https://doi.org/10.4224/40001836

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=1fbd9904-57f8-4fbe-a679-b31033315329 https://publications-cnrc.canada.ca/fra/voir/objet/?id=1fbd9904-57f8-4fbe-a679-b31033315329

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Lithium battery transport: assessment of the environmental conditions

for lithium batteries shipping

Lithium Battery Transport

Assessment of the environmental

conditions for lithium batteries shipping

Date: October 29th, 2019

Lithium Battery Transport Research Program Page 2 of 413

1.

Table of Contents

2. Table of Figures ... 6 3. Table of Tables ... 8 4. Disclaimer ... 9 5. Executive summary ...10 6. Glossary ...12 7. Introduction ...158. Objectives of this study ...17

9. Air shipping of lithium batteries overview ...18

9.1 Courier considered in this study ...18

9.1.1 Canada Post ...18

9.1.2 Dalsey, Hillblom, Lynn (DHL) ...19

9.1.3 FedEx Express ...20

9.1.4 Purolator ...22

9.1.5 United Parcel Service (UPS) ...23

9.1.6 Courier service selection ...24

9.2 Dangerous goods training ...24

9.2.1 Training providers ...25 9.2.2 Trained personnel ...25 9.2.3 Training control ...25 9.3 Customs regulations ...26 10. Experimental plan ...28 10.1 Packages design ...28

10.1.1 Type A package: 5 kg, non-DG ...29

10.1.2 Type B package: 5 kg, PI966-Section II ...30

10.1.3 Type C package: 32 kg, non-DG ...32

10.1.4 Type D package: 32 kg, PI966-Section II ...34

10.1.5 Type E package: 5 kg Class 9 ...35

10.1.6 Type F package: 32 kg Class 9 ...36

10.2 Data acquisition system ...37

10.2.1 Data logging sensors ...37

Lithium Battery Transport Research Program Page 3 of 413

10.2.3 Sensor calibration ...42

10.3 Destinations ...45

10.3.1 Import and Export of lithium ion batteries ...45

10.3.2 Original list of destinations ...47

10.3.3 Shipping issues with original planned destinations ...47

10.3.4 Revised list of destinations...47

10.4 Data analysis methods ...48

10.5 Shipping plan ...51

11. Results and Discussions ...52

11.1 Pilot shipping experiment ...52

11.2 European destination ...58

11.2.1 Switzerland ...58

11.3 Middle East destination ...59

11.3.1 Dubai ...59

11.4 North American destinations ...60

11.4.1 New York ...60 11.4.2 Montréal, QC ...61 11.4.3 Toronto, ON ...61 11.5 Asian destinations ...62 11.5.1 Shanghai ...62 11.5.2 Hong Kong ...63 11.5.3 Shenzhen ...66 11.6 Comparative analysis ...69 11.6.1 Altitude...69 11.6.2 Temperature ...70 11.6.3 Humidity ...73 11.6.4 Shock ...77 11.6.5 Vibration ...83 11.6.6 Drop Height ...87 12. Summary of results ...89 13. Recommendations ...90 14. References ...91

Lithium Battery Transport Research Program Page 4 of 413

15. Annex A: Aluminum mounting frame vibration testing ...95

16. Annex B: Customs Regulations ...97

16.1 Canada - China ...97

16.2 Canada - Hong Kong ... 104

16.3 Canada - United Arab Emirates ... 105

16.4 Canada - United States of America ... 106

16.5 Canada - Switzerland ... 106

17. Annex C: Packing Instructions for type E package 5kg, Class 9 ... 107

18. Annex D: Packing Instruction for type F package 32 kg, Class 9 ... 108

19. Annex E: shipper’s declaration for Dangerous Goods ... 109

20. Annex F: DHL account ... 110

20.1 Dangerous Goods pre-approval documents ... 110

20.2 Shipping Amendment Request Form ... 116

21. Annex G: Original Experimental plan ... 118

22. Annex H: Experimental shipments carried out ... 120

23. Annex I: Experimental Shipping Reports ... 122

23.1 Europe ... 122 23.1.1 Zürich-FedEx-Type A ... 122 23.1.2 Zürich-FedEx-Type B ... 131 23.2 Middle East ... 139 23.2.1 Dubai-FedEx-Type A ... 139 23.2.2 Dubai-UPS-Type A ... 147 23.3 North America ... 156 23.3.1 New York-FedEx-Type A ... 156 23.3.2 Montreal-FedEx-Type A ... 164 23.3.3 Toronto-Canada Post-Type D ... 172 23.4 Asia ... 180 23.4.1 Shanghai-FedEx-Type A ... 180 23.4.2 Shanghai-FedEx-Type A ... 189 23.4.3 Shanghai-UPS-Type A ... 197 23.4.4 Hong Kong-FedEx-Type A ... 210 23.4.5 Hong Kong-FedEx-Type C ... 219

Lithium Battery Transport Research Program Page 5 of 413 23.4.6 Hong Kong-UPS-Type C ... 227 23.4.7 Hong Kong-FedEx-Type A ... 236 23.4.8 Hong Kong-FedEx-Type E ... 246 23.4.9 Hong Kong-FedEx-Type F ... 256 23.4.10 Hong Kong-UPS-Type B ... 266 23.4.11 Hong Kong-UPS-Type D ... 276 23.4.12 Shenzhen-FedEx-Type A ... 286 23.4.13 Shenzhen-FedEx-Type B ... 298 23.4.14 Shenzhen-FedEx-Type A ... 309 23.4.15 Shenzhen-FedEx-Type B ... 320 23.4.16 Shenzhen-FedEx-Type C ... 331 23.4.17 Shenzhen-FedEx-Type D ... 341 23.4.18 Shenzhen-UPS-Type A ... 351 23.4.19 Shenzhen-UPS-Type B ... 361 23.4.20 Shenzhen-DHL-Type C ... 372 23.4.21 Shenzhen-DHL-Type D ... 382 23.4.22 Shenzhen-DHL-Type A ... 393 23.4.23 Shenzhen-DHL-Type B ... 403

Lithium Battery Transport Research Program Page 6 of 413

2.

Table of Figures

Figure 1: Canada import/export of lithium-ion batteries (HS 850760) valued in millions of CAN$

...15

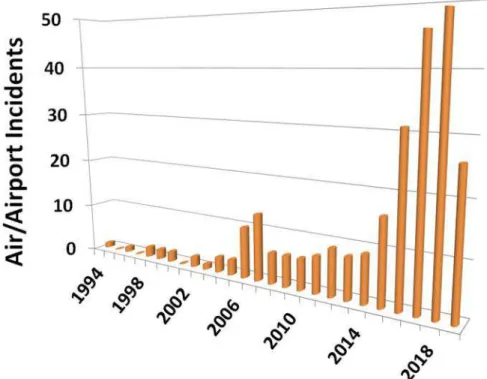

Figure 2: FAA reported air and airport incidents related to lithium batteries up to August 1st 2019. ...16

Figure 3: Lithium battery packaging guidelines...22

Figure 4: H Taping Method...22

Figure 5: Chain of custody for lithium ion batteries where a shipper’s declaration of dangerous goods is required ...26

Figure 6: 18650 lithium ion cells received at NRC for testing ...28

Figure 7: 18650 lithium ion cells shipping packages as seen on eBay ...28

Figure 8: Type A package ready for shipping ...30

Figure 9: Content of type A package ...30

Figure 10: Marking applied on type B packages ...31

Figure 11: Type B package ready to be shipped with UN 3481 marking ...32

Figure 12: Content of type B packages with fully discharged lithium ion Cells ...32

