Publisher’s version / Version de l'éditeur:

Adhesives Age, 31, 5, pp. 20-23, 1988-05

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Exposure evaluation of sealants with low movement capability

Karpati, K. K.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=6aee23ab-f2f3-4d90-ae75-72d6111503ac

https://publications-cnrc.canada.ca/fra/voir/objet/?id=6aee23ab-f2f3-4d90-ae75-72d6111503ac

Ser

National Research

Consell national

TH1

$1

Council Canada

de recherches Canada

N21d

no.

1568

Institute for

lnstitut de

c. 2

Research in

recherche en

BLDG

Construction

construction

Exposure Evaluation of Sealants with

Low Movement Capability

by K.K. Karpati

Reprinted from

Adhesives Age

Vol. 31, No. 5, May 1988

p. 20

-

24

(IRC Paper No. 1568)

ABSTRACT

Low-movement-capability sealant. can be quickly evaluated by using a strain-cycling rack,

because failures start to occur within a few months if

the

material is poor. If failures do not

occur within the fmt winter, then the specimens

can last many years.

Les

produits d'ttanchBtt ayant une faible capacid de mouvement peuvent

etrerapidement

tvaluts au moyen d'un appareillage de dtformation cyclique. car les dkfaillances

commencent B

seproduire apds quelques mois si le mattriau est dtfectueux. S'ils ne

prksentent aucune dtfaillance au cours du premier hiver, les produits d'ttanchtitt peuvent

durer alors de nombreuses anntes.

Exposure Evaluation of Sealants

With Low Movement Capability

By K.K. Karpati

Research Officer (ret.)

National Research Council of Canada

Institute for Research in Construction

Ottawa, Ontario

KIA

OR6 Canada

T

he performance of sealants hasbeen investigated by the Institute for Research in Construction with the object of deriving a laboratory method for testing their performance. Establishing whether a laboratory test can predict the performance of sealants in service requires exterior exposure un- der conditions that realistically simulate that service. Because of the marked ef- fect of building joint movement on the performance of sealants, especially in winter, the method developed for eval- uating them comprises exposure on a rack where air temperature variations reproduce as nearly as possible the width changes that sealants have to withstand in service (1).

Owing to the wide range in the move- ment capability of the various sealant types (2), most of the separate studies have been restricted to one generic type

( 3 , 4 , 5 ) . In the work reported here,

however, the behavior of several low modulus sealants (those not claimed to perform a t movements greater than

+

10% of the sealant bead width) was examined on the strain-cycling rack.Experimental

Two sets of low-movement-capability sealants were exposed on the strain-cy- cling exposure rack at different times. The first exposure, started in the fall of 1974, lasted three years and consisted of a solvent-borne acrylic and a butyl seal- ant with claimed maximum movement capabilities of

+

7.5% and k 5% (ex- pressed in percent of specimen width), coded A and B respectively. The second exposure started in the early summer of 1978 and lasted until the end of summer 1980. The set was made up of three sol- vent-borne acrylic sealants (coded AS, AP, AU) from different manufacturers, two latex acrylics (AC, AH) with a claimed maximum+

10% movement capability, and one chlorosulfonated polyethylene (H) with claimed move- ment capability of+

12.5%.The specimen and substrate sizes and the preparation method were the same as those used for other chemical types

Figure 1. Solvent acrylic sealant (Code A) in compression during summer of third year of exposure. l a (left): * 5 % , l b (right): +29% yearly joint width change.

of sealant (3,4). During preparation the backing material was a fragile polyure- thane foam film that crumbled away on touch and did not interfere with the movements of the sealant. For sub- strates, aluminum and cement-mortar bars were used (preparation of the ce- ment-mortar bars is described in Refer- ence 6). Four to eight specimens were exposed on both aluminum and cement- mortar substrates for each of the six products in the second set. (The ce- ment-mortar substrates weakened around the attaching screws and often cracked, but were successfully repaired with epoxy adhesive.)

The yearly amplitudes of movement produced on the specimens of the first set started at

+

5% and increased about+

0.7% with each specimen for the first 12 specimens, then increased+

3% from+

14% to k 29%; there was a to- tal of 18 specimens for each chemical type. The yearly amplitudes of move- ment produced on the second set of specimens ranged in a year from about+

5% to+

11% of the joint width. The duplicate specimens on each substrate were placed at different movement lo- cations on the rack as space allowed.Materials with lower claimed movement capability were placed towards the lower movement end of the rack.

