COGENERATION AND UTILITY PLANNING FREDERICK H. PICKEL

July 1982 Energy Laboratory Utility Systems Program

Massachusetts Institute of Technology MIT Energy Laboratory Report

7VVKl /cC24 1 r~ F.I.T. UiBRARIES

SEP ,1 9

1983

L~I2CXLJ~

L

ABSTRACT

COGENERATION AND UTILITY PLANNING Frederick H. Pickel

.This research refines methods for forecast-rfg customer

cogeneration to assist electric utility planning for power supply and tariff design. The study employs a physically-based, or

engineering-economic process, approach to cogeneration forecasting that accounts for both cogeneration investment and operating choices by the utility's customers. This approach reflects the long-term uncertainties in the fuel and electric prices affecting those customer choices and the short-run uncertainties influencing cogeneration plant performance. The analysis devotes special attention to the effect of

utility tariffs on the customer's decision to build and operate a cogeneration plant and the resulting impact of these plant investment

and operating choices by the customer on the utility.

To identify the important factors in the forecasting process, detailed case studies have been carried out for 7 large commercial or industrial sites in southern New England; an aggregate forecast is then made using survey data from 123 sites with existing boiler facilities. Under the assumed economic conditions, coal-fired steam

turbine cogeneration is found to be economic at sites much smaller than previously has been thought to be economic.

Since southern New England is a region with slow electric load growth, utility planning of cogeneration tariff policy is the primary use for the modeling techniques in the case study. Cogeneration has an adverse impact on the utility's customers and stockholders when the utility's marginal cost, which is assumed to be the price for

electricity purchases from cogenerators, drops below its average tariff cost. The impact is diminished by designing tariffs so that the reduction in a customer's tariff costs through cogeneration

matches the utility's marginal cost reduction as closely as possible. When the utility can pay slightly less than the marginal cost, the latitude for the tariff design increases.

PREFACE AND ACKNOWLEDGMENTS

This report is a portion of the research efforts on utility operation and planning being carried out within the Utility Systems Program at the MIT Energy Laboratory. It is based on the doctoral dissertation by Pickel (1982), with only minor revisions. Other major research projects within the Utility Systems Program have developed coordinated models for power system planning, analyses of the

integration of solar photovoltaics and other alternate energy sources into the utility system, and new approaches for electricity pricing that encourage customer responsiveness to power system conditions.

The study was supported, in part, by research funds provided under contract to the MIT Energy Laboratory by New England Power Service Company, a subsidiary of the New England Electric System. Of course, neither New England Power Service Company nor any of its affiliates, officers, directors, agents, or employees makes any warranty or representation of the accuracy or completeness of this document.

Professor Fred C. Schweppe has provided extensive encouragement and advice, which was required to coax this research to completion. Richard Tabors, as co-supervisor, provided the Energy Laboratory base from which I could obtain funding and accomplish the research.

Together they are responsible for the continuity of MIT's utility planning research at the Energy Laboratory and the Electric Power Systems Engineering Laboratory, of which this report is a component. Professors David H. Marks, David C. White, and Henry D. Jacoby have

long assisted and encouraged me in my doctoral program and my pursuit of this research.

The insights of my colleagues at New England Electric, in

particular Frederic E. Greenman, William G. Hayes, Michael S. Hirsch, John L. Levett, and John W. Newsham, have enabled me to add special touches of realism to the study. In addition, I am grateful to

numerous individuals in industrial firms and other utilities who have helped educate me on the subject of cogeneration and have provided the data required for this study.

Alice Sanderson typed and retyped this report, quietly prodding the progress. Richard Desjardins graciously prepared the many figures.

I must especially thank Carol Chilk for her support, sacrifice, and patience while this was being completed. The completion of this research rewards countless prayers and enduring faith of my mother.

SUMMARY TABLE OF CONTENTS

PREFACE AND ACKNOWLEDGEMENTS Chapter 1 Chapter 2 Chapter 3 Chapter 4 Appendix A Appendix B Appendix C Appendix D Appendix D Introduction

A Customer's Perspective on the Adoption of Cogeneration

Estimating the Impact of Customer Cogeneration on a Utility

Conclusions

Symbols, Abbreviations, and Conversion Factors Examples of Typical Industrial and Large

Commercial Electricity Tariffs Site and Survey Data Assumptions

Cogeneration Technology and Cost Summary Modeling Summary REFERENCES BIOGRAPHICAL NOTE 151 230 244 255 267 280 316 327 334

TABLE OF CONTENTS

Page

ABSTRACT 2

PREFACE AND ACKNOWLEDGEMENTS 3

SUMMARY TABLE OF CONTENTS 4

TABLE OF CONTENTS 5

LIST OF FIGURES 11

LIST OF TABLES 14

CHAPTER 1: INTRODUCTION 18

1.1 An overview of cogeneration history and policy studies 20

1.1.1 The decline of cogeneration 20

1.1.2 Cogeneration studies 24 National level 24 Regional level 28 Utility level 30 Project level 31 Comments 31

1.2 Utility planning for customer cogeneration 33 1.2.1 Cogeneration-utility interactions 34 1.2.2 Electric load forecasting and customer

cogeneration 37

Electric load forecasting methods 38 Physically-based cogeneration forecasting 40

1.3 Organization of the report 41

CHAPTER 2: A CUSTOMER'S PERSPECTIVE ON THE ADOPTION OF COGENERATION 45

TABLE OF CONTENTS (continued) 2.2 The basic economics of cogeneration

2.2.1 Selecting and operating a cogeneration plant 2.2.1.1 Selection of utility tariffs under

cogeneration

2.2.1.2 Economic operation of a cogeneration plant

2.2.1.3 Sizing the cogeneration plant 2.2.1.4 Selecting the minimum cost plant

One design versus an existing boiler Comparison of multiple designs versus an existing boiler

2.2.2 The complications imposed by realistic utility tariffs

2.2.2.1 An introduction to utility ratemaking a industrial tariffs

2.2.2;2 The difficulties associated with typical utility tariffs for a cogenerating customer

2.3 Modeling the optimal economic design and operation of a cogeneration and boiler plant

2.3.1 Description of the cogeneration plant analysis model

2.3.1.1 The minimization of plant operatinq cos nd

ts Plant performance modeling

Operating cost escalation

Selection of minimum cost operating policy by year

2.3.1.2 The investment decision analysis

Page 49 50 52 53 59 68 82 92 95 96 101 102 110 i11 112

1

;:IeeF"ILI aTABLE OF CONTENTS (continued)

Page

Financial analysis 112

Expected value calculation 112 Minimum present cost plant design 118 2.3.1.3 Sensitivity analysis of operating and

investment decisions 125

2.3.2 Overview of plant studies by technology and site 131

2.3.3 Simplification of the model 134

2.3.4 Comparison of analytical and modeling results 137

2.4 Summary 148

CHAPTER 3: ESTIMATING THE IMPACT OF CUSTOMER COGENERATION ON

A UTILITY 151

3.1 The impact on the utility from cogeneration by a

single customer 151

3.1.1 The basic economics of the impact upon a utility

from customer cogeneration 156

3.1.1.1 The influence on the utility from each level of a customer's decision to

cogenerate 157

The levels of impact 159

Combined impact 160

3.1.1.2 Special complications for the utility

arising from typical tariffs 165 3.1.2 Modeling the impact from a customer cogeneration

system 171

3.1.2.1 An example of the impact from a single

8

TABLE OF CONTENTS (continued)

3.1.2.2 Modeling utility policies to reduce the impact from customer cogeneration

by limiting the tariff menu 177 3.1.2.3 Overview of the different site studies 182 3.1.2.4 Simplification of the modeling 185 3.1.2.5 Comparison of analytical and modeling

estimates of the utility impact 188 3.2 An aggregate forecast of the impact from cogeneration 190

