HAL Id: hal-02008617

https://hal.archives-ouvertes.fr/hal-02008617

Submitted on 5 Feb 2019HAL is a multi-disciplinary open access

archive for the deposit and dissemination of sci-entific research documents, whether they are pub-lished or not. The documents may come from teaching and research institutions in France or abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est destinée au dépôt et à la diffusion de documents scientifiques de niveau recherche, publiés ou non, émanant des établissements d’enseignement et de recherche français ou étrangers, des laboratoires publics ou privés.

Heterogeneous twinning during directional solidification

of multi-crystalline silicon

J. W. Jhang, Gabrielle Regula, Guillaume Reinhart, Nathalie

Mangelinck-Noël, C. W. Lan

To cite this version:

J. W. Jhang, Gabrielle Regula, Guillaume Reinhart, Nathalie Mangelinck-Noël, C. W. Lan. Heteroge-neous twinning during directional solidification of multi-crystalline silicon. Journal of Crystal Growth, Elsevier, 2019, 508, pp.42-49. �10.1016/j.jcrysgro.2018.12.005�. �hal-02008617�

1

Heterogeneous Twinning during directional solidification of multi-crystalline

silicon

J.W. Jhanga,G. Regulab, G. Reinhartb, N. Mangelinck-Noëlb, C.W. Lana*

a

Department of Chemical Engineering, National Taiwan University, Taipei, 10617,

Taiwan

b

Aix Marseille Univ, Université de Toulon, CNRS, IM2NP, Marseille, France

*Corresponding author: cwlan@ntu.edu.tw; Tel.: 886-2-2363-3917

2

Abstract

Heterogeneous twinning nucleation from the wall or gas interface during

directional solidification of silicon have been modelled, and further used to clarify the

details of twining observed in situ in X-ray synchrotron imaging experiments [1]. It is

found that the heterogeneous twinning from the wall/grains or wall/gas/grain

trijunctions requires much lower undercoolings leading to much higher twinning

probability. The lower attachment energy and the contact area are the key factors for

the heterogeneous nucleation of twins.

Keywords: A1. Twinning; A1. Heterogeneous; A1. Undercooling; A1. Facets; A1.

3

1. Introduction

Twin boundaries in silicon have attracted much attention in recent years due to

their significance in solar cells [1-3]. Most of the twin boundaries in silicon are issued

from 3 twin nucleation on {111} facets [4, 5], which has been studied extensively [6-9]. Among them, the in situ observations through synchrotron X-ray [1-2] have

revealed dynamic features of the twin formation from facets, as well as the defect

formation related to the twinning, during directional solidification of silicon slabs in a

boron nitride crucible. Nevertheless, the role of the crucible wall and of the gas phase

has not yet been understood during twinning. To understand the detailed nucleation

mechanisms, heterogeneous twin nucleation models are necessary.

Duffar and Nadri [10] were the first to extend the Voronkov model [11] to

study twinning during the growth of multi-crystalline silicon (mc-Si). Recently, Lin

and Lan [12] revised this model by considering the interaction between the nucleus

and the neighboring grain. With this modification, referred as Lin’s model, an

estimated undercooling of around 1 K for noticeable twining could be obtained which

is consistent with the literature reported values although slightly higher [13].

Nevertheless, this model showed that the interaction of the nucleus with the

neighboring grains was significant, and the grain boundary (GB) with the twinned

grain on the {111} growth facets was a crucial factor. In addition, Lin and Lan [12]

mentioned that most twin crystals nucleated from the facet-facet groove at the

trijunction (TJ), especially from the non-∑ GBs due to the larger undercooling in the

deeper groove. This model explained the nucleation and twinning mechanism at the

4

explain the more realistic situation of the three-grain tri-junctions (3GTJ) on the

interface during ingot growth, Jain et al. [14], further developed a three-dimensional

model, referred as Jain’s model. With the 3GTJ model, the twinning from certain

grains during mc-Si growth experiments [15] was correctly predicted. More

importantly, the required undercooling for twining was in the order of 0.3 K, which

was consistent with the measured value [2, 13].

