Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Institute for Research in

Construction), 1986

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=a7ebf32f-f0e6-49f8-bf35-ea7088155aa5

https://publications-cnrc.canada.ca/fra/voir/objet/?id=a7ebf32f-f0e6-49f8-bf35-ea7088155aa5

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001373

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Residual strength of fire-exposed reinforced concrete columns

Lie, T. T.; Rowe, T. J.; Lin, T. D.

I

Ser

THI.

Natlonal Research

Condl

naknrd

IY21d

9

Councl

M.

d.

nchnehr-

0.

1412

c .

2

Institute for

lnstitut de

BLDG

Research in

recherche en

-- 1

Construction

construction

Reddual Strength

of

F b

Exposed Reinforced

Concrete

Columns

by T.T. Lie,

T.J. Rowe and T.D. Lin

Reprinted from

"Evaluation and Repair of Fire Damage to Concrete"

American -Concrete lnstitute

SP 92-9, 1986, p. 153-174

(IRC Paper No. 1412)

Price $2.00

NRCC 26486

I NRC-

CIS71I R C

L I B R A R Y

JAN

16 ;?Ei

B I B L ~ O T H ~ Q U E

1 R C

CNRC-

IClSTd i f f d r e n t e s p e r i o d e s , p u i s r e f r o i d i s . C e t t e e t u d e c o m p o r t a i t l ' u t i l i s a t i o n d'un modkle m a t h h a t i q u e , d ' u n e methode d ' e s s a i aux u l t r a - s o n s e t d'une d t h o d e d ' e s s a i d e chargement. Les t e m p e r a t u r e s e t les r e s i s t a n c e s r e s i d u e l l e s c a l c u l b s d e s poteaux t e s t e s o n t €it6 c o m p a r C s

3

c e l l e s o b t e n u e s p a r mesure. On a a u s s i compare les v i t e s s e s d e s i m p u l s i o n s c a l c u l e e s e t m e s u r h s . Les r 6 s u l t a t s o n t r e v e l 6 que l ' e m p l o i du mode d e c a l c u le t

d e l a t e c h n i q u e d e mesure d e l a v i t e s s e d e s i m p u l s i o n s d e c r i t s dans l ' b t u d e permet d ' d v a l u e r a v e c une p r e c i s i o n s u f f i s a n t e ,3

t o u t e s f i n s p r a t i q u e s , l a r e s i s t a n c e r g s i d u e l l e d e s poteaux d e S t o n .Reinforced Concrete Columns

by

T

T.

Lie,

T

J.

Rowe,

and

T.

D.

Lin

Synopsis:

A

study was carried out to assess the residual strength

of reinforced concrete columns after exposure to a standard fire

for various lengths of time, and cooling. The use of a

mathematical model, an ultrasonic pulse test method and a load test

method are investigated. Calculated temperatures and residual

strengths of test columns were compared with those measured.

Comparisons were also made between calculated and measured pulse

velocities. The results indicated that using the calculation

procedure and the method of measuring pulse velocity described in

the study, the residual strength of concrete columns can be

assessed with an accuracy sufficient for practical purposes.

Keywords: columns (supports); compressive strength; deformation;

fires; fire tests; loads (forces); reinforced concrete; strength;

temperature; ultrasonic tests

T.T. LIE

i s

a r e s e a r c h o f f i c e r w i t h t h e D i v i s i o n of B u i l d i n g Research, N a t i o n a l Research Council of Canada. H e worked f o r s e v e r a l y e a r s i n Europe and Japan b e f o r e j o i n i n g t h e NRC i n 1967. He i s c u r r e n t l y s t u d y i n g s t r u c t u r a l f i r e r e s i s t a n c e , which i n c l u d e s t e s t i n g and c a l c u l a t i o n of t h e f i r e r e s i s t a n c e of s t r u c t u r a lmembers. T.J. ROWE i s Manager, F i r e Research S e c t i o n , C o n s t r u c t i o n Technology L a b o r a t o r i e s , a d i v i s i o n of t h e P o r t l a n d Cement

A s s o c i a t i o n , Skokie, I l l i n o i s . He i s i n v o l v e d i n i n v e s t i g a t i o n s of s t r u c t u r a l problems and f a i l u r e s , l a r g e - s c a l e s t r u c t u r a l and f i r e t e s t i n g , n o n d e s t r u c t i v e t e s t i n g of c o n c r e t e , and e v a l u a t i o n s i n v o l v i n g f i r e d a m a g e d s t r u c t u r e s . Rowe i s a member of ACI Committee 216, F i r e R e s i s t a n c e and F i r e P r o t e c t i o n of S t r u c t u r e s . T.D. LIN

i s

p r i n c i p a l r e s e a r c h e n g i n e e r w i t h t h e C o n s t r u c t i o n Technology L a b o r a t o r i e s of PCA. His work i n v o l v e s t h e o r e t i c a l a n a l y s i s , d e s i g n and f i r e t e s t s of f u l l s c a l e s t r u c t u r a l elements. He h a s 15 y e a r s e x p e r i e n c e i n t h e s t u d y of r e i n f o r c e d c o n c r e t e s t r u c t u r e s exposed t o f i r e . INTRODUCTION The r e s i d u a l s t r e n g t h of f i r e d a m a g e d c o n c r e t e s t r u c t u r a l members i s a n i m p o r t a n t f a c t o r i n d e t e r m i n i n g t h e f e a s i b i l i t y of r e p a i r of t h e s t r u c t u r e . The r e s t o r a t i o n of l o a d - c a r r y i n g c a p a c i t y and f i r e r e s i s t a n c e of a f i r e d a m a g e d s t r u c t u r e t o a n a c c e p t a b l e l e v e l i s r e q u i r e d by r e l e v a n t b u i l d i n g codes. Often, r e p a i r i s more economical, b o t h i n terms of c o s t and t i m e , t h a n demolishing and r e b u i l d i n g t h e s t r u c t u r e .i

