Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Technical Paper (National Research Council of Canada. Division of Building

Research), 1967-09

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=6b37b5b6-feda-4221-852f-736233ea1991 https://publications-cnrc.canada.ca/fra/voir/objet/?id=6b37b5b6-feda-4221-852f-736233ea1991 For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20374973

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire Endurance of Door Assemblies

i:ler ltll:i l-- ! l : , r l-- + ' ' : ; . r r . f , U , i -. i -. r l i J i l . 1 ' . ,.,.j-:" :,:, ! t J l - \ i

\lational

Fiesearch

]ouncilCanada

Conseil

de recherches

national

Canada

/

"l

;:"'t'/

FIRE ENDURANCE

OF DOOR

ASSEMBLIES

Fl. +'i f. L.\'; E n BY

MURDOCH

GALBREATI{

T E C H N I C A L P A P E R N O . 2 5 I O F T H E D I V I S I O N O F B U I L D I N G R E S E A R C HOTTAWA

SEPTEMBER 1967

F R I C E f t . O O N R C 9 7 4 6NATIONAL RESEARCH COUNCIL OF CANADA DIVISION Or. BUILDING RESEARCH

FIRE ENDURANCE OF DOOR ASSEMBLIES

by

Murdoch Galbreath

A N , A l y Z r ? D

T e c h n i c a l P a p e r N o . 2 5 I of the

Division of Buitding Research

OTTAWA S e p t e m b e r 1 9 6 7

A S T M E I 5 Z , o f t h e A m e r i c a n S o c i e t y f o r T e s t i n g a n d Materials, and BS476 of the British Standards rnstitution and the Standards

of France and Denmark. There is no published inforrnation

relating to tests carried out in accordance with the Standard M e t h o d o f F i r e T e s t o f D o o r A s s e r n b l i e s , C S A B 5 4 . 4 o f t h e Canadian Standar ds As sociation.

Tests of assernblies that contain rnaterials identified

by trade narrre only have been excluded frorn this paper because these assernblies cannot be adequately identified.

S P E C I A L I N T R O D T I C T I O N

T H I S P U B L I C A T I O N H A S B E E N P R E P A R E D T O B R I N G T O C E T I . I E R IN CONVENIENT FORM A LIMITED AMOUNT OF THE INFORMATION

S C A T T E R E D T H R O U G H O U T T H E P U B L I S H E D L I T E R A T U R E O N F I R E

ENDURANCE OF DOOR ASSEMBLIES. IT IS INTENDED FOR INFORMATION PURPOSES ONLY AND IS NOT TO BE REGARDED AS AN OFFICIAL LISTING O R R A T I N G . T H E D E S I G N E R , M A N U F A C T U R E R , O R B U I L D I N G O F F I C i A L M A Y F I N D I T N E C E S S A R Y T O E X E R C I S E J U D G E M E N T O N A S S E M B L I E S DIFFERING FROM THOSE FOR WHICH TEST OR RATING INFORMATiON IS

AVAILABLE, AND IN SUCH CASES THE INFORMATION NOW ASSEMBLED

M A Y B E U S E F U L .

A L L T H E T E S T I N F O R M A T I O N I N T H I S P U B L I C A T I O N I S I N C L U D E D WITI{ THE PERMISSION OF THE ORIGINAL AUTHQRS AND PUBLISHERS. I T H A S B E E N R E A R R A N G E D T O B R I N G T O G E T H E R C O N V E N I E N T L Y A L L THE RESULTS ON THE SAME OR SIMILAR N4ATERIALS WHEREVER THIS

IS APPROPRIATE. IN MANY CASES THE DETAILED DESCRIPTIONS

PROVIDED IN THE ORIGINAL PUBLICATIONS HAVE HAD TO BE ABBREViATEI) OR OMITTED. REFERENCE SHOULD ALWAYS BE MADE TO THE ORIGINAL PUBLICATIONS FOR VERIFICATION OF THE DESCzuPTION AND METHOD OF

T E S T B E F O R E P L A C I N G G R E A T W E I G H T O N I N D I V I D U A L V A L U E S . T H E V A R I O U S I T E M S A R E C R O S S R E F E R E N C E D T O T H E B I B L I

-O G R A P T I Y , W H I C } { L I S T S T H E S -O U R C E P U B L I C A T I -O N S . N -O REPR-ODLICTI-ON SHOULD RE MADE OF ANY OF THIS MATEzuAL WITHOUT THE PERMISSION OF TI]E ORIGINAL PTiBLISHERS.