In this paper, we extend Jain’s model [14] to the heterogeneous twinning. The

cases involving the wall/grains, wall/gas/grain, and gas/grain junctions are modeled

and discussed. The models are further used to explain the possible twinning locations

characterized during in situ X-ray synchrotron imaging experiments [1, 2]. The

detailed model developed is described in the next section. Section 3 is developed to

results and discussion, followed by conclusions in Section 4.

2. Heterogeneous twinning model

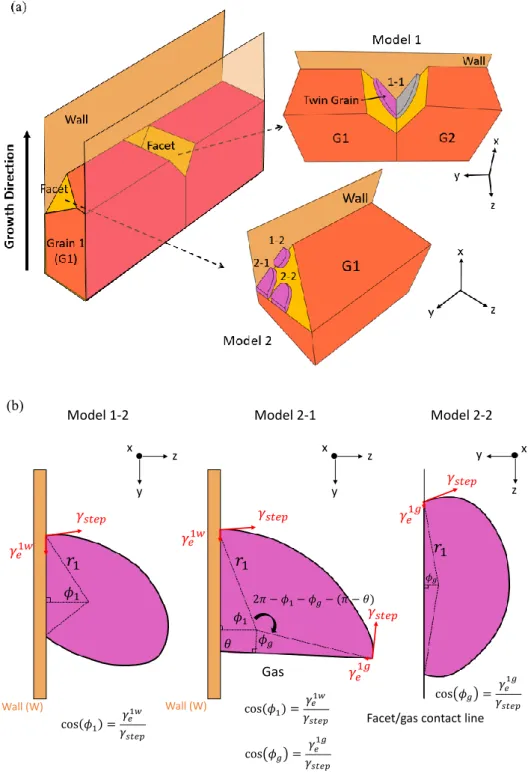

In general, there are several possible heterogeneous twinning situations during

directional solidification observed as well in experiments [1, 2], as summarized in Fig.

1(a), where the schematic of the slab growth is shown on the left figure. As shown,

model 1-1 considers two facets in contact with the crucible wall, so that there is a

wall/G1/G2 TJ and a GB exists between G1 and G2. This model is similar to Jain’s

model by replacing the third grain by the crucible wall. In model 1-2, there is only one

facet in contact with the wall, which occurs on the edge facet. Model 2 takes the gas

phase into consideration. Again, there are two cases for twin nucleation as shown in

5

considers the nucleation from the facet/gas contact line (model 2-2). The force

balances at the junctions for different models are described schematically in Fig. 1(b).

We first consider two facets in contact with the wall (model 1-1), as shown in

Fig. 2. The schematic of the facet and GB planes are shown in Fig. 2(a) and of a

nucleus viewed from the top in contact with the facet, as well as the force balances at

the junctions, are depicted in Fig. 2(b). Again, the nucleus is assumed to be a circular

disc on the facet, as in Jain’s model [14]. Therefore, the angles defined are based on

the view angle normal to the facet, or the angles are normal to the facet. As shown in

Fig. 2(a), each grain contributes with a {111} facet at the TJ, and the facets may not

have the same size. The GB plane is assumed to be parallel to the direction of

solidification, which is generally true for random angle GBs after grain competition

during growth [10]. In addition, the angle could be calculated from the normal vectors of the GB plane and the crucible wall. Again, for the convenience of the

discussion, we assume that the GB is normal to the wall, i.e., = 90o, without losing the generality. In Hurle’s model [16], the first criterion for a facet growth nucleus to

attach at the TJ is that the free energy associated with a step attaching the TJ needs

to be lower than the normal step free energy . Because in the model 1-1, there are

two steps from G1 and G2, the criterion for two steps anchoring at the TJ becomes

, which is similar to Lin’s and Jain’s models. The interaction between a

nucleus step coming from G1 or G2 and the surface of the wall, i.e., the facet-wall

groove, also needs to be considered. Hence, and could be calculated as

6 , (1 ) , (2 ) , (3 )

where is the GB energy. The superscript 1w or 2w indicates the junction between

G1 or G2 and the crucible wall. For silicon, is in the range of 0.45~0.5 J/m2 at

1473 K as reported in the experiments by Otsuki [17]; here we again pick 0.4842 J/m2,

which was a fitting parameter used previously [14]. Also, is the surface free

energy of a {111} plane, and according to Hurle [16] the value is 0.257 J/m2. In

addition, (0.324 nm) is the height of an atomic silicon layer in the direction.

