Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building Research), 1960-08-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=ca8530e6-2668-4746-ac83-c14eddfd4431 https://publications-cnrc.canada.ca/fra/voir/objet/?id=ca8530e6-2668-4746-ac83-c14eddfd4431

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20377828

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Small brick panel tests at Halifax: an investigation of "time", "tap", and "flow" factors in the assembly of small brick panels for leakage and bond strength tests

NATIONAL RESEARCH COUNCIL CANADA

DIVISION OF BUILDING

RESEARCH

SMALL BRICK PANEL 'ZESTS AT HA.LIFAX

An I n v e s t i g a t i o n of ffIPimel', "Tap", a n d "Flow1' F a c t o r s

i n

t h e Assembly of Small B r i c k P a n e l s f o r Leakage and Bond S t r e n g t h T e s t s I n t e r n a l R e p o r t No. 196 of t h e D i v i s i o n of B u i l d i n g Research O t t a w a August 1960A n e x t e n s i v e program o f l a b o r a t o r y i n v e s t i g a t i o n s o f t h e r a i n p e n e t r a t i o n and bond s t r e n g t h c h a r a c t e r i s t i c s of b r i c k masonry i s

i n

p r o g r e s s a t t h e A t l a n t i c R e g i o n a l S t a t i o ni n

H a l i f a x a s w e l l a s a t t h e l a b o r a t o r i e s of t h e D i v i s i o ni n

Ottawa. The s t a n d a r d i z e d t e c h n i q u e s which have b e e n d e v e l o p e d f o r t h i s program a r e d e s c r i b e d i n p r e v i o u s r e p o r t s . The c o m p l e x i t y of t h e problem of e n s u r i n g good performance of b r i c k masonry a s t o bond s t r e n g t h and r a i n p e n e t r a t i o n a r e d e m o n s t r a t e d i n p a r t by t h e r e s u l t s now r e p o r t e d from c o n t r o l l e d t e s t si n

which s e v e r a l of t h e p r i n c i p a l f a c t o r s o p e r a t i v e a t t h e t i m e of l a y i n g have b e e n v a r i e d s y s t e m a t i c a l l y , The a u t h o r , a c h e m i s t and a r e s e a r c h o f f i c e r w i t h t h e A t l a n t i c R e g i o n a l S t a t i o n of t h e D i v i s i o n , h a s d e v o t e d h i s f u l l t i m e f o r t h e p a s t s e v e r a l y e a r s t o performance s t u d i e s of b r i c k masonry, Ottawa August 1960N, B e

Hutcheon A s s i s t a n t D i r e c t o rSMALL BRICK PANEL TESTS AT HALIFAX

A n I n v e s t i g a t i o n of "Time", "Tap", and "Plown F a c t o r s

i n

t h e Assembly of Small Brick Panels f o r Leakageand Bond S t r e n g t h T e s t s by

J , I. Davison

Pollowing t h e preliminary program of leakage and bond s t r e n g t h t e s t s on small b r i c k panels i n t h e A t l a n t i c Regional Laboratory, an i n v e s t i g a t i o n of some of t h e f a c t o r s involved i n t h e assembly of t h e panels was undertdken. S p e c i f i c a l l y , t h e

e f f e c t of v a r y i n g t h e "timen, " t a p n , and "flown f a c t o r s was s t u d i e d ; t h i s r e p o r t r e c o r d s t h e r e s u l t s of t h e s e s t u d i e s ,

F i r s t ,

it

i s n e c e s s a r y t o d e f i n e t h e t e r n s "time", "tap", and "flow". "Timet' r e f e r s t o t h e time i n t e r v a l between t h e p l a c i n gof t h e mortar bed on a bottom b r i c k and l a y i n g t h e next b r i c k on t h a t mortar, A previous s t u d y on moisture l o s s e s from mortars d u r i n g e a r l y c o n t a c t w i t h b r i c k s (DBR I n t e r n a l Report No. 173) pointed t o t h e importance of t h i s time i n t e r v a l , For t h e purpose of t h i s s t u d y t h r e e times--30, 60, and 90 seconds a r e used.

A f t e r l a y i n g a b r i c k on t h e mortar bed it i s a n impact by a t a p p i n g device which i s i n e f f e c t a weight of known s i z e dropping through 1& i n , This t a p p i n g device was developed a t t h e National Bureau of Standards, Washington, D O C . , where a weight of 2 l b was used i n p r e p a r i n g c r o s s e d - b r i c k c o u p l e t s , T h i s became known a s t h e Standard Tap and was used d u r i n g t h e previous study. Use of t h i s 2-lb t a p was questioned s i n c e t h e a r e a of t h e mortar bed involved i n small panel assembly (approximately 8 i n . by

3 s

i n . ) was s l i g h t l y more t h a n double t h a t involved i n assembling crossed- b r i ck c o u p l e t s (approximately 3s i n . by 32 i n , ) .In

t h i s study two weights were used; a 4-lb weight r e f e r r e d t o a s a "heavy" t a p , and a 2-lb, weight h o w n a s t h e t l l i g h t ' t t a p .The t h i r d f a c t o r i n v e s t i g a t e d was t h e flow of t h e mortar used, "Flown r e f e r s t o t h e p l a s t i c c o n s i s t e n c y of t h e mortar a s measured by t h e standard flow t a b l e method o u t l i n e d i n A e S o T o M o T e n t a t i v e Method of Test f o r Compressive S t r e n g t h of Hydraulic Cement Mortars (C109-54T), I n t h i s study low-flow mortars having a value between 105 t o 115 per c e n t and high-flow mortars wi$h a value i n t h e range 115 t o 125 per c e n t a r e used,

Seventy-two panels have now been completed and r e s u l t s a r e presented i n t h i s r e p o r t , Also included a r e r e s u l t s f o r twelve panels assembled with brown b r i c k s i n i n i t i a l r a t e of a b s o r p t i o n ( I , R , A , ) range 18,O t o 22,2 gm and t h r e e mortars i n o r d e r t o l e a r n something of t h e bonding a b i l i t y of t h e s e b r i c k s which a r e i n t h e h i g h e s t s u c t i o n rpnge of l o c a l b r i c k s ,

M a t e r i a l s

B r i c k s , - Three d i f f e r e n t stiff-mud b r i c k s manufactured i n t h e a r e a were used,

*he

f i r s t a r e d b r i c k having a n I o R o A e below5

gm, t h e second a buff b r i c k having an I o R o A o of between 8 and 1 8 gm, and t h e t h i r d a brown b r i c k having a n I , R , A , of between 18 and 26 gm,Other a b s o r p t i o n p r o p e r t i e s of t h e t h r e e b r i c k a a r e l i s t e d i n Table I , Mortar,- Three d i f f e r e n t mortars were used i n assembling panels f o r t h i s study:

1) Masonry cement mortar c o n t a i n i n g 1 p a r t by volume masonry cement t o 3 p a r t s sand,

2 ) Cement lime mortar c o n t a i n i n g 1 p a r t b y v o l ~ ~ m e portland cement, 1 p a r t lime p u t t y , and 6 p a r t s sand,

3 ) Cement lime mortar c o n t a i n i n g 1 p a r t by volume p o r t l a n d cement, 2 p a r t s lime p u t t y , and

9

p a r t s sand,TABLE

I

Table of t h e B r i c k s Absorption ( $ Dry Weight) I . R , A . 24 h r 5 hr S a t u r a t i o n 9 / 3 0 s q in./mfn ( a ) Submersion (b ) B o i l i n g ( c ) C o e f f i c i e n t ( d ) Red 0.5 t o 2,5 0.3 t o 2,2 0.6 t o 2,9 0.43 t o 0.73 Buff 5.2 t o 19.5 6.2 t o 7.37,8

t o 9.0 0,79 t o 0,82 Brown 4.4 t o 22,O 1 , 6 t o 3.2 3.1 t o5 , 3

0,52 t o 0.59 ( a ) Amount of water absorbed by a d r y b r i c k when placed i n w a t e r( l a r g e s t s u r f a c e down) t o a depth of 1/8 i n , f o r one minute ( c o r r e c t e d t o a s t a n d a r d a r e a 30 s q in.)

( b ) Amount of water absorbed by a b r i c k expressed a s a percentage of

i t s

d r y weight when t h e b r i c k Is submerged i n water a t room temperature f o r 24 hr.( c ) Apount of w a t e r absorbed by a b r i c k expressed a s a percentage of i t s dry weight when a f t e r t h e 24-hr submersion t e s t it i s

submerged i n b o i l i n g w a t e r f o r 5 h r , t h e n cooled t o room temperature i n water.

( d ) R a t i o of amounts of w a t e r absorbed i n t e s t s ( b ) and ( c ) o r t h e r a t i o of t h e e a s i l y f i l l e d pore space t o t h e t o t a l pore space i n a b r i c k .

