Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Laboratory Memorandum; no. LM-2004-11, 2004

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=c9dab33f-7d6b-4cb7-bfa1-9e6e8ae072cc

https://publications-cnrc.canada.ca/fra/voir/objet/?id=c9dab33f-7d6b-4cb7-bfa1-9e6e8ae072cc

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/8896237

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The Dynamic Response of Capacitance Wave Probes

National Research Council Canada Institute for Ocean Technology Conseil national de recherches Canada Institut des technologies oc ´eaniques

Laboratory Memorandum

LM-2004-11

The Dynamic Response of Capacitance Wave Probes

J. Wheeler

April 2004

DOCUMENTATION PAGE

REPORT NUMBER

LM-2004-11

NRC REPORT NUMBER DATE

April 23, 2004

REPORT SECURITY CLASSIFICATIONUnclassified

DISTRIBUTION

Unlimited

TITLETHE DYNAMIC RESPONSE OF CAPACITANCE WAVE PROBES

AUTHOR(S)

Justin Wheeler

CORPORATE AUTHOR(S)/PERFORMING AGENCY(S)

Institute for Ocean Technology, National Research Council, St. John’s, NL

PUBLICATIONSPONSORING AGENCY(S)

IMD PROJECT NUMBER NRC FILE NUMBER

KEY WORDS

Wave probe, capacitance, dynamic, response, static,

calibration

PAGES124

FIGS.16

TABLES2

SUMMARYThis report assesses the dynamic uncertainty in capacitance wave probe measurements

when calibrated and applied statically. It also proves which wave probe circuitry typically

produces the least error over the specified frequency and amplitude ranges.

The experiment was conducted using the Oceanic Corp. 3-Axis Linear Table Arrangement,

which required custom Visual Basic motor controller software and several custom Igor

procedures for run-generation and final data analysis.

Based on the final data analysis, the investigation shows that both the Branckner and

modified wave probe circuitries reported similar dynamic errors (about ± 3 mm) with offsets

close to zero, while the unmodified circuitry consistently showed greater errors with an

offset of 3 mm.

ADDRESS

National Research Council

Institute for Ocean Technology

P. O. Box 12093, Station 'A'

St. John's, Newfoundland, Canada

A1B 3T5

National Research Council Conseil national de recherches Canada Canada Institute for Ocean Institut des technologies Technology océaniques

THE DYNAMIC RESPONSE OF CAPACITANCE WAVE PROBES

LM-2004-11

Justin Wheeler

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Table of Contents

Table of Figures ... ii

Nomenclature... iii

1. Introduction... 1

2. Three-Axis Linear Table Arrangement... 2

2.1 – Visual Basic Motor Control Software... 3

2.2 – Igor Profile Generation & Analysis Software... 4

2.2.1 – Apparatus Limitations & Acceleration Analysis ... 6

2.2.1.1 – Manual Maximum Acceleration Calculation Methodology ... 7

2.2.1.2 – Methodology of Testing for Maximum Linear Acceleration ... 9

2.2.1.3 – Maximum Acceleration Discussion... 9

3. Data Analysis & Experimental Discussion... 11

3.1 – Igor Data Analysis Software... 11

3.2 – Discussion of Results... 12

4. Conclusions... 20

5. References... 21

Appendix A: Igor Plots of Experimental Data... 22

Appendix B: Motor Controller Source Code ... 40

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Table of Figures

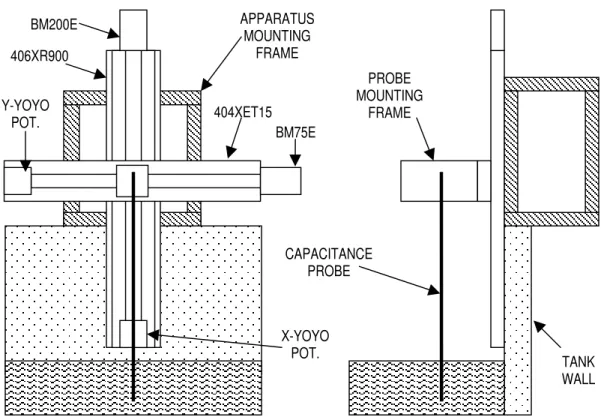

Figure 1 – 3-Axis Linear Table Arrangement schematic... 2

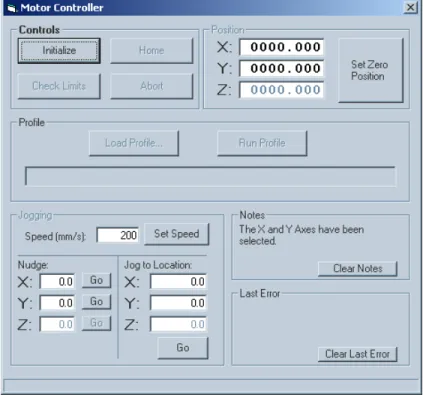

Figure 2 – Motor control software, main window. ... 4

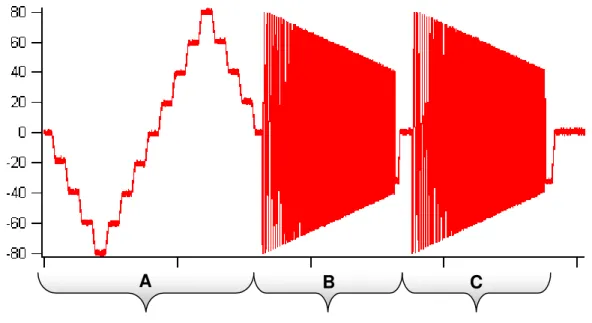

Figure 3 – Entire movement profile... 6

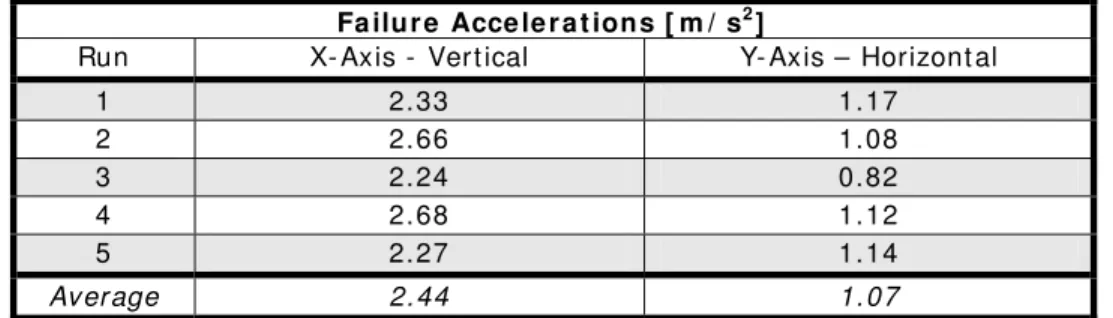

Table 1 – Experimental failure accelerations of the linear table apparatus. ... 9

