3rd International Conference on Bio-Based Building Materials

June 26th - 28th 2019

Belfast, UK

ID_ P234

SOME MECHANICAL AND THERMAL PROPERTIES OF VEGETABLE

AGGREGATES CEMENT COMPOSITES: EVALUATION OF A NEW BINDER

BASED ON LIME

Cristel Onésippe1 *, Rijaniaina Valéry Ratiarisoa1, Ketty Bilba1, Holmer Savastano Junior2 and

Marie-Ange Arsène1

1COVACHIM-M2E EA3592, Université des Antilles, Campus de Fouillole, Pointe-à-Pitre, 97157,

Guadeloupe, FWI

2 Department of Biosystems engineering (ZEB), Universidade de São Paulo, São Paulo, Brazil

*Corresponding author; e-mail: cristel.onesippe@univ-antilles.fr

Abstract

Composite materials incorporating vegetable matter have known an increasingly interest during the past decades. These environmental friendly materials offer advantages such as low-cost and reduction of electrical consumption by air conditioning. This research investigates and compares some physical, thermal and mechanical properties of (1) a cement and sugar cane bagasse ashes binder and (2) an eco-friendly binder based on bagasse ashes and hydrated lime Ca(OH)2. These

binders are mixed with vegetable aggregates of bagasse and coconut (various contents - 5 to 20 wt%). The lightweight eco-friendly binder is performed with low energy consumption and low CO2

emission materials, compared to cement. Before their incorporation in the binder, the bagasse and coconut aggregates were characterized and compared by using optical microscopy, thermal degradation, apparent and specific density, water absorption and granulometry. The analysis of these characteristics allowed to predict the influence of these aggregates on apparent density, flexural and compressive strengths (28 days) and thermal conductivity (56 days). Experimental investigations showed that the incorporation of vegetable aggregates into an inorganic matrix results in a decrease in the compressive and flexural strengths of the composite.Flexural and compressive strengths of cement – bagasse ashes binder are higher by a factor 2 to 4 than that of bagasse ahes - lime binder. But after addition of aggregates, the decrease of strength is less marked in case of bagasse ashes - lime binder: decrease by a factor 4 in bagasse ashes - lime binder and reduction by a factor 8 to 10 in cement – bagasse ashes binder. The vegetable aggregates allow a reduction of the density of the coumpound binder by up to 57% and their presence induces thermal insulation properties to the composite, specially in case of composite materials made of bagasse ashes - lime binder.

Keywords:

Vegetable aggregates; lime binder; mechanical properties; thermal conductivity.

1 INTRODUCTION

Guadeloupe (FWI) is a tropical island located in a seismic and hurricane-prone region [Arsène 2015]. This is the reason why, traditionally, the infrastructures and houses are built of cement concrete [Rodier 2014].

Cement is one of the most used materials in the field of civil engineering, its raw materials - limestone and clay - being widely available [Worrell 2001]. In fact, cement gives concrete its ability to withstand compressive forces, which improves the mechanical behavior of materials subjected to seismic and climatic hazards.

The final purpose of this study is to valorize agro-industrial residues as materials for housing and construction in order to reduce electricity consumption due, partly, to air-conditioning. To achieve this goal our research proposes the development of two alternative binders: a cement + sugar cane bagasse ashes one and

an hydrated lime Ca(OH)2 – as replacement of the

cement - + sugar cane bagasse ashes one. This latter binder is a lightweight one compared to cement.

Lime, a pozzolanic material [Holland 2012], is used as one of the alternatives to cement all over the world since ancient times [Acharya 2016]. It is obtained at a lower temperature than that required for the production of clinker (about 800°C [Duggal 2009] for lime against 1450°C for cement [Abdo 2008]) reducing the energy cost and CO2 emissions of binder production [Koteng

2015]. The use of vegetables aggregates as reinforcement of composites materials has been booming for a few decades [Nozahic 2012]. This kind of reinforcement is known to impart insulating properties to cement composites [Onésippe 2010].

