Publisher’s version / Version de l'éditeur:

Proceedings, British Ceramic Society, 27, pp. 1-6, 1978-12

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Residual stress in clay bricks

Ritchie, T.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=edf79b77-90fd-44d2-a320-20f3826b098e

https://publications-cnrc.canada.ca/fra/voir/objet/?id=edf79b77-90fd-44d2-a320-20f3826b098e

Ser

ational

ResearchConseil national

TH1

1

uncil Canada

derecherches Canada

N2ld

no.

893

Icop. 2

IrnLlatT%

I

~ - ~ . . - - . ~ ,/RESIDUAL STRESS IN CLAY BRICKS

Reprinted from

Proceedingo

No.

27, British Ceramic Society L o d B e a r i ~ Brickwork(VI)

December 1978, p. 1 6

DBR Paper

No.

893Division

of

Building RerearchSO MMAIRE

On a r e m a r q u C q u e d i v e r s e s b r i q u e s d l a r g i l e ont Cte s o u m i s e s

8

d e s c o n t r a i n t e s , c a r l e u r longueur a Cte modifiCe p a r s u i t e du dCgagement d e s c o n t r a i n t e s . Ces c o n t r a i n t e s s o n t a t t r i b u k e s8

l a c u i s s o n d e s b r i q u e s e t peuvent a t t e i n d r e j u s q u 1 8 1 7 5 0 pi/lb2 (12.0 MPa). On a a u s s i r e m a r q u k d e s c o n t r a i n t e s r e s i d u e l l e s dans d e v i e i l l e s b r i q u e s provenant d e bPtiments dkmolis.

T o u t e f o i s , l e f a i t q u e d e s c o n t r a i n t e s aient kt6 e x e r - c e e s s u r l e s b r i q u e s ne s e m b l e p a s a v o i r influ6 s u r l e rendernent d e s o u v r a g e s en b r i q u e s .RESIDUAL STRESS IIJ CLAY BRICKS

T . R I T C H I E Materials Section, Division of Building Research, National Research Council of Canada,

Ottawa.

ANALYZEC:

ABSTRACT

Clay b r i c k s from several sources were found t o he i n a s t r e s s e d condition, a s indicated by t h e i r length changes t h a t apparently r e s u l t e d from s t r e s s r e l i e f . The s t r e s s , a t t r i b u t e d t o t h e f i r i n g o f t h e b r i c k s during manufacture, varied i n amount from very low values t o a maximwn estimated t o be about 22.0 fl/mm2. Residual s t r e s s was a l s o found i n old b r i c k s recovered from demolished buildings; t h e i r stressed condition apparently did not a f f e c t t h e performance o f t h e brickwork.

1 . STRESSES

It4

BRICKSThe high heat required in the firing of bricks subjects them to stress and may cause them to crack. Factors involved in the occurrence of such "firing cracks" have been described by K.E.

ell'

and include temperature gradients in the brick that cause one part of a brick to expand or contract differently from another, thus setting up stresses that may result in cracking. In addition, the brick may be composed of materials that expand or contract at various rates and amounts, even when heated to the same temperature, tl~us stressing the brick, possibly to fracture. Laminar flow of material formed by extrusion, by bringing fine particles to the slip-planes and by producing particle orientation at these planes, may result in their non-uniformity; different dimensional changes of the main portion of the brick and that part at the slip-planes may stress the brick enough to provide yet another cause of firing cracks.Even though the conditions that produce firing cracks in some bricks may not cause sufficient stressing in other bricks to crack them, the existence of stress in bricks should be expected. The studies described here indicate that residual stress, probably attributable to the temperature gradients in firing and the resulting differential dimensional changes, exists in many clay bricks as indicated by the length changes that occurred when perforated bricks were cut through the face into the perforations, and when solid bricks were cut

longitudinally to remove a portion of the brick, such procedures apparently relieving a stressed condition.

T. Ritchie 2. METHOD OF TEST

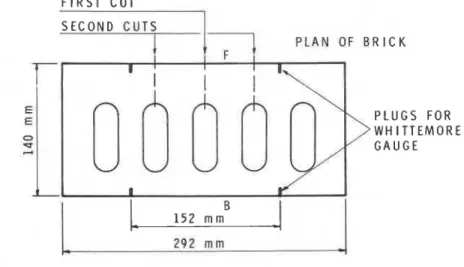

The bricks to be studied were fitted with reference points for length measurements by means of the Whittemore gauge. Holes spaced 152 mm apart were drilled in the face and back of the bricks to receive cylindrical brass plugs which were cemented in the holes with epoxy resin. The plugs had been drilled previously and countersunk to receive the points of the gauge, the dial of which was marked in 0.0001-in. (0.0025 mm) increments.