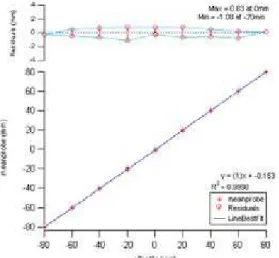

Figure 4 – Sample calibration plot for the Branckner wave probe. ... 11

Figure 5 – Nomenclature of zero-crossing analysis parameters. ... 12

Figure 6 – Sample Branckner calibration ... 13

Figure 7 – Sample modified-circuit calibration ... 13

Figure 8 – Sample unmodified-circuit calibration ... 13

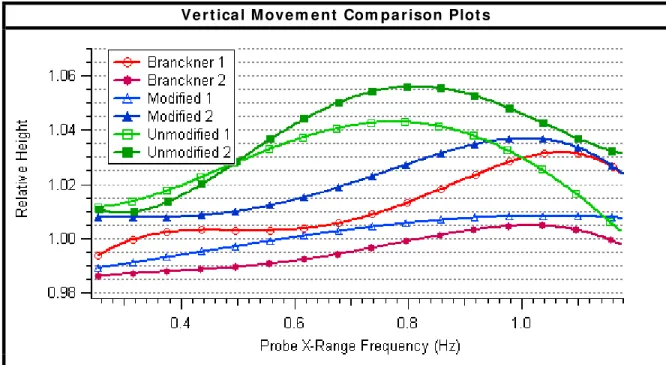

Figure 9 – Relative height comparison during vertical movement... 14

Figure 10 - Height difference during vertical movement. ... 14

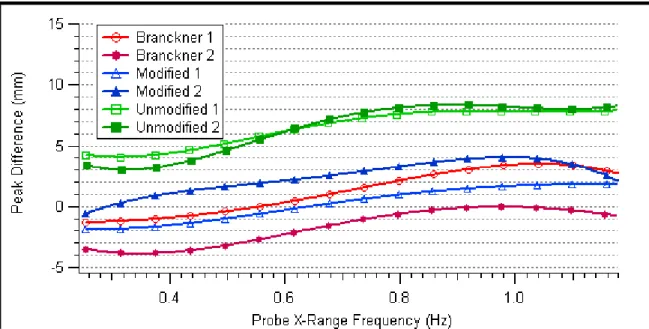

Figure 11 - Peak difference during vertical movement. ... 15

Figure 12 – Trough difference during vertical movement... 15

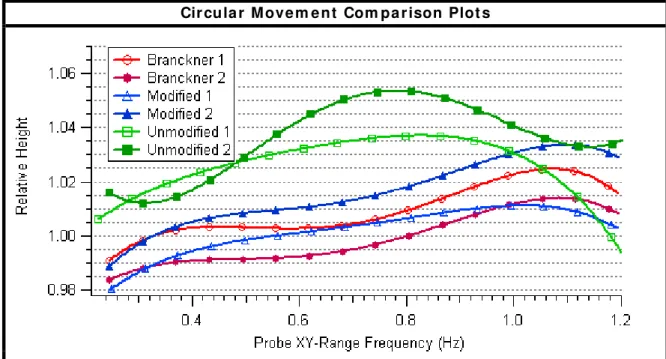

Figure 13 – Relative height comparison during circular movement... 16

Figure 14 – Height difference comparison during circular movement... 16

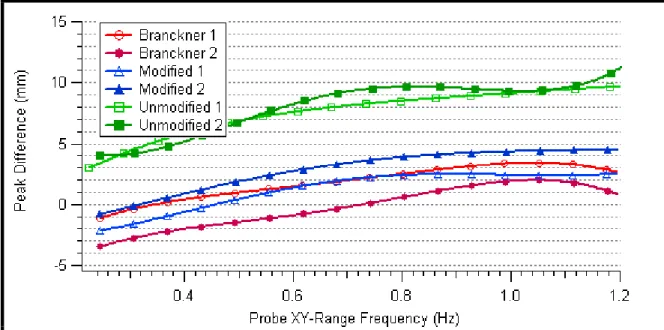

Figure 15 – Peak difference comparison during circular movement. ... 17

Figure 16 – Trough difference comparison during circular movement. ... 17

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Nomenclature

Sym bol N a m e Un it s

A0 St art Am plit ude m

Af End Am plit ude m

f0 St art Frequency m

ff End Frequency m

p Profile line num ber - -

n Tot al num ber of point s in profile - -

t Current t im e s

∑

T

α Net t orque oz- inα Angular accelerat ion rad/ s2

JT Tot al rot at ional inert ia oz- in- s2

e Ballscrew efficiency [ decim al]

Tm Mot or t orque oz- in

Tg Opposing t or que due t o gr avit y ( for

non-horizont al axes) oz- in

TNL No load t orque oz- in

Tω Viscous t orque oz- in

W Weight lbf

P Ballscrew pit ch rev/ in

Ipk Peak current delivered t o m ot or A Kt Torque const ant of t he specific m ot or oz- in/ A

aL Linear accelerat ion

in/ s2 or m / s2

Jm Rot at ional inert ia of t he m ot or oz- in- s2

Js Rot at ional inert ia of t he ballscrew oz- in- s2

JRL

Reflect ed rot at ional inert ia from t he accelerat ed load as seen by t he

ballscrew

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

1. Introduction

Importance of accurate and reliable wave probes is fundamental to the proper

evaluation of ship hull designs and tank tests where specific types of waves are

generated. Successful experimentation should be both accurate and repeatable, and

knowing the dynamic response of wave probes is useful in evaluating test results. At this

time, it is standard practice to calibrate wave probes using time-independent methods.

One method, for example, is to ‘step’ the probe through a controlled range of wave

heights (or water depths), producing a calibration factor when complete. Assuming that

the same calibration applies to a time-varying set of waves, it is used in experiments.

Purpose of this investigation is two-fold. First, to assess the uncertainty in the

dynamic response of wave probes in general, and second, based on these results, to

choose the best wave probe circuitry to be used in future projects at NRC-IOT.

Currently, there are three wave probe circuits available: Branckner, modified, and

unmodified. The Branckner probe is a commercially available product, while the

modified probe contains updated circuitry of the unmodified wave probe, both of which

were constructed in-house.

To perform this experiment, a three-axis linear table arrangement was used to

move the capacitance wave probe in user-specified paths. In developing profiles for the

probe to follow, several milestones had to be met. First, stable and flexible motor control

software was necessary to control the three-degree-of-freedom arrangement. Second,

software to generate (and evaluate) motion profiles was also required. Apparatus

limitations, mainly maximum motor torque (therefore maximum linear acceleration of the

attached capacitance probe) were calculated and tested empirically to ultimately provide

a safe working range for generated motion profiles. Once the experimentation was

complete, software was also required to automatically analyze, plot, and print data for

final evaluation.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

2. Three-Axis Linear Table Arrangement

The three-axis linear table arrangement and accompanying mounting frame is an

apparatus designed and owned by Oceanic Corporation and was used to precisely

maneuver the capacitance wave probe.