To a s s e s s t h e r e s i d u a l s t r e n g t h of f i r e - e x p o s e d r e i n f o r c e d c o n c r e t e columns, s t u d i e s sponsored j o i n t l y by t h e N a t i o n a l Research Council of Canada (NRCC) and t h e P o r t l a n d Cement

A s s o c i a t i o n (PCA) were r e c e n t l y c a r r i e d o u t . Both t h e o r e t i c a l and e x p e r i m e n t a l s t u d i e s were performed. These s t u d i e s i n c l u d e :

Development of a mathematical model t o c a l c u l a t e t h e t e m p e r a t u r e s i n t h e columns, and t h e i r s t r e n g t h , d u r i n g and a f t e r e x p o s u r e t o f i r e .

S u b j e c t i n g loaded t e s t columns t o a s t a n d a r d f i r e f o r v a r i o u s l e n g t h s of time, and c o o l i n g of t h e columns i n an environment of s t a n d a r d i z e d d e c r e a s i n g t e m p e r a t u r e s ; measurement of column t e m p e r a t u r e s d u r i n g and a f t e r exposure t o f i r e u n t i l n e a r ambient t e m p e r a t u r e s a r e reached i n t h e column.

Comparing t h e measured i n t e r n a l t e m p e r a t u r e s of t h e column d u r i n g and a f t e r e x p o s u r e t o f i r e w i t h c a l c u l a t e d t e m p e r a t u r e s .

Applying u l t r a s o n i c methods of n o n d e s t r u c t i v e t e s t i n g t o monitor changes i n c o n c r e t e m a t e r i a l p r o p e r t i e s of t h e columns b e f o r e and a f t e r e x p o s u r e t o f i r e ; e v a l u a t i o n of r e l a t i o n s h i p s between measured p u l s e v e l o c i t i e s and c o n c r e t e q u a l i t y , compressive s t r e n g t h , and modulus of e l a s t i c i t y .

Determining t h e u l t i m a t e a x i a l s t r e n g t h of t h e columns a f t e r exposure t o f i r e , under c o n d i t i o n s of n e a r ambient i n t e r n a l c o n c r e t e t e m p e r a t u r e s .

Comparing measured r e s i d u a l s t r e n g t h s of t h e columns with c a l c u l a t e d values.

I n t h e c u r r e n t s t u d i e s , two 305 x 305 mm r e i n f o r c e d c o n c r e t e columns made with s i l i c e o u s aggregate were i n v e s t i g a t e d . The columns were c o n s t r u c t e d by t h e Construction Technology

Laboratories of PCA and t e s t e d i n t h e l a b o r a t o r i e s of t h e Division of Building Research of NRCC. The measured r e s u l t s of t h e s e t e s t s and t h e c a l c u l a t e d r e s u l t s a r e discussed i n t h i s paper.

CALCULATION PROCEDURE

The a n a l y s i s of t h e performance of a column d u r i n g and a f t e r exposure t o f i r e involves t h e c a l c u l a t i o n of temperatures,

deformations, and t h e s t r e s s e s of t h e column. The c a l c u l a t i o n procedure i s described i n d e t a i l i n Reference 1 and w i l l not be f u r t h e r discussed here. Information i s provided with regard t o t h e environment temperatures and t h e p r o p e r t i e s of t h e concrete and t h e r e i n f o r c i n g s t e e l during and a f t e r exposure t o f i r e .

Environment Temperatures

A s i n t h e previous s t u d y [ I ] , t h e temperature course of t h e environment, i.e. t h e f i r e t o which t h e column i s exposed, i s assumed t o follow t h a t of t h e standard f i r e d e s c r i b e d i n ASTM E-119

[ 2 ] . A f t e r exposure t o f i r e t h e temperature of t h e environment is assumed t o d e c r e a s e t o room temperature according t o t h e r e l a t i o n s s p e c i f i e d i n IS0 834 Standard [3]. Depending on t h e d u r a t i o n of exposure t o t h e f i r e , t h e r a t e of d e c r e a s e of temperature i s a s follows (Fig. 1): dT/dt = 625OC/h f o r t h

<

0.5 h ( 1 ) dT/dt = 250 ( 3-

t h ) OC/h f o r 0.5 < t h < 2h ( 2 ) dT/dt = 250°C/h f o r t h>

2 h ( 3 ) where t = t h e time i n hours, t h = t h e d u r a t i o n of t h e f i r e i n hours, T = t h e f i r e temperature, a t t i m e t , i n hours. P r o p e r t i e s of S t e e l and ConcreteIn t h e c a l c u l a t i o n s , t h e same e q u a t i o n s were used f o r t h e thermal p r o p e r t i e s and s t r e s s - s t r a i n r e l a t i o n s of concrete and s t e e l a s those described i n Reference 1. However, t h e s t u d i e s

d e s c r i b e d i n Reference 1 were concerned only w i t h t h e p e r i o d of r i s i n g f i r e temperatures. For p e r i o d s i n which t h e s t e e l o r c o n c r e t e c o n t r a c t s , a s i s t h e c a s e d u r i n g c o o l i n g , o t h e r

s t r e s s - s t r a i n r e l a t i o n s were assumed, i n which t h e stress r e d u c e s w i t h t h e s t r a i n a c c o r d i n g t o a s t r a i g h t l i n e t h a t i s p a r a l l e l t o t h e t a n g e n t of t h e s t r e s s - s t r a i n c u r v e a t t h e o r i g i n (Figs. 3 and 5). The s t r e s s - s t r a i n c u r v e s f o r t h e r e i n f o r c i n g s t e e l and t h e c o n c r e t e a t e l e v a t e d t e m p e r a t u r e s a r e i l l u s t r a t e d i n Figs. 2-5.

