Publisher’s version / Version de l'éditeur:

Materials Research and Standards, 3, 4, pp. 293-295, 1963-04

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Comparison of two spark-gap testers for asphalt films

Jones, P. M.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=62b908f3-42d1-4045-9af1-ffaf1cfa2742

https://publications-cnrc.canada.ca/fra/voir/objet/?id=62b908f3-42d1-4045-9af1-ffaf1cfa2742

N21r2

no.

184

c .2

BLDG

Ag

&%VzgD

Comparison of Two Spark-Gap Testers

for Asphalt Films

By

P.

M. JONESRESEARCH PAPER NO. 164 of the

DIVISION OF BUILDING RESEARCH

NATIONAL RESEARCH COUNCIL

Canada

Autbrized Reprint from the Copyrighted Materials Research & Standards, Vol. 3, No. 4

Published by the

American Society for Testing and Materials

1963 NRC 7087

Comparison of Two Spark-Gap Testers for

Asphalt Films

By P.

M.

JONES( N ANY S ~ U D Y of the physical degradation of asphalt coatings during natural or accelerated meatlier- ing tests, some means of detecting and recording failures must be available. IClectrometric methods suggested by Strieter (1)' and later modified by Weet- man (2) were the first attempts to augment visual esaminations. This procedure mas improved by the spark- gap tester described by 13oenau and Baum (3). Together with a method of evaluating failure by the plioto- graphic technique of Hunter, Gzemski, and Laskaris ( 4 ) , these comprise the tentative ASTM Method of 'Sest

D 1670-59 T ?

NRC I n s t r u m e n t

Several years ago, before AS'I'AI hiIethod D 1670 mas published, attempts were made a t the National Research Council of Canada t o co~lstruct a spark- gap tester. Some of the specified con]- ponents were not readily available, and attempts were made t o construct a n apparatus witli other materials. Sev- eral difficulties mere encountered, so t h a t it was not possible t o acliiel-e the specified values of voltage and current. The metal chassis caused breakdown of the resistors, and no relinl~lc means of

N O T G D I S C U S S I O N O F T I I I S PAL'Zlt I S I N V I T E D , e ~ t h e r for puhlicat~on or for t h e attention of t h e author or authors. Ad- dress all communications to ASTM Head- quarters. 1916 Race St., Philadelphia 3, Pa.

1 T h e boldface numbers in p a r c ~ ~ t l ~ e s c s

rcfer t o tlie list of references appcnd~btl to this paper.

2 11STh1 AIetl~od of Test for Fnllure End-

point in A c c t ~ l ~ ~ r i i t e d a n d Outdoor Wc:~ther- i r ~ x of Biturrli~ious Jlaterials (D 1G70 - 50 T ) . 1SG1 Book of .\STAT St:~lidards, P a r t 4, B. 1327.

A comparison of a lllore sophisticated spark-gap tester with the one specified in the ASTM Method of Test for Failure Endpoint in Accelerated a l d Outdoor Weathering of Bituminous Materials ( D 1670) shows that the latter instrument requires no further complication.

The probe unit is s l ~ o w n before t h e plioto- gragliic paper is placcd on t h e asgl~illt pallel t o record t h e failure detected by t l ~ c p r o b c s wlrcll the>, passovcl. the panel.

Fig. 1.-NRC spark-gap apparatus.

nicasuring tlie voltage was available. A

compronlise was reached in a n apparatus t h a t operated a t t h e specified current and a t the highest voltage possible mith- out causing breakdown by internal shorting. This particular arrangement,

however, resulted in some burning of t h e asphalt during the test. Since these espcriences cast some doubt on t h e suitability of the design, an apparatus was constructed to operate o n slightly different principles. A comparison of this new N R C design with a l)roperly constructed al)paratus as specified in the present ASTM method confirms t h e adequacy of t h e ASThI stnnc1:ircl appara- tus.