According to Food Directorate of Agriculture and Forestry from Guadeloupe, the island produces 680000 tons/year of sugar cane mainly used for the sugar and rum industries. Bagasse is the solid lignocellulosic

leftover after extraction of juice from the sugar cane stalk and is cheap compared to synthetic fibres [Yadav 2015]. Sugar cane bagasse ashes (CBA) are a by-product obtained after calcination of sugar cane bagasse for energy production. CBA are materials mainly composed with silicon dioxide, aluminum and iron oxides [Rodier 2014]. These ashes have a low density and its storage outside induces the pollution of soil, air and water [Ratiarisoa 2018]. CBA are also considered as pozzolanic materials [Rossignolo 2018]. The two alternative eco-friendly binders are mixed with vegetable aggregates of two botanical species of various contents ranging from 5 to 20% wt: sugar cane bagasse and coconut. Prior to their incorporation in the binder, it was crucial for us to characterize the vegetable aggregates by various methods : optical microscopy, thermal degradation, apparent and specific density, water absorption and granulometry in order to predict the influence of the presence of these aggregates on the binders properties and on the mechanical properties of the final composites.

The composites were then investigated : apparent density, flexural and compressive strengths and thermal conductivity after 28 days of curing.

2 MATERIALS 2.1 Cement

The cement used in this study is a commercial AALBORG WHITE ® - CEM I 52,5 R Portland cement.

It is composed of more than 95% by weight of clinker and contains gypsum (as setting regulator).

Physical and mechanical properties of the cement used are summarized in Tab. 1 [Aalborg white 2015].

Tab. 1: Physical and mechanical properties of cement CEM I 52,5 R.

Properties Values

Compressive strength 1 day 24 MPa 2 days 43 MPa 7 days 61 MPa 28 days 73 MPa Beginning of setting (Vicat) 156 minutes Specific density 3120 kg/m3

Hydration heat 350 J/g

Specific surface (Blaine) 396 m2/kg Expansion (Chatelier) 0.4 mm

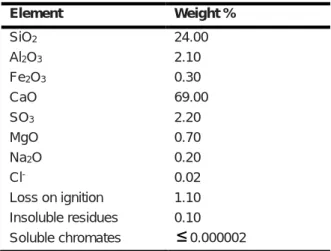

Chemical characteristics of cement are presented in Tab.2. As we can see, this cement has a low alkali content (Na2O < 0.2%) and a very low soluble chromates content. Bogue formulae allow the determination of the different cement phases from the chemical composition. This Bogue composition is presented in Tab. 3. As demonstrated by others [Ouyang 1988]as the content of C3A is low (< 5%), this

cement is supposed to be resistant to sulphate attack.

2.2 Hydrated lime

The hydrated lime was a commercial calcium hydroxide with more than 95 wt % of Ca(OH)2 content (VETEC /

SIGMA-ALDRICH Brazil).

2.3 Sugar cane bagasse ashes (CBA)

The sugar cane bagasse ashes (CBA) are from Montebello distillery (Petit-Bourg, Guadeloupe).

Tab.2 : Chemical composition of cement [Aalborg white 2015]. Element Weight % SiO2 24.00 Al2O3 2.10 Fe2O3 0.30 CaO 69.00 SO3 2.20 MgO 0.70 Na2O 0.20 Cl- 0.02 Loss on ignition 1.10 Insoluble residues 0.10 Soluble chromates 0.000002

Tab.3: Mineralogic phases of cement [Aalborg white 2015]. Cement phases % C3S 77 C2S 15 C3A 5 C4AF 1

In laboratory, these CBA are re-calcinated at 600°C in order to prevent the presence of unburned particles. To optimize the pozzolanic reaction and to minimize trace of impurity, after re-calcination, CBA are sieved manually with a threshold diameter ranging from 45 to 63 m.

2.4 Sugar cane bagasse and coconut aggregates

The sugar cane bagasse aggregates came also from Montebello distillery. Coconut aggregates (cocos

nucifera L.) were collected from coconut endocarp.

Aggregates were obtained by grinding with a knife mill (Restch, France) and were sieved. Aggregates preserved for study ranged from 1 to 6 mm. Their shapes are presented in Fig. 1. Theses images were collected by a binocular magnification.

(a) (b)

Fig. 1 : Image of (a) bagasse and (b) coconut aggregates.

2.5 Superplasticizer

The superplasticizer used is CHRYSO®fluid Premia 205 based on modified polycarboxylate.

2.6 Formulations

Composites were elaborated according to the sequence of steps indicated by Ratiarisoa [Ratiarisoa 2018]. Two types of binders were used:

- C – CBA, where C is for cement and CBA is for bagasse ashes

- CBA – CH, where CBA is for bagasse ashes and CH for lime.