3.2.1 Exploratory forecasts of the maximum cogeneration

capacity development 198

A simple single technology forecast 199

A simple multi-technology forecast 204

3.2.3 Forecasting using the cogeneration plant

investment and operation model 211

3.3 Summary and conclusions 227

CHAPTER 4: CONCLUSIONS 230

4.1 Research results 230

4.1.1 Cogeneration economics from the utility's

perspective 231

4.1.2 Forecasting cogeneration at the utility level 234 4.1.3 Physically-based electric load forecasting 236

4.2 Directions for further research 237

4.2.1 Cogeneration economics and utility planning

research 238

4.2.2 Cogeneration forecasting research 239 4.2.3 Physically-based electric load forecasting

research 240

TABLE OF CONTENTS (continued)

APPI

AP P

AP P

ENDIX A: SYMBOLS, ABBREVIATIONS, AND CONVERSION FACTORS ENDIX B: EXAMPLES OF TYPICAL INDUSTRIAL AND LARGE COMMERCIAL

ELECTRICITY TARIFFS

B.1 A traditional industrial tariff B.2 An energy-only industrial tariff 8.3 A time-of-use industrial tariff

B.4 A supplemental provision for customers who cogenerate B.5 A special cogeneration tariff

ENDIX C: SITE AND SURVEY DATA ASSUMPTIONS C.1 Detailed modeling data

C..1 Steam loads C.1,2 Electric loads

C.2 Modeling data for survey sources

C.2.1 Steam loads from survey sources C.2.2 Electric loads from survey sources ENDIX D: COGENERATION TECHNOLOGY AND COST SUMMARY

D.1 Components of cost and performance

D.,1 Fuel efficiency and output shares D.1.2 Plant reliability

D.1.3 Environmental factors D.1,.4 Capital costs

D.1.5 Operation and maintenance costs D.2 Cogeneration and steam technologies

D.2.1 Diesel cogeneration systems AP P Page 244 255 256 259 260 262 263 267 267 267 270 270 274 274 280• 281 283 287 290 290 299 302 302

10

TABLE OF CONTENTS (continued)

D.2.2 Gas turbine cogeneration systems D.2.3 Steam turbine cogeneration

D.2.4 Air conditioning chilled water systems combined with cogeneration

D.3 Summary and.comments APPENDIX E: MODELING SUMMARY REFERENCES BIOGRAPHICAL NOTE Page 305 308 311 313 316 327 334 i:

IST OF FIGURES LIST OF FIGURES Figure N( 1.1 1.2 1.3 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 Page

Estimated share of cogeneration in total U.S. electric and industrial steam energy supply Total U.S. electricity production and estimated cogeneration with projections for 1985

Cogeneration-utility interactions

Economic operation of a cogeneration plant Optimal sizing of cogeneration plant capacity

Cost components for diesel cogeneration per unit of steam Components in the cost of cogeneration systems

per unit of steam

Steam loads and cogeneration operating savings Sensitivity of the net present value of

cogeneration projects to unit cost reduction and peak electricity price conditions

Sensitivity of the net present value of oil-fired cogeneration to oil prices when electricity

credits are based on oil

Sensitivity of the net present value of oil-fired cogeneration to oil prices when electricity

credits are based on coal

The incremental cost of demand or energy use charges Comparative incremental value of additional

cogeneration on a net sale/internal usage basis by the large manufacturer on the H rate

The site steam and electricity cost analysis model Monthly average steam usage and the simulated shift-by-shift steam load duration curve for the large manufacturer

Results for the large manufacturer

21 23 35 58 64 66 69 73 76 79 80 87 91 98 108 119 o.

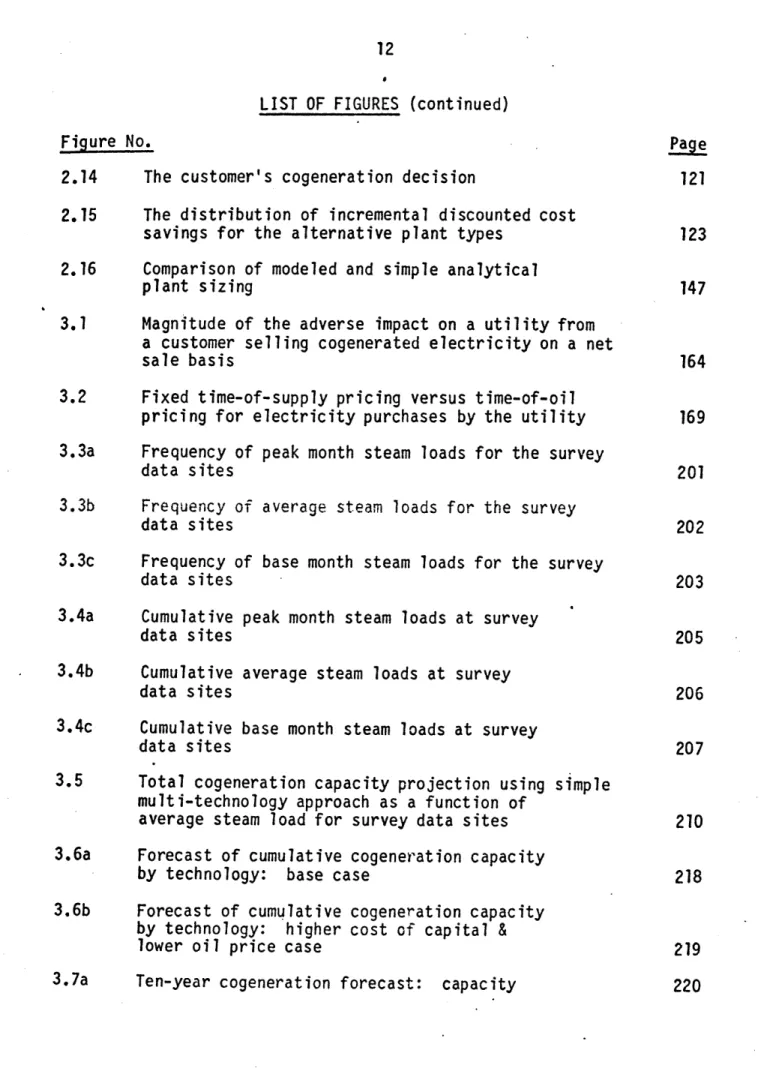

LIST OF FIGURES (continued)

Figure No. Page

2.14 The customer's cogeneration decision 121

2.15 The distribution of incremental discounted cost

savings for the alternative plant types 123 2.16 Comparison of modeled and simple analytical

plant sizing 147

3.1 Magnitude of the adverse impact on a utility from a customer selling cogenerated electricity on a net

sale basis 164

3.2 Fixed time-of-supply pricing versus time-of-oil

pricing for electricity purchases by the utility 169 3.3a Frequency of peak month steam loads for the survey

data sites 201

3.3b Frequency of average steam loads for the survey

data sites 202

3.3c Frequency of base month steam loads for the survey

data sites 203

3.4a Cumulative peak month steam loads at survey

data sites 205

3.4b Cumulative average steam loads at survey

data sites 206

3.4c Cumulative base month steam loads at survey

data sites 207

3.5 Total cogeneration capacity projection using simple multi-technology approach as a function of

average steam load for survey data sites 210 3.6a Forecast of cumulative cogeneration capacity

by technology: base case 218

3.6b Forecast of cumulative cogeneration capacity by technology: higher cost of capital &

lower oil price case 219

Ten-year cogeneration forecast: capacity _I___W___*il~fl__llII

LIST OF FIGURES (continued) Figure No.