Figure 13: Side view of the packing arrangement of 32 kg packages ...32

Figure 14: Type C package with 1 type A package and 1 ballast package ...33

Figure 15: Type C package ready to be shipped ...34

Figure 16: Type D package ready to be shipped ...34

Figure 17: Type E package 5 kg, Class9 ready for shipping ...36

Figure 18: Type F package 32 kg, Class 9 ready for shipping ...37

Figure 19: Sensor Mounting Frame with Aluminum Frame ...41

Figure 20: Steel mounting frame with Shocklog 298 and Shock Recorder TRE38 installed in shipping package ...42

Figure 21: Frequency response of the steel frame mounted with shocklog 298 ...45

Figure 22: Import and Export of lithium ion batteries to and from Canada ...46

Figure 23: Data logging system on Aluminum frame ...52

Figure 24: FedEx Sense Aware device ...52

Figure 25: Tracking dashboard from FedEx Sense Aware web portal ...53

Figure 26: Graphical summary from FedEx Sense Aware web portal ...54

Figure 27: Data recorded from Shocklog 298 for the pilot shipping experiment ...55

Figure 28: Statistics of the environmental conditions during ground and air transportation ...56

Figure 29: Number of shock according to the transportation method ...57

Figure 30: Ground conditions at the identified locations ...58

Figure 31: Lowest pressure recorded by shipping destination ...69

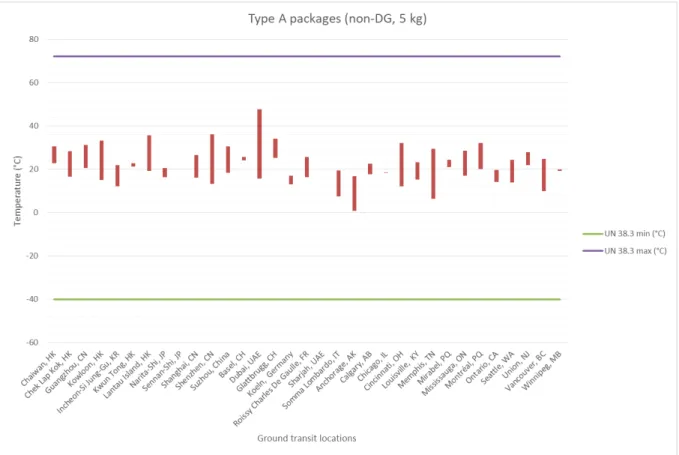

Figure 32: Lowest and highest temperature recorded for each transit location for packages type A (non-DG, 5 kg) ...70

Figure 33: Lowest and highest temperature recorded for each transit location for packages type B (DG, 5 kg) ...71

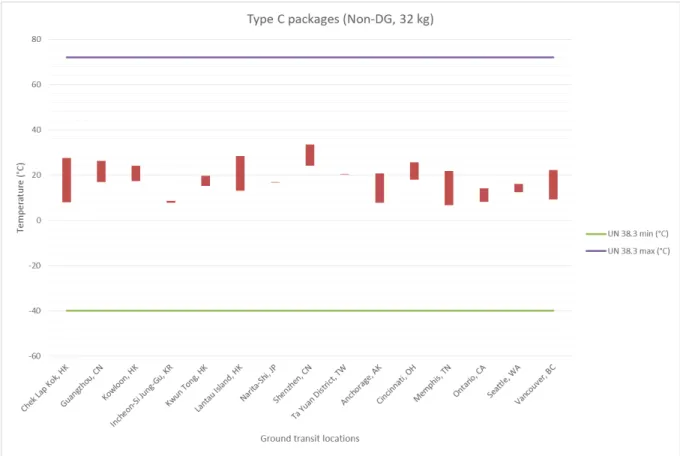

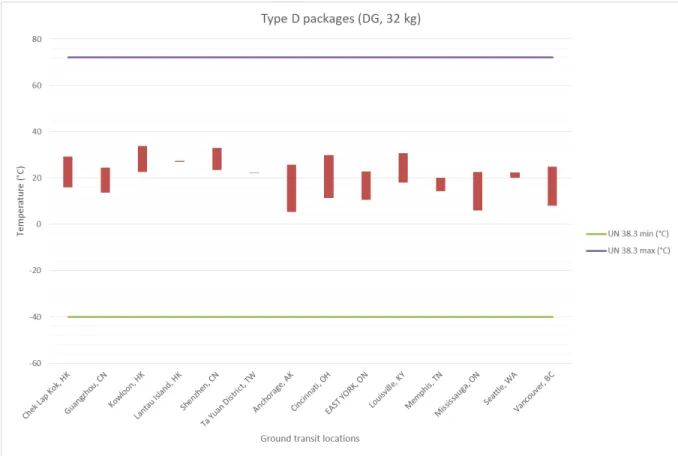

Lithium Battery Transport Research Program Page 7 of 413 Figure 34: Lowest and highest temperature recorded for each transit location for packages type C (non-DG, 32 kg) ...72 Figure 35: Lowest and highest temperature recorded for each transit location for packages type D (DG, 32 kg) ...73 Figure 36: Lowest and highest humidity recorded for each transit location for packages type A (non-DG, 5 kg) ...74 Figure 37: Lowest and highest humidity recorded for each transit location for packages type B (DG, 5 kg) ...75 Figure 38: Lowest and highest humidity recorded for each transit location for packages type C (non-DG, 32 kg) ...76 Figure 39: Lowest and highest humidity recorded for each transit location for packages type D (DG, 32 kg) ...77 Figure 40: Highest shock recorded for each transit location for packages type A (non-DG, 5 kg) ...78 Figure 41: Highest shock recorded for each transit location for packages type B (DG, 5 kg) ...79 Figure 42: Highest shock recorded for each transit location for packages type C (non-DG, 32 kg) ...80 Figure 43: Highest shock recorded for each transit location for packages type D (DG, 32 kg) ...81 Figure 44: Number of shock recorded according to their amplitude during air transportation...82 Figure 45: Number of shock recorded according to their amplitude during ground transportation ...82 Figure 46: Number of shock recorded according to their amplitude during handling ...83 Figure 47: Highest vibrations recorded for each transit location for packages type A (non-DG, 5 kg) ...84 Figure 48: Highest vibrations recorded for each transit location for packages type B (DG, 5 kg) ...85 Figure 49: Highest vibrations recorded for each transit location for packages type C (non-DG, 32 kg) ...86 Figure 50: Highest vibrations recorded for each transit location for packages type D (DG, 32 kg) ...87 Figure 51: Highest drop height for each shipping experiment ...88 Figure 52: Recorded drop heights according to their tracked location ...88

Lithium Battery Transport Research Program Page 8 of 413

3.

Table of Tables

Table 1: Acceptance Requirements ...19

Table 2: Courier service available for shipping lithium ion batteries...24

Table 10: Type of packages used in this study ...29

Table 3: Data logging requirements ...38

Table 4: Data logging sensors feature comparison (1/2) ...39

Table 5: Data logging sensors feature comparison (2/2) ...40

Table 6: Data logging sensor pressure calibration ...42

Table 7: Data logging sensor temperature and humidity calibration ...43

Table 8: Drop height calibration of Shocklog 298 ...43

Table 9: Drop height calibration of Shock Recorder TRE38 ...44

Table 11: List of parameters analysed for each shipment ...48

Table 12: Environmental Conditions Summary for Hong Kong destination ...64

Table 13: Observations for each shipping experiments for Hong Kong destination ...65

Table 14: Environmental Conditions Summary for Shenzhen destination...66

Lithium Battery Transport Research Program Page 9 of 413

4.

Disclaimer

This report reflects the views of the authors only and does not reflect the views or policies of Transport Canada.

