Publisher’s version / Version de l'éditeur:

Key Engineering Materials, 347, pp. 505-510, 2007

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4028/www.scientific.net/KEM.347.505

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Structural health monitoring of aerospace structures with sol-gel spray sensors

Ouahabi, A.; Thomas, M.; Kobayashi, M.; Jen, C. -K.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=fe1e18db-9774-4a0f-a1b4-dd24a2b2cd52 https://publications-cnrc.canada.ca/fra/voir/objet/?id=fe1e18db-9774-4a0f-a1b4-dd24a2b2cd52

! " " # " $ %% & ' ( $ ) $ *+ + , , & -./ " 0 1 0 1 ) $ 20 342 5 6 6 5 5 5 6 " " 5 7 6 " " 8

A new approach is proposed for conducting structural health monitoring, based on newly developed piezoceramic sensors. They are fabricated by a sol gel spray technique. The potential application of these sensors may be broad. These sensors have been evaluated for structural health monitoring studies. The purpose of the present study aims the detection and the localization of defects by the means of these new piezoceramic sensors. Nine sensors were integrated onto a metallic plate with moving masses. The plate was excited by an impact at a specific location and the vibratory signals from sensors were recorded simultaneously. The analysis of signals obtained from nine locations was correlated with a numerical simulation in order to identify at each time the location of the mass.

Non destructive testing (NDT) of materials are commonly performed to identify, characterize, assess voids, defects and damage in metals, metal alloys, composites and other materials [1]. Furthermore, the increasing demand to improve the performance, reduce downtime, increase reliability and extend the life of transportation vehicles, structures and engineering systems, requires the use of systems that have integrated capabilities with built in sensors that perceive and process in service information and take actions to accomplish desired operations and tasks [2]. Piezoelectric ceramic sensors and actuators are commonly used as key candidates for smart materials and structures. They have been used as structural vibration actuators, structural health monitoring sensors, non destructive evaluation probes for materials and structures, etc [3]. Thick (≥ 40 .m) piezoelectric ceramic films can be made by the technologies of jet printing [4], dipping [5], tape casting [6], hydrothermal method [7], etc.

Here, an alternative sol gel spray technique is used. They take form of thick film layers with substrates having different shapes. An important characteristic of these sensors is that they can be coated directly onto desired sensing locations of planar or curved structures. These sensors present a considerable advantage because their fabrication focuses on the use of hand held tools. It is possible to obtain a thickness ranging between 25 and 150 .m and a diameter which can be less than centimeter. Their operating temperature ranges from 100°C to 440°C [3]. For example, they can be applied as sensors onto thin metallic and flexible membranes or around cylindrical surfaces. The purpose of the present study aims the detection and the localization of defects by the means of new piezoceramic sensors in the form of thin layers of piezoelectric materials coated directly onto the structures.

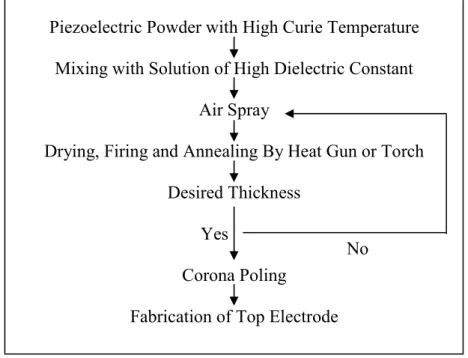

The fabrication process was first developed at Queen’s [8]. The piezoelectric particles are dispersed in the sol gel solution to produce a thick piezoelectric film [3, 9]. The spray can be carried out by an air gun at room temperature and it is simple and inexpensive. The ball milled sub micron

All rights reserved. No part of contents of this paper may be reproduced or transmitted in any form or by any means without the written permission of the publisher: Trans Tech Publications Ltd, Switzerland, www.ttp.net. (ID: 132.246.232.2-19/07/10,14:51:10)

piezoelectric lead zirconate titanate (PZT) or bismuth titanate (BIT) powders were dispersed into PZT sol gel solution. The PZT and BIT powders were chosen because of their high piezoelectric constant and high Curie temperature (675°C), respectively. The final PZT/PZT or BIT/PZT mixture (paint) was then sprayed directly onto selected metallic substrates, such as stainless steel through an airbrush. With this sol gel spray technique, the films can be produced at desired locations using a paper shadow mask. After spraying the coating, thermal treatments such as drying, firing and/or annealing were normally carried out using a heat gun. In special cases in this study a furnace would be used and mentioned specifically. Multiple coatings were made in order to reach desired film thicknesses. The film thickness is between 40 and 200 .m. Piezoelectric films were then electrically poled using a corona discharging technique. The corona poling method was chosen because it could pole the piezoelectric film over a large area with complex geometries. Finally, silver paste, platinum paste or silver paint spray method was used to form the top electrodes at room temperature. The measured relative dielectric constant of the PZT/PZT film and BIT/PZT film was about 320 and 80,

respectively. The d33 measured by an optical interferometer was 30 1012m/V for PZT/PZT and 10

