Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-963, 1980-12

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=822ba60d-a760-40a3-b20a-ea2d180006d8 https://publications-cnrc.canada.ca/fra/voir/objet/?id=822ba60d-a760-40a3-b20a-ea2d180006d8

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001696

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire performance standards and the problem of fire risk assessment

Harmathy, T. Z.

Ser

TH1

~ 2 1 d

National Research

Conseil national

no. 963

I

*

Council Canada

de recherches Canada

FIRE PERFORMANCE STANDARDS A N D THE

PROBLEM OF FIRE RISK ASSESSMENT

by

T.Z.

HarmathyANALYZED

0977

Reprinted from Fire and Materials

Vol.

4,

No.4, December

1980 p. 173-

176DBR Paper No. 963

Division of Building Research

SOMMAI

RE

On estime que l'glaboration d'une s6rie d'essais

compl6mentaires de performance, et d'un algorithme pour

calculer

5

partir des r6sultats de ces essais le dangerinh6rent aux produits, est prgalable

5

tout progrss versFire Performance Standards and the Problem of

Fire

Risk

Assessment?

T. Z. Harmathy

Fire Research Station, Division of Building Research, National Research Council of Canada, Ottawa, Canada KIA OR6

It is submitted that the development of a set of complementary performance test standards and of an algorithm for calculating from the test results the inherent potential of products for harm is the prerequisite of any progress towards a coherent fire risk assessment philosophy.

INTRODUCTION

With the existence of so many fire test standards one might easily get the impression that virtually all tools are now available for assessing the danger presented by the use of various products. The sad fact is that progress towards establishing a rational foundation for test- based assessment of the fire problem is painfully slow. The reasons are twofold. First, for most fire tests the interpretation of the test results is anything but clear. Second, each fire test addresses a particular segment of the complex picture of the possible danger presented by fire; no coherent philosophy has yet been devised as to how to fit the various segments together.

The prevailing problem was probably best charac- terized by Rouxl when, after presenting the results of five imaginary fire tests performed on five coffee tables, he asked which of the coffee tables would be most propitious for use in a residential unit. Clearly, selection depends on personal judgement, on the weighing of the disadvantages of, say, easy ignitability against smoke producing propensity or liability for high flame spread, and so on.

The purpose of this paper is to analyse the difficulties associated with the assessment of the fire problem and, by suggesting possible solutions, to stimulate creative thinking.

PROPERTY TESTS AND PERFORMANCE TESTS Broadly speaking, there are two kinds of test: property tests and performance tests. Property tests are conducted to determine well-defined material properties such as density, thermal conductivity, modulus of elasticity and heat of combustion. Dozens of test techniques are usually available for measuring each of these properties and the test results are expected to show close agree- ment as long as the tests are based on theoretically sound principles. That being so, there is no real need

t

This paper is a contribution from the Division of Building Research, National Research Council of Canada, and is published with the approval of the Director of the Division.for standardizing property tests; the purpose of stan- dardization is mainly the specification of the reference condition for the specimen.

Performance tests are conducted to determine the behaviour of products under a given set of conditions. These include (I) attributes of the product itself, such as size, shape and orientation, and (2) a numberof extraneous factors, such as force, heat flux, flame impingement, etc. The results of the performance tests depend partly on the properties of the product material and partly on the conditions to which the pro- duct is subjected. The need for performance tests arises whenever the response of the product to a process characterized by a set of conditions is either not well understood or too complex for mathematical analysis. Standardizing performance tests is clearly a necessity.

It the problem to be answered is not too complex, it is possible to devise a performance test that will make the test result depend on one, two, or at the most on a few essential conditions. The tensile test for metals is a good example. The deformation of the test sample depends primarily on the force applied and is relatively insensitive to such conditions as specimen size and strain rate. Consequently, the test results are expected to apply to a wide range of practical conditions.

If the test result is found to be sensitive to several conditions, it is a clear indication that either the test is poorly devised or its scope is too wide. Such performance tests are justifiable only if they simulate conditions that frequently arise in practice.

The E-84 tunnel test is an example of a less than perfect performance test. In it, the following conditions are directly or indirectly specified: size and orientation of the test specimen, heat communicated to the specimen and method of communication, direction and rate of air flow past the specimen, and thermal feedback to the specimen as determined by the size of the tunnel and its lining materials. None of the set conditions can be

regarded as simulating cases occurring frequently in practice. Consequently the results of tunnel tests would

be rneaningfui only if it could be proved that they are insensitive, within reasonable limits, to the set conditions. As such proof cannot be provided, the results are of limited value.