Tab.4 : Formulations of bagasse ashes - cement composites reinforced by vegetable aggregates For all samples : mass of SPP = 1.8 g.

Samples CBA mass (g) Lime mass (g) Binder mass (g) Bagasse aggregates mass (g) Coconut aggregates mass (g) Water mass (g) Pre-wetting water mass (g) (%) C-CBA 70 30 100 - 0.48 0 C-CBA/Ba5 70 30 100 5 0.58 5 5 C-CBA/Ba10 70 30 100 10 0.58 10 10 C-CBA/Ba20 70 30 100 20 0.58 20 20 C-CBA/Co5 70 30 100 5 0.58 5 5 C-CBA/Co10 70 30 100 10 0.58 10 10 C-CBA/Co20 70 30 100 20 0.58 20 20

To these binders were added various contents of vegetable aggregates (bagasse or coconut) in order to obtain composites whose precise formulations are reported in the Tab. 4 and Tab. 5.

The mass contents in aggregates make it possible to improve the thermal and hydrous comfort. In order to reduce the amount of water-soluble compounds that can hinder the hydration of the binder, the aggregates have been previously soaked in water for 48 hours (mass ratio water / granulate = 20) and then filtered and placed in the oven at 60 °C until the stabilization of the mass. The following nomenclature has been adopted for the composites: Matrix / AggregateP where matrix is for the type of binder (C – CBA or CBA – CH), aggregate is for the type of aggregates used i.e. Ba for bagasse aggregates and Co for coconut aggregates, is mass content (%) of aggregates with respect to the binder and P is added when the aggregates have been pre-treated with lime. After elaboration, the samples were kept in a sealed box at 25 ° C until testing.

3 METHODS

3.1 Granulometry characteristics

The granulometry of vegetable aggregates was determined by image analysis using a desktop scanner. The images were scanned according to the recommendations of Picandet [Picandet 2012] and were then processed by the Image J software in order to know the size distribution of particles.

3.2 Thermal measurements

Thermogravimetric measurements are a question of measuring the loss of mass of a sample placed in a crucible according to the thermal treatment undergone. The sample is subjected to a rise ramp of 10 °C / min between 50 and 900 °C. The results are then analyzed using the OriginPro 2015 software to identify the nature and content of the various compounds present in the material.

Thermal conductivity of composites has been measured with a thermal conductimeter ‘‘CT-mètre” with a thermal probe (Controlab, France). At least four measurements per composite were conducted in order to evaluate the standard deviation of the results.

3.3 Density measurements

Specific density measurements have been measured using helium gas intrusion under helium gas flow with

a ‘‘Pycnomatic” Thermo Electron Corporation equipment (France) pycnometer. Four measurements were conducted for each sample at 25°C, relative humidity of 70–80%.

Apparent density of aggregates has been determined according to the protocol established by the standard RILEM – TC 236 – BBM [Amziane 2017]. At least, three measurements were conducted at 25°C. Apparent density (dry and wet) and apparent porosity of composites were measured according to the protocol described by standard ASTM C948-81 [ASTM 2016]. The tests were performed on five different samples for each formulation of composites.

3.4 Water absorption

Aggregates water absorption was determined by following the protocol RILEM TC – 236 – BBM [Amziane 2017]. Three measurements were conducted. Composites water absorption was established according to standard ASTM C948-81 [ASTM 2016]. The tests were performed on five different samples for each formulation of composites.

3.5 Flexural and compressive strengths

The mechanical properties have been measured with an universal machine (Instron, USA). Prior to measurements, samples were stored in an hermetic enclosure at 25°C. The mechanical tests were carried out at 28 days of curing according to standard [NF-EN 196-1, 2016] with a cell of 300 kN. In three-points flexion, the loading speed was 0.05 kN / s, while it was 2.4 kN / s for the compression tests.

4 RESULTS AND DISCUSSION

4.1 Characterization of vegetable aggregates 4.1.1 Morphology

Sugar cane bagasse and coconut aggregates, observed by binocular loupe, are respectively showed by Fig. 2 and Fig 3. They are mainly composed of particles (Fig. 2a and Fig. 3a) and vegetable fibers (Fig. 2b and Fig. 3b).

Tab.5 : Formulations of bagasse ashes - lime composites reinforced by vegetable aggregates For all samples : mass of SPP = 2 g, mass of K2SO4 = 3 g.