The apparatus consists of three Parker Daedal ballscrew driven tables, which can

be arranged in several practical ways, allowing the user maximum flexibility in

performable operations. Largest of the three is the x-axis, model 406XR900, which

allows 900 mm of travel. The y- and z-axes are 404XET15 and 404XET07 models,

respectively offering 633 mm and 233 mm of travel. Linear tables are driven by

Aerotech motors, which are powered by Aerotech BA-20 amplifiers. The x-axis utilizes

an Aerotech BM200E brushless DC motor, while the remaining two axes use the smaller

Aerotech BM75E models. Specifications of these components are contained in Appendix

C on their respective manufacturer product sheets. The linear axes would be used to

drive the wave probe in specified patterns, simulating the passing of waves. Yoyo

potentiometers were attached to each axis to record accurate baseline displacements for

comparison with displacements reported by the wave probes. The yoyo potentiometers

have a maximum error of 0.25%.

This experiment required only two-degrees of freedom, namely vertical and

horizontal. Since this was the case, the x-axis was mounted vertically and the y-axis was

mounted horizontally onto the x-axis carriage, as shown below in Figure 1.

Figur e 1 – 3- Axis Linear Table Ar r angem ent schem at ic.

APPARATUS

MOUNTING

FRAME

BM200E

406XR900

PROBE

MOUNTING

FRAME

BM75E

404XET15

Y-YOYO

POT.

X-YOYO

POT.

CAPACITANCE

PROBE

TANK

WALL

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

The ‘capacitance probe’ was fixed to a small mounting frame, which was then

attached to the y-axis carriage. The capacitance probe consists of a Teflon-coated

stainless steel cable of 0.44 mm in total diameter. This fine stainless steel wire has a

diameter of 0.36 mm with 0.08 mm of Teflon coating. A capacitance probe works on the

premise that both the wire and the water act as the plates of the capacitor, while the

Teflon coating acts as the dielectric. Thus, as the water level changes, the capacitance

follows accordingly.

A cable is run from the capacitance probe into the wave probe circuitry being

tested. Each of the three wave probe circuits in question convert the capacitance into a

voltage, which is then fed through a signal conditioner panel into the data acquisition

computer. Data is collected at 1000Hz through the GEDAP VMS software package, with

typical run lengths of 780 seconds.

2.1 – Visual Basic Motor Control Software

Once the components were assembled and tested, software was required to control

the movement of the capacitance wave probe. Visual Basic 6 was the language of choice

due to its rapid development rate and wide range of compatibility with various operating

systems. An initial, skeleton package already existed, but for our purposes, a more

full-featured version was required.

After the software development phase was complete, the motor control program

proved to be very robust and dependable. It has the ability to control each axis

simultaneously and independently and will allow the user to select any arrangement for

axes setup, from the simple single-axis case to the three-axis scenario or any combination

in between. It also provides real-time visual feedback of each carriage position. The user

can choose to move the axes to a position they specify, or can generate a movement

profile in tab-delimited text format and import it into the control program. The profile

defines a time and corresponding x-, y-, and z-axis positions for each ‘point’ in the

movement and the apparatus will respond accordingly. A screen shot of the main

interface of the motor controller software is shown in Figure 2.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure 2 – Mot or cont rol soft w are, m ain w indow. For source code, see Appendix B.

2.2 – Igor Profile Generation & Analysis Software

Generation of precise and prolonged movement profiles would be very

cumbersome and time consuming to perform manually, even with the use of Microsoft

Excel. A procedure was written in Igor Pro that would perform this task.

It was decided to create sweeped sinusoidal movement profiles for the dynamic

ranges of our test. It is in these sinusoidal regions that the user could examine the

response of the wave probes in time-varying wave scenarios. The Igor procedure

handling this creates the profiles based on the following functions.

)

2

sin(

)

(

t

A

ft

x

=

∆

π

∆

(1)

)

2

2

sin(

)

(

t

=

∆

A

π

∆

ft

+

π

y

(2)

Where

]

/

)

[(

0 0p

A

A

n

A

A

=

+

f−

∆

(3)

]

/

)

[(

0 0p

f

f

n

f

f

=

+

f−

∆

(4)

And

A

0= Start Amplitude [m]

A

f= End Amplitude [m]

f

0= Start Frequency [Hz]

f

f= End Frequency [Hz]

p = Profile line number

n = Total number of points in profile

t = Current time [s]

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Note that amplitudes and frequencies specified above are user-configurable within

the procedure, allowing for generation of specific movement profiles. During run-time

execution of the function, the user also specifies the total run length (in seconds), from

which Igor determines n, the total number of points in the profile. A complete movement

profile follows in Figure 3, and a zoomed view of the sinusoid is shown in Figure 5.

There were three types of movement profiles generated for the probe to follow.

First, there is a ‘stepped’ range of movement where the probe is moved vertically a given

distance and held there a short period of time. This range was created manually in Excel,

requiring less than twenty entries. It is over this stepped range that static calibrations are

performed, using the x-yoyo potentiometer measurements as the reference data.

Additionally, vertical and circular movements were created. The vertical range

would be used to examine the dynamic response of the wave probes during normal

dynamic calibration. It is known that the small meniscus surrounding the capacitance

probe reduces the accuracy of experiments. In an attempt to remedy this, the circular

movement should produce a much smaller meniscus due to the tangential velocity at the

peaks and troughs. This circular motion represents real tests since water particle velocity

is perpendicular to the probe at the wave peak and trough. Generating these dynamic

ranges required the use of the Igor procedure mentioned above. Vertical movement

utilized only the x-axis while circular movements were slightly more complex. They

were achieved by running both the x- and y-axes simultaneously with matching

frequencies and amplitudes, but with the y-axis

2

π

radians out of phase.

Creation of an entire movement profile, including both static and dynamic ranges

required exporting generated data from Igor into Excel. Within Excel, the user combined

the stepped profile and dynamic ranges of data. Once combined, exporting the profile in

tab-delimited text format was performed from Excel, ready for use by the motor

controller software (see section 2.1). A sample plot of a full run is shown next in Figure

3.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

A

B C

Figure 3 – Ent ire m ovem ent profile.

Sect ion A show s t he st epped port ion of t he r un, w hile sect ions B and C show dynam ic port ions. Sect ion B consist s of only vert ical m ot ion ( x- ax is) and sect ion C is t he cir cular port ion ( bot h x - and y- axes) .

2.2.1 – Apparatus Limitations & Acceleration Analysis

Apparatus limitations prevented the user from generating motion profiles over the

necessary frequency range (from 0.2 Hz to 1.2 Hz) with large amplitudes. This

frequency range was tested because this is the operating range of the wave-boards in the

Ocean Engineering Basin and the Tow Tank. The largest runs provided by the apparatus

began with an 80 mm amplitude at 0.2 Hz to an end amplitude of 10 mm at 1.2 Hz.