3.7b Ten-year cogeneration forecast: expected energy output 3.7c Ten-year cogeneration forecast: expected

utility impact

3.8 Distribution of utility impact for aggregate forecast

C.1 Comparison of steam load duration data and estimates for the hospital site

D.1 Capital cost of boilers

D.2 Net capital cost of cogeneration equipment D.3 Gross capital cost per MBTU/hour of boiler

and cogeneration equipment

D.4 Gross capital cost per kilowatt of cogeneration equipment

D.5 Variation of gas turbine efficiency with unit capacity 221 222 226 269 294 296 297 298 307

14

LIST OF TABLES Table No.

1.1 Typology of cogeneration studies 2.1 Site survey

2.2 Cogenerated electricity sales choice

2.3 Examples of incremental fuel operating costs and optimal economic operation for cogeneration systems 2.4 Overview of the model implementation

2.5 Plant operating modes 2.6 The menu of tariff options

2.7 Fuel and utility conversion scenarios

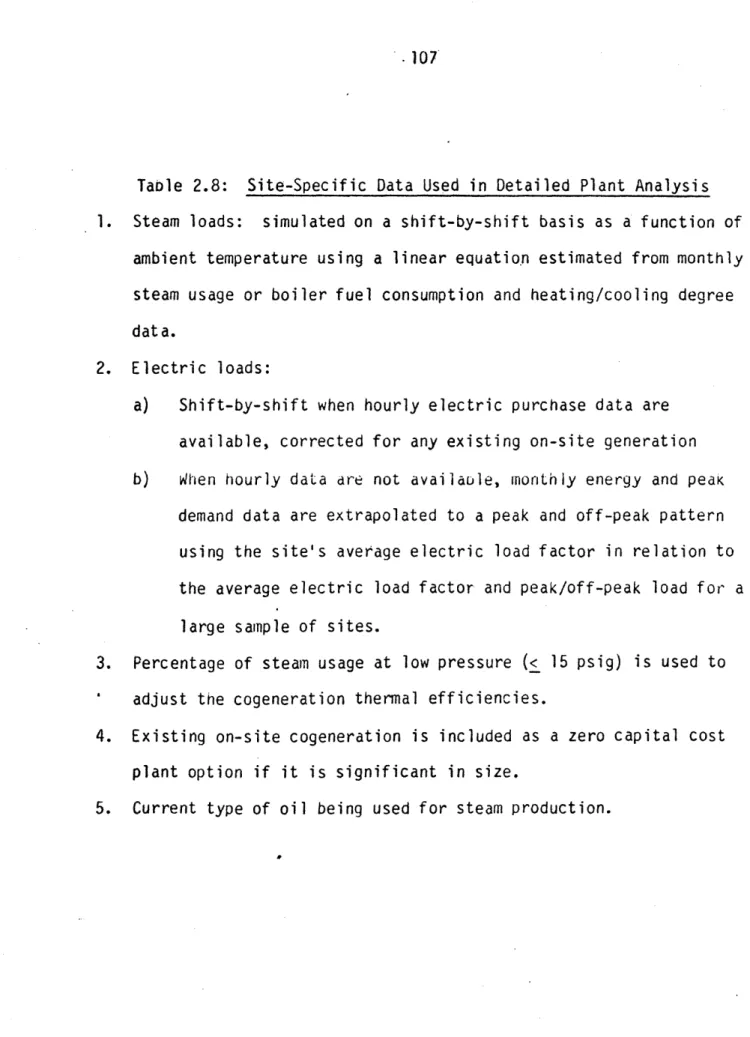

2.8 Site-specific data used in detailed plant analysis 2.9 Sample operating analysis for the large manufacturing

site

2.10 Cash flow analysis for the existing oil-fired boiler versus a new coal-fired steam turbine cogeneration plant 2.11 Components in adjusted present value for a coal

cogeneration plant at the large manufacturing site 2.12 The impact of fuel and electricity price uncertainties

on the value of a cogeneration plant

2.13 The optimal operating policies by scenario for an oil-fired steam turbine cogeneration plant at the

large manufacturing site in 1985

2.14 Sensitivity of the plant net present value because of restrictions or economic changes

2.15 Net present value of new plants

2.16 Site-specific data used in aggregate plant analysis 2.17 Present value for the replacement of an oil boiler 2.18 The value of time-of-oil pricing for the firm relative

to all tariffs with fixed time-of-supply pricing

Page 25 48 52 60 99 103 104 105 107 113 115 117 120 126 128 132 136 138 139

r~L~

e 5. iLIST OF TABLES (continued)

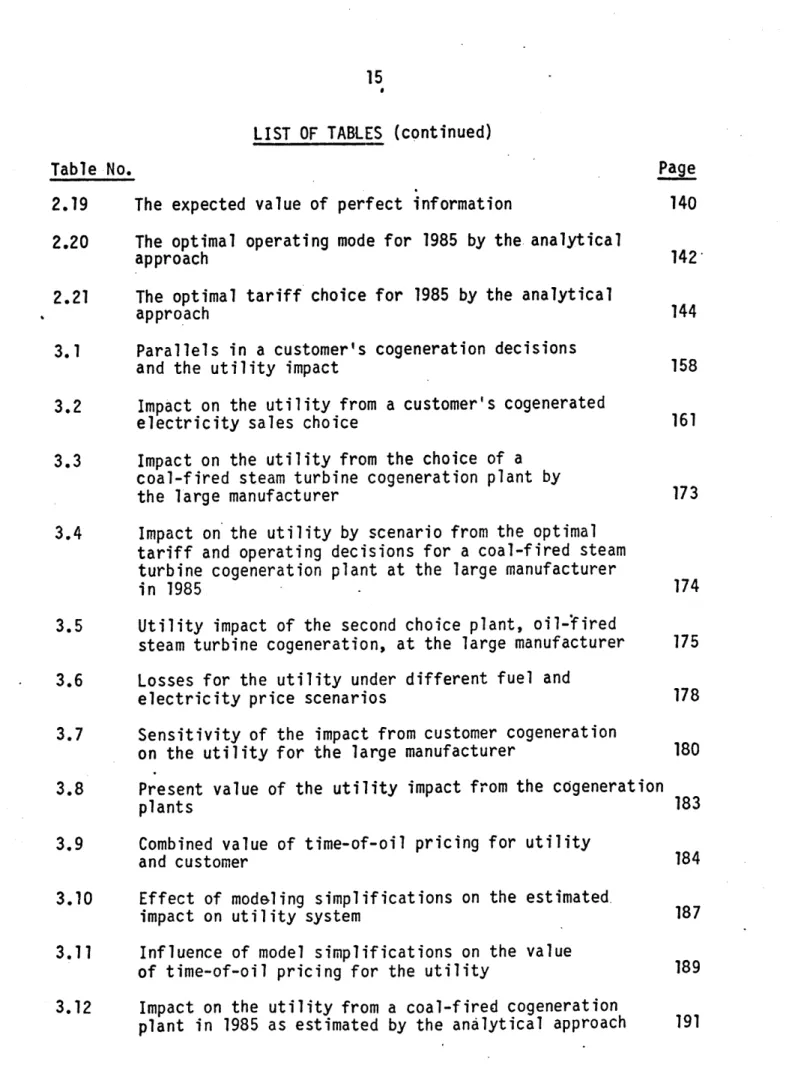

Table No. Page

2.19 The expected value of perfect information 140 2.20 The optimal operating mode for 1985 by the analytical

approach 142

2.21 The optimal tariff choice for 1985 by the analytical

approach 144

3.1 Parallels in a customer's cogeneration decisions

and the utility impact 158

3.2 Impact on the utility from a customer's cogenerated

electricity sales choice 161

3.3 Impact on the utility from the choice of a coal-fired steam turbine cogeneration plant by

the large manufacturer 173

3.4 Impact on the utility by scenario from the optimal tariff and operating decisions for a coal-fired steam turbine cogeneration plant at the large manufacturer

in 1985 174

3.5 Utility impact of the second choice plant, oil-fired

steam turbine cogeneration, at the large manufacturer 175 3.6 Losses for the utility under different fuel and

electricity price scenarios 178

3.7 Sensitivity of the impact from customer cogeneration

on the utility for the large manufacturer 180 3.8 Present value of the utility impact from the cogeneration

plants 183

3.9 Combined value of time-of-oil pricing for utility

and customer 184

3.10 Effect of modeling simplifications on the estimated.

impact on utility system 187

3.11 Influence of model simplifications on the value

of time-of-oil pricing for the utility 189 3.12 Impact on the utility from a coal-fired cogeneration

LIST OF TABLES (continued) Table No.

