HAL Id: hal-00796549

https://hal.archives-ouvertes.fr/hal-00796549

Submitted on 4 Mar 2013HAL is a multi-disciplinary open access archive for the deposit and dissemination of sci-entific research documents, whether they are pub-lished or not. The documents may come from teaching and research institutions in France or abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est destinée au dépôt et à la diffusion de documents scientifiques de niveau recherche, publiés ou non, émanant des établissements d’enseignement et de recherche français ou étrangers, des laboratoires publics ou privés.

Resistance to decay fungi of ammonium borate oleate

treated wood

Florent Lyon, Marie-France Thévenon, Antonio Pizzi, Joseph Gril

To cite this version:

Florent Lyon, Marie-France Thévenon, Antonio Pizzi, Joseph Gril. Resistance to decay fungi of ammonium borate oleate treated wood. 40th Annual Meeting of of the International Research Group on Wood Protection, May 2009, Pékin, China. �hal-00796549�

40th Annual Meeting of the International Research Group on Wood Protection (IRG/WP 09), Beijing, CN, 24-28.05.09

Resistance to decay fungi of ammonium borate oleate treated wood

F. Lyon1, M.-F. Thevenon2, A. Pizzi3, J.Gril1 1

Laboratory of Mechanical and Civil Engineering, UMR5508 CNRS, University of Montpellier2, Place Eugène Bataillon, cc048, 34095 Montpellier Cedex, France

2

CIRAD, Wood Preservation Laboratory, TA B40/16, 34398 Montpellier Cedex 5, France 3

ENSTIB-LERMAB, University of Nancy 1, BP1041, 88051 Epinal Cedex 09, France

Paper prepared for the 40th Annual Meeting Beijing, China 24-28 May 2009 IRG SECRETARIAT Box 5609 SE-114 86 Stockholm Sweden www.irg-wp.com Disclaimer

The opinions expressed in this document are those of the author(s) and are not necessarily the opinions or policy of the IRG Organization.

Resistance to decay fungi of ammonium borate oleate treated wood

F. Lyon1, M.-F. Thevenon2, A. Pizzi3, J.Gril11

Laboratory of Mechanical and Civil Engineering, UMR5508 CNRS, University of Montpellier2, Place Eugène Bataillon, cc048, 34095 Montpellier Cedex, France

lyon@lmgc.univ-montp2.fr, lyon_florent@hotmail.com, jgril@lmgc.univ-montp2.fr

2

CIRAD, Wood Preservation Laboratory, TA B40/16, 34398 Montpellier Cedex 5, France

marie-france.thevenon@cirad.fr

3

ENSTIB-LERMAB, University of Nancy 1, BP1041, 88051 Epinal Cedex 09, France

antonio.pizzi@enstib.uhp-nancy.fr

ABSTRACT

Ammonium borate oleate molecule (ABO) produced from reaction between boric acid, ammonia and oleic acid was tested as wood preservative treatment against brown and white rot fungi according to European standards. This compound was prepared according to a previous study which has proved existence of synthesis reaction and effectiveness against termites (Lyon et al. 2007b).

Four solutions of ABO in ethanol were then produced and impregnated sapwood specimens of Beech and Pine exposed to fungi Coniophora puteana and Coriolus versicolor. Efficiency thresholds were found in each case except for Pine samples exposed to Coniophora puteana. Combination of the biocide effect of boron, and the water repellence of fatty acids allowed to provide resistance of leached wood specimens against fungi.