A l l m a t e r i a l s were t h e same a s t h o s e used i n t h e previous s t u d y , and mortars were mixed i n a Hobart

M50

mixer i n a s i m i l a r manner, S u f f i c i e n t w a t e r , t h e a c t u a l q u a n t i t y having bee^ p r e d e t e r - mined by experiment, was added t o give t h e mortar t h e r e q u i r e d flow, Panel AssemblySmall panels were assembled u s i n g f i v e b r i c k s placed one on t o p of t h e o t h e r w i t h f o u r mortar j o i n t s , following t h e procedu4-e o u t l i n e d , i n %he previous work w i t h t h e necessary adjustments f o r v a r i a t i o n s i n time and t a p ,

The masonry l a b o r a t o r y had been a i r - c o n d i t i o n e d t o c r e a t e c o n d i t i o n s of 70°F and

50

p e r c e n tR,H,

before t h i s p r o j e c t began, Although temperature and humidity were g e n e r a l l y i n t h f s range d u r i n g t h e s t u d y , occasional breakdowns i n t h e u n i t caused some v a r i a t i o n , t h e o u t e r l i m i t s being 62 t o 80°P f o r temperature and43 t o 60 p e r cent f o r

R,H,

Leakage T e s t s

Leakage t e s t s were done i n t h e u s u a l manner u s i n g t h e D.B,R, Small Panel Leakage Apparatus, During t h e 24-hour t e s t

period a f i l m of water i s maintained on t h e f a c e of t h e panel which i s a l s o s u b j e c t e d t o a n a i r p r e s s u r e of 2 i n , o f water, Thus con- d i t i o n s of a 50 mph wind-driven r a i n a r e simulated,

Bond S t r e n g t h T e s t s

Bond s t r e n g t h t e s t s were done 'on a l l panels subsequent t o leakage t e s t s , When t h e l a t t e r were completed, panels were kept i n t h e l a b o r a t o r y u n t i l ready f o r bond s t r e n g t h t e s t s , Three d i f f e r e n t methods were used t o o b t a i n bond s t r e n g t h . v a l u e s :

1) With t h e bending a p p a r a t u s used i n previous s t u d i e s some bond s t r e n g t h v a l u e s f o r p a n e l s 1 t o 6 were obtained,

2 ) Remainfng v a l u e s f o ~ p a n e l s 1 t o 6 were o b t a i n e d w i t h t h e t e n s l l e s t r e n g t h machlne a t Nova S c o t i a T e c h n i c a l

2011

ege ,Clamplng frames from t h e bending a p p a r a t u s were adapted t o f i t

t h i s machine,

3 ) Remaining bond s t r e n g t h v a l u e s were o b t a i n e d w i t h t h e new bond s t r e n g t h a p p a r a t u s developed by t h e D i v i s i o n a t Ottawa, The method i s described i n DBR I n t e r n a l Report No, 175; t h e a p p a r a - t u s i s shown i n F i g , 1, I n a d d i t i o n t o t h l s dlf'f'erence i n t h e

method of t e s t i n g , t h e r e was a c o n s i d e r a b l e v a r i a t i o n i n t h e age of e a r l y p a n e l s when t e s t e d , With t h e a r r i v a l of t h e new a p p a r a t u s from Ottawa t h e curing p e r i o d was r e g u l a t e d , and p a n e l s 30 t o 8 4 were t e s t e d one week a f t e r leakage t e s t s o r 2 1 days a f t e r f a b r l c a - t i o n , Curing p e r i o d s f o r p a n e l s 1 t o

30,

however, were a s h l g h a s 88 days from d a t e of p a n e l assembly t o bond s t r e n g t h t e s t s , Bond s t r e n g t h v a l u e s a r e , t h e r e f o r e , n o t comparable I n many c a s e sbecause of t h e d i f f e r e n t techniques used and a l s o because of t h e d i f f e r e n c e c u r i n g p e r i o d s ,

R e s u l t s from P a n e l s 1 t o 1 2

The f i r s t twelve p a n e l s were assembled w i t h r e d b r i c k s

w i t h v e r y low s u c t i o n v a l u e s ( I , . R , A , 1 t o 2,6 g m ) , Two m o r t a r s ,

a 1 : 3 masonry cement: sand and a l : 1 : 6 cement: lime p u t t y : sand were u s e d , t h e f o r m e r with odd-numbered p a n e l s and t h e l a t t e r w i t h even-numbered p a n e l s , ~ o r - b a r s were low flow (105 t o 115 p e r c e n t ) , t h e average b e l n g 109 p e r c e n t , Heavy t a p was used f o r a l l pan.els, The v a r i a b l e f o r t h e s e p a n e l s

w k s

t h e tlme f a c t o r , Tlme i n t e n a l s o f 38, 60, and 90 seconds were used f o r p a n e l s1

' t o4,

5

t o 8 , a n d3

t o 12 r e s p e c t i v e l y , R e s u l t s a r e summarized i n Table11;

a d e t a i l e d d i s c u s s i o n f o l l o w s ,TABLE I1

General Summary

--

Panels 1 t o 1 2 30 Sec 60 Sec 1: 3 n i l Leakage 1:1:6 n i l Bond S t r e n g t h 59.6 p s i 80,8 p s i n i 1 n i l 7506 p s i 67,6 p s i 90 Sec n i l n i l 5 4 0 7 p s i 5 7 3 p s i ( a ) Panels 1 t o-

4

m e r e was some d i s c o l o r a t i o n of cement-lime mortar j o i n t s a t t h e end of t h e leakage t e s t ; t h e masonry cement mortar j o i n t s had a l e s s e r degree of d i s c o l o r a t i o n , m e r e was no dampness on t h e back of any of t h e panels. A comparison can be made of bond s t r e n g t h r e s u l t s and v a l u e s obtained with t h e bending machine and t h e t e n s i l e s t r e n g t h machine from t h e information i n Table 111.

TABLE I11

Bond S t r e n g t h R e s u l t s ( p s i ) -,.- Panels 1 t o

4

Panel N o S o Tech Machine Bending Apparatus

No. Age a t Test

-

J o i n t # l J o i n t +2 J o i n t 7T3 J o i n t #4 Average 1 37 days 51.74 g 0

9

8 0 0 4 65.7 6 1 0 9 2 36 days 4704 70,6 l 0 8 , 5 9 5 0 1 80,4 3 32 days4 1 0

3 74

a 0% 49.6 63.0 57*04 73 days 72,3 1 2 l 0 4 115 o 9 79 1. 97 2

%Frame s l i p p e d during f i r s t a t t e m p t , F r a c t u r e occurred a f t e r subsequent adjustment.

Although average r e s u l t s obtained with t h e bending appara- t u s a r e h i g h e r t h a n t h o s e obtained with t h e t e n s i l e s t r e n g t h machinc, t h e h i g h e s t i n d i v i d u a l value w a s obtained with t h e t e n s i l e strengtki machine; i n some c a s e s , r e s u l t s from t h e two machines a r e comparable,

e . g . , r e s u l t s f o r panel No,

4 .

The considerable v a r i a t i o n i n v a l u e s f o r t h e same panel i s t y p i c a l of r e s u l t s f o r a l l panels no m a t t e r what method was used, Highest v a l u e s occurred with cement- lime mortar j o i n t s , Visual examination showed e x c e l l e n t bond; many of t h e breaks occurred through t h e mortar beds r a t h e r t h a n a t an i n t e r f a c e between b r i c k s and mortar,( b ) Panels

5

t o 8A l l mortar j o i n t s f o r cement-lime mortar panels were d i s c o l o u r e d a t end of t e s t while only one of e i g h t masonry cement mortar j o i n t s showed any d i s c o l o r a t i o n ,

TABLE I V

---

Bond S t r e n g t h Results ( p s i )

--

Panels 5 t o 8Panel R,S, Tech Machine Bending Apparatus

No. Age a t Test J o i n t #

1

J o i n t #2 J o i n t#3

--

J o i n t #4 Average Broke during5

72 days 63.7 12,1+ 75*0 s e t - u p 69

$5:- 6 71 days 637

99,9

95.1 85,8 8 6 , l Broke during 7-:wc 91 days s e t -up 8$,3 77-5 77.5 79 8 8 88 days 53,7 67.1 3009 $40849

0 1+

This j o i n t was probably damaged during s e t - u p ,4:-

Two values only. 'f556 Values f o r Panels 7 and 8 were obtained with t h e new bond s t r e n g t h apparatus,

Bond s t r e n g t h r e s u l t s i n Table I V permit a comparison of r e s u l t s of t h e t h r e e techniques used, Results of j o i n t s 1 and

3

of panel5 ,

t h e former obtained on t h eN.

S o Tech Machine and t h e l a t t e r with t h e bending' a p p a r a t u s , a r e comparable with t h e t h r e e values f o r panel 7 obtained with t h e new bond s t r e n g t h apparatus.Both panels were assembled with masonry cement; h l g h e r v a l u e s f o r panel

7

might be exflained by an a d d i t i o n a l1 9

days curfng period, The range from t h e low value of 6 3 0 7 p s i obtained with t h e N , S , Tech Machine t o t h e high value of 8 4 0 3 p s i obtained with t h e new bond s t r e n g t h apparatus i s n o t unusually high, i n f a c t it i s n o t a s g r e a t a s t h e rangein

t h e values f o r t h e o t h e r panels, Nos, 6and 8 l i s t e d i n Table I V . Values f o r panels 6 and 8 p r e s e n t an i n t e r e s t i n g c o n t r a s t t o t h e foregoing r e s u l t s : bond s t r e n g t h s f o r panel 8 , cured f o r

71

days, obtained with t h e new bond s t r e n g t h apparatus were much lower t h a n v a l u e s f o r panel 6 cured f o r 88days where t w o values were obtained with each of t h e o t h e r machines, It i s d i f f i c u l t t o say how much of t h i s spread i s due t o d i f f e r e n c e i n techniques f o r such d i f f e r e n c e s q u i t e o f t e n occur i n l a t e r work where only t h e new machine i s used, It should a l s o be noted t h a t i n panel 6 t h e average value obtained with t h e bending apparatus i s h i g h e r t h a n t h a t obtained with t h e N O S o Tech Machine although t h e h i g h e s t i n d i v i d u a l value occurred with t h e l a t t e r , A s a r e s u l t of t h e low average f o r panel 8 , bond s t r e n g t h values f o r masonry cement mortar j o i n t s were b e t t e r t h a n those f o r cement-lime mortar, This f s questionable i n t h e l i g h t of overwhelming evidence t o t h e c o n t r a r y and i n t h i s case may be t h e r e s u l t of a combination of circumstances including d i f f e r e n t techniques,