3.13 Classes of customer information employed in the construction of a cogeneration forecast

3.14 Utility sales in 1978 and growth rates expected to 1990

3.15 Coverage of the survey relative to the total utility sales

3.16 Sensitivity of the simple multi-technology forecast 3.17 Model forecast of cogeneration capacity, energy,

and utility impact

3.18 Sensitivity of forecast cogeneration capacity and energy output in 1985

3.19 Sensitivity of the utility impact to economic and environmental assumptions

3.20 Utility impact by scenario

4.1 Impact on the utility from a customer's cogenerated electricity sales choice

A.1 Conversion factors and abbreviations A.2 Subscripts and superscripts for symbols A.3 Symbols

C.] Information from utility survey of major industrial and commercial customers

C.2 Steam usage pattern information derived from survey data

C.3 Electrical usage pattern information derived from survey data

D.1 Equipment performance and cost data sources D.2 Plant output shares

D.3 Assumed plant reliabilities

Page 193 196 197 212 215 217 224 225 232 244 245 246 271 275 278 282 285 288 Yi _~-Lsll~a~L--~-- Uru~ar;u~~--s~- -~--. -

-rr-17

LIST OF TABLES (continued) Table No.

D.4 Capital costs and tax credits

D.5 Time distribution of capital expenditures D.6 Operating and maintenance costs

D.7 Comparative air conditioning chilled water costs D.8 Cost and performance summary for cogeneration plants

serving a constant 50 MBTU/hr high pressure steam load E.1 Summary of detailed modeling assumptions

E.2 Real fuel price escalation rates

E.3 Share of fuel types in average utility fuel mix E.4 Share of coal as marginal cost utility fuel E.5 Summary of aggregate modeling assumptions

Page 292 300 303 312 315 317 322 323 324 325

I

Chapter 1 INTRODUCTION

Cogeneration, or the simultaneous production of heat and electric or mechanical power, emerged as one of the main components of the energy conservation strategies in the past decade. All the major of national energy legislation in the past few years has adopted special tax treatment, exemptions from fuel use restrictions, and electricity and natural gas regulatory policy changes that are intended to

encourage cogeneration's more wide-spread adoption in anticipation of its higher energy conversion efficiencies.l The most debated issue has been the reform of rates between individual cogenerators and the

local electric utility. Many of the cogeneration studies in the late 1970's urged an analysis of the exact impact from current electric utility rates upon cogeneration project economics.2 The changes

influenced or mandated by the Public Utilities Regulatory Policies Act

1The Powerplant and Industrial Fuel Use Act of 1978 (PL95-620), the Public Utility Regulatory Policies Act of 1978 (PL95-617),

hereinafter PURPA, the Natural Gas Policy Act of 1978 (PL95-621), the Energy Tax Act of 1978 (PL95-618), and the Windfall Profit Tax Act (PL96-223). Both PURPA and regulations deriving from it are now under several major court challenges, with the original decisions against the law and against the regulations now on appeal. Mississippi v. Federal Energy Regulatory Commission, No. J79-0212(c), slip op. (U.S.C.S., S. Miss., February 19, 1982), argued No. 80-1749 (U.S. January 19, 1982). American Electric Power Service Corp. v. Federal Energy Resulatory Commission, No. 80-1789, slip op. (D.C. Cir., January 22, 1982), rehearing denied (D.C. Cir., April 9, 1982).

2

Resource Planning Associates (1977), Pickel (1978), and TRW and ThermoElectron (1979).

of 1978 have reached the implementation stage and the pilot cogeneration projects of the mid-1970's are nearing completion.

The purpose of this research is the refinement of cogeneration forecasting methods to supplement the information used in long-range, electric utility planning for capacity expansion and for tariff

design. It employs a physically-based, or engineering-economic process, approach to cogeneration forecasting that accounts for both

investment and operating choices by the cogenerating customers and reflects the long-term uncertainties in conditions affecting those customer choices and the short-run uncertainties influencing

cogeneration plant performance. To identify the important factors in the forecasting process, detailed case studies have been carried out for 7 large commercial or industrial sites in southern New England; an

aggregate forecast is then made using survey data from 123 sites with existing boiler plants. The analysis devotes special attention to the

influence of utility tariffs on the customer's decision to build and operate a cogeneration plant and on the resulting economic impact of these plant and operating choices by the customer on the utility.

This chapter provides a brief history of cogeneration's role in U.S. steam and electricity supply along with a short survey of recent cogeneration studies. An introduction to utility planning for

customer cogeneration'and the application of physically-based electric load forecasting techniques to cogeneration follows the survey. The introduction concludes with a discussion of the report's organization.

20

1.1 AN OVERVIEW OF COGENERATION HISTORY AND POLICY STUDIES

SThe

two products from cogeneration, steam and electricity, are both important components in total U.S. fuel consumption. Fuels for the generation of industrial process steam constituted nearly 17 percent of the total U.S. fuel consumption in the late 1960's.3 Only transportation and combined residential and commercial space heating exceeded this share for the end use of fuels. Electricity generation, which is not an end use, received about 21 percent of the total fuel consumed. Given these large shares for steam andelectricity in total fuel consumption, cogeneration has attracted the attention of policy makers, who have questioned why such an apparently fuel-efficient technology has seemingly diminished in importance since

the 1930's.

1.1.1 The Decline of Cogeneration

Cogeneration has long been a technique for supplying industrial and large commercial steam needs while simultaneously producting electricity. For example, many paper mills provided power for the local towns earlier in this century. The relative importance of cogeneration in electricity supply has declined since the 1940's, as illustrated by Figure 1.1. Its share in electricity supply has

dropped from 18 percent in 1941 to less than 4 percent in 1979.4

3Stanford Research Institute (1972).

4Electricity data from Edison Electric Institute (annually), a

personal communication with Sam Ferraro, Federal Power Commission (December 1975), and U.S. Energy Information Administration (1980).

ESTIMATED

SHARE OF COGENERATION

IN

TOTAL U.S. ELECTRIC

AND INDUSTRIAL STEAM

ENERGY SUPPLY

0-8 ST M 6- 4-6-0-ELE

NN_ N_ TRICITY 4 , , ... 2... 4 .... . . 1935 1940 1945 1950 1955 1960 1965 1985 YEAR Figure 1 I 0. 1980 --1970 197522

This continual drop in the relative share of electricity supply does not tell the whole story. Cogeneration also serves steam needs, but industrial energy use has grown historically at a rate much slower than total electricity consumption. This growth rate differential can explain a large part of the relative decline of cogeneration in

electricity supply. Figure 1.1 also gives a crude estimate of

cogeneration's share in industrial steam supply; in steam supply, the role of cogeneration did not decline continually over the last 40 years but only during the last 15 years. The total amount of

cogenerated electricity started to decline after the events of 1973,

as Figure 1.2 shows; this is in contrast Lo t ie forecasts by a broad range of studies and the intended purposes of a variety of government

5

, programs.