A s can be s e e n i n Figs. 2 and 4, s t e e l and c o n c r e t e l o s e s t r e n g t h when h e a t e d t o h i g h temperatures. I n t h e c a l c u l a t i o n s i t was assumed t h a t s t e e l r e t a i n s i t s o r i g i n a l t e n s i l e s t r e n g t h a f t e r

c o o l i n g . The compressive s t r e n g t h of c o n c r e t e a f t e r c o o l i n g , however, i s reduced. The r e d u c t i o n i n s t r e n g t h of t h e c o n c r e t e depends t o a h i g h degree on t h e t e m p e r a t u r e t o which t h e c o n c r e t e h a s been h e a t e d and t o some e x t e n t a l s o on t h e l o a d t o which t h e c o n c r e t e was s u b j e c t e d d u r i n g h e a t i n g . I n t h e c a l c u l a t i o n s ,

approximate v a l u e s d e r i v e d from l i t e r a t u r e [ 4 , 5 ] have been used f o r e s t i m a t i n g r e s i d u a l compressive s t r e n g t h of s i l i c e o u s a g g r e g a t e c o n c r e t e . Because i n f o r m a t i o n on t h e dependance of t h e c o n c r e t e s t r e n g t h on l o a d i s meagre and t h e r e i s c o n s i d e r a b l e s c a t t e r i n t h e v a l u e s g i v e n i n t h e l i t e r a t u r e f o r t h e r e s i d u a l s t r e n g t h , t h e i n f l u e n c e of load was n o t considered. This t e n d s t o lower t h e v a l u e s of t h e e s t i m a t e d r e s i d u a l s t r e n g t h of t h e c o n c r e t e . These v a l u e s can be g i v e n a s a f u n c t i o n of t h e maximum t e m p e r a t u r e a t t a i n e d by t h e c o n c r e t e , by t h e f o l l o w i n g r e l a t i o n s (Fig. 6 ) f o r O°C

<

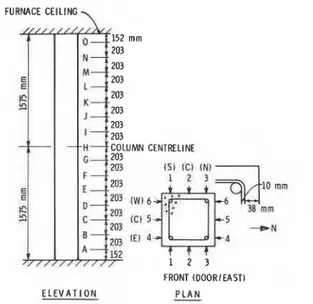

T < 500°C f o r 500°C < T < 700°C f o r T > 700°C where f r = r e s i d u a l s t r e n g t h of t h e c o n c r e t e , = i n i t i a l s t r e n g t h of t h e c o n c r e t e , = h i g h e s t temperature a t t a i n e d by t h e c o n c r e t e . TEST SPECIMENS*The specimens were s q u a r e , t i e d , r e i n f o r c e d c o n c r e t e columns, made w i t h s i l i c e o u s aggregate. They were 3810 am l o n g and had a c r o s s - s e c t i o n s i z e of 305 x 305 mm. Twenty-five-mm d i a m e t e r l o n g i -

t u d i n a l r e i n f o r c i n g b a r s and lO-mm d i a m e t e r t i e s were used. The l o c a t i o n of t h e main r e i n f o r c i n g b a r s , which were welded t o s t e e l end p l a t e s , and t h e l o c a t i o n s of t h e t i e s a r e shown i n Fig. 7.

The y i e l d stress of t h e main r e i n f o r c i n g b a r s was 444 MPa and t h a t of t h e

ties

was 427 MPa. The u l t i m a t e t e n s i l e s t r e n g t h was 730 MPa f o r t h e main b a r s and 671 MPa f o r t h e t i e s .The c o n c r e t e mix was designed f o r a compressive s t r e n g t h of approximately 35 MPa. The mix p r o p o r t i o n s were a s f o l l o w s :

Cement 325 kg/m3

Water 140 kg/m3

Sand 874 kg/m3

Coarse Aggregate 1058 kg/m3.

The a v e r a g e compressive c y l i n d e r s t r e n g t h of t h e c o n c r e t e of t h e two columns t e s t e d , measured on t h e day of t h e f i r e t e s t , was 38.9 MPa f o r Column A and 41.8 MPa f o r Column B. The m o i s t u r e c o n d i t i o n a t t h e c e n t r e of Column A was approximately e q u i v a l e n t t o t h a t i n e q u i l i b r i u m w i t h a i r of 87% r e l a t i v e humidity a t room t e m p e r a t u r e , and of Column B, w i t h a i r of 82%

RH.

Chromel-alumel thermocouples, 0.91 mm t h i c k , were i n s t a l l e d a t mid-height of t h e columns f o r measuring c o n c r e t e t e m p e r a t u r e s a t d i f f e r e n t l o c a t i o n s i n t h e c r o s s - s e c t i o n .

TEST APPARATUS F i r e T e s t s

The f i r e t e s t s were c a r r i e d o u t by exposing t h e columns t o f i r e i n a f u r n a c e s p e c i a l l y b u i l t f o r t h e t e s t i n g of loaded columns and w a l l s . The test f u r n a c e was designed t o produce t h e c o n d i t i o n s t o which a member might be s u b j e c t e d d u r i n g a f i r e , w i t h r e s p e c t t o t e m p e r a t u r e , s t r u c t u r a l l o a d , and h e a t t r a n s f e r . It c o n s i s t s of a s t e e l framework, supported by f o u r s t e e l columns, and t h e f u r n a c e chamber i n s i d e t h e framework. The c h a r a c t e r i s t i c s and instrumen- t a t i o n of t h e f u r n a c e a r e d e s c r i b e d i n d e t a i l i n Reference 6.