Visual examination revealed a good e x t e n t of bond f o r a l l panels i n t h i s group ~ 5 t h many f r a c t u r e s occurring through t h e mortar bedso

( c ) Panels

9

t o-

12Leakage performance was s i m i l a r t o t h e 60-second panels: j o i n t s I n panels 10 and 12 were discoloured a t end of t e s t while t h e r e was no i n d i c a t i o n of any moisture p e n e t r a t i o n on pariels

9

and 11, Bond s t r e n g t h values were somewhat lower f o r t h i s group than those previously obtained ( s e e Table V ) ,TABLE V

Bond S t r e n g t h R e s u l t s ( p s i )

--

Panels9

t o 12 PanelNo, Age a t T e s t

-

J o i n t # l J o i n t #2 J o i n t # 3 J o i n t -&4 Average9

83 days+

23 2 -:E--

-. 4709+

49.9 4S0910 84 days f i e -

-

---

- -

-

5 7 0 21 5

o5

5 7 0 211 8 4 days 74.0 7 2 - 3 6 1 , l 34.1 6004 12 8 3 days 66,3 53,O 59,2 52-5 57.8

% No value-- j o i n t broken d u r i n g s e t - u p ,

+

Two low v a l u e s probably r e s u l t of damaging j o i n t s d u r i n g s e t - u p o These v a l u e s n o t fncluded i n average, Two low v a l u e s and t h r e e broken j o i n t s i n panels9

and 10 a r e a r e s u l t of inexperience i n u s i n g t h e new bond s t r e n g t h machine, B e t t e r average r e s u l t s were obtained f o r cement-lime mortar panels t h a n t h o s e assembled with masonry cemenV mortar,The b e s t s i n g l e panel r e s u l t occurred, however, i n No, 11, a masonry cement mortar panel,

Visual examination revealed t h a t e x t e n t o f bond was n o t a s good a s f o r t h e prevlous group and a l s o t h a t t h e masonry cement panel had g r e a t e r e x t e n t of bond t h a n t h e cement-lime p a n e l s ,

There were small unbonded a r e a s i n t h e j o i n t s of t h e s e p a n e l s , and t h e perfmeters were n o t a s t i g h t a s i n previous panels.

General

Leakage,- D f s c o l o r a t f o n of cement-lime mortar j o i n t s i n d i c a t e s t h a t panels assembled with t h i s mortar absorbed more water t h a n t h o s e panels u s i n g masonry cement, This i s supported

by r e s u l t s l i s t e d i n t h e f o l l o w i n g t a b l e and obtained by weighing panels before and a f t e r t h e leakage t e s t ,

Ma s onry Cement Cement Lime Mortar Mortar Time I n t e r v a l P a n e l s P a n e l s 30 s e c 90.5

a

60 s e c 6 9 g m 78 i5m 117.Ogm 90 s e c 54 1 1 2 - 0 gmWATER ABSORBED

!BY

R.F,D BRICK PANELS DURING LEAKAGE TESTThe h i g h e r a b s o r p t i o n by t h e cement-lime p a n e l s may be due t o incomplete c a r b o n a t i o n of lime i n t h e m o r t a r s a f t e r t h e 14-day c u r i n g p e r i o d , From t h e s t a n d p o i n t o f leakage r e s u l t s t h e d i f f e r e n c e i n time i n t e r v a l i n assembling p a n e l s 1 t o 1 2 does n o t a p p e a r t o have any p a r t i c u l a r s i g n i f i c a n c e .

Bond S t r e n g t h

For t h e r e a s o n s mentioned p r e v i o u s l y a comparison of bond s t r e n g t h v a l u e s f o r t h e s e p a n e l s i s n o t s i g n i f i c a n t

,

b u ts e v e r a l c o n c l u s i o n s may be drawn from t h e r e s u l t s :

1) Values f o r cement-lime m o r t a r p a n e l s were somewhat h i g h e r t h a n f o r masonry cement p a n e l s .

2 ) Values f o r cement-lime p a n e l s d e c r e a s e a s t h e time i n t e r v a l i s i n c r e a s e d from 30 t o 90 seconds, T h i s t r e n d

was

n o t e v i d e n t , however,i n

r e s u l t s f o r masonry cement panels.V i s u a l examination i n d i c a t e d e x c e l l e n t e x t e n t of bond f o r 30- and 60-second p a n e l s while 90-second p a n e l s were n o t a s completely bonded,

Conclusions

B r i c k s

i n

t h e low s u c t i o n range bbnd s a t i s f a c t o r i l y w l t h masonry cement and cement-lime mortar u s i n g t h r e e time i n t e r v a l s1) From v i s u a l examination and r e c o r d s of w a t e r absorp- t i o n d u r i n g leakage t e s t s , masonry cement m o r t a r p a n e l s a r e

s l i g h t l y s u p e r i o r i n r e s i s t a n c e t o leakage t h a n cement-lime m o r t a r p a n e l s a f t e r

1 4

days c u r i n g p e r i o d .2 ) Bond s t r e n g t h v a l u e s a r e somewhat h i g h e r f o r cement- lime m o r t a r p a n e l s t h a n f o r masonry cement m o r t a r p a n e l s .

3 ) Bond s t r e n g t h v a l u e s and v i s u a l examinations i n d i c a t e d e c r e a s i n g e x t e n t of bond a s t i m e f a c t o r i n c r e a s e s i n t h e c a s e of cement-lime mortar,

R e s u l t s from p a n e l s 1 3 t o 24

This group of p a n e l s was a d u p l i c a t e of t h e f i r s t twelve s u b s t i t u t i n g b u f f b r i c k s i n t h e I . R o A . range 11.0 t o 16.8 gm f o r t h e r e d b r i c k s p r e v i o u s l y used. The same two m o r t a r s were used i n t h e low-flow range--average flow b e i n g 108.1 p e r c e n t - - w i t h a heavy t a p . Again t h e t i m e i n t e r v a l was t h e v a r i a b l e , f o u r p a n e l s (dup- l i c a t e s w i t h each of t h e t w o m o r t a r s ) b e i n g assembled w i t h each of t h e t h r e e t i m e s 30, 60, and 90 seconds, R e s u l t s a r e summarized i n Table V I and t h e n d i s c u s s e d . TABLE V I General Summary

- -

P a n e l s 1 3 t o 24 Leakage 30 Sec r i i l n i l 60 Sec 90 Sec Bond 1: 3 2 3 , 1 p s i 20,3 p s i 1 4 ~ 0 p s i S t r e n g t h 1:1:6 68.9 p s i 38.8 p s i 2 5 . 1 p s i 2:. One p a n e l d i d n o t l e a k - - o t h e r one l e a k e d 1,124 ml, ( a ) P a n e l s 1 3 t o 16o n l y i n d i c a t i o n of m o i s t u r e p e n e t r a t i o n was i n s l i g h t d i s c o l o r a t i o n a t t h e e n d s of two of t h e m o r t a r j o i n t s i n p a n e l 1 6 which had b e e n assembled w i t h a cement-lime m o r t a r . Bond s t r e n g t h v a l u e s , a l l o b t a i n e d w i t h t h e new bond s t r e n g t h a p p a r a t u s a f t e r c u r i n g p e r i o d s of 79 t o 8 3 d a y s , a r e l i s t e d i n T a b l e V I I .

TABLE

V I IBond S t r e n g t h R e s u l t s ( p s i ) , - - P a n e l s 1 3 t o 1 6 P a n e l

No, Age a t T e s t J o i n t # l J o i n t # 2

-

J o i n t # 3 ~ o i n t & Average1 3 8 3 days 21.6 30.0 40.3 2 3 * 4 28.8

1 4 82 d a y s 79 o 0 78.2 64.5 56 4 69.5

1 5

82 d a y s 13.7 1 6 . 8 20.6 l 8 , 5 1 7 . 4 1 6 79 d a y s 8 0 , 6 55.6 6 2 , 9 7 4 0 2 6 8 , 3R e s u l t s f o r p a n e l s 1 4 and 1 6 (cement-lime m o r t a r s ) a r e much h i g h e r a t 68,9 p s i t h a n t h e 23.1 p s i v a l u e f o r masonry cement m o r t a r p a n e l s . V i s u a l e x a m i n a t i o n of b r o k e n j o i n t s r e v e a l e d good e x t e n t of bond, b u t n o t q u i t e a s good a s t h e e x t e n t of bond s e e n w i t h t h e r e d b r i c k s . The b o n d i n g was n o t a s good a b o u t t h e p e r i - m e t e r s , and s m a l l i n d e n t a t i o n s i n t h e s u r f a c e of t h e b r i c k were n o t c o m p l e t e l y f i l l e d w i t h m o r t a r ,

( b ) P a n e l s 1 7 t o 20

A l l f o u r p a n e l s l e a k e d , Only p a n e l 20, however, s t a r t e d

t o l e a k immediately. The o t h e r t h r e e p a n e l s s t a r t e d t o l e a k from