Samples CBA mass (g) Lime mass (g) Binder mass (g) Bagasse aggregates mass (g) Coconut aggregates mass (g) Water mass (g) Pre-wetting water mass (g) (%) CBA–CH 70 30 100 - 70 0 CBA–CH/Ba5 70 30 100 5 80 5 5 CBA-CH/Ba10 70 30 100 10 80 10 10 CBA–CH/Ba20 70 30 100 20 80 20 20 CBA–CH/Co5 70 30 100 5 80 5 5 CBA–CH/Co10 70 30 100 10 80 10 10 CBA–CH/Co20 70 30 100 20 80 20 20 (a) (b)

Fig.2: Sugar cane bagasse aggregates.

(a) (b)

Fig. 3: Coconut aggregates. 4.1.2 Thermal decomposition

Several peaks are highlighted:

- around 100°C: departure of the free water contained in aggregates [Ouensanga 1988] [Rodier 2014] [Sedan 2007];

- around 280°C: decomposition of the least thermally stable elements i.e. hemicelluloses, pectins and extractives [Magniont 2010] [Ouensanga 1988] [Sedan 2007] ;

- around 330°C: this main peak corresponds to the decomposition of cellulose [Magniont 2010] [Ouensanga 1988] [Rodier 2014] [Sedan 2007]. Furthermore,between 160 and 650°C, takes place the decomposition of lignin [Bilba 2003]. [Ouensanga 1988] [Rodier 2014].

Sugar cane bagasse aggregates appear to be rich in hemicelluloses and sugars unfavorable to the hydration of the binder [Bilba 2003] [Rodier 2014].

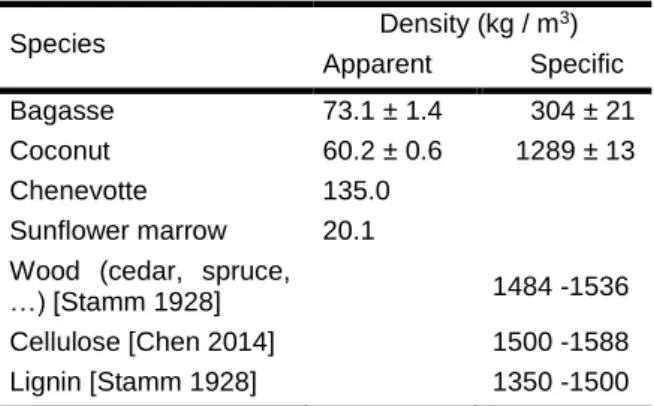

4.1.3 Apparent and specific densities

Vegetables aggregates densities are summarized in Tab. 6. Bulk densities of the aggregates have intermediate values compared to those of the sunflower marrow and the chenevotte. The specific densities of bagasse and coconut aggregates are slightly lower than those of cellulose, lignin and some woods. The cementitious materials have a specific density of the order of 3000 kg / m3 [Aalborg white 2015];

incorporating vegetable aggregates into a mineral matrix should lighten the final composite material.

Fig. 4: Thermal decomposition of vegetable aggregates.

Tab. 6: Specific and apparent densities of few vegetables aggregates. Species Density (kg / m 3) Apparent Specific Bagasse 73.1 ± 1.4 304 ± 21 Coconut 60.2 ± 0.6 1289 ± 13 Chenevotte 135.0 Sunflower marrow 20.1 Wood (cedar, spruce,

…) [Stamm 1928] 1484 -1536 Cellulose [Chen 2014] 1500 -1588 Lignin [Stamm 1928] 1350 -1500

4.1.4 Granulometry

The particle size assessment by image analysis makes it possible to determine the surface and the cumulative surface by representing the quantity of aggregates according to their length and their aspect ratio (Length / Diameter). The particle length distribution is presented by Fig. 5. The maximum length of aggregates is 25 mm.

(a) (b)

Fig. 5: Distribution of (a) the maximum length and (b) aspect ratio of vegetable aggregates.

Coconut aggregates contain more than 50% particles smaller than 5 mm whereas there is less than 30% for

bagasse aggregates. Bagasse aggregates are mainly composed of fibres of lengths between 2 and 8 mm which represent about 73% of bagasse particles studied. Fig. 5 summarizes the aspect ratio of vegetables aggregates. More than 80% of coconut aggregates have an aspect ratio of less than 2.5. The aggregates of bagasse are more elongated than those of coconut because more than 50% of bagasse granulates have an aspect ratio greater than 2.5. For both types of aggregates, less than 4% of the particles have an aspect ratio between 8 and 14.