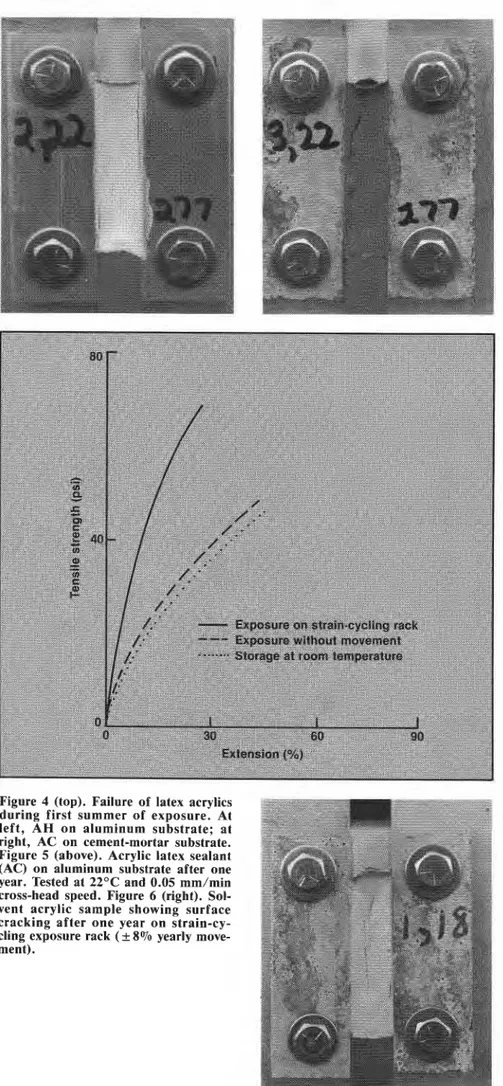

The tensile curves for acrylic A, at a cross-head speed of 5 mm/min, were recorded after one month's curing in a constant temperature room (22OC), af- ter six months' and one year's exposure on the strain-cycling rack, and after one year o n a n exposure rack without movement. Tensile testing at the end of the three-year exposure was not done because of permanent deformation of the sealant. In the second set, tensile tests after one year of exposure were conducted at a speed of 0.05 mm/min on the solvent-borne acrylics, the chlo- rosulfonated polyethylene and the spec- imens of the one latex acrylic that Bad not failed (AC on aluminum).

Results and Discussion

After the exposures were concluded, the following results were noted.First Exposure Set. In the first expo-

sure the solvent-borne acrylic sealant (code A) performed very well for the three years, even at high amplitudes of yearly movement (maximum +29% of

Figure 2 (top). Solvent acrylic exposures (Code A) on strain-cycling rack (SCR), on rack without movement (FX) and af- ter laboratory storage (CTR). Tested at 22°C and 5 mm/min cross-head speed. Figure 3 (bottom). Specimen location and evaluation on strain-cycling rack in second experiment.

joint width change investigated), al- though the claim was for only +7.5%

yearly movement. It progressively ac- quired a crease in the center on the south exposure side and a bulge on the north side. Figure 1 (a and b) shows the appearance of specimens after nearly three years of exposure, in the summer when temperatures of about 100°F were measured in the sealant. The specimen in Figure l a is compressed about 5% of its width and that in Figure l b about

29%. Where the crease occurs there is a thinned section of the sealant t h a t bulges on the opposite side. When the joint opens in winter, the crease and bulge unfold so that the sealant main- tains a barrier against air, water and dust.

The sealant remained soft throughout the three years. As shown by the tensile results in Figure 2, the specimens ex- posed on the rack without movement showed considerable hardening com- pared with the specimens cured for one

-t 2 5 0 / x snths TR, 1 mon'

--==:*=

A

a n n2: no fallure but surface cracked IN: no failure after two years

of exposure

polyernylen T: tested after one yoar of

month in the constant-temperature room. The curves obtained for strain- cycled exposures are intermediate with regard t o l o a d , while the extension shows little change. The results from the strain-cycled one-year exposure are grouped relatively closely in spite of the large differences in movement. There is a small drop in load from *7% and *9% to the

+

17% and +25% range when the results are averaged, but the difference is small when compared with the curves from the six-month expo- sures.It can therefore be concluded that width cycling, however small the ampli- tude, has a softening effect on this sol- vent-borne acrylic sealant. Exposure without movement produced hardening of the specimens but, because it pro- duced no failure or permanent defor- mation, its importance as a factor de- termining the performance of the seal- ant is smaller than the cyclic movement that would eventually produce failure by permanent deformation, i.e., pro- gressive thinning of the cross-section. The same conclusion was reached for silicone (3) and two-part polysulfide (4) sealants in previous investigations.

All eighteen butyl sealant specimens of the same product failed adhesively in the first winter.

Second Exposure Set. The results for the second exposure set at the end of two years are shown in Figure 3. Both acrylic latex sealants started to fail dur- ing the first summer - two of six spec-

I?: small I. * i L _ h 1 fet faflure 'Ad rate 'Ad A i : air Cm: ce ubstrate --.L-.

-

aonesive failu solvent ac 'Ck red in cer e during i e durlng 1 ner I : crack ' faiflur 3 laifur I ter lfrst sumn first wlnte lstex acr] lorosulfor . " - - * L A - * u L tated eI-Cr

!

-

tzxposure on srraln-cycltng rack---

Exposure without movement.

..-.-..