3

t o 5 m i n u t e s a f t e r t h e s t a r t of t e s t . P a n e l 1 7 had w a t e r showing on j o i n t 2 , b u t t h e l e a k d i d n o t c o n t i n u e and t h e r e was i n s u f f i c i e n t l e a k a g e t o run o f f t h e b a c k o f t h e p a n e l f o r measurement, The o t h e r masonry cement p a n e l , No, 1 9 , l e a k e d t h e most- -

1 , 1 2 4 m l , s t a r t i n g a t 5 m i n u t e s and l e a k i n g s t e a d i l y t h r o u g h o u t t h e t e s t . The cement-. l i m e m o r t a r p a n e l s l e a k e d 240 and 765 m l r e s p e c t i v e l y and d i f f e r e d from t h e masonry cement p a n e l s i n t h a t l e a k a g e s t o p p e d p r i o r t o t h eend of t e s t , p r o b a b l y due t o a s w e l l i n g s h u t of l e a k a g e p a t h s , Most of t h e l e a k a g e f o r t h e cement-lime m o r t a r p a n e l s o c c u r r e d d u r i n g t h e f i r s t h o u r of t e s t and d e c l i n e d k t e a d i l y t h e r e a f t e r . Maximum r a t e of l e a k a g e of 8 m l f o r p a n e l 20 o c c u r r e d between 1 0 and 60 m i n u t e s , Maximum r a t e s were a b o u t 2 - 0 m l f o r p a n e l 18 and 0 , 9 m l f o r p a n e l 1 9 . P a n e l 18 l e a k e d q u i t e p r o f u s e l y d u r i n g t h e f i r s t h o u r and t h e n d e c r e a s e d i n l e a k a g e r a t e ; p a n e l 1 9 l e a k e d s t e a d i l y t h r o u g h o u t t h e t e s t a s c a n be s e e n when l e a k a g e d u r i n g ' t h e f i r s t h o u r , 55 m l , i s compared w i t h t o t a l l e a k a g e o f 1 , 1 2 4 m l , TABLE VIII Bond S t r e n g t h R e s u l t s ( p s i )

--

P a n e l s 1 7 t o 20 Pane 1No. Age

a t

T e s t J o i n t # 1 J o i n t # 2 J o i n t # 3 J o i n t # 4 Average Broken d u r i n g 1 7 78 d a y s 37.1 22.6 s e t - u p 21,O 2 6 , 9 18 7 8 d a y s 65.3 75.8 5 8 , 8 2 0 0 2 5 5 0 0 Broken d u r i n g 1 9 74 d a y s 4 - 0 23.9 1 2 , 9 s e t - u p 1 3 6 Broken d u r i n g 20 73 d a y s s e t -up 2 4 - 2 10.0 17.2 1 7 . 1 A breakdown o f bond s t r e n g t h v a l u e s f o r t h e s e f o u r p a n e l s , 1 o b t a i n e da t

a g e 78 t o 7 3 d a y s , i s g i v e n i n T a b l e V I I I , Again a v e r a g e v a l u e f o r cement-lime m o r t a r p a n e l s a t 38,8 p s i i s b e t t e r t h a n t h e2 0 , 3 psi' v a l u e f o r masonry cement m o r t a r p a n e l s , Values f o r p a n e l s

1 9 and 20 a r e much l o w e r t h a n f o r t h e i r d u p l i c a t e s , p a n e l s

1 7

and 18. V i s u a l e x a m i n a t i o n r e v e a l e d a l e s s e r e x t e n t of bond t h a nin

t h e prevZ.ous p a n e l--

bonding w a s d e f i n i t e l y ' i n f e r i o r i n p e r i m e t e r a r e a s . Three m o r t a r j o i n t s were b r o k e n d u r i n g s e t t i n g - u p o p e r a t i o n smortar j o i n t s from panels

17,

18, and 1 9 can be seen i n Pig. 2. ( c ) Panels 21 t o 24Water came through mortar j o i n t s of a l l f o u r panels a s soon a s t h e leakage t e s t was s t a r t e d , b u t t h e r e was no measurable run-off u n t i l 3 t o

5

minutes because of t h e a b s o r p t i v e power of t h e b r i c k s . Masonry cement mortar panels leaked a n average of3,350,5 m l h i g h e r t h a n t h e 1,215

m l

average f o r t h e cement-lime mortar panels. Average maximum r a t e of leakage was h i g h e r f o r t h ecement-lime mortar panels a t 1 3 m l a s compared with t h e 11 m l r a t e f o r t h e masonry cement mortar panels. Maximum leakage occurred d u r i n g t h e f i r s t 1 0 t o 1 5 minutes of leakage t e s t f o r both p a n e l s , The cement-lime mortar panels leaked more d u r i n g t h e f i r s t hour and t h e n leakage r a t e decreased u n t i l t h e r e was no a p p r e c i a b l e leakage n e a r t h e end of t h e t e s t ; t h e masonry cement mortar panels leaked q u i t e s t e a d i l y throughout t h e t e s t . The r a t e of leakage d u r i n g t h e l a s t hour was only 30 t o 40 p e r c e n t of t h a t , d u r i n g t h e f i r s t hour b u t was s t i l l q u i t e s u b s t a n t i a l , Bond s t r e n g t h t e s t s were done a t c u r i n g p e r i o d s of 72 t o

76

days; a breakdown of r e s u l t s i s presented i n TableIX.

TABLE I X

Bond S t r e n g t h R e s u l t s ( p s i )

--

Panels 21 t o 24 Pane 1NO. Age a t Test J o i n t # - 1 J o i n t # 2 ~ o i n t # 3 Broken Broken during d u r i n g 21 75 days 15.3 s e t - u p s e t - u p Broken d u r i n g 22 76 days 20,2 43*5 s e t - u p , I 1 23 73 days 28.4 19,O 4 - 0 24 72 days 27,O 21.8 21.3 J o i n W 4 Average 1 7 - 0 26.9 Broken d u r i n g s e t - u p 17.1 Broken d u r i n g s e t - u p 23-0

Cement-lime m o r t a r p a n e l s had a h i g h e r average bond s t r e n g t h a t 2 5 , l p s i t h a n masonry cement p a n e l s a t

1 4 , O

p s i ,Values a r e lower t h a n t h o s e f o r 60-second p a n e l s , and t h e i n c r e a s e d number o f broken j o i n t s can a l s o be a t t r i b u t e d t o l e s s e r degree of bonding, Visual examination r e v e a l e d v e r y l i t t l e e x t e n t of bond. J o i n t s appeared t o be "dry" and i n a l l c a s e s t h e t o p b r i c k l i f t e d c l e a n l y from t h e mortar bed c o n t r a s t i n g w i t h p r e v i o u s p a n e l s where b r e a k s occurred through mortar beds o r where p a r t of m o r t a r bed

clung t o ypper b r i c k when f r a c t u r e d , Leak channels were found i n s e v e r a l c a s e s , n o t a b l y i n p a n e l 24, b u t t h e y were n o t a r e s u l t o f slumping i n t h e m o r t a r beds, a change i n t e c h n i q u e having e l i m i n a t e d t h i s problem, Ekamination o f t h e bond s t r e n g t h r e s u l t s i n Table I X p o i n t s up a n o t h e r i n t e r e s t i n g f e a t u r e a l s o n o t e d i n l a t e r r e s u l t s , B e s t bond s t r e n g t h v a l u e s occur i n upper j o i n t s of p a n e l s r a t h e r t h a n i n lower j o i n t s a s might be expected s i n c e lower ~ o i n t s have a d d i t i o n a l " t a p s r t given t o b r i c k s above and a l s o c a r r y a d d i t i o n a l weight o f upper b r i c k s d u r i n g t h e s e t t i n g p e r i o d , There may be

s e v e r a l r e a s o n s f o r t h i s t r e n d :

1) Tapping o f upper b r i c k s may d i s t v b bond i n lower j o i n t s where mortar h a s

n o t

y e t had a chance t o harden enough t o r e s i s t s t r a i n--

t h i s i s p a r t i c u l a r l y n o t i c e a b l e where m o r t a r h a s l o s t a l o t of moisture needed f o r p l a s t i c i t y a si n

t h e above c a s e ,2 ) 'Phe "shockrt of b r e a k i n g t o p j o i n t s may weaken t h o s e

below and t h u s c o n t r i b u t e t o lower v a l u e s f o r t h e s e ~ o i n t s . General

This s e r i e s of twelve p a n e l s g i v e s a n e x c e l l e n t p i c t u r e of t h e e f f e c t of tfme i n t e r v a l d u r i n g p a n e l assembly, Leakage and bond s t r e n g t h r e s u l t s a r e f u r t h e r supported by t h e w a t e r

absorbed by t h e p a n e l s d u r i n g t h e leakqge t e s t a s shown i n Fig,

3,

A comparison of leakage and bond s t r e n g t h r e s u l t s f o r t h e s e twelve p a n e l s i n d i c a t e s a s h a r p d e t e r i o r a t i o n of r e s u l t s a t

t h e 60-set. time i n t e r v a l . A t t h i s p o i n t t h e r e a r e some good leakage and bond s t r e n g t h r e s u l t s and some poor ones.

Conclusions

1) Leakage and bond s t r e n g t h r e s u l t s d e t e r i o r a t e p r o g r e s s i v e l y w i t h l e n g t h e n i n g of t h e time i n t e r v a l between p l a c i n g a mortar bed and l a y i n g buff b r i c k s ( I . R . A . 11.0 t o 16.8 gm) i n t h e mortar.