The following features ucrc included

in the N R C instrument:

1. X more even n,aveforn~ than t h a t produced by t h e automobile coil in t h e convcl~tional apparatus;

2. A spark having a very low current,

SO as t o eliminate any burning of the asphalt;

3. A constallt high voltage;

4. A niultiple-segment probe unit rather than a single probe.

The single probe detects only one fail- ure and could miss one or more failure 11oints when detecting a stronger one. The multiple probe unit has 9 segments, each isolated from the others by a 1- lllegolln~ resistor. The probes are G:

in. long. Since the ASTM h~lethod specifies a lucite counting grid having ,+-in. squares with only one flaw in each square required for failure, it was P. M. JONES is a graduate of the University of London, where he received a B.Sc. in 1956. H e joined the staff of the Division of Building Research of the National Research Council of Canada in 1957 and has been engaged in physical and chemical studies on the performance and degradation of bitumi- nous r o o h g materials.

April

7

963

HAMMOND

$

~

~

.05,uf~

~

"

VARIAC PULSE-

5 0 0 0 VDC TRANS. TYPE I 0 * 2 3 2 2 5 HIGH VOLTAGE TO PROBE UNIT HAMMOND 115 VACFig. 2.-Electrical circuit diagram for NRC spark-gap apparatus.

tliouglit tliat the accuracy of the ~nc~tliocl would be considerably iml)roved. The

NRC

probe unit is sl~olvn in Fig. I . l'hc circuit diagram is shown in Fig. 2.A filanlent transformer a t the lower left-hand side has its primary winding connectecl to the 110-v 60-cycle line. The secondary \vincling feeds a phase- shift netnrork tliat consists essentially of n resistance in series vvitll a capacitance. 13y varying the resistance a phase shift of approsimately -180 cleg can be protluced a t the junction of the resist- ance and capacitance. The voltage is constant a t this point and is fed through a 470,000-ohin grid-limiting resistor to the first grid of a 12AX7 tube. Grid- limiting action clips a portion of the positive-going grid voltage. The out- put a t this stage is fed to the second half of the 12AX7, which is operated a t zero bias. There is sufficieut grid swing to produce cut-off, and the resulting plate voltage is a square wave. A 100 ppf capacitor and a 100,000-ohm resistor differentiates the square wave and feeds a 12AU7 cathode follower. The posi- tive-going pulse provides trigger for a thyratron tube (type 3C 45).

This thyratron tube is supplied with a sinusoidal plate voltage from a high- voltage tmnsformer through a choke

coil. Load oli the tlijratro~i is the primary of a pulse transforiner connected to the plate through a 0.05 pf capacitor and n 100 pI-I coil. Across the primary of the pulse transforll~er n IN1130 silicon diode is placcd to eliminate any of the positive pulses.

By controlling the pllase shift, the thyratron is triggered rvhcn tlie plate voltage reaches a n~asimum. With each trigger pulse on the thyratron the 0.05 pf condenser is discharged througl~

is controlled 113 the variable tap on t h e 1)rimary of tlie high-voltage transformer. In the oper:~tion of the equipment t h e line voltage is set a t 120 v and the high- voltage transformer is adjusted to pro- duce an outlrut voltage of 12,000 v. The voltage m v e lasts for about 2 psec and the peak current during this time is 12 milliamp. As this peak current lasts for only 2 pscc and recurs 60 times per second, the average current is 1.4 the primary of the pulse transformer and

a single high-voltage ~ ~ u l s e

-

-

-

- is ~>roduced ASTM Instrumenton the secondary. After ASTM Method D 1670-59 T

The magnit~ide of this output pulse nras issued, the components for the tcst-

TABLE I.-CHAItACTERISTICS O F ASPHALTS.

Softening Specific Flash

Point,a Penetration6 a t Gravityc Duc- P ~ i n t . ~ Asphalt Description deg Fahr 32 F 77 F 115 F a t 77 P tilityd deg Fahr

No. 1 . . .South Americari 217.6 1 3 . 7 18.8 29.7 1.0184 2 . 5 505 No. 2 . . .Western Canadian blend 230.9 1 2 . 0 14.7 26.5 1.0268 1 . 5 530 No. 3 . . . Westcrn Canadian blend 221.2 1 2 . 2 15.3 26.2 1.0180 1 . 6 540 a ASTM D 36 - 26, Test for Softening Poirlt of Bituminous AIaterials.