The addition of aggregates in the matrix should reduce the flexural strength of the final composite material because a high aspect ratio is required for the promotion of composite flexural properties [ACI 1996].

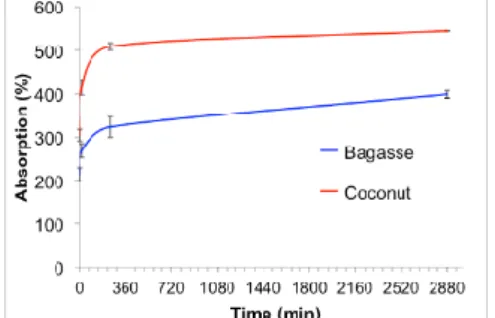

4.1.5 Water absorption

Fig. 6 shows the evolution of the average water absorption of the aggregates as a function of time. Coconut aggregates absorb more water than bagasse ones. Indeed, after one minute, the absorption of coconut aggregates is 319% against 209% for bagasse. After 2 days, the coconut aggregates absorbed 545% of their initial mass, compared with 400% for bagasse granulates.

The water absorption by the vegetable aggregates should lead to a competition between the water necessary for the hydration of the matrix and the water absorbed by the aggregates, thus disturbing the process of hydration of the matrix [Bilba 2003].

Fig. 6: Average water absorption of aggregates as a function of time.

4.2 Composites characterization

4.2.1 Composites based on cement – bagasse ashes binder

Fig.7 presents the evolution of compressive strength of composites according to the mass content of aggregates.

Fig.7: Compressive strength of C – CBA binder composites.

As expected, the compressive strength of the composites decreases as the mass content of the aggregates increases. Indeed, aggregates, that are less resistant than the matrix, induce a lower resistance of the composite compared to the matrix. The decrease in

compressive strength is slightly marked for composites incorporating coconut aggregates. This could be attributed to the chemical composition and morphological characteristics of the aggregates. In fact, hemicelluloses and water-soluble compounds, more present in bagasse than in coconut aggregates (Fig. 4), disrupt the hydration of the cement matrix and reduce its strengthening [Arsène 2015]. In addition, coconut aggregates absorb more water than bagasse aggregates (Fig. 6), thus reducing the excess water in the binder (Water / binder = 0.7).

Fig. 8 is the representation of the bending strength of the composites according to the mass proportion of aggregates. The flexural strength of composites decreases as the proportion of plant aggregates increases. Aggregates do not contribute to an increase in flexural strength because their maximum aspect ratio is 14 for an average of about 6. A high aspect ratio (20 to 100) is required for improvement of flexural properties of composites [ACI 1996]. The decrease in flexural strength is less marked for composites incorporating coconut aggregates. This difference could be related to the content of the soluble compounds that could inhibit or disrupt the hydration of the cement matrix [Arsène 2015] and whose contents are different in coconut or bagasse aggregates. Although coconut aggregates have a lower form factor than bagasse aggregates (Fig. 5), the flexural strength is higher for composites including coconut aggregates.

The apparent densities of composites (Fig. 9) incorporating bagasse aggregates are slightly greater than those of composites based on coconut aggregates. This is probably due to the fact that the bulk density of bagasse aggregates is higher than that of coconut aggregates (Tab. 6).

Fig. 8: Flexural strength of C – CBA binder composites.

Fig. 9: Density of the C – CBA binder composites.

For a fiber content ranging from 0 to 20%, the thermal conductivities are between 386 and 580 W / (m.K) (Fig. 10). No significant difference is found for thermal conductivity according to the nature of the aggregates incorporated for a given amount of aggregates.

Fig. 10: Thermal conductivity of C – CBA binder composites.

4.2.2 Composites based on bagasse ashes – lime binder

As in the case of cement – bagasse ashes binder composites, the compressive strength of bagasse ashes - lime composites decreases as the mass content of aggregates increases (Fig. 11). Indeed, a reduction of up to 90% is noted for an aggregate content of 20%. For composites incorporating coconut aggregates, with increasing content of aggregates, the decrease of mechanical properties is more regular.Considering the standard deviations, no significant difference is found in the evolution of the compressive strength of composites, incorporating treated and untreated aggregates, at 28 days, it decreases with the content of vegetable aggregates. This last point indicates the decrease of the compactness of the composite caused by the introduction of voids together with the aggregates employed [Sadrmomtazi 2018].