Moreover, (0.473 J/m2) and (0.372 J/m2) are the surface energies at the

wall/solid and wall/melt interfaces, respectively. The facet angles and are the

angle between the facets and the GB plane as shown in Fig. 2(a); and are the

angle between the facets and the wall; the angle is usually not equal to unless

the GB plate is perpendicular to the wall. Once the growth direction is known, e.g., in

direction, in the reference coordinate, the facet angles can be easily

calculated. The grain orientations could be obtained from the Electron Backscatter

Diffraction (EBSD) data.

The next step is to calculate the free energy to create the critical nucleus. The

angle and in Fig. 2(b) can be determined by the force balances at the

7

area for the nucleus on the facet as shown in Fig. 2(c) can be calculated as explained

in [14]. In Fig. 2(c), the angles, normal to the facet, with the superscript prime

indicate they are defined at the top surface of the nuclei. Then, the free energy of

formation for the facet nucleus can be calculated as follows:

, (4) where (5) and . (6)

In Eq. (4), is the entropy of solidification ( J m-3 K-1) and is the

undercooling. and are the area of the surface steps and volume of the

truncated nucleus, respectively; is the area of the edge of the truncated nucleus

between the crucible wall and the nucleus i ( , and is the area of

the edge of the truncated nucleus between G1 and G2.

Figure 3(a) shows the plot of the Gibbs free energy required for the facet

nucleation for an undercooling of 2.8 K with the facet angle ; , and

; .The comparison is also made with Jain’s model [14]. As shown,

the radius of the critical nucleus and the energy barrier in model 1-1 are much smaller than that in Jain’s model. The main reason is that the additional contact energy with the wall ( is much smaller than , which eases nucleation. As a

consequence, the attaching energy in model 1-1 is lower.

8

taken into account, while the facet on G2 keeps the same orientation. Then, the free

energy of formation for a twinned nucleus can be written as:

,

(7)

where is the energy for forming a twin plane at the bottom of the nucleus on G1

and is the bottom contact area of the twin grain nucleus with the parent grain.

Other terms in Eq. (7) are the same as those in Eq. (4). For comparison purposes, we

utilize the twinning energy of 2 mJ/m2 as used in [14]. It should be mentioned that the

twin energy was predicted to be around 20 to 60 mJ/m2 at 0 K for silicon [18].

However, the value is most likely much smaller near the melting temperature (1683 K)

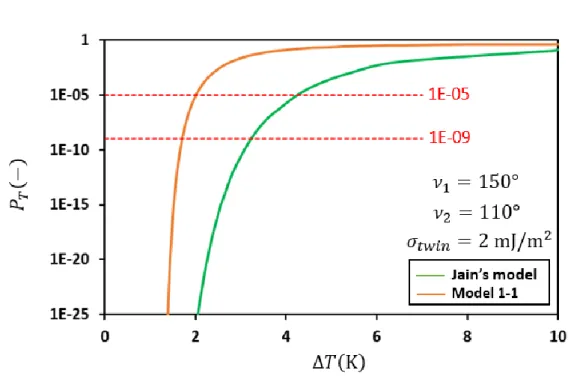

as the examples discussed in [14]. Moreover, the Gibbs free energy for twin

nucleation is plotted in Fig. 3(b). As shown, both the Gibbs free energy and the

critical radius for twin nucleation are higher than that for facet growth studied above. As compared with Jain’s model, the twin nucleation is easier because of the additional contribution from the wall. After the free energy barriers of formation for the faceted

and twinned nuclei are obtained, we can further calculate the twinning probability

according to [10] as: , (8)

where and are the free energy barriers for facet and twin nucleation,

respectively; is the Boltzmann constant. The twinning probability as a function of

the undercooling is shown in Fig. 3(c), where the probability based on Jain’s model is

9

higher than that in Jain’s model for all undercooling.

