Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Institute for Research in Construction), 1990-08

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=03d91aeb-a365-4e40-9451-1e10644d6de9 https://publications-cnrc.canada.ca/fra/voir/objet/?id=03d91aeb-a365-4e40-9451-1e10644d6de9

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20375074

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire performance of external insulation system: observations made after the fire at 393 Kennedy Street, Winnipeg, Manitoba, January 10, 1990

L I B R A R Y

"

MAR 1

1993

B I B L ~ O X H E Q U E

Internal Report No. 596

Date of issue: Augsut 1990

This is an internal report of the Institute for Research in Construction. Although not intended for general distribution, it may be cited as a reference in other publications

INTRODUCTION

This report describes a fire that occurred at an apamnent building at 393 Kennedy Street, Winnipeg, Manitoba on January 10, 1990. The building was clad with an Exterior Insulation and Finish System (EIFS) which provides good thermal insulation and

protection from moisture at a relatively low cost, however, such systems are combustible.

1

Typically, an EIFS is a non-loadbearing exterior wall cladding system consisting of an insulation board attached with adhesive or mechanically fastened to a substrate, a base1 coat applied to the outer face of the insulating board, glass fibre reinforcing mesh embedded in the base coat and a decorative finish coat The insulation is usually plastic foam board containing flame retardants. The adhesive and the base coat often contain sand in a mixture of Portland Cement and a synthetic resin which acts as a binding agent The finish coat usually contains sand or aggregate and a synthetic resin

as

a binder.For the f m t time, the 1990 edition of the National Building Code of Canada (Nl3CC)l allows the limited use of combustible cladding, such as EIFS, on buildings required to be of noncombustible construction provided that the cladding passes the full- scale

fire

test prescribed by the Code and that the building does not pose an exposureproblem to an adjacent property. This full-scale test replicates a typical post-flashover fire venting through a window opening and exposing the wall above the window. The NBCC is a model code which the provinces may adopt or may modify to suit their specific needs. For that reason, some provinces may have different requirements regarding the use of combustible cladding assemblies.

THE BUILDING

The building, located at 393 Kennedy Street, was constructed in 1987 and is a 75 unit, 8-storey apamnent buildiing with an open-air parking garage located on the

Ground Floor (Figure 1). Three sides of the building face streets. The fourth side (north) faces the blank wall of an adjacent building. The parking garage is open on the east side and partially open on the north side as shown by the dashed line in Figure 1. The main entrance to the building is located on the west side, opposite the parking garage. There is a garage entrance door from the building in the south-west comer of the garage. A large (1 1 m wide by 8 m deep) canopyldeck covers the south-east access to the garage.

The building was not sprinklered except for the garbage chute and the garbage room. There were no fire detectors or sprinklers installed in the parking garage. A single- stage central fire alarm was installed in the building with the annunciator panel near the front entrance. The building is located within 3 blocks of the city's largest fire station.

The building's exterior walls were covered with an Exterior Insulation and Finish System. Plastic foam insulation of different thicknesses was used on different portions of the facade. The EIFS was applied to an exterior grade gypsum sheathing on a steel stud frame or on masonry. Most of the exterior walls of the building were also insulated with glass-fibre bats which filled the wall cavities between the steel studs. The foam insulation was typically 75 mm (3 in.) thick, except in limited areas where thicker foam (140 mm (5 112 in.)) was used to create architectural features. Figure 2 shows the east facade of the building with the shaded (dotted) areas indicating the locations where the thicker foam was applied. The north wall, located 3 m (10 ft) from the adjacent building, was constructed of masonry and insulated with the EIFS using the 140 mm (5 112 in.) thick foam. No

horizontal fire barriers (£ire stopping) were incorporated within the EIFS. It should be noted that this EIFS was installed on the building prior to the inclusion of the previously mentioned requirements in the 1990 edition of the NBC.

The parking garage located on the Ground Floor can accommodate 54 cars.

Additional parking space was located outside, adjacent to the east wall of the building. The floor above the garage was a two hour fire resistance-rated reinforced concrete slab. The reinforced concrete columns supporting the floor slab had a two hour fire resistance rating. A service space was created beneath this concrete slab by a suspended ceiling constructed of 16 mm (518 in.) thick gypsum board. Rigid foam insulation 65 mm (2 112 in.) thick was attached to the gypsum board from below and was covered on the garage side by an

a

aluminum soffit. THE FIRE

The fire occurred in the early morning of January 10,1990 which was a rather warm winter day in Winnipeg. At 5:00 a.m. the temperature at the airport was -3OC (27'F) and it was foggy with a light drizzle. The wind was from the south at 28 km/h (17 mph).

