HAL Id: hal-01904321

https://hal.archives-ouvertes.fr/hal-01904321

Submitted on 24 Oct 2018

HAL is a multi-disciplinary open access archive for the deposit and dissemination of sci-entific research documents, whether they are pub-lished or not. The documents may come from teaching and research institutions in France or abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est destinée au dépôt et à la diffusion de documents scientifiques de niveau recherche, publiés ou non, émanant des établissements d’enseignement et de recherche français ou étrangers, des laboratoires publics ou privés.

Montmorillonite colloids: I. Characterization and

stability of dispersions with different size fractions

Knapp Karin Norrfors, Muriel Bouby, Stephanie Heck, Nicolas Finck, Remi

Marsac, Thorsten Schäfer, Horst Geckeis, Susanna Wold

To cite this version:

Knapp Karin Norrfors, Muriel Bouby, Stephanie Heck, Nicolas Finck, Remi Marsac, et al.. Montmo-rillonite colloids: I. Characterization and stability of dispersions with different size fractions. Applied Clay Science, Elsevier, 2015, 114, pp.179 - 189. �10.1016/j.clay.2015.05.028�. �hal-01904321�

1

Montmorillonite colloids. I: Characterization and stability of dispersions

1

with different size fractions

2

Knapp Karin Norrfors*a,b, Muriel Boubya, Stephanie Hecka, Nicolas Fincka, Rémi Marsaca, Thorsten Schäfera, Horst Geckeisa

3

and Susanna Woldb

4

a: Karlsruhe Institute of Technology (KIT), Institute for Nuclear Waste Disposal (INE), P.O. Box 3640, D-760 21 Karlsruhe,

5

Germany

6

b: School of Chemical Science and Engineering, Applied Physical Chemistry, KTH Royal Institute of Technology,

7

Teknikringen 30, SE-100 44 Stockholm, Sweden

8

*Corresponding author. E-mail: norrfors@kth.se (K.K. Norrfors) Tel: +46 8 7909279. Fax: +46 8 7908772.

9

10

Abstract

11

Bentonite is planned to be used as a technical barrier in the final storage of spent nuclear fuel

12

and high level vitrified waste. In contact with ground water of low ionic strength,

13

montmorillonite colloids may be released from the bentonite buffer and thereby enhance the

14

transport of radionuclides (RNs) sorbed. In the present case, clay colloids represent

15

aggregates of several clay mineral layers. It is of major importance to determine RN sorption

16

properties for different sizes of montmorillonite aggregates, since size fractionation may

17

occur during particle transport in natural media. In this study, a protocol for size fractionation

18

of clay aggregates is developed, by sequential and direct centrifugation, in presence and

19

absence of organic matter. Seven colloidal fractions of different mean aggregate sizes are

20

obtained ranging, when considering the mean equivalent hydrodynamic sphere diameter

21

(ESD), from ~960 nm down to ~85 nm. Applying mathematical treatments (Jennings and

22

Parslow, 1988) and approximating the clay aggregates to regular disc-shaped stacks of clay

23

mineral sheets, results in mean surface diameters varying from ~1.5 µm down to ~190 nm.

24

All these colloidal fractions are characterized by XRD, IC and ICP-OES where they are found

2

to have the same chemical composition. The number of edge sites (aluminol and silanol) is

26

estimated (in mol/kg) for each colloidal fraction according to (Tournassat et al., 2003). It is

27

calculated from the mean particle sizes obtained from AsFlFFF and PCS measurements,

28

where the clay aggregates are approximated to regular disc-shaped stacks of clay mineral

29

sheets. The estimated number of edge sites varies significantly for the different clay

30

dispersions. In addition, stability studies using the various clay colloidal fractions are

31

performed by addition of NaCl, CaCl2 or MgCl2, in presence or absence of organic matter,

32

where no difference in stability is found.

33

Keywords

34

Montmorillonite colloids, characterization, size separation, number of edge sites, nuclear

35

waste disposal, colloidal stability

36

1 Introduction

37

In Swedish and Finnish repository designs (SKB, 2010; Vieno and Ikonen, 2005), high level

38

nuclear waste is foreseen to be placed in massive metal canisters, surrounded by a large

39

volume of natural or compacted bentonite as a barrier. The functionality of the clay is

40

primarily to stabilize the canister in case of movements in the bedrock and to seal small

41

fractures in the vicinity of the canister. The barrier is planned to prevent corrosive elements

42

from the surrounding, such as sulfide, thiosulfate and polythionates (Macdonald and

Sharifi-43

Asl, 2011) to come in contact with the canister. In case of canister failure, the barrier should

44

retard radionuclides (RNs) present in the spent nuclear fuel to be transported through the

45

geosphere towards the biosphere. Due to its high swelling pressure, cation exchange capacity

46

and retention properties, bentonite has an excellent buffer capacity (Karnland et al., 2006).

47

The main mineral component in bentonite is montmorillonite, an Al-rich smectite. Smectites

48

are intrinsically small particles, whereby they can be of colloidal sizes (i.e. particles of 1 nm -

3

1 µm in at least one dimension in dispersion (Stumm, 1993)). In this work, the term clay

50

colloids refer to aggregates, consisting of stacks of several clay mineral layers.

51

Over the estimated lifetime of the storage (i.e. 1 million years) in northern countries such as

52

Sweden and Finland (SKB, 2010), cycles of glaciations can be expected. In the worst case

53

scenario expected in Sweden, a large amount of glacial melt water will be transported through

54

fractures in the bedrock, down to repository depth and displace the old ground water that has

55

equilibrated with mineral surfaces for a very long time. Glacial melt water has a chemical

56

composition with low ionic strength, different from the original porewater. The chemical

57

composition of future glacial melt water is assumed to be similar to glacial melt waters of

58

today. It can be simulated by water types of pH 8-9 and low ionic strength, i.e. 5·10-4 M in the

59

worst case scenario cited above (Brown, 2002). The montmorillonite colloid stability is

60

known to increase with decreasing ionic strength, as demonstrated in several laboratories and

61

field experiments studies over a few months’ timeframe (Geckeis et al., 2004; Missana et al.,

62

2003; Schäfer et al., 2012) and can also be calculated from the DVLO-theory (Liu et al.,

63

2008). In contact with glacial melt water, the bentonite barrier may release montmorillonite

64

colloids that can be transported away from the barrier through the geosphere. In case of large

65

mass loss, the buffer functionality will be endangered. Also, in the case of a canister failure,

66

the transport of RNs can be enhanced, when transported by mobile montmorillonite colloids

67

(Möri et al., 2003).

68

Physically, colloid mobility depends strongly on the geometry of the fractures in the bedrock,

69

where fracture size distribution, surface roughness and surface charge are the most important

70

characteristics (Darbha et al., 2010; Filby et al., 2008). Chemically, the colloid mobility is

71

influenced by the mineral composition of the fracture filling material (FFM) and the pore

72

water matrix. The colloid mobility is also dependent on physical and chemical properties of

73

the clay aggregates themselves, i.e. the size heterogeneity, mineral composition and surface

4

charge. The physical and chemical properties of the bedrock are specific for each fracture,

75

though in general a separation of particles according to their size during transport is expected

76

in most systems. In a clean fracture system, i.e. fractures with low amount of FFM, and with a

77

high water velocity, a laminar flow is expected and transport of all colloid sizes is expected

78

more or less equally due to their ability to be transported with the water flow (Huber et al.,

79

2012). In contrary, if the fracture contains a larger amount of FFM, it will act as a porous

80

material, where the larger particles can be transported faster as a result of size exclusion

81

effects, sticking, clogging etc. Due to the possible particle size separation in bedrock

82

fractures, the size of the montmorillonite aggregates produced and their stability are important

83

parameters for RN transport. The thermodynamic and kinetic strength of RN-colloid

84

interaction determine the potential flux of radiotoxic waste components through the

85

geosphere. In fact, those RNs being weakly bound to colloids or showing a relatively fast

86

desorption from colloids will most likely not be carried by the montmorillonite colloids but

87

will be sorbed by the mineral surfaces instead (Huber et al., 2014).