T. Z . HARMATHY

I

GROUPING OF PRODUCTSThe difficulties in fire performance testing depend a great deal on which of the following phases of a fire the test is associated with: (1) incipient phase, (2) ad- vanced preflashover phase, and (3) fully developed phase. [n the incipient phase the behaviour of a product depends mainly on its own properties and geometric attributes; it is unaffected by such extraneous factors as surrounding objects, ventilation, etc. At the very beginning a chair, for example, will burn in exactly the same way whether it is in a furnished room or in a stone cave. As the flames grow taller, and perhaps other items are ignited, however, the burning becomes sensitive to more external factors such as adjacent objects, compartment lining, ventilation and oxygen level. Finally, in the fully developed phase fairly uniform conditions arise that can be predicted with considerable accuracy.

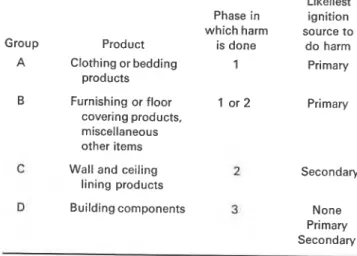

The purpose of all fire performance tests is the assess- ment of some aspect of the potential for harm associated with various products. The nature of the potential for harm of a bedding material is clearly different from that of a building column; and although no two products are exactly identical in this regard, practicality demands that all products be divided, based on potential for harm, into a finite number of groups. Clearly, time is an important factor in the grouping. Thus the various products can be divided according to the phase in which their potential for principal harm is likely to develop: Phase 1, Phase 2 or Phase 3. Furthermore, the potential for harm should be considered in conjunction with the likeliest source of ignition: primary, small energy

source (e.g, lighted cigarette, match fire. grease fire), or secondary, large energy source ( e . ~ . waste-basket fire, burning furniture).

Based on these considerations, it is tentatively suggested that products to be found in residential and office occupancies should be grouped as follows (Table 1):

Group A : clothing and bedding products characterized by very short time to do harm (in other words by poten- tial for harm in Phase 1 of the fire) and by the fact that the likeliest ignition sources are primary sources.

Group B : furnishing and floor covering products and Table 1. Grouping of products with respect to potential for

harm

Likeliest Phase in ignition which harm source to

Group Product is done do harm

A Clothing or bedding 1 Primary

products

B Furnishing or floor 1 o r 2 Primary

covering products, miscellaneous other items

C Wall and ceiling 2 Secondary

lining products

D Building components 3 None

Primary Secondary

miscellaneous other items such as books and paper products. For these, the time to do harm is somewhat longer (potential for harm in Phases 1 or 2 of the fire) and ignition usually occurs by primary ignition sources.

Group C : wall and ceiling lining products. For these the time to do harm is still longer (potential for harm in Phase 2 of the fire) and ignition occurs by secondary sources.

Group D : building components. The critical times are I

very long (potential for harm in Phase 3). Ignition may not occur, but if it does it is by either primary (e.g. a shorted wire in a wall) or secondary source.

There are relatively few problems in developing performance test standards for products that belong in Group A. The harm is expected to be done in Phase 1 of the fire when, as mentioned, the product performance depends mainly on the properties of the product material and the geometric attributes of the product. The only problem is to select the suitable size, shape and orienta- tion of the test sample and the likeliest ignition source. If appropriately devised, the test will yield information regarding the true performance of the product, and there- fore, it is believed, no caveat needs to be added to the test specification.

Again, there are no major problems in developing good performance test standards for Group D products, those tending to do harm in Phase 3, that is, during the fully developed period of the fire, because the conditions for this period can be fairly well defined.

The real problems arise with products likely to do harm in Phase 2, that is, under advanced preflashover conditions. As Table 1 shows. furnishings and floor

-

coverings as well as wall and ceiling lining products are of this kind. The predominant potential for harm usually relates to rate of burning or rate of flame spread. These phenomena are strongly influenced by extraneous factors such as thermal feedback, direction and rate of air flow, nearness of other objects, oxygen level in the atmosphere. The difficulties with Phase 2 performance tests are exemplified by the tunnel test and corner wall tests. It appears that progress towards developing good Phase 2 performance tests will depend on how thoroughly the mechanisms of burning and flame spread are under- stood.- -