In the city, it was probably a few degrees warmer with a somewhat lower wind. The fust alarm came in to the fire department 5:07 a.m.. A second alarm was transmitted at 5 1 0 a.m.. Priority by responding units was given to life safety. The building occupants were safely evacuated through the main exit which was well separated from the garage (Figure 1).

The fire started in the garage and very quickly involved all 25 cars that were parked there at that time (Figure 3). The first row of cars, parked outside adjacent to the east wall of the building, was also involved in the fue (Figure 4).

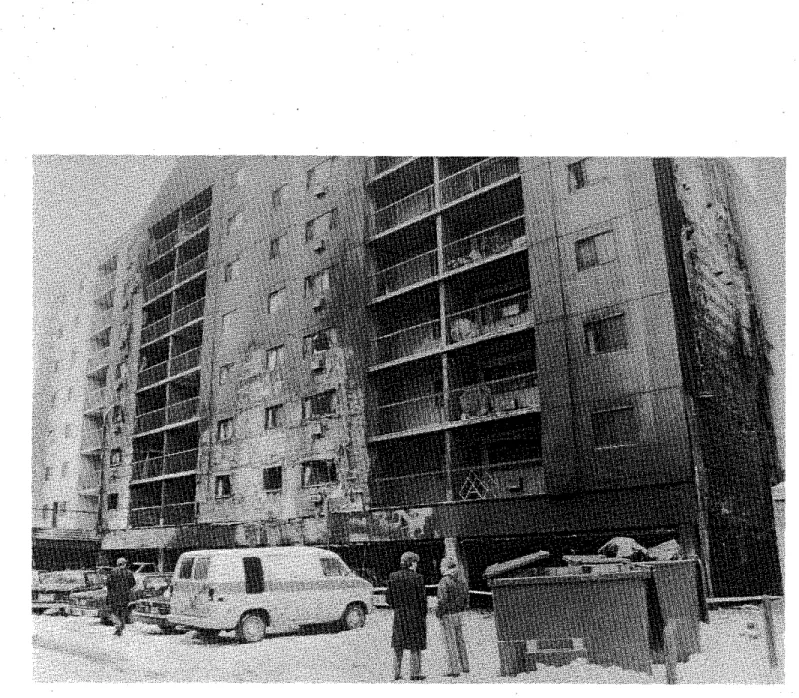

The flames issuing from the garage exposed and eventually ignited the EIFS on the exterior walls. The fm spread on the facade extended to the top of the fourth storey, except for a narrow strip on the east facade, where the f i e travelled up to the top of the seventh storey, and on the north facade where the f i e spread to the top of the wall. The extent of f i e spread on the north facade is shown in Figure 5.

The fire was extinguished quickly by the fire department using deluge and fog streams.

The damage caused by the fire included:

- smoke and water damage throughout the interior of the building. Smoke entered the building through penetrations in the floor slab above the parking garage, shattered window panes, damaged air conditioning units and kitchen and bathroom vents. - vehicles

-

the facade itself.-

-

the services located above the garage ceiling- the structural elements in the garage (mostly columns) ANALYSIS OF FIRE GROWTH

The rapid spread of fire throughout the parking garage can be, at least in part, attributed to the inadequate protection of the foamed plastic insulation board on the ceiling of the garage. This lightweight combustible thermoplastic insulation in the ceiling could have promoted fire spread in three ways:

- reducing heat loss to the ceiling thus allowing the initiating flames to stay hotter and extend farther horizontally than would be the case with a heat absorbing ceiling

- providing ignition sources to the cars, already preheated by the radiation from the flames at the ceiling, in the form of buming drops of molten plastic.