2 ) For t h e c o n d i t i o n s under which t h i s s e r i e s of panels was

assembled t h e c r i t i c a l time f o r p l a c i n g buff b r i c k , i , e . t h e time l i m i t f o r p l a c i n g b r i c k s i n mortar t o o b t a i n s a t i s f a c t o r y bond, i s something l e s s t h a n 60 seconds.

Panels 25 t o 32

Eight panels were assembled w i t h r e d b r i c k s i n t h e I . R , A , range 1.0 t o 2.7 gm, t h e same two m o r t a r s , 30- and 60-sec time i n t e r v a l s , 'Ilut w i t h l i g h t t a p f o r a comparison w l t h panels 1 t o 8

(heavy t a p ) . The masonry cement and cement-lime mortars used had a n average flow of 111.3 p e r c e n t a s compared w i t h 107"6 p e r c e n t f o r panels

5

t o 12. R e s u l t s w i l l f i r s t be discussed a s a group and l a t e r compared w i t h t h e heavy t a p panels.TABLE

X

Mortar Used Ma s onry Cement ( 1 : 3 ) Cement Lime ( 1 : 1 : 6 )General Summary

--

Panels 25 t o 32Leakage R e s u l t s Bond S t r e n g t h ( p s i ) 30 Sec 60 Sec 30 Sec 60 Sec

n i l n i l 37.6 17.9

Mortar Mortar

203rs

j o i n t s75%

( a ) Panels 25 t o 28

There was no leakage f o r any of t h e f o u r 60-sec panels. D i s c o l o r a t i o n of s i x of t h e e i g h t mortar j o i n t s i n d i c a t e d some moisture p e n e t r a t i o n of cement -lime mortar panels. A breakdown of bond s t r e n g t h v a l u e s f o r t h e f o u r panels i s given i n Table X I ,

Bond S t r e n g t h R e s u l t s ( p s i )

--

Panels 25 t o 28 PanelNo. A g e a t Test J o i n t # l J o i n t & 2 J o i n t # 3 Joint Average

-

25 31 days 21.3 12.4 1 6 , 9 2.6 1 3 0 3

26 70 days 48.2 20.3 31.7 42 6 5 35.7

27 32 days 28.4 26,7

29.9

4 0 5 22,428 28 days 54.2 22.9 30.1

410

3 37.1Average value of 36,4 p s i f o r cement-lime mortar panels i s twice t h e average value of

17.9

p s i f o r masonry cement p a n e l s , Age of panels a t time of t e s t was 28 t o 32 days, Visual examina- t i o n r e v e a l e d good e x t e n t of bond i n a l l c a s e s w i t h p a r t i c u l a r l ygood bonding about t h e perimeters. There were some small unbonded a r e a s i n t h e c e n t r e p o r t i o n of t h e mortar beds, I n a l l c a s e s t h e t o p b r i c k l i f t e d from t h e mortar bed a t f r a c t u r e .

( b ) Panels 29 t o 32

There was no leakage f o r t h e 30-sec panels. Some mois- t u r e p e n e t r a t i o n was i n d i c a t e d i n t h e cement-lime mortar j o i n t s by d i s c o l o u r i n g of f i v e of t h e e i g h t mortar j o i n t s f o r t h e s e two p a n e l s ,

TABLE X I 1

Bond S t r e n g t h R e s u l t s ( p s i )

--

P a n e l s 29 t o 32 Pane 1No. Age a t T e s t J o i n t # l , J o i n t # 2 J o i n t # 3 J o i n t #4 Average 29 27 days 14.4 29.6 43.0 30.1 2 9 & 3 30 21 days 3 4 * 1 39.6 70.9 58.5 50.8 31 21 days 42.5 45.5 45.8 50.0 45.9 32 21 days 38.9 73.0 48.2 65.4 56.4 Once a g a i n a v e r a g e r e s u l t of 53.6 p s i f o r cement-lime m o r t a r p a n e l s i s s u p e r i o r t o t h e 37.6 p s i v a l u e f o r masonry cement m o r t a r p a n e l s . Vfsual e x a m i n a t i o n r e v e a l e d n i c e t i g h t p e r i m e t e r s and g e n e r a l l y good e x t e n t of bond w i t h some s m a l l unbonded a r e a s

i n t h e c e n t r e of m o r t a r beds. Some of t h e cement-lime m o r t a r j o i n t s f r a c t u r e d t h r o u g h t h e m o r t a r b e d s , b u t f r a c t u r e s g e n e r a l l y f o l l o w e d t h e p a t t e r n of b r e a k i n g between t o p b r i c k and m o r t a r bed, Some of t h e cement-lime m o r t a r beds were damp a t t i m e of f r a c t u r e , P a n e l 29 was t e s t e d a t a g e 27 d a y s , It was t h e l a s t of t h e b a c k l o g a w a i t i n g bond s t r e n g t h t e s t and r e m a i n i n g p a n e l s were t e s t e d a t t h e u s u a l 2 1 days. F o r t y p i c a l m o r t a r j o i n t s from p a n e l s Nos. 30 and 31 s e e F i g ,

4 ,

bottom row.Genera 1

P i g m e 5 shows w a t e r a b s o r p t i o n by b o t h 30- and 60-sec p a n e l s d u r i n g t h e l e a k a g e t e s t .

Both 30- and 60-sec p a n e l s assembled w i t h masonry cement a b s o r b e d i d e n t i c a l amounts of w a t e r ; t h e 30-sec cement - l i m e p a n e l was o n l y s l i g h t l y b e t t e r t h a n t h e 60-sec p a n e l . On t h e b a s i s o f m o i s t u r e a b s o r p t i o n r e s u l t s and v i s u a l o b s e r v a t i o n s of l e a k a g e t e s t s , t i g h t e s t p a n e l s r e s u l t from u s e of masonry cement m o r t a r s , w h i l e bond s t r e n g t h r e s u l t s show t h a t s t r o n g e r bond d e v e l o p s

between t h i s b r i c k and cement-lime m o r t a r . Bond s t r e n g t h r e s u l t s a l s o i n d i c a t e s u p e r i o r i t y of 30-sec p a n e l s o v e r 60-sec p a n e l s .

Comparison o f Light and Heavy Tap

Panels 24 t o 32 vs Panels 1 t o 8

-

Lea?xage,- Results of leakaget e s t s f o r panels o f low-suction b r i c k s and masonry cement and cement- lime mortars, assembled with l i g h t and heavy t a p a s t h e v a r i a b l e , i n d i c a t e very l i t t l e d i f f e r e n c e between t h e two t a p s ,

1) m e r e was no leakage f o r any o f t h e panels.

2 ) There was some s l i g h t d i s c o l o r a t i o n o f j o i n t s i n panels of masonry cement mortar and assembled with heavy t a p ,

3 ) Masonry cement mortar panels assembled with heavy t a p absorbed more water during t h e leakage t e s t than l i g h t t a p panels ( F i g , 61,

4 )

Moisture absorption f o r cement-lime mortar panels was s l i g h t l y higher f o r l i g h t t a p than f o r heavy t a p panels,Thus f r o m leakage r e s u l t s t h e r e i s no r e a l evidence i n favour of using e i t h e r l i g h t o r heavy t a p i n assembling l o w s u c t i o n b r i c k s with e i t h e r of t h e above mortars. Evidence favouring l i g h t t a p with masonry cement mortar and heavy t a p with cement-lime

mortar i s i n d i c a t e d only by comparison of water absorbed by t h e panels during t e s t ,

Bond Strength Results

A comparison o f bond s t r e n g t h values f o r t h e s e panels i n d i c a t e s b e n e f i t f r o m t h e use o f the heavy t a p .

C!oppafilbn o f Bond ~ t a e n g - t h Values ( p s i ) For Panels Assembled With Light and Heavy Tap

Tap Light Heavy

30-Sec Panels 60-Sec Panels

Ma s onry Cement

-

Ma s onry Cement-

Cement Lime Cement Lime *

Mortar Mortar Mortar Mortar

3T06 53*6 1 7 0 9 36.4

It must be remembered, however, t h a t v a l u e s f o r heavy t a p panels were obtained with t h r e e d i f f e r e n t machines and a r e t h e r e f o r e o f l i m i t e d value i n a comparison of t h i s n a t u r e , R e s u l t s from Panels

33

t o 40In

previous work with buff b r i c k s having s u c t i o n r a t e s ranging f r o m 11 t o 16,8, t h e r e was some d i f f i c u l t y i n g e t t i n g a leak-proof panel. With t h i s i n mind,a

s e r i e s of e i g h t panels was assembled u s i n g buff b r i c k s ( I . R . A , range1 1 . 4

t o l6,O gm) with t h e same t w o mortars w i t h a h i g h e r ffow range(115

t o 125 p e r c e n t ) . The average mortar flow f o r t h e e i g h t panels was 119-2 p e r c e n t . Two time i n t e r v a l s , 30 and 60 s e c , were used and a l l panels were assembled with heavy t a p , Again a l l panels were assembled i nd u p l i c a t e . R e s u l t s a r e summarized in Table X I V and t h e n discussed i n d e t a i l .

T m L E X I V

General Summary

--

Panels33

t o 40Mortar Used Leakage R e s u l t s Bond S t r e n g t h ( p s i )

30 Sec 60 Sec 30 Sec 60 Sec

Na s onry

Cement ( 1 : 3 ) n i l n i l 21,6 21,7

Cement-

Lime (1:1:6)

n i l

n i l 72*95S09

( a ) Panels

33

t o 36-

LeakageThere were no l e a k s n o r was t h e r e any d i s c o l o r a t i o n o f mortar j o i n t s f o r t h e f o u r 30-sec panels u s i n g e i t h e r type o f

1 mortar,

Bond S t r e n g t h

Bond s t r e n g t h v a l u e s f o r t h e f o u r panels a r e l i s t e d i n Table XV.