U l t r a s o n i c T e s t s

U l t r a s o n i c t e s t s t o measure t h e p u l s e v e l o c i t y of c o n c r e t e i n t h e column were made u s i n g a commercially a v a i l a b l e i n s t r u m e n t , known a s a V-Meter [ 7 ] . The t e s t arrangement u t i l i z i n g t h i s

equipment i s shown s c h e m a t i c a l l y i n Fig. 8. The V-Meter s u p p l i e s a t r a i n of s h a r p , e l e c t r i c a l p u l s e s t o a t r a n s m i t t i n g t r a n s d u c e r i n a c o u s t i c c o n t a c t w i t h t h e c o n c r e t e s u r f a c e . The e l e c t r i c a l p u l s e s a r e c o n v e r t e d t o low frequency (54 kHz) mechanical p u l s e s by p i e z o e l e c t r i c elements i n t h e t r a n s d u c e r assembly. The mechanical p u l s e s p r o p a g a t e through t h e c o n c r e t e and a r e s e n s e d by t h e

r e c e i v i n g t r a n s d u c e r l o c a t e d a t a known d i s t a n c e . The mechanical energy i s reconverted t o e l e c t r i c s i g n a l by t h e transducer. The e l e c t r i c a l s i g n a l s a r e subsequently amplified and displayed on an o s c i l l o s c o p e . The V-Meter u t i l i z e s a p r e c i s e c a l i b r a t e d time d e l a y c i r c u i t r y t o c a l c u l a t e and d i s p l a y t h e t r a n s i t time of t h e p u l s e through t h e concrete. From t h e t r a n s i t time and t h e t h i c k n e s s of t h e c o n c r e t e a s measured a s t h e s t r a i g h t l i n e d i s t a n c e between t h e two t r a n s d u c e r s , t h e p u l s e v e l o c i t y can be c a l c u l a t e d . This v e l o c i t y i s a measure of t h e q u a l i t y of t h e c o n c r e t e , and i s r e l a t e d t o compressive s t r e n g t h and dynamic modulus of e l a s t i c i t y .

TEST CONDITIONS AND PROCEDURE F i r e T e s t s

The columns were i n s t a l l e d i n t h e t e s t f u r n a c e by b o l t i n g t h e i r s t e e l end-plates t o a loading head a t t h e t o p and a h y d r a u l i c j a c k a t t h e bottom. Concentric l o a d s were a p p l i e d t o t h e columns about one hour b e f o r e t h e f i r e t e s t s . The load on Column A was 992 kN and t h a t on Column B, 1022

kN.

During t h e t e s t s t h e h e a t i n p u t i n t o t h e f u r n a c e was

c o n t r o l l e d s o t h a t t h e average temperature followed a s c l o s e l y a s p o s s i b l e t h e s t a n d a r d temperature-time r e l a t i o n s d e s c r i b e d e a r l i e r i n t h e p r e s e n t paper. The accuracy of c o n t r o l d u r i n g both t e s t s was such t h a t t h e d u r a t i o n of t h e average f u r n a c e temperature from t h a t given by t h e s t a n d a r d temperature-time r e l a t i o n s was l e s s than 10°C, except i n t h e f i r s t 3-5 minutes of t h e t e s t and a f t e r t h e f u r n a c e had cooled down t o below 100°C. Column A was exposed t o f i r e f o r one hour and Column B f o r two hours b e f o r e t h e s t a r t of t h e cooling period. Measurements were made of t h e f u r n a c e

temperatures d u r i n g t h e f i r e exposure and c o o l i n g p e r i o d s u n t i l t h e average f u r n a c e temperature reached near ambient temperature. Measurements were a l s o made of t h e c o n c r e t e temperatures a t v a r i o u s l o c a t i o n s d u r i n g t h e f i r e exposure and c o o l i n g periods. During t h e s e p e r i o d s t h e load was k e p t c o n s t a n t and t h e a x i a l deformation of t h e column was measured u n t i l t h e temperatures i n t h e column reached v a l u e s c l o s e t o ambient temperature. A t t h a t s t a g e , which was reached about one day a f t e r t h e c o o l i n g period s t a r t e d , t h e l o a d on t h e column was i n c r e a s e d a t a r a t e of 12.5 kN p e r minute u n t i l t h e column f a i l e d .

U l t r a s o n i c T e s t s

P r i o r t o t h e s t a r t of t h e f i r e t e s t , o v e r 90 p u l s e v e l o c i t y measurements were made through t h e c r o s s - s e c t i o n a t v a r i o u s loca- t i o n s a l o n g a v e r t i c a l p r o f i l e of t h e column. A l a y o u t of loca- t i o n s of t h e p u l s e v e l o c i t y measurements is presented i n Fig. 9.

Pulse v e l o c i t y measurements were a l s o made on companion 152 x 305 mm c o n c r e t e c y l i n d e r s of Column A and Column

B.

Thecylinders were fabricated at the time the columns were cast, and

then maintained at curing and storage conditions identical to those

of the columns. The pulse velocity measurements were made along

both the transverse and the longitudinal axis of the cylinders.

The cylinders were subsequently tested for compressive strength on

the day of the fire test.

Approximately 20 hours after the start of the fire test, pulse

velocity measurements were attempted at each of the test grid

locations identified in Fig. 9. At approximately 25 hours after

the start of the test, a region near mid-height of the column,

between Elevations F and G, was chipped to a depth of 1 to 3 in.