88

Simplified models of RN and clay colloid transport are currently used in safety assessments

89

for estimating the RN transport, but presently they do not take into consideration the size

90

heterogeneity of the clay aggregates (Vahlund and Hermansson, 2006). Consequently, one

91

may wonder whether normalized sorption coefficients (KD) for RNs are valid expressions for

92

quantifying RN-montmorillonite interactions, since the ratio is given for a mean particle size

93

distribution and do not take into account polydispersity. An alternative, and perhaps better,

94

expression for quantifying the sorption capacities of surface complexed RNs is to take into

95

consideration the amount of edge sites in the colloidal dispersions. With this treatment,

96

eventual size dependent differences will be taken into account. This is valid as long as the

97

smaller particles are miniatures of the larger clay mineral particles, which may not be the case

98

for nanosized particles (Bergaya et al., 2006). Note that this approach is not adapted for RNs

5

sorbing by cation exchange (i.e. Cs+, Sr+ etc.). Large differences in surface structure between

100

larger and smaller clay particles may also be reflected in macroscopic properties, such as

101

colloidal stability (Bessho and Degueldre, 2009). In modeling, transport of RNs may be

102

under- or overestimated (Wold, 2010), e.g. the KD-values are not accurate if only the smaller

103

aggregates are transported and not the larger ones, or vice versa. Normalizing sorption

104

capacity to the number of edge sites might improve transport calculations of RNs sorbed to

105

different clay aggregate sizes. Furthermore, this treatment of KD-values could be implemented

106

to other systems, such as metal complexation to particles and their retardation in soils, as well

107

as colloidal transport in soil and surface waters (Gao et al., 1997; Lee et al., 2001; Nakamaru

108

and Uchida, 2008; Oliver et al., 2006). In addition to questionable normalization of sorption,

109

i.e. KD-values in transport modelling, there is a lack of sorption and desorption kinetic data

110

for RNs onto different size fractions of montmorillonite aggregates which should be

111

implemented for improved safety assessments calculations (Wold, 2010).

112

The aim of this work is to develop a method to separate montmorillonite aggregates into

113

defined size fractions, to characterize these fractions and finally to determine if the mean clay

114

aggregate size has any influence on the colloidal stability of montmorillonite. We describe the

115

protocol used to obtain different size fractions, a protocol which may be applied to any type of

116

clay dispersions. In addition, characterization of the different clay aggregate fractions such as

117

mean size, concentration, and the chemical composition of the colloidal dispersions is

118

presented. Furthermore, we describe stability studies performed on the colloidal fractions in

119

order to investigate the influence of ions which can be present in glacial melt water (Na+,

120

Ca2+, Mg2+ (Missana et al., 2003)) or degraded organic matter (Bhatia et al., 2010). In

121

separate studies (Norrfors et al., 2015), we investigate the RNs sorption/desorption behavior

122

in presence of these clay aggregate size fractions.

123

2 Material and Methods

6

2.1 Clay, organic matter, chemicals, synthetic ground water

125

All samples are prepared with ultra-pure water (Milli-Q system, 18.2 MΩ/cm resistivity) and

126

chemicals of reagent grade. The source of silicon was a standard solution of Si in H2O (1000

127

mg/L, Spex Certiprep). The Wyoming MX-80 bentonite from American Colloid Co. is used

128

as starting material for all experiments without any pretreatment. The MX-80 contains

129

approximately 82% montmorillonite with the structural formula:

130

Na0.30(Al1.55Fe0.21Mg0.24)(Si3.96Al0.04)O10(OH)2, Mw = 372.6 g/mol (Karnland et al., 2006) and

131

has a cation exchange capacity (CEC) of approximately 0.75 meq/g (measured according to

132

(Meier and Kahr, 1999)).

133

The fulvic acid (FA-573) used as organic matter in this study was extracted from a natural

134

ground water (Gohy573) originating from the Gorleben site, Germany (Wolf et al., 2004) and

135

subsequently purified and characterized. A detailed description can be found in (Wolf et al.,

136

2004). The elemental composition of the FA used in this work is as follows (Wolf et al.,

137

2004): C: (54.1 ± 0.1) %, H: (4.23 ± 0.08) %, O: (38.94 ± 0.04) %, N: (1.38 ± 0.02) % and S:

138

(1.32 ± 0.01) %. The proton exchange capacity is 6.82 ± 0.04 meq/g. In this study, a small

139

amount of FA is weighted, dispersed in NaOH and diluted in the corresponding initial clay

140

stock dispersions as described below. The dissolved organic carbon content is measured with

141

a TOC analyser (TOC-5000, Shimadzu).

142

A synthetic carbonated ground water (SGW) is prepared in order to simulate a glacial melt

143

water of low ionic strength. In the present case, we tend to the composition of the granitic

144

groundwater coming from the Grimsel Test Site (Geckeis et al., 2004; Möri et al., 2003). This

145

is done by mixing the requested amounts of the different salts (NaOH, NaCl, CaCl2, MgCl2,

146

NaF, Na2SO4 and NaHCO3) and an aliquot of the Si standard solution in ultra-pure water. The

147

final composition of the SGW is the following: Na+ (28.4 mg/L, 1.2 mM), Ca2+ (1.49 mg/L,

148

0.05 mM), F- (2.8 mg/L, 0.1 mM), Cl- (2.64 mg/L, 0.074 mM), SO42- (4.13 mg/L, 0.04 mM),

7

Si (0.014 mg/L, 0.5 µM) and HCO3- (84 mg/L, 1.4 mM). The ionic strength is below 2∙10-3 M

150

and the pH is 8.4 ± 0.1.

151 152

2.2 Fractionation by sequential and direct (ultra-)centrifugation

153

50 g of unpurified MX-80 bentonite is added to 5 L SGW (10 g clay/L). The dispersion is

154

regularly stirred during one day and then let to settle during three days in order to remove the

155

larger clay fractions and accessory mineral phases. After sedimentation the top 4 L are

156

isolated. It constitutes the colloidal dispersion S0. The residual solid phase (named R0) is

157

stored for further studies (Figure S1 in the supporting information file 1 (SIF-1)). Sequential

158

centrifugation (Thermo Scientific Centrifuge 2.0, with 50 mL PE centrifugation tubes, VWR,

159

Germany) or ultra-centrifugation (Beckmann Ultracentrifuge, XL90, with 100 mL Quick-seal

160

centrifuge tubes, Beckmann) is then performed at increasing speeds and times to obtain

161

various clay colloidal dispersions, starting from the supernatant S0 similarly to the protocol

162

presented in (Perret et al., 1994). The resulting supernatant after the first centrifugation step

163

corresponds to the colloidal dispersion S1 and the corresponding solid residual, R1.

164

Thereafter, the sequential centrifugation is repeated three times, where the last centrifugation

165

step is an ultra-centrifugation, leading to the supernatant S3.5. A schematic diagram for the

166

fractionation protocol is presented in the supporting information file 1, SIF-1, Figure S2. The

167

corresponding centrifugation times and speeds are summarized in Table 1. Higher

168

centrifugation speeds (up to 235 000 g) and filtrations (see SIF-2) are tested but result in

169

removing a too large part of the clay particles. Consequently, only the fractions S0 to S3.5 are

170

used in the present work.

171

In addition to the sequential centrifugation, and for comparison, two supernatants (noted with

172

the prefix UC and UC, FA) are collected directly from the supernatant S0 after only one

ultra-173

centrifugation step, using the same speed and time as the ones used to obtain the dispersion

8

S3.5. For that purpose, an initial supernatant S0 is collected after 1 day stirring and 3 days

175

sedimentation as described above, in presence (UC, FA) or absence (UC) of 11.8 mg/L FA.

176

Finally, the truly dissolved concentrations of Si, Al, Ca, Mg and Fe in equilibrium with clay

177

minerals are those determined after the strongest centrifugation step (1h at 235 000 g, SIF-2).

178

To determine the amount of each element in the clay particles, the truly dissolved

179

concentration is subtracted from the total concentration measured in the dispersion.

180

181

Table 1: Conditions for fractionation of the clay dispersions, and clay aggregate sizes expected in the

182

residuals (Ri) and in the supernatants (Si).

183

Dispersion

Conditions of separation (C: centrifugation; UC: ultracentrifugation)

Size expected in the ith residual clay fraction (Ri)

in nm

Size expected in the ith supernatant (Si) in nm S0 3 days sedimentation 1000 ≤ R0 0 ≤ S0 ≤ 1000 S1 C: 30 min (S0) at 313 g 450 ≤ R1 ≤ 1000 0 ≤ S1 ≤ 450 S2 C: 1 h (S1) at 700 g 200 ≤ R2 ≤ 450 0 ≤ S2 ≤ 200 S3 C: 4 h (S2) at 1200 g 70 ≤ R3 ≤ 200 0 ≤ S3 ≤ 70 S3.5 UC: 30 min (S3) at 26 000 g 50 ≤ R3.5 ≤ 70 0 ≤ S3.5 ≤ 50 S3.5UC UC: 30 min (S0) at 26 000 ga 50 ≤ R3.5UC 0 ≤ S3.5UC ≤ 50 S3.5UC, FA UC: 30 min (S0) at 26 000 ga 50 ≤ R3.5UC, FA 0 ≤ S3.5UC, FA ≤ 50 a: one step ultra-centrifugation from a colloidal dispersion S0 obtained after stirring and sedimentation of a

184

MX80 dispersion at 10 g/L in presence or absence of 11.8 mg/L FA .

