Publisher’s version / Version de l'éditeur:

Proceedings of the American society for composites, 2011-09-26

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Thermoset-natural fiber composites using nanocomposites for mass transit applications

Ngo, Tri-Dung; Trudel-Boucher, David; Ton-That, Minh-Tan; Labonté, Sylvain

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=8a11e012-a1f0-4ba8-a48c-45a83d3a3b17 https://publications-cnrc.canada.ca/fra/voir/objet/?id=8a11e012-a1f0-4ba8-a48c-45a83d3a3b17

COVER SHEET

Title: Thermoset-Natural Fiber Composites using Nanocomposites for Mass Transit Applications

Authors: Tri Dung Ngo

David Trudel-Boucher Minh Tan Ton-That Sylvain Labonté

ABSTRACT

Mass transit vehicle weight has grown significantly over the last 20 years penalizing the road infrastructure, fuel consumption and environmental signature. Increased use of lightweight, high-strength and new sustainable composites for mass transit vehicle components is a promising avenue to explore since weight reduction is one of the few ways Canadian mass transit vehicle manufacturers can influence fuel consumption and hence help reduce greenhouse gases emissions. Weight saving opportunities could possibly be obtained by the use of natural fiber and hybrid composites as compared to “traditional” glass fiber based composites. The use of nanocomposites to improve the property of resins without any significant increase in density could also be a possible avenue to obtain the high performance composite with weight saving.

In this paper, the role of nanoparticles on the performance improvement of natural fibers thermoset composites was investigated. Different nanoparticles such as Cloisite Na+, 10A, 20A and 30B, Perkalite G100, Nanocryl C140 were first dispersed in a thermoset resin before performing the impregnation of the natural fiber fabric. Natural fiber composites were prepared by hand lay-up followed by a vacuum step and by infusion. The quality of dispersion and intercalation/exfoliation was analyzed by X-ray diffraction (XRD), field emission gun scanning electron microscopy (FEGSEM) and transmission electron microscopy (TEM). Mechanical performance and fire resistance of nanoreinforced thermoset resin and natural fiber composites were also evaluated. The results obtained demonstrate that the presence of nanoparticles can improve the the tensile strength, tensile modulus and fire resistance performance of the resin and of the natural fiber composites. The levels of improvement of the properties were seen to vary with the type of nanoparticles used.

_____________

Tri Dung Ngo, David Trudel-Boucher, Minh Tan Ton-That, Sylvain Labonté Industrial Materials Institute, National Research Council of Canada

INTRODUCTION

Unsaturated polyesters (UP) and vinyl esters (VE) are prime candidates for use in composites for transportation and/or infrastructures. The characteristics of these materials have also proven to be extremely appealing to markets as automotive, marine, building, electrical applications, corrosion resistant structures and consumer goods. However, the physical properties of the vinyl ester networks are, in general, superior to the unsaturated polyesters, particularly regarding corrosion resistance.

Studies on nanocomposites based on UP and VE began about ten years ago [1-6]. In general, the addition of nano-particles increases the tensile and flexural modulus, the fracture toughness, and the barrier and flammability properties of nanocomposites compared to the neat resin. Kornmann et al. [1] stated that the incorporation of organoclay (Na bentonite treated with silane) increased the modulus of UP up to 25%, the strength remaining however similar. They also found that the fracture toughness improved by a factor of up to 3. Finally, they claimed that exfoliation is achieved, although no conclusive morphological analysis is presented. Besides increasing modulus, another advantage of adding nanoclays, is the improvement of flammability properties. The peak and the average heat release rates (HRR) can be significantly improved for vinyl ester nanocomposites at low mass fraction (below 6 wt %). Furthermore, the primary difference (aside from HRR) between the flammability properties of pure vinyl esters and nanocomposites is the mass loss rate (MLR), while the heat of combustion (Hc), soot (SEA) and carbon monoxide yields were unchanged [7]. Clay shortens ignition time but also lowers the peak heat release rate (PHRR) by about 30% [8]. The PHRR was also lower for unsaturated polyester-based nanocomposites with nanoclays (Cloisite 10A, 15A, 25A, and C30B) than neat UP [9]. The effect can be more pronounced when combined with other flame retardants.