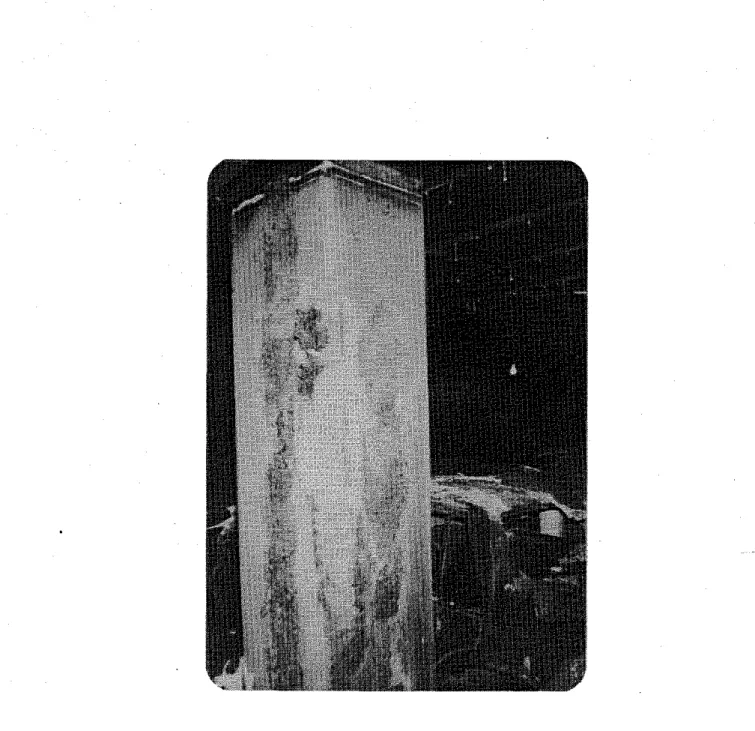

The damage to the concrete columns in the garage (Figure 6) indicates that the fire

in the garage was very intense and developed very rapidly. Spalling, such as shown in Figure 6, is normally caused by the high pressure of water vapour inside concrete. This pressure is created by rapid headng that produces water vapour inside concrete at a rate higher than that at which vapour can be released via the pores in the concrete.

EXPOSURETO THEFACADE

In the central section of the east facade (Figure 7), it can be estimated that the flames, originating in the garage, reached the third storey. This is based on the marks left on the noncombustible portion of the facade (concrete block wall separating balconies) and on the damage to the EIFS below the balcony window on the third storey, as indicated in Figure 7. ~ h ' l s particular area could not havd been dmaged by the flami propagation on the ElFS as it is isolated From the rest of the facade bv non-combustible elements of the facade. Similar estimates cannot be made for other &aged areas because of the possible combination of the effects of the exposing flames from the garage and the flame conmbuted by the EIFS.

One can speculate that the flames, issuing from the parldng garage extended to diierent heights depending on both location and the geometry of the facade. Four

distinctive areas are depicted in Figure 8. Figure 8 (a) shows the simplest geometry, a flat wall extending above the opening from the parking garage. In this area, flames were able to travel upwards without meeting any obstacles.

Figure 8 (b) shows the possible effect of the canopy which protected the facade above it. The space under the canopy also served as a reservoir for flames and unburned combustible gases that could escape laterally and enhance the flames issuing from the portion of the parking garage wall opening next to the canopy. Based on such effects by the canopy, one could expect a reduced fire exposure directiy above the canopy and an - increased exposure in the adjacent wall areas, especially on the downwind side (north) of - the canopy.

Figure 8 (c) shows a section through the portion of the facade with balconies. The balconies formed a series of obstacles to the spread of flames. Hence the extent of the flames should be less than on the flat wall (Figure 8 (a)).

Figure 8 (d) shows a section through the north facade of the building. The geometry is similar to that shown in Figure 8 (a) with the exception that another building was located within 3 m of the exposed facade. The two walls facing each other create a configuration that promotes upward flame spread as a result of enhanced heat feedback to the exposed wall. The exposure in this area was intensified even more by the south wind which would drive flames across the parking garage to the opening in the north wall.

PERFORMANCE OF THE EIFS

It should be noted that much of the information given in this section of the report was gained

from

a research project undertaken by the National Fire Laboratory of the Institute for Research in Construction. This research information was not available at the time of construction of the building in question.An exposure to intense heat causes various degrees of damage to an EIFS depending on the intensity and the duration of the exposure. The damage results from shrinkage and melting of the plastic foam, decomposition of binders and melting of the reinforcing glass fibre mesh. The thermal destruction of an EIFS is usually accompanied

by the combustion of gaseous hydrocarbons released by the decomposing organic components of the EIFS. A portion of the heat created by this combustion is fed back to the EIFS and helps in the further destruction of the system. The remaining heat is dispersed to the environment. In an extreme case, the heat feedback from the burning wall is

sufficient for destruction to continue, without any external heat exposure. This latter scenario would be expected to cause the fire to spread to the top of the wall, regardless of the height of the wall. The following factors influence whether this self-supported flame spread can occur:

-

the heating value of the EIFS per unit area. The higher the heating value per unit area the higher the potential heat feedback to the cladding.-

the resistance of the "sldn" of the EIFS to thermal assault. The higher the resistance the more heat is dispersed to the environment before the new fuel within the EIFS isexposed.