Larger amplitudes might yield a better idea of wave probe response, but the

amplifier-motor-ballscrew arrangements could not physically produce the torque required to move

with higher linear accelerations. Additionally, wave-breaking limits restrict the size of

waves produced at given frequencies, so this 160 mm range was deemed appropriate.

Based on the peak torque provided by the motors, corresponding maximum linear

accelerations were manually calculated. Next, a series of controlled runs were performed

using the apparatus to establish empirical, real-world limitations. Furthermore, the Igor

profile generation software has the ability to analyze the profiles after creation and

automatically plot accelerations. Comparing calculated and empirical maximum

accelerations allowed the user to examine upper-acceleration limits that were shown on

the Igor acceleration plots immediately after profile generation. If accelerations were

shown to reach beyond the upper limits substantially, the apparatus would fail during

profile-execution and the run would have to be re-generated with different amplitude

parameters.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

2.2.1.1 – Manual Maximum Acceleration Calculation Methodology

Maximum linear accelerations were determined for each of the two axes used in

this set of experiments using the following theory.

Calculations are based on the fact that the sum of torques about the axis of

rotation is equal to the total system rotational inertia multiplied by the angular

acceleration, divided by the efficiency of the system, or

e

J

T

tα

α∑

=

(5)

1Where

= Net torque [oz-in]

∑

T

αα = Angular acceleration [rad/s

2]

J

T= Total rotational inertia [oz-in-s

2]

e = Ballscrew efficiency

Summing the torques about the ballscrew (measured in oz-in),

∑

T

α=

T

m−

T

g−

T

NL−

T

ω(6)

1Where

T

m= Motor torque

T

g= Opposing torque due to gravity (for non-horizontal

axes)

T

NL= No load torque

T

ω= Viscous torque

Additionally,

eP

W

T

g=

2

.

55

(7)

where

T

g= Gravitational torque [oz-in]

W = Weight [lb]

e = Ballscrew efficiency

P = Ballscrew pitch [rev/in]

Also,

t pk mI

K

T

=

(8)

where

T

m= Output motor torque [oz-in]

I

pk= Peak current delivered to motor [A]

K

t= Torque constant of the specific motor [oz-in/A]

Peak current delivered to each motor is dependent upon DIP-switch settings on

the BA-20 amplifier. For the BM200E, the current is limited to 46% of 20 A, which is

9.2 A. The BA-20 amplifier is configured to allow 40% of 20 A to the BM75E y-axis

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

motor, 8 A. The torque constants are found on the spec sheet for the motors. See

Appendix C.

Next,

LPa

π

α

=

2

(9)

where

α = Angular acceleration [rad/s

2]

P = Ballscrew pitch [rev/in]

e = Ballscrew efficiency

a

L= Linear acceleration [in/s

2

]

Substituting (7), (8), and (9) into (6), and solving for the linear acceleration,

P

J

eP

W

T

K

I

e

a

T NL t pk Lπ

2

55

.

2

)

(

⎟

⎠

⎞

⎜

⎝

⎛

−

−

=

(10)

Then, converting linear acceleration from in/s

2to m/s

2is a trivial matter of multiplying

⎥

⎦

⎤

⎢

⎣

⎡

⋅

⎥⎦

⎤

⎢⎣

⎡

⋅

⎥⎦

⎤

⎢⎣

⎡

=

ft

m

in

ft

s

in

a

a

L L2808

.

3

1

12

1

2(11)

Using Equation 11 will yield an acceleration comparable (in units) to that which would

be found through Igor analysis.

To calculate maximum linear acceleration for the vertical x-axis, Equation 10

could be used directly. To find the maximum linear acceleration for the

horizontally-oriented y-axis, Equation 9 must be modified to remove gravitational torque, T

g, term.

For this case,

(

)

P

J

T

K

I

e

a

T NL t pk Lπ

2

)

(

−

=

(12)

and Equation 11 can again be used to convert the units of acceleration.

Several equations use the total rotational inertia, J

Tterm, which consists of, in

this case, inertial effects of the motor, screw, and reflected effect of the load being

accelerated, and has units of oz-in-s

2.

RL s m T

J

J

J

J

=

+

+

(13)

where

J

T= Total rotational inertia

J

m= Rotational inertia of the motor

J

s= Rotational inertia of the ballscrew

And

200105

.

0

P

W

J

RL=

(14)

where

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

J

RL= Reflected rotational inertia from the accelerated load

as seen by the ballscrew

W = Weight [lb]

P = Ballscrew pitch [rev/in]

Performing these calculations led to maximum linear accelerations of 1.25 m/s

2for the x-axis and 3.32 m/s

2for the smaller y-axis.

2.2.1.2 – Methodology of Testing for Maximum Linear Acceleration

In an attempt to confirm calculations performed in section 2.2.1.1, a set of runs

was conducted using the linear axes apparatus. These movement profiles were generated

using varying amplitudes, frequencies, and run lengths, attempting to make the setup

produce an amplifier fault.

If a fault was indeed produced, the motor controller software reported the point at

which it occurred in the profile. These failure points were recorded for each run, and

then used to analyze the individual runs in the Igor Profile Generation and Analysis

software. At each point, the software displayed the linear acceleration that caused failure.

A sample of the results is summarized in Table 1.

Fa ilu r e Acce le r a t ion s [ m / s2]

Run X- Axis - Vert ical Y- Axis – Horizont al

1 2.33 1.17 2 2.66 1.08 3 2.24 0.82 4 2.68 1.12 5 2.27 1.14 Average 2.44 1.07

Table 1 – Experim ent al failure accelerat ions of t he linear t able apparat us.

2.2.1.3 – Maximum Acceleration Discussion

A comparison of calculated and actual accelerations shows differences, as one

may expect, between the two for each axis. Although each set does not compare exactly,

they seem to agree within reasonable amounts since most differences can be explained.

Considering values for the vertical x-axis, the calculated value appears to be

lower than that which occurred during experimentation. The calculated acceleration was

about 1.2 m/s

2while experimental values average to about 2.4 m/s

2. One may expect that

calculated values would be more than empirical values, but such is not the case here. It is

possible that although certain losses (for example, small added inertia of the

motor-to-screw coupling) are not taken into account, the motor does output more torque than

calculated. This could be due to several reasons. First of all, one must realize the

difference between maximum and continuous torque (which then translates into

maximum and continuous linear acceleration). Maximum torque is the peak torque that

can be instantaneously produced, while the continuous torque is the highest torque a

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

motor can sustain for longer periods of time. Maximum (or peak) torque is higher than

continuous torque values. It is possible in our case that the maximum calculated

acceleration corresponds closer to a continuous torque value whereas experimental values

show a more instantaneous peak acceleration. Also, the BA-20 amplifier could be

allowing slightly more current to reach the motor than its settings show, resulting in a

higher torque output from the motor. The motor itself may be able to run at

higher-output settings than guaranteed in its specification sheets. It is also possible that the

estimated masses are slightly off and then, going further, one must look at how Igor

calculates derivatives in finding the double-derivative of the movement profile to produce

profile acceleration data. It is possible that small errors created by the Igor differentiation

algorithm result in values that are slightly different than expected.