Neither Transport Canada, nor its employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy or completeness of any information contained in this report, or process described herein, and assumes no responsibility for

anyone's use of the information. Transport Canada is not responsible for errors or omissions in this report and makes no representations as to the accuracy or completeness of the information. Transport Canada does not endorse products or companies. Reference in this report to any specific commercial products, process, or service by trade name, trademark, manufacturer, or otherwise, does not constitute or imply its endorsement, recommendation, or favoring by Transport Canada and shall not be used for advertising or service endorsement purposes. Trade or company names appear in this report only because they are essential to the objectives of the report.

References and hyperlinks to external web sites do not constitute endorsement by Transport Canada of the linked web sites, or the information, products or services contained therein. Transport Canada does not exercise any editorial control over the information you may find at these locations.

Lithium Battery Transport Research Program Page 10 of 413

5.

Executive summary

This report presents the results of a study into the environmental conditions of lithium ion batteries shipping. It follows the 2016 report “Lithium Batteries Market Data Collection and Analysis” presenting the results of a lithium batteries market survey and the 2016 report

“Review of Environmental Conditions during Freight Transportation” presenting a review of past research and analysis of the applicable and relevant regulations and standards.

The study was carried out mainly on transportation routes between Western Canada and Asia. Other routes with Europe, Middle-East, and North America were assessed for reference and comparison. Two packages sizes (5kg, 32kg), and different dangerous goods markings (non-DG, DG) were evaluated.

Amongst the 44 round trip shipping experiments carried out, it was found that all the packages were shipped within the testing limits for temperature, pressure, and shock. Only one package experienced a fall height higher than 1.2 m. This single occurrence amongst 44 shipments evidences the risk of packages falling from above their tested limits. However due to the limited number of shipments being carried out, no statistical analysis can be drawn. With such limited number of occurrence, it is suggested that future study with a larger sample size may be helpful in determine whether this is a widespread problem.

In all the shipping experiments, it was found that ten packages were exposed to levels of random vibrations higher than the limit recommended of 1.49 grms for air transportation. While this may be a concern, the United Nation test method for lithium batteries does not specify any random vibration testing method, only a frequency sweep aimed at identifying potential

resonance frequencies of the cell or the battery assembly. A further investigation is suggested to the matter to determine if United Nation test method frequency sweep shall use higher level of peak acceleration to reflect the harsher conditions.

More than half of packages were exposed to levels of relative humidity above 75 %RH during ground transportation, handling and storage. When the packages were stored for more than two weeks, the outer boxes tend to exhibit signs of reduced rigidity even for outer boxes with

certified performance.

Since this reduced performance would affect the protection level at which the package would have been certified, it is suggested that qualification of certified cardboard boxes take into account the long-term exposure to high level of relative humidity on the mechanical

performance evaluation. Currently, a 24-hour conditioning of the package at 23°C with 50 %RH is required. This conditioning phase should represent more closely the storage conditions of packages, such as 75 %RH.

The human factor played a significant role in the course of this study. Administrative controls vary amongst courier companies. While all courier companies used in this study strictly applies the control of dangerous goods whenever a shipper’s declaration for dangerous goods is required, it was observed discrepancies about the control of packages that do not require shipper’s declaration but still contain small amount of lithium batteries. For these packages, the discrepancy ranges from no observable check by the courier company to a full inspection of the

Lithium Battery Transport Research Program Page 11 of 413 content at time of pickup. Based on these observation, it is suggested that for best practice, before accepting the packages, courier companies should inspect the package content with uncertified shippers. Courier companies could accept packages without inspection only from shippers holding a valid dangerous goods training certificate.

It was further observed that the shipper’s declaration for dangerous goods does not include any reference to the customs classification of goods. This missing information hinder the ability to determine the percentage of goods being shipped as dangerous goods in any particular product classification. Hence, it is suggested that the shippers would add the harmonized system code of the goods being shipped in the shipper’s declaration form. Such information could then be correlated with the total flow of commodities recorded by the customs and be used to determine the risk level in the respective product classifications.

Lithium Battery Transport Research Program Page 12 of 413

6.

Glossary

ADG – Accessible Dangerous Goods: Goods that must be accessible to the flight crew in-flight.

ADR – Accord Dangereux Routier APO – Army Post Office

BEV – Battery Electric Vehicle

CAO – Cargo Aircraft Only: some dangerous goods are only allowed to be transported on cargo aircraft for safety reasons.

CAGR - Compound Annual Growth Rate

Consumer commodity – An alternate description used to identify a Limited Quantity shipment. Consumer Commodity shipments are dangerous goods.

Contained in equipment – A lithium-ion or lithium metal battery contained in equipment means a battery that is embedded in the device.

DG – Dangerous Goods

DGD – Shipper’s Declaration for Dangerous Goods

DGR – Dangerous Goods Regulations published by the International Air Transport Association

DOD – Department of Defense DPO – Diplomatic Post Office

Excepted quantity – An exception in the regulations that allows for very small amounts and/or very low risk dangerous goods to be prepared for transport without meeting all the requirements for fully regulated shipments.

FPO – Fleet Post Office

Fully regulated – Fully regulated substances and materials offered for transport require full marking, labelling, specification packaging (where applicable) and dangerous goods documentation.

Handling label – A label that identifies specific features or requirements for the proper handling of a shipment.

Hazard label – A label that defines the class/division of dangerous goods contained in a shipment. Hazard labels must always be displayed “square on point” (diamond shaped). IATA – International Air Transport Association

ICAO TI – International Civil Aviation Organization Technical Instructions

IDG – Inaccessible Dangerous Goods: packages that do not need to be accessed by the flight crew in-flight.

Lithium Battery Transport Research Program Page 13 of 413 IMDG - International Maritime Dangerous Goods

IMM – International Mail Manual

Limited quantity – An exception in the regulations that allows for small quantities of dangerous goods to be prepared for transport without meeting all the requirements for fully regulated shipments.

Lithium battery – A lithium battery is one or more cells electrically connected (such as a laptop battery).

Lithium cell – A single encased unit consisting of one positive and one negative electrode that exhibits a voltage differential across the two terminals (such as an AA battery).

Lithium-ion battery – Lithium-ion batteries are rechargeable, do not contain metallic lithium, and have a high energy density.

Lithium metal battery – Lithium metal batteries are usually non-rechargeable, contain metallic lithium, and have a higher energy density than other non-rechargeable batteries. NIST – National Institute of Standards and Technology

ORM-D – Other regulated materials for domestic transport only

Overpack – An enclosure used by a single shipper to contain one or more packages and to form one handling unity for convenience of handling and stowage.

Packed with equipment – A lithium ion or lithium metal battery packed with equipment is not embedded in the device.

PAX – Passenger airplane

PHEV – Plug-In Hybrid Electric Vehicle PI – Packing Instructions

RH – Relative Humidity SDS – Safety data sheet

Safety mark – Any identifier on a dangerous goods shipment used to show compliance with the regulations or the type of dangerous goods contained in the shipment.

SoC – State of charge

TDG – Transportation of Dangerous Goods

TDGA – Transportation of Dangerous Goods Act (Canada)

TDGR – Transportation of Dangerous Goods Regulations (Canada) UN – United Nations

UN number – The official number assigned by the United Nations dangerous goods regulatory body to individual chemicals, materials or products.

Lithium Battery Transport Research Program Page 15 of 413

7.