Various types of nanoclays and nano-particles with different forms can be supplied by Southern Clay Products, Inc., Nanocor, Inc., Akzo Nobel, and Nano Resins. These nanoclays are treated with different organic compounds in order to improve their compatibility with the matrix and dispersion in different types of polymer systems. Among all the available nanoclays, it is not clear however which ones are the good candidates for fabricating the VE nanocomposites. The best method to prepare vinyl ester nanocomposites is also something that needs to be determined (influence on mixing, curing, and performance etc). In the present work, the results obtained for the synthesis and properties of vinyl ester nanocomposite with different types of nano-particles are reported. In addition, the mixing method in close chamber is also investigated to minimize the loss of styrene during mixing since it may affect the properties of the vinyl ester nanocomposites.

EXPERIMENTAL Materials

The vinyl ester resin selected for this study was Hydropel® R037, from AOC. Cobalt naphthanate (CoNap) from Progress Plastiques and Luperox DDM-9 (mixture of methyl ethyl ketone peroxide - MEKP) from Arkema Canada Inc. were used as an

accelerator and initiator, respectively. Different types of nano-particles were selected for this work. Four nanoclays from Southern Clay Product (Cloisite® Na+, 10A, 20A and 30B) and one from Akzo Nobel (Perkalite® G100). Cloisite® 10A, 20A and 30B are organoclays based on natural montmorillonite but differing in intercalant chemistry. Cloisite® Na+ is a natural montmorillonite (untreated). Perkalite® G100 is an aluminum magnesium Layered Double Hydroxide (LDH), synthetic clay modified with unsaturated fatty acid. Finally, Nanocryl® C140 from Nano Resins is a colloidal silica sol in a hexandioldiacrylate binding agent.

The 5% of nano-particles were incorporated into vinyl ester Hydropel using a Magic Lab mixer with closed chamber except for the C140, which was incorporated in the VE by mechanical mixer for just 2 min. The nanoclays were first mixed with VE using the mechanical mixer for 2 min, and then passed through the Magic Lab mixer at the speed of 10000 and 20000 rpm. The materials were cured at room temperature for 2 days then post cured at 140°C for 1 hour.

The natural fiber was used in this study was hemp mat provided by the Composites Innovation Centre (CIC). Fibers were either not clean or clean with hot water at 80°C. Natural fiber composites were prepared by hand lay-up followed by a vacuum step and by infusion. The composites were cured at room temperature for 2 days then posted cured at 140°C for 1 hour.

Measurements

To evaluate the intercalation/exfoliation of the nanoclay in the polymer matrix, XRD patterns were obtained from the surface of the samples with a Bruker Discover 8 powder X-ray diffractometer with CuKα radiation. A Hitachi-S4700 FEGSEM was used to observe the dispersion of nano-particles in the VE matrix at the micro-level. For dispersion at the nano-level, ultra-thin (50 to 80 nm) sections of nanocomposite samples were prepared with a cryoultramicrotome and supported on a copper 200 mesh grid for observation with a Hitachi H9000 TEM.

The DSC data were obtained on a Perkin-Elmer DSC7 instrument using nitrogen atmosphere. The samples were heated from 20°C to 180°C (dynamic scan) at heating rate of 10°C·min-1 to follow the heat evolution due to the chemical reaction occurring in this temperature range. To determine the Tg, the cured samples were heated in a TA-Q1000 DSC instrument using nitrogen atmosphere from 20°C to 180°C at 20°C·min-1, then cooled to 20°C at 20°C·min-1 to minimize the enthalpy relaxation in the second heating scan, which involved reheating to 180°C at 20°C·min-1.

The tensile and flexural properties of the VE with and without nano-particles were determined at room temperature according to ASTM D638 on an Instron machine.