5These statistics are derived from industrial generation

statistics (see note 4). Not all industrial generation is

cogeneration: in 1979, 4.3 percent was from hydro, 4.0 percent was from gas turbines, 4.5 percent was from diesel, and 87.2 percent was from steam turbines. In 1945, steam provided 85 percent of industrial generation. This analysis assumed a fixed 87 percent of industrial generation was cogeneration. The estimate of steam production from cogeneration was made by assuming a constant ratio between electricity and steam output from cogeneration over this period, taking the ratio of industrial cogeneration to total fuel consumption from Chigioji (1979, p. 15), and calibrating the ratio on an estimate of

cogeneration in steam supply for 1976 from Resource Planning

Associates (1977, Ex. 5). Since the Energy Information Administration has altered and may abandon the gathering of statistics on industrial generation (personal communication with Melvin Johnson, U.S. Energy Information Administration, 1980), the industrial generation decrease after 1977 may be due, in part, to tne collection procedure changes. The projections for 1985 are derived from Dow et al (1975, pp. 88, 121), ThermoElectron (1976, table 6.32), Resource Planning Associates (1977, exhibits l.d and 4), and Pickel (1978, pp. 160-173), and U.S.

TOTAL U.S. ELECTRICITY PRODUCTION AND

ESTI MATED

COGENERATION

WITH

PROJECTIONS FOR

1985

10,000t . - " COGENERATION PROJECTIONS FOR 1985 I-Ar U EThermo Electron (1976) - _-___J_ _ _ ... .. _... Dow (1975) LL 0 _ _ Pickel (1978)

INDUS RIAL COGENERATIC N - RPA (1977)

z .- GAO (1980)

-J _ _ _ _

YEAR

o 24

1.1.2 Cogeneration Studies

Attracted to the substantially higher energy efficiencies associated with cogeneration over separated steam and electricity generation, long series of studies have offered reasons and proposed programs for increased utilization of cogeneration by industry. The analyses have covered the national, regional, utility and individual project levels from public policy, scholarly, utility, equipment manufacturer, and industrial firm perspectives. This section briefly surveys a limited group of these studies. Table 1.1 offers a typology of these works.

National Level

At the national policy level, the study by Dow Chemical et al. (1975) brought the subject of cogeneration to the attention of policy makers, suggesting substantial energy and capital savings through cogeneration by coal and nuclear facilities at very large industrial sites. The ThermoElectron report (1976) for the Federal Energy

Administration on three major steam using industries suggested greater electricity production and energy savings at medium sized industrial sites were possible through the use of gas turbine and diesel

engine-based cogeneration systems; they also recommended large federal investment tax credits and regulatory changes to combat a perceived hesitancy by industry and utilities to get involved in these expensive projects. Resource Planning Associates (1977, revised 1981), in a study covering six industries,projected much more moderate energy

Typology of Cogeneration Studies

Perspective

Public Industrial/ General

Policy Utility Manufacturers Analysis

National Dow (1975) Manuel et al. Schweizer & Williams

Level (1980) Sieck (1978) (1978)

ThermoElectron Synergistic Pickel (1978)

(1976) Resources (1981) RPA (1977,1981) Camm (1981) GAO (1980) Joskow (1981) TRW/TE (1979) NASA (1980)

Regional/ Williams (1976) Dittrich & Wakefield

State Level Allon (1977) (1975)

Mass. Gov. Comm. RPA (1979)

(1978)

Calif. PUC Helliwell &

(1978) Cox (1979)

Utility/ Bright, Davitian TVA (1979) Charmichael RPA (1980)

Plant Level Martorella (1978)

(1980)

ConEd (1979) Gordon &

DeRienzo (1979)

RPA (1980b) NEES (1978) Table 1.1:

savings and a slower growth of cogeneration both with and without federal incentives for industrial.

These policy studies heavily influenced the inclusion of special provisions for cogeneration in the National Energy Act. The Public Utility Regulatory Policies Act of 1978 (PURPA) required the

development of rules governing the purchase and sale of electricity by utilities from qualifying cogeneration facilities. The Powerplant and Industrial Fuel Use Act of 1978 allows special exemptions from coal conversion for some industrial cogeneration plants. The Energy Tax Act of 1978 indirectly includes special investment tax credits for portions of some copeneration technology capital costs and altersd depreciation provisions for oil and gas-fired boilers in a way that influences cogeneration economics. The Windfall Profit Tax Act of 1980 specifically allows special investment tax credits for non-oil and gas-fired cogeneration equipment. The Natural Gas Policy Act of 1978 allows the Federal Energy Regulatory Commission to exempt

qualifying industrial cogeneration facilities using natural gas from the incremental pricing provisions of that act; FERC has exercised this option.

Several national policy studies have followed this legislation. The U.S. General Accounting Office (1980) completed a review of cogeneration policy using the same general method as the Resource

Planning Associates (1977) study. TRW and ThermoElectron (1979) examined regional and industry differences in selecting the optimal cogeneration plant designs under current economic conditions. Two I~--~-"^---

-~----27

studies coordinated by the National Aeronautics and Space

Administration (1980) have explored the potential for different advanced technologies in cogeneration.

Several scholarly studies have also examined cogeneration at the national level. Williams (1978) provided a summary of policy reports up to that time and perspectives on cogeneration as a complement to other current and future electricity sources, especially as they relate to national oil import policy. Pickel (1978) explored the economics of cogeneration from an industrial organization perspective,

simulating the perfect market performance expected for cogeneration in the U.S. given historical and possible future cost conditions and

comparing this to historical market performance. Camm (1981) providea an international comparison of cogeneration's role by examining it in the Swedish national power system, where many large industrial firms own cogeneration and hydroelectric plants and interchange electricity with the national electricity grid. Joskow (1981) and Joskow and Jones (1981) discussed the fundamental microeconomics of cogeneration and its role in total U.S. electricity producton in the light of the microeconomic discussion.6

From the utility perspective, research by Synergic Resources Corp. (1981) for the Electric Power Research Institute has developed

historical statistics on the cost and performance of cogeneration systems. In addition, a project by Manuel et al. (1980) has developed

6

The plant sizing analysis in Joskow and Jones (1981) and Joskow (1981) is similar to that in Section 2.2.1.3 of this report.

28

detailed mathematical models for characterizing the design and

economics of cogeneration systems; results from these models are summarized to make national level forecasts of cogeneration. This project makes a simple attempt to characterize utility tariffs, but it lacks the treatment of long and short-term uncertainties needed for the analysis of a specific utility's rates.

A number of equipment .manufacturers have entered or considered entering the cogeneration equipment business. Few of the studies in support of these decisions, however, have been published. An

exception is Schweizer and Sieck (1978), who used detailed

characterizations of cogeneration plants to develop their projections for U.S. cogeneration.

Regional Level

At the state and regional level, New Jersey was one of the first states to explore cogeneration as a means for reducing energy

consumption; this evolved into a dispute between a public interest group and one of the state's major utilities over the magnitude of potential cogeneration in the state.7 The California Energy,

Resources, Conservation, and Development Commission, through its facility siting powers, and the California Public Utilities

Commission, through its powers of rate regulation and determination of need, have explored the potential for cogeneration in California

within a number of siting and rate-setting hearings. The California PUC, in a landmark case, reduced the allowed rate-of-return for Pacific Gas and Electric Company until PG&E had added specified amounts of cogenerated power to their energy supply.8 In

Massachusetts, a federally funded Governor's Commission examined the state barriers to increased cogeneration and estimated possible development for cogeneration in New England.9 A commission in Texas

has completed a plan for expanding industrial cogeneration within that state.10

From a methodological perspective, Resource Planning Associates (1979) have developed a general approach for states to follow in examining the potential development of cogeneration in their energy plans. A study by Wakefield (1975) evaluated the impact of a large cogeneration project on the local utility system operations and

planning along with'its influence on regional interfuel competition. Helliwell and Cox (1979) evaluated the influence of marginal versus average cost industrial pricing upon cogeneration in the paper and pulp industry and the resulting impact on regional electricity planning for British Columbia, Canada.

