Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez

pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the

first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

4th International Building Physics Conference (4th IBPC) [Proceedings],

2009-06-14

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=6b961ba8-cede-4e34-af51-acd6ebd7528c

https://publications-cnrc.canada.ca/fra/voir/objet/?id=6b961ba8-cede-4e34-af51-acd6ebd7528c

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. /

La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version

acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Moisture Management and Energy Rating in Building Envelopes / Part I

: A field monitoring study of interstitial condensation in wood-frame

walls in cold climate

W. Maref, M. Armstrong , M. Rousseau

Part I- A FIELD MONITORING STUDY OF INTERSTITIAL

CONDENSATION IN WOOD-FRAME WALLS IN COLD CLIMATE

MOISTURE MANAGEMENT AND

ENERGY ANALYSIS IN BUILDINGS

2 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Team

K. Abdulghani

W. Lei

M. Armstrong

W. Maref

Outline

Background & Objectives

Field Exposure of Wall Facility (FEWF)

Part I

•

Experimental Approach

–

Construction Details

–

FEWF Instrumentation

•

Results and Discussion

Ventilation and Wall Research House Facility

2. FIELD EXPOSURE

OF WALL FACILITY –

(FEWF) BES

Study & compare traditional

& innovative BE strategies

1. VENTILATION,

HEATING AND

COOLING FACILITY

- IE

Study & compare

traditional & innovative

ventilation, heating &

cooling strategies

Field Exposure of Wall Facility (FEWF)

Objectives

•

Compare performance of different side-by-side wall assemblies

•

improve understanding of HAM response of wall and window

assemblies exposed to naturally occurring climate loads of

Ottawa as well as to indoor environment loads of T, RH and P

defined by occupancy and HVAC systems.

6 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

IRC Field Exposure of Wall

Facility (FEWF)

Roadmap

•

Year 1 (2006-2007) Commission the facility by monitoring three identical

test specimens of traditional construction (2x6) through Fall, Winter and

Spring.

(Part I)

•

Year 2 (2007-2008) Partnership with CMHC & NRCan to investigate the

effects of two energy retrofit strategies on the wetting and drying potential

of wall assemblies.

(Part II)

•

Year

3

(2008-2009)

Partnership

with

FPInnovation

(Forintek)

to

investigate the effects of the interior air/vapour barrier polyethylene

membrane on the wetting and drying potential of wall assemblies and

extending the project with CMHC & NRCan for one retrofit strategy.

•

Year 4 (2009-2010) Partnership with CMHC & NRCan to investigate the

the dynamic heat transmission characteristics through Insulated Concrete

Form (ICF) wall assemblies over a full year cycle of weather exposure

•

Year 5 (2010-2011) PERD Project to Test the Next Generation Envelope

Systems (i.e. Vacuum Insulated Panel)

•

Year 6 and beyond Investigate the performance of wall specimens of

different innovative designs based on industrial collaboration/partnership.

Objectives

•

Validate: identical test specimens, protocol and

instrumentation

•

Characterize heat and moisture response

8 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

DETEC_9 DETEC_11

T_10

T_8

16.0

T_9

RHT_7

DETEC_12MP_1

2.0

DETEC_10T_7

RHT_6

15.0

20.0

17.0

3.0

LAYER 4 - Interior Face of OSB

HF_1

(W2 only)

JW_3

DETEC ThermistorHeat Flux

Moisture Pin

Wireless

Relative Humidity

10 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

14.0

7.0

DETEC_17 DETEC_16MP_3

LAYER 5 - Stud Cavity

DETEC_15

MP_2

HF_2

(W2 only)

RHT_9

15.0

T_13

T_14

17.0

T_11

RHT_8

T_12

LAYER 6 - Interior Face of Insulation & Stud

Cavity (Exterior side of Vapour Barrier)

P_3

(Low Pressure)

7.3

10.0

HF_3

(W2 only)

JW_4

Delta Pressure

12 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

LAYER 7 - Interior Face of Drywall

17.0

15.0

T_18

T_17

RHT_10 (air)

T_16

T_15

7.0

T_19

(W2 and W3 only)

Thermocouple

14 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

W3

W2

Methodology - Instrumentation

Instrumentation - Plan View

Interior

Drywall

Air/Vapour Barrier

Stud Cavity with

Glass Fibre Insulation

Vinyl Siding

Sheathing Membrane

OSB

Air Pressure sensor

Moisture Pins

RH and T sensor

Thermocouple

Exterior

Wireless RH&T Sensor

16 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/

12 CCSTB Montréal, May 2009

Exterior

Interior

Vinyl Siding

Sheathing Membrane

OSB

Stud Cavity with

Fiberglass Insulation

Vapour Barrier

Drywall

Material

P1

P2

P3

P Chamber

Reference for all Pressure Sensors: Room Interior

Pressure Tap Locations

+ve pressure

= pressure at

the tap

location is

higher than

the pressure

in the room

18 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Experimental Approach

Challenging the wall experimental begins:

•

Stage 1- Create air leakage path and monitor

under naturally occurring int. and ext. conditions

on two of three specimens (1 week)

20 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Air Leakage

Path

Challenging the wall experimental begins:

•

Stage 1- Create air leakage path and monitor

under naturally occurring int. and ext. conditions

on two of three specimens (1 week)

•

Stage 2- Increase indoor RH to 70% and induce 5

Pa positive pressure while air leak is present in

two specimens, for a certain period of time

22 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

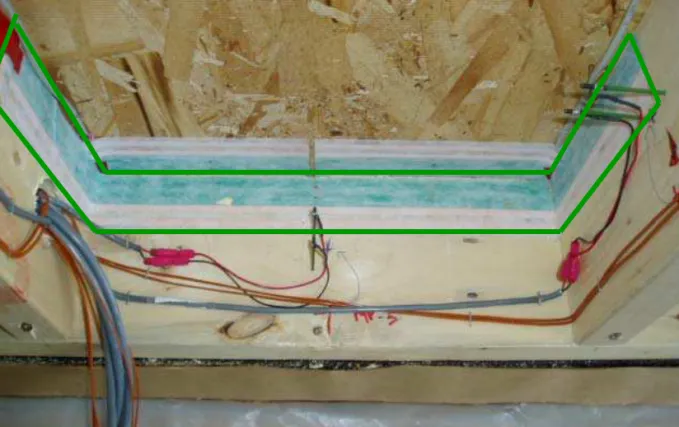

Drywall

W1

W2

W3

Conditioning Chamber on the Room Side

Walls 2 and 3 exposed to

chamber conditions

Control T, RH, Pressure

Deficiency in air barrier

Challenging the wall experimental begins:

•

Stage 1- Create air leakage path and monitor

under naturally occurring int. and ext. conditions

on two of three specimens (1 week)

•

Stage 2- Increase indoor RH to 70% and induce 5

Pa positive pressure while air leak is present in

two specimens, for a certain period of time

•

Stage 3- Return to naturally occurring conditions

to monitor drying. Disassemble the indoor

chamber

24 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

26 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition A

• 0 Pa pressure

• 70% RH

Condition B

• 5 Pa pressure

• 50% RH

28 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition C

• 5 Pa pressure

• 30% RH

Condition D

• 0 Pa pressure

• 50% RH

30 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Diagram for Moisture

Detection Tape Locations

on the interior of the OSB

32 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Diagram for Moisture

Detection Tape Locations

in the Stud Cavity

Wind speed data

is from the Ottawa

Airport

34 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Wind from the West causes

+ve pressures and infiltration

Wind from the East causes

–ve pressures and exfiltration

36 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

When the chamber is

pressurized, the exfiltration

condition is forced (chamber

and stud cavity pressure is

higher than exterior pressure)

When the chamber is

pressurized, the exfiltration

condition is forced (chamber

and stud cavity pressure is

higher than exterior pressure)

Except when +ve pressures

from North and West winds

negate the effect.

38 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Conditions

Condition

Pressure

RH

Opening

Week

A

0 Pa

70%

None

7

B

5 Pa

50%

6 mm

3 days in

week 8

(22 to 24 Feb)

C

5 Pa

~30%

3 mm

2 days in

week 11

(16 to 17 Mar)

D

0 Pa

50%

3 mm

15

40 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

42 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition A:

0 Pa, 70% RH, no opening

• Despite the high humidity on the interior of the room

(71%), the humidity behind the air/vapour barrier is

low, 15%

• The location with the highest RH is the interior of the

OSB, at ~81% - still below dewpoint

T

RH

T

Interior

T

• The dewpoint of room

air is ~17°C, a condition

met by temperatures

partway through the

insulation

• The interior of the wall

44 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

• A large drop in the

moisture content of the

air occurs across the

vapour barrier

• Air moisture content on

the exterior side of the

vapour barrier is nearly

identical to the reference

wall – with no added

indoor humidity loads

Condition A:

0 Pa, 70% RH, no opening

46 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Resistance (k

Ω

)

Condition A:

0 Pa, 70% RH, no opening

• The interior surface of

the OSB remains dry at

all moisture detection

tape locations

Interior

Exterior

Condition B:

5 Pa, 50% RH, 6mm opening

• The interior of the room is at 49% RH, the humidity

behind the air/vapour barrier is 30% RH – indicating

T

RH

48 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

• The dewpoint of room

air is ~12°C, a condition

met by temperatures at

the middle of the

insulation

• The opening in the

vapour barrier allows

moisture to enter the

cavity, condensation is

expected anywhere to the

exterior of the insulation

• The pressure and

opening allow the high

RH to enter the interior of

the wall

• Air moisture content on

the exterior side of the

50 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Resistance (k

Ω

)

Condition B:

5 Pa, 50% RH, 6mm opening

The interior surface of the

OSB is wet, particularly at

the base of the wall

Low resistance indicates the

presence of liquid

Slit in OSB

Drying

Wetting

Wetting

Condition B:

5 Pa, 50% RH, 6mm opening

For a large portion of the

Condition B period, wind

52 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition B:

5 Pa, 50% RH, 6mm opening

In two instances, the exterior pressure

dropped below the chamber pressure,

allowing exfiltration, and corresponding

to the wetting patterns

54 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

FEWF Wall 2 - Stud - Layer 5 - Liquid

0

20000

40000

60000

80000

100000

120000

2/23/07

12:00

2/23/07

18:00

2/24/07 0:00 2/24/07 6:00

2/24/07

12:00

2/24/07

18:00

2/25/07 0:00

Date and Time

R

esi

st

an

c

e

(

k

¬

)

215L

216L

217L

Resistance (k

Ω

)

Condition B:

5 Pa, 50% RH, 6mm opening

Low resistance indicates the

presence of liquid at the base

of the stud cavity

56 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Results

After

Before

58 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition C:

5 Pa, 30% RH, 3mm opening

• The interior of the room is at 27% RH, the humidity

behind the air/vapour barrier is 29% RH – indicating

that moisture is being introduced through the opening

• The location with the highest RH is the interior of the

OSB, at 100% - condensation would be expected

Interior

Exterior

T

RH

•The dewpoint of room air

is ~4°C, a condition met

by temperatures towards

the outside of the

insulation

• The opening in the

60 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

• The pressure and

opening allow the

humidity to enter the

interior of the wall

• Air moisture content on

the exterior side of the

vapour barrier is higher

than the reference wall –

with no added indoor

humidity loads

Condition C:

5 Pa, 30% RH, 3mm opening

East winds for the majority of Condition C, kept

exterior pressures low and allowed the Chamber and

Stud Cavity Pressures to remain above the Exterior

Pressure, creating an exfiltration condition

62 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition C:

5 Pa, 30% RH, 3mm opening

A change in wind direction towards the end of

Condition C brought exterior pressure conditions

close to stud cavity and chamber pressure.

Condition C:

5 Pa, 30% RH, 3mm opening

The interior surface of the

OSB is wet, particularly at

the base of the wall

Resistance (k

Ω

)

64 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition C:

5 Pa, 30% RH, 3mm opening

Low resistance indicates the

presence of liquid at the base

of the stud cavity

Resistance (k

Ω

Condition D:

0 Pa, 50% RH, 3mm opening

• The interior of the room is at 50% RH, the humidity

behind the air/vapour barrier is 27% RH

Interior

Exterior

T

RH

66 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

•The dewpoint of room air

is ~12°C, a condition met

by temperatures at the

middle of the insulation

•Condensation is

expected at the OSB,

however, measurements

indicate that room air is

not exfiltrating as much

as in Conditions B and C

• While the air moisture

content on the exterior

side of the vapour barrier

is higher than the

reference wall, the effect

is not as pronounced as

Conditions B and C –

68 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition D:

0 Pa, 50% RH, 3mm opening

West winds dominate at the

beginning and end of Condition D,

creating conditions for infiltration

Condition D:

0 Pa, 50% RH, 3mm opening

East winds cause the exterior pressure to

be below the interior pressure, resulting in

exfiltration conditions

70 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

Condition D:

0 Pa, 50% RH, 3mm opening

The interior surface of the

OSB is dry at all

measured locations

Resistance (k

Ω

)

Condition D:

0 Pa, 50% RH, 3mm opening

Resistance (k

Ω

)

The surface of the stud

cavity is dry

72 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009

SUMMARY

Successful characterization of hygrothermal

performance.

Water detection tape provided valuable data

on wetting locations

Strong relationship between wind conditions

and air infiltration/exfiltration

SUMMARY (Cont’d)

We looked at risk of condensation due to

exfiltration (wetting) combined with infiltration

(drying)

Similar results for the three test specimens

FEWF can be used for future exposure tests:

74 – Moisture Management in Buildings / Gestion de l’humidité dans les bâtiments – 12thCCBST/ 12 CCSTB Montréal, May 2009