Results for the horizontally oriented y-axis showed the opposite, but seemingly

more reasonable. The calculated maximum acceleration was about 3.3 m/s

2, compared to

an experimental limitation of about 1.1 m/s

2. In this case, the calculated value seems

much more reasonable since intermittent but excessive vibrations were noticed on this

axis, which certainly caused a large increase in friction, which in turn resulted in a much

lower actual acceleration. Additionally, the added mass effect of the wave probe moving

through the water certainly reduced the obtainable maximum acceleration.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

3. Data Analysis & Experimental Discussion

3.1 – Igor Data Analysis Software

Analysis of the massive data files collected by the PC was performed by a custom

routine written in Igor on a run-by-run basis. First, the software would perform a

calibration on the data based on the stepped section of the run. Then, the run would be

split into two more sections, the x-range (wherein the probe was moved only vertically),

and the xy-range (wherein the probe was moved in a circular fashion). On each of these

sections, a zero crossing analysis was performed and results plotted. A five-term

polynomial was fitted through each plot to indicate a trend line. Finally, these trend lines

were plotted against each other to graphically indicate the differences in wave-height

measurements between probes.

After importing the DAC file into Igor, the software began data analysis by

calibrating the data reported by the wave probe being tested. This calibration was

performed against the reference x-yoyo potentiometer readings, based on the stepped

range of the movement profile, using a custom least-squares algorithm that is based on

the full-cycle step range. That is, the initial four steps up, eight steps down, then four

steps up to the starting point once again, referring to Figure 3. Calibrations yield a linear

equation and a plot showing residuals and raw data, as seen in Figure 4. These

calibrations were then applied to convert the raw data (in volts) into physical units of

millimeters.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Not e t he residuals, equat ion for t he line of best fit and t he R2 value.

Next, the software used this calibrated data in the zero-crossing analysis phase.

Zero-crossing analysis (or ZCA) was performed on both the vertical (x-range) and

circular (xy-range) of each run separately. The idea behind ZCA was, through software,

to count the number of times the data crossed the zero point, recording the time between

crossings, and the maximum (or minimum) data value in each wave cycle. The

maximum value in a cycle was termed a ‘peak’ and the minimum, a ‘trough’. The

difference between a set of peaks and troughs was referred to as a ‘height’, as seen in

Figure 5.

t f ∆ = 1 Height Peak Trough TimeFigure 5 – Nom enclat ure of zero- crossing analysis param et er s.

Analysis software used this data to perform calculations and plot final graphs,

showing trends and probe comparisons. For each probe circuit from each run, four plots

were generated, all against frequency: height difference, peak difference, trough

difference, and relative height. Each respective difference consisted of the probe value

less the baseline yoyo potentiometer value. Relative height consists of the probe value

divided by the yoyo value. Each graph displays the raw data points with a fifth-degree

trend line. These additional plots are included in Appendix A. For a final comparison of

wave probes, trend lines for each probe are compared against each other on summary

plots, which will follow in the next section.

3.2 – Discussion of Results

To assess the uncertainty in the dynamic response of these wave probes, one must

consider both the standard calibration graphs and the final trend line comparison graphs.

There are eight final comparison graphs, shown in the following figures, on which the

experimental discussion is based. Recommendations as to which probe should be used in

future results are also based on these plots.

The static calibration comparisons for each probe show that they are all very

accurate during static tests. Figure 6 shows a Bracnkner calibration, with an R

2= 0.9998.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure 7 shows that the modified circuitry provides static calibrations with an R

2=

0.9989 while Figure 8 shows the unmodified is also comparable with an R

2= 0.9896.

Both the Branckner and modified circuitries produce very small residuals (up to 2.7 mm)

while the unmodified circuitry reports residuals of nearly 9 mm.

Figure 6 – Sam ple Branckner calibrat ion Figure 7 – Sam ple m odified- circuit calibrat ion

Figure 8 – Sam ple unm odified- circuit calibrat ion

Figures 9 through 16 show the dynamic response of the wave probes when

calibrated under static conditions.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

V e r t ica l M ove m e n t Com pa r ison Plot s

Figur e 9 – Relat ive height com parison dur ing vert ical m ov em ent .

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure 11 - Peak difference during ver t ical m ovem ent .

Figure 12 – Trough differ ence during vert ical m ovem ent .

In comparing these graphs obtained from the vertical ranges of data, the

Branckner probe tends to report very similar results as the modified probe, while the

unmodified probe not only reports different trends but seems to show a larger biased error

altogether. In terms of height differences (see Figure 10), one could expect the

Branckner circuitry to operate with ±2.5 mm error with a 0.5 mm offset over the

frequency range in question when calibrated statically. The modified probe may produce

errors of ± 2.8 mm with a –0.7 mm offset. Though the unmodified probe circuitry

produces a similar ± 2.5 mm of error, it is centered about a 3.5 mm offset. That is, in

using the unmodified circuitry, the average error might be 3.5 mm as opposed to 0.5 mm

in the Branckner case, or –0.7 mm in the modified case. Similar situations arise in

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

interpreting the peak and trough difference plots (see Figures 11 & 12). The Branckner

and modified probes report similar operating ranges, with average differences less than a

millimeter from zero, while the unmodified probe reports average differences about 3.5

mm above zero.

Interpretation of the circular movement plots may lead to more conclusive results

if similar phenomena occur. See figures 13 to 16.

Cir cu la r M ove m e n t Com pa r ison Plot s

Figure 13 – Relat iv e height com parison dur ing circular m ov em ent .

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure 15 – Peak difference com parison dur ing cir cular m ovem ent .

Figure 16 – Trough differ ence com parison during cir cular m ovem ent .

Figures 13 through 16 show comparable results. The height difference plot

(figure 14) indicates that Branckner and modified probe circuitries operate with an error

of ±2 mm and ±3 mm respectively, with zero offset. The unmodified probe shows an

error of ±3 mm, but again, the average error seems to be about 3 mm. Figure 15, the

peak difference plot shows that the unmodified probe records average differences of

about 6 mm. The trough difference plot in Figure 16 displays a similar result. On these

plots, the Branckner and modified probe data is very close to each other. The peak

difference and trough difference plots from the circular movement (Figures 15 & 16)

show a greater positive bias than those from the vertical movement (Figures 11 & 12).