Fig. 12 is the evolution of flexural strength of CBA – CH binder composites according to the mass content of aggregates.

Fig. 11 : Compressive strength of CBA – CH binder composites.

As with the bagasse cement-ash cement binder, the flexural strength of bagasse-lime ash composites / vegetable aggregates decreased as the proportion of plant aggregates increased. However, there is no significant difference between the flexural strength of the 5% by weight coconut aggregate composite and that of the control matrix. The presence of a higher proportion of hemicellulose in bagasse aggregates compared to coconut aggregates could disturb and inhibit the hydration of the binder [Sedan 2007] resulting in a decrease in compressive and bending strengths of the composite including bagasse aggregates compared to that containing coconut aggregates (50% reduction).

Fig. 12 : Flexural strength of CBA – CH binder composites.

The apparent density of the composites varies between 430 and 1147 kg / m3 (Fig. 13). The lime pretreatment

of the aggregates has no noticeable effect on the variation of the density of the composites.

Fig.13 : Apparent density of CBA – CH binder composites.

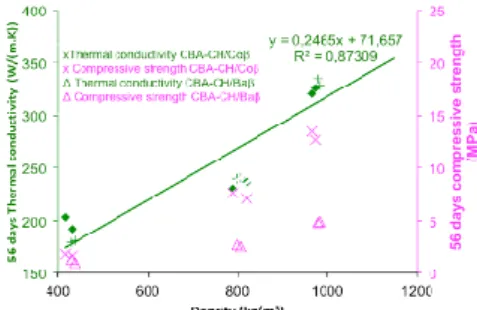

The thermal conductivity at 56 days of the CBA – CH binder composites varies between 181 and 375 W / (m.K) (Fig. 14). In general, ash-lime compounds produce more insulating composites than cement – bagasse ashes binder composites. Indeed the thermal conductivity of these can be up to 55% higher than those developed with a matrix containing lime.

Fig. 14 : Thermal conductivity of CBA – CH binder composites.

As shown by Fig. 15, the thermal conductivity of CBA – CH binder composites evolves linearly with their apparent density. However, a decrease in thermal conductivity is accompanied by a reduction in the compressive strength of the composite.

4.2.3 Effect of nature / content of aggregates and of effect of nature of binder

The incorporation of vegetable aggregates into an inorganic matrix results in a decrease in the compressive and flexural strengths of the composites. In fact, bagasse and coconut aggregates have an average form factor of the order of 6. In addition, they comprise compounds (hemicellulose and water-soluble) which inhibit the hydration of the matrix and are responsible of their mechanical behaviour.

Fig. 15 : Evolution of thermal conductivity and compressive strength of CBA –CH binder composites

according to their density.

The compressive strengths of the C - CBA binder composites are generally 4 times higher than those of the CBA - CH binder composites (Fig.7 and Fig.11). The composites incorporating coconut aggregates exhibit an decrease in the normalized compressive strength [Huang 2017](Fig. 16), compared to that of the C - CBA or CBA - CH binders, as a function of the quasi-similar coconut aggregates content. A more marked reduction in compressive strength as a function of the bagasse aggregates content was observed for the CBA - CH / Baβ and CBA - CH / BaβP composites compared to those of the C - CBA / BaβP composites. This fact could be attributed to a weaker interface transition zone in CBA – CH composites [Ferreira 2018].

Fig. 16 : Evolution of the normalized compressive strength compared to that of C - CBA and CBA - CH

binders as a function of the aggregates content.

According to Fig . 17, vegetable aggregates reduce the initial density of the combined binder up to 57%.

Fig. 17 : Evolution of the normalized density compared to that of the combined binder C - CBA and CBA - CH

of the composites as a function of the aggregates content.

This decrease is more marked for the CBA - CH / Granulatβ composites compared to the C - CBA / Granulatβ composites. This difference is mainly attributed to the higher water demand of the CBA - CH / Granulatβ composite (water / binder ratio 0.70 to 1.00) compared to that of the C – CBA / Granulatβ composite (water / binder ratio 0.48 at 0.78). In fact, the excess water will generate porosity, subsequently reducing the

final density of the composite [Onésippe 2010]. Moreover, the incorporation of aggregates in the binder leads to a more insulating material, the thermal conductivity decreases by 52% for an incorporation of 20% by mass of aggregates.