185

The pH of all isolated supernatants is measured over a four months’ time period and remains

186

stable at 9.4 ± 0.2. All the collected supernatants and solid residues are stored at +4°C in

187

darkness before characterization and use in stability studies.

188

2.3 Characterization of the clay colloidal dispersions

9

2.3.1 Ion and clay particle concentrations determination

190

The element compositions are determined in all dispersions over time by Ion Chromatography

191

(IC, ICS-3000) and ICP-OES (Optima 2000 DV, PerkinElmer). The samples are acidified

192

before the ICP-OES measurements in 2% HNO3 (Merck, ultrapure) plus a drop of HF (Merck,

193

suprapure, 48%).

194

2.3.2 Mineral phase composition

195

Mineral phases composing the clay particle dispersions and the solid residues are determined

196

by XRD. The aim is to detect possible differences in the composition between the different

197

size fractions. XRD data are collected on residuals and supernatants prepared as oriented

198

samples obtained by drying on sample holders (low background Si wafers). The residuals are

199

prepared by dilution of the solid-gel like dispersions in ultra-pure water. The SGW alone is

200

also analyzed as a reference to identify any phase that could precipitate in the supernatants or

201

residuals upon drying. X-ray diffractograms for all samples (raw MX-80, the supernatants and

202

the residues) are also collected after saturation with ethylene glycol (SIF-4). Powder

203

diffractograms are recorded with a D8 Advance (Bruker) diffractometer (Cu Kα radiation)

204

equipped with an energy dispersive detector (Sol-X). The phases are identified with the

205

DIFFRAC.EVA version 2.0 software (Bruker) by comparison with the JCPDS 2 database.

206

2.3.3 Content of organic matter

207

The total amount of organic carbon in the dispersions prepared in presence of FA is measured

208

with a TOC analyser (TOC-5000, Shimadzu). A change in the FA concentration is obtained

209

after ultra-centrifugation (final [FA] = 8.3 mg/L compared to 11.8 mg/L initially). This result

210

indicates that a third of the organic matter might be associated with the clay aggregates while

211

most of the FA (two thirds) remains in the dispersion under the present experimental

212

conditions, as expected for these small-sized molecules and at the present pH.

10

2.3.4 Size distribution measurements

214

The size distributions of montmorillonite aggregates in all dispersions are determined by

215

Photon Correlation Spectroscopy (PCS, homodyne single beam ZetaPlus System equipped

216

with a 50mW solid-state laser emitting at 632 nm, Brookhaven Inc, USA) and Asymmetric

217

Flow Field-Flow Fractionation system (AsFlFFF, HRFFF 10.000 AF4, Postnova Analytics,

218

Landsberg, Germany) coupled to a UV-Vis. detector (LambdaMax LC Modell 481, Waters,

219

Milford, USA) and an Inductively-Coupled Plasma-Mass Spectrometer (ICP-MS, X–Series2,

220

Thermo Scientific, Germany).

221

AsFlFFF/UV-Vis./MALLS/ICP-MS has previously been used for characterization of natural

222

or synthetic clays colloids (Bouby et al., 2012; Bouby et al., 2011; Bouby et al., 2004; Finck

223

et al., 2012; Plaschke et al., 2001). In this study, the clay dispersions obtained after

224

fractionation (Si) . are diluted to ~20 mg/L clay particles in SGW before injection into

225

the system. Details on the equipment, the fractionation conditions and the calibration are

226

given in the supporting information file (SIF-3).

227

For the PCS measurements, the clay dispersions are diluted to 10 mg/L in a disposable plastic

228

cuvette and measured over 5 runs consisting of 10 measurements of 15 s each, i.e. 50

229

measurements, for determination of mean hydrodynamic diameters.

230

231

2.4 Clay particle stability studies

232

Stability studies are performed using PCS-measurements according to the experimental

233

protocol described in (Behrens et al., 2000; Czigány et al., 2005; Holthoff et al., 1996;

234

Kretzschmar et al., 1998). The particle stability ratios (W) are calculated from the initial

11

agglomeration rates. The stability ratio is defined as the ratio between the fast agglomeration

236

rate to the measured agglomeration rate in the present sample:

237 𝑊 = → / ( ) → / Equation 1 238

where rh is the hydrodynamic radius (nm), t the time (s) and C the particle concentration

239

(mg/L), the suffix f represents the fast agglomeration rate. Equation 1 is derived from the

240

following Equations 2 and 3:

241

→ = 𝛽𝑘𝐶 Equation 2

242

𝑊 = ( ) = Equation 3

243

where is an optical factor (depending on the scattering angle, the wavelength of the light

244

and the particle radius), k is the agglomeration rate and is the particle-particle attachment

245

efficiency and so-called the sticking probability. Consequently, W approaches 1 when the

246

particles are unstable under the chemical conditions tested, while for stable dispersions, W

247

tends to go to infinity (set arbitrarily to 101-102 values in our experiments to fit into the

248

graphs).

249

In this study, W is determined at pH 7, while the ionic strength was varied between 0.01 and 3

250

M by using the electrolytes NaCl, CaCl2 or MgCl2. In addition, experiments in presence or

251

absence of FA are performed, since FA is known to stabilize montmorillonite particles

252

(Furukawa and Watkins, 2012). The clay particle concentration is fixed to 10 mg/L by prior

253

dilution throughout all measurements, and all the supernatants listed in Table 1 are studied.

254

The initial intensity-weighted hydrodynamic mean diameter is measured first during 45 s

255

before addition of the electrolyte to the dispersion. Thereafter, the evolution of the particle

256

hydrodynamic diameter is monitored, after affecting the dispersion by simultaneous addition

12

of concentrated electrolyte aliquots (NaCl, CaCl2 or MgCl2) and NaOH to reach the desired

258

chemical conditions. All samples are measured up to between 20 and 40 min after addition of

259

the electrolyte, with measurements of 15 s each. To investigate the effects of addition of FA, a

260

final concentration of 10.2 mg FA/L is added to all clay dispersions. Thereafter, 0.1 M CaCl2

261

is added to the dispersions and the results are compared to measurements in absence of FA.

262

As the pH cannot be monitored at the same time in the cuvette used for the PCS measurement,

263

it is measured in parallel in a second cuvette with a dispersion of identical composition.

264

The initial agglomeration rate is determined by fitting a second-order polynomial to the

265

experimental data, using the first 15-35 data points of each set of data. The initial

266

agglomeration rates are then compared and normalized to the fastest initial agglomeration rate

267

(determined for each electrolyte at 3M IS) for each colloidal fraction to obtain the

268

corresponding W value.

269

270

3 Results and Discussion

271

3.1 Characterization of the clay colloidal dispersions

272

3.1.1 Ion and colloid concentrations

273

The concentrations of all analyzed elements are presented in Table 2, where the mean values

274

obtained from several measurements are given. The clay colloid concentrations ([Coll.]) are

275

calculated from Al-concentrations according to the theoretical structural formula (Karnland et

276

al., 2006). The molar ratios of the different elements are calculated from the ICP-OES- and

277

IC-results and may be compared to the theoretical values based on the assumed stoichiometry.

278

Table 2: Element and colloid concentrations in the clay colloidal dispersions measured by ICP-OES and

279

IC and colloidal fraction distributions calculated from the mean concentration of four main and minor

280

clay constituents (Si, Al, Mg, and Fe). The recovered amount of colloids in the dispersions is presented as

13

percentage compared to the initial colloidal concentration in S0. *: This corresponds to the amount of

282

stable colloids in the dispersions after letting settle the dispersions during 2 months without any shaking.

283

The elemental mole ratios are corrected by the free aqueous concentrations determined after the strongest

284

ultracentrifugation, which are 7.5∙10-5 M Si, 4.1∙10-6 M Mg, 7.2∙10-7 M Fe, 3.7∙10-6 M Al and 8.5∙10-6 M Ca.