Keywords: Ammonium borate oleate, decay test, boron leaching, leaching procedure. 1. INTRODUCTION

Boron compounds, such as boric acid or borates have broad spectrum effectiveness against wood degrading organisms like fungi and termites and have been used for years as wood preservation active ingredients (Lloyd 1997, 1998, Drysdale 1994, Grace et al. 1992, 1994a,b)

Nevertheless borates are easily leached out under outdoor exposure because of their water solubility (Cockroft and Levy 1973, Lloyd and Manning 1995, Peylo and Willeitner 1997). Different solutions have been developed to try to reduce boron leaching like utilization of borates under low moisture condition, chemical combination to produce less leachable compounds like proteins (Thevenon et al. 1997, 1998, 2003, Polus-Ratajczak and Mazela 2004), complex with tannins (Pizzi and Baecker 1996, Thevenon 1999), ester borates (Mohareb et al. 2004) or amine (Kartal and Imamura 2004, Petric et al. 2001 . Addition of hydrophobic agents or coating like varnish or paint has also been considered with various efficiencies depending on coating permeability (Homan and Militz 1995, Mohareb et al. 2002, Pavlic et al. 2001, Petric et al. 2001).

Treatments involving vegetable oils (Megnis et al. 2002, Militz 2002, Olsson et al. 2001) or natural-oils derived of fatty acids (Lyon et al. 2007a, Pizzi 1993a,b) appear to be interesting for wood preservation by reducing wood equilibrium moisture content and leaching of extractives like tannins, thus decreasing insects attacks and fungi decay (Welzbacher and Rapp 2002). Combination of oleic acid and boric acid in a new wood preservative ammonium borate oleate (ABO) proved its efficiency for boron retention and resistance to termites. ABO formulations in ethanol allow to retain about 50% of boron after leaching by chemical combination of boron to

fatty acids and water repellence (Lyon et al. 2007b). ABO prevents termite’s attacks when used at the same boron retention load than boric acid.

Following this previous study on synthesis of ABO and resistance to termite of ABO treated wood, the aim of this new study is to evaluate resistance of ABO treated wood to decay fungi according to the guidelines of European standard EN113 (1996)

2. EXPERIMENTAL METHODS

2.1 Synthesis of boric acid ammonium oleate (BAO)

Synthesis of ammonium borate oleate salt follows a two step reaction; (1) Reaction between a one mol boric acid aqueous solution and one mol of ammonia provided by a 27% concentrated solution. This reaction is enhanced by stirring of the mix at 80°C during 1 hour; (2) Reaction of the previous obtained compound with 4 moles of oleic acid enhanced by a strong hot mixing at 80 °C during 1 hour (Lyon, 2007)

2.2 Preparation of wood specimens

Specimens of Pine sapwood (Pinus sylvestris) and Beech (Fagus sylvatica) were prepared according to the EN113 requirements. Samples sizes were 50 x25x15 mm3 (L,R,T). Specimens were oven-dried at 103°C for 24 hours to determine their anhydrous weight and then treated by vacuum/ pressure.

2.3 Treatment

Specimens were treated by a 30-minutes vacuum treatment at 20 kpa absolute pressure with four treatment solutions of ABO in ethanol obtained by dilution of an initial reaction mix containing 0.1 mol of boric acid and 0.4 mol of oleic acid in the different volumes of ethanol (EtOH) below. C1: 1100 ml EtOH ., C2: 700 ml EtOH ., C3: 450 ml EtOH ., C4: 250 ml EtOH. One set has been treated as control with ethanol only.

Specimens were then weighted in their saturated state to determine the ABO and boron uptake (kg/m3 BAE) and then reconditioned at 20°C and 75% relative humidity during two weeks until their stabilization.

2.4 Leaching procedure

Leaching procedure for European specimens was conducted according to the European Standard EN84 (1997). Specimens were soaked in distilled water (5 volumes of water for 1 volume of wood) under 15-minutes vacuum at 4 kpa absolute pressure. After returning to atmosphere pressure, water was changed nine times within the next 14 days including one change at the end of first and second days and without more than 3 days between to water changes.

2.5 Decay Test

Treated wood specimens were exposed to white-rot fungus Coriolus versicolor (Linnaeus) Quélet [CTB 863 A] and brown-rot fungus Coniophora puteana (Schumacher ex Fries) Karsten [BAM Ebw. 15] according to EN 113.

Fungal culture was prepared by dissolution of 40g of malt extract and 20g of agar-agar into 1000ml of distilled water. Glass jars were filled with about 70 ml of malt-agar medium and sterilized at 121°C for 20 minutes. The fungal strains were introduced on thesterilized solid medium.