5 SUMMARY

The new combined binder, based on lime, developed in this study has a higher compressive strength than the bagasse ashes - lime binders studied in the literature. Indeed, Martirena Hernandez et al. [Martirena Hernandez 1998] reported a 28 days compressive strength of 13.7 MPa for bagasse ashes - lime binder, the 28 days compressive strength of NHL 5 lime, reported in [NF EN 459 - 1 2012], is between 5 and 15 MPa and that of 28 days Tradical PF70 binder reported by [Nguyen 2010] is 10 MPa. The incorporation of vegetable aggregates into the CBA - CH and C - CBA combined binders results in a decrease in compressive strength and flexural strength of the composite. Bagasse and coconut aggregates have an average form factor in the order of 6 while a higher form factor (20 to 100) is required to improve the bending properties of composites [ACI 1996]. In addition, they include organic compounds (hemicellulose and water-soluble) which inhibit the hydration of the binder. Vegetable aggregates reduce the initial density of the compound binder up to 57% and their incorporation into the binder leads to a more insulating material, which could be used as an internal wall in houses.

6 ACKNOWLEDGMENTS

The authors thank the program ANR – 12 –IS09 – 0002 – 01 (Programme ANR Blanc International II 2012) for its financial support.

7 REFERENCES

[Aalborg white 2015] Aalborg white; Déclaration de performance et fiche technique. Aalborg Portland, Danemark, 2015.

[Abdo 2008] Abdo J., Techniques de l’ingénieur, Les matériaux de construction traditionnels - Ciments -C920 - Editions T.I. [Paris, France], REF: TIB224DUO, 2008. [Acharya 2016] Acharya, P.K. ; Patro, S.K. ; Strength, sorption and abrasion charactristics of concrete using ferrochrome ash (FCA) and lime as partial replacement of cement. Cement and concrete comosites,November 2016, volume 74, 16-25.

[ACI 1996] ACI Committee. State-of-the-art report on fiber reinforced concrete ACI 544.1R-96. American concrete institute, 1996, 66.

[Amziane 2017] Amziane, S.; Collet, F.; Lawrence, M.; Magniont C. et al. Recommendation of the RILEM TC 236 – BBM: characterization testing of hemp shiv to determine the initial water content, water absorption, dry density, particle size distribution and thermal conductivity. Materials structures, 2017, volume 50, number 3, 167.

[Arsène 2015] Arsène, M.-A.; Bilba, K.; Onésippe, C.; Rodier, L.; Thermal and flexural properties of bagasse/cement composites. Green Materials, 2016,volume 3, issue 4, 132-143.

[ASTM 2016] ASTM C948-81. Standard test method for dry and wet bulk density, water absorption and apparent density of thin sections of glass-fiber reinforced

concrete. ASTM International, West Conshohocken, PA, www.astm.org, Standard, 2016.

[Bilba 2003] Bilba, K.; Arsène, M.-A.; Ouensanga, A.; Sugar cane bagasse fibre reinforced cement composites. Part I. Influence of the botanical components on the setting of cement/bagasse composites. Cement and concrete composites, 2003, volume 25, number 1, 91-96.

[Chen 2014] Chen, H. Biotechnology of lignocellulose: theory and practice. Book, 2014.

[Duggal 2009] Duggal, S.K.; Building Materials. In: New Age International, 2009.

[Ferreira 2018] Ferreira, S.R.; Pepe, M.; Martinelli, E.; de Andrade Silva, F. et al. Influence of natural fibers characteristics on the interface mechanics with cement based matrices. Composites part B: engineering, May 2018, volume 140, 183-196.

[Holland 2012] Holland, N.L.; Nichols, A.; Nichols J.; The use of lime in concrete as cement replacement, change in physical properties. ASTM STP 1557 - Symposium on Lime: Building on the 100-Year Legacy of ASTM Committee C07 At: San Diego Volume: 1. [Huang 2017] Huang, G. ; Wang, P. ; Effects of preparation conditions on properties of rigid polyurethane foam composites based on liquefied bagasse and jute fibre. Polymer testing, July 2017, volume 60, 266-273.

