Design by Decay, Decay by Design

Andrea LingBachelors of Environmental Studies in Architecture, University of Waterloo, 2004

Master of Architecture, University of Waterloo, 2007

Submitted to the Program in Media Arts and Sciences, School of Architecture and Planning,

in partial fulfillment of the requirements for the degree of Master of Science in Media Arts and Sciences

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

September 2018

Massachusetts Institute of Technology 2018. All rights reserved.

Signature redacted

' -i-Author, Andrea Ling Program in Media Arts and Sciences

July 30, 018

Signature redacted

Certified by (eri

O)man

Associate Professor of edia Arts and Sciences Thesis Advisor

Signature redacted

Accepted by Tod

a over

Academic FTad

Program in Media Arts and Sciences

MASSACHUSETTS INSTITUTE

OF TECHNOLOGY

Design by Decay, Decay by Design

Andrea Ling

Submitted to the Program in Media Arts and Sciences, School of Architecture and Planning,

in partial fulfillment of the requirements for the degree of Master of Science in Media Arts and Sciences

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

September 2018

Massachusetts Institute of Technology 2018. All rights reserved.

Signature redacted

7

Approved by James Weaver,Senior Research Scientist,

Design by Decay, Decay by Design

Andrea Ling

Submitted to the Program in Media Arts and Sciences, School of Architecture and Planning,

in partial fulfillment of the requirements for the degree of Master of Science in Media Arts and Sciences

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY September 2018

Massachusetts Institute of Technology 2018. All rights reserved.

Signature redacted

Approved by Heather Paxson,Professor of Anthropology, Department of Anthropology

e6-Abstract

THE USE of biological agents, such as bacteria, fungi, plant material, and insects, is proposed as a viable design methodology that can include end-of-life material treatment and re-use as part of the design process. Decay, typically thought of as a destructive process with spatially and temporally unpredictable results can be potentially designed to high levels of spatial and temporal tunability, such that the product of decay can still be of value to the designer. In particular, could microbes, in combination with water, be guided to selec-tively disintegrate, and potentially also then be harnessed as agents of assembly, enabling design construction instead of destruction? What would the ecology of this system that includes the microbes, biocompatible substrate, and contextual environment, look like? How might it behave and how might this affect how

ar-chitects design the built environment?

The main goal of this thesis is to understand how water-induced decay of biocomposite-based artifacts might be designed such that the deterioration process has use-value for the designed artifact and how this decay might be harnessed as a formative agent instead of only as a deconstructive one. This understanding will be informed by the execution and analysis of a series of case study projects that include:

Aguahoja: Artifacts and Hexes Aguahoja: Colonization

Aguahoja: Pavilion

For these projects, water-based composites of chitosan, cellulose, and pectin, will be additively printed into architectural-scale artifacts and panels which are used as the skin of a small pavilion. The use of the chitin-cellulose-pectin composite introduces a water-dependent biocompatible material system that can act as the base scaffold for biofilms and microbial colonies. A series of material characterization tests were done to understand the nuances of the different bio-composites. Working challenges for this system included warping and uncontrolled deflections due to changing relative humidity and the gradual and constant dehydration of the material. This hydration dependent activity also dictated flexibility rigidity, and colour. Water is used to initiate the disintegration of the panels as well as initiate the growth of microbial cultures on the panels.

The projects described here are intended to serve as examples of how a designer might be able to incorporate biological agency into her process. It is not intended as a comprehensive guidebook, but rather as case studies of how one might use nascent biological tools in current design methodology and how that methodology might have to change in order to leverage biology in her process.

Acknowledgements

THANK-YOU to my supervisor, Neri Oxman, for providing such an inspiring place to learn, and to my readers Heather Paxson and James Weaver for their enthusiasm, insights, and discourse that helped shape my thoughts.

Thank you to team

Aguahoja

-Jorge Duro-Royo, Timothy Yen-Ju Tai, Nicolas Hogan, and Barrak Darweesh, and the ever patient Joshua Van Zak. It was a privilege to work, learn, and argue with you, and I am truly proud of what we were able to make together.Thank you to the rest of the Mediated Matter family - Levi VV Cai, Daniel Lizardo, Markus Kayser, Sunanda Sharma, Chikara Inamura, Christoph Bader, Dominik Kolb, Julian Leland, Rachel Smith, Michael Stern, Joao Costa, Sara Falcone, Zijay Tang, Jean Disset, Nassia Inglessis, Kelly Donavan, and Natalia Casas. You are some of the most talented and dedicated people I have worked with and it has been a joy to be your colleague, friend and fellow dreamer.

Thank-you Daniel Levine, Amos Golan, Tim Savas, and Pranam Chattarjee for their assistance and technical advice these past few years. Sincerest thanks to Linda Peterson and Keira Horowitz.

Finally, my time at MIT would not have been possible without the support of those who helped me maintain life at home so that I could make a new one here. Mom, Dad, Andrew, Julie, Ian, Olivia, Christine, Jonah, and Debbie, I miss you and owe you all a great debt.

Dedication

Contents

Chapter 1Introduction 15

The nature of decay 18

Functional failure versus decay 19

Why design decay at product and architectural scale? 20

Chapter 2

A case for biologically derived materials 23

Chitosan, cellulose, pectin 27

Water 28

Composites 29

Chapter 3

Aguahoja 31

Fabrication platform 32

Aguahoja: Artifacts and Hexes 35

Material characterization and performance 38

Deformation and dissociation behaviour 48

Conclusions 58

Aguahoja: Colonization 59

Biocompatability 59

Designing Decay 64

Water-induced dissociation 67

Rot and colonization 74

Chapter 4 Aguahoja Pavilion 77 Making a tree 77 Structural map 79 Solar map 82 Rain map 82 Predicted dissociation 83 Evaluation 84 Conclusion 87 Appendix A 89

Aguahoja Artifact Library

Appendix B 127

Aguahoja Pavilion

List of Illustrations

1 Living pigments in Gwion Gwion rock art, Kimberly, Australia. https://en.wikipedia.org/wiki/Bradshaw-rock-paintings 15 2 Biology, Environment, Fabrication, and Design as partners in design ecosystem. 16

3 Vespers, Series 3, Mask 1, Mediated Matter, 2016. Image credit: Domink Kolb. 17

4 The Roman Colosseum, Giovanni Battista Piranesi, 1757. Image credit: https://en.wikipedia.org/wiki/File:Giovanni_

18

BattistaPiranesi,_TheColosseum.png

Sarajevo Scar Lebbeus Woods, 1997. Image credit: Lebbeus Woods ExperimentalArchitecture

Packard Plant, Detroit, Michigan, 2017. Image credit: www.detroitcurbed.com

5 Banyan trees, Angkor Wat, Cambodia. 19

6 Material property charts, image credit: http://teachingresources.grantadesign.com/Charts-overview

6a Young's modulus aganst density 23

6b Compressive strength aganst density 23

6a Compressive strength against cost 23

6a Young's modulus against embodied energy 23

7 Material property chart of natural materials, plotting tensile strength against desnsity. Image credit: Mogas- 24 Soldevila, Duro-Royo, et al., 2015, adapted from Ashby, 1995.