1012m/V for BIT/PZT. The thickness mode electromechanical coupling constant measured was 0.2

for PZT/PZT and that for BIT/PZT was lower. Fig. 1 presents the flow chart of the fabrication process of the thick film described above.

Fig. 1: Flow chart of the fabrication process of piezoelectric thick film.

The numerical and experimental study of integration of this kind of sensors has been developed for the defective and no defective plate in order to compare between them, and to extract a conclusion concerning the effectiveness of these sensors for the detection and the localization of the defects.

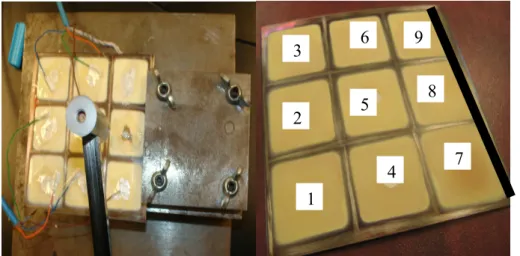

Nine of piezoceramic PZT/PZT sensors were deposited onto a steel plate (100 ×100 × 0.5 mm) as shown in Fig. 2. The thickness of theses piezoceramics is 40 .m thick. The electrodes have been mounted on each piezoceramic layer by using a silver pen. The wires were glued with silver epoxy. The plate is mounted in clamped configuration. A small moving mass of 3 grams is bonded to the plate at different locations to simulate a defect in the plate. At each location of the mass, an experimental modal analysis has been conducted by using the impact technique and compared with the results obtained without mass. The vibratory response was simultaneously collected at each

Piezoelectric Powder with High Curie Temperature Mixing with Solution of High Dielectric Constant

Air Spray

Drying, Firing and Annealing By Heat Gun or Torch Desired Thickness

Yes

Corona Poling

Fabrication of Top Electrode No

location with the piezoceramic sensors and the impact was measured with force sensor. The first five natural frequencies were analysed. Fig. 3 presents one of the frequency response functions (FRF). As expected, the effect of added mass can be easily detected from the decrease of natural frequencies. However, it can be noticed that the sensitivity of the decrease is not the same at each natural frequency. The variation of each natural frequency accordingly with the position of the added mass will be demonstrated in the latter section.

Fig. 2: Clamped plate under impact excitation (Hammer) and classification of sensors.

% %% *8 2%% %% % %% % +3 9 ":& ; % %% %% < <-< = < <-< =

Fig. 3: FRF of defective (mass at location 1) and no defective plate.

We have noticed a hardening effect in time of the piezoceramic layers that have produced an increase from a small amount (up to 10%), of the natural frequencies of the plate. Also, comparative tests with an accelerometer show that this sol gel spray sensor is able to be used as sensor because it delivers the same type of signal without amplifier.

1 2 3 4 5 6 7 8 9

The cantilever plate has been discretized into 28×28 finite elements, as shown in Fig. 4, and the effect of piezoceramic layers has been considered. The first five natural frequencies of the plate were numerically computed without mass and with the mass located at various positions ( ) (i = 1,…9). Figure 5 shows the corresponding mode shapes (ANSYS©). It was revealed that the mode shapes are not affected by the position of the added mass.

Fig. 4: FEM modelization of plate with piezoceramic layers.