A C K N O W L E D G E M E N T . I I I E P E R M I S S I O N G I V E N B I ' A U T H O R S , A G E N C I E S , A N D P U B I . I S F I E R S T O R E P R O D U C E T I - I E M A T E R I A L O N W H I C H T H I S P U B L I C A T I O N I S I } A S E D I S G R E A T L Y A P P R E C I A T E D . ( i i )

2 . 0

2 . r

z . z

2 . 3 2 . 4? . 5

? . 6

2 . 7

2 . 8 Test Inforrnation F i r e E x p o s u r e T e s t s o f O t d F i r e p r o o f e d W o o d D o o r s b y U n d e r w r i t e r s r L a b o r a t o r i e s I n c .Fire E>cposure Tests of Ordinary Wood Doors by Underwriters I Laboratorie s Inc.

F i r e T e s t s o n W o o d D o o r s , b y G . C . M a c N a u g h t o n and T. J. Martin. F i r e R e s i s t a n c e T e s t s o f S o l i d W o o d F l u s h D o o r s , by V.P. Miniutti. E s s a i s d e R S s i s t a n c e a u F e u d e P o r t e s e n B o i s o u ) B a s e d e B o i s , b y J . P . F a c k l e r .

Brandtekniske Forsog rned Entredore by

Gerhard Hansen and H. 'Winckelrnann, Statens

Byggeforskningsinstitot SBI. Rapport 31,

I Kornrnission Hos Teknisk Forlag, Kobenhavn,

1 9 s 9 .

Door as Barriers to Fire and Srnoke by H. Shoub a n d D . G r o s s , B u i l d i n g S c i e n c e , S e r i e s 3 , U . S . Dept. of Cornrnerce, National Bureau of Standards, ' W a s h i n g t o n ,

M a r c h 1 9 6 6 .

Review of Test Data

n a

(,

U

Investigations on Building Fires, Part IV, Fire R e s i s t a n c e o f T i r n b e r D o o r s , b Y C . J . W e b s t e r a n d L . A . A s h t o n . 1 3

z 3

z 8

5 0 6 5 6 9 ( i i i )S e c t i o n 2 . 3 - F i r e T . J .

LIST OF TABLES AND FIGURES

T e s t s o n W o o d D o o r s b y G . C . M a c N a u g h t o n a n d M a r t i n . Table F i g u r e Table T a b l e F i g u r e Figure F i g u r e T a b I e T a b l e F i g u r e 3 . t 3 . A ' ? . 4 . I 2 . 4 . 2 2 . 4 . A 2 . 4 . B 2 . 4 . c ? . 5 . L 2 . 5 . 2 2 . 5 . A 2 . 8 . I 2 . 8 . A

z .

z .

F i r e R e s i s t a n c e o f D o o r A s s e r n b l i e s .Details of Construction of Four Types of Doors T e s t e d .

F i r e R e s i s t a n c e o f D o o r A s s e m b l i e s . F i r e R e s i s t a n c e o f W o o d P a n e l s . D e t a i l s o f D o o r A s s e r n b l i e s .