TABLE

XVBond S t r e n g t h R e s u l t s ( p s i )

--

Panels 33 t o 36 PanelNo. Age a t Test J o i n t #1 J o i n t # 2 J o i n t #3 J o i n t # 4 Average

33 23 days 33.9 37 1 20,6 7 0 1 24,0 7

34 21 days g3,9 62,9 74 2 5 0 - 3 70- 3

35

21 days 7 o 7 35.2 6.8 24,2 1 8 , 536 21 days 74,2 82,6 89.0 5 6 , s 75 a 7

These panels were t e s t e d a f t e r t h e normal c u r i n g p e r i o d of 2 1 t o 23 days

--

average bond s t r e n g t h of 72.9 p s i f o r cement- lime mortars was much h i g h e r t h a n t h e 21,6 p s i value f o r masonry cemenk mortar,Visual examination of broken masonry cement p a n e l s r e v e a l e d much g r e a t e r e x t e n t of bond t h a n would be expected from t h e v a l u e s obtained, There was good e x t e n t o f bond i n a l l c a s e s , some small unbonded a r e a s being noted about t h e p e r i m e t e r s , These probably developed a s a r e s u l t of some of t h i s very p l a s t i c mortar being f o r c e d out o f t h e mortar j o i n t by t h e heavy t a p , There was e x c e l l e n t e x t e n t o f bond f o r t h e cement-lime mortar panels. M o s t breaks occurred through t h e mortar beds r a t h e r t h a n between t h e t o p b r i c k and mortar bed a s f n t h e case o f t h e masonry cement panels ( s e e Pig,

4 ,

t o p row), S e v e r a l of t h e cement-lime mortar beds were s t i l l damp when t h e j o i n t s were broken,Sometimes t h e r e was a n i n c o n s i s t e n c y o f r e s u l t s w i t h i n t h e same panel: Note t h e spread i n v a l u e s from 7 , 1 p s i t o 3 7 , l p s i f o r panel 1 and from 50,3 p s i t o 93,9 p s i f o r panel 2, This p a t t e r n

o f i n c o n s i s t e n c y i s c h a r a c t e r i s t i c o f a l l DBR bond s t r e n g t h t e s t s on small panels, Bond s t r e n g t h t e s t s a r e , however, providing

v a l u a b l e information. Since a b s o l u t e bond s t r e n g t h v a l u e s a r e n o t of prime concern i n t h i s s t u d y , i n c o n s i s t e n c y i n v a l u e s i s simply noted f o r t h e r e c o r d ,

( b ) P a n e l s 37 t o 40

-

LeakageThere was n o l e a k a g e and n o d i s c o l o r a t i o n of m o r t a r j o i n t s f o r a n y of t h e f o u r 6 0 - s e c p a n e l s , Bond S t r e n g t h Bond s t r e n g t h v a l u e s d e t e r m i n e d a t 20 t o 2 2 d a y s a r e g i v e n i n T a b l e X V I , Once a g a i n t h e a v e r a g e v a l u e of 59,G p s i f o r t h e cement-lime r p o ~ a r p a n e l s 1s much h i g h e r t h a n t h e 2 1 , 7 p s i v a l u e o b t a i n e d f o r t h e masonry cement m o r t a r p a n e l s , TABLE X V I Bond S t r e n R t h R e s u l t s ( ~ s i )

-

P a n e l s 37 t o 40 P a n e lNo. Age a t T e s t Joint -

k!L

J o i n t #2 J o i n t#3

J o i n t #4 Average37 20 d a y s 3 y 0

9

1 8 . 7 4 e 8 29,O 21,638 22 d a y s 8 7 1 7 3 0 4 5 3 0 2 3 3 0 9 6 1 , 3

39 21 d a y s 1 2 , l 29.0 z 0 5 20 .'7 21.8

40 2 1 d a y s 6 3 . 3 64.5 53.2 3 7 0 1 56,O

The a v e r a g e v a l u e f o r cemen%-ilme m o r t a r p a n e l s i s l o w e r e d by low v a l u e s I n t h e bottom j o l n t o f b o t h p a n e l s Nos, 38 a n d 40, The o c c u r r e n c e of low v a l u e s I n t h e bcttorn j o i n t of p a n e l s i s s i m i - l a r t o t h e d i s c r e p a n c y o f j o i n t - t o - j o i n t v a l u e s i n t h e same p a n e l , a n u n e x p e c t e d r e s u l t i n bond s t r e n g t h t e s t s , T h i s m a t t e r w i l l b e r e f e r r e d t o l a t e r ,

V ~ s u a ; examination a g a i n r e v e a l e d good e x t e n t o f bond, I n t h e masonry cement p a n e l s it i s a g a i n a c a s e of good e x t e n t of bond b u t no s t r e n g t h , Wlth t h e s e p a n e l s t h e t o p b r i c k i n v a n a b l y l i f t e d o f f t h e m o r t a r b e d ; b r e a k i n g of cement - l i m e m o r t a r j o i n t s was u s u a l l y accompanied b y a shattering o f t h e m o r t a r j o i n t

- -

many brealrs o c c u r r e d d l r e c t l y t h r o u g h t h e , m o r t a r bed i t s e l f and i n some c a s e s t h e b r e a k o c c u r r e d between t h e m o r t a r bed a n d t h e l o w e rb r i c k , Typical mortar j o i n t s from t h e s e panels a r e shown i n Fig, 7 . General Conclusions

A l l panels i n t h i s s e r i e s performed w e l l d u r i n g leakage

t e s t s , There was no obvious d i f f e r e n c e be-bween 30- and 60-sec p a n e l s , A comparison of water absorbed d u r i n g t h e leakage t e s t f o r 30- and 60-sec panels w i t h both mortars shows very l i t t l e d i f f e r e n c e ( f i g , 8 ) .

Bond s t r e n g t h v a l u e s i n d i c a t e g r e a t e r s t r e n g t h of cement- lime ,over masonry cement mortars. Values f o r 30- and 60-sec masonry cement panels a r e comparable, but 30-sec panel r e s u l t s a r e s u p e r i o r t o 60-sec panel r e s u l t s f o r cement-lime mortar panels.

Visual examination r e v e a l e d a good e x t e n t of bond f o r a l l panels. Some small unbonded a r e a s about t h e p e r i m e t e r of masonry cement panels p o s s i b l y r e s u l t from mortar being f o r c e d from t h e j o i n t by t h e heavy t a p , There was e x c e l l e n t e x t e n t of bond f o r cement-lime p a n e l s ,

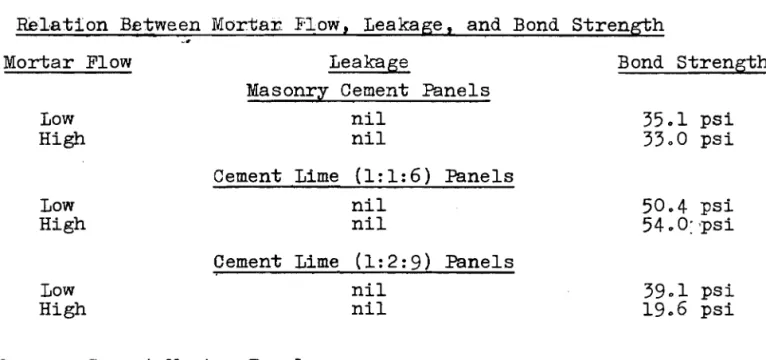

Comparison of High and Low Plow Mortars

Leakage and bond s t r e n g t h r e s u l t s f o r panels assembled with l o w and h i g h f l o w mortars a r e compared i n Table X V I I where r e s u l t s f o r panels 12 t o 20 a r e compared with r e s u l t s f o r p a n e l s 32 t o 40. Average f l o w o f mortars used i n t h e former panels was 109 p e r c e n t while flow f o r t h e l a t t e r was 119,Z p e r c e n t , Bricks were buff i n t h e I.R.A. range 1 1 t o 16.7 gm. Panels were assembled w i t h t w o time i n t e r v a l s

- -

30 and 60 s e c and t h e heavy t a p wasTABLE X V I I

Comparison of High and Low Plow Panel? Masonry Cement

Leakage R e s u l t s Bond S t r e n g t h R e s u l t s

mow

-

30 Sec 60 Sec 30 Sec 60 SecLow n i l 562 m l 2 3 , l 2 0 0 3

High n i l n i l 21a6 21.7

Cement-Lime Mortar

Leakage R e s u l t s Bond S t r e n g t h R e s u l t s Flow

-

30 Sec 60 Sec 30 Sec 60 SeeLow n i l 502 m l 68.9 3 8 , s

High n i l n i l 7Z09 58,9

TABLE X V I I I

Comparison of Water Absorbed by Panels Assembled w i t h High and Low Flow Mortars During Leakage Test

Masonry Cement Cement -Lime

Flow 30 Sec 60 Sec 30 Sec 60 Sec

Low 597 gm 734 @ 610 gm 723 gm

High 496 gm 420 gm 418 gm 431 gm

It can be seen t h a t panels assembled with h i g h flow mortars were s u p e r i o r t o t h o s e assembled w i t h l o w flow mortars, This conclusion i s supported by leakage r e s u l t s and a l s o by com- p a r i s o n of w a t e r absorbed by t h e p a n e l s d u r i n g leakage t e s t s , There i s v e r y l i t t l e d i f f e r e n c e f o r panels assembled w i t h 30-sec

time i n t e r v a l , There

was

no leakage o r evidence of leakage f o r any of t h e s e panels w i t h t h e exception of some d i s c o l o r a t i o n a t t h e end of one of t h e cement-lime mortar j o i n t s i n a p a n e l assembledw i t h a low flow mortar, However, panels u s i n g h i g h flow mortars

had t i g h t e s t j o i n t s according t o lower moisture a b s o r p t i o n d u r i n g leakage t e s t s ,