Wood specimens were sterilized by gamma ray introduced into the jars on full mycelium-covered surface. Jars were then placed at 20°C and 70% of relative humidity during 16 weeks.

Mass loss of specimens was calculated as the difference of final and initial oven-dried weight of each sample.

3. RESULTS AND DISCUSSION 3.1 Exposition to brown rot fungus

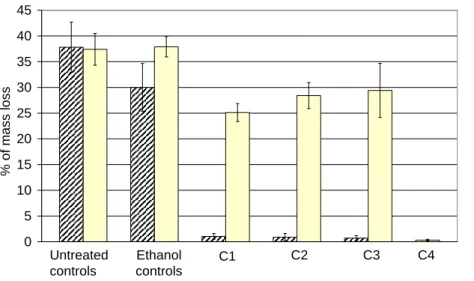

Results in Table 1 and Figure 1 below indicate mass losses of beech specimens treated with ethanolic solutions of ABO of various concentrations; from the lowest (C1) to the highest (C4). Table 1: Mass losses in sapwood specimens of Beech (Fagus sylvatica) treated with boric acid

ammonium oleate ethanolic solutions and exposed to brown rot fungus Coniophora puteana during a 16-weeks test (EN113).

Beech

(Fagus sylvatica)

Retention load of unleached samples

(Kg/m3 BAE) (1)

Mass loss by Coniophora

puteana (%), mean (SD) (2)

Treatment Kg/m3 BAE Leached Unleached C1 1.84 (0.40) 25.1 (1.75) 1.04 (0.55) C2 2.92 (0.65) 28.4 (2.53) 0.89 (0.72) C3 4.61 (0.90) 29.4 (5.25) 0.70 (0.50) C4 6.68 (2.45) 0.31 (0.17) - Ethanol control - 37.9 (1.97) 30.0 (4.64) Untreated control - 37.4 (3.10) 37.8 (4.88)

(1) Average of 20 replicate specimens (2) Average of 4 replicate specimens

Values in parenthesis are standard deviations.

0 5 10 15 20 25 30 35 40 45 % of m as s los s Untreated controls C2 C1 Ethanol controls C3 C4

Figure 1: Mass losses of sapwood specimens of Beech (Fagus sylvatica) treated with boric acid

ammonium oleate ethanolic solutions and exposed to brown rot fungus Coniophora puteana during a 16-weeks test (European Standard EN113).Leached , unleached .

All un-weathered ABO treated specimens are considered resistant to Coniophora puteana according to European standard EN 113 with mass losses close or below 1% in each situation. Weathering process according to EN 84 has a great impact on specimen’s resistance. Specimens treated with solutions from C1 to C3 are non resistant to Coniophora puteana when exposed after leaching. We do not have indications about boric acid amounts leached out but it seems that a great part of it has been removed by the water impregnation. Mass losses close to untreated samples with are 25 to 29% for those concentrations.

It is interesting to notice that standard deviations of mass losses increase as concentration of solution increase; from 1.75 to 5.25 which is a very high standard deviation.

It seems that heterogeneity is induced by leaching procedure. This variation increases as initial retention load does. This could be explained by the oily composition of chemical. In some cases water penetrates inside specimens removing some chemicals, in some others leaching is reduced. Mass losses are following the same evolution. This effect could be dependant on specimens’ anatomy .

Specimens treated with C4 solution have a very low mass loss of 0.31 % after leaching and exposure. Mass losses are homogenous with a very low standard deviation of 0.17. Regarding results for lower concentrations, resistance is probably not due to concentration of boron remaining but more to fatty acid content which have reduced leaching and water uptake. Efficiency threshold is then probably between C3 and C4.

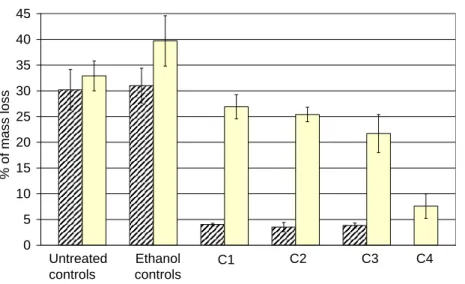

Results indicated by Table 2 and Figure 2 are a bit different for Pine specimens exposed to

Coniophora puteana.