-

the thickness of plastic foam. Development of voids and channels in an insulating board, caused by the melting and shrinkage of the plastic foam when exposed to fire, is more l~kely to be an issue in a thick board than in a thin board since a deeper channel will be created in which the fire can spread2. Such channels made in the insulating board may promote fire spread behind the coating and cause additional exposure to the coating from inside of the cladding. A thicker foam is also likely to have a higher heating value per unit area- the presence of horizontal fire stops. Horizontal fire stops provide barriers against the upward convection of heat behind the coating and the flow of molten plastic down to the combustion zone.

-

geomeuy. The shape of the facade may either help to disperse heat to the environment or enhance heat feedback to the cladding. Intemal comers and vertical channels tend to increase heat feedback, while features disrupting vertical air movement along the wall, such as balconies, canopies and other horizontal projections, protect the cladding above these features from direct exposure to flames. Two parallel walls separated by a short distance constitute another configuration which enhances vertical fue spread because of enhanced upward movement of flames caused by the stack effect and the reradiation of heat to the involved wall from the adjacent wall.The damage to the EIFS in the 393 Kennedy Street fire was substantial, however, in most areas it was as would be expected considering the fire to which it was exposed3. There were two exceptions

-

a vertical strip on the east facade and the north facade. Both of these areas had 140 mm (5 112 in.) thick insulation board. In the NFL research previously mentioned, the thickest EIFS evaluated had 100 mm (4 in.) thick foam.However, there were other areas on the east facade where the thicker insulation board was applied and where fire spread was much less. The additional factors that could possibly contribute to the extensive fire spread in some areas, and not in others, were geometric factors. The north wall faced an adjacent building located 3 m away. The vertical strip on the east facade was located close to and downwind from the canopy. This area probably received a higher fue exposure than others. Such additional exposure could easily destroy the coating and force the fire into the thicker foam

CONCLUSIONS

This f i e has brought four major problems to light:

1. The potential severe fire hazard associated with an open parking garage that is not protected with any fire a l m or extinguishing system and exposing a building situated above it. A similar fire occurred in Richmond,.British Columbia, in 1983. Poorly protected combustible insulation on the ceiling of the parking garages was another common factor in these fires.

2 . EIFS are combustible and, as such, care must be taken in their design and installation to

assume that fire safety is a major factor. An assumption that passing a full-scale test provides equivalency to noncombustible cladding in all cases could be dangerous since it may lead to applications that were not envisaged by Code-writing bodies. These applications could result in greater fire spread than experienced in the tested

applications.

3. The basic characteristics of any field-applied system should be the same as those of a system tested for fire spread in a laboratory. Changing such characteristics as the foam thickness may change the fire performance of the system.

4. The installation of fire stopping every storey or every second storey should be seriously considered especially when using combustible EIFS on high-rise buildings. Such fire stops are strongly recommended by British researchers4>.

ACKNOWLEDGEMENTS

The author wishes to thank the following persons and organizations for their help in

collecting the information used in this report

M. J. Frye of The Department of Environmental Planning of The City of Winnipeg W. K. Rankin of Cooper Rankin Architects

W. W. Wilson of The F i Department of The City of Winnipeg D. W. C. Newton of The a c e of the Fire Commissioner of Manitoba F. Marriot, witness

Council of EIFS Indusmes Canada Prairie Masonry Institute

The author appreciates the financial support provided by the Canadian Construction Materials Centre and the Codes Section of IRC.

REFERENCES

1. National Building Code of Canada, National Research Council of Canada, 1990.

fl 2. Choi, K.K., Taylor,W., Combustibility of insulation in cavity walls, Journal of Fire

Sciences, Vo1..2, MayIJune 1984.

3. Oleszkiewicz,

I.,

F i e spread on building facades, presented at the International F i e Protection Engineering Institute - V, Ottawa, May 21-31, 1989.4. Rogowski, B.F.W., Ramaprasad, R., Southern, J.R., Fire performances of extemal thermal insulation for walls of multi-storey buildings, Building Research Establishment Report BR 135, Borehamwood, Hertfordshire, 1988.

5. Extemal walls: combustible extemal plastic insulation: horizontal fire barriers, Defect Action Sheet, DAS 131, Building Research Establishment

,

Watford, 1989.EAST

Figure 1. Ground floor plan

KENNEDY STREET MAIN ENTRANCE

v

I

E F

$ 5

N 57.7m

(190') A GARAGE ENTRANCEPARKING GARAGE

FOR 54 CARS

~ 1 1 1 1 1 1 - 1 1 1 1 1 1 1 1 1 - 1 I I 1 I I I I - 1 1 1 W-(103

I

I I I I I II CANOPY I I

OPEN PARKING

I

Figure 7. Central portion of the East facade. Arrow indicates damage to ElFS caused by exposure to flames issuing from parking garage