(25 to 75

mm)to remove loose, delaminated material. Chipping was

performed with hand tools. The resulting exposed shape of the

column was nearly round, as shown in Fig. 10. Pulse velocity

measurements were also made through the column in the region.

RESULTS AND DISCUSSION

Column Temperatures

Previous studies

[I],

in which several columns were tested,

showed that the mathematical model used for the calculation of

temperatures in siliceous concrete columns during fire exposure

gives reasonably accurate predictions. In general, predicted

temperatures were slightly higher than those measured, probably

because of conservative assumptions for the mechanism of heat

transfer from the furnace to the column.

The columns tested in the present study were made from the

same siliceous aggregate concrete. Using the same procedure and

thermal properties described in Reference 1, the temperature

history of the columns was calculated. There was again good

agreement between the calculated and the measured temperature

curves. Figures 11 and 12 present measured and calculated

temperatures of the concrete as a function of time for various

depths along the centerline of the column.

Ultrasonic Test Method

The use of ultrasonic test methods to evaluate material prop-

erties and defects in concrete is widespread

[ 8 ] .These techniques

are based on detecting changes in amplitude, phase, and direction

of mechanical waves as they propagate through a concrete member.

Changes in wave characteristics generally indicate a corresponding

change in internal structural make-up of the concrete.

Pulse velocity measurements made prior to exposure to fire

ranged from 4360 to 4665 m/s over the height of Columns A and

B.

The average measured reading was 4510 and 4560 m/s for Columns A

and B, respectively.

Results of pulse velocity tests and corresponding compressive

strengths for 152

x305 mm concrete control cylinders are presented

in Table 1.

TABLE 1 Average measured pulse velocity and compressive strength

for 152

x305

mmcompanion cylinders

Average

Compressive

Cylinder

Pulse Velocity

Strength

Column

No.

(m/s

1

(MPa

1

A

1

4570

37.7

A

2

4600

39.0

A

3

4615

40.0

B

1

4665

42.1

Relationships between pulse velocity and compressive strength

as determined by tests of cylindrical specimens have been compiled

by many investigators. It is important to realize, however, that

these relationships can vary significantly between concrete mixes,

due to differences in aggregates, waterlcement ratios, air content,

moisture content, and density. Plots of pulse velocity versus

compressive strength from references 9 and 10 are presented as

Figs. 13 and 14, respectively. Figure 14 additionally presents a

curve identifying "fire damaged" concrete. Due to dehydration,

matrix restructuring, and micro cracking, there is a significant

decrease in measured pulse velocities for a given compressive

strength for "fire damaged" concrete compared to "undamaged"

material.

The relationship between residual compressive strength and

temperature exposure for siliceous concretes is presented in

Fig. 15. This plot, from Reference 4, indicates an approximate

residual strength of 70, 50, and 20% of original for concrete

exposed to 300, 500, and 700°C, respectively.

Calculations were performed to predict pulse velocity values

for Columns A and B exposed to a one-hour and a two-hour fire,

respectively. The following sequence was employed:

1.

Maximum internal temperatures at various distances from the

exposed face were derived from recorded values.

2.

Measured temperatures were related to anticipated strength for

each zone of temperature exposure within the column, based on

data presented in Fig. 15.

3.

Strength values for each zone of temperature exposure within

the column were related to anticipated pulse velocity values

based on data presented in Figs. 13 and 14.

4.

Utilizing the "total transit time" computational approach, in-

dividual pulse velocity values were combined for each tempera-

ture zone to calculate total, through-section pulse velocities.

P o s t - f i r e v e l o c i t y values c a l c u l a t e d u t i l i z i n g t h e above approach ranged from 1500-2000 m / s f o r Column A and from

1100-1500 m / s f o r Column B. These r e s u l t s compare favourably t o a c t u a l measured v a l u e s of 1200-2000 m / s f o r Column A and

1000-1600 m / s f o r Column

B.

Axial Deformation and S t r e n g t h

Deformation The a x i a l deformations measured d u r i n g t h e t e s t s and t h e c a l c u l a t e d deformations a r e shown f o r Column A i n Fig. 16 and f o r Column B i n Fig. 17. Up t o a t e s t time of f o u r h o u r s , t h e r e i s good agreement between c a l c u l a t e d and measured

deformations. A f t e r t h i s time, t h e d i f f e r e n c e s between c a l c u l a t e d and measured deformations become considerable.

A good agreement between c a l c u l a t e d and measured deformations was a l s o found i n e a r l i e r t e s t s on r e i n f o r c e d c o n c r e t e columns, which were exposed t o f i r e u n t i l t h e column f a i l e d [ I ] . These t e s t s g e n e r a l l y l a s t e d from two t o f i v e hours and d i d not i n c l u d e a c o o l i n g period. The good agreement f o r t e s t s without a c o o l i n g period and f o r t h e p r e s e n t t e s t s i n t h e f i r s t few hours may be a t t r i b u t e d t o t h e f a c t t h a t , f o r r i s i n g temperatures and s t r a i n s of t h e c o n c r e t e and s t e e l , t h e e f f e c t of c r e e p i s included i n t h e s t r e s s - s t r a i n r e l a t i o n s used i n t h e mathematical model. Because of i n s u f f i c i e n t d a t a and complexity of t h e model, t h e e f f e c t of c r e e p i s n o t included i n t h e s t r e s s - s t r a i n r e l a t i o n s f o r d e c r e a s i n g temperatures and s t r a i n s of t h e c o n c r e t e and s t e e l . It i s l i k e l y t h a t t h i s , and shrinkage of t h e c o n c r e t e , a r e t h e main r e a s o n s f o r t h e c o n s i d e r a b l e d i f f e r e n c e between c a l c u l a t e d and measured

deformations a f t e r about f o u r hours.