285 Dispersion [Coll.] mg/L [Al] mg/L [Mg] mg/L [Si] mg/L [Fe] mg/L [Ca] mg/L [Na] mg/L [F] mg/L [SO4] mg/L [Cl] mg/L S0 1127 ± 170 133 ± 20 20 ± 2 382 ± 110 32 ± 2 8.6 ± 0.5 87 ± 1 2.9 ± 0.5 37 ± 3 5 ± 1 S1 746 ± 68 88 ± 8 13.6 ± 0.4 252 ± 70 21.4 ± 0.6 5.7 ± 0.1 82 ± 2 2.9 ± 0.5 37 ± 3 3.9 ± 0.3 S2 551 ± 34 65 ± 4 9.9 ± 0.6 178 ± 46 15 ± 2 4.0 ± 0.2 76 ± 2 2.9 ± 0.5 37 ± 4 3.9 ± 0.4 S3 280 ± 26 33 ± 3 5.5 ± 0.2 99 ± 25 8 ± 1 2.5 77 3.0 ± 0.4 37 ± 4 3.8 ± 0.2 S3.5 96 ± 6 11.3 ± 0.6 1.9 ± 0.1 40 ± 18 2.7 ± 0.1 1.1 73 2.9 36 3.6 S3.5UC 90 ± 6 10.6 ± 0.6 1.8 ± 0.1 40 ± 18 2.8 ± 0.3 1.0 74 2.7 36 4.7 S3.5UC, FA 125 ± 3 14.7 ± 0.3 2.5 ± 0.1 51 ± 18 3.5 ± 0.1 1.6 75 3.0 36 4.8 SGW 1.6 28 2.5 3.2 2.9 Dispersion Si/Al mole ratio Al/Mg mole ratio Al/Fe mole ratio Al/Ca mole ratio Mg/Fe mole ratio Recovered colloids (%) S0 2.7 6.0 8.6 23.9 1.4 100 ± 0 (43 ± 1*) S1 2.7 5.9 8.5 24.4 1.5 67 ± 4 (47 ± 2*) S2 2.6 6.0 9.0 26.4 1.5 48 ± 5 (43 ± 2*) S3 2.8 5.5 8.6 22.7 1.6 25 ± 2 (22 ± 1*) S3.5 3.0 5.6 8.7 22.0 1.6 9.4 ± 0.1 S3.5UC 3.2 5.6 7.9 23.8 1.4 9.0 ± 0.2 S3.5UC, FA 3.1 5.5 8.7 17.3 1.6 12.1 ± 0.1 Theoretical values 2.49 6.62 7.57 1.14 286

14

As expected, the montmorillonite colloid concentration decreases with the number of

287

sequential centrifugation steps, for increasing centrifugation speed and time (Table 2). There

288

is no doubt that the particles consist of montmorillonite in all dispersions as the Si/Al, Al/Mg,

289

Al/Fe and Mg/Fe mole ratios are in fair agreement with those obtained from the theoretical

290

structural formula of montmorillonite (Table 2). Molar element ratios in the clay fraction are

291

corrected for the free aqueous concentration of dissolved elements in the dispersions. These

292

free aqueous concentrations are obtained from the supernatant of a sample centrifuged at 235

293

000 g where all clay mineral particles are assumed to be removed (SIF-2). The calcium

294

concentrations in the dispersions decrease with increasing numbers of centrifugation steps

295

similar to the decrease of colloid concentrations (Table 2) suggesting its association to the

296

clay aggregates, possibly due to ion exchange binding at the permanently charged basal plane.

297

Even though calcium does not appear in the theoretical formula, it is known that unpurified

298

MX80 bentonite contains calcium based accessory minerals, like calcite (Bradbury and

299

Baeyens, 2002; Karnland et al., 2006; Vuorinen and Snellman, 1998).

300

In addition, the results show a direct release of several elements from the unpurified bentonite

301

to the SGW, which is here the background electrolyte (Table 2). A drastic increase of sodium

302

and sulfate and, to a lower extend, fluoride and chloride is observed as already reported in the

303

literature (Bradbury and Baeyens, 2002; Vuorinen and Snellman, 1998). This can be

304

explained, altogether, by the presence of NaCl (1.35 mmol/kg), fluorite (CaF2), gypsum

305

(CaSO4) and celestite (SrSO4) in the unpurified MX80 (Bradbury and Baeyens, 2002;

306

Vuorinen and Snellman, 1998). The dissolution of NaCl from the unpurified starting material

307

cannot explain the large increase of sodium concentration in the supernatants. In addition, no

308

increase in Ca concentration is observed (the concentration of Sr is not measured). Cation

309

exchange reactions, where divalent cations (Ca/Sr) are favored over monovalent ones (Na),

310

may explain why the Na release is enhanced and no variation in Ca concentration is observed

15

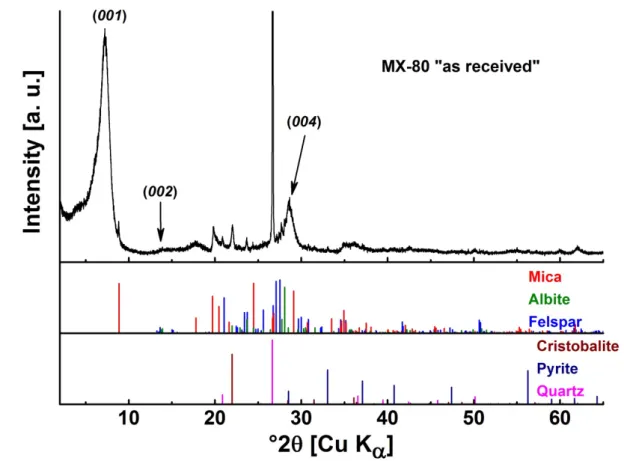

(Gaucher et al., 2009). Another process involving dissolution of pyrite, which is found in the

312

XRD analysis (Figure 1), can explain the release of sulfate. However, this should be

313

accompanied by a drop of pH. Thus, it is not considered as the most important process.

314

3.1.2 Colloidal distribution in the montmorillonite fractions and long-term stability of

315

the dispersions

316

The mean clay colloidal concentrations after each centrifugation are calculated from the

317

concentrations obtained for the four main and minor montmorillonite constituents (Si, Al, Mg,

318

and Fe). They are compared to the initial concentration of colloids, which allows determining

319

the colloidal recoveries, Table 2.

320

From the total amount of colloids initially present in S0, approx. 9 % remain in the dispersion

321

S3.5 (Table 2) which is the dispersion obtained at the last fractionation step after using 27 000

322

g centrifugation. The similarity of the results obtained after one direct

ultra-323

centrifugation step (S3.5UC, 9.0 ± 0.2 %) is noticeable. A slightly higher recovery of clay

324

colloids is obtained in presence of fulvic acids (S3.5UC,FA, 12.1 ± 0.1 %), which indicates that

325

the negatively charged FA may have stabilized a part of the montmorillonite colloids initially

326

present in dispersion (Furukawa and Watkins, 2012; Kretzschmar et al., 1998).

327

To determine the long-term stability of the dispersions, the same analyses were performed 2

328

months later, without any shaking during that time or prior to the sampling. It is found that

329

not all dispersions are stable over time. This is particularly true for the dispersions S0 and S1

330

as indicated by the percentage of colloids recovered after 2 months (Table 2, marked with *)

331

showing that 57 % and 26 % of the clay colloids, respectively, have sedimented during this

332

time period. This indicates that these dispersions contain various sizes fractions, from large to

333

smaller clay aggregates, as expected from the sequential separation protocol.

334

3.1.3 Mineral phase composition

16

The as-received material, MX-80, consists mainly of montmorillonite, as indicated by the

336

corresponding X-ray diffractogram (Figure 1). Accessory minerals are present in the

337

unpurified bentonite such as quartz, cristobalite and mica, as well as trace amounts of albite,

338

feldspar and pyrite. No attempt was made to quantify their content. This bentonite

339

composition agrees well with reported data (Hu et al., 2009).

340

341

Figure 1: X-ray diffractogram of the as-received MX-80 and identification of the accessory minerals by

342

comparison with database. Montmorillonite 00l planes are indicated in brackets.