Introduction

Currently, vast quantities of consumer products such as personal electronic devices (e.g., smartphones, e-cigarette, tablets and laptops), power tools and large equipment containing lithium batteries are being fabricated and transported daily. Lithium batteries and specifically lithium-ion batteries are witnessing a significant and growing market share with an ever-increasing demand. In 2018, BCC Research valued the global lithium battery market at $22.7 billion (USD) at the wholesale level, $2.6 billion (USD) higher than 2017. BCC Research estimated the global market in 2023 based on their forecast to top $47.4 billion (USD), approximating 15.8% Compound Annual Growth Rate (CAGR) from 2018 to 2023 [1]. In Canada, the data for the importation and exportation of lithium-ion batteries using

Harmonization System (HS) 850760 for lithium ion electric accumulators showed a concurrent growth trend as illustrated in Figure 1 [2].

Figure 1: Canada import/export of lithium-ion batteries (HS 850760) valued in millions of CAN$

Some attractive attributes of lithium batteries are their intrinsic high volumetric and gravimetric energy density, design flexibility, cost-effectiveness and relatively benign materials of

construction compared to other types of batteries. Lithium-ion batteries are the dominant technology in the portable electronics and power tools industries. They are demonstrated to be the leading technology for the automotive and renewable energy sectors. This growing demand is increasing the pressure on those responsible for safely transporting lithium batteries,

specifically as many of these devices are currently being transported by air throughout the world. Indeed, the United States Federal Aviation Administration (FAA) incident chart showed

Lithium Battery Transport Research Program Page 16 of 413 an upsurge of battery related incidents particularly, in recent years, although considerable effort has been made to mitigate lithium batteries related safety issues. Figure 2 illustrates this

upsurge of battery related incidents over the last two decades throughout the air transportation cycle. FAA reported events involve smoke, fire, extreme heat or explosion involving lithium batteries [3]. It shall be noted however that most incident reported were not related to packages marked as dangerous goods in cargo.

Figure 2: FAA reported air and airport incidents related to lithium batteries up to August 1st 2019 (including cabin, cargo, and carry-on).

All batteries have the inherent danger of short circuits leading to thermal runaway and fire. However, the consequences of lithium battery failure are more of a concern because lithium batteries tend to react more violently, and the resulting fires are more difficult to extinguish. These consequences are further amplified if that failure happens in the cargo hold of an airplane.

There have been some recent examples of lithium batteries failing in Canada while in the air transportation system. Fortunately, these incidents have all occurred while the batteries and cells were on the ground or had been detected before any catastrophic event happened while in the air (WestJet, CBC news article June 2018 [4]). However, it is expected that with the

increased production and use of lithium batteries, the risk of more similar incidents happening while in the air will also increase.

Lithium batteries are classified as Class 9 dangerous goods. The shipping of lithium batteries during import/export and within Canada is regulated by the following:

Lithium Battery Transport Research Program Page 17 of 413 Transportation of Dangerous Goods Act, 1992 and its regulations

International Air Transport Association (IATA) International Civil Aviation Organization (ICAO) International Maritime Dangerous Goods (IMDG).

All of these regulations refer to testing requirements as per the United Nations (UN)

Recommendations on the Transport of Dangerous Goods Model Regulations and UN Manual of Tests and Criteria.

Lithium batteries are classified as Class 9 referring to “miscellaneous dangerous goods” under the following UN numbers:

UN3090, LITHIUM METAL BATTERIES

UN3091, LITHIUM METAL BATTERIES CONTAINED IN EQUIPMENT, or LITHIUM METAL BATTERIES PACKED WITH EQUIPMENT

UN3480, LITHIUM ION BATTERIES

UN3481, LITHIUM ION BATTERIES CONTAINED IN EQUIPMENT, or LITHIUM ION BATTERIES PACKED WITH EQUIPMENT

As part of Transport Canada’s mandate for public safety, the Transportation of Dangerous Goods (TDG) program established a research program on lithium batteries to better understand and respond to the public on risks involved with the transportation of lithium battery shipments by air. Transport Canada required additional research and data to be in an informed position to assess and mitigate the potentially high-risk lithium batteries pose on air transport. This multi-year collaborative study represents an experimental endeavor to help TDG directorate assess risk, develop strategies to mitigate and control risk, and impact on safety.

8.

Objectives of this study

The study involves the development and the execution of an experimental plan to assess the environmental and potential abuse conditions that lithium batteries are exposed to during shipping and handling by the various modes of transport (air and ground). The experimental plan was carried out from January 2017 to September 2019. The study included the

instrumentation of packages and batteries in air shipment and handling. This study aimed to assess the adequacy of current packaging and battery testing requirements [5] and develop evidence-based recommendations in regard to UN Manual of Test and Criteria [6] for lithium batteries and ASTM D4332-14 [7], ASTM D7386 [8] and ASTM D4169 [9] for package testing. The study encompasses the recording of parameters such as temperature, humidity, vibration, shock and pressure that a package would experience during a shipping cycle. Many

destinations, both nationally and internationally, have been selected for this study with a particular emphasis on China, a large exporter of lithium batteries. The instrumented packages were sent and received under different labelling as TDG (packages containing lithium batteries) and non-TDG (packages not containing any dangerous goods) for different masses and sizes. Metadata such as shipping process and regulations implementation differences among the main

Lithium Battery Transport Research Program Page 18 of 413 courier companies have been captured. The study also identifies hurdles encountered due to the differences in countries’ customs and brokerage practices.

9.

Air shipping of lithium batteries overview

In the following sections, an overview of the courier companies operating in Canada are presented with their relevant specificities for lithium batteries. Based on this information, a number of courier companies were selected to carry out the experimental plan.

A summary of observations in regards to the dangerous goods training is presented, which link the regulatory requirements with their implementations by the stakeholders. This summary is followed by an overview of the customs regulations for sending and returning lithium batteries. Note: this overview should not be considered a source of information regarding TDG policies of the different courier services. It is included in this report for the sole purpose of providing guidance to the present study.

9.1

Courier considered in this study

A review of the courier services available in Canada has been carried out to identify the courier services that could be used for this study. Canada Post, DHL, FedEx, Purolator, and UPS have been reviewed. The company overview and their specifics related to shipping dangerous good, and in particular, lithium batteries are presented below. Based on the review of their services and limitations in regard to international shipping of dangerous goods, the shipping experiments would be carried out using DHL, FedEx and UPS only.

9.1.1 Canada Post

9.1.1.1

Company overview

Established in 1867, Canada Post is a Crown Corporation serving as one of Canada’s main postal delivery service with over 6,200 retail offices and 64,000 employees [10]. Originally known as “Royal Mail Canada” during the 1960s, in 1981, Canada Post changed its name to what it is known as today [11].

9.1.1.2

TDG handling policies

Canada Post will not accept packages that contain goods classified as dangerous under the Transportation of Dangerous Goods Act and Regulations, with the exception of lithium batteries. Canada Post allows shippers to reuse shipping boxes as long as all of the previous package markings and labels have been removed completely, even if the package was wrapped in paper. This is because the package wrapping might become damaged during shipment, causing the previous labels or markings to become visible, making it undeliverable [12].

Lithium Battery Transport Research Program Page 19 of 413

9.1.1.3

Specifics on lithium batteries

Lithium cells and batteries used in music storage devices, cameras, cellular devices, and laptops are considered acceptable for delivery, whereas lithium-powered vehicles, such as hoverboards, self-balancing boards/wheels, electric bicycles and wheelchair batteries are not considered acceptable for delivery. Lithium batteries must also satisfy the requirements in Schedule 2, Special Provision 34 of the Transportation of Dangerous Goods Regulations. Before shipping, check the International Destinations Listing to confirm that the intended place of destination accepts devices with lithium batteries installed. The shipper is required to fill out a Customs Declaration form and ensure that the content of the package is properly declared (U.S. & International only) [13].