A change in the dial reading of 0.0025 m in relation to the 152 m distance between the plugs, thus represented movement of somewhat less than 0.002 %.

Measurements were made along the long axis of the brick. Perforated bricks, formed by extrusion, were checked for stress by cutting through the face into a perforation, leaving the back intact. Length changes of the face and back resulting fro77 the cutting were considered to represent the effect of relief of stress in the brick. Other bricks were tested by cutting them longitudinally to remove a slab about 25 m thick from both the face and back of the brick; their length changes were considered to indicate the effect of relieving stress.

Because cutting the bricks required the use of a diamond saw operating under water spray which resulted in dry bricks becoming wet, the bricks were soaked in water prior to the first measurement, made before cutting.

3. RESULTS

Ten samples of a large-format brick 140 nun wide and 292 nun

long, which had been formed by stiff extrusion with five slots, were fitted on the face and back with reference points for length measurement, as shown in Figure 1. The wet bricks were measured,

F I R S T C U T

S E C O N D

C U T S

I

1-

3 IP L A N

U F

B R I C K

r

I I rc

P L U G S F O R

WH I T T E M O R E

u A0)

/I

b>>

G A U G E

L

1 5 2 r n m B

I

2 9 2rnm

-

1

Residual Stress

in Clay

Bricks

then the saw blade was run through the face (F) into the centre slot and the bricks were neasured again. Two additional saw cuts were then made through the face into the slots adjoining the central one, after which the measurements were repeated. The back of the brick (B) was not cut.

The results of the measurements in Table 1 indicate that substantial length changes resulted from the cutting of the bricks. The first cut produced length changes in the faces varying from 0.002 to 0.018 % of the length before cutting. The second cutting produced additional changes, such that the total movement ranged from 0.005 to 0.045 % The two bricks (Nos. 5 and 8) of greatest length change after the first cutting, broke when the second cuts were made.

Table 1

Length changes ( + or -) of bricks

Length change % of original - second cut cumulative Brick Face of brick Back of brick

No' =st cut Second First cut Second cut

1 -0.015 -0.045 +O .002 +O .005 2 +0.003 +O .005 0 -0.002 3 +0.007 +0.012 -0.002 -0.002 4 -0.003 -0.015 +O .002 +O .005 5 +0.018 A -0.007

*

6 -3.005 -0.013 +O .002 +0.002 7 -0.012 -0.028 +0.002 +O .003 8 +0.018*

-0.022 x 9 -0.002 -0.013 0 0 10 M.010 +0.022 -0.002 -0.003*

bricks broke in cuttingHalf the bricks of the ten tested exhibited expansion of the face when cut, the remainder shrinkage. The amount of movement of the face was generally greater than that of the back, and the movement of the face was opposite in direction to that of the back.

Ten samples each of two additional large-format bricks were also tested. These bricks were the same size as the first, but instead of having the five slots of the first brick they had circular perforations arranged in two rows of five each. The bricks were cut initially through the face into the centre hole of the first row, then cuts were made into the holes on each side of the central one.

4

T.

RitchieLength change occurred in these bricks when they were cut, but the amount of movement was less than that of the first brick. The maximum length change of the ten bricks of one lot was 0.008 % and of the ten other bricks, 0.010 %. The bricks of both lots produced movement of the face opposite in direction to that of the back.

4. AMOUNT OF STRESS

An estimate of the stress level in certain bricks was obtained by determining the amount of stress that had to be applied to a brick to produce a length change equivalent to that resulting from its stress-relief on being cut. This procedure is considered to be somewhat analogous to that used2 to determine the stress in restrained structural members that attempt to change length as a result of temperature change; the amount of stress is that required to produce strain equal to the unrestrained movement calculated from the coefficient of thermal expansion and the modulus of elasticity of the material.

