Optimization of demolding temperature for throughput improvement of nanoimprint lithography

Texte intégral

Figure

Documents relatifs

The process design specification problems that this study sought to achieve were as follows: (a) what combination of the optimum liquid-to-gas molar flow rate ratio and column

D’après nos calculs, moins de 1 % des ménages vietnamiens ont un effort budgétaire élevé pour l’électricité et sont officiellement pauvres. Pourtant la France n’est

This consisted of a series of questions, i.e., demographic questions but also questions on the stress perceived (Covid-19 stress, home stress, job stress, anxiety), the

Les transformations rapides (foncières, sociales, environnementales) questionnent le caractère de marge de cette région fronta- lière telle que l’on en trouve beaucoup dans les

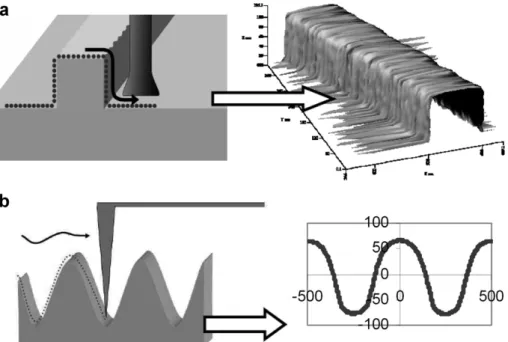

Real time measurement results 共solid line兲: 共a兲 CD and 共b兲 height of resist feature vs the processing time in HBr /O 2 without bias power.. 3D AFM data 共cross shape

Simulations of five different periods have been designed to address the objec- tives of the sixth phase of the Coupled Model Intercom- parison Project (CMIP6): the millennium prior

Item A: adopt strict principles of material organization and time management. Managerial, Animation and Team Management Skills: Item C: generate knowledge and take into

We first measured the buoyant mass and passage times of hundreds of single cells from a human lung adenocarcinoma cell line, H1975 (Fig. 1C), to validate our method.. As expected,