RESULTS AND DISCUSSION

X-ray diffraction curves of the vinyl ester nanocomposites with different types of nano-particles are shown in Figure 1. The results indicate that the layer separation of nanoclays or degree of intercalation is considerably higher when mixed to the VE resin than the original nanoclay themselves (the XRD peak shift to the left or to the smaller angle) except the one prepared with Cloisite Na. It means that the nanoclay has been further intercalated by the matrix. There is no peak remaining on the XRD

curve for G100 nanoparticles. This suggests that G100 nanoparticles are almost entirely exfoliated in the VE resin. However, the XRD results alone cannot demonstrate whether nanoclays are exfoliated in the VE resin or not, and also do not present the quality of dispersion of nano-particles. Therefore SEM and TEM characterization will be used to complete the characterization. C140 contains nano-silica particles and are thus different from nanoclays which have layered structures. Therefore, no peak appears on the XRD for C140 in the range of angles investigated.

0 500 1000 1500 2000 Hydropel Na Hydropel-Na 2 4 6 8 10 In te n s it y ( c o u n ts) θ (ο) 0 500 1000 1500 2000 Hydropel 10A Hydropel-10A 2 4 6 8 10 In te ns it y ( c ou n ts ) θ (ο) 0 500 1000 1500 2000 2500 3000 Hydropel 20A Hydropel-20A 2 4 6 8 10 In te n s it y ( c o u n ts ) θ (ο) 0 500 1000 1500 2000 Hydropel 30B Hydropel-30B 2 4 6 8 10 In te n s it y ( c o u n ts ) θ (ο) 0 1250 2500 3750 5000 Hydropel G100 Hydropel-G100 2 4 6 8 10 In te ns it y ( c ou n ts ) θ (ο) 0 1250 2500 3750 5000 Hydropel C140 Hydropel-C140 2 4 6 8 10 In te ns it y ( c ou n ts ) θ (ο)

Figure 1. XRD curves for Hydropel with different nano-particles

Figure 2 presents the microstructures of nanocomposite samples observed by FEGSEM. The bright spots on the backscattered images correspond to clay aggregates or nano-silica particles (For C140). Apparently, a portion of the clay remains at the micro-scale level with different size populations depending on the clay

type. However, due to the limitation of the SEM, one should not rule out the possibility that some exfoliation does take place. This will be confirmed by the results from TEM as can be seen in Figure 3. From Figure 2, it seems that C20A and G100 were dispersed more uniformly in the Hydropel compared to Na, 10A, 30B. However, G100 shows much smaller particles in the VE. C140 also shows a uniform dispersion in Hydropel and the particles size is the smallest. The TEM results (Figure 3) are in agreement with those derived from XRD and SEM. Figure 3 shows the presence of large aggregates for Na, 10A, 20A, while the G100 is almost exfoliated into individual layers in the VE resin.

Figure 3. TEM photos for Hydropel with different nano-particles

The DSC and transformation curves of the vinyl ester and its nanocomposites are shown in Figures 4. As shown in this picture, the presence and the type of nano-particles has an effect on the curing of the vinyl ester. Among all nano-nano-particles investigated, C140 seems to have the less effect on curing. The nanoclay Na has a slight effect on the heat flow and the rate of curing. The organoclays 10A, 20A, 30B also slightly influence the heat flow and the rate of curing. There are two peaks on the heat flow curves for the VE with the presence of these organoclays where there is only one peak on the VE curve. This may due to the intercalation treatment on the surface of these organoclays as mentioned in the materials. The G100 has strong effect on the curing of vinyl ester Hydropel. G100 delayed the curing reaction of the resin.

The glass transition temperature of vinyl ester and its nanocomposites are shown in Table 1. The presence of Na, G100, and C140 does not affect Tg of Hydropel. However 10A, 20A, and 30Bslighty influenced Tg since measured valued are generally a couple of degrees lower that the one of the neat resin. While Na is a natural montmorilloinite, Perkalite G100 is aluminum magnesium LDH synthetic clay modified with unsaturated fatty acid, C140 is colloidal silica sols in a hexandioldiacrylate binding agent. The modified unsaturated fatty acid f G100 and hexandioldiacrylate for C140 contain a double bonds which can form a cross link with VE during curing. Because of this, the addition of Na, G100 and C140 do not lower the Tg of VE. The change in the Tg of VE with the presence of 10A, 20A, and 30B

may be caused by the presence the intercalant on these nanoclays which may not react during curing. 0 0.5 1 1.5 2 Hydropel Hydropel-Na Hydropel-10A Hydropel-20A Hydropel-30B Hydropel-G100 Hydropel-C140 40 60 80 100 120 140 160 180 He at Fl o w ( W /g ) Temperature (oC) 0 20 40 60 80 100 Hydropel Hydropel-Na Hydropel-10A Hydropel-20A Hydropel-30B Hydropel-G100 Hydropel-C140 40 60 80 100 120 140 160 180 He at Fl o w ( W /g ) Temperature (oC)