S t r e n g t h The c a l c u l a t e d r e s i d u a l a x i a l s t r e n g t h of Column A

was 1725 kN and of Column B, 2470 kN. The s t r e n g t h s measured a f t e r c o o l i n g of t h e columns t o n e a r ambient temperatures, were 1987 kN f o r Column A and 2671 kN f o r Column B. Calculated s t r e n g t h s a r e about t e n percent lower t h a n t h o s e measured.

F a c t o r s t h a t may have c o n t r i b u t e d t o t h e d i f f e r e n c e s i n c l u d e t h e somewhat c o n s e r v a t i v e p r e d i c t i o n of column temperatures and n e g l e c t of c r e e p i n t h e c o o l i n g period. Implied i n t h i s r e l a t i o n i s t h e assumption t h a t t h e r e s i d u a l s t r e n g t h of t h e c o n c r e t e i s only a f u n c t i o n of t h e maximum temperature a t t a i n e d by t h e

concrete. It i s known t h a t t h e r e s i d u a l s t r e n g t h i s t o some e x t e n t a f f e c t e d by t h e l o a d on t h e c o n c r e t e d u r i n g heating. S t u d i e s

[4,11,12] showed t h a t t h e r e s i d u a l s t r e n g t h of c o n c r e t e specimens heated under s t r e s s was h i g h e r t h a n t h a t of specimens h e a t e d unstressed. Above a c r i t i c a l s t r e s s of about one-third of t h e compressive s t r e n g t h of t h e c o n c r e t e , however, t h e r e s i d u a l s t r e n g t h was no longer a f f e c t e d by t h e s t r e s s .

The n e g l e c t of t h e i n f l u e n c e of c r e e p and load i n t h e

c a l c u l a t i o n s i s expected t o r e s u l t i n a lower c a l c u l a t e d r e s i d u a l s t r e n g t h . It appears, however, t h a t t h e n e g l e c t of t h e i n f l u e n c e

of t h e s e f a c t o r s does not i n t r o d u c e l a r g e e r r o r s . Thus t h e r e s u l t s suggest t h a t i t i s j u s t i f i e d t o c o n s i d e r t h e r e s i d u a l s t r e n g t h of a concrete column t h a t has been exposed t o f i r e a s p r i n c i p a l l y

dependent on t h e maximum temperatures a t t a i n e d i n t h e concrete. In Figs. 18 and 19, c a l c u l a t e d maximum temperatures reached a t v a r i o u s depths i n t h e column a r e shown, a s w e l l a s t h e r e s i d u a l s t r e n g t h of t h e c o n c r e t e a t v a r i o u s depths a f t e r cooling. Figure 18 shows t h e temperature and s t r e n g t h d i s t r i b u t i o n f o r Column A, which was exposed f o r one hour t o f i r e , and Fig. 19 f o r Column B, which was exposed t o f i r e f o r two hours.

In t h e s e f i g u r e s a l s o t h e p r o f i l e s of t h e s e c t i o n s a r e shown a f t e r f u r t h e r chipping off of t h e weaker concrete with handtools a few weeks a f t e r t h e t e s t . The p r o f i l e s a r e r a t h e r i r r e g u l a r , w i t h most of t h e c o n c r e t e coming off a t t h e corners. The c o n c r e t e a t t h e c o r n e r s s e p a r a t e d from t h e column along v e r t i c a l cracks and came off r a t h e r e a s i l y i n e s s e n t i a l l y triangular-shaped pieces. The cracks were formed a f t e r t h e exposure t o f i r e , and can be a t t r i b u t e d t o t h e f a c t t h a t t h e i n n e r p a r t of t h e column was s t i l l i n c r e a s i n g i n temperature, whereas t h e o u t e r p a r t was c o o l i n g s u b s t a n t i a l l y .

A comparison between t h e p r o f i l e s of t h e remaining c o n c r e t e s e c t i o n s and t h e c a l c u l a t e d isotherms i n d i c a t e s t h a t a c a l c u l a t e d maximum c o n c r e t e temperature of about 550°C i s a reasonable l i m i t a t which t h e concrete possesses s i g n i f i c a n t r e s i d u a l s t r e n g t h . Because c a l c u l a t e d temperatures a r e about t e n percent c o n s e r v a t i v e , t h e a c t u a l temperature a t t h e l o c a t i o n s where t h i s l i m i t i n g

temperature i s reached, i s about 500°C. A t t h i s temperature t h e r e s i d u a l s t r e n g t h of t h e c o n c r e t e , immediately a f t e r cooling down is s t i l l about f i f t y percent of t h e o r i g i n a l s t r e n g t h . A f t e r t h i s , t h e s t r e n g t h reduces somewhat w i t h time f o r s e v e r a l days [4,13-151 but t h e c o n c r e t e w i l l l a t e r r e h y d r a t e and g r a d u a l l y r e g a i n most of i t s o r i g i n a l s t r e n g t h (Fig. 20).

CONCLUSIONS

Various methods can be used t o a s s e s s t h e r e s i d u a l s t r e n g t h of fire-exposed r e i n f o r c e d concrete columns. In t h i s study t h e use of a mathematical model, an u l t r a s o n i c p u l s e t e s t method and a load t e s t method were i n v e s t i g a t e d . The r e s u l t s of t h e study i n d i c a t e t h a t :

1. The column temperatures p r e d i c t e d by t h e model a r e i n good agreement with those measured, although t h e p r e d i c t e d temperatures a r e somewhat conservative.