8 Dimensions of non-standardized cowhide. 25

9 Plain sawn vs quarter sawn vw rift sawn lumber. 25

10 Sources of the biologically derived materials used in this thesis, including cellulose, chitiosan, pectin, cornstarch, 27 and calcium carbonate. Image adapted from Van Zak, Duro-Royo et al, 2018.

11 Aguahoja pavilion, view from interior. Photo by Jonathan Williams. 31 12 Original water-based digital fabrication (WDF) platform developed by Mediated Matter, 2014. Image credit: Laia 32

Mogas-Soldevila, Water-based Digital Design and Fabrication, 2015, p38.

13 Design workflow of original WDF platform, 2014. Image credit: Mogas-Soldevila, Duro-Royo, et al., 2015.

33

14 Typical multi-layered print strategy for WDF platform V2.0, 2017. 33

15 WDF platform V2.0, Autodesk Build Space, 2017. 33

16 WDF system protocol, 2017. 34

17a Aguahoja exhibition, Mediated Matter, MIT Media Lab, October 2017. Photo by Joao Costa. 36

17b Aguahoja exhibition, Mediated Matter, National Academy of Sciences, 2018. Photo by Nic Hogan. 36

18 Identification system of Aguahoa samples. 37

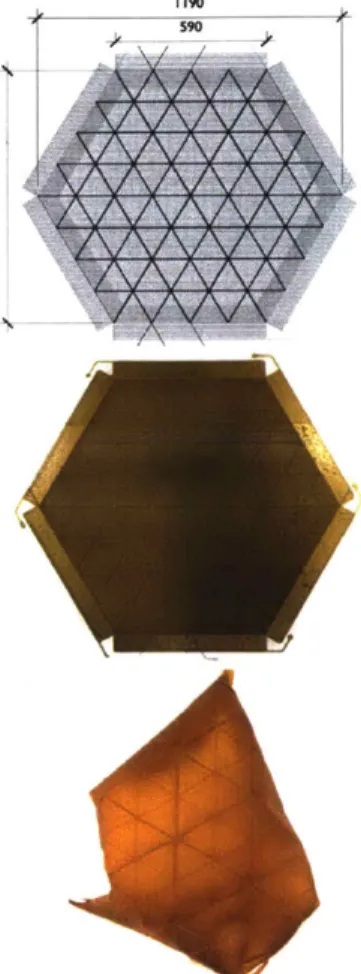

19 Different composites pf chitosan, cellulose, pectin, and other additives, 2016. Photos by Timothy Tai. 38 20a Tensile testing of various biocement compositions graph, 2016. Figure adapted Van Zak, Duro-Royo et al, 2018. 40 20b Material characterization of selected composites, 2016. Figure adapted from Van Zak, Duro-Royo et al, 2018. 40 21 Effect of material composition on colour gradation of composites, 2017. 42 22 Effect of material compostion and print parameters on performance of large scale samples, 2017. Figure from 43 Van Zak, Duro-Royo et al, 2018.

23 Effect of material composition and print parameters on performance of medium scale samples, 2017. 44 24a Hexagon panel: original toolpath, fresh print, dried print, 2016. 45 24b Quad mesh panel: original toolpath, fresh print, degraded print, 2017. 46 24c Leaf panel from original WDF platform: original toolpath, fresh print, 1 month old print, 3 year old print, 2014. 46

25 Humidity dependent activity on medium scale sample 47 26 Effect of chitosan : cellulose ratio in shell layer on water-induced deformation over time 50

27 Effect of toolpath strategy on water-induced deformation over time

51

28 Effect of material distribution (density) on water-induced dissociation over time

54

29 Effect of material distribtuion (spatial patterning) on water-induced dissociation over time. Image credit: Tai, Bader, 54

Ling et al, 2018.

30 Simulation of water-induced dissociation on samples with variable material distribution. Image credit: Tai, Bader,

55

Ling et al, 2018.

31 Effect of equal quantity, similar material distribution on water-induced dissociation over time

57

32 List of relationships between base ingredients of skin and shell layers and geometric hierarchy on performative 58

behaviour of bio-composite panels

33 Effect of variable material distribution (spatial patterning) on direction of mold growth 59

34a Grid sample exhibiting mold growth at Day 4

60

34b Initial SCOBY test in 4 different aqueous pectin-chitosan compositions

60

35 Fungal experiments: chitosan / cellulose / pectin / control mix cakes innoculated with pink oyster spores 62 36 Fungal experiments: resuilts of fruiting after 7 weeks on species compatible mixes 63

37 Design of 1: 5 scale maquettes of Aguahoja pavilion

64

38 1 : 5 scale maquettes with different material composition and toolpath geometry

65

39 Decay box: cold box, 14-160C, interior view

67

40 Decay box: hot box, 30-381C, exterior view

67

41 Views and print strategy of Maquette 1 68

42 Views and print strategy of Maquette 2

68

43 Views and print strategy of Maquette 3 70

44 Views and print strategy of Maquette 4 70

45 Time lapse of water-induced dissociation of maquettes 1 & 2, cool temp, high humidity, over 25 days

72

46 Time lapse of water-induced failure of maquettes 3 & 4, high temp, high humidity over 20 days 73

47 Close-up view of mycelium growth on maquette 1

74

48 Aguahoja pavilion, 2018. Photo by Joao Costa.

76

49 Original pavilion image by Christoph Bader.

77

50 3D printed (FDM) plastic skeleton, MIT Media Lab, 2018. Model by Timothy Tai, print by Stratasys.

77

51 Slmulation of structural, solar, and rain mappings on Aguahoja pavilion by Christoph Bader 79 52 Across-scale design strategy of bio-composite panels of Aguahoja, refer to Duro-Royo, Van Zak, Ling, Tai et al 2018 80

53 Structural, solar, and rain maps compiled to dictate print parameters, chemical composition, and toolpath geometry

81

& density. 4 map renderings by Timothy Tai. Top images adapted from Duro-Royo, Van Zak, Ling, Tai et al, 2018.