8California Public Utilities Commission 011-26 (filed Sept. 6,

1978). 9

Massachusetts Governor's Commission on Cogeneration (1978).

Utility Level

A number of utilities have performed stuaies of cogeneration within their individual service areas, although the studies have

usually been unpublicized unless they were required in the regulatory or legislative process. The two major classes of analysis are studies

of avoided costs for the determination of electricity purchase rates under the state implementations of the Federal Energy Regulatory

Commission rules issued under PURPA and forecasts of industrial and commercial cogeneration required for rate and capacity planning. The earliest publicized report was prepared by Dittrich and Allon (1977) of Public Service Electric and Gas Co. of New Jersey, which was a part of the New Jersey legislative study noted above. All the California utilities have prepared forecasts and cogeneration rate studies as required under their PUC's resolutions.II The TVA (1979), as a part of its capacity and fuel planning, undertook a major study of

cogeneration at existing industrial sites, the development of

large-scale industrial energy centers, and the possibilities for the conversion of existing regular generation plants to cogeneration.

Consolidated Edison has performed studies of cogeneration economics at a surveyed group of customer sites and then calculated the impact of these conversions.12 New England Electric, at the same time as tne Massachusetts Governor's Commission on Cogeneration mentioned above,

11California Public Utilities Commission, Docket OIR-2 (Filed

SSeptember

3, 1980).12Described

31

made an extensive survey of its larger customers and calculated the

cost from the customer's perspective of converting to 13

cogeneration. Resource Planning Associates (1980b) nas made

projections for the Pacific Gas and Electric territory using the same basic method employed in the RPA(1977) national study.

Project Level

A large number of detailed analyses have been made of cogeneration at individual plant sites; they can be separated into studies for

large industrial plant sites and for

heating-ventilating-air-conditioning systems in commercial complexes. A typical process industry case study is documented by Gordon and De Rienzo.14

Because of the continually changing mix of steam, cooling, and

electrical needs, HVAC-based systems require more elaborate studies, as discussed in Channichael (1978) or Bright, Davitian, and Martorella (1980).15

Comments

These studies span the globe from Sweden to San Diego, offering

13Communications with New England Electric personnel (1979 et

.seq).

14From Gordon and DeRienzo of Dravo Corp. at the EPRI

Cogeneration Workshop (1979).

15Appendix D discusses some of the problems with incorporating

absorbtion air conditioning, but this report does not examine in detail the combined addition of cogeneration and absorbtion air

recommendations on everything from federal tax policy to the brand of scrubber for coal systems; several factors, however, characterize their approach to analyzing cogeneration. First, recognizing that an industrial or commercial establishment must use the heat output from the plant, most studies make some calculation of the economics of a cogeneration plant from the firm's prospective.16

Second, as the studies become more geographically localized in their scale, cogeneration forecasts are more likely to be based on an enumeration of potential sites rather than an estimate based on

aggregate fuel consumption with an allowance for the scale of the

individual sites in the population. The forecasts base( on tne

enumeration of potential cogeneration sites commonly estimate a lower potential for cogeneration than those based on aggregate energy data for the same area.

Finally, nearly'every study has assumed a small number of

characteristic cogeneration plant types, one approach to the sizing of

the cogeneration relative to the plant's steam and electric loads, and one principle set of fuel and electricity prices. Within these

studies there has been no explicit consideration of the substantial plant performance and electricity and fuel price uncertainties.

1

GOne attempt to apply econometric methods to cogeneration was in an appendix to the U.S. General Accounting Office (1980) report.

1.2 UTILITY PLANNING FOR CUSTOMER COGENERATION

A utility may require the adaptation of its capacity, rate-making, and operating plans in response to the potential development of new cogeneration in its service territory. Significant growth in customer cogeneration might alter capacity requirements or shift the desired generation capacity mix. The utility's profits may change adversely because tariffs for cogenerating or potentially cogenerating customers affect each firm's cogeneration plant design and operation and may alter incentives for electric energy conservation and load management for the inplant loads. The operation of the cogeneration plants influences the economic operation of the utility's plants. Finally, the dispersed cogeneration plants can affect the physical Dehavior of the power system.

As noted at the start of the introduction, this research refines cogeneration forecasting methods to improve the information provided for long-range electric utility for planning capacity expansion and tariff design. Previous studies of cogeneration at the utility level have been ad hoc and only rarely documented in a way that provides a reproducible procedure for a similar situation.17 Furthermore, the

forecasting of cogeneration must be coordinated with tne other aspects of capacity and rate planning. Specifically, it must be directly compatible with other components of the electric load and revenue

17

Exceptions are Resource Planning Associates (1980b) and -Tennessee Valley Authority (1979), although they do not mention any

i

34forecast. In the process of attaining these goals, the project also extends an aspect of the physically-based, or process, approach to

electric load forecasting.

This section, first, discusses the economic interactions that influence the level of industrial cogeneration and, then, the utilization of this economic understanding within physically-based electric load forecasting approach to obtain the information needed for utility planning.

1.2.1 Cogeneration-Utility Interactions

Figure 1.3 provides a scheoatic of the major econosmic interacLioris

between the utility and the industrial sector. The industrial firms, or even the large commercial customers, must select sources for their heat and electricity needs, which are influenced by the costs of heat and electricity. In this conceptual perspective, the supply of heat and steam is separated from the basic industrial process needs so the technologies for providing heat and power can be determined

independently of the selection of heat and electricity use in the basic industrial (or commercial) process needs.18 Assuming that steam is the principle of heat requirement need tnat will be under investigation here, the supply of heat and electricity amounts to

18This separation of industrial energy demand into a main and

sub-production function (here, into basic processes and into

electricity and steam services) is an intellectual step-child of the separation discussed in Berndt (1978) and Berndt and Wood (1979) in their discussion of engineering versus economic approaches to

COGENERATION-

UTILITY INTERACTIONS

INDUSTRIAL SECTOR BY SITE

aI at -I 41 BASIC INDUSTRIAL PROCESSES AT INDIVIDUAL SITES ELECTRICITY 8 STEAM COSTS ELECTRICITY & STEAM USAGE ELECTRICITY PURCHASE & SALE COST QUANTITIES BOUGHT 8 SOLD -WEATHER

-- FUEL COSTS

il~

-I

CAPITAL COSTS

liii

Figure 1. 3

4 VV

STEAM & ELECTRICITY SERVICES THE UTILITY - OPERATIONS - EXPANSION -RATES MACROECONOMIC CONDITIONS

I Q

I' I I I I| I l qlI EQUIPMENT COSTS

I CAPITAL COSTS -... iraising steam in boilers or through cogeneration and producing

electricity or buying it from the utility. The steam and electricity services question will be the main point of study. Influences upon

the underlying demands for steam and electricity by the basic industrial processes will be discussed qualitatively.

The industrial firm's choice of steam and electrical services is affected by fuel costs, equipment costs, capital market conditions, taxes, and electricity tariffs, as illustrated by Figure 1.3.