The effect of the facet angles ( and ) on the twinning probability has been

further studied and data are gathered in Fig. 4. As shown, with a larger facet angle, for

a given twinning probability, the required undercooling is smaller. Again, this is due

to the effect of the angle on the truncated volume and of the smaller . As

shown in Fig. 4, with and , the critical undercooling for frequent

twin nucleation ( is around in model 1-1, and this

undercooling is consistent with the value estimated from the experiments ( )

[13].

Model 1-2 is a simplified case of model 1-1, which is shown in Fig. 1(a) for

the facet at the edge. Because there is only one facet in contact with the wall, the free

energy associated with a step attaching the junction, the free energies of

formation for the faceted and twinned nucleus can be calculated as follows:

, (9) , (10) . (11)

Similarly, the twinning probability for different undercoolings could also be

calculated. For the same angle, e.g. =110o, the required undercooling for twining is

about 5 to 6 K for model 1-2 having a probability of 10-5 as compared to 2 K in model

1-1. Similarly for the same undercooling , the twinning probability increases as the

facet angle increases. Again, this is due to the smaller attaching energy and to the

10

Next we consider the wall/grain/gas trijunction (model 2-1) as presented in Fig.

1 for the facet at the edge. Similarly, the criterion for the occurrence of facets at the

junction is that the free energies and associated with a step attaching the

junction needs to be lower than the normal step free energy. Thus, the attaching

energies , , and the free energies of formation for the faceted and twinned

nuclei can be written as:

, (12) , (13) , and (14) , (15)

where the facet angle is the angle between the facet and the gas, and (0.604

J/m2) and (0.75 J/m2) are the gas/crystal and gas/melt interfacial energies,

respectively; and are the edge areas of the truncated nucleus on the wall

and gas sides, respectively. For =110o, =60o, and =50o

, the required

undercooling for twining is about 3.2 K for model 2-1 having a probability of 10-5 as

compared to 2 K in model 1-1; the contact angle is the angle between the crystal

edge and the wall. Similar to the previous cases, the twinning probability increases

with the increasing facet angles due to the lower attaching energy and to the lower

11

decreases, the twinning probability increases as a result of the lower contact area.

Model 2-2 is a simplified case of model 2-1, which considers the nucleation

from the facet/gas contact line as shown in Fig. 1. The free energy associated with

a step attaching the junction, the free energy of formation for the faceted and twinned

nucleus can be formulated as follows:

, (16) , (17) and . (18)

The twinning probability curves with the effect of the facet angle as a function

of the undercooling are similar to model 2.1, but the undercooling is about 1.5 K

higher for the similar angles, i.e., . Again, the higher facet angle leads to

the higher twinning probability due to the smaller attaching energy and lower

contact area.

3. Results and discussion

To validate our models, three cases from the experiments developed by the

IM2NP team [1, 2, 19] are selected for comparison. We first consider one experiment

of growth from a seed oriented <100> in the solidification direction and presented in

details in [2, 19]. The EBSD map of the final grain structure is shown in Fig. 5(a). For

this experiment, two cases labeled as Cases 1 and 2 are considered. The Case 1

12

shown by the in situ X-ray imaging during this experiments, the 3 twin grain (purple on the inverse pole figure EBSD map Fig. 5) nucleates on the {111} facet of

G1 in the grain boundary groove, instead of the one of G2. The enlarged figure of

Case 1 is shown in Fig. 5(b), while Case 2 in Fig. 5(c). The evolution of a typical

facetted/facetted groove at the solid-liquid interface during directional solidification

in the same experiment was described by Stamelou et al. [2]. With a sufficient

undercooling, a twin grain can nucleate on one of the facets. However, there are two

possibilities for this twinning: at the G1/G2 GB away from the wall or at the

G1/G2/wall TJ. For the former case, Lin’s 2D model [12] is a proper one to apply

because the bisector rule could be adopted for Case 1. However, for the latter, we

need to apply model 1-1. To predict the correct site for twin nucleation, we need to

compare the twinning probability of both models under the same undercooling.