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

This is most likely due to the stretching of the Teflon-coated wire as the capacitance

probe moves horizontally through the water.

Overall, there appears to be two general patterns in the data. First, both the peak

difference and trough difference seems to increase with frequency. This indicates that

during the movement profile, the wave probes report a mean water level greater than that

before or after the run. This phenomenon is common to capacitance wave probe

measurements and has been referred to as ‘setup’. Another reason for this is that the

water drag produced by pulling the capacitance probe through the water increases

proportionally with frequency, which temporarily stretches the Teflon-coated wire. To

put another way, the positive bias of peak differences and trough differences increases

with cycle frequency. This, however, does not affect the height difference results as the

peaks and troughs increase in the same fashion with time.

Second, as each run progresses, noise or scatter in the recorded data tends to

increase. This could be due to several reasons. The main reason for this is most likely

due to the fact that the capacitance probe is only about 250 mm from the trim tank wall,

which may create interfering reflections of waves in the tank. Another possible reason is

that the water in the tank may contain contaminants, which can build up on the wire

during a run, resulting in slightly more inaccuracies. It may be easier to notice this trend

by looking at the raw data plots found in Appendix A.

Differences between the static calibrations and dynamic records are drawn from

comparisons between the static calibration plots (Figures 6 to 8) and the corresponding

relative height plots shown previously in Figures 10 and 13. The Branckner probe, based

on the static calibration, has residuals ranging from –1.08 mm to 1.04 mm, with an R

2value of 0.9998. Its dynamic response shows maximum height differences of –2 mm to

+3 mm. The modified wave probe shows residuals of –3.15 mm to 2.41 mm with R

2=

0.9987. Dynamic responses show maximum height differences of about –3 mm to +3

mm. The unmodified probe has residuals from –8.93 mm to 6.67 mm (R

2= 0.9896),

while its dynamic records indicate height differences between 0 and 6 mm.

The Branckner and unmodified circuitry show that static calibrations do not

directly explain their response to time-varying water levels. The Branckner electronic

design has a residual range of only about 2 mm while its dynamic counterpart is about 5

mm. The opposite occurs for the unmodified wave probe. Its static calibrations show a

residual range significantly higher than its maximum dynamic height difference range: 14

mm in static residuals compared to only 6 mm for dynamic height differences. It may be

also useful to point out that for the unmodified probe electronics, the average residual

difference tends closer to zero while the average dynamic height difference, as previously

stated, tends to be about 3.5 mm. In contrast, the modified wave probe data has a

residual range of about 5.5 mm while its dynamic range is very much similar. These

discrepancies still indicate that it might be useful to incorporate dynamic responses into

wave probe calibrations. Table 2 summarizes the static and dynamic error comparisons.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

St a t ic a n d D y n a m ic Er r or Su m m a r ie s [ m m ]

St at ic Dynam ic Height

Difference ( Vert ical)

Dynam ic Height Difference ( Circular) Probe Range Offset Range Offset Range Offset

Branckner ± 1 0 ± 2.5 0.5 ± 2 0

Modified ± 2.75 - 0.7 ± 2.75 0.75 ± 3 0

Unm odified ± 7.80 - 1.1 ± 2.5 3 ± 3 3

Table 2 – St at ic and dynam ic error sum m ar ies.

Based on final data, the most accurate devices are the Branckner probe and the

modified probe. Each of these probes reports very much similar data. If cost were not a

factor, one may choose the Branckner probe since it seems to collect data with less noise

in the channel (see data scatter in Appendix A) than the other probes. If cost is a factor,

the modified probe can most certainly be used with no major tradeoff in accuracy.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

4. Conclusions

Based on the experimental performance, both goals mentioned in the introduction

are met. First, discrepancies between static calibrations and dynamic responses indicate

that static calibrations do not directly describe dynamic capacitance wave probe

measurements. This may be worth considering during certain types of tank tests since

inherent errors can be expected. Estimates of these errors can be found in Section 3.2,

Table 2.

Finally, experimental data also indicates that the Branckner and modified wave

probes report data with comparable accuracy over the tested frequency range. In static

calibrations, the Branckner probe circuitry reports errors of ± 1 mm, while it reports ± 2

mm with no offset during the circular movements. The modified circuitry reports static

errors of ± 2.75mm with an offset of –0.7 mm, with dynamic height errors ± 3 mm

without an offset. The unmodified probe reports similar error ranges, but it has offsets of

3 mm typically.

So, if cost is no factor, one may choose to purchase and use Branckner wave

probes since they seem less susceptible to noise interference. On the other hand, since

the modified wave probe still produces similar results, it can still be used with

confidence. The unmodified wave probe, in comparison, seems to measure wave heights

with less accuracy. It should not be used for experiments requiring high-accuracy.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

5. References

1) Aerotech Motion Control Product Guide (1993). Aerotech, Inc., pp.142-143.

2) Ratcliffe, T. and Wilson, M. (1989). “Uncertainty in the Measurement of Ship Model

Wave Profiles and Wave Pattern Resistance”. Proceedings of the 22

ndAmerican Tow

Tank Conference. St. John’s, NF, Canada. August 8 – 11, 1989. pp. 408-416.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure A-1 – Branckner calibration, run 1.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure A-3 – Modified probe calibration, run 1.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Figure A-5 – Unmodified probe calibration, run 1.

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

Form – Form1.frm: This is the main form in operating the motor controller. Option Explicit

'Dim Profile As MovementProfile Private Function CheckLimits() Dim ErrorMessage As String Dim XError As Boolean Dim YError As Boolean Dim ZError As Boolean XError = False

YError = False ZError = False

' Check overall ranges

If (Profile.xMax - Profile.xMin) > (Val(Config("XMax")) - Val(Config("XMin"))) Then

XError = True End If

If (Profile.yMax - Profile.yMin) > (Val(Config("YMax")) - Val(Config("YMin"))) Then

YError = True End If

If (Profile.zMax - Profile.zMin) > (Val(Config("ZMax")) - Val(Config("ZMin"))) Then

ZError = True End If

If XError Or YError Or ZError Then

ErrorMessage = "Profile range too large. (" If XError Then ErrorMessage = ErrorMessage & "X " If YError Then ErrorMessage = ErrorMessage & "Y " If ZError Then ErrorMessage = ErrorMessage & "Z " ErrorMessage = ErrorMessage & "Axis)"

MsgBox ErrorMessage LastError = ErrorMessage CheckLimits = False Exit Function End If ' Check offsets Dim XExceed As Single Dim YExceed As Single Dim ZExceed As Single XExceed = 0

YExceed = 0 ZExceed = 0

If XAxis And Not YAxis And Not ZAxis Then

If (Profile.xMin - XOffset) < Val(Config("XMin")) Then

XExceed = -Round(Val(Config("XMin")) - Profile.xMin + XOffset, 2)