343

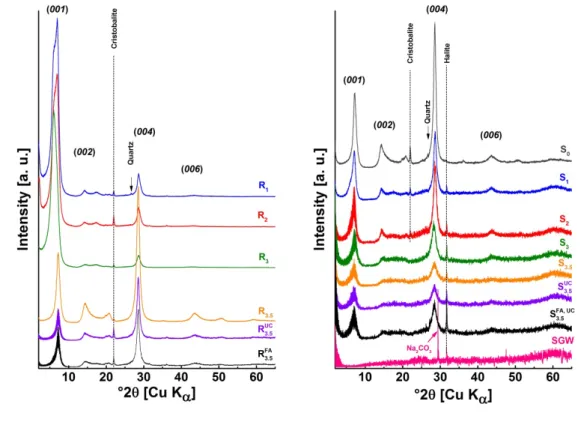

The supernatants and residuals are all analyzed after each fractionation step (Figure 2). The

344

solid material in R0 has identical mineralogical composition as the raw material. Obviously,

345

the accessory phases settled down during the first fractionation step resulting in that

346

cristobalite is detected only in the first sample and that quartz can be detected only in S0 and

347

R1. All samples, both residuals and supernatants, exhibit intense reflections at 12.2–14.6 Å

348

(7.2–6.0° 2θ) and ~3.14 Å (28.6° 2θ) corresponding to 001 and 004 reflections of

17

montmorillonite. The 001 reflection or basal spacing (i.e. d(001)), which corresponds to the c

350

dimension of the elemental unit cell, is dependent on the hydration state (Ferrage et al., 2005;

351

Meunier, 2005). In this study, all supernatants and residuals have a basal spacing

352

corresponding to the presence of one (12.2 Å) and two water molecules (14.6 Å) in the

353

interlayer. In R1 and R2, the clay is obviously heterogeneous in the hydration state as both

354

states may be present as shown by the broad 001 reflection. The clay interlayer hydration state

355

depends on the layer charge and the ambient relative humidity, not on the fractionation

356

procedure. All samples also exhibit less intense 00l reflections typical of clay minerals, such

357

as 002 and 006. Finally, all residues have a similar mineralogical composition except the

358

quartz detected in trace amounts in R1. Likewise, all suspended particles in supernatants have

359

a similar mineralogical composition, except S0, S1 and S2 that contain cristobalite and S0 that

360

contains additionally trace amount of quartz. Finally, only halite (NaCl) and Na2CO3 could be

361

detected in SGW meaning that these phases crystallized upon drying. Halite could be detected

362

in some supernatants. None of these phases (NaCl or Na2CO3) could be detected in the

363

residues.

364

All supernatants and residuals exhibit similar basal spacing after saturation with ethylene

365

glycol (SIF-4). The expansion to 17.0 ± 0.2 Å for d(001) is typical of smectite swelling, and

366

thus consistent with montmorillonite being the main component of MX-80.

18 368

Figure 2: X-ray diffractograms for all residuals (left) and supernatants (right) obtained by fractionation.

369

One can see the similarities between the residuals and supernatants, which implies a similar structure of

370

the montmorillonite in the different samples. In addition, a decrease in accessory minerals with the

371

number of centrifugation steps is seen. The montmorillonite 00l planes are indicated in brackets.

372

3.1.4 Clay aggregate size distribution measurements

373

3.1.4.1 AsFlFFF

374

Since aluminium is one of the main components of montmorillonite, the Al-data obtained

375

from the AsFlFFF/ICP-MS-measurements are used as a clay indicator. All Al-ICP-MS data

376

are presented in Figure 3 after transformation of fractograms in mass versus size by using 1)

377

the mass calibration method (left side, Figure 3a) as developed before in previous studies

378

(Bouby et al., 2008) and 2) the size calibration (right side, figure 3b), according to (Schimpf

379

et al., 2000).

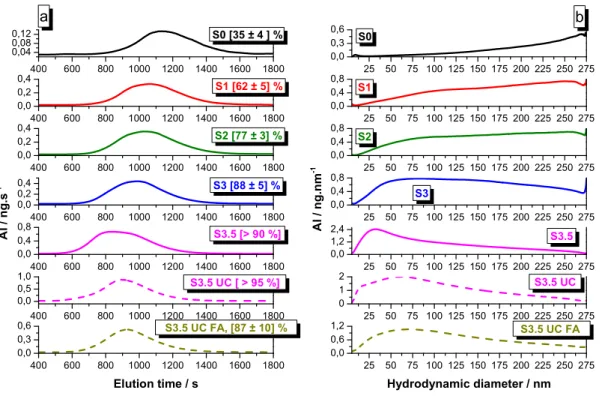

19 381

Figure 3: Al-ICP-MS fractograms obtained after injection (100 µL) of the different clay dispersions, all

382

diluted to 20 mg/L clay prior to injection. Left: fractograms transformed using the calibration in mass

383

concentration as a function of elution time (Bouby et al., 2008). Right: fractograms further transformed

384

by using the calibrations to size (Schimpf et al., 2000). The percentage in bracket indicates the colloid

385

recovery in the measurements. These are all smoothed data and a mean result of two measurements.

386

At a first look, a broad size distribution is obtained for each dispersion, ranging from 10 up to

387

275 nm. Some shoulders are clearly visible in the fractograms, indicating the presence of

388

different size fractions in the dispersions. A separation into different well-resolved size

389

fractions is not achieved due to the conditions selected for the AsFlFFF measurements (see

390

SIF-3). Nevertheless, the fractograms show clearly that the mean size of the aggregates in the

391

dispersions is decreasing with the number of fractionation steps. This is clearly evidenced by

392

the significant variation of the fractogram maxima and the mean sizes of the different

393

colloidal dispersions (Figure 3 and Table 3).

394 400 600 800 1000 1200 1400 1600 1800 0,04 0,08 0,12 S0 [35 ± 4 ] % 400 600 800 1000 1200 1400 1600 1800 0,0 0,2 0,4 S1 [62 ± 5] % 400 600 800 1000 1200 1400 1600 1800 0,0 0,2 0,4 S2 [77 ± 3] % 400 600 800 1000 1200 1400 1600 1800 0,0 0,2 0,4 A l / n g .s -1 S3 [88 ± 5] % 400 600 800 1000 1200 1400 1600 1800 0,0 0,4 0,8 S3.5 [> 90 %] 400 600 800 1000 1200 1400 1600 1800 0,0 0,5 1,0 S3.5 UC [ > 95 %] 400 600 800 1000 1200 1400 1600 1800 0,0 0,3 0,6 S3.5 UC FA, [87 ± 10] % Elution time / s a 25 50 75 100 125 150 175 200 225 250 275 0,0 0,3 0,6 S0 25 50 75 100 125 150 175 200 225 250 275 0,0 0,4 0,8 S1 25 50 75 100 125 150 175 200 225 250 275 0,0 0,4 0,8 S2 25 50 75 100 125 150 175 200 225 250 275 0,0 0,4 0,8 A l / n g .n m -1 S3 25 50 75 100 125 150 175 200 225 250 275 0,0 1,2 2,4 S3.5 25 50 75 100 125 150 175 200 225 250 275 0 1 2 S3.5 UC 25 50 75 100 125 150 175 200 225 250 275 0,0 0,6 1,2 S3.5 UC FA Hydrodynamic diameter / nm b

20

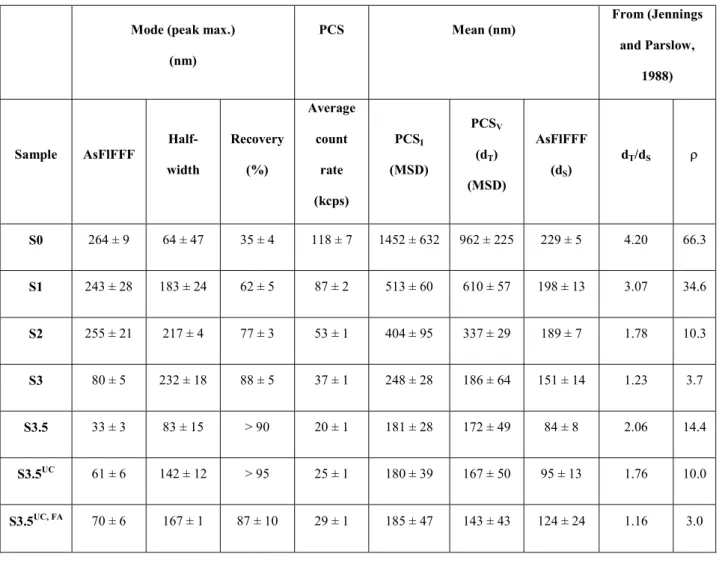

Table 3: Peak maxima and mean aggregate sizes of the dispersions obtained from AsFlFFF-/ICP-MS

395

measurements with the corresponding mean intensity (I)- and volume (V)-weighted sizes determined from

396

PCS analysis from the multimodal size distribution (MSD). The colloid recovery in the

AsFlFFF-397

measurements increases with decreasing sizes. dT/dS: equivalent spherical diameter (ESD) ratios, where dT

398

is the ESD for a translating disc-shaped particle determined by PCS (mean volume-weighted value, PCSV)

399

and dS is the equivalent Stokes’ spherical diameter for a sedimenting particle determined by AsFlFFF

400

(mean value); : calculated axial ratio, see section 3.1.4.2 for details.