The corresponding Euler angles of G1 (parent grain), G2 and twin grain

obtained from EBSD are listed in Table 1(a). The eight [111] vectors of each grain

could be obtained from its Euler angles, and so as the corresponding facet angles

and shown in Fig. 2(a). Again, we assume the GB angle to be in

the calculation, and the GB energy ( ) is chosen to be 0.48 J/m2 [12]. With the facet

angles and , the attaching energies could be calculated as described previously.

The corresponding facet angles and the attaching energy values associated with facet

1 and facet 2 of model 1-1 and 2D nucleation model are listed in Table 1(b) and (c),

respectively. It can be seen that for both facets of model 1-1, the attaching energy to

the nucleus/grains/wall TJ is negative and that for facet 1, it is slightly lower due to

13

twinned nucleus for both facets for model 1-1 are significantly lower than Lin’s 2D

model with the observed undercooling (T = 0.35 K), and the critical radius of the

twin nucleus is about 2.1 nm.

The energy barrier for the twining on facet 1 of model 1-1 turns out to be the

lowest; the barrier for facet 2 should be the same if the bisector rule is applied.

Accordingly, the twinning probability ( ) is the highest in the three situations.

The contact area and probability of twinning calculated by both models for Case 1 are

listed in Table 1(d). As shown, beside the probability, the corresponding contact area

of the nucleus on facet 1 is also the lowest one. Because the twin energy term is the

lowest, the twinning is more likely to occur at facet1/GB/wall TJ. On the contrary,

with the undercooling of 0.35 K, we could not find an energy barrier of twinning on

the facet based on Lin’s 2D model within a reasonable nucleus size, so that the

twinning is not likely. Therefore, we could conclude that for Case 1 the twinning on

facet 1 at the G1/GB/wall TJ is the most thermodynamically favorable at the

measured undercooling, and this is consistent with the experimental result.

For Case 2 in Fig. 5(c), the twin formation from both facets appear at

the edges of the solid-liquid interface. For this case, we focus on the twinning

phenomenon on the left hand side of the graph and test model 2-1 (facet/gas/wall TJ)

or model 2-2 (facet/gas contact line) for predicting the twinning probability. The

corresponding Euler angles of the parent (G1) and twin grains are also obtained from

EBSD data, as listed in Table 2(a). The corresponding facet angles could then be

calculated as presented in Table 2(b). We set the angle to be for model 2-1 for

14

the attaching energy values, contact area and twinning probabilities associated with

the {111} facet are calculated and listed in Table 2(c) and (d). It can be seen that the

facet of model 2-1 has a positive value, which would increase the energy barrier

of formation for a twinned nucleus, but the bottom contact area of the nucleus in

model 2-1 is much lower than that in model 2-2. In addition, the contribution of the

twin energy is also lower to the energy barrier of twinning on the facet in model 2-1.

As a result, the energy barrier for twinning from model 2-1 is slightly lower, but the

difference is quite small. The critical radius for twinning is 22 nm for model 2-1 and

23 nm for model 2-2 at an undercooling of 4 K. Thus, the twinning at the

facet/gas/wall TJ is more likely than that at the facet/gas contact line. The

undercooling in the model needs to be higher (4 K). In the experiments [2], the

undercooling at the edge is indeed higher than in the grain boundary grooves and this

is revealed by the larger facets observed. However, the measured values were always

lower than 1 K which implied that twin nucleation occurred before an undercooling of

4 K was reached. It could also mean that an additional mechanism eases nucleation as

the presence of defects on the {111} facet such as dislocations and/or the presence of

impurities.

The last case is shown in Fig. 6, where the EBSD map in Fig. 6(a) is from [1]

and the area inside the box is labeled as Case 3 in the following. The schematic of the

twin formation during crystal growth is illustrated in Fig. 6(b), where the twin grain

appears form the left and continues to grow to the right. For this case, the twin could

nucleate from facet/wall contact line (model 1-2) or from facet/gas/wall TJ (model

15

also obtained by EBSD and summarized in Table 3(a) and the calculated facet angles

for both models are listed in Table 3(b); the angle in model 2-1 is assumed to be

in the calculation.