54 Aguahoja panels, predicted time to dissociate in salt water. Image credit: Nic Hogan.

83

55 Aguahoja pavilion, 2018. Photo by Joao Costa.

86

Appendix A Aguahoja Artifact Library, 2018. Photos by TImothy Tai, Nic Hogan, and Andrea Ling. 90

Chapter 1

Introduction

IN AUSTRALIA, the Bradshaw rock paintings are estimated to be between 46 000 to 70 000 years old. Often located in areas exposed to sun and rain, the paintings are remarkable in that they have never been repainted, yet they remain vivid and clear, especially when compared to other rock art in the area of comparable age. When swabbed, archaeologists found that in many of the Bradshaw paintings, the original paint has disappeared and what remains is a biofilm of a symbiotic black fungus and red cyanobacteria whose ancestors are thought to have used the nutrients in the original paint to start their first colonies (Yusoff 2014). The fungus, in particular, is growth conservative, cannibalizing its predecessors in situ, and is dependent on the cyanobacteria for sugar while the bacteria relies on the fungus for water supply; the two organisms need to be in close proximity to each other to survive. These circumstances have contributed to the biofilm's tendency to remain faithful to the confines of the original drawing, rendering it in living pigment instead of paint and permitting a longevity and legacy that is not possible with the non-living alternate.

The Bradshaw paintings exemplify some of the remarkable advantages living material systems have over the non-living - adaptation, repair, controlled replication, and living preservation. A handful of the paintings however have overgrown and have lost their original lines. Incorporating biological matter and living organisms in design and manufacture means one is introducing inherent agency into a material system and thus also embracing a degree of risk and uncertainty concerning the final product (Pye 1968). With this risk and uncertainty, however, is also the potential to incorporate legacy, diversity, and variation during the process which in contemporary industrial practice are either impossible or undesired. In this thesis, water-induced decay, which is traditionally combatted against with traditional material systems, is viewed as a means to create a new system of organization.

1 The term legacy is used here in reference to the ability of living organisms to

reproduce and pass on embodied intelligence to successive generations.

1

Living pigments in Gwion Gwion

rock art, Kimberly, Western Australia.

Why is this important? Because designers are reaching a point where biological tools are now accessible yet they demand a different design process to use them successfully. In comparison with previous design methods involving contractual drawings where we specify materials that are homogenous and often agnostic to environmental conditions, assembly systems that depend on standardization and locations that are fixed or at least predictable, we cannot design with biological materials and biological agents in the same prescriptive fashion. We cannot be certain of the outcome in the same way we are certain about the outcome of, for example, a structure that depends on metal extrusions from a factory or laser-cut and assembled plastic. We can however, be precise about the process that we use to design with, mediating and responding to the idiosyncrasies of the biological system and the environmental conditions with synthetic and designed intervention. Thus with the use of biologics, the process of design has the potential to move from a conceptual, prescriptive practice towards an embodied, reactive one.

"Nature-inspired

Design and Design-inspired Nature: designing by,

with, and for nature"

2 The incorporation of biology, as an

equal partner in the design ecology that

includes creative intent, environmental

conditions as well as fabrication

technologies. Each of these elements

influence the other, and are in turn

shaped by the others, creating a recursive system by which things can be made.

Environment

Biology P Artifact - Fabrication

Design

The Mediated Matter group led by Professor Neri Oxman, subscribes to a philosophy where design can be, in part, the process of connecting natural systems into a design ecology of conception, environment, and fabrication. The practice goes beyond using nature as inspiration for form-finding strategies and creating biomimetic artifacts and instead involves the leveraging of biological systems and their modes of

information transmission, replication, and energy optimization to make things that offer a new model of design synthesis.

The group of designers, computer scientists, engineers, and biologists work together to create medium- to large-scale artifacts using novel fabrication platforms that integrate computation with synthetic biology and design. Many of these projects are conceived following the principles of Material Ecology which Oxman describes as an "ecology ofthe artificia?'(Oxman 20 1Ob, 6) defined by synthesized relationships between the computational, biological, and material systems that link the built environment with the natural environment across all scales from micro (molecular and chemical) to macro (scale of the built environment that we inhabit). The group follows a design approach that eschews the assembly of homogeneous components made of mono-materials in favour of growth, via additive manufacturing processes such as 3D printing. These processes can incorporate property gradients of multiple materials and multi-functionality into a seamless whole. The term growth is used in both a transformative sense, in that additive manufacturing processes lend themselves to the slow accumulation of matter similar to growth, as well as the literal sense, in that some of the technologies that are used in the manufacturing process include biological ones where the growth of microbes and other living organisms is integrated into designed artifacts. An example of this is the group's Vespers2 project, a series of 3D-printed death masks that make use of the multi-material printing capabilities of the Stratasys 3D-printers. The different materials have different durometers and toxicities associated with them, and can be graded such that different areas of the masks will be more pliant than others or more hospitable to microbial growth despite being printed together as a whole. The third series of the masks are washed in an inducer bath which is selectively absorbed by different regions and E coli are distributed on them, growing in areas that are more hospitable. The E. coli have been genetically engineered to produce colour in the presence of the inducer, resulting in pigment distribution that reflects the selective distribution of microbial gene induction on the masks.

In this synthesis, biological matter and living systems can then be additively prescribed to create elements of the built environment. With this integration also comes the possibility of incorporating natural modes of failure and death into designed artifacts, as well as the organic recycling of material elements back into ecological systems. The artifacts are then no longer terminal end products, but instead a particular

2 Project team: Neri Oxman (principle investigator), Christoph Bader, Dominik Kolb, Rachel Smith, Sunanda Sharma, 2016. Refer to project information: http://

matter.media.mit.edu/environments/details/vespers-third-series

3 Vespers, Series 3, Mask 1,

Mediated Matter, 2016. Image

credit: Dominik Kolb.

4 Architectural decay, from top to bottom: The Roman Colosseum, as depicted by Giovanni Battista Piranesi,

1757. Sarajevo Scar, by Lebbeus

Woods, 1997. Packard Plant, Detroit, Michigan, 2017.

arrangement of matter at a specific time point along the lifetime of that matter, available for transformation to another form via decay and subsequent growth.