As described in Table 1, Canada Post would accept packages containing up to 4 cells or 2 batteries installed in equipment (UN3481 and UN3091) for air shipment. Canada Post does not require any label for these packages.

Table 1: Acceptance Requirements[13]

Description of Content Label Domestic U.S.A. & International

Air Surface Parcels Only Installed in Equipment (Max. of

4 cells or 2 batteries) UN3481, UN3091

No ✔ ✔ ✔

Installed in Equipment (More than 4 cells or 2 batteries) UN3481, UN3091

Yes Not Accepted ✔ Not Accepted

Packed with, not installed in Equipment

UN3481, UN3091

Yes Not Accepted ✔ Not Accepted

Batteries on their own

UN3480, UN3090 Yes Not Accepted ✔ Not Accepted

9.1.2 Dalsey, Hillblom, Lynn (DHL)

9.1.2.1

Company overview

DHL began as a postal and logistics company in Germany during 1969, and has since continued to expand internationally, delivering in over 227 countries [14]. DHL has four corporate divisions, including Post-eCommerce-Parcel, Express, Global Forwarding, Freight, and Supply Chain [15].

9.1.2.2

TDG handling policies

DHL does not permit substances such as dangerous goods waste and munitions of war. Conditions to ship depend on country restrictions and local laws and regulations. DHL only

Lithium Battery Transport Research Program Page 20 of 413 accepts dangerous goods from an approved customer. All dangerous goods must adhere to the IATA/ICAO dangerous goods guidelines, and boxes for shipment must be packed, labelled, and marked correctly. The shipper’s declaration for dangerous goods form must be completed and if applicable, signed by the shipper only, as well as accompanying the shipment. In addition, all state and operator variations must be followed through. All dangerous goods ready for shipment must be booked and approved by DHL Express before the pickup in order to be accepted. Note that dangerous goods for shipment are subject to additional charges [16].

9.1.2.3

Specifics on lithium batteries

As of January 2019, DHL specified on their website that under Section I, IA or IB of the lithium battery packing instructions, the Class 9 Miscellaneous dangerous goods hazard label was accepted until the end of December 2018 for lithium battery packages. Customers were also permitted to use lithium battery handling labels for lithium battery packages under Section IB or Section II of the lithium battery packing instructions until the end of December 2018. Electronic products that are powered by lithium batteries, such as rechargeable (lithium ion) or non-rechargeable (lithium metal), are subject to the lithium battery rules and regulations. These regulations apply when [17]:

Lithium batteries are packed and shipped as individual items [17]

Lithium batteries are packed separately but shipped with equipment in the same box [17]

Lithium batteries are contained or installed in equipment and therefore shipped in the same box [17]

9.1.3 FedEx Express

9.1.3.1

Company overview

FedEx Express, formerly known as Federal Express Corporation, is an overnight package delivery service company founded by Frederick W. Smith in Memphis, Tennessee, 1971. As one of the world’s largest delivery service companies, FedEx operates in 211 countries and ships over 4 million packages every day to over 220 countries [18]. FedEx operates through four main subsidiaries – FedEx Services, FedEx Express, FedEx Ground, and FedEx Freight [19].

9.1.3.2

TDG handling policies

FedEx Express is one of the largest carriers of dangerous goods worldwide. Only specific dangerous goods are not accepted, such as radioactive goods with a transport index higher than 10, explosives other than division 1.4, hazardous waste (including waste lithium batteries under special provision A183), toxic gases, and infectious substances. Furthermore, FedEx will not accept packages containing dangerous goods for shipping to or from locations where dangerous goods service is not available.

Lithium Battery Transport Research Program Page 21 of 413 Miscellaneous dangerous goods include dry ice (carbon dioxide, solid), consumer commodities, lifesaving appliances (self-inflating, or containing dangerous goods as equipment), airbag inflators and or airbag modules, battery-powered equipment, machines incorporating internal combustion engines, lithium batteries, and magnetized material [20].

Shippers are required to complete the intra-Canada (within Canada) or international shipment form through the electronic shipping solutions page as well as the Shipper’s Declaration for Dangerous Goods for their intra-Canada or international shipment. The Shipper’s Declaration can only be completed online in typed or computer-generated forms and cannot be handwritten [21].

9.1.3.3

Specifics on lithium batteries

FedEx Express will not accept or ship [24]:

Recalled or defective batteries, either as a stand-alone unit or contained with equipment; Recalled or defective lithium batteries contained in electronic equipment, such as a

laptop;

Waste batteries or batteries being shipped for recycling or disposal. (See IATA Special Provisions A154 and A183 as well as FX-04 (e) for additional details on these

restrictions.)

FedEx Authorized ShipCenter® locations, FedEx OnSite locations, and FedEx ShipSite®

locations do not accept dangerous goods. FedEx Office® Print and Ship Center locations do not accept regulated battery shipments, with the exception of lithium battery shipments meeting Section II IATA regulations.

FedEx requires shippers to indicate that the package contains lithium batteries only for quantities of lithium batteries requiring a class 9 label on the outer package. When shipping small quantities of lithium batteries classified as UN3481-Section II or UN3091-Section II, shippers should only follow the FedEx recommended guidelines for lithium battery packing. Figure 3 and Figure 4 describe FedEx guidelines for packaging lithium batteries (metal and ion) as well as adequately closing the package using the H taping method.

Lithium Battery Transport Research Program Page 22 of 413 Figure 3: Lithium battery packaging guidelines[22] Figure 4: H Taping Method[22]

9.1.4 Purolator

9.1.4.1

Company overview

Established in 1960 and branded initially as Trans Canadian Couriers, Purolator underwent a name change to Purolator Courier Ltd. in 1973 [23]. Purolator is a freight, package, and logistics courier company with 12,000 employees, with its headquarters located in Mississauga, Ontario, Canada. Purolator is 91% owned by Canada Post, 7% owned by Rainmaker Investments, and 2% owned by others [24].

9.1.4.2

TDG handling policies

Purolator is a leading Canadian carrier of dangerous goods for both air and ground transport. Purolator accepts a wide range of dangerous goods for transport within Canada and to the United States. Purolator does not accept dangerous goods shipments to international

destinations apart from the United States. Some classes of dangerous goods are not accepted for transportation within Canada and to the United States, such as explosive, toxic gases. Dangerous Goods Class 9 is accepted to the United States by air but with restriction depending on UN numbers and quantities [25].

9.1.4.3

Specifics on lithium batteries

Purolator will not accept dangerous goods for carriage from Canada to, or to Canada from, international (non-U.S.) points, with the exception of lithium metal batteries contained in or packed with equipment (UN3091) and with the exception of lithium ion batteries contained in or packed with equipment (UN3481) prepared under Section II of the applicable IATA packaging instructions. Shipments containing UN 3090 lithium metal batteries or UN 3480 lithium ion batteries prepared according to Section II of the IATA packaging instructions are not accepted by Purolator for carriage [26].

Lithium Battery Transport Research Program Page 23 of 413

9.1.5 United Parcel Service (UPS)

9.1.5.1

Company overview

United Parcel Service (UPS) was founded in 1907 in the United States and is one of the world’s leading package delivery companies, focusing on the transportation of goods globally across more than 200 countries and territories [27]. Its headquarters are located in Atlanta, Georgia. With more than 434,000 employees internationally, UPS has expanded its business to supply chain and freight management services. The supply chain and freight management services include logistics and distribution, transportation and freight (air, sea, ground, and rail), freight forwarding, international trade management, customs brokerage, and less-than-truckload brokerage and transportation management services [28].

9.1.5.2

TDG handling policies

Shippers must be pre-approved by UPS for shipping dangerous goods. To obtain pre-approval, shippers must have a daily pick-up set up with UPS. Daily pick-up is arranged with UPS only for high volume/frequent shippers.