Mass losses of unleached samples are also very low but higher than for Beech samples.

Leached samples have mass losses decreasing from 26.9 % (C1) to 21.7% (C3). This decrease of mass loss seems to be correlated with boron retention.

Specimens treated with C4 solutions have an average mass loss of about 7.6% after leaching. This result is to high to consider specimens as resistant. Decrease of mass loss compared to C3 solution is maybe due to combination of high initial boron retention and reduction of leaching because of high oil content. Mass losses decrease as ABO concentration increases but no efficiency threshold has been determined in this case.

Table2: Mass losses in sapwood specimens of Pine (Pinus sylvestris) treated with boric acid ammonium oleate ethanolic solutions and exposed to brown rot fungus Coniophora puteana during a 16-weeks test (European Standard EN113).

Pine (Pinus sylvestris) Retention load of unleached samples (Kg/m3 BAE) (1)

Mass loss by Coniophora

puteana (%), mean (SD) (2)

Treatment Kg/m3 BAE Leached Unleached C1 2.49 (0.58) 26.9 (5.63) 4.03 (0.52) C2 4.57 (0.24) 25.4 (3.72) 3.51 (2.27) C3 6.59 (0.35) 21.7 (2.41) 3.82 (1.82) C4 9.30 (0.97) 7.59 (3.38) - Ethanol control - 39.7 (6.29) 31.0 (2.59) Untreated control - 32.9 (7.19) 30.2 (5.40)

(1) Average of 20 replicate specimens (2) Average of 4 replicate specimens

0 5 10 15 20 25 30 35 40 45 % of m as s los s Untreated controls C2 C1 Ethanol controls C3 C4

Figure 2: Comparison Mass losses of sapwood specimens of Pine (Pinus sylvestris) treated with boric acid ammonium oleate ethanolic solutions and exposed to brown rot fungus Coniophora puteana during a 16-weeks test (European Standard EN113).Leached , unleached .

3.2 Exposition to white rot fungus

Table 3 and Figure 3 indicate results for Beech specimens exposured to white rot fungus

Coriolus versicolor.

Unleached samples are considered as resistant according to EN113 with mass losses from 0.5 to 2%.

Leached wood specimens previously treated with C1, C2 and C3 ABO solutions are non resistant to Coriolus versicolor . Boron retention after leaching and fatty acids content are probably too low to prevent the fungal attack.

Efficiency threshold is almost reached for treatment with a C4 solution. Mass loss is about 3.24 % in this case. This effect may be due to combined effect of boron retention and hydrophobic properties of specimens provided by higher fatty acid content.

Table 3: Mass losses in sapwood specimens of Beech (Fagus sylvatica) treated with boric acid

ammonium oleate ethanolic solutions and exposed to white rot fungus Coriolus versicolor during a 16-weeks test (European Standard EN113).

Beech (Fagus sylvatica) Retention load of unleached samples (Kg/m3 BAE) (1)

Mass loss by Coriolus

versicolor (%), mean (SD) (2)

Treatment Kg/m3 BAE Leached Unleached C1 1.78 (0.28) 22.8 (2.35) 0.46 (0.23) C2 2.97 (0.96) 22.2 (1.41) 1.34 (0.90) C3 4.79 (0.73) 19.8 (3.70) 1.97 (0.49) C4 7.42 (1.53) 3.24 (2.39) - Ethanol control - 24.0 (4.92) 30.0 (3.39) Untreated control - 24.3 (2.90) 22.6 (3.96)

(1) Average of 20 replicate specimens (2) Average of 4 replicate specimens

0 5 10 15 20 25 30 35 % of m as s los s Untreated controls C2 C1 Ethanol controls C3 C4

Figure 3: Mass losses of sapwood specimens of Beech (Fagus sylvatica) treated with boric acid ammonium oleate ethanolic solutions and exposed to white rot fungus Coriolus versicolor during a 16-weeks test (European Standard EN113).Leached , unleached .