The nature of decay

In its most generic sense, decay indicates a decline or decrease of vitality, from a previously healthy, robust state to one much less so. With regards to buildings and products, decay is typically viewed as destructive, the product of the workings of climate, weather, biology and time on construction with spatially unpredictable and non-uniform results. In architecture, decay has long been looked upon with either a call for repair for buildings that conservationists deem worthy of saving in their efforts to curate heritage, or through a lens of romanticism and / or critical fetishism. For instance, Giovanni Battista Piranesi's etchings of Ancient Rome depict the derelict monuments with a fair amount of artistic license, to make the buildings more epic in their disrepair. Lebbeus Woods' highly frenetic speculative designs are situated upon the remnants of war torn cities in the former Yugoslavia, depicting decay as a product of violence and crisis, and ruins as artifacts that could be precariously built upon rather than razed. And more recently, architectural tours of abandoned buildings in Detroit like the Packard Plant or the Michigan Central Station, allow the curious to gawk at the physical detritus of failed industrial and socio-economic institutions. These examples regard decay in building as a type of ruin fantasy, signifying a normally wistful, sometimes violent, and always gradual, process of heritagization.

Decay in nature however can be viewed differently. Nature's decay is as constructive as it is destructive, indicative of not merely the opportunity for renewal, but of the process of actual renewal. In science, decay is the process by which matter decomposes into constituent elements; it can be abiotic, resulting from chemical or physical means of decomposition, or it can be biotic (biodegradation) where the breakdown is caused by living organisms. When in reference to biology, decay is the decomposition of matter that was once living and now dead. One system's entropy however, is another system's organization and decay agents such as fungus, bacteria, slime molds and small insects convert dead tissue into forms that are useable for growth either by the decomposers or other organisms. It is with this lens that this thesis views decay: as a both destructive and constructive agent, that happens gradually over the span of months or years, with minimal energy input, and generates organized, useful output.

Functional failure versus decay

In living organisms, decomposition begins upon death. When living, organisms have a constant incursion of energy (for instance, sunlight or food) fueling metabolic activity that maintains a state of dynamic homeostasis to prevent decay from occurring prematurely. Organisms show failing functional capacity at varying rates - organisms that age, such as mammals and birds, start to fail as they past maturity, with decreased ability to maintain homeostasis and respond to stress. They tend to have a limited lifespan, at the end of which they will die from age-related complications. The decline is slow in comparison to the lifespan; for instance, humans reach peak muscle mass in their late 20s and early 30s, yet they can live for another 50-70 years with that muscle mass slowly declining. (Plants, in contrast, tend to get stronger with age, as their cells are perpetually embryonic and are capable of growing indefinitely, limited only by their weight and laws of physics.) The failure is slow and graceful (where graceful failure is defined as failure where a system's functionality is retained, albeit at a reduced level, despite having portions of the system broken down), and where plenty of notice is given before the organism dies.

Buildings, however, are subjected to degrading forces from the moment their construction is complete and energy inputs are required to maintain acceptable interior environmental conditions against these forces rather than "growing" or augmenting any of its systems. But the degradation of a building's constituent elements is much slower than the decay of organic tissue, despite starting much earlier in the lifespan of the building. It is thus useful to determine when the degradation is to such an extent that a building no longer meets its functional criteria (failure points) as opposed to when the building's material elements have completely degraded into constituent elements. For the purposes of this thesis, building failure occurs when any system or component of the building fails to an extent that it is no longer able to be occupied. Performance failures (Parfitt 2012) can include (but are not limited to):

- Structural failures, where loss of load carrying capacity results from the material being stressed past the strength limit

e Building envelope (facades, roof, waterproofing, sealants, flashing) failures, where breaks in the skin prevent the building use - Environmental systems (HVAC, plumbing, lighting) failures,

where functional capacity of these systems is lost

5 Strangler fig (Banyan) trees growing

in Angkor Wat, Cambodia The growth

of these trees around and through the ruins of Ta Phrom temple are an example of constructive decay at a macro-scale.

By integrating the design of biological decay into built structures and products, designers introduce the possibility of accommodating not only programmed failure but also graceful failure when needed. In modern building practice, wear or damage is not usually accommodated for in design. Aging is addressed by a specific mode of repair - concealing, replacing, or restoring that which is broken so that the artifact looks or functions as newly as possible. We design structures to resist damage, however, we tend not to design for situations where functional capacity is retained despite damage. A quick survey of major bridge failures in the 2 0th century (Wikipedia

Contributers n.d.)

shows the majority ofthese failures result in the demolition and / or complete rebuilding of the bridge, not in the retaining of the original structure. Biology has an inherent tendency to make visible the processes of wear, damage and age, as well as an ability to function even with major damage. For instance, the loss of a limb, while taraumatic and scarring, does not necessarily mean that the organism cannot still live and function. The same could not be said of a building which has lost use of a few of its structural members. Nature's mode of addressing wear and tear, as well as serious damage, can be advantageous for design to borrow from.

Why design decay at product and architectural scale?

Common material systems developed between the industrial revolution and the 2 0th century are based on an extractive view of resource and

energy consumption and waste management. Construction materials such as concrete, metal alloys, and petroleum-based plastics are structurally sound and environmentally resistant, supposedly providing architecture with its firmitas3. Yet these materials are often assembled together without consideration of either the lifespans of their assemblies or the long-term future of the components from which they are made. Modernist buildings using concrete and glass curtain wall systems built post-WWII have a life expectancy of 60 years (Normandin, Kyle C. 2013) before major failures occur; for contemporary big box store construction this number drops to 15-20 years. The metals, plastics, and glass that make up the buildings however take between 100 to 1 million years to degrade (Science Learning Hub 2018), or 5X to 50000X the lifespan of the building they initially formed. In contrast, a red oak tree may live up to 500 years and the wood it produces can provide lumber that will be structurally sound for centuries; however, in the

3 From Vitruvius's Ten Books on Architecture, which outlines how architecture

should be founded onfirmitas (strength or durability - the building should be robust and remain in good condition), utilitas (utility - it should be useful for

conditions of a North American forest floor, a dead oak can rot away in 80 years (Heisman 2015), or 0. 16X its potential lifespan. Other living systems, even animals with structural skeletons, have similarly small decomposition to lifespan ratios, reflective of the ease with which the components of dead matter can reintegrate as vital building blocks back into the ecosystem and begin a new system of organization.