Goods that meet the definition of Limited quantities and consumer commodities under the Transportation of Dangerous Goods Regulations (TDGR) may be shipped within Canada using UPS Standard service only. Limited quantity and consumer commodity shipments are prohibited from origins and to destinations not accessible by ground transportation even when such

shipments are prepared using UPS Standard service. Dangerous goods that do not meet the TDGR definition of limited quantity or consumer commodity, or that require transportation by a mode other than ground, are accepted for transportation only as a pre-arranged, separately contracted service [29].

Dangerous goods that are regulated by the International Civil Aviation Organization (ICAO) as published in the International Air Transport Association (IATA) dangerous goods regulations and the Canadian TDGR are accepted for transportation only as a pre-arranged, separately

contracted service. Restrictions apply to commodities carried, quantities and available transportation services [29].

9.1.5.3

Specifics on lithium batteries

UPS has changed their requirements for shipping lithium batteries by air starting January 1, 2017. With this change in effect, U.S. Air and international Air shipments of lithium-ion or metal cells and batteries shipped without equipment must ship as fully regulated dangerous goods [30].

UPS will no longer accept shipments of Section II of IATA Packing Instructions 965 (ion, UN3480), 968 (metal, UN3090), and 49 CFR 173.185(c) for air shipment under reduced

regulations. These shipments must be fully regulated dangerous goods shipments and prepared and packed as such. Before shipping lithium ion batteries or lithium metal batteries without equipment by air, shippers will need to enter a UPS dangerous goods service agreement first.

Lithium Battery Transport Research Program Page 24 of 413 This requirement does not apply to UPS Ground shipments. Shippers may expect to pay

additional service fees to these changes [30].

9.1.6 Courier service selection

As described in the above sections, the courier services have their specific requirements for dealing with lithium ion batteries. A summary of these specificities is provided in Table 2. Canada Post does not accept dangerous goods for air transportation and Purolator accepts them for shipping only within Canada. While UPS requires the shipper to be pre-authorized by their dangerous goods department for shipping lithium ion batteries as PI966-Section I, DHL requires such pre-authorization for PI966-Section I and Section II.

The couriers selected for this study were DHL, FedEx and UPS, since all three accept lithium batteries under PI966 Section I and II and ship internationally. However, Canada Post and Purolator were used for one domestic shipment each to gain information about their dangerous goods handling practices.

Table 2: Courier service available for shipping lithium ion batteries Service Availability in Vancouver, BC Shipping PI966-Section I Shipping PI966-Section II

Canada Post Yes No Yes

DHL Yes Yes (*) Yes (*)

FedEx Yes Yes Yes

Purolator Yes Canada domestic only Yes

UPS Yes Yes (*) Yes

(*) Shipper must be pre-authorized by the shipping company

9.2

Dangerous goods training

According to the TDGR subsection 6.1 [31] , “a person who handles, offers for transport or transports dangerous goods must:

a) be adequately trained and hold a training certificate in accordance with this Part; or b) perform those activities in the presence and under the direct supervision of a person

who is adequately trained and who holds a training certificate in accordance with this Part.”

As a key element in the transportation cycle, the training of personnel dealing with dangerous goods is important as it directly impacts the safe transportation of dangerous goods. In the following section, an overview of these training is presented based on what have been experienced during this study.

Lithium Battery Transport Research Program Page 25 of 413

9.2.1 Training providers

Training providers would offer specific types of trainings for ground transportation and air transportation. Ground transportation training is required to ship dangerous goods by ground as well as receiving dangerous goods. Air transportation training is required to ship dangerous goods by air, while ground transportation training is required to receive dangerous goods and ship them by ground.

These dangerous goods trainings are available in-class or online. In-class training is usually the preferred option as it provides opportunities for students to gather more insights about not only the regulations, but also the best practices. For example, the following practices regarding how to complete the “Shipper’s Declaration for Dangerous Goods” (example provided on Annex 19) were provided by a local dangerous goods instructor, but were not offered in the online course [32]:

The instruction “Delete non-applicable” means the non-applicable mention must be crossed out with black lines

A black pen must be used to sign the document. The document must have only black and red colours.

9.2.2 Trained personnel

To ensure that only qualified personnel can ship dangerous goods, only personnel holding a valid training certificate are allowed to fill and sign the required dangerous good declaration. Completing a declaration requires a thorough knowledge of the dangerous goods regulations as exact wordings from the IATA DGR [33] must be used to fill this form.

A dangerous goods declaration is not required to ship small quantities of lithium batteries. Hence, while any quantities of lithium batteries are considered dangerous goods, for small quantities there are no controls in place to ensure that only trained personnel would certify that the small quantity being shipped is, in fact, within the recommended limited specified by IATA. Furthermore, IATA regulations do not require packaging with UN-certified performance. Only a “strong rigid outer packaging” is required, which can be a vague definition for unqualified personnel.

9.2.3 Training control

UPS requires shippers to be pre-approved by their dangerous goods department. Such approval is given only to a large volume account for a given daily pick-up location. Shippers have to describe their internal procedures for dangerous goods handling as well as providing copies of valid dangerous goods training certificates. However, such pre-approval is not required for shipping a small volume of lithium batteries.

DHL requires shippers to be pre-approved by DHL dangerous goods department. The approval is specific to a pick-up location but doesn’t require any volume of the shipment. The approval process is similar to the one of UPS. Furthermore, DHL requires such approval for any amount

Lithium Battery Transport Research Program Page 26 of 413 of lithium batteries. This would ensure that any package with a lithium battery marking has effectively been prepared by qualified personnel.

FedEx does not require shippers to be pre-approved. However, packages with a shipper’s declaration for dangerous goods are thoroughly inspected, and any deviation from the DGR are motives of rejection.

Figure 5 describes the chain of custody of lithium ion batteries shipped as dangerous goods as UN3481 – PI966-Section I. Evidenced by shipments during this study, this chain of custody is strictly enforced by the courier companies. However, when a shipper’s declaration of dangerous goods is not required (UN3481 – PI966-Section II), this chain of custody couldn’t be

ascertained.

Figure 5: Chain of custody for lithium ion batteries where a shipper’s declaration of dangerous goods is required

9.3

Customs regulations

Customs regulations for import and export varies from country to country and will define if and how products can be exported from one country and imported to another. Some details are provided on Annex 16. These regulations rely on the Harmonized Commodity Description and Coding System (HS) established by the World Customs Organization (WCO). Like more than 200 countries, Canada has adopted this system to regulate the import and export of products. The current HS code counts over 5000 groups of products that are described by a 6-digits number. For example, rechargeable lithium ion batteries would have the HS code “8507.60”, which represents the group of products described by “electric accumulators; lithium-ion, including separators, whether or not rectangular (including square).”

Lithium Battery Transport Research Program Page 27 of 413 However, with the multiplication of a variety of products, particularly in the electronics sector, a need appeared to expand the number of groups to track the flow of commodities better. In that regard, China has adopted a 10-digits HS code, which refines the existing groups in several sub-groups. Any products going through Chinese customs must be identified with the adequate 10-digits HS code. Hence, the 6-digits code for lithium ion batteries would decompose as follow:

8507.60.0000: Lithium ion

8507.60.0010: Lithium ion accumulator’s monomer for Battery Electric Vehicle (BEV) and Plug-In Hybrid Electric Vehicle (PHEV), capacity ≥ 10 Ah, specific

power ≥ 110 Wh/kg

8507.60.0020: Lithium ion accumulators system for BEV and PHEV, including

accumulators modular, container, cover, cooling system, management system, specific power ≥ 80 Wh/kg

8507.60.0090: Other lithium ion accumulators

Concerning shipping our data acquisition systems, the HS code for lithium ion batteries cannot be used as it doesn’t represent the actual content of the package. The selection of the adequate HS code for our data acquisition system is not trivial as such a system could meet the

description of several HS groups.