Figure 4. DSC and transformation curves for Hydropel and Hydropel with different nano-particles

TABLE 1. TG FOR HYDROPEL AND ITS NANOCOMPOSITE WITH DIFFERENT NANO-PARTICLES Sample Tg (°C) Hydropel 118.9 ± 0.3 Hydropel-Na 118.1 ± 0.2 Hydropel-10A 110.7 ± 0.5 Hydropel-20A 113.3 ± 0.7 Hydropel-30B 111.4 ± 0.8 Hydropel-G100 118.4 ± 0.2 Hydropel-C140 116.0 ± 1.2

Tensile properties of Hydropel and its nanocomposites are shown in Figure 5. In general, the modulus of Hydropel increased with the addition of nano-particles. This is similar to the results reported in the literatures [1, 3, 4]. The tensile strength of Hydropel nanocomposites increased compared to Hydropel, except G100. It is very interesting to note here that for the case of clay Na, even without treatment on the surface for the compatibility with the VE resin, the presence of Na in VE also shows improvement of the modulus but also strength and strain of VE. The result seems even better compared to the organoclays. The increase of the strength and strain of VE with the incorporation of nano-particles, especially nanoclays, is interesting since a reduction of these properties is generally observed [5, 8]. The presence of C140 slightly increases the modulus of VE but significantly improve the strength and strain. This result also pulls out that both the level of dispersion and chemistry of clay treatment affect on the performance of VE nanocomposites. For the impact properties, if the error bar is taken into account, the nano-particles do not seems to have an effect on the impact property of the VE resin (Figure 6).

3000 3500 4000 4500 5000 H y dr op e l H y drop el -N a H y d rop el-10A H y d rop el-20A H y d rop el-30B H y dr op e l-G 1 0 0 H y d rop e l-C1 4 0 Te n s il e M o du lu s ( M Pa ) (a) 25 35 45 55 65 Hy dr o p e l Hy dr o p e l-N a Hy d ro p e l-1 0 A Hy d ro p el -2 0 A Hy d ro p e l-3 0 B Hy dr o p el -G 10 0 H y d ro p el -C 14 0 Tensi le S tr e n g th (MPa ) (b) 0 1 2 3 Hy d ro p el Hy d ro p e l-N a Hy d ro p el -1 0 A Hy d ro p e l-2 0 A Hy d ro p el -3 0 B H yd ro p e l-G 1 0 0 H yd ro p e l-C 1 4 0 Te n s il e S tr a in ( % ) (c)

Figure 5. Tensile properties of Hydropel with different nano-particles

5 10 15 20 25 Hy d ro p e l Hy d ro p e l-N a Hy d ro p e l-1 0 A Hy d ro p e l-2 0 A Hy d ro p e l-3 0 B H y d ro p el -G 10 0 Hy d rop e l-C 1 4 0 Im p a c t ( J /m )

Figure 6. Impact properties of Hydropel with different nano-particles

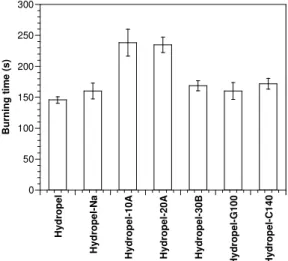

The effect of nanoparticles on the fire resistance of resin samples was also investigated and the result of the vertical burning times (flaming times) of the Hydropel and its nanocomposites are shown in Figure 7. The results indicate that

burning time varies depending on the type of nanoparticles used. The nanoclays Cloisite 10A and 20A have a significant positive effect on fire resistance of Hydropel compared to the other nanoparticles used in this study (≈ 65% increase in burning time). This confirms the flame retardant behaviour of the montmorillonites as reported in the literature for other polymer systems.

