this can offer an economical solution for obtaining a required fire-resistance rating where fire fire-resistance governs the design.

The main objective of the experimental studies, such as those described above, is to generate fire-resistance data for immediate use by the construction industry. These studies also provide information for the development of general methods of calculating fire resistance of concrete-filled steel columns.

Experimental and theoretical studies have been completed for normal strength concrete-filled steel columns, and com-puter programs (Lie 1994; Kodur and Lie 1996) have been developed for predicting the fire resistance of these columns. At present, work is at an advanced stage in the development of material properties, namely thermal, mechanical, and de-formation properties, for high strength concrete and steel-fibre-reinforced high strength concrete. These properties will be incorporated into the existing computer programs and the programs will be upgraded by incorporating other factors that influence the behaviour of high strength concrete-filled HSS columns.

These computer programs will be used to develop design equations which can be used in the normal course of struc-tural design. A designer can arrive at a desired fire-resistance value by varying different parameters. The use of computer programs can lead to an optimum design that is not only economical but also based on rational design prin-ciples.

Based on the information presented, the following conclu-sions can be drawn:

(1) Concrete filling offers an attractive alternative for pro-ducing fire resistance in HSS columns.

(2) The behaviour of high strength concrete-filled steel col-umns is significantly different from that of normal strength concrete-filled HSS columns.

(3) The fire-resistance rating of high strength concrete-filled HSS columns can be significantly improved by adding steel fibre reinforcement to concrete.

ASTM. 1990. Standard methods of fire tests on building construc-tion and materials. Standard ASTM E119-88, American Society for Testing and Materials, Philadelphia, Pa.

Chabot, M., and Lie, T.T. 1992. Experimental studies on the fire resistance of hollow steel columns filled with bar-reinforced concrete. Institute for Research in Construction, National Re-search Council of Canada, Ottawa, Ont., IRC Internal Report No. 628.

CSA. 1989. Limit states design of steel structures. Standard CAN/CSA-S16.1-M89, Canadian Standards Association, Rexdale, Ont.

Kodur, V.K.R. 1998. Design equations for evaluating fire resis-tance of SFRC-filled steel columns. ASCE Journal of Structural Engineering, 124(6): 671–677.

Kodur, V.K.R., and Lie, T.T. 1995a. Fire performance of concrete-filled hollow steel columns. Journal of Fire Protection Engi-neering, 7(3): 89–98.

Kodur, V.K.R., and Lie, T.T. 1995b. Experimental studies on the fire resistance of circular hollow steel columns filled with steel-fibre-reinforced concrete. Institute for Research in Construction, National Research Council, Ottawa, Ont., IRC Internal Report No. 691.

Kodur, V.K.R., and Lie, T.T. 1996. Fire resistance of circular steel columns filled with fibre-reinforced concrete. ASCE Journal of Structural Engineering, 122(7): 776–782.

Lie, T.T. 1980. New facility to determine fire resistance of col-umns. Canadian Journal of Civil Engineering, 7(3): 551–558. Lie, T.T. 1994. Fire resistance of circular steel columns filled with

bar-reinforced concrete. ASCE Journal of Structural Engi-neering, 120(5): 1489–1509.

Lie, T.T., and Chabot, M. 1992. Experimental studies on the fire resistance of hollow steel columns filled with plain concrete. In-stitute for Research in Construction, National Research Council of Canada, Ottawa, Ont., IRC Internal Report No. 611. Lie, T.T., and Kodur, V.K.R. 1996a. Fire resistance of steel

col-umns filled with bar-reinforced concrete. ASCE Journal of Structural Engineering, 121(1): 30–36.

Lie, T.T., and Kodur, V.K.R. 1996b. Thermal and mechanical prop-erties of steel-fibre-reinforced concrete at elevated temperatures. Canadian Journal of Civil Engineering, 23(2): 511–517. Phan, L.T. 1996. Fire performance of high-strength concrete: a

re-port of the state-of-the-art. National Institute of Standards and Technology, Gaithersburg, Md.

Prion, H.G.L., and Baraka, M. 1994. Thin-walled tubes filled with high strength concrete. Canadian Journal of Civil Engineering, 21(1): 207–218.

ULC. 1989. Standard methods of fire endurance tests of building construction and materials. Standard CAN/ULC-S101-M89, Un-derwriters’ Laboratories of Canada, Scarborough, Ont.