401

Mode (peak max.) (nm) PCS Mean (nm) From (Jennings and Parslow, 1988) Sample AsFlFFF Half-width Recovery (%) Average count rate (kcps) PCSI (MSD) PCSV (dT) (MSD) AsFlFFF (dS) dT/dS S0 264 ± 9 64 ± 47 35 ± 4 118 ± 7 1452 ± 632 962 ± 225 229 ± 5 4.20 66.3 S1 243 ± 28 183 ± 24 62 ± 5 87 ± 2 513 ± 60 610 ± 57 198 ± 13 3.07 34.6 S2 255 ± 21 217 ± 4 77 ± 3 53 ± 1 404 ± 95 337 ± 29 189 ± 7 1.78 10.3 S3 80 ± 5 232 ± 18 88 ± 5 37 ± 1 248 ± 28 186 ± 64 151 ± 14 1.23 3.7 S3.5 33 ± 3 83 ± 15 > 90 20 ± 1 181 ± 28 172 ± 49 84 ± 8 2.06 14.4 S3.5UC 61 ± 6 142 ± 12 > 95 25 ± 1 180 ± 39 167 ± 50 95 ± 13 1.76 10.0 S3.5UC, FA 70 ± 6 167 ± 1 87 ± 10 29 ± 1 185 ± 47 143 ± 43 124 ± 24 1.16 3.0 402

The half-width values decrease only slightly for the dispersions S0 to S3.5 indicating that a

403

rather broad character of the size distributions remains. In addition, it should be noted that the

404

mean clay aggregate sizes obtained in the dispersions is higher than expected (Table 1),

405

especially for the dispersions where the smallest size is expected, i.e. in S3 and all S3.5

406

dispersions. This may be interpreted as an incomplete sedimentation during the centrifugation

21

due to the inaccurate assumption made considering a spherical shape of the particles in the

408

Stokes’ law calculation, since the particle shape is of high importance while included in

409

Stokes’ law (Kunkel, 1948).

410

The colloid recovery for each AsFlFFF-measurement (indicated in brackets in the legend in

411

Figure 3a and in Table 3, 4th column) can also help to understand the results. One explanation

412

for the low recoveries in S0 to S2 runs is the loss of particles in the AsFlFFF-channel due to

413

an irreversible attachment of notably larger sized aggregates to the membrane during the

414

fractionation process. The lower recovery of the Al-mass especially for the dispersions S0 and

415

S1 indicates the presence of large aggregates attaching to the accumulation wall in the

416

channel or moving too slowly to be detected under these conditions. This is in agreement with

417

the slow sedimentation process observed in the unstirred dispersions S0 and S1 over time

418

(Table 2). The recovery increases significantly with higher centrifugation forces, where higher

419

recoveries are reached for the dispersions obtained after the ultra-centrifugation step (S3.5 and

420 S3.5UC). 421 422 3.1.4.2 PCS 423

To complement the AsFlFFF analysis, the dispersions are monitored by PCS after dilution to

424

10 mg/L clay. The results of the PCS analyses are presented in Table 3. The table presents the

425

average count rates (in kilo counts per second (kcps)) which clearly decrease for

426

centrifugation steps with higher rotation rates, even though the colloid mass concentrations

427

are the same. Since the scattered intensity is highly dependent on the particle size, this is in

428

line with the size variations seen in the AsFlFFF-measurements (Table 3). The corresponding

429

values for the mean diameters of the clay aggregates are given, both as intensity-weighted

430

(PCSI) and as volume-weighted (PCSV) in Table 3 as obtained from the measurements by

22

considering the multimodal size distribution using the Non-Negatively constrained Least

432

Squares (NNLS) algorithm to fit the data (Bro and De Jong, 1997). The volume-weighted

433

diameter values (PCSV) are those which can be compared directly with the AsFlFFF data.

434

Looking into Table 3 (column 7 and 8), the results are comparable. The differences are

435

explained by losses of large particles in the AsFlFFF channel (especially for samples S0 and

436

S1) and by recalling that the PCS preferentially detect larger sized entities.

437

Nowadays, it is recognized that several techniques have to be used to combine the results

438

from particle size measurements and draw a more realistic description of a natural or synthetic

439

sample, containing particles of irregular shapes, especially clay nanoparticles (Beckett et al.,

440

1997; Bowen, 2002; Bowen et al., 2002; Cadene et al., 2005; Gallego-Urrea et al., 2014;

441

Gantenbein et al., 2011; Plaschke et al., 2001; Veghte and Freedman, 2014). More

442

information can be obtained from the AsFlFFF and PCS data following the development of

443

(Jennings and Parslow, 1988) extended by e.g. (Bowen et al., 2002), (Pabst and Berthold,

444

2007) and (Gantenbein et al., 2011). In brief, whatever equipment is used, the dimensions

445

obtained are equivalent sphere diameters (ESD) i.e. the diameters of spheres that would

446

behave the same as the particles in the sample, as a function of the method used. One should

447

have in mind that the ESD describes a 3-dimensional object with only one number. Flow FFF

448

provides a direct access to the Stokes’ diameter dS (Schimpf et al., 2000). “Particles under the

449

influence of Brownian agitation translate for all orientations and it is the random orientation

450

translation that is analysed in the PCS method” (Jennings and Parslow, 1988). Accordingly,

451

the PCS gives access to the equivalent diameter from frictional translatory diffusion data, dT.

452

Consequently, except for spherical particles, one cannot expect the derived ESD to be

453

identical from the two techniques as different physical phenomena are the basis of the

454

measurements. This is used presently as an advantage considering that no identical results

455

reveal the non-sphericity of the particles to be analysed and can thus serve to measure it. We

23

develop that possibility in the following discussion by comparing the ESD values (dS)

457

obtained with the AsFlFFF and the ESD values (dT) obtained with the PCS, i.e. the

volume-458

weighted ones from the MSD fitting.

459

According to Jennings (Jennings, 1993), a comparison between the ESD values from the

460

AsFlFFF (dS) and PCS (dT) gives access to the mean clay axial ratio (ρ) for the aggregates in

461

each dispersions defined as the aggregate surface diameter to thickness ratio for each

462

dispersions. In previous works (Jennings, 1993; Jennings and Parslow, 1988), Jennings

463

presents the mathematical expressions of the equivalent spherical diameter (ESD) according

464

to the analytical method used for its determination which are functions of the axial ratio. The

465

equations are given primarily for oblate and prolate spheroids with two limiting geometry

466

cases considered: the rod and the disc (to which the clay aggregate geometry may be

467

simplified). The ESD for a translating disc-shaped particle (dT) and the equivalent Stokes’

468

diameter (dS) for a sedimenting particle are expressed in equation (4) and (5) as (Jennings and

469 Parslow, 1988): 470 = ∙ Equation 4 471 = Equation 5 472

where = /t is the axial ratio of the disc-shaped particle, with being the surface diameter

473

of the disc-shaped particle and t its thickness.

474

Consequently, for a given particle, the ratio of these two ESD expressions may be used

475

inversely a posteriori to evaluate the axial or aspect ratio () of the particle and thus to obtain

476

the value of and t, if the clay aggregate is approximated by a disc of diameter and

477

thickness t. In the present work, the ratio dT/dS correspond to the ratio of the ESD determined

24

by AsFlFFF (dS) and PCS (dT) (volume-weighted mean value, PCSv). The calculated dT/dS

479

from the experimental mean diameters are presented in Table 3. The theoretical curve

480

d /d = f() obtained from Equation 4 and Equation 5 is plotted in Figure 4 and is used to

481

deduce the axial ratio () for each clay colloid dispersion reported in Table 3.

482

483

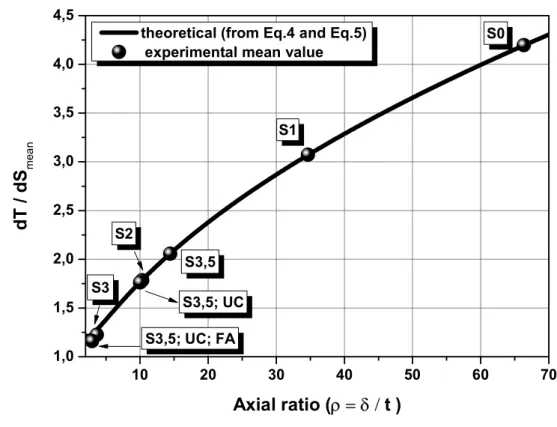

Figure 4: Theoretical dT/dS-ratio values calculated as a function of the axial ratio (black line) using

484

equations (4) and (5). The dT/dS-ratio values determined from the experimental mean PCS and AsFlFFF

485

ESD data are reported for each dispersion. A posteriori, the corresponding axial ratio is obtained and

486

presented in Table 3.