Knowing that each group have their specific customs requirements, it is essential to choose it accurately. For example, our data logging system could fit into the description “Other automatic data processing machines, presented in the form of systems” of the HS code 84714999. However, upon further verifications, this code is used for products requiring a connection to a power outlet. Hence, these products would require an electrical certification to be allowed to enter in the destination country. In China, product in this category requires a China Compulsory Certification.

For our shipments, the 6-digits HS code used was 9031.80, “Instruments, appliances and machines; for measuring or checking not considered in chapter 90”. And the 10-digits HS code used was 9031.80.9090, “Other measuring and testing equipment, apparatuses and machines (not specified or included elsewhere in Chapter 90)”.

Most courier companies are now providing custom clearance services and act on behalf of the exporter and importer at the customs. In China, the customs regulations do not allow courier companies to represent the Chinese importer or exporter. A company wishing to import or export products must have their own registered customs broker or hire the services of a

registered customs broker. The registered customs broker would need to provide a copy of the Power of Attorney they received from the company.

Furthermore, a company located in China wishing to export products that are made under a foreign brand name must provide to the Chinese customs a certificate of exportation from the brand name, allowing them to export a given quantity of products per year to specific countries. For the Chinese destinations covered in this study, a Chinese customs broker was hired to assist with the importation and exportation of our packages in and out of China.

Lithium Battery Transport Research Program Page 28 of 413

10. Experimental plan

Thanks to air transportation regulations and related standards, lithium batteries are being shipped around the world in various forms, shapes, weights and conditions. As a consequence, the task of estimating the environmental conditions of lithium batteries in air transportation and compliance of shipping packages to the regulations and standards encompasses a large number of variables. For our experimental plan, we have limited the variables to be the following:

Courier service Package weight Package marking Shipping route

The courier services were discussed in section 9.1. Due to various restrictions and service availability, only FedEx, UPS and DHL were considered in our experimental plan.

In the following section, the packages design, packages instrumentation and shipping routes are discussed.

10.1 Packages design

The most popular type of lithium ion cells, the 18650, are shipped by manufacturers in packages of 100 cells. The total gross weight of such packages is about 5 kg. These packages would be shipped individually or as several 100-cell packages bundled in an outer box. Package design varies significantly from one supplier to another. NRC routinely receives packages of lithium ion batteries. Figure 6 below shows the use of a spacer that prevents any contact between individual cells. A plastic sheet is also placed on top and bottom. Figure 7 illustrates one of the multiple variations of packaging observed from online vendors of lithium ion batteries. The spacing is kept to a minimum, and the protective plastic sheet is absent.

Figure 6: 18650 lithium ion cells received at NRC for testing

Figure 7: 18650 lithium ion cells shipping packages as seen on eBay

Lithium Battery Transport Research Program Page 29 of 413 Package mass plays an essential role in their handling by the courier services. Our study was planning to evaluate a broad range of mass, from small 2.5 kg packages to large packages weighing up to 32 kg. During our literature review on environmental shipping conditions [5], it was found that small light packages were being placed with many other packages in large shipping bags. It was that in such situations, the shocks and vibrations experienced by the packages were much smaller than of large packages handled individually. On the other side of the range, large packages loaded on pallets experiences many small shocks and drop heights than individual packages. However, vibrations were comparable to individually handled packages.

Hence, for this present study, two sizes of packages were used to evaluate the difference in shipping conditions. A small, 5 kg package was designed following the specifications of packages used to ship lithium ion cells of type 18650 with 100 individual cells by package. A large, 32 kg package was designed to evaluate the shipping of lithium batteries in packages that are too heavy to be carried by hand.

For a few shipments, variations of these packages were designed to meet the requirements of lithium ion batteries shipped under Class 9, when cells have to power above 20 Wh or batteries have power above 100 Wh.

Table 3: Type of packages used in this study

Net weight (kg) PI966-Section I (Class 9) PI966-Section II (marked) Type A 5 No No Type B 5 No Yes Type C 32 No No Type D 32 No Yes Type E 5 Yes No Type F 32 Yes No

10.1.1 Type A package: 5 kg, non-DG

A single wall cardboard box, model S-4311 distributed by ULINE in Canada, was used. Their specifications are as followed:

Dimensions:

Outside (L x W x H): 10 3/8” x 10 3/8” x 3 5/8" (26.35 cm x 26.35 cm x 9.2 cm) Inside (L x W X H): 10” x 10” x 3” (25.4 cm x 25.4 cm x 7.6 cm)

Specifications: Seams are glued.

Meets ASTM D5118 and D3951.

32 Edge Crush Test: Shipping up to 30 lbs (13.61 kg)

Figure 8 and Figure 9 show the outside of type A (non-DG, 5 kg) package ready for shipping and its content with the data logger mounted on a steel frame.

Lithium Battery Transport Research Program Page 30 of 413 Figure 8: Type A package ready for shipping Figure 9: Content of type A package

These packages would represent the typical size and mass of a package that can be handled by hand within the courier companies. These packages do not contain any lithium batteries. It has been reported in the literature [5] that small and lighter packages are often placed in shipping bags to facilitate the handling of multiple small packages. In these bags, packages are only indirectly exposed to environmental shipping conditions. Shocks and vibrations are

distributed amongst several package. The previous study did not specify whether this practice applied to every small packages or only to regular unmarked packages.

10.1.2 Type B package: 5 kg, PI966-Section II

Type B (PI966-Section II, 5 kg) packages use the same single wall cardboard boxes as type A (non-DG, 5 kg) packages described above. However, four lithium ion cells of type 18650, fully discharged, are placed with the data logger. Each cell is individually bagged in a plastic pouch. They are placed between two layers of packing foams to ensure the cells will not move even if the package is dropped from a significant height (up to 2 m). A lithium ion battery marking is placed on the outer box according to UN 3481 – Packing Instructions (PI) 966 Section II (Figure 10).

Lithium Battery Transport Research Program Page 31 of 413 Figure 10: Marking applied on type B packages

A mention “Lithium ion batteries packed with equipment - PI 966 Section II,” is added on the same side of the DGR required UN3481 label.

Note that the height of these 5 kg boxes does not allow us to use the recommended size of the lithium ion marking (W x H: 120 mm x 110 mm). Instead, the size of our marking was reduced to the minimum allowed by IATA (W x H: 105 mm x 74 mm) to fit on the side of the package. Hence, the size of our marking was W x H: 80 mm x 74 mm to keep the same aspect ratio as the recommended label.

The slight discrepancy in the width, 80 mm instead of the recommended 105 mm, was only noticed by DHL and was a reason for DHL to request the use of a marking with the

Lithium Battery Transport Research Program Page 32 of 413 Figure 11: Type B package ready to be shipped with UN

3481 marking Figure 12: Content of type B packages with fully discharged lithium ion Cells

10.1.3 Type C package: 32 kg, non-DG

Type C (non-DG, 32 kg) packages are composed of one package type A (non-DG, 5 kg) and five packages acting as ballast to simulate the weight of additional lithium batteries that would be shipped in one large package. These packages do not contain any lithium batteries. 5 kg of vacuum-bagged gravel packed with the same cardboard box of package type A (non-DG, 5 kg) has been used to make the ballast packages.

However, for destinations in China, 5 kg of solid aluminum blocks were used instead of gravel, as gravel is not allowed for importation in China.