In parallel with this discontinuity in time and energy needed to degrade a building after failure compared to that needed to decompose organisms after death, is also the variation in energy needed for the creation and maintenance of the material systems and buildings that house the body as opposed to the energy needed to create and maintain the body itself. In Fire and Memory, Luis Fernandez-Galiano outlines the relationship between architecture and energy through a "metaphorical plundering... of ecology and thermodynamics." (Fernandez-Galiano 2000, xii). He highlights how exosomatic energy, the energy required to construct and maintain a building that can house our body) can be, in industrialized nations, up to 1

OOX

more than endosomatic energy, the actual energy required to grow and maintain the body that is to be housed. However, in non-industrialized nations, exosomatic consumption can be reduced in some cases to 1/3 of endosomatic consumption, indicating that making artifacts to house the body does not have to be highly resource intensive (2000, 263-64).As buildings become obsolete or when structures fail, these constituent parts are left behind in landfills and take centuries to degrade. Contemporary sustainable building practices are still largely dependent on construction materials that require high energy processes to be made usable and to be recycled for re-use. The use of biologically derived materials presents an alternative model of material use, where both growth and decay can be constructively programmed into the lifecycle of a structure with increasingly levels of spatial and temporal tunability and resolution. And actively introducing microbial agents of decay to the system affords us the opportunity to use their activities in a constructive manner. Part of the impetus to program both growth and decay into the life of a building is to realign the energy required to make the structure to be more in tune with what is required to maintain the organisms that use the structure as well as realign the time and energy required to degrade an object to be more in tune with its usage or functional life. In Material Ecology first design practice, the relationship between artifact and energy can become a much more literal understanding of ecological systems and thermodynamic hierarchies and their interactions with what we makc.

In her book Curated Decay: Heritage beyond Saving, Caitlin DeSilvey presents case studies of heritage building sites that are consciously left to fall into disrepair as an alternative to material conservation. She discusses decay as an active choice in heritage preservation, not because the buildings are not necessarily worth saving, but because transience can be as meaningful as permanence. Value is not only in the durable, but also in the temporary, where the scarcity unit is the duration of time that thing may have existed. To DeSilvey, allowing cultural artifacts to naturally deteriorate represents an openness to improvisation and uncertainty as well as possibility. Incorporating decay embraces risk in that it opens a work up to forces traditionally outside of our own making and planning.

But what if we could indeed plan for some of these forces? In her essay, Cultures on Culture, Grace Kim tracks the work of cultural conservators and micro-biologists in Italy who are trying to restore Renaissance paintings and architectural ruins with the assistance of microbial communities whose metabolic activity work to clean and protect the surfaces of cultural heritage rather than deteriorate them. These "bacteria-masons " (Kim 2016, 177) are sprayed onto artifacts so that they can create site specific biofilms while metabolizing undesirable elements that work to harm the artifacts; conservators decide what surfaces to spray, how long to let the microbe communities thrive and whether or not to remove them after a certain point. It is a multi-species undertaking, with human work guiding the microscopic work of bacteria for desired macroscopic results.

In this thesis, a similar methodology is attempted in the decay of constructed artifacts to catalogue the effect of certain organisms on the constructs and gauge whether their growth could be guided in any way to predictable effect. Artifact decay is thus not only allowed, but actively pursued, not just improvised, but heavily mediated through species selection, contol of environmental conditions, and templating of nutrients, such that the product of the decay points to a new construct, with macroscopic effect. In pursuing the biological decay of structures we are trying to embrace mutability as a desired quality in the built world as well as guarantee that the mechanisms of constructive renewal will be embedded into the artifact.

Chapter 2

A case for biologically derived materials

IN ORDER to design the decay of structures, one has to select what will decay. Figure 6 shows material property charts for a range of materials we commonly use (natural materials are represented in dark green), relating parameters such as compressive and tensile strength to density, thermal expansion to thermal conductivity, compressive strength to economic cost, and tensile strength to embodied energy cost. In general, man-made materials4, such as metal alloys, technical ceramics, glass, and composites, exhibit higher strength performance capabilities, however the price of that strength is heavy weight, high embodied energy and high economic cost. In comparison, natural materials, such as wood, cork, and leather, while exhibiting lower total strength capabilities, have excellent strength per weight performance (for instance, cellulose, per unit weight, has a much higher efficiency in tension than steel (Ashby et al. 1995)), and have much less embodied energy and lower economic costs. Natural materials tend to be less durable than man-made materials, take less time to degrade, and are in general, chemically simpler. They offer an alternative towards material types with reduced environmental impact and low carbon emissions.

Biologically derived materials as a subset of natural materials are materials derived from or created by living organisms, including plant-based cellulose, lignin, pectin, and hemi-cellulose materials and animal-based collagen, keratin, and chitin animal-based materials. Biological materials tend to be environmentally responsive, partially due to the fact that they are derived from living matter whose properties were environmentally dependent. They exhibit a wide range of behavior depending on the environment and living organisms are able to tune their structures to fit the performance criteria of the physiological condition (Oxman 2010a,

47).

4 All materials around us are ultimately derived from nature, however, for the purposes of this thesis, we are defining natural materials as materials such as stone, wood, leathers, shell, bone, silk, and cotton, that require substantially less processing and treatment, as well as less energy input to be made usable as opposed to man-made materials such as metal alloys, glass, technical ceramics, concrete, and petroleum based polymers.

""

. ...

-I,

6a Young's modulus (tensile strength)

against density

ILI-6b Compressive strength versus

density

al

1

6c Strength versus Cost

-ftttaWPP Q"-. "o

6d Young's modulus versus

Embodied Energy

1000

100

10

;0

MODULUS- DENSITY

ARAL

YOUNG'S MODULUS E (OP) CERAMICS

DENSITY p (Mg/rn) / AND

fill@ PARAULL (11sPIRPSCULM 0DMP

IN0L0ULD 0 11MS/J04WADWOUNSTY -CAke

/ Ia

STIFFNESS iAO VAM MLVIALL

WUIDE noo SHIL

LINES PIN to CO a"on

/ - 0 PLY

No v S

LoC. BA'LSA ANf

P

tweiPOLYMERS

0.1 canGEuLg

/ ""* *LearmNAURAL

P =C

IL'O'o

ELAS1OMERS| 0.01 NAU L "TINtaMATEIL

CaAesa&.M

0.00l0

01

0.03

0.1

0.3

1.0

3.0

10

density p

/

Mg

m-3

7 Material property chart of natural materials plotting tensile strength against density. Cellulose and chitin are noted in salmon.

Similar materials such as shell, enamel, and coral are noted in orchre. Image credit: Mogas-Soldevila, Duro-Royo et al, 2015,

adapted from Ashby, 1995.