The attaching energy values, contact area and twinning probability associated

with the facet in both models are listed in Table 3(c) and (d). It can be seen that model

2-1 has a negative attaching energy, which would help to decrease the energy barrier

for twinning. In addition, the bottom contact area of the nuclei in model 2-1 is lower

than that in model 1-2, so that the contribution of twin energy is also lower to the

nucleation barrier in model 2-1. The energy barrier for the twin nucleation from the

facet/gas/wall TJ (model 2-1) is indeed lower than that from the facet/gas junction

(model 2-2); the undercooling is set at 2.6 K. The critical radius for twining is 47 nm

at the facet/gas/wall TJ, which is only half of that at the facet/gas contact line. The

twinning probability in Table 3(d) further indicates that the twinning from the

facet/gas/wall TJ is more favorable as also demonstrated for the same situation in Fig.

5.

4. Conclusions

In this study, the 3GTJ model proposed by Jain et al. [14] is extended to the

heterogeneous twinning considering the wall and gas boundaries; the models are

developed for the wall/grains/GB, wall/grain, wall/gas/grain, and gas/grain TJs. It is

observed that the radius of critical truncated nucleus and the energy barrier in model

1-1 (wall/G1/G2 TJ) are much smaller than that in Jain’s 3GTJ model. The models are

16

good agreement including the predicted undercooling. It is found that twin grain

nucleation probability is higher at the edge of the sample and/or at the crucible walls,

where the attaching energy and the bottom contact area of the twin nucleus tend to be

lower which is as well in nice agreement with what is generally observed during

directional solidification.

Acknowledgement

This work was supported by the Ministry of Science and Technology of Taiwan

for the group in Taiwan and by the French National Research Agency (ANR) with Project CrySaLID (No ANR-14-CE05-0046-01). The collaboration between both groups was sustained in both countries by the PhD ORCHID framework (project No

35898SB).

References

[1] M.G. Tsoutsouva, T. Riberi-Beridot, G. Regula, G. Reinhart, J. Baruchel, F. Guittonneau, L. Barrallier, N. Mangelinck-Noel, In situ investigation of the structural defect generation and evolution during the directional solidification of < 110 > seeded growth Si, Acta Mater. 115 (2016) 210-223.

[2] V. Stamelou, M.G. Tsoutsouva, T. Riberi-Beridot, G. Reinhart, G. Regula, J. Baruchel, N. Mangelinck-Noel, {111} facet growth laws and grain competition during silicon crystallization, J. Cryst. Growth 479 (2017) 1-8.

[3] H.J. Moller, C. Funke, M. Rinio, S. Scholz, Multicrystalline silicon for solar cells, Thin Solid Films 487(1-2) (2005) 179-187.

[4] K. Nagashio, K. Kuribayashi, Growth mechanism of twin-related and twin-free facet Si dendrites, Acta Mater. 53(10) (2005) 3021-3029.

[5] C.I. Drowley, G.A. Reid, R. Hull, Model for facet and sidewall defect formation during selective epitaxial-growth of (001) silicon, Appl. Phys. Lett. 52(7) (1988) 546-548.

17

epitaxial regrowth rate from Si-implanted amorphous Si, Appl. Phys. Lett. 49(7) (1978) 3906-3911.

[7] C.W.T. Bulle-Lieuwma, A.H. van Ommen, L.J. van IJzendoorn, Microstructure of heteroepitaxial Si/CoSi2/Si formed by Co implantation into (100) and (111) Si,

Appl. Phys. Lett. 54(3) (1989) 244-246.

[8] A. Bourret, J.J. Bacmann, Atomic-structure of grain-boundaries in semiconductors Studied by electron-microscopy (analogy and differences with surfaces), Surf. Sci. 162(1-3) (1985) 495-509.

[9] A. Garg, W.A.T. Clark, J.P. Hirth, Dissociated and faceted large-angle coincident-site-lattice boundaries in silicon, Philos.. Mag A 59(3) (1989) 479-499.

[10] T. Duffar, A. Nadri, On the twinning occurrence in bulk semiconductor crystal growth, Scripta. Mater. 62(12) (2010) 955-960.

[11] V. V. Voronkov, Processes at the boundary of a crystallization front, Sov. Phys . Crystallogr. 19 (1975) 573-577.