The arrangement of these packages is illustrated in Figure 16.

Lithium Battery Transport Research Program Page 33 of 413 The outer box uses a double-wall cardboard box, model S-12603 distributed by ULINE in

Canada. The specifications are as followed: Dimensions:

Outside (L x W x H): 20 3/4” x 12 3/4” x 13 (52.7 cm x 32.38 cm x 33 cm) Inside (L x W X H): 20” x 12” x 12” (51 cm x 30 cm x 30 cm)

Specifications: Seams are glued. Meets ASTM D5118

275 Edge Crush Test: Shipping up to 80 lbs (36.3 kg)

Cardboard honeycomb (ULINE S-16335, ½” thick and S-12834, 1” thick) have been used to fill the gaps within the aluminum ballast packages (sides, top and bottom) and between the six packages and the outer box (sides and top only). Cardboard honeycomb was placed only on the top to reduce interference when measuring the shock and vibrations during handling.

Heavy parcel marking was placed on each side of the outer box as required by the National Institute for Occupational Safety and Health for parcels heavier than 23 kg.

Lithium Battery Transport Research Program Page 34 of 413 Figure 15: Type C package ready to be shipped

10.1.4 Type D package: 32 kg, PI966-Section II

Type D Section II, 32 kg) packages are composed of one package type B (PI966-Section II, 5 kg) and the same five ballast packages used in type C (non-DG, 32 kg) packages. In addition to the heavy parcel marking, the same marking of a type B (PI966-Section II, 5 kg) package is applied: a lithium ion battery marking is placed on the outer box according to UN 3481 - PI 966 Section II, lithium ion batteries packed with equipment, and a mention “lithium ion batteries packed with equipment - PI 966 Section II,” on the same side.

Lithium Battery Transport Research Program Page 35 of 413

10.1.5 Type E package: 5 kg Class 9

A double-wall cardboard box, model 15SPA distributed by ICC in Canada, was used. Their specifications are as followed:

Dimensions:

Inside (L x W X H): 15”x 15” x 15” (38.1 cm x 38.1 cm x 38.1 cm) Specifications:

UN specifications: 4GV/X21.5/S Meets ASTM D5118

Maximum gross weight: 47.4 lb (21.5 kg)

The cardboard box is accompanied by specific packing instructions (an example is provided on Annex 17) that must be followed in order to meet the specifications for which the cardboard box has been certified. In that regard, the data acquisition system (data logging sensors mounted on a steel frame) has been wrapped with two sheets of bubble wrap and secured clear tape. A minimum of 1 ½” distance on all sides was ensured using packing peanuts. Packing peanut filling ensured a snug fit to prevent any movement.

A Class 9 diamond mark is applied on the longest side of the outer box. On the same side, the shipper and consignee names and addresses and the mention “lithium ion batteries packed with Equipment” with the net weight of lithium ion batteries have been applied.

The marking on the outer box is strictly controlled by the carriers’ dangerous goods inspector. This inspection occurs at the courier company reception facility, where courier pickup drivers deliver the packages they have collected.

The assessment relies on the shipper’s declaration for dangerous goods, the Safety Data Sheet (SDS), and the certification of State-of-Charge (SoC) provided by the shipper. Section 14 of the SDS defines the transportation requirements. The shipper’s declaration for dangerous goods would refer to the DG Class specified in the SDS, identify the marking to be used on the outer package, the type of packing, and the packing instruction. It also relies on the UN Certification printed by the manufacturer on the outer box.

Lithium Battery Transport Research Program Page 36 of 413 Figure 17: Type E package 5 kg, Class9 ready for shipping

10.1.6 Type F package: 32 kg Class 9

A double-wall cardboard box, model SP24 distributed by ICC in Canada was used. Their specifications are as followed:

Dimensions:

Inside (L x W X H): 20.75" x 20.75" x 12.5" (52.71 cm x 52.71 cm x 31.75 cm) Specifications:

UN specifications: 4GV/X38.6/S Meets ASTM D5118

Maximum gross weight: 84.9 lb (38.6 kg)

The cardboard box is accompanied with specific packing instructions (example provided on Annex 18) that must be followed in order to meet the specifications for which the cardboard box has been certified. In that regard, the inner side of the box was lined with the liner bag provided. A layer of 2 ¼” of vermiculite absorbent / cushioning material was placed on the bottom of the package. The data acquisition system was placed on top of this layer. The remaining void of the package was further filled with vermiculite absorbent / cushioning material. The liner bag was then closed with a single knot before sealing the box.

A lithium battery Class 9 diamond mark is applied on the longest side of the outer box. On the same side, the shipper and consignee names and addresses and the mention “lithium ion batteries packed with Equipment” with the net weight of lithium ion batteries has been applied. Marking cautioning about the heavy package have been applied on the four sides of the outer packaging.

Lithium Battery Transport Research Program Page 37 of 413 Figure 18: Type F package 32 kg, Class 9 ready for shipping

10.2 Data acquisition system

A data acquisition system has been designed to measure the environmental conditions that packages of lithium ion batteries would experience during transportation cycles that include air transportation.

The data acquisition system would be composed of sensors, signal processors, data acquisition and storage devices. These are often packaged into a single instrument, a data logging sensor. To measure the shocks and vibrations experienced by the package, the data logging sensor is mounted on a frame that will transmit shocks and vibrations without interference.

Once built, the data acquisition system has been calibrated for each environmental parameter and within the range commonly reported in the literature.

10.2.1 Data logging sensors

A review of the commercially available data logging sensors has been carried out to identify the most suitable devices to be used to measure the environmental conditions during shipping. The following table summarizes the requirements:

Lithium Battery Transport Research Program Page 38 of 413 Table 4: Data logging requirements

Parameter Requirement Comments

Pressure Required Record ambient pressure to identify depressurization events occurring during flights

Temperature Required Record ambient temperature to identify extreme temperatures that may occur during the shipping cycle

Humidity Required Record ambient humidity to identify extreme temperatures that may occur during the shipping cycle

Vibration Required Record vibrations transmitted to the package during the transportation cycle

Shock Required Record the shocks the package may receive during the transportation cycle

Tilt and Roll Optional Record the tilt and roll of the package to identify the handling periods of the packages

Free fall height Required Record the maximum free fall height of the package during the transportation cycle

Luminosity Optional Record the luminosity inside the package to identify the period the packages have been opened.

Electromagnetic Compatibility

Required Device certified to RTCA D0-160D for Radiated Emission as required by ICAO

Powered by alkaline battery

Required Do not introduce lithium battery hazard in the packages

A comprehensive search was carried out to compare the available commercially available devices. The following tables (Table 5 and Table 6) summarize the features of an adequate data logger commercially available.

The Shocklog 298 was selected because it met all required specifications, and also provided the optional specification of recording the tilt and roll of the packages.

During the experiments, it was found that the analysis of the shocks recorded couldn’t provide an accurate measurement of the free-fall drop height, the parameter used to qualify lithium batteries for air transportation.

Shocks are typically reported by data logger devices as a measure of acceleration or deceleration. These measurements represent what is experienced by the data logger. Hence, the amplitude of the shocks will be reduced by any cushioning materials such as the outer cardboard box, and protective foam.

In comparison, the free-fall height is based on the duration of the fall during which, the accelerometers report a null acceleration. This measure is, therefore, independent of the packaging. It was therefore decided to add a secondary data logging sensor (Shock Recorder TRE38) to the following packages.

![Figure 22: Import and Export of lithium ion batteries to and from Canada [35]](https://thumb-eu.123doks.com/thumbv2/123doknet/14001564.455978/47.1188.108.1072.100.576/figure-import-export-lithium-ion-batteries-canada.webp)