4. CONCLUSIONS

Exposure tests of Beech and Pine sapwood specimens to fungi Coniophora puteana and Coriolus

versicolor have shown promising results.

Treatment of wood with ammonium borate oleate salt allowed protecting wood even after leaching procedure. In most of cases efficiency threshold has been determined as retention between C3 and C4 solutions. Exposure of Pine specimens to Coniophora puteana is an exception. In this case, efficiency threshold is higher and not determined in this study.

Boron leaching data are missing but if we consider that boron leached is about 50% as observed in a previous Japanese study (Lyon et al, 2007b), it would indicate that efficiency threshold is about 3.0 to 5.0 Kg/m3. As these values are higher than bibliographical threshold reported, it is reliable to consider that boron leaching has been more important than 50%.

Leaching of ABO treated wood specimens seems more important for European procedure (vacuum pressure) than for Japanese procedure (dipping).

Efficiency of ABO salt is based on repellence provided by fatty acids which allows reducing boron leaching and penetration of water and fungi. This treatment can be considered as a combination of a biocide and a coating produce. In this case vacuum leaching procedure is inappropriate to place specimens in real exposure conditions because it forces penetration of water. This observation reminds the lack of appropriated standardized procedure of testing for combined biocide and coating treatment.

5. REFERENCES

Cockroft, R, Levy J F (1973): Bibliography on the use of boron compounds in the preservation of wood, Journal of Institute of Wood Science 33(6)3, 28-37.

Drysdale, J A (1994): Boron Treatments for the Preservation of Wood.–A review of efficacy data for fungi and termites. The International Research Group on Wood Preservation. Doc IRG/WP 94-30037. IRG secretariat, Stockholm, Sweden.

European Norm EN113 (1996). Wood preservatives, Test method for determining the protective effectiveness against wood destroying Basidiomycetes, Determination of the toxic values. AFNOR

European Norm EN84 (1997). Wood preservatives, Accelerated ageing of treated wood prior to biological testing, Leaching procedure. AFNOR

Grace, J K, Yamamoto, R T (1994a): Simulation of remedial borate treatments intended to reduce attack on Douglas-fir lumber by the Formosan subterranean termites (Isoptera : Rhinotermitidae), Journal of Economical Entomology, 87 (6), 1547-1554.

Grace, J K, Tsunoda, K, Byrne, A, Morris, P I (1994b): Field evaluation of borate-treated lumber under conditions of high termite hazard. Abstract. In: Proceeding of Wood Preservation. In the

90s and Beyond

Homan, W.J, Militz, H (1995): Influence of surface coating on the leachability of boric acid and bifluorides spruce wood. The International Research Group on Wood Preservation. Doc IRG/WP 95-50050. IRG secretariat, Stockholm, Sweden.

Kartal, S N, Imamura, Y (2004): Effects of N’-N-(1, 8-Naphthalyl) hydroxylamine (NHA-Na) and hydroxynaphthalimide (NHA-H) on boron leachability and biological degradation of wood,

Holz als Roh und Werkstoff, 62, 378-385.

Lloyd, J D (1997): International borate status of borate preservative systems. In: Proceedings of

The Second International Conference on Wood Protection with Diffusible Preservatives and Pesticides, ed. Forests Products Society. Alabama, pp. 45-54.

Lloyd, J D (1998): Borates and their biological applications. The International Research Group

on Wood Preservation. Doc IRG/WP 98-30178. IRG secretariat, Stockholm, Sweden.

Lloyd, J D, Manning, M J (1995): Developments in borate preservation technology, Annual convention of the British wood preserving and damp-proofing association, 7 p.

Lyon, F. (2007). Amélioration de la durée de vie d’essences de bois peu durables à l’aide d’un traitement combiné borates/huiles végétales. Thèse de Doctorat, Université de Montpellier II, France.

Lyon F., Thevenon M.F, Hwang W.-J., Imamura Y., Gril J., Pizzi A. (2007a). Effect of an oil heat treatment on the leachability and biological resistance of boric acid impregnated wood.