RISK AND POTENTIAL FOR HARM

I

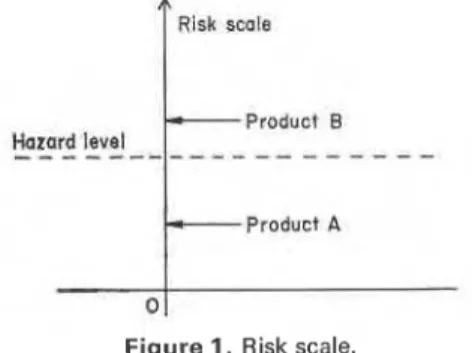

As mentioned earlier, how to fit together the various pieces of information to obtain an overall picture of the potential danger presented by a product is still un- resolved. It has been usual to talk about the 'risk' involved in the use of products. Fire risk is traditionally defined as follows:

Fire risk = probability of occurrence

x probability of exposure x potential for harm

(1)

Using this formula one can assign to any product, at least in principle, a risk number on a scale running from

0 to infinity (Fig. 1). The authority having jurisdiction is expected to draw the line of hazard level that separates the acceptable (low risk) products from the unacceptable (high risk) products. Thus, product B in Fig. 1 is hazar- dous, product A is not.

F I R E PERFORMANCE STANDARDS AND T H E PROBLEM O F F I R E R I S K ASSESSMENT

Product B

Hazard level

Producf A

Table 2. Weighting factors

Product group Factor for PH component A B C D a (Ignitability) 0.40 0.20 0.20 0.20 b (Smoke) 0.05 0.30 0.20 0.05 c (Toxicity) 0 0.10 0.05 0.05 d (Burning 1) 0.40 0.35 0 0 e (Burning 2) 0 0 0.50 0 f (Structural failure) 0 0 0 0.65

Figure 1. Risk scale. g (Extinguishment) 0.15 0.05 0.05 0.05

Of the three factors in the formula for fire risk only the third, the potential for harm, is product-related; in other words, only the third can possibly be assessed from the test data. The other two, probability of occur- rence and probability of exposure, are to be derived from information, statistical in nature, that has very little relevance to the product itself. Apart from the fact that collection and interpretation of statistical data are outside the traditional scope of standards writing organizations, it is believed that standard writers would better serve the ultimate goal of the emergence of a practical system for fire risk assessment by concentrating their efforts on developing a procedure and an algorithm for the evaluation of the product-related term in the expression of fire risk, namely the potential for harm. The following is an outline of the author's thoughts on the subject.

The potential for harm, PH for brevity, is visualized as having several components. A tentative list of these PH components is given below. The list should be scrutinized and possibly expanded or shortened.

(1) Ignition by plausible ignition source

(2) Intense smoke production

(3) Production of toxic gases

(4) High burning rate or high flame spread rate in

Phase 1 fire

(5) High burning rate or high flame spread rate in Phase 2 fire

(6) Structural failure

(7) Resistance to extinguishment

Once the list has been established, the important work of selecting the most appropriate performance test methods for quantification of each PH component can begin; if some of the existing test methods prove unsatisfactory, the work of developing suitable new methods must be attempted.

The results of a set of well-chosen performance tests will yield a set of PH component numbers. The overall PH can then be obtained by an agreed-upon algorithm, for example, by the weighted summation of the PH

component numbers :

If the overall PH is to be regarded as a true product

descriptor, the weighting factors cannot be made de-

pendent on the circumstances of use of the product. It

is therefore a practical necessity (and clearly a sirnplfica-

tion) to regard the factors a, b

. . .

g as constants withineach of the tour product groups. Eventually these values may be decided by statistical analysis, but at the present

time the only way to choose them is by apriori reason-

ing. The values listed in Table 2 reflect the author's

personal judgement: for clothing and bedding products,

Group A, ignitability and Phase 1 burning or flame

spread are the most important PH characteristics;

for furnishing and floor coverings, Group B, smoke

production and Phase 1 burning or flame spread; for lining materials, Group C , Phase 2 burning or flame

spread; and for building components, Group D, struc-

tural failure.