A brick from the same lot as those cut, and fitted like them with reference pins for length-change determination, was capped on the ends to provide plane surfaces for compressive loading. The brick was placed in the testing machine, loaded, and the change in dimension corresponding to various loadings was noted. The stress producing a particular amount of length change in the brick was calculated on the basis of the brick's minimum cross-sectional area.

The stress-strain relationships for samples of the three large-format bricks described p~eviously are shown in Figure 2, along with the maximum length change that occurred in those samples of each of the three bricks cut for stress-relief. It is seen that in the case of the brick that showed length-change of 0.069 mm on being cut, the corresponding stress was about 12 N/mm2 while for the other bricks the stress level was between 3.4 and 4.8 N/mm2.

5. TESTS OF OLD B R I C K S

Bricks obtained from several demolished buildings were also studied. They varied in age from about 20 to 100 years, and included bricks formed by the soft-mud, dry-press and extrusion methods. Their residual stress was determined by fitting the bricks as before with reference plugs on the face and back, then cutting off a 28 mm slice from the face and back. The length change resulting from the removal of these parts of the brick was considered to represent the effects of the release of stress.

In all, 57 bricks obtained from several demolished buildings were studied, of which 37 bricks changed length on being cut. The 20 bricks that did not change dimension included all five bricks taken from one of the buildings, and eight of the ten bricks taken from another building. ,

Residual Stress in Clay Bricks 5 M A X I M U M MOVEMENT RESULTING

(

r

F R O M STRESS-RELIEF I N BRICKC

/'

STRESS-STRAIN /' T E S T RESULTS f 0 - - - 0 /. .

. .

. .

. .

.

.

/ 0.-.-.

0 / /-

/

-

/

/d

/ / /:',

6

....

//

...

/-.-.

/-

r

S T R E S S CORRESPONDING.

'/ TO M A X I M U M I .Om MOVEMENT DUE TO.

STRESS-RELIEF ,>..;Id'

-

-

II

I I I II

02

4

6

8

10

12

14

16

S T R E S S ,

~ l m m *

FIGURE 2-Stresslstrain relationships for brick specimens.

One of the structures from which extruded bricks were obtained was the Ottawa Journal Building, erected in 1914 and demolished 60 years later. All samples of the bricks that were tested changed length when cut, the maximum length change being 0.010 %. This amount of movement, according to stress-strain measurements of the bricks, reflected a stress level in the brick of about 2.7 ~ / r n ~ . The bricks of this building, and those obtained from other demolition, appeared to have performed well, with no indication of distress in the bricks or the brickwork.

6.

CONCLUSIONS

The firing of clay bricks stresses them and may produce "fire cracks" or internal stress. The stressed condition of

I

6T.

Ritchiecertain bricks was indicated by their length change when stress was relieved, as, for example, when a saw cut was made through

the face into a perforation, or when the outer part of the brick was removed by cutting the brick longitudinally.

Internal stress was detected in 9 2 of 100 newly-made bricks, representing the production of eight different plants. Some lots of bricks contained unstressed and stressed units, while the level of stress varied considerably. The maximum internal stress

2

of the bricks studied was estimated to be 12 N/mm

.

Bricks may retain internal stress for a long period of time, as shown by tests of bricks taken from demolished buildings. There was no indication, however, that the performance of these particular bricks or the walls they formed had been adversely affected by the stressed condition of the bricks.

I

ACKNOWLEDGEMENTSThis paper is published with the approval of ihc, Director of the Division of Building Research, of the National Research Council of Canada.

REFERENCES

1. BELL, R.E., Firing Cracks in Clays. Canadian Ceram.Soc., 44, 1975.

This publication i s being distributed by the Mvinion of Building R e s e a r c h of the National R e s e a r c h Council of Canada. It should not be reproduced in whole o r in p a r t without permission of the original publisher. The Di- vision would be glad to be of a s s i s t a n c e in obtaining such permission.

Publications of the Division may be obtained by mail- ing the appropriate remittance (a Bank, Express, o r P o s t Office Money Order, o r a cheque, m a d e payable to the Receiver General of Canada, c r e d i t NRC) to the N a t i o n a l R e ~ e a r c h Council of Canada. Ottawa. K1A 0 x 6 .

Stamps a r e not acceptable.

A l i s t of allpublications of the Division i s available and m a y be obtained f r o m the Publications Section, Division of Building Research, National R e s e a r c h Council of Canada, Ottawa. KIA 0x6.