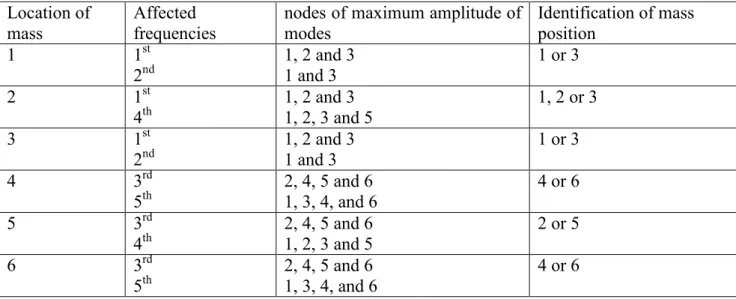

Accordingly to the location of the mass (0 means without defect), Fig. 5 shows clearly a decrease of natural frequencies. That decrease is more sensitive to some specific frequencies accordingly with the position of maximum amplitude of modes, as it is put in evidence by arrows). By investigating simultaneously all the natural frequencies that are most affected when the added mass is located at a specific position, and by analysing the location of maximum amplitude for each considered mode, it is now possible to locate the possible positions of defect. Table 1 shows the process of identification. By considering more modes, the process of identification will be more accurate. The variation of frequencies when the mass was located close to the clamp was not enough sensitive to conclude.

Location of mass

Affected frequencies

nodes of maximum amplitude of modes Identification of mass position 1 1st 2nd 1, 2 and 3 1 and 3 1 or 3 2 1st 4th 1, 2 and 3 1, 2, 3 and 5 1, 2 or 3 3 1st 2nd 1, 2 and 3 1 and 3 1 or 3 4 3rd 5th 2, 4, 5 and 6 1, 3, 4, and 6 4 or 6 5 3rd 4th 2, 4, 5 and 6 1, 2, 3 and 5 2 or 5 6 3rd 5th 2, 4, 5 and 6 1, 3, 4, and 6 4 or 6

Table 1: Identification of possible locations of defect.

Mode 1 Mode 2 Mode 3 Mode 4 +%/ + % + / + % + / ++% ++/ % + 2 / 3 . > ? % ! " # $ % & ' +> +? 2% 2 2 2+ % + 2 / 3 . > ? % ! " $ % & ( ?2 ?3 ?> %% % %2 %3 % + 2 / 3 . > ? % ! " $ % & ) +/ 2% 2/ /% // 3% 3/ % + 2 / 3 . > ? % ! " # $ % &

Mode 5 Fig. 5: Variation of natural frequencies with added mass.

New integrated thick piezoceramic sensors were used for the detection and the localization of defects. They seem effective for potential structural health monitoring. Their advantage lies in the fabrication that focused on the use of the handheld and readily accessible equipment to perform sol gel spray technique. The merits of these sensors are mainly in their miniature and lightweight (film thickness ≥ 40 .m), flexible, non destructive test and smart sensing site. An application of these sensors in order to detect a light added mass was successful, by analysing the decrease of frequency produced by the mass. Furthermore, an analysis of the more affected frequencies and their corresponding modes allowed for the identification of possible locations of the mass.

! "

The authors are grateful to the support of the Industrial Materials Institute (IMI), National Research Council of Canada (NRC), and the Consortium for Research and Innovation in Aerospace in Quebec (CRIAQ).

#

[1] A.S. Birks, R.E. Green, Jr and P. McIntire in: , 2nd Ed.,

volume 7 of Ultrasonic Testing, ASNT (1991).

[2] M T. Kundu: Ultrasonic Nondestructive Evaluation: Engineering and Biological Material Characterization (CRC Press, New York, 2004).

[3] M. Kobayashi and C. K. Jen: Smart Materials and Structures Vol. 13 (2004), p.951

[4] H. Adachi, Y. Kuroda, T. Imahashi and K. Yanagisawa: J. J. Appl. Phys. Vol. 36 (1997), p.1159

[5] K.L. Gentry, J.M. Zara, S. D. Bu, C. B. Eom and S.W. Smith: Proc. IEEE Ultrason. Symp Vol. 2 (2000), p. 977

[6] C. Galassi, E. Roncari, C. Capiani and P. Pinasco : J. Eur. Ceram. Soc. Vol. 17 (1997), p. 367 [7] M. Shimomura, T. Tsurumi, Y. Ohba and M. Daimon: J. J. Appl. Phys. Vol. 30 (1991), p. 2174 [8] A. Barrow, T.E. Petroff, R.P. Tandon and M. Sayer: J. Appl. Phys. Vol. 81 (1997), p. 876 [9] M. Kobayashi, T. R. Olding, M. Sayer and C. K. Jen: Ultrasonics Vol. 39 (2002), p. 675

* +// +3% +3/ +.% +./ +>% % + 2 / 3 . > ? % ! " # $ % &

Structural Health Monitoring of Aerospace Structures with Sol-Gel Spray Sensors