487

Obviously, > 1 for each dispersion as expected for clay aggregates having a disc-shaped

488

geometry. Interestingly, the -values are decreasing with increasing fractionation steps from

489

~35 (S1) down to ~3.7 (S3). (Note: due to the low AsFlFFF recovery, the -value obtained for

490 S0 (~66) is biased). 491 10 20 30 40 50 60 70 1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5 S3,5; UC; FA S3,5; UC S3 S2 S3,5 S1

theoretical (from Eq.4 and Eq.5) experimental mean value

d T / d S m ea n Axial ratio (t) S0

25

Once -values are known for each dispersion, one can back-calculate the corresponding mean

492

surface diameter, , and thickness, t, by using Equation 4 and Equation 5. The number of clay

493

layers is calculated by taking 1.3 nm as the thickness of one single clay mineral layer (basal

494

spacing) obtained by XRD results and according to (Meunier, 2005). The results are

495

summarized in Table 4. According to literature, the clay aggregates dimensions reported in

496

this work are plausible (Bergaya et al., 2006; Bouby et al., 2011; Hauser et al., 2002; Missana

497

et al., 2003; Plaschke et al., 2001; Schramm and Kwak, 1982a, b; Sposito, 1992; Tournassat et

498

al., 2011; Tournassat et al., 2003). The aspect ratio values determined agree with literature

499

data (Ali and Bandyopadhyay, 2013; Cadene et al., 2005; Gélinas and Vidal, 2010; Plaschke

500

et al., 2001; Tournassat et al., 2011; Tournassat et al., 2003; Weber et al., 2014; Veghte and

501

Freedman, 2014). Pictures obtained from SEM analysis of the dispersions S0 to S3 are

502

presented in the supporting file (see SIF-5). A raw evaluation of the AsFlFFF/MALLS data

503

according to (Baalousha et al., 2005; Baalousha et al., 2006; Kammer et al., 2005) allows to

504

compare the hydrodynamic (Rh) versus gyration (Rg) radius. The corresponding ratio (Rg/Rh),

505

called the shape factor, varies in the range [1.5-4] for the present measurements, and equals to

506

1 for a spherical particle. The shape factor increases as soon as the particles deviate from a

507

spherical shape, indicating that the montmorillonite aggregates are non-spherical.

508

Table 4: Mean disc surface diameters () and number of layers calculated from PCS and AsFlFFF mean

509

equivalent sphere diameters (ESD) and the mathematical equations 4 and 5, according to (Jennings and

510

Parslow, 1988) for the clay aggregates. The number of layers is calculated by taking 1.3 nm as the

511

thickness, t, of one clay sheet, according to XRD results when considering one water layer.

512 Sample Axial ratio = /t PCS dT/ AsFlFFF dS/ (disc Ø; nm) t (disc thickness; nm) Number of layers S0 66.3 0.643 0.226 1496 23 17 S1 34.6 0.648 0.325 940 27 21 S2 10.3 0.675 0.449 500 48 37

26 S3 3.7 0.743 0.546 250 68 52 S3.5 14.4 0.664 0.303 258 18 14 S3.5UC 10.0 0.676 0.385 246 25 19 S3.5UC,FA 3.0 0.767 0.546 187 63 48 513

By plotting the oblate spheroid ESD as a function of the axial ratio (Jennings and Parslow,

514

1988), the ESD is found to always be smaller than the true dimension, . This is true for both

515

measurement techniques used in this study as well (Table 4). From S0 to S3, there is a clear

516

trend in decreasing surface diameter, and increasing thickness, t. Nevertheless, the AsFlFFF

517

results are obtained from measurements with rather low recoveries while the PCS is detecting

518

all aggregates in the dispersion. Consequently, the results presented in Table 4 can only be

519

considered as partly representative of the complete samples due to the low recoveries in the

520

AsFlFFF-measurements. If one considers the dispersions where ≥ 50% of the mass is

521

recovered (S1 and smaller), the mean disc surface diameter () of the clay aggregates is

522

decreasing, whereas the thickness (t) is increasing with further fractionation steps. The

523

difference between the dispersion S3 and S3.5 appears only in the thickness of the clay

524

aggregates. As expected, comparable results are obtained for the dispersions S3.5 (obtained

525

after continuous (ultra-)centrifugation steps) and S3.5UC (obtained after one single

ultra-526

centrifugation step). Interestingly, the thickness, and thus number of clay sheets, appears

527

slightly higher in presence of FA during the fractionation, which may indicate that the

528

presence of FA could stabilize thicker clay aggregates, i.e. maintain a larger number of

529

stacked clay mineral layers together.

530

In conclusion, the fractionation protocol developed in the present study enables to obtain

531

heterogeneous dispersions of clay aggregates. Assimilating the clay aggregates to discs of

532

surface diameter and thickness t, the results indicate presence of aggregates with mean

27

surface diameters ranging from ~245 nm up to 1500 nm and with mean thicknesses ranging

534

from ~18 up to 70 nm (~14 to 52 clay layers). In presence of FA during the fractionation, clay

535

aggregates with a surface diameter of ~190 nm can be isolated, but with a slightly larger

536

thickness (~63 nm) as those obtained under the same fractionation conditions in absence of

537

FA. The present results would greatly benefit of complementary investigations involving the

538

use of other microscopy techniques like AFM.

539

3.1.5 An attempt to estimate the mean number of edge sites

540

By approximating clay aggregates to discs of mean diameter , estimations of the mean

541

number of edge sites in each clay dispersion were performed. This will be used in an attempt

542

for better interpretation of the data for radionuclides sorption by surface complexation and

543

sorption reversibility (manuscripts in preparation).

544

Estimations of the number of edge sites are performed according to the work of White and

545

Zelazny (White and Zelazny, 1988) and Tournassat et al. (Tournassat et al., 2003), assuming a

546

clay density of 2.7 g/cm³, and are presented in Table 5. It is considered that the stacking of

547

clay mineral layers does not change the accessibility to the lateral surfaces, only the interlayer

548

basal surfaces are not accessible.

549

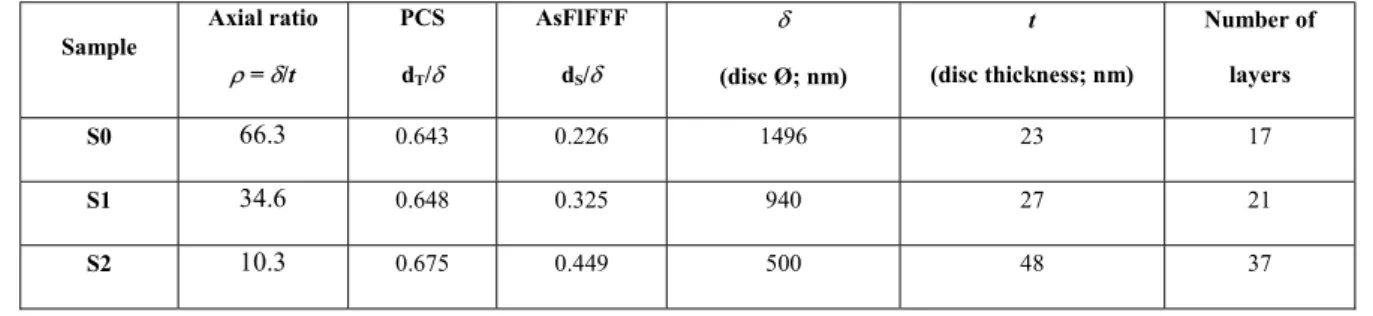

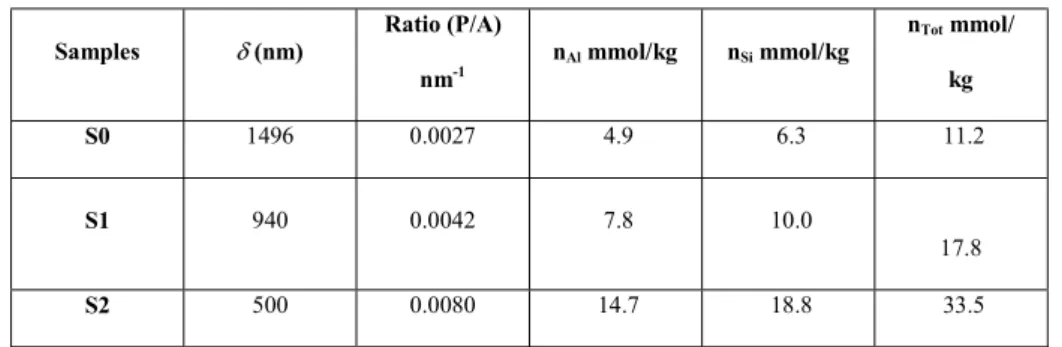

Table 5: Estimation of the mean number of edge sites for each clay dispersion from PCS- and

AsFlFFF-550

data. The perimeter of a clay stack is noted as P and is calculated by using the clay aggregate disc

551

diameter . The clay disc area (A) is calculated by using as the mean diameter of the clay aggregate as

552

well. .