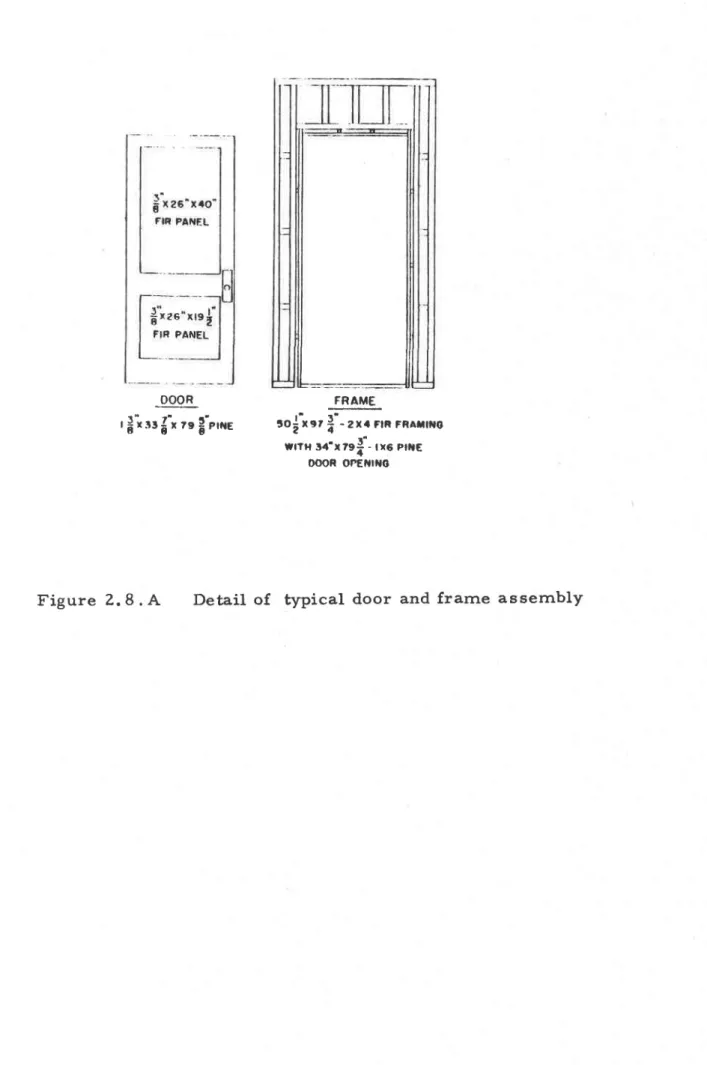

Arrangernent of Panels for Fire Resistance T e s t s . C o r n p a r i s o n o f t h e F i r e R e s i s t a n c e o f H a r d a n d S o f t W o o d s o f V a r i o u s T h i c k n e s s e s . C o n s t r u c t i o n D e t a i l s o f S o l i d W o o d F l u s h D o o r s T e s t e d a t U . S . F o r e s t P r o d u c t s L a b o r a t o r y . S u m r n a r y o f O b s e r v a t i o n s o n F i r e R e s i s t a n c e T e s t s o f S o l i d W o o d F l u s h D o o r A s s e r n b l i e s . R e s u l t s o f F i r e R e s i s t a n c e T e s t s o n F l u s h W o o d D o o r s . R e s i s t a n c e a u F e u d e P o r t e s e n B o i s o u ) B a s e d e P . F a c k l e r . F i r e R e s i s t a n c e o f D o o r A s s e r n b l i e s . D e t a i l o f T y p i c a l D o o r a n d F r a m e A s s e m b l y . S g c t i o n 2 . j ! - I n v e s t i g a t i o n s o n B u i l d i n g F i r e s b y C . J . W e b s t e r a n d L . A . A s h t o n . S e c t i o n 2 . 5 - F i r e R e s i s t a n c e T e s t s o f S o l i d W o o d F I u s h D o c r s b y V. P. Miniutti. S e c t i o n 2 . 6 - E s s a i s d e B o i s b y J . F i g u r e S e c t i o n 2 . 8 -2 . 6 . ( A , B , C , D , E , F , G ) D e t a i l s o f D o o r A s s e r n b l i e s D o o r s a s B a r r i e r s t o F i r e a n d S r n o k e b v H . S h o u b a n d D . G r o s s . T a b l e F i g u r e ( i v )

JabIe T a b l e T a b I e 3 . 2 3 . 3 3 . 4 F i r e T e s t s o f S o l i d W o o d D o o r s . F i r e T e s t s o f P a n e l l e d W o o d D o o r s . F i r e T e s t s o f H o l l o w W o o d D o o r s . ( v )

FIRE ENDURA}TCE OF DOOR ASSEMBLIES

by

Murdoch Galbreath

PART I FIRE ENDURANCE OF DOOR ASSEMBLIES

I n r e c q n t y e a r s i n c r e a s e d a t t e n t i o n h a s b e e n p a i d t o t h e p r o v i s i o n pf flre separation within buildings, and there has been a corresponding increase in the dernand for inforrnation relating to the fire endurance of door assernblieg. $ltJrough tJrere are standard rnethods of fire test of floop assernblies,there is little published test inforrnation available.