Annals of Forest Sciences. 64. 673-678.

Lyon F., Pizzi A., Imamura Y., Thevenon M.F., Kartal N., Gril J. (2007b): Leachability and termite resistance of wood treated with a new preservative: Boric acid ammonium oleate. Holz

als Roh und Werkstoff. 65(5), 359-366.

Megnis M., Olsson T.,Varna J., Lindberg H. (2002): Mechanical performance of linseed oil impregnated pine as correlated to the uptake level, Wood Science and Technolology. 36. 1-18.

Militz H., Thermal treatment of wood (2002): European processes and their background. The

International Research Group on Wood Preservation, Doc IRG/WP 02-40241. IRG Secretariat

Stockholm, Sweden.

Mohareb A., Van Acker J., Stevens M. (2002): Effect of protective additives on leachability and efficacy of borate treated wood. The International Research Group on Wood Preservation. Doc IRG/WP 02-30290. IRG Secretariat Stockholm, Sweden.

Mohareb, A, Van Acker, J, Stevens, M, (2004): Leachability and efficacy of fatty acid derived boron esters as wood preservatives. The International Research Group on Wood Preservation. Doc IRG/WP 04-30351. IRG secretariat, Stockholm, Sweden.

Olsson T., Marklund B., Lindberg H. (2001): Characterisation of linseed oil impregnated pine exposed for biological degradation-A case study. Proceeding of Cost Action E 22, Reinbek, Germany.

Pavlic, M, Krijcej, B, Tomazic, M, Petric, M, (2001): Performance of exterior coatings on spruce wood treated with boron containing wood preservative. University of Ljubljana, report.

Petric, M, Pavlic, M, Cadez, F (2001): Leaching of the new boron based biocide from coated wood. The International Research Group on Wood Preservation. Doc IRG/WP 01-30267. IRG secretariat, Stockholm, Sweden.

Peylo, A, Willeitner, H (1997): Leaching of boron more than 3 years after exposure. The

International Research Group on Wood Preservation. Doc IRG/WP 97-30143. IRG secretariat,

Stockholm, Sweden.

Pizzi, A (1993a): A new approach to non-toxic, wide-spectrum, ground-contact wood preservatives, Part 1: Approach and reaction mechanisms, Holzforschung, 47, 253-260.

Pizzi, A (1993b): A new approach to non-toxic, wide-spectrum, ground-contact wood preservatives, Part 2: Accelerated and field biological tests, Holzforschung, 47, 343-348.

Pizzi, A, Baecker, A W (1996): A new boron fixation mechanism for non-toxic wood preservatives, Holzforschung, 50(6), 507-510.

Polus-Ratajczaak, I, Mazela, B (2004): The use of blood protein in wood preservatives, Holz als

Roh und Werkstoff, 62(3), 181-183.

Thevenon, M-F, Pizzi, A, Haluk, J P (1997): Non-toxic albumin and soja protein borates as ground-contact wood preservatives, Holz als Roh und Werkstoff, 55(5), 293-296.

Thevenon, M-F, Pizzi, A, Haluk, J P (1998): One-step tannin fixation of non-toxic protein borates wood preservatives, Holz als Roh und Werkstoff, 56(1), 90.

Thevenon, M-F (1999): Développement de formulations de produits de préservation du bois à faible toxicité et à longue durée d’action. Applications aux associations acide borique-tannins condensés et aux associations acide borique-protéines. Thèse de Doctorat. Technologie Industrielles-Sciences du bois. Université Nancy I, France.

Thevenon, M-F, Pizzi, A (2003): Polyborate ions influence on the durability of wood treated with non-toxic protein borate preservatives, Holz als Roh und Werkstoff, 61(6), 457-464.

Welzbacher C.R., Rapp. A.O. (2002): Comparison of thermally wood originating from four industrial scale processes-durability. The International Research Group on Wood Preservation Doc No IRG/WP 02-40229. IRG Secretariat Stockholm, Sweden.