[Koteng 2015] Koteng, D.O. ; Chen, C.-T. ; Strength development of lime – pozzolana pastes with silica fume and fly ash. Construction building materials, 2015, volume 84, 294-300.

[Magniont 2010] Magniont, C. Contribution à la formulation et à la caractérisation d’un écomatériau de construction à base d’agroressources. Thesis, Université de Toulouse – Paul Sabatier, 2010.

[Martirena Hernandez 1998] Martirena Hernandez, J. ; Middendorf, B. ;Gehrke, M. ; Budelmann, H. ; Use of wastes of the sugar industry as pozzolana in lime – pozzolana binders : study of the reaction. Cement and concrete research, 1998, volume 28, number 11, 1525-1536.

[NF-EN 196-1, 2016] NF EN 196 – 1. Méthodes d’essais des ciments – Partie 1: determination des resistances. Standard, 2016.

[NF EN 459 - 1 2012] NF EN 459 – 1. Chaux de construction – Partie 1: definitions, specifications et critères de conformité. Standard, 2012.

[Nguyen 2010] Nguyen, T.T. Contribution à l’étude de la formulation et du procédé de fabrication d’éléments de construction en béton de chanvre. Thesis, Université de Bretagne Sud, 2010.

[Nozahic 2012] Nozahic, V. Vers une nouvelle démarche de conception des bétons de végétaux lignocellulosiques basée sur la compréhension et l’amélioration de l’interface liant /végétal : application à des granulats de chènevotte et de tige de tournesol

associés à un liant ponce / chaux, Thesis, Université de Clermont – Ferrand, 2012.

[Onésippe 2010] Onésippe, C.; Passé-Coutrin, N.; Toro, F.; Delvasto, S. et al.; Sugarcane bagasse fibers reinforced cement composites: thermal considerations. Composites: Part A, 2010, volume 41, 549-556. [Ouensanga 1988] Ouensanga, A.; Picard, C.; Thermal degradation of sugar cane bagasse. Thermochimica acta, March 1988, volume 125, 89-97.

[Ouyang 1988] Ouyang, C.; Nanni, A.; Chang W.F.; Internal and external sources of sulfate ions in Portland cement mortar: two types of chemical attack. Cement and concrete research, 1988, volume 18, number 5, 699-709.

[Picandet 2012] Picandet, V.; Recommendation for particle size distribution, Report, 2012.

[Ratiarisoa 2018] Ratiarisoa, V.R. Valorisation de résidus agroindustriels comme matériaux dans l’habitat et la construction: utilisation de la bagasse dans les liants composés minéraux et les composites. Thesis, Université des Antilles, 2018.

[Rodier 2014] Rodier, L. Matériaux de construction en zone tropicale humide: potentialities de sous-produits ou de matériaux naturels locaux en substitution ou addition à la matrice cimentaire. Thesis, Université des Antilles et de la Guyane, 2014.

[Rossignolo 2018] Rossignolo, J.A.; Borrachero, M.V.; Soriano, L.; Paya, J.; Influence of microwave oven calcination on the pozzolanicity of sugar cane bagasse ashes (SCBA) from the cogeneration industry. Construction and building materials, October 2018, volume 187, 892-902.

[Sadrmomtazi 2018] Sadrmomotazi, A.; Tahmouresi, B.; Saradar, A.; Effects of silica fume on mechanical strength and microstructure of basalt fiber reinforced cementitious composites (BFRCC). construction and building materials, February 2018, volume 162, 321-333.

[Sedan 2007] Sedan, D. Etudes des interactions physico-chimiques aux interfaces fibres de chanvre/ciment: influence sur les propriétés mécaniques du composite. Thesis, Université de Limoges, 2007.

[Stamm 1928] Stamm, A.J.; Density of wood substance, absorption by wood and permeability of wood. Journal of physical chemistry, 1928, volume 33, number 3, 398-414.

[Worrell 2001] Worrell, E.; Price, L.; Martin, N.; Hendricks, C. et al.; Carbon dioxide emissions from the global cement industry. Annual review of energy and the environment, November 2001, volume 26, 303-329. [Yadav 2015] Yadav, S. ;Gupta, G. ; Bhatnagar, R. ; Review on composition and properties of bagasse fibers. International journal of scientific & engineering research, May 2015, volume 6, issue 15, 143-14.

http://daaf.guadeloupe.agriculture.gouv.fr/Canne-a-sucre - website visited on december 17 2018