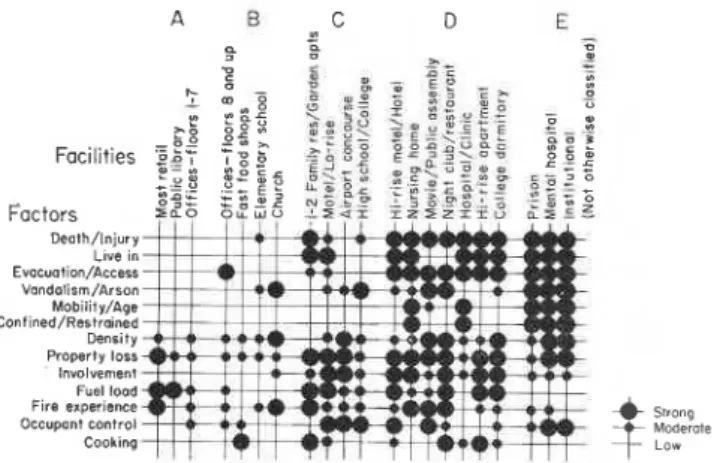

With the outlined procedure, each product can be

characterized by a PH number on a scale from 0 to

infinity (Fig. 2). As the PH number is a true product descriptor, it cannot serve directly as a basis for making decisions on the acceptability of the product; it must first be converted into a risk number. If probabilistic considerations are used, as suggested by Eqn (I), the standards writers cannot be of direct help. Indirectly. however, they can offer further help, as demonstrated by the ASTM E05.15 Task Group on Upholstered

F ~ r n i t u r e . ~ Based on a priori reasoning, the Task Group

divided the environments in which upholstered furniture may be used into five classes (classes A to E, Fig. 3). The long-term value of such classification is that it provides a guide for collecting statistical data. In addi- tion, it has an immediate impact because in a crude way

PH

scale

T

where : PH = overall potential for harm ;

PHI, pH2

.

. .

PH7=component potential forharm numbers ;

a, b, c

. .

.

g=weighting factors.Many will probably recognize that from the point of view of the alogrithm used Eqn (2) is similar to that proposed by Herpol2 for the calculation of a so-called

'reaction to fire index'. Figure 2. Potential for harm scale.

1

T. Z . HARMATHY-

-

4 m n Factors Deoth/lnjury Live in Evacuation/Accees Vondalism/Arsan Mobilit y/Age :onfined/Restrained Density Property loss involvement Fuel load Fire experience Occupant control Cookingnumber is higher or lower than the allowable level for the occupancy class in which it is to be used.

Obviously, the weakness of this procedure is that, for the present at least, drawing the allowable PH levels is an arbitrary act. It seems that using stochastic considera- tions of one kind or another is unavoidable when making rational decisions.

CONCLUSION

strong

Moderate

Most existing fire test standards grew out of practical necessity at periods when the problems they were designed to solve were only partially understood. None was intended for use in conjunction with others to form a

Figure 3. Occupancy classification for upholstered furniture.

(Reprinted, with permission, from ASTM Standardization News, Segment in a mosaic of understanding' a July 1978. Copyright, American Society for Testing and Materials, Set of good, relevant performance skldards that comple- 191 6 Race Street, Philadelphia, Pa. 191 03.) ment each other is clearly the prerequisite of any attempt to proceed towards a coherent fire risk assessment

it allows the direct use of the PH scale in decision making. philosophy. At this time it would be presumptuous to

As illustrated in Fig. 2, allowable PH levels may be aim at more than the development of a sound method for

assigned to the five classes, and the acceptability of a assessing products with respect to their intrinsic potential

piece of furniture may be based on whether its PH for harm.

REFERENCES

1. J. H. Roux, The Scope and Limitations of Fire Testing, 3. ASTM E05.15 Task Group on Upholstered Furniture, Develop- presented at Fifth International Fire, Security and Safety ment of a Concept for Fire Hazard Classification of Up- Exhibition and Conference, London, England (25 April 1978). holstered Furniture. ASTM Standardization News, p. 16 2. G. A. Herpol, Noncombustibility-Its Definition, Measure- (July 1978).

ment, and Applications, I n Ignition, Heat Release, and

Noncombustibility of Materials, Am. Soc. Test. Mater. Received 1 1 February 1980 Spec. Tech. Publ. 502, L 9 (1 972). 0 Heyden & Son Ltd, 1980

This publication is being d i s t r i b u t e d by the Division of Building R e s e a r c h of the National R e s e a r c h Council of Canada. I t should not b e reproduced i n whole o r in p a r t without p e r m i s s i o n of the original publisher. The Di- vision would b e glad to b e cf a s s i s t a n c e i n obtaining s u c h p e r m i s s i o n .

Publications of the Division m a y b e obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e ( a Bank, E x p r e s s , o r P o s t Office Money O r d e r , o r a cheque, m a d e payable t o ,the R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) t o t h e National R e s e a r c h Council of Canada, Ottawa. KIA OR6

.

S t a m p s a r e not acceptable.A l i s t of a l l publications of the Division i s available and m a y b e obtained f r o m the Publications Sec tion, Division of Building R e s e a r c h , National R e s e a r c h Council of