6 ASTM D 5

-

59T. Penetration of Bituminous Materials.ASTM D 71 - 52, Test for Specific Gravity of Asphalts and Tar Pitches.

' I ASTM D 113 - 44, Test for Ductility of Bituminous Materials. i S T N D 92

-

57. Test for Flash Point by Clevelaild Open Cup.ing apparatus and the ineasuring appara- tus became available. A plastic lam- inate chassis eliminated some of the breakdown problems, and with an elec- trostatic voltmeter it was possible t o measure and t o adjust tlle voltage. The ASTM apparatus was adjusted t o give a n output of 8000 v and 180 pamp.

A comparison of the two testers was nlade to answer the following cluestions: 1. Does tlle high current of the ASTM apparatus produce burning?

2. Does the single probe give in- :~c*curatc results?

3. Does the lower voltage selected for the ASTM tester result in different values for asphalt durability?

Testing

T o colnparc: results from the two instruments, asphalt panels were sub- jected t o a n accelerated weathering test. Three asphalts were exposed as films 2 t by 54 in. by 25 mils tliick on 22 by 6-in. aluminum sheet. These asphalts and their measured physical characteristics are listed in Table

I.

T h e l~anels were prepared by the hy- draulic press method (5). Glass fabric coated with Teflon was used instead of the specified destrin-coated paper t o prevent adhesion of the aspllalt t o the press. Four sets of panels of each asphalt were prepared. T h e first set was tested with the conventional ASTM instru- ment; the second set was tested with the modifiecl or N R C instrument; the third set was first tested with t h e N R C instrument and then with tlle ASTM instrument; and the fourtll set was tested with the ASTM instrument and then with theNRC

instrument. Each set consisted of four individual panels exposed in the same single-arc Weather- Ometer a t different times (6). The Weather-Onleter was operated in accord- ance with ASTM Method D 529 - 59 T 3 using cycle A. Since it was not possible t o cool the deionized water, a water temperature of 55 F was used.During exposure the specimens mere rotated in accordance with the rotation plan in ASTlM lMethod D 529 - 59 T and tested every 5 cycles. The failures mere counted on the spark photographs using a 260-square grid.

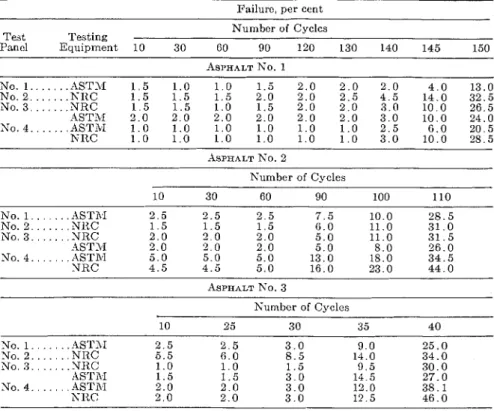

T h e results for certain selected nun]- bers of cycles are given in Table 11 and the numbers of cycles t o procluce 10 per cent failure of the asphalts are sum- marized in Table 111.

Conclusion

The two testers gave similar values for a n arbitrary failure point when this point was for extensive areas of failure.

3 ASThI Recommended Practice for Ac-

celerated Weathering Test of Bituminous i\lnteri,zls ( D 529 - 59 T ) , 1961 Book of tlSThI Stai~dards, P a r t 4. p. 1233.

TABLE 11.-EI?I:I<CT O I ~ TESTIXG P I ~ O C E D U I ~ E ON I ~ E C O I ~ D E D PEI~CENTAGE

FAILUItE O F ASPIIALTS. Failurc, per cent Numbcr of Cycles Test Testing Panel E n u i ~ m c n t 10 30 60 90 120 130 140 145 150 NRC 1 . 0 1 . 0 1 . 0 1 . 0 1 . 0 1 . 0 3 . 0 1 0 . 0 2 8 . 5 Numbcr of Cvcles KO. 1 . . . . . . ..ASTkI 2 . 5 2 . 5 2 . 5 7 . 5 10.0 2 8 . 5 No. 2 . .

.