In addition to the use of biologically derived materials is the development of biological systems (many of them systems typically associated with decay), for the direct production of designed materials, from the micro- to macro-scale. Most of these production methods are still nascent, however they show promise in leveraging already established biological processes into making designed and engineered forms that can eventually replace conventional building materials (Bechthold and Weaver 2017). Examples include:

- Raising mycelium to making lightweight structural components, such as fiberboard or bricks - Guiding the growth of bamboo or trees for grown custom furniture or scaffolds

-

Templating silkworms to spin flat sheets of silk in desired patterns

or locations for uses other than making a silk cocoon

-

Engineering bacteria to produce pigments, fibers, and other

additives or products

Biological materials and their systems of production are difficult to

standardize, due to both their non-standard origins (living things, see

Figure8) and environmental responsiveness that makes them fluctuate

in dimension, weight, water content, colour or other attributes.

For example, in construction, to make uniform units of wood (a

material that is hygroscopic and will expand and contract with changes

in relative humidity), one must remove the bark, branches and other

elements that betray the original growth conditions, making the lumber

units small enough such that they will be dimensionally stable or at least

behave in a predictable manner (see Figure 9) with uniform mechanical

properties.

Some of the most stable wood products, such as chipboard or high grade

plywood, are based on breaking down the original wood to such small

units, that of a chip or a millimeter thin sheet of wood, and covering

these parts with adhesive, such that the wood's original anisotropy and

responsiveness is subsumed. Whereas on the tree, the same wood would

exist in a graded structural hierarchy with heterogeneous behavior (truck

vs branch vs twig), and mechanical properties would depend on the

graded distribution of cellulose, lignin, and other structural fibers. With

biologically derived materials that are used in commercial applications,

such as polylactic acid based (cornstarch) plastics, mycelium bricks, and

cellulose based products, intense effort has been applied to

"generic-ize" the material system such that performance can be predictable and

the material homogenous, at the expense of other attributes such as

variability, adaptability or responsiveness. In their essay, Countering

the Engineering Mindset, bio-artists Oron Catts and Ionat Zurr present

concerns about approaching the techniques and materials of biology

with a design methodology that they regard as "traditional

engineering...

where the technologies using living things isfindamentally no different than

making technologies with inanimate materials. "(Catts and Zurr 2014, 37)

Treating living or biological matter as equivalent to inanimate material

makes

iteasier to fragment and dissociate the material from

itsin vivo

context into constituent parts, abstracting

its'liveliness' via technical

mediation and reducing opportunity for variant behaviour.

'4Y

V_..

r

RA COm Hkmg

0 46-U M ft Ow .w.

8 Non-standardized cowhide, with

variable shape, dimensions, and area

9 Plain sawn versus Quarter sawn

versus Rift sawn wood with different

material characteristics due to wood's

anisotropy revealed during processing

(cutting). Plain sawn wood shows the

most varied appearance, creates the

least waste, and is the least

"stable"

or most environmentally sensitive cut.

In comparison, rift sawn wood has the

most even, homogenous appearance,

creates the most waste to produce.

Quarter sawn wood creates a medium

level of waste and is more stable than

plain sawn.

Herein lies the problematic heart of working with biologically derived materials within a system of product making that demands uniformity: it is difficult to reconcile variation and some of the dynamic advantages these materials have within a building methodology that prefers the inert and static .For the purposes of this thesis, it is questionable if this is the correct strategy with these materials. David Pye's discussion on the value of risk versus the value of certainty in workmanship in The Nature and Art of Workmanship, can be used to underscore some of the challenges that designers have when working with biologically derived materials or biological agents. For Pye, the certainty of results that industrial technology affords production is paid for by homogenous "cinferiorforms" (Pye 1968) that are produced without thought or care. This is in opposition to hand-crafted objects where a maker's skill is causal to the personalization of the object and where the outcome is at risk and unknowable until production is finished. When working with biologically derived materials that act with a certain degree of agency and whose behaviour is so variable with environmental conditions, how does one take advantage of the dynamism of the material and accommodate the unpredictable while still maintaining design influence?

With this question in mind, what makes biologically derived materials of special interest to this thesis is their biocompatability and the ease with which they biodegrade,5 an ease that is partially due to the same environmental responsiveness that makes them hard to work with. During decomposition, biological materials can become a scaffold onto which organisms can grow, act on, and change, usually much more readily than man-made materials. This is seen in biomaterial scaffolds used in tissue engineering, for instance, degradable silk scaffolds used in bone regenesis can be manipulated so that more extensive bone mineralization occurs in scaffolds that are triggered to decay faster (Park S-H, Gil ES, Shi H, Kim HJ, Lee K 2010). An additional example is the already discussed Gwion Gwion cave paintings where the original paint was a biocompatible material that black fungus and red cyanobacteria were able to use for their first few generations, before establishing symbiotic populations that could sustain themselves after the paint had been digested. In contrast, it has been a challenge to find organisms that thrive on the decomposition of man-made materials. Organisms that digest plastics, metals, and other man-made materials are still outliers in the detritivore community while the agents that degrade biologically derived materials can be found in common backyard compost.

5 The EU's standards on biodegradability from 2000 establish a bio-based material

is biodegradable if 90% of the material will disintegrate into pieces smaller than

Chitosan, cellulose, pectin

6Water

[H20]Cellulose

[(C

6H,

100dj

Chitin -> Chitosan

[(CaH1

30

5N)rJ

Cornstarch

[C27H402J

The materials explored in this thesis are mainly water-based composites

of three ingredients: chitosan, cellulose, and pectin. They are some of

the most abundant biopolymers on the planet, with chitin and cellulose

produced as waste products in fishing and forestry respectively. They

offer huge diversity in the natural forms they can make with a large range

of physical and mechanical properties (Ashby et al. 1995) depending on

water content, additives and geometry. They are biocompatible, require

little processing to use, and have short decay cycles when mixed with

water (Nishiyama et al. 1996). Additives such as glycerin, cornstarch,

calcium carbonate, and casein were also added to some of the mixes.

The composites are based on a chitosan-cellulose mix as the structural

"shell" layer, which when deposited onto films, can provide varying

amounts of tensile strength to the print, depending on the deposition

volume. The substrate film ("skin" layer) consists of pectin with varying

amounts of chitosan, which dictates surface texture, rigidity, stickiness,

and solubility.