Electricity tariffs are likewise influenced by fuel prices, similar equipment costs, capital market conditions, taxes, and the overall demand for electricity. Tne overall demand for electricity is the combined load from all sectors less any cogeneration. The analysis here accounts for the influences of fuel prices and equipment costs on electricity rates; the changes in net electric loads because of

cogeneration, however, are not directly included. This allows full consideration of fuel, equipment, and capital market changes that affect the industrial choices directly and indirectly through electricity tariffs without going through the elaborate procedures needed to make a full equilibrium model of the local industrial and utility electricity market. This major simplification is valid as long as the cogeneration forecast does not shift the nominal total values used for developing the utility capacity and revenue plans, i.e., a change in cogeneration from this forecast does not

I substantially upset the whole utility plan, feeding back upon the

1.2.2 Electric Load Forecasting and Customer Cogeneration

Within the planning process, the utility must consider three

components within a cogeneration forecast for it to be useful for both capacity and rate decisions: first, a description of how electric loads will change; second, an estimate of the change in utility revenues because of cogeneration or any rate schedule changes

I influencing cogeneration; third, the change in utility production costs from any cogeneration. The latter two components combine to form an estimate of the final profit or net revenue requirements

impact on the utility because of the load change.19 Each component needs to be further characterized by a time scale ranging from hours to years. For example, steam usage may be very high on a cold day, so existing cogeneration plants would probably be running near full steam output; consequently, cogenerated electric output might be higher on cold days. At another extreme of the time scale, once a customer decides to build a cogeneration plant, it will be several years before

it is in full operation, and it will have the potential for generating electricity for decades. Finally, the cogeneration forecast must be

19This report combines the ratepayer's (all electricity

customers of the utility) and the utility stockholder's interests under the umbrella term "utility". The exact impact on each of these two groups from a change in cogenerated electricity and its attendant

cost and revenue changes depends upon the regulatory process for setting the utility's rates. Often fuel cost changes will be

reflected immediately in fuel adjustment charge changes for the ratepayers; changes in the per kWh utilization of the total utility ratebase will be bourne by the stockholders until a revision in tariff levels under a formal rate hearing. See Section 3.1.1.1 for a more complete discussion.

coordinated with the overall utility electric load forecast.

Electric Load Forecasting Methods

Since forecasts of electricity consumption are one of the fundamental aspects of electric utility planning, many research efforts have developed, discussed, and categorized approaches for modeling and projecting changes in peak electric loads and electric energy consumption. Like the cogeneration studies, they have been conducted at the national, regional, and utility level from both the

public and private perspectives. This section discusses only the methods designed primarily to assist a specific utility's planning.

Three general types of analysis have been employed for the medium -and long-range of one to twenty years required for utility rate and

capacity planning. Time series analysis provides only elaborate extrapolation of historical data. Econometric analysis links historical information and hypothesized economic relationships to estimate possible future electricity usage, but it cannot adequately address the diversity of technological and rate design questions asked concerning cogeneration policies. Finally, engineering-economic

process or physically-based approaches to electric load forecasting disaggregate the specific process components that make up the total

load, forecast changes in these components, and then recombine them to make a full forecast. The Energy Modeling Forum (1980), Mahmouo

(1980), and Woodard (1972), among others, have surveyed the utility load forecasting subject area.

This report follows the phyically-based school of thought

discussed in Ruane, Manichaikul, Schweppe, and Woodard (1978). This perspective within the engineering-economic process method of analysis decomposes the electric load into electrical devices or cohesive

groups of devices, called elemental demands or loads. Each elemental load is separated into two further factors, a representation of the capital stock for each device and of the utilization for each device:

Device Device

Elemental = Capital x Utilization

Load Stock Factor

1

1(1.1)

The elemental load can be categorized by device, usage class, and customer. For example, micro-wave ovens might represent an elemental demand in the ovens device class, in the cooking usage class, and in the residential user'group. Woodward (1974) pioneered this general approach, applying it to the residential sector. The works by Galiana ()971) and by Mahmood and Schweppe (1980) are related through their treatment of weather effects on the utilization factor in the

elemental demand. Ruane (1980) extended this approach for the

residential sector. Manichaikul (1978), examining the influence of time-of-day pricing in the industrial sector, advanced the treatment of the utilization factor by considering both the effect of the

underlying process usage and the economic operating choices made by the industrial firm. All these studies have devoted extensive

40 process fluctuations.

Physically-Based Cogeneration Forecasting

In applying this approach to cogeneration load forecasting, three modifications and additions to the previous works must be made.

First, a customer generation source becomes a negative load. Second, the capital stock factor must now specifically treat an economic decision by the customer to add cogeneration capacity. Finally, the utilization of the cogeneration capital stock becomes conditional on long-term economic uncertainties as well as short-term weather and cogeneration plant outage uncertainties.

As noted above, a useful cogeneration forecast requires estimates for changes in three components: electric load, revenues from the

customers, and utility production costs. Taking a si.ngle customer of the utility, these can be defined in the format of physically-based

load modeling--first, the electric loads can be described as:

instantaneous- instantaneous

net load sum of site

from a = elemental - cogeneration

customer loads (1.2)

where

[an

instantaneous] [device ] instantaneouselemental load = capital stock x Idevice utilization

factor (1.3)

and, more specifically,

instantaneous cogeneration plant cogeneration plant site = plant electri- utilization factor

and

cogeneration plant] rplant economic plant availability utilization factorJ = utilization x and load following

sub-factor sub-factor (1.5)

Second, the costs are:

instantaneous instantaneous instantaneous cost to serve = power system Ix net load from

customer incremental cost a customer Third, the revenues for a billing period are:

revenue from a the tariff, selected by the customer, customer over = computed on the relevant history of the

a month customer's loads and generation

(1.6)

(1.7)

The utility can directly influence the revenues and costs through changes in the tariffs available and the production costs. The

customer affects the loads and, ultimately, the revenues and costs through capital stock, device utilization, and tariff type choices. The tariff can be affected by past and present loads, so changes in elemental loads can influence the economics of the cogeneration plant and visa versa.

1.3 ORGANIZATION OF THE REPORT

To improve cogeneration forecasting for utility capacity and

tariff planning, efforts must be made in three areas. First, a better understanding is required concerning the major economic motivations behind a firm's decision to build and operate a cogeneration plant and the impact of these decisions on the local utility. Second,

cogeneration forecasting techniques that project electric load, revenue, and cost changes for a utility must be developed. Third,

given the nature of cogeneration economics, extensions are necessary to the general physically-based approach to electric load forecasting, especially the inclusion of long-run uncertainties in fuel and

electricity prices and their influence on the individual cogeneration plant's operating policies.

In the exploration of improvements to cogeneration electric load forecasting, this report addresses itself to two questions:

* How does customer cogeneration influence an electric utility's loads, revenues, and costs?

* What are the major influences on a customer's decisions to build and operate a cogeneration plant?

Since the second question must be addressed to answer the first, the next chapter examines the economics of cogeneration from an industrial firm's perspective, taking into account the long and short-term

uncertainties that affect the firm's choice. Returning to the utility perspective, the third chapter uses the physically-based approach to electric load forecasting to project cogeneration development in a specific utility area, estimating total cogeneration capacity development and its possible operation under various fuel and electricity price scenarios. The fourth chapter discusses the

implications of chapter three's results for utility planning,

suggesting approaches for limiting any adverse impacts of cogeneration while cooperating in the public policy goal of promoting energy

conservaion. The fourth chapter then summarizes the methodological aspects of the forecasting research and suggests directions for

# 43

further inquiry. Appendices describe the cogeneration moael used in Chapters 2 and 3 and provide documentation of the economic and

technical assumptions used in the case studies.

An analysis of cogeneration requires attention to too many factors to be done in the abstract. To identify the key influences on the utility and the local firms, this research had to be carried out for a specific utility and on information from the local industrial and

large commercial establishments, all of which are sites with existing boiler plants. Detailed site information for 7 large commercial or industrial facilities is used in case studies in Chapters 2 and 3 in order to test the relevance of economic and modeling assumptions; the aggregate forecast examples in Chapter 3 use survey data from 123 sites.