553

Samples (nm) Ratio (P/A)

nm-1 nAl mmol/kg nSi mmol/kg

nTot mmol/ kg S0 1496 0.0027 4.9 6.3 11.2 S1 940 0.0042 7.8 10.0 17.8 S2 500 0.0080 14.7 18.8 33.5

28 S3 250 0.0161 29.4 37.6 67.0 S3.5 258 0.0152 28.4 36.3 64.7 S3.5UC 246 0.0162 29.8 38.1 67.9 S3.5UC,FA 187 0.0214 39.3 50.2 89.5 554

The results show variations up to a factor ~8, but they are only considered as approximations

555

since the aggregate dimensions are underestimated. Taking a regular disc to mimic smectite

556

aggregates does not take into account their convexities and concavities which lead to an

557

increase in their surface area and perimeter. When considering the dispersions with the

558

smaller mean clay size (S3.5, S3.5UC and S3.5UC,FA), the results are in agreement with those of

559

Tournassat et al. (Tournassat et al., 2003).

560

3.2 Stability studies

561

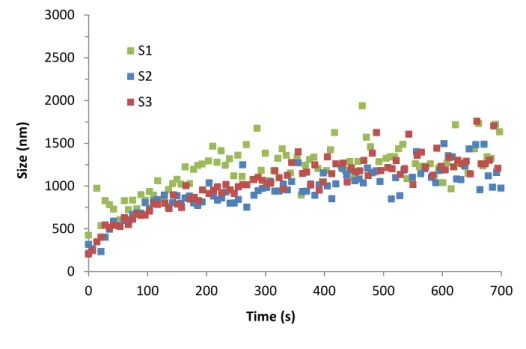

Evaluation of the Al-AsFlFFF/ICP-MS fractograms for the montmorillonite fractions reveals

562

broad clay aggregate size distributions that might be constituted by several different clay size

563

fractions (Figure 3). Consequently, it is not surprising that the data obtained from the stability

564

studies are very scattered (Figure 5). Therefore, it becomes challenging to clearly observe the

565

increase in mean particle size which reflects the agglomeration rate (especially for the

566

dispersion S0 which will not be further considered). In addition, one has to consider that the

567

agglomeration behavior of smaller sized particles are probably hidden by the dominant

568

scattered light intensities from larger particles as the PCS preferentially detect those larger

569

sized entities. Nevertheless, the results from the data evaluation are less scattered for the

570

dispersions obtained after several centrifugation steps (S3 and S3.5).

29 572

Figure 5: Increase in hydrodynamic diameter for three of the montmorillonite dispersions while adding

573

0.01 M CaCl2 to the dispersions at pH 7.

574

575

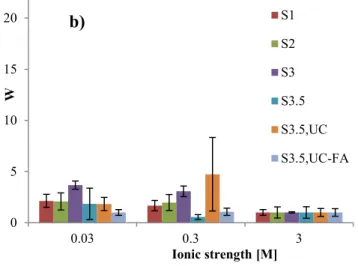

The calculated stability ratios (W) for all dispersions at pH 7 and for different ionic strengths

576

are presented in Figure 6. The presented W-values are obtained for an ionic strength set by

577

addition of the electrolytes NaCl, CaCl2 or MgCl2. As expected, W decreases with increasing

578

ionic strength. This is clearly seen after addition of NaCl (Figure 6a) and is consistent with

579

the DLVO-theory. Furthermore, addition of CaCl2 and MgCl2 affects the montmorillonite

580

particles more strongly than addition of the same ionic strength set by NaCl since the lowest

581

concentrations of CaCl2 and MgCl2 are already enough to destabilize the montmorillonite

582

particles (Figure 6b and 6c), as expected from previous studies (Schudel et al., 1997). This is

583

in line with the well-known Shulze-Hardy rule (Overbeek, 1980). The decrease in stability

584

ratio in presence of divalent cations is partly explained by specific interaction of divalent

585

cations as previously reported in the literature (French et al., 2009; Keiding and Nielsen,

586

1997; Norrfors, 2015; Oncsik et al., 2014; Pantina and Furst, 2006).

587 0 500 1000 1500 2000 2500 3000 0 100 200 300 400 500 600 700 Si ze (n m ) Time (s) S1 S2 S3

30

According to the DVLO-theory, considering the interaction between two identical spherical

588

particles, the calculated Van der Waals (VdW)-forces increase for increasing particle size

589

(Ottewill and Shaw, 1966; Reerink and Overbeek, 1954; Shah et al., 2002). However, it has

590

been found previously that in a system of high ionic strength, i.e. where no electrostatic

591

repulsions are present, the kinetic energy dominates over the VdW-forces and the

592

agglomeration rate constants of spherical latex particles are therefore independent of the

593

particle size (Norrfors, 2015). Even though clay aggregates are known to have different

594

shapes and compositions than the latex particles present in the previous study (Norrfors,

595

2015), the domination of the kinetic energy can be one explanation of the absence of

596

significant differences between the colloidal dispersions in this study (Figure 6). The absence

597

of particle size dependency on the stability ratios is further in agreement with previous studies

598

(Behrens et al., 2000; Ottewill and Shaw, 1966) but once again, one should have in mind that

599

PCS measurements in polydisperse dispersions favour larger sized particles and thereby

600

hiding the agglomeration behaviour of the smaller sized ones. Previous studies of

601

polydisperse dispersions (Chang and Wang, 2004; Jia and Iwata, 2010) indicate that their

602

stability ratio is smaller than for a mono disperse system, which may be seen in this study.

31 604

605

606

Figure 6: Stability ratios for the colloidal dispersions after addition of a) NaCl b) CaCl2 or c) MgCl2, at pH

607

7. Infinity is set to 20 in the figures.

608

609

Finally, no significant differences in stability are observed in presence or absence of FA in the

610

dispersions. Previous studies present a stabilization of the clay particles in presence of FA

611

(Kretzschmar et al., 1998) and notice that the stabilization properties of FA decreases with

612

increasing pH, due to the lower FA adsorption to clay surfaces. In the present study of

613

agglomeration, coursed by addition of CaCl2, the relative high concentration of divalent ions,

614 0 5 10 15 20 25 0.01 0.1 1 3 W Ionic strength [M] S1 S2 S3 S3.5 S3.5,UC S3.5,UC-FA a) 0 5 10 15 20 0.03 0.3 3 W Ionic strength [M] S1 S2 S3 S3.5 S3.5,UC S3.5,UC-FA b) 0 5 10 15 20 0.03 0.3 3 W Ionic strength [M] c) S1 S2 S3 S3.5 S3.5,UC S3.5,UC-FA

32

Ca2+, induced agglomeration with the same agglomeration rate in both presence and absence

615

of FA.

616

4 Conclusions

617

A protocol to obtain montmorillonite colloid dispersions with different size fractions

618

is developed in this study. It is based on a sedimentation step followed by sequential

619

or direct (ultra-)centrifugation.

620

Montmorillonite aggregates of same composition are proved to be present in the

621

different dispersions as concluded from both the chemical analysis and the XRD

622

results. Calcium is associated to the clay particles as natural calcite or due to the fast

623

ionic exchange processes arising under the present experimental conditions. An instant

624

release of sodium and sulfate occurs when the bentonite is suspended in the SGW.

625

This is explained by dissolution of gypsum or/and celestite naturally present in the

626

unpurified MX-80 bentonite.

627

Mean equivalent sphere diameters (EDS) values obtained by different methods agree

628

when normalized to comparable physical properties, leading to a mean hydrodynamic

629

size of the clay aggregates from ~960 nm down to ~ 85 nm. Nevertheless, after

630

applying mathematical treatments, the differences recorded in the initial data between

631

the AsFlFFF (giving the Stokes’ diameter) and the PCS (giving a frictional translatory

632

diffusion diameter) are used to estimate the mean diameter and the thickness t of the

633

clay aggregates in the different dispersions after approximating those to regular

disc-634

shaped aggregates consisting of stacked clay mineral layers. According to our

635

calculation, varies from 1.5 µm down to ~190 nm and t lies in the range of 18 to 70

636

nm. The number of sheets (clay mineral layers) is determined by dividing the

637

thickness t by 1.3 nm (thickness of one single clay layer in basal spacing). The