0 50 100 150 200 250 300 Hy d ro p e l H y dr op el-N a H ydr op el-10A H ydr op el-20A H ydr op el-30B Hy d ro p el -G 100 H y dr op e l-C 1 4 0 B u rn in g ti me (s )

Figure 7: Burning time for Hydropel R037 and its nanocomposites with different nano-particles (5 phr loading level)

With the results obtain, the nanoclay 20A was selected to continue to study their effect on the performance of the natural composite especially the fire resistance. The result of the vertical burning times (flaming times) of the hemp composite with and without presence of nanoclay are shown in Figure 8. The results show that the burning time of the composite increased with cleaned fiber and the presence of clay but the one with the presence of the nanoclay is more evident.

200 220 240 260 280 300 B u rn in g ti m e (s )

VE-Hemp VE-cleaned Hemp VE nano-Hemp

CONCLUSION

Vinyl ester nanocomposites based on different types of nano-particles and its composites with natural fiber has been studied. The types of nano-particles play a very important role in the formation of vinyl ester nanocomposites. The presence of particles, the quality of particles dispersion, compatibility between the nano-particles and the vinyl ester affect the curing reactions of the vinyl ester, the viscosity of the vinyl ester and the performance of the final nanocomposites. It is interesting to mention that not only the modulus of vinyl ester increases with the incorporation of particles but also the strength and strain increased for some types of nano-particles. The presence of clay in the resin also greatly affects the flammability performance of the resin and final composite.

ACKNOWLEDGEMENT

The authors wish to acknowledge the financial support from the ASM-NGV Program.

REFERENCES

1. Kornmann, X., L. A. Berglund, and J. Sterte. 1998. “Nanocomposites Based on Montmorillonite and Unsaturated Polyester,” J., Polym. Eng. Sci., 38 (8): 1351-1358.

2. Barber, G. D., R. F. Storey, and R. B. Moore. 1999. “Formation of Cation-Exchanged Clay Nanocomposites,” American Chemical Society, Division of Polymer Chemistry, 40 (2): 768-769. 3. Shah, A. P. and R. K. Gupta. 2002. “Flammability and Mechanical Properties of Vinyl Ester/Clay

Nanocomposites,” ANTEC.

4. Shah, A. P., R. K. Gupta, H. V. S. Gangarao, and C. E. Powell. 2002. “Moisture Diffusion through Vinyl Ester Nanocomposites made with Montmorillonite Clay,” Polym. Eng. Sci., 42 (9): 1852-1863.

5. Drozdov, A. D., J. D. Christiansen, R. K. Gupta, and A. P. Shah. 2003. “Model for Anomalous Moisture Diffusion through a Polymer-Clay Nanocomposite,” Journal of Polymer Science, Part-B-

Polymer Physics, 41 (5): 476-492.

6. Someya, Y. and M. Shibata. 2004. “Morphology, Thermal, and Mechanical Properties of Vinylester Resin Nanocomposites with Various Organo-Modified Montmorillonites,” Polym. Eng. Sci., 44 (11): 2041-2046.

7. Gilman J. W., T. Kashiwagi, J. Brown, S. Lomakin, E. P. Giannelis, and E. Manias. 1998. “Flammability Studies of Polymer Layered Silicate Nanocomposites,”

International-SAMPE-Symposium-and-Exhibition SAMPE, Covina, USA, 43 (1): 1053-1066.

8. Chigwada, G., P. Jash, D. D. Jiang, and C. A. Wilkie. 2005. “Fire Retardancy of Vinyl Ester Nanocomposites: Synergy with Phosphorus-Based Fire Retardants,” Polymer Degradation and

Stability, 89: 85-100.

9. Nazare, S., B.K. Kandola, and, A. R. Horrocks. 2006. “Flame-Retardant Unsaturated Polyester Resin Incorporating Nanoclays,” Polymers for Advanced Technologies, Polym. Adv. Technol., 17: 294-303.