Bond s t r e n g t h r e s u l t s a r e comparable f o r h i g h and low flow panels assembled a t 30 s e c , S l i g h t l y h i g h e r values f o r low flow masonry cement panels a r e o f f s e t by s i m i l a r l y h i g h e r v a l u e s f o r h i g h flow cement-lime panels. However, f o r 60-sec panels high flow mortars give b e s t bond s t r e n g t h r e s u l t s , p a r t i c u l a r l y f o r

I

cement-lime mortar; t h e d i f f e r e n c e i s n o t g r e a t f o r masonry cement mortar,

Conclusions

High f l o w mortars bond buff b r i c k s i n t h e s u c t i o n range based on leakage r e s u l t s alrkady

b e t t e r t h a n low flow mortars with 1

11 t o 15 gm, This conclusion i s shown and, t o a l e s s e r degree, bond s t r e n g t h r e s u l t s ,

It i s i n t e r e s t i n g t o note t h a t only minor d i f f e r e n c e s occur i n panels assembled with a 30-sec time i n t e r v a l , There i s , however, a marked d i f f e r e n c e i n r e s u l t s f o r panels assembled with a 60-sec time i n t e r v a l ,

R e s u l t s from Panels

4 1

t o 48Panels

4 1

t o4 8

were d u p l i c a t e s o f t h e previous e i g h t panels u s i n g a b r i c k having a lower s u c t i o n r a t e , B u f f b r i c k s wLth a n I , R , A , range 8 t o 10 gm were used w i t h masonry cement andcement-lime mortars having h i g h f l o w , Panels were assembled a t 30- and 60-sec time i n t e r v a l s u s i n g heavy t a p ,

Results a r e l i s t d d i n Table X I X and t h e n discussed i n more d e t a i l , Average flow f o r mortars used was 123,4 p e r c e n t .

TABLE X I X

G e n e r a l Summary

--

P a n e l s 4 1 t o 48M o r t a r Used Leakage R e s u l t s Bond S t r e n g t h ( p s i ) 30 Sec 60 Sec

--

30 Sec 6 0 Sec Ma s o n r y Cement ( 1 : 3 )n i l

n i l 22.9 25.3 Cement- Lime ( 1 : 1 : 6 ) n i l n i l 50.2 55.1 ( a ) P a n e l s 4 1 t o 44 LeakageThere was n o l e a k a g e n o r was t h e r e a n y i n d i c a t i o n o f m o i s t u r e p e n e t r a t i o n b y d i s c o l o r a t i o n of m o r t a r j o i n t s i n a n y of t h e f o u r

30-sec p a n e l s , Bond S t r e n g t h

A l l p a n e l s were t e s t e d a f t e r t h e n o r m a l c u r i n g p e r i o > d o f 2 1 t o 22 d a y s . Average v a l u e of 50.2 p s i f o r cement-lime m o r t a r p a n e l s was h i g h e r than t h e 23,O p s i v a l u e f o r masonry cement m o r t a r p a n e l s , There was g r e a t v a r i a t i o n

i n

r e s u l t s . P a n e l 4 1 a v e r a g e d 1 6 , 3 p s i vs 29.7 p s i f o r p a n e l 42; p a n e l 4 3 a v e r a g e d 38.1 p s i v s 6 2 , 3 p s i f o r p a n e l 44. Values f o r p a n e l s 4 1 a n d 42 (masonry cement) r a n g e d from 9.7 t o 38.0 p s i w h i l e t h e e i g h t cement-lime m o r t a rp a n e l v a l u e s r a n g e d between 20.9 t o 80.6 p s i , TABLE

XX

Bond S t r e n g t h R e s u l t s ( p s i )

--

P a n e l s 4 1 t o 44 P a n e lNo. Age a t T e s t J o i n t $1 J o i n t #2 J o i n t

a 3

J o i n t #4 Average 4 1 2 1 d a y s 23.4 12.6 1903 9.7 16,,3 42 2 1 d a y s 25.8 38.0 34 • 0 2 1 - 0 29.7 4 3 2 1 d a y s 20,9 39.5 44.3 47.6 3 B a 1 44 22 d a y s 44.3 80.6 71,O 5 3 * 2 6 2 , 3V i s u a l e x a m i n a t i o n r e v e a l e d good e x t e n t o f bond

i n

a l l c a s e s , Some of t h e cement-lime m o r t a r j o i n t s were s t i l l damp when f r a c - t u r e d . M o r t a r j o i n t s f r o m p a n e l s Nos, 41, 42, a n d 44 a r e showni n

P i g o 9, ( b ) P a n e l s 45 t o 48 Again t h e r e was no l e a k a g e a n d n o i n d i c a t i o n of m o i s t u r e p e n e t ' r a t i o niy

d i s c o l o r a t i o n o f m o r t a r j o i n t s f o r a n y o f t h e 6 0 - s e c p a n e l s ,TABLE

XXI

Bond S t r e n g t h Results ( p s i )--

P a n e l s 45 t o 48 P a n e lNo. Age a t T e s t J o i n t #l J o i n t #2 J o i n t #3 J o i n t #4 Average 45 2 3 d a y s

17.7

49.7 28.2 3 1 0 4 3 1 846 22 d a y s 28,5 g 0 7 1 5 . 3 2 1 0 3

l 8 , 7

47 22 d a y s 56,4 4 0 0 3 5 0 - 3 4 3 0 5 47 6 48 2 1 d a y s 8 0 - 3 5 3 e 5 70 5 46 , O 62,G

Bond strength t e s t s were done a t 2 1 t o 23 d a y s . Values f o r cement-lime m o r t a r p a n e l s a v e r a g e d 5 5 , l p s i compared w i t h 2 5 , 3 p s i f o r masonry cement m o r t a r p a n d . ~ , G r e a t v a r i a t i o n i n v a l u e s o b t a i n e d was a g a i n n o t e d , V i s u a l e x a m i n a t i o n r e v e a l e d good e x t e n t of bond i n a l l c a s e s , Some o f t h e cement-lime m o r t a r j o i n t s f r a c - t u r e d t h r o u g h t h e m o r t a r b e d s w h i l e some j o i n t s of masonry cement m o r t a r ( p a n e l 4 5 ) f r a c t u r e d w i t h a " s h a t t e r i n g t t of t h e m o r t a r bed, Values f o r p a n e l 45 a r e amohg t h e b e s t f o r masonry cement m o r t a r . B t e n t of bond i n t h i s p a n e l a n d a l s o i n p a n e l s 47 a n d 48 c a n b e

General

Leakage r e s u l t s f o r both 30- and 60-sec panels a r e e x c e l l e n t , The water a b s o r p t i o n r e s u l t s during t h e leakage t e s t give a f i n e r comparison ( P i g . 11).

Results i n d i c a t e t h a t 30-sec masonry cement panels were t i g h t e r t h a n t h o s e assembled a t 60 s e c , There was no g r e a t d i f - f e r e n c e between t h e 30- and 60-sec panels f o r t h e cement-lime mortar panels, The 60-sec masonry cement panel absorbed t h e most water, but t h e r e was no r e a l d i f f e r e n c e between 30-sec panels with e i t h e r mortar,

Bond S t r e n g t h Results

Bond s t r e n g t h r e s u l t s a r e c o n s i s t e n t i n i n d i c a t i n g s u p e r i o r i t y o f cement-lime mortar, and v a l u e s f o r 60-sec panels a r e b e t t e r t h a n t h o s e f o r 30-sec panels, I n comparing t h e s e v a l u e s t h e g r e a t v a r i a t i o n i n r e s u l t s must be kept

in

mind, Por example, t h e low value f o r panel 43 i s t h e reason f o r t h e d i f f e r e n c e i n v a l u e s f o r 30- and 60-sec cement-lime mortar panels. On t h e o t h e r hand, v a l u e s f o r 30-sec masonry cement panels a r e c o n s i s t e n t l y lower t h a n 60-sec panel v a l u e s , Bond s t r e n g t h r e s u l t s i n d i c a t i n g s t r o n g e r bond f o r 60-sec masonry cement panels c o n f l i c t w i t hevidence shown by water a b s o r p t i o n during leakage t e s t s which i n d i c a t e d t h a t 30-sec panels had t h e t i g h t e s t j o i n t s ,

There was no leakage f o r panels assembled with e i t h e r b r i c k s i n t h e s u c t i o n range 8 t o 1 0 gm n o r i n t h e h i g h e r 1 1 t o

15

gmrange, Water a b s o r p t i o n by panels during leakage t e s t s , however, i n d i c a t e s t h a t b r i c k s i n t h e lower s u c t i o n range formed t h e t i g h t e s t panels, This evidence i s f u r t h e r supported by bond s t r e n g t h v a l u e s f o r t h e masonry cement mortar p a n e l s , but v a l u e s f o r cement-lime mortars a r e lower t h a n those f o r panels assembled with .the h i g h e r s u c t i o n b r i c k s ,