Chitosan is a deacetylated derivative of the natural polysaccharide

chitin. Chitin is the second most abundant biopolymer on the planet

and is structurally similar to cellulose. It is found in arthropod shells,

fish scales, and fungal cell walls. Chitin is extremely water responsive

-the same material that forms -the rigid plates of crustaceans also makes

up the flexible material of

itsjoints, depending on how much water

the chitin absorbs. Chitosan has a similar level of water responsiveness

and exhibits gradable swelling from less than 10% water to over 90%

water. Chitosan is used in fertilizers, edible films, pharmaceuticals, and

biomedical scaffolds as it is highly biocompatible

(J.

et al., n.d.). In

open field, both chitin and chitosan films will degrade completely after

6 months (Makarios-Laham and Lee 1995).

6 This section describes the composites used in the bulk of the thesis research and is drawn from 3 publications, of which I am co-author on. The publications

are: "Parametric Chemistry: Revere Engineering Biomaterial Composites for Robotic Manufacturing of Bio-Cement Structures across Scales," "Designing Decay: Parametric Material Distribution for Controled Dissociation of Water-based Biopoymer Composites," and "Designing a Tree: Fabrication InformedPerformative Behavior."

Pectin

Calcium Carbonate

[C

6H

100

7]

[CaCOQ

10 Sources of the different biologically

derived materials investigated in this

thesis, including the 2 most abundant

biopolymers on the planet, cellulose

and chitin. Cellulose is a structural

polysaccacharide from plants and

is the most abundant biopolymer on

the planet. Chitosan is a derivative

of chitin, a structural polysaccharide

found in the exoskeleton of insects and

crustaceans and is the second most

abundant biopolymer on the planet.

Pectin is a structural polysaccharide

from the non-woody part of plants.

Calcium carbonate is the main mineral

component of pearls, shells, and eggs

and adds strength to bones. Cornstarch

is a polysaccharide derived from corn,

used in bioplastics and adhesives,

as well as a thickening agent in food.

Image adapted from Van Zak,

Duro-Royo et al, 2018.

Cellulose is the most abundant biopolymer on the planet and is a polysaccharide that provides stiffness to plant cell walls and is a building block of textiles. The cellulose we use is short white methyl-cellulose fibers typically used in construction to reinforce concrete. When suspended in a hydrogel, chitosan will contract and curl as it dries, whereas cellulose will add flexibility and stability to the composite during drying. Cellulose has exceptional biodegradability, with mass losses of over 70% when buried in soil for 70 days (Kalka et al. 2014).

Pectin is a polysaccharide found in fruit skins and cores as well as in structural complexes of trunks and branches of trees and degrades more quickly than either cellulose or chitosan.. It is used in food products and cosmetics. In solution, pectin forms a sticky hydrogel that absorbs water into its fibrous network and sets when cooled. We use the elastic pectin film as a base for more rigid chitosan-cellulose lines because the dried pectin bonds with the overlying print that can resist chitosan's tendency to contract and curl when drying.

Water

The biological materials used for construction in this thesis are water based. Water is used here to create structure, maintain structure, and destroy structure.

Water is the basis of all life, a universal solvent, essential because in its liquid form and simple polarity is an efficient way of transferring materials into and out of living cells at life-sustaining temperatures. Water facilitates phenotype, the customization of a creature's physical and chemical properties though growth and decomposition, as a function of environmental conditions and genotype (Oxman 2018). The absorption and desorption of water by biological materials can be used to vary properties such as turgidity (for instance, a squid beak can tune its stiffness based on the amount of water it has in its limited volume), flexibility (chitin with a higher water content will be more flexible), and shape (loss of water will cause shape changes in plants such as wilting or curling). Water mediates energy by transferring the building blocks of energy (food, nutrients) into cells, expelling the waste, facilitating growth and assembly. It also mediates gradation, as it disperses the concentration of molecules within a structure, diluting and concentrating ingredients with its fluctuation. It is needed to sustain living organisms and is thus a prerequisite for a material to be biocompatible. It is also a prerequisite for biodegradation, as it mediates

decay in the same way that it facilitates growth. The two processes are the same for water, as it transfers the useful out of the dead to pass on to the living. Design by decay, decay by design is thus design using water and decay induced by water.

Composites

The typical mixing protocol for the hydrogels is as follows (Van Zak et

al. 2018):

Pectin hydrogels: We use apple pectin powder in ratios of 25% to 45% (w/v (weight to volume)) (VWR, Radnor, PA) and glycerin content of 2% to 5% (v/v). Water is heated to 980C and glycerin is mixed in. Pectin is added slowly and mixed with a hand mixer. In some of the earlier formulas, 5% acetic acid is added to the pectin mixture which made for darker and more brittle films that were mold resistant. In other formulas, no acetic acid is added, resulting in pliant, more degradable films. In later formulas, 2% - 8% chitosan (w/v) is sifted in slowly and mixed until uniform. If chitosan is added, the temperature of the solution is then lowered to 37oC, and acetic acid is added as a final step while using the hand mixer to homogenize the solution. The chitosan would make the pectin films stronger and rougher and take longer to degrade.

Chitosan hydrogels: We use chitosan powder in ratios of 3% to 12% (w/v) (85% de-acetylated VWR, Radnor, PA). Water is heated to 78oC, at which point chitosan powder is stirred in; at this point the chitosan is not soluble. The solution temperature is lowered to 370C, and acetic acid is added in ratios of 2 parts chitosan and 1 part acid and mixed with a hand mixer; the acetylation makes the chitosan soluble and the solution thickens immediately. A 3% concentration solution has a translucent appearance and consistency of thin honey whereas a 12% concentration solution is dark amber brown and extremely viscous.

Chitosan-cellulose composites: We use chitosan powder in ratios of 4% - 14% (w/v) (85% de-acetylated VWR, Radnor, PA). In formulas that use cornstarch, water is heated to 950C for 20 minutes and 4% -10% cornstarch added while stirring vigorously. In formulas without cornstarch this step is omitted. The temperature is lowered to 78oC, at which point chitosan powder is stirred in. The solution temperature is lowered to 370C, and acetic acid is added in ratios of 2 parts chitosan and 1 part acid. In formulas where calcium carbonate is added, 1% -8%

to avoid rapid expansion. In other formulas this step is omitted. Finally, 40% -70% cellulose fiber (v/v) is sifted in slowly to form an extremely viscous hydrogel, which is then homogenized with the mixer.

"Nature's building blocks are... not as unique as their structuring in that it is not so much the material properties of the components as their arrangement within the natural composites that give rise to such a vast range ofproperties. Thus we may postulate that Material Structure is an important design property of natural design as well as a signifcant body of design knowledge."

