Publisher’s version / Version de l'éditeur:

Home Builder, 24, 6, p. 10, 2011-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Progress in the use of vacuum insulation panels in construction

Mukhopadhyaya, P.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=42d46c8c-8a45-465f-9f92-b4e2d9f35701 https://publications-cnrc.canada.ca/fra/voir/objet/?id=42d46c8c-8a45-465f-9f92-b4e2d9f35701

Progress in the use of vacuum

insulation panels in construction

Mukhopadhyaya, P.

NRCC-54541

A version of this document is published in:

Home Builder, 24, (6), pp. 10, November-01-11 (Aussi disponible en français: Progrès réalisés

dans l’utilisation des panneaux isolants sous vide dans le bâtiment)

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Progress in the Use of Vacuum Insulation Panels in Construction

By Phalguni Mukhopadhyaya

This article reviews research taking place in various countries to advance the technology, performance and durability of vacuum insulation panels for use in construction.

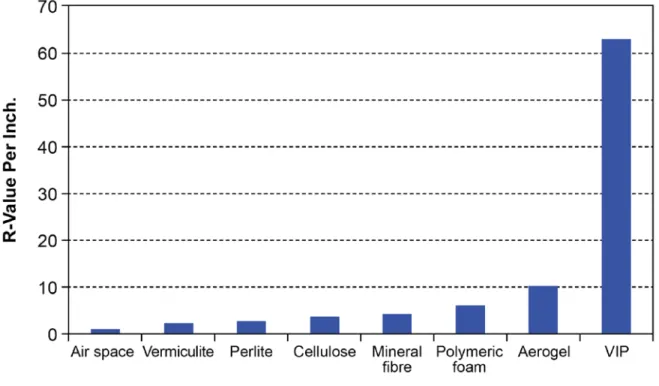

In the March 2011 edition of Home Builder, NRC-IRC reported on advances made for using vacuum insulation panels (VIPs), which provide insulating values up to R-60 per inch or even higher . As reported then, cost, durability and concerns about puncturing of the gas barrier foil were main impediments to widespread adoption of the technology in construction.

Figure 1. Thermal resistivity of VIPs compared to common insulating materials In September 2011, NRC-IRC hosted the 10th International Vacuum Insulation Symposium (IVIS-X 2011) in Ottawa. Some of the main advances reported are summarized here.

VIP research is active in Scandanavia. A 1930s multi-family building in Gothenburg, Sweden, was retrofitted by adding 20-mm VIPs and 30-mm glass wool boards. The re-used wood cladding was attached to the structure through glass wool strapping and glass wool strips

between the VIPs and included a 28-mm air space. The use of VIPs to retrofit about one million apartment units is being investigated. Researchers in Norway are examining a family of

In Germany, VIPs have been used successfully to insulate thermal energy storage tanks, providing ten times the insulating values of previously used methods. After supplying VIPs for ten years, a German manufacturer recognized that the complexity of needing to order VIPs in sizes to fit specific building spaces was an impediment to widespread use. As a solution for floor applications, the company now manufactures VIPs in five standard sizes that can be used to cover almost the entire area, with the remaining strip insulated with polyurethane sheathing. This innovation has minimal impact on the effective insulating value, and VIP orders are filled from stock sizes, speeding delivery time.

The Swiss are investigating the use of double layers of VIPs in lieu of thick, single-layer VIPs to reduce edge thermal bridging and improve lifespan, which is adversely affected as panels get thicker. Another symposium presentation advocated the use of only standard-size VIP panels so that the performance of production batches can be verified prior to installation, and so that replacements are available in case of damage during transportation or installation.

Research in the UK has developed a VIP that uses an oval-shaped steel vacuum core covered with polyurethane to provide a plane surface that is overlain with a thin protective layer of steel. While vacuum insulating panels are known to provide very high insulating values, their

consistent performance over time needs confirmation. Researchers in France are developing models to better predict service life.

There is keen interest in VIPs in Asia. Korea has mandated significant reductions in building energy usage and researchers are studying the use of VIPs in walls and doors and windows with vacuum glass to achieve targets. The thermal performance of VIPs is known to degrade over time due to deterioration of the vacuum, especially gas permeation through heat-sealed flanges. An apparatus for measuring gas loss has been developed in Korea and a novel method for using metal wire in the heat seals to reduce permeability has been proposed. Research in Japan is said to have developed an edge seal that reduces gas permeance by 50%.

In Canada, CMHC and NRCan have constructed a net-zero house in Burnaby, B.C., that uses VIPs protected within and between standard 2x6 framing at 24” spacing. The VIPs provide an effective insulating value of R 38.5 to 42 and also function as the air/vapour barrier.

A wall of a commercial building in Whitehorse, Yukon, was retrofitted with 12-mm (1/2- in.) thick VIPs installed between strapping. The holes in the metal siding were predrilled to align with the strapping to ensure fasteners did not puncture the VIPs. Infrared imaging indicated that none of the VIPs was damaged during construction.

NRC-IRC is a partner in a Canadian initiative to develop construction details for next-generation building envelopes using wood-frame technology. The current project is focusing on laboratory and field testing of highly insulated wall assemblies. Another project is investigating the use of VIPs to improve the thermal performance of commercial flat roofs. As well, NRC-IRC is conducting laboratory and field work on other aspects of VIP’s, which will be reported in detail at another time.

A U.S. manufacturer reported the development of a VIP providing an effective R value of 56 (10 RSI) from a panel less than 1.5 in. (40 mm) thick. The panel has a hermetically welded stainless steel foil vacuum envelope that is said to be durable and have a service life of 50 to 100 years. The developments reported here indicate the significant progress being made toward refining vacuum insulated panels to reduce building energy use.

Dr. Mukhopadhyaya is a senior research officer in Building Envelope and Structure program of the NRC Institute for Research in Construction. As the Chairman of IVIS-X 2011

(www.ivis2011.org), he played a lead role in organizing the symposium. He can be reached at (613) 993-9600 or phalguni.mukhopadhyaya@nrc-cnrc.gc.ca.