2. The a x i a l deformations p r e d i c t e d by t h e model a r e f a i r l y a c c u r a t e f o r t h e f i r s t few hours, but d e v i a t e from t h o s e measured i n t h e c o o l i n g period. The d e v i a t i o n can be

a t t r i b u t e d t o c r e e p , which i s taken i n t o account i n t h e model only f o r t h e period of r i s i n g column temperatures. The creep

d i d n o t s i g n i f i c a n t l y a f f e c t t h e r e s i d u a l s t r e n g t h of t h e column.

3. P u l s e v e l o c i t y measured by t h e u l t r a s o n i c test method

c o r r e l a t e d w e l l w i t h t h e r e s i d u a l s t r e n g t h and q u a l i t y of t h e fire-damaged c o n c r e t e .

4. C a l c u l a t e d r e s i d u a l s t r e n g t h s of t h e columns a r e about t e n p e r c e n t lower t h a n t h o s e measured. I n t h e l i g h t of t h e complexity of r e s i d u a l s t r e n g t h e v a l u a t i o n , t h e agreement between t h e c a l c u l a t e d and measured s t r e n g t h s c a n b e r e g a r d e d a s s a t i s f a c t o r y .

I n summary, u s i n g t h e c a l c u l a t i o n p r o c e d u r e and t h e method of measuring p u l s e v e l o c i t y d e s c r i b e d i n t h i s s t u d y , t h e r e s i d u a l s t r e n g t h of c o n c r e t e columns c a n be a s s e s s e d w i t h a n a c c u r a c y t h a t i s s u f f i c i e n t f o r p r a c t i c a l purposes.

REFERENCES

1. L i e , T.T., Lin, T.D., A l l e n , D.E. and Abrams, M.S., F i r e R e s i s t a n c e of R e i n f o r c e d Concrete Columns, N a t i o n a l Research Council Canada, D i v i s i o n of B u i l d i n g Research, DBR Paper 1166, NRCC 23065, Ottawa, 1984.

2. Standard Methods of F i r e T e s t s of B u i l d i n g C o n s t r u c t i o n and M a t e r i a l s , ANSI/ASTM E119-83, American S o c i e t y f o r T e s t i n g and M a t e r i a l s , P h i l a d e l p h i a , 1983.

3. F i r e - r e s i s t a n c e T e s t s

-

Elements of B u i l d i n g C o n s t r u c t i o n , I n t e r n a t i o n a l S t a n d a r d ISO-834, Geneva, 1975.4. Abrams, M.S., Compressive S t r e n g t h of Concrete a t Temperatures t o 1600 F, American C o n c r e t e I n s t i t u t e , S p e c i a l P u b l i c a t i o n SP-25, Temperature and Concrete, D e t r o i t , pp. 33-58.

5. Assessment of F i r e d a m a g e d Concrete S t r u c t u r e s and R e p a i r by Gunnite, Concrete S o c i e t y T e c h n i c a l Report No. 15, The Concrete S o c i e t y , London, 1978.

6. L i e , T.T., New F a c i l i t y t o Determine F i r e R e s i s t a n c e of

Columns, Canadian J o u r n a l of C i v i l E n g i n e e r i n g , Vol. 7, No. 3, 1980.

7. James E l e c t r o n i c s , Inc., " I n s t r u c t i o n Manual f o r Model C-4899 V-Meter", Manual No. F-0062, Chicago, May 1977.

8. Hanson, N.W., Rowe, T.J., A n s t e d t , D., and Corley, W.G.,

V i b r a t i o n Techniques f o r E v a l u a t i o n of D e f e c t s i n Concrete, Vol. 52, P r o d u c t i v e A p p l i c a t i o n s of Mechanical V i b r a t i o n s , Applied Mechanics D i v i s i o n (ASME), New York, 1982, p. 107. 9. Rowe, T.J., E v a l u a t i o n of Concrete i n Columns a t t h e P a r i s h

Tower Company (Mission, Kansas 6620 1)

,

submitted by Construction Technology L a b o r a t o r i e s , a d i v i s i o n of t h e P o r t l a n d Cement A s s o c i a t i o n , Sept., 1981.10. Watkeys, D.G., N o n d e s t r u c t i v e T e s t i n g of Concrete Subject t o F i r e Attack, M.Sc. (Eng.) Thesis, University of London, UK,

1955.

11. Malhotra, H.L., The E f f e c t of Temperature on t h e Compressive S t r e n g t h of Concrete, Magazine of Concrete Research, Vol. 8, No. 23, 1956.

12. Weigler, H., and F i s h e r , R., Beton b e i Temperaturen von 100 C

b i s 750 C, Beton H e r s t e l l u n g Verwendung, V. 18, No. 2, 1968. 13. Zoldners, N.G., E f f e c t of High Temperatures on Concretes

I n c o r p o r a t i n g D i f f e r e n t Aggregates, Mines Branch Research Report No. 64, Department of Mines and Technical Surveys, Ottawa, 1960.

14. Weigler, H., and F i s h e r , R., E f f e c t of Temperatures above 100 C on t h e Compressive S t r e n g t h of Cement Mortar, Behaviour of Concrete a t High Temperatures, B u l l e t i n 164, Deutscher Ausschuss f u r S t a h l b e t o n , 1964.

15. Harada, T., Research on F i r e Proof of Concrete and Reinforced Concrete C o n s t r u c t i o n , Tokyo I n s t i t u t e of Technology, 1961.