[12] H.K. Lin, C.W. Lan, Revisiting the twinning mechanism in directional solidification of multi-crystalline silicon sheet, Acta Mater. 131 (2017) 1-10. [13] A. Tandjaoui, N. Mangelinck-Noel, G. Reinhart, B. Billia, T. Lafford, J.

Baruchel, Investigation of grain boundary grooves at the solid-liquid interface during directional solidification of multi-crystalline silicon: in situ characterization by X-ray imaging, J. Cryst. Growth 377 (2013) 203-211.

[14] T. Jain, H.K. Lin, C.W. Lan, Twinning mechanism at three-grain tri-junction during directional solidification of multi-crystalline silicon, Acta Mater. 144(Supplement C) (2018) 41-50.

[15] Y.T. Wong, C. Hsu, C.W. Lan, Development of grain structures of multi-crystalline silicon from randomly orientated seeds in directional solidification, J. Cryst. Growth 387 (2014) 10-15.

[16] D.T.J. Hurle, A Mechanism for Twin Formation during Czochralski and encapsulated vertical bridgman growth of III-V compound semiconductors, J. Cryst. Growth 147(3-4) (1995) 239-250.

[17] A. Otsuki, Energies of (001) twist grain boundaries in silicon, Acta Mater. 49(10) (2001) 1737-1745.

[18] R. Hull, INSPEC, Properties of crystalline silicon, INSPEC, the Institution of Electrical Engineers, 1999.

[19] Thècle Riberi-Béridot, In situ characterization by X-ray synchrotron imaging of the solidification of silicon for the photovoltaic applications: control of the grain structure and interaction with the defects and the impurities, PhD Thesis, Aix Marseille Univ (2017).

Table Captions:

Table 1 (a) The corresponding Euler angles of parent grain (G1), G2 and twin grain;

(b) the corresponding facet angles; (c) the attaching energy values associated

with both {111} facets for model 1-1 and for 2D nucleation model; (d) the

contact area ( ) and the probability of twinning calculated by model 1-1

and 2D nucleation model for Case 1.

Table 2 (a) The corresponding Euler angles of parent grain (G1) and twin grain; (b)

the corresponding facet angles; (c) the attaching energy values associated with

a {111} facet for models 2-1 and 2-2; (d) the contact area ( ) and

probability of twinning calculated by models 2-1 and 2-2 for Case 2.

Table 3 (a) The corresponding Euler angles of parent grain (G1) and twin grain; (b)

the corresponding facet angles; (c) the attaching energy values associated with

a {111} facet for models 1-2 and 2-1; (d) the contact area ( ) and

probability of twinning calculated by models 1-2 and 2-1 for Case 3.

Table 1 (a) The corresponding Euler angles of parent grain (G1), G2 and twin grain;

(b) the corresponding facet angles; (c) the attaching energy values associated with

both {111} facets for model 1-1 and for 2D nucleation model; (d) the contact area

( ) and the probability of twinning calculated by model 1-1 and 2D nucleation

model for Case 1.

(a)

Euler angles Parent Grain (G1) G2 Twin Grain (b) Model Model 1-1 Facet 1 Model 1-1 Facet 2 2D nucleation model (c) Model (J/m2) (J/m2) (J/m2) Model 1-1 Facet 1 Model 1-1 Facet 2 2D nucleation model (d) Model (nm2) Probability Model 1-1 Facet 1 Model 1-1 Facet 2 2D nucleation model Table 1

Table 2 (a) The corresponding Euler angles of parent grain (G1) and twin grain; (b)

the corresponding facet angles; (c) the attaching energy values associated with a

{111} facet for models 2-1 and s2-2; (d) the contact area ( ) and probability of

twinning calculated by models 2-1 and 2-2 for Case 2.

(a)

Euler angles Parent Grain (G1) Twin Grain (b) Model Model 2-1 Model 2-2 (c) Model (J/m2) (J/m2) Model 2-1 Model 2-2 (d) Model (nm2) Probability Model 2-1 Model 2-2 Table 2

Table 3 (a) The corresponding Euler angles of parent grain (G1) and twin grain; (b)

the corresponding facet angles; (c) the attaching energy values associated with a

{111} facet for models 1-2 and 2-1; (d) the contact area ( ) and probability of

twinning calculated by models 1-2 and 2-1 for Case 3.