. . . . NltC 1 . 5 1 . 5 1 . 5 6 . 0 11.0 31 .O No. 3 . . . . h RC 2 . 0 2 . 0 2 . 0 5 . 0 11.0 3 1 . 5 ASTh.1 2.0 2 . 0 2.0 5 . 0 8 . 0 2 6 . 0 No. 4 . . . . ASTM 5 . 0 5 . 0 5.0 13.0 18.0 3 4 . 5 NRC 4 . 5 4 . 5 5.0 16.0 23.0 4 4 . 0 ASPIIALT No. 3 Number of Cycles No. 1 . . . . . . .ASTAI 2 . 5 2 . 5 3 . 0 9 . 0 25.0 No. 2 . . . . . NRC 6 . 5 6 . 0 8 . 5 11.0 34.0 No. 3 . . . . N l t C 1 . 0 1 . 0 1 . 5 9 . 5 3 0 . 0 ASTM 1 . 5 1 . 5 3 . 0 14.5 27.0 No. 4 . . . . ASTM 2 . 0 2 . 0 3 . 0 12.0 3 8 . 1 NItC: 2 . 0 2 . 0 3 . 0 1 ? . 5 4 6 . 0N o evidence was found of asphalt burn- ing by the higher current of the ASTM tester. The multiple-probe unit detects more failures in initial exposure, but differences are small when a 10 per cent failure point is used. The NRC tester indicates slightly more failures, but this does not result in any appreci- able lowering of the durability rating. The refinenlents in the electrical per- formance of t h e N R C apparatus are achieved nt the espense of an increased number of con~ponents and much more complicated circuitry. They do not lead t o any marked inlproveillent over the results obtained with the much simpler ASTM a p p a r n t ~ ~ s .

Acknowledg?nent:

The help of K. d y u k a w a of the Radio and Electrical Engineering Division in the design and construction of the modified apparatus is gratefully ac- knowledged. This paper is published with the approval of t h e Director of the Division of Building Research, Na- tional Research Council of Cannda.

REFERENCES

( 1 ) 0. G. Stricter, "Propascd Method for Accelcrated Weathering of Bitu~ninous Materials," Proceedings, Am. Soc. Testing Mats., Vol. 33, Part 11, 1). 381 (1933).

( 2 ) B. Weetman, "Accelerated Weather- ing of Bit~iininous ilIaterials: Effect of Operating Variables," P7~oceedrngs, An]. Soc. Testing Mats., Vol. 43, p. 1154 (1943).

(3) A. 11. Bocilari and L. A. 11. B:~unl, "The Desig11 and Application of R

Spark-Gap Instrument for Detecting Crack Failures of Asphalt Coztings During Weathering Tcsts," Sym- posium on Acce1er:tted Durability Testing of Bituminous Materials

ASTfiI Sl'P Aro. 94, Am. Sor. Testing Mats., pp. 153-1G1 (1949).

(4) J . B. Hunter, F. C. Gzemski, and L. Laskaris, "A Ncw Method for Evalu- ating Failure of Bituminous Materials Due to Weathering," Symposium on Accelerated Durability Testing of Bituminous Materials, ASl'M S T P

N o . 9L. Am. Soc. Testing Mats., - TIP. - - 144-150 (1949).

TABLE 111.-DURABILITY I N DAYS

(51-9 CYCLE) OF TI-IE ASPHALTS ( 5 ) S. H. Greenfelcl, "A 1Mcthod of P r o

10 P E R C E N T FAILURE LEVEL. ~arinrr

.

-

Uniform Films of Bitu1ninou.qAsp11,zlt Materials," ASTM BULI'ETIN, NO.

193, Oct., 1953, pp. 50-53. Test Testing No. No. No.

Panel Equipment 1 2 3 ( 6 ) S. H. Greenfeld, E. W. Mertens, and P. Mr. M. Jo1111, "A Statistical Study No. 1 . . . .ASTnlI 150 100 40

No. 2. . . N R C 145 100 35 of Weather-Omcter Data o n Coating-

No. 3 . . . N R C 150 100 40 Grade Asphalts," Symposium on Bi

ASTM 150 110 35 tuminous Waterproofing and Roofing

No. 4 . . . .ASTAI 150 90 35

NItC 150 90 35 Materials, ASTilI S2'P Aro. 680, An)

Soc. Testing Mats., pp. 29-37 (1959).