(Oxman 2010a, 47)

In her thesis, Material-based Design Computation, Oxman draws upon Peter Pearce's Structure in Nature is a Strategy for Design and his idea of one of the underlying principles in biological fabrication is to use a minimal inventory of components to create maximal diversity in forms that have different properties in different areas. She extends this further by postulating that these different properties are generated not by the inherent material qualities of the base components but in their spatial arrangement within the composite structure. Different regions of a structure will behave differently even though they contain the same base components, because the arrangement of their components is different in those regions (Oxman, 2010). Heterogeneity is acquired through gradation and not through uniqueness. This is the basis for the parameterization of the chemistry of the chitosan, cellulose, and pectin composites. By tuning the amount, location, and water content (and thus the chemical interaction) of three common polysaccharides we are able to create structures with a range of material properties including vastly different dissociation and decay properties. Proportional relationships between pH, surface roughness, and hydrophilicity of pectin and chitosan-cellulose skin-shell systems yield different colors, which correlate to differential stiffness, strength, shape change, brittleness, and solubility product constant (kd) across large-scale panels (Van Zak et al.

2018)

Chapter

3

Aguahoja

11 Team Aguahoja (from right to

left):

NeriOxman

(principle investigator), Joshua Van Zak, Nic Hogan, Yen-Ju (Tim) Tai, Barrak Darweesh, Jorge Duro-Royo, Andrea Ling, February 2018. Photo by Jonathan Williams.TO DESIGN decay, we needed to design an object that we could decay. To that end, the group has spent the last 4 years developing large scale water based artifacts that could be subjected to water-induced degradation as well as the fabrication platform for constructing these artifacts. Entitled Aguahoja, or water leaves, the work culminated in the design and fabrication of a 5 meter tall pavilion exhibited in the lobby of the MIT Media Lab in February 2018.

12 Original water-based digital

fabrication system featuring pneumatic

extrusion of multimaterials via a robotic

arm developed by Mediated Matter

in 2014. Image credit: Laia

Mogas-Soldevila, Water-based Digital Design

and Fabrication, 2015, p38.

Fabrication Platform

LIPm

We

used

a water-based digital fabrication (WDF) platform first

developed by Mediated Matter

7in 2014. The WDF platform consists of

a custom pneumatic extrusion system attached to a robotic arm that is

fed toolpath data according to design parameters that can also include

feedback environmental data (Duro-Royo, Mogas-Soldevila, and Oxman

2014, 2015). Water-based colloids that contain chitosan and cellulose

are extruded by the system along the programmed toolpaths to deposit

material vertically in 2.5D (not quite 3D printing because the material

is unable to build up beyond a centimeter in Z-height and has much

larger range in the X and Y axis). Designs are generated in Grasshopper

computationally tailoring motion path to material composition, nozzle

size, speed, air pressure, and distance from the printing bed or substrate.

The platform is designed under principles of Fabrication Information

Modelling (FIM). In the FIM environment, material density, and

therefore structural capability, as well as degradability, is controlled by

characteristics of the extrusion process and the material itself (Lizardo

2018) (Duro-Royo, Mogas-Soldevila, and Oxman 2014, 2015). Instead

of manually drawing discrete patterns of lines to be printed by the robot,

a continuous 2D map of material stiffness (appears similar to a thermal

image) is generated based on design requirements. The structural map is

then used to generate a map of extrusion pressure which is also informed

by the choice of material to be extruded. The output of the pressure

map is a 2D grid, with line spacing / density and extrusion width

graded according to pressure and material characteristics. The design,

Oruch" wbw MU~M" FAW MAP M 20ON~W*"ns b --ILAP cow 30 Swc0* M

13

Design workflow of the original

water-based digital fabrication platform

(2014) where the initial pressure

map (far left) is used to generate

robotic toolpaths (center left) which in

combination with a tuned system of

fans (center right) control the rate of

evaporation of the printed chitosan.

The final 3D artifact is shown on the far

right. Image credit: Mogas-Soldevila,

Duro-Royo et al, 2015.

though intentional, is emergent from the dialogue between material and fabrication technology.

The first iteration of this fabrication platform produced 1-2 meter scaled self-supporting structures made primarily of chitosan that are light weight and fully biodegradable. The version of the platform that I used during this thesis consists of 2 large-scale ABB robotic arms working in concert to produce seamless 2-4 meter scaled panels that formed a material library as well as a set of panels that were assembled together into the pavilion. Typical prints utilized a pectin based bottom layer (the skin or shell layer) on top of which a chitosan-cellulose based structural layer (the structure or skeleton layer) is deposited in open cell or grid-like geometries.

Clitosan-shel layer

-Pectin skin

14 Typical multi-layered print strategy

of water-based digital fabrication

system V2.0 where multi-materials are

deposited additively.

15 Water-based digital fabrication

system V2.0, at Autodesk Build Space.

The system consists of a 6-axis ABB

IRB

4600 robotic arm and a custom

pneumatic extrusion end-effector

attached. Images of the sample print

patter show the system is capable of

Typical printing protocol is as follows:

1.

The aluminum substrate is prepared with a small amount of mineraloil to allow us to remove the panel when it is dry from the sheet. 2. The biomaterials are packed into cartridges and loaded into the

holster of a rotating, multi-material end-effector. The cartridges have interchangeable nozzle diameters which are chosen in relation to the viscosity of the material and the desired resolution of the print. For instance, if we wanted to print a thin pectin film as the base layer, we could use a large diameter nozzle, printing at low pressure and high speed. If we wanted thicker films, we would deposit the material at higher pressures or slower speeds. If we want a high resolution print with one of the chitosan-cellulose mixes we would use a fine needle nozzle with a higher pressure to deposit the material. If we needed stronger structural lines in the print, we would increase the pressure or decrease the speed of the print to increase the amount of material deposited. If the toolpath geometry has many sharp turns, print speed would be reduced with a corresponding decrease in pressure to maintain line thickness, minimize dragging, and prevent too much material from being deposited.

3. Air pressure, the distance of the nozzle from the substrate, and the speed of the robotic arm are all set as input parameters, informed by the desired linetype we wish to print in that geometry (for instance, thick versus thin, consistent line width versus variable)

4. Toolpath instructions, complete with meta-data that corresponds to the parameters already listed as well as direction and location of movement, are sent to the robots. A complete layer of the desired geometry is printed in the materials as specified by the toolpath. If the panel is to have a pectin skin, a solid base film of pectin is first printed and allowed to dry until moderately dry before any chitosan-cellulose layers are printed. Additives can also be deposited in the print layer in the desired geometric patterns.