(a)

Euler angles Parent Grain (G1) Twin Grain (b) Model Model 1-2 Model 2-1 (c) Model (J/m2) (J/m2) Model 1-2 Model 2-1 (d) Model (nm2) Probability Model 1-2 Model 2-1 Table 3

Figure Captions:

Fig. 1 (a) Schematic of the possible heterogeneous twinning sites; (b) schematic for force balances at the TJ’s for model 1-2, model 2-1 and model 2-2.

Fig. 2 (a) The facet-facet/wall groove; (b) the top view of the nucleus and the force balances required at the TJ’s; (c) the final shape of the truncated nucleus on facet 1 for model 1-1. In Fig. 2(c), the angles, normal to the facet, with the

superscript prime indicate they are defined at the top surface of the nucleus.

Fig. 3 (a) Free energy of formation for a faceted nucleus with a facet angle

for an undercooling of 2.8 K in both models; J/m2;(b)

free energy of formation for a twinned nucleus with a facet angle

for an undercooling of 2.8 K in both models; J/m2 and

mJ/m2;(c) twinning probability at the facet angle as a

function of the undercooling at J/m2 and mJ/m2.

Fig. 4 Effect of the facet angles on the twinning probability as a function of the

undercooling for model 1-1 with 2 mJ/m2

.

Fig. 5 (a) EBSD IPF (Inverse Pole Figure) map along the growth direction of the

grain structure after growth from a seed oriented <100> from the experiment

described in details in [2, 19] ; (b) zoom in a region of twin nucleation

corresponding Case 1 (grain boundary groove); (c) zoom in a region of twin

nucleation corresponding Case 2 (edge {111} facet).

Fig. 6 (a) EBSD IPF (Inverse Pole Figure) map along the growth direction of the grain

structure after growth from a seed oriented <110> from the experiment

described in details in [1]. Twin grain growth from SLG TJ (Case 3); (b)

schematic showing the twin formation at the solid-liquid interface during

Fig. 1 (a) Schematic of the possible heterogeneous twinning sites; (b) schematic for force balances at the TJ’s for model 1-2, model 2-1 and model 2-2.

Fig. 2 (a) The facet-facet/wall groove; (b) the top view of the nucleus and the force balances required at the TJ’s; (c) the final shape of the truncated nucleus on facet 1 for model 1-1. In Fig. 2(c), the angles, normal to the facet, with the superscript prime

indicate they are defined at the top surface of the nucleus.

Fig. 3 (a) Free energy of formation for a faceted nucleus with a facet angle

for an undercooling of 2.8 K in both models; J/m2;(b)

free energy of formation for a twinned nucleus with a facet angle

for an undercooling of 2.8 K in both models; J/m2

and

mJ/m2;(c) twinning probability at the facet angle as a

function of the undercooling at J/m2 and

Fig. 4 Effect of the facet angles on the twinning probability as a function of the

undercooling for model 1-1 with 2 mJ/m2.

Fig. 5 (a) EBSD IPF (Inverse Pole Figure) map along the growth direction of the

grain structure after growth from a seed oriented <100> from the experiment

described in details in [2, 19] ; (b) zoom in a region of twin nucleation

corresponding Case 1 (grain boundary groove);(c) zoom in a region of twin

nucleation corresponding Case 2 (edge {111} facet).

Fig. 6 (a) EBSD IPF (Inverse Pole Figure) map along the growth direction of the grain

structure after growth from a seed oriented <110> from the experiment

described in details in [1]. Twin grain growth from SLG TJ (Case 3);(b)

schematic showing the twin formation at the solid-liquid interface during

directional solidification for Case 3.

![Fig. 6 (a) EBSD IPF (Inverse Pole Figure) map along the growth direction of the grain structure after growth from a seed oriented <110> from the experiment described in details in [1]](https://thumb-eu.123doks.com/thumbv2/123doknet/14666796.741005/31.892.191.698.217.606/inverse-figure-direction-structure-oriented-experiment-described-details.webp)