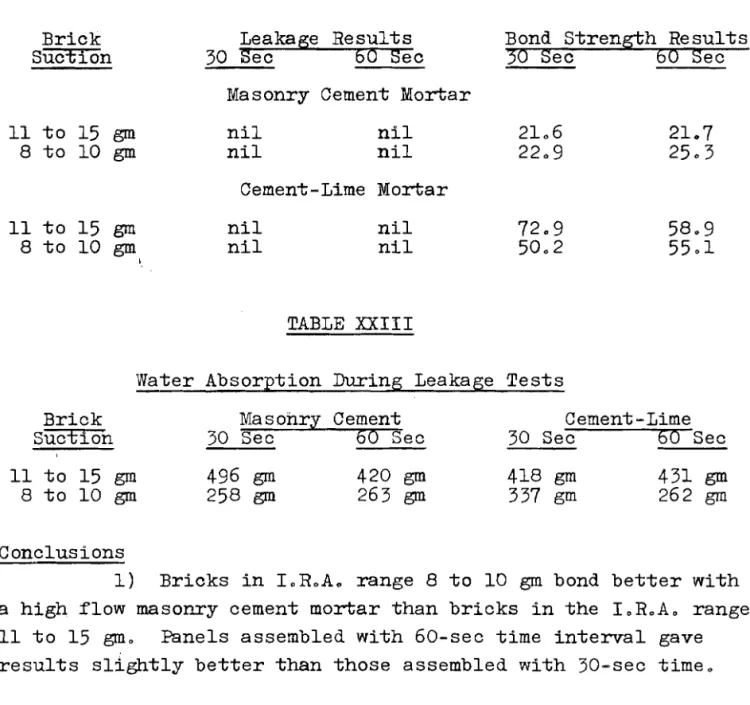

TABLE

XXII

Comparison of Panels Using Bricks 1,R.A. 11 t o 15 g m with Panels Using Bricks I o R , A . 8 t o 1 0 gm

Uslng Masonry Cement and Cement-Lime Mortars

Brick ~ u c t f o n

Leakage R e s u l t s

30 Sec 60 Sec

Masonry Cement Mortar

n i l n i l

n i l

n i l

Cement -Lime Mortar n i l n i l n i l n i l Bond S t r e n g t h Results 50 Sec 60 Sec TABLE X X I I I

Water Absorption During Leakage T e s t s Masonry Cement

30 Sec 60 Sec

Cement -Lime

30 Sec 60 Sec

Conclusions

1) Bricks i n I . R , A , range 8 t o 10 g m bond b e t t e r with a high f l o w masonry cement mortar t h a n b r i c k s i n t h e I ,R.A, range 11 t o 15 gm, Panels assembled with 60-sec time i n t e r v a l gave r e s u l t s s l i g h t l y b e t t e r t h a n t h o s e assembled with 30-sec time,

2 ) According t o leakage r e s u l t s , b r i c k s i n t h e s u c t i o n range 8

t b

10 gm bond s l i g h t l y b e t t e r with cement-lime mortars t h a n b r i c k s i n t h e h i g h e r s u c t i o n range, However, bond s t r e n g t h v a l u e s i n d i c a t e t h a t a s t r o n g e r bond i s formed by t h e h i g h e r s u c t i o n b r i c k s ,Panels assembled w i t h 30-sec time i n t e r v a l gave b e s t r e s u l t s w i t h h i g h e r s u c t i o n b r i c k s ; 60-sec panels were b e t t e r w i t h lower s u c t i o n b r i c k s .

3 ) This i n d i c a t e s t h a t a s t h 6 s u c t i o n of t h e b r i c k s d e c r e a s e s . . t h e time f a c t o r i n assembling b r i c k s becomes of l e s s

importance. I n f a c t , when u s i n g a h i g h flow mortar, it i s d e s i r a b l e t o allow a s h o r t time i n t e r v a l b e f o r e l a y i n g t h e second b r i c k s o t h a t t h e f i r s t b r i c k may repove any excess of water from t h e mortar,

I t t h e r e f o r e f o l l o w s t h a t f o r a b r i c k of known s u c t i o n t h e r e i s an optimum mortar moisture c o n t e n t a t which b e s t bond w i l l

occur between t h e two.

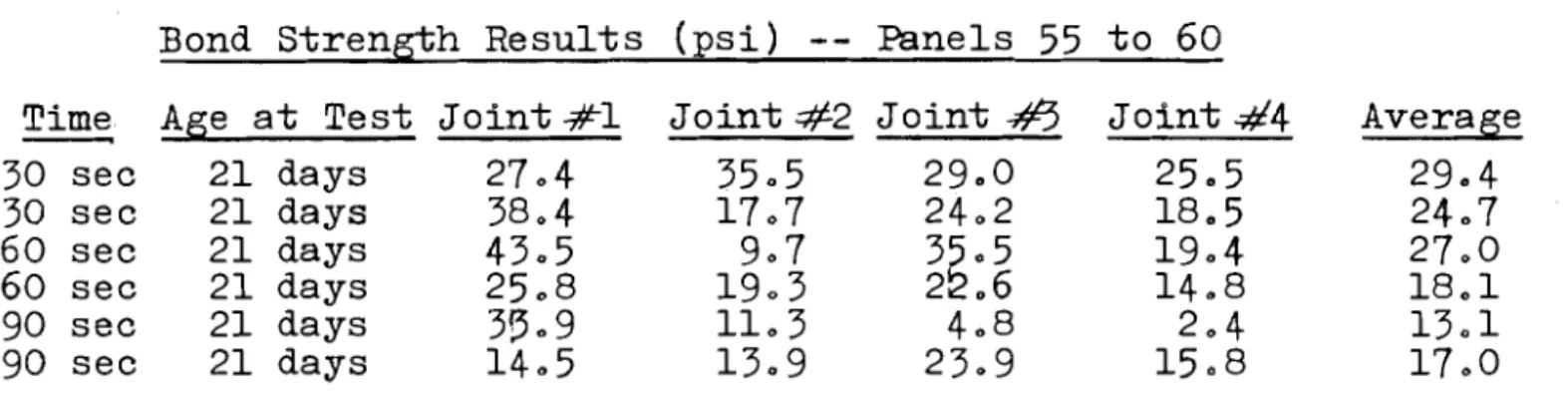

R e s u l t s from Panels 49 t o 54

I n reviewing t h e program t o d a t e it i s b e l i e v e d t h a t t h e r e should be a d d i t i o n a l evidence concerning t h e '%apt' f a c t o r

p a r t i c u l a r l y f o r t h e buff b r i c k s i n t h e s u c t i o n range 11 t o

1 5

0.Accordingly, s i x panels were assembled w i t h buff b r i c k s

i n

t h e s u c t i o n rdnge 1 0 - 6 t o 1 4 , 3 gm, t h r e e w i t h masonry cement mortar, and t h r e e w i t h cement-lime mortar, and one panel w i t h each mortar a t each of t h e f o l l o w i n g time i n t e r v a l s : 30, 60, and 90 seconds, Light t a p was used with low flow mortars, R e s u l t s a r e t o be com- pared w i t h t h o s e f o r panels 1 3 t o 24 f o r which t h e heavy t a p was used, Average f l o w f o r t h e six panels was 110,4 p e r c e n t , R e s u l t s a r e given i n Table X X I V and a r e t h e n discussled i n more d e t a i l , <( a ) Panels

49

t o5 1

!These panels were assembled w i t h masonry cement mortar, Panels

49

and 50, assembled with 30- and 60-sec time i n t e r v a l s , d i d n o t l e a k and t h e r e was no d i s c o l o u r i n g of mortar j o i n t s . How- e v e r , B n e l51,

assembled a t 90 seconds, leaxed immediately. T o t a l leakage d u r i n g t h e t e s t was 113 ml; of t h i s78

ml occurred d u r i n gt h e f i r s t hour of t e s t . llhe maximum leakage r a t e of 2,8 ml/min occurred between t h e f i f t h and t e n t h minute of t e s t .

TABLE XXIV

General Summary

--

Panels49

t o54

Bond S t r e n g t h Values Leaka e R e s u l t s

Mortar Used 30 Sec e c 30 Sec

6

w

90 SecM ~ S O N Y Cement (1:3) n i 1 n i l 113.0 r n l 17,4 10.4 6 , 9 Cement Lime (1:1:6) n i l 6 0 5

m l

6,0 m l 25.4 16,9 8 - 0 Bond S t r e n g t h Bond s t r e n g t h r e s u l t s a r e l i s t e di n

Table XXV, TABLE XXV Bond S t r e n g t h R e s u l t s ( p s i )--

Panels49

t o5 1

PanelNo, Age a t Test J o i n t # l J o i n t # 2 J o i n t & 3 J o i n t & Average

49

21 days 28.4 20.2 4.8 1 6 . 1 174

50 21 days 1 4 - 2 24.2 l , 6 1 0 6 10,4

5 1

22 days 0 5,6 21,8 0 69

Bond s t r e n g t h v a l u e s give a good p i c t u r e of t h e time

e f f e c t , Values s t e a d i l y decrease a s t h e time i n t e r v a l i s i n c r e a s e d from 30 t o 90 seconds, The l a s t t w o j o i n t s o f panel 50 and j o i n t s

1 and 4 of panel

5 1

had n e g l i g i b l e o r very low s t r e n g t h s . S i m i l a r l y t h e r e was a low s t r e n g t h f o r j o i n t 3 of panel49.

A l l of t h e s ev a l u e s were included i n t h e a v e r a g e s , b u t t h e r e l a t i v e r a t i n g of t h e v a r i o u s t e s t s would n o t have been changed had t h e y been omdtted,