Since this study was performed in association wit'h a large New England electric utility, many of the conditions and issues reflect

the situation in that region. This analysis, however, provides a general approach for examining the impact of cogeneration on utilities

in other regions as well.20 Furthermore, a cogeneration forecast must be coordinated with the overall electric load forecast; the development of a physically-based load forecasting model for New England, described in NEPOOL Load Forecasting Task Force and

2 0

To maintain confidentiality for the utility and the private firms, the analysis in this report has altered some aspects of the

data and economic assumtions so that--while representative--they do not precisely reflect the conditions at the specific firms or the

utility. In particular, the tariffs used in the calculations are the same as those actually offered.

44

Battelle-Columbus (1977), provides a similar type of overall

forecasting model with which this type of cogeneration forecast could be coordinated after revisions.

45

Chapter 2

A CUSTOMER'S PERSPECTIVE ON THE ADOPTION OF COGENERATION

During the last decade, fimnns have witnessed extraordinary

increases in the energy components of their operating costs. In real terms nationwide, tne price of electricity for industrial uses has risen by 100 percent while fuel oil for boilers has risen 300 percent from 1973 through mid-1981.1 Tnese cost increases have forced tne re-examination of opportunities for industrial energy conservation ana substitution of energy sources. Owing to the widespread use of Doth steam and electricity in many industries, the cogeneration of heat and mechanical or electrical power has been one of the most widely

discussed energy cost reduction opportunities for the industrial sector. This chapter explores the economic motivations for the conversion to cogeneration from the private firm's viewpoint. To provide a realistic perspective, the first section describes electricity and -steam production and usage at seven industrial and large commercial

sites in southern New England. Any specific plant site faces local fuel prices and electricity tariffs; the detailed analytical work for this chapter devoted extensive effort to careful inclusion of the influences from the local electricity tariffs. The complex nature of these tariffs, however, often occludes the general understanding of the economic forces underlying the tariffs. Consequently, the second

1Based on statistics from the U.S. Department of Energy

Information Adminstration (Uecember 1981) and the GNP price deflator.

46

section begins with a discussion of the economic incentives related to cogeneration plant operation, sizing, and selection without regard to specific utility tariffs. At the end of that section, several

complications induced by realistic utility tariffs are described. The analysis of cogeneration requires too many details to be carried out entirely in the abstract: the third section, therefore, describes the application of a detailed model of cogeneration project economics to six of the seven industrial and commercial sites. This model

calculates the present value of the expected cash flows from

alternative boiler and cogeneration plants at a site, allowing tne firm to shift operating modes and tariffs over time; the model captures the major fuel and electricity price uncertainties impinging upon the firm2 by employing a decision analysis approach.

Note that this chapter takes the perspective of the utility's customer throughout the discussion of cogeneration economics. Chapter 3 will provide a parallel analysis from the utility's perspective.

2.1 SITE STUDIES

To both reduce the number of details in the evaluation of

cogeneration systems and focus the analysis on realistic situations, the study surveyed seven industrial and large commercial sites in the -service territory of the utility. The selection of the sites was

2Tnroughout the next two chapters, the term site will De used to

refer to the whole of an industrial or commerciaT-facility. The term plant will refer only to the boiler or cogeneration equipment at the

a 47

intentionally diverse; they all, however, are major customers of the utility, each with a peak electric load of more than 1 MW. They ranged from a multi-story office building to a large manufacturing facility with over 120 separate buildings at a single location.

Two major factors affected the selection of potential sites for the visits and. study:

1. the importance of that particular site type to the utility's load, either as an existing customer group or as a new group through growth (altnough this chapter adopts the customer's perspective, it is important to focus on the important customers).

2. the availability of data on steam and electricity use at the given site.

Since the commercial sector of the specific utility .studied is a larger share of the total load than the industrial sector, and the commercial sector is expected to grow more quickly, the surveys included several sites of that class. In addition, to explore the differences between sites of the same industry, the large and medium manufacturing sites were selected since they produce similar product lines.

Table 2.1 summarizes the size, steam and electric loads, and tne existing equipment at the seven sites. The first site visited,

interestingly enough, could not be converted to cogeneration without great difficulty because of the distributed nature of its cooling equipment and its minimal heating needs. The Large Manufacturer site will be discussed the most since it is used as the example for

Table 2.1: SITE SURVEY

Steam Loads Elec- Using (est.) tric Low Peak/

Loads Pressure Median/ Avg. Steam Base

(KW) (Percent) (MBtu/hr)

Existing Plant Equipment Genera-tion Boilers Cooling (Fuel) Compu- 650,000 ft2 ter 1500 employees Assembly Plant Office Build-ing 750,000 ft2 5 floors Paper 165,000 ft2 Mill 600 employees Medium 700,000 ft2 Manu- 1300 employees facturer approx. 1200 2150 5070 2410 Large 126 buildings 8280 Manu- 4000 employees facturer .Hos-pital 296,000 ft2 1,000 employees 264 beds College 19 buildings 2400 students 500 staff 480 700 100% 15/0/0 45 KW emergency diesel 10% 23/5/0 3000 KW emergency diesel 15% 69/42/35 300 KW steam cogenera-tion 0% 36/21/17 485 KW emergency diesel 0% 179/85/58 67% 17/7/4 100% 37/8/0 6000 KW steam cogenera-tion 1250 KW emergency diesel 250 KW steam co- genera-tion roof- 20 MBtu/hr top (#2 oil) electric 3000 2 @ 40 ton MBtu/hr elec- (#2 oil) tric chillers 60 MBtu/hr 30 MBtu/hr 10 MBtu/hr (#6 oil) 900 2 @ 25 tons MBtu/hr roof- (#6 oil) top & central electric 1300 200 MBtu/hr tons (#6 oil) electric & 950 tons ab-sorption 125 20 MBtu/nr tons 13 MBtu/hr electric (#6 oil) & 600 tons ikb-sorption 500 20 MBtu/hr tons 2 @ 15 roof- M8tu/hr top (#6 oil) electric Size of Faci I ity

demonstrating each aspect of the cogeneration modeling for a single site.

One unanticipated result of the site surveys was the wide variation in steam loads from season to season because of plant heating and

cooling loads from space conaitioning needs or ambient temperature effects on the process steam loads. Even energy intensive paper and manufacturing plants had winter/summer steam load ratios of 2:1 to

3:1. Section 2.3.1 and Appendices C and E contain further information on the site heat and electric loads.

2.2 THE BASIC ECONOMICS OF COGENERATION

Since any firm can obtain its steam and electricity needs from a cheap package boiler and through electricity purchases from the local utility, the decision to build a cogeneration plant involves making a major capital investment with the intention of lowering future

operating costs. Since the project must be justified by these future operating cost reductions, the future operating decisions must be considered at the time of the project's design and selection. This section explores the basic economics behind this trade-off between capital expenditures and the possibility of lower future operating costs.

Although the ultimate goal of this study is to explore the impact of utility tariffs, the complications contained in them often obscure the fundamental effects--the exposition of the basic economics in Section 2.2.1 avoids the details of the realistic tariff schedules.

Section 2.2.2 introduces some- of the complexities associated with realistic utility tariffs and cogeneration.

2.2.1 Selecting and Operating a Cogeneration Plant

Any industrial or large commercial site considering the

installation of a cogeneration plant must contemplate two levels of decisions concerning the plant:

* At the design or capital investment stage,

- the type of plant to be built and its fuel capabilities;

- the size of the plant in relation to the site's steam and

electric loads;

* At each point over the operating life of the plant built,

- the disposition of the cogeneration plant's electric output; it can be used to serve internal electric loads at the site, thereby reducing the electricity bill for the firm, or it can be sold directly to the utility.

- the level of operation of the plant at each instant; for example, it could be operated all the time, meeting all steam loads up to its capacity, or it could operate only during peak hours, allowing a regular boiler to meet all the steam loads during off-peak hours, or it could operate in

coordination with the utility.

This section explores in a simplified manner these alternatives faced by the customer.