ElseIf (Profile.xMax - XOffset) > Val(Config("XMax")) Then

XExceed = Round((Profile.xMax - XOffset) - Val(Config("XMax")), 2)

End If

ElseIf Not XAxis And YAxis And Not ZAxis Then

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

2)

ElseIf (Profile.yMax - YOffset) > Val(Config("YMax")) Then

YExceed = Round((Profile.yMax - YOffset) - Val(Config("YMax")), 2)

End If

ElseIf Not XAxis And Not YAxis And ZAxis Then

If (Profile.zMin - ZOffset) < Val(Config("ZMin")) Then

ZExceed = -Round(Val(Config("ZMin")) - Profile.zMin + ZOffset, 2)

ElseIf (Profile.zMax - ZOffset) > Val(Config("ZMax")) Then

ZExceed = Round((Profile.zMax - ZOffset) - Val(Config("ZMax")), 2)

End If

ElseIf XAxis And YAxis And Not ZAxis Then

If (Profile.xMin - XOffset) < Val(Config("XMin")) Then

XExceed = -Round(Val(Config("XMin")) - Profile.xMin + XOffset, 2)

ElseIf (Profile.xMax - XOffset) > Val(Config("XMax")) Then

XExceed = Round((Profile.xMax - XOffset) - Val(Config("XMax")), 2)

End If

If (Profile.yMin - YOffset) < Val(Config("YMin")) Then

YExceed = -Round(Val(Config("YMin")) - Profile.yMin + YOffset, 2)

ElseIf (Profile.yMax - YOffset) > Val(Config("YMax")) Then

YExceed = Round((Profile.yMax - YOffset) - Val(Config("YMax")), 2)

End If

ElseIf XAxis And Not YAxis And ZAxis Then

If (Profile.xMin - XOffset) < Val(Config("XMin")) Then

XExceed = -Round(Val(Config("XMin")) - Profile.xMin + XOffset, 2)

ElseIf (Profile.xMax - XOffset) > Val(Config("XMax")) Then

XExceed = Round((Profile.xMax - XOffset) - Val(Config("XMax")), 2)

End If

If (Profile.zMin - ZOffset) < Val(Config("ZMin")) Then

ZExceed = -Round(Val(Config("ZMin")) - Profile.zMin + ZOffset, 2)

ElseIf (Profile.zMax - ZOffset) > Val(Config("ZMax")) Then

ZExceed = Round((Profile.zMax - ZOffset) - Val(Config("ZMax")), 2)

End If

ElseIf XAxis And YAxis And ZAxis Then

If (Profile.xMin - XOffset) < Val(Config("XMin")) Then

XExceed = -Round(Val(Config("XMin")) - Profile.xMin + XOffset, 2)

ElseIf (Profile.xMax - XOffset) > Val(Config("XMax")) Then

XExceed = Round((Profile.xMax - XOffset) - Val(Config("XMax")), 2)

End If

If (Profile.yMin - YOffset) < Val(Config("YMin")) Then

YExceed = -Round(Val(Config("YMin")) - Profile.yMin + YOffset, 2)

ElseIf (Profile.yMax - YOffset) > Val(Config("YMax")) Then

YExceed = Round((Profile.yMax - YOffset) - Val(Config("YMax")), 2)

End If

If (Profile.zMin - ZOffset) < Val(Config("ZMin")) Then

ZExceed = -Round(Val(Config("ZMin")) - Profile.zMin + ZOffset, 2)

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

ElseIf (Profile.zMax - ZOffset) > Val(Config("ZMax")) Then

ZExceed = Round((Profile.zMax - ZOffset) - Val(Config("ZMax")), 2)

End If

ElseIf Not XAxis And YAxis And ZAxis Then

If (Profile.yMin - YOffset) < Val(Config("YMin")) Then

YExceed = -Round(Val(Config("YMin")) - Profile.yMin + YOffset, 2)

ElseIf (Profile.yMax - YOffset) > Val(Config("YMax")) Then

YExceed = Round((Profile.yMax - YOffset) - Val(Config("YMax")), 2)

End If

If (Profile.zMin - ZOffset) < Val(Config("ZMin")) Then

ZExceed = -Round(Val(Config("ZMin")) - Profile.zMin + ZOffset, 2)

ElseIf (Profile.zMax - ZOffset) > Val(Config("ZMax")) Then

ZExceed = Round((Profile.zMax - ZOffset) - Val(Config("ZMax")), 2)

End If Else

LastError = "Error finding exceeding values for selected axes." MsgBox LastError

End If

If (XExceed <> 0) Or (YExceed <> 0) Or (ZExceed <> 0) Then ErrorMessage = "Profile extremes exceed safe limits." If XExceed <> 0 Then

ErrorMessage = ErrorMessage & vbCrLf & "X, by " & XExceed & "mm" End If

If YExceed <> 0 Then

ErrorMessage = ErrorMessage & vbCrLf & "Y, by " & YExceed & "mm" End If

If ZExceed <> 0 Then

ErrorMessage = ErrorMessage & vbCrLf & "Z, by " & ZExceed & "mm" End If MsgBox ErrorMessage LastError = ErrorMessage CheckLimits = False Exit Function End If CheckLimits = True End Function

Private Sub Abort_Click() running = False

WAPIAerAbort End Sub

Private Sub cmdClearNotes_Click() lblSelected = ""

End Sub

Private Sub cmdSetSpeed_Click()

'set the global "velocity" variable based on the numeric value in text box If Not IsNumeric(JogSpeed.text) Then

MsgBox ("Speed must be a numeric value. Setting default value of 200. Press 'Set Speed' to apply the new speed.")

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

JogSpeed.text = "200" Velocity = Val(JogSpeed.text) Else Velocity = Val(JogSpeed.text) End If End SubPrivate Sub Command1_Click() lblLastError.Caption = "" End Sub

Private Sub Execute_Click() 'On Error GoTo done If running Then

MsgBox "Already Running" Exit Sub

Else

If Not CheckLimits() Then Exit Sub End If running = True Jogging.Enabled = False LoadProfile.Enabled = False

sCmd = SeekStart(XAxis, YAxis, ZAxis) SendCommand sCmd

StatusBar.SimpleText = "Located 1st position." ' WaitForMoveToFinish

StatusBar.SimpleText = "Waiting for 5 seconds to continue profile..." sCmd = "DWELL 5000"

SendCommand sCmd 'WaitForMoveToFinish

' Start executing the movement profile.

StatusBar.SimpleText = "Executing loaded profile..."