F i g . 1-Temperature o f e n v i r o n m e n t as a f u n c t i o n o f t i m e d u r i n g a n d a f t e r f i r e f o r v a r i o u s d u r a t i o n s ( t h ) o f t h e h e a t i n g p e r i o d

S T R A I N . c s

F i g . 2 - S t r e s s - s t r a i n c u r v e s f o r t h e r e i n f o r c i n g s t e e l a t v a r i o u s t e m p e r a t u r e s ( y i e l d s t r e n g t h =

443

MPa)S T R A I N . E

Fig. 4-Stress-strain curves for concrete at various temperatures (compressive strength = 35 MPa)

I

6 0 0 5 0 0 400 I VI- 300 0 0. 01 0. 02 0. 03 0. 04 0. 05 S T R A I N . E ,Fig. 3-Stress-strain relationship for steel after decrease of strain

I I I I

-

-

-

-

T = 40OCC-

--

r WITH DECREASE O F S T R A I N-

0 1 I I IS T R A I N , E c F i g . 5 - S t r e s s - s t r a i n r e l a t i o n s h i p f o r c o n c r e t e a f t e r d e c r e a s e of s t r a i n TEMPERATURE, "C F i g . 6-Residual s t r e n g t h o f s i l i c e o u s c o n c r e t e a f t e r c o o l i n g a s a f u n c t i o n of t h e t e m p e r a t u r e a t t a i n e d by t h e c o n c r e t e

[4,5]

/4B mm COVER TO MAIN REINFORCING BAR

u

305 mm

533 x 533 x 25 mm

THICK STEEL PLATE 7

Fig. 7-Test column and location of reinforcing bars

TRANSMIllING RECEIVING

FURNACE CEILING

\

CENTRILINE

FRONT (DOORIEAST) E L E V A T I O N

-

P L A NFig. 9-Location of pulse velocity measurements

1 SOUTH NORTH 4 DIRECTION THICKNESS OF CONCRETE mrn E - W 292 N - S 279 SE - NW 276 N€ - SW 287 1 - 1 307 2 - 2 286 3 - 3 285 4 - 4 286 SE BAR - M BAR 200 SW BAR - SE BAR 201 NW BAR

-

SW BAR 199 NE BAR - NW BAR 192-

CALCULATED---

M E A S U R E D 200'

25 m m D E P T H 0 a 100 f. W rr 0 64 m m DEPTH T I M E , m i n F i g . 11-Temperature o f c o n c r e t e a s a f u n c t i o n o f t i m e f o r v a r i o u s d e p t h s a l o n g c e n t e r l i n e o f column A ( f i r e e x p o s u r e t i m e : 1 h o u r ) 0 0 200 400 600 800 1WO 1200 1400 1600 T I M E , m i n CALCULATED F i g . 12-Temperature o f c o n c r e t e a s a f u n c t i o n o f t i m e f o r v a r i o u s d e p t h s a l o n g c e n t e r l i n e o f ColumnB

( f i r e e x p o s u r e t i m e : 2 h o u r s )2 0 0 0 1 t I I I I

1

6 0 5 0 4 0 3 0 20 10 0

C O M P R E S S I V E S T R E N G T H . M P a

Fig. 13-Pulse velocity-compressive strength relationship

[ 8 ]C O M P R E S S I V E S T R E N G T H . M P a

125 I I I I I

-

-

-

L1: l DUAL STRENGTH 0 --

*\

a I I I I I I 1 0 100 200 300 400 500 6 0 0 700 800 TEMPERATURE. 'CFig. 15-Residual strength and modulus relation

[ 4 ]

12 I I I I I I I 1 0

-

CALCULATED-

----

MEASURED-

-

W o - 6-

2 - 8-

4- - 1 0-

X < - 1 2-

I - 1 4 - 16 I I L I I I f 0 200 4 0 0 6 0 0 8 0 0 1000 1200 1400 1600 T I M E , minFig. 16-Axial deformation as a function of time (fire exposure time:

1

hour, Column A)-.

--_

---__

- 2 6 - 2 8 CALCULATED---

M E A S U R E D - 3 A T I M E , m i nFig. 17-Axial deformation as a function of time (fire exposure

time:

2

hours, Column

B)

MAXIMUM RESIDUAL STRENGTH TEMPERATURE DEPTH, (FRACTION OF REACHED. "C mm ORIGINAL STRENGTHI

4

t

h

I

' ~ P R O F I L E OF SECTION AFTER REMOVAL OF WEAKER CONCRETEFig. 18-Calculated maximum temperatures reached at various depths

during heating and cooling period and residual strength at various

depths after cooling; profile of section after weaker concrete has

been removed (fire exposure time: 1 hour, Column

A)

MAXIMUM RESIDUAL STRENGTH TEMPERATURE DEPTH, (FRACTION OF REACHED, "C mm ORIGINAL STRENGTH)

4

+

+

i

PROFILE OF SECTION AFTER REMOVAL OF WEAKER CONCRETEFig. 19-Calculated maximum temperatures reached at various depths during heating and cooling period and residual strength at various depths after cooling; profile of section after weaker concrete has been removed (fire exposure time: 2 hours, Column

B)

" 0 1 2 3 4 5 6 7 8 9 1 0 1 1 1 2

T I M E , m o n t h s

Fig. 20-Natural recovery of compressive strength of concrete, heated at various temperatures [ 1 2 ]

![Fig. 13-Pulse velocity-compressive strength relationship [ 8 ]](https://thumb-eu.123doks.com/thumbv2/123doknet/14294352.493100/22.619.150.471.80.368/fig-pulse-velocity-compressive-strength-relationship.webp)

![Fig. 15-Residual strength and modulus relation [ 4 ]](https://thumb-eu.123doks.com/thumbv2/123doknet/14294352.493100/23.619.163.511.69.289/fig-residual-strength-modulus-relation.webp)

![Fig. 20-Natural recovery of compressive strength of concrete, heated at various temperatures [ 1 2 ]](https://thumb-eu.123doks.com/thumbv2/123doknet/14294352.493100/25.615.165.495.555.861/natural-recovery-compressive-strength-concrete-heated-various-temperatures.webp)