Storage at room temperature-

Figure 4 (top). Failure of latex acrylics during first summer of exposure. At left, A H on aluminum substrate; at right, AC on cement-mortar substrate. Figure 5 (above). Acrylic latex sealant (AC) on aluminum substrate after one year. Tested at 22OC and 0.05 mm/min cross-head speed. Figure 6 (right). Sol- vent acrylic sample showing surface cracking after one year on strain-cy- cling exposure rack (f 8% yearly move-

ment).

sion (%)

imens in each case - with most of the remainder failing during the first win- ter. Failures were adhesive, except for some specimens of AC on cement-mor- tar that failed by cracking along the center (Figure 4). The averaged tensile test results from specimens of AC on aluminum are shown in Figure 5. It is clear that exposure without cycling had little effect. When subjected to move- ment during exposure, there was con- siderable hardening and some loss of

Lo w-movement-capability

sealants can be quickly

evaluated by using

a strain-cycling rack,

because failures start

to occur within a few

months

if

the material

is

poor. If failures

do not occur within

the first winter,

then the specimens

can last many years.

extensibility not observed with other types of sealant. The latex acrylics were generally hard, with loads at failure at least 10 times those of solvent-borne acrylics; this explains their failure. (Note difference in scales of Figures 2 and 5.)

Two of the solvent acrylics, AU and

AS, had tensile curves shaped like those of sealant A in the first exposure. The second sealants were tested, however, at a cross-head speed one-hundredth that of sealant A; because of the time-tem- perature inverse relation, testing at the slower speed would make them appear more flexible. These solvent acrylics also performed well during the two years of exposure, although all had some surface cracking. An example of this cracking after one year of exposure on the strain-cycling rack is shown in Figure 6. The third solvent acrylic, AP, did not yield the shape of tensile curves observed with the others. Rather, it had the shape of the latex types,. although the load at failure was similar t o the other solvent types but with lower ex- tensibility, ranging from 100%-120% after one year of exposure (22OC and

0.05 mm/min cross-head speed). It per-

formed well during the two years and remained soft.

The chlorosulfonated polyethylene sealant also performed well during the exposure, remaining soft for the obser- vation period. The tensile curves were similar to those of product A but with a much broader maximum.

No failures were observed o n the specimens exposed without movement.

Conclusions

The strain-cycling exposure rack can provide a quick evaluation of low- movement-capability sealants because failures start t o occur within a few months if the material is poor. If they d o not occur during the first winter, then the specimens can last many years and at higher amplitudes of movement than are generally claimed by the man- ufacturers, giving a good safety margin for the product.

Tensile tests demonstrated consider- able hardening of most of the sealants as a result of exposure alone. Exposure without movement, however, did not produce failure, indicating that weath- ering by itself is of minor importance in sealant performance. Strain-cycling markedly reduced the hardening of sol- vent-borne acrylics but had the opposite effect on latex acrylics. Hence, the for- mer are more desirable since they did not fail during the exposure period.

The most important factor influenc- ing performance is cyclic movement, as has been found with other types of seal- ant. Consequently, it should be possible to develop a performance-related labo- ratory test as was done for other types

of sealant. For polysulfide (7) and for silicone sealants (8), cycling on vises can be the basis of the laboratory test. For acrylics, given the considerable harden- ing observed on exposure, accelerated aging with heat or combined heat and ultraviolet exposure should be included with cycling in the laboratory test. Ten- sile tests should be suitable for checking equivalence of accelerated aging to out- door exposure as the specimens regis- tered large changes in tensile properties when exposed.

In such a test, softer types of sealant should fail by permanent deformation, with cavity and bulge formation similar to that observed on a polysulfide (4), but harder varieties may show adhesive failure before any permanent deforma- tion can occur. Any laboratory test should be confirmed by exposure tests on the strain-cycling rack before being adopted for specification compliance testing.

References

(1) Karpati, K.K., Solvason, K.R., and Sereda, P.J. 1977. Weathering rack for sealants. Journal of Coatings

Technology, Vol. 49, No. 626, p. 44.

(2) Baldwin, R. 1976. Selecting high performance building sealants. Plant

Engineering, Jan. 8, pp. 58-64.

(3) Karpati, K.K. 1980. Weathering of silicone sealant on a strain-cycling exposure rack. ADHESIVES AGE, Vol. 23, No. 22, pp. 41-47.

(4) Karpati, K.K. 1984. Investigation of the factors influencing the outdoor performance of two-part polysulfide sealants. Journal of Coatings Tech- nology, Vol. 56, No. 719, pp. 57-60. (5) Karpati, K.K. Performance of poly- urethane sealants on a strain-cycling exposure rack. To be published. (6) K a r p a t i , K.K. 1978. New test

method for resistance to water im- mersion; some results obtained with two-part polysulfide sealant. Jour-

nal of Coatings Technology, Vol.

50, No. 641, pp. 66-69.

(7) Karpati, K.K. 1987. Laboratory fa- tigue test of a two-part polysulfide sealant correlated to outdoor per- formance. Durability of Building Materials, Vol. 5, No. 1, pp. 35-51. (8) Karpati, K.K. Laboratory fatigue

test of chemically curing silicone sealants correlated to outdoor per- formance. To be published.

Acknowledgment

The author wishes to thank R.C. See- ley for experimental assistance and H.E. Ashton for assistance in preparing the paper.