' Enable Target Tracking mode ' Must do this for each axis

'Call the generic EnableTracking subroutine EnableTracking

'Call generic continue profile subroutine. ContinueProfile

'Call generic disable tracking subroutine once profile is complete. DisableTracking

lblSelected.Caption = "Ready to send abort command..." WAPIAerAbort

lblSelected.Caption = "Abort Command sent." End If

End Sub

Private Sub Form_Load()

If XAxis And Not YAxis And Not ZAxis Then

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

DisableY DisableZ

ElseIf Not XAxis And YAxis And Not ZAxis Then

lblSelected.Caption = "Only the Y-Axis has been selected." DisableX

DisableZ

ElseIf Not XAxis And Not YAxis And ZAxis Then

lblSelected.Caption = "Only the Z-Axis has been selected." DisableX

DisableY

ElseIf XAxis And YAxis And Not ZAxis Then

lblSelected.Caption = "The X and Y Axes have been selected." DisableZ

ElseIf XAxis And Not YAxis And ZAxis Then

lblSelected.Caption = "The X and Z Axes have been selected." DisableY

ElseIf Not XAxis And YAxis And ZAxis Then

lblSelected.Caption = "The Y and Z Axes have been selected." DisableX

Else

lblSelected.Caption = "The X, Y and Z Axes have been selected." End If running = False Velocity = 200 LastError = "" XOffset = 0 YOffset = 0 ZOffset = 0

'Set Profile = New MovementProfile

If Not ParseConfig("C:\u500\mmi\controller.cfg", Config) Then

MsgBox "Error reading configuration file, creating one with default values."

If CreateDefaultConfigFile("C:\u500\mmi\controller.cfg") Then ParseConfig "c:\u500\mmi\controller.cfg", Config

Else

Unload Form1 End If

End If End Sub

Private Sub Form_Unload(Cancel As Integer) If XAxis And Not YAxis And Not ZAxis Then WAPIAerSend "DI X"

ElseIf Not XAxis And YAxis And Not ZAxis Then WAPIAerSend "DI Y"

ElseIf Not XAxis And Not YAxis And ZAxis Then WAPIAerSend "DI Z"

ElseIf XAxis And YAxis And Not ZAxis Then WAPIAerSend "DI X Y"

ElseIf XAxis And Not YAxis And ZAxis Then WAPIAerSend "DI X Z"

ElseIf XAxis And YAxis And ZAxis Then WAPIAerSend "DI X Y Z"

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

WAPIAerSend "DI Y Z" Else

LastError = "Error disabling the axes." MsgBox LastError

End If

WAPIAerClose 0

'now destroy all instances of the forms. Set Form1 = Nothing

Set frmStartup = Nothing Unload Form1

Unload frmStartup End Sub

Private Sub Home_Click()

'Call generic homing subroutine. GoHome

'Set this home position as zero and update the offsets Zero

StatusBar.SimpleText = "Ready..."

End Sub

Private Sub InitializeU500_Click() Dim result As Long

result = Initialize() If result = 0 Then LoadProfile.Enabled = True Abort.Enabled = True Jogging.Enabled = True Position.Enabled = True Timer.Enabled = True Home.Enabled = True StatusBar.SimpleText = "Ready..." Else

LastError = "Error Initializing U500 Controller: " & result MsgBox LastError

End If End Sub

Private Sub JogSpeed_LostFocus()

If Not IsNumeric(JogSpeed.text) Then JogSpeed.text = "200" End Sub

Private Sub JogToLoc_Click() Dim sCmd As String

Dim RealX As Single, RealY As Single, RealZ As Single Dim InRange As Boolean

InRange = True

Th e D yna m ic Re spon se of Ca pa cit a n ce W a ve Pr obe s

Just in Wheeler

LM- 2004- 11

If Not IsNumeric(YJogLoc.text) Then YJogLoc.text = "0.0" If Not IsNumeric(ZJogLoc.text) Then ZJogLoc.text = "0.0"

RealX = XJogLoc.text - XOffset RealY = YJogLoc.text - YOffset RealZ = ZJogLoc.text - ZOffset

If RealX < Val(Config("XMin")) Or RealX > Val(Config("XMax")) Then

MsgBox "X Value out of range. " & Round(Val(Config("XMin")) + XOffset, 2) & " <= x <= " & Round(Val(Config("XMax")) + XOffset, 2)

LastError = "X Value out of range. " InRange = False

ElseIf RealY < Val(Config("YMin")) Or RealY > Val(Config("YMax")) Then MsgBox "Y Value out of range. " & Round(Val(Config("YMin")) + YOffset, 2) & " <= y <= " & Round(Val(Config("YMax")) + YOffset, 2)

LastError = "Y Value out of range. " InRange = False

ElseIf RealZ < Val(Config("ZMin")) Or RealZ > Val(Config("ZMax")) Then MsgBox "Z Value out of range. " & Round(Val(Config("ZMin")) + ZOffset, 2) & " <= z <= " & Round(Val(Config("ZMax")) + ZOffset, 2)

LastError = "Z Value out of range. " InRange = False

End If

If InRange Then

If XAxis And Not YAxis And Not ZAxis Then sCmd = "G0" & _

" X" & Round(RealX * Val(Config("XCal"))) & _ " XF" & Round(Velocity * Val(Config("XCal"))) ElseIf Not XAxis And YAxis And Not ZAxis Then sCmd = "G0" & _

" Y" & Round(RealY * Val(Config("YCal"))) & _ " YF" & Round(Velocity * Val(Config("YCal"))) ElseIf Not XAxis And Not YAxis And ZAxis Then sCmd = "G0" & _

" Z" & Round(RealZ * Val(Config("ZCal"))) & _ " ZF" & Round(Velocity * Val(Config("ZCal"))) ElseIf XAxis And YAxis And Not ZAxis Then

sCmd = "G0" & _

" X" & Round(RealX * Val(Config("XCal"))) & _ " XF" & Round(Velocity * Val(Config("XCal"))) & _ " Y" & Round(RealY * Val(Config("YCal"))) & _ " YF" & Round(Velocity * Val(Config("YCal"))) ElseIf XAxis And YAxis And ZAxis Then

sCmd = "G0" & _

" X" & Round(RealX * Val(Config("XCal"))) & _ " XF" & Round(Velocity * Val(Config("XCal"))) & _ " Y" & Round(RealY * Val(Config("YCal"))) & _ " YF" & Round(Velocity * Val(Config("YCal"))) & _ " Z" & Round(RealZ * Val(Config("ZCal"))) & _ " ZF" & Round(Velocity * Val(Config("ZCal"))) ElseIf XAxis And Not YAxis And ZAxis Then

sCmd = "G0" & _

" X" & Round(RealX * Val(Config("XCal"))) & _ " XF" & Round(Velocity * Val(Config("XCal"))) & _ " Z" & Round(RealZ * Val(Config("ZCal"))) & _ " ZF" & Round(Velocity * Val(Config("ZCal"))) ElseIf Not XAxis And YAxis And ZAxis Then

sCmd = "G0" & _

" Y" & Round(RealY * Val(Config("YCal"))) & _ " YF" & Round(Velocity * Val(Config("YCal"))) & _ " Z" & Round(RealZ * Val(Config("ZCal"))) & _