irtost of the testing in North Arnerica has been carried out by Underwritersl L a b o r a t o r i e o I n e . , w h o d o n o t r e l e a s e f u l l d e t a i l s o f a t e s t e d a s s e r n b l y because of the nature of their service. They do, however, publish lists of acceptable doors, frarnes and hardware tJrat may be identified by the

U n d e r w r i t e r s t L a b o r a t o r i e s I a b e l .

T o m e e t b u i l d i n g c o d e r e q u i r e r n e n t s , t h e r e f o r e , o n e i s f o r c e d either to use a labelled door assernbly or to conduct a fire test. The National Building Code, however, does perrnit the use of solid wood doors in certain Iocations without test and without lirnitation on frarnes or hard-w a r e .

S E C T I O N 1 . T

T e s t M e t h o d s

The standard rnethod of fire test of door assernblies that is generally r e c o g n i z e d i n N o r t h A r n e r i c a a n d o n e t h a t i s t h e b a s i s o f t h e U n d e r w r i t e r s r l a b o r a t o r y t e s t i n g i s A S T M F I 5 Z o f t h e A m e r i c a n S o c i e t y f o r T e s t i n g a n d M a t e r i a l s . T h e c o r r e s p o n d i n g C a n a d i a n s t a n d a r d i s C S A 8 5 4 . 4 o f t h e Canadian Standards Association. In botJr test rnethods the door assembly is exposed to a furnace that follows the same tirne-ternperature relation as t h e S t a n c l a r d M e t h o d o f F i r e T e s t o f B u i l d i n g C o n s t r u c t i o n s a n d M a t e r i a l s , A S T M E t l 9 . T h e r e a r e n o s p e c i f i c l i m i t s o n t e m p e r a t u r e r i s e o n t h e u n -exposed side in ASTM ELs? or on passage of flames or flaming on t.he

u n e x p o s e d s i d e . T e r n p e r a t u r e s o n t h e u n e x p o s e d f a c e a r e , h o w e v e r , r e c o r d e d . Failure is determined by the developrnent of openings or by the rnovement of a door in relation to the frarne beyond specified lirnits. After fire exposure the door assernbly rnust rernain in place and not develop any openings during

the criteria used for deterrnining failure.

The British test is 85476 of the British Standards Institution and i n c l u d e s d o o r s i n t h e d e s c r i p t i o n o f t e s t s f o r w a l l s , f l o o r s , c o l u r n n s a n d b e a r n s . T h e g e n e r a l c r i t e r i a f o r f a i l u r e a r e ( l ) c o l l a p s e , { Z l d e v e l o p m e n t o f c r a c k s o r f i s s u r e s t h r o u g h w h i c h f l a r n e s c a n p a s s , ( 3 ) a n a v e r a g e t e r n p e r a t u r e r i s e o n t h e u n e x p o s e d s u r f a c e o f . l 3 9 C d t g ( 2 5 0 F d e g ) o r a t e r n p e r a t u r e r i s e o f I 8 0 C d e g ( 3 2 5 F d e g ) a t o n e p o i n t . T h i s l a s t r e q u i r e -rnent rnay be waived for doors, etc,, when it is not intended that cornbusti-ble rnaterials will be placed against the elernent in service. During tJle series of British tests of door assernblies included in this paPer another criterion was adopted. Sorne penetration of flarne around the door was considered acceptable and tJ:e door assernbly was said to have rrceased to b e o f u s e a s a f i r e s t o p t r o n l y w h e n a c r a c k 6 i n . I o n g a p p e a r e d o r w h e n an opening or an area of flaming on the r+nexposed surface developed that w a s 6 i n . s q u a r e ( S e c t i o n 2 . 4 ) .

In the French test there are four criteria for failure and three

c l a s s i f i c a t i o n s o f f i r e e n d u r a n c e . T h e c r i t e r i a ' f o r f a i l u r e a r e ( l ) s t r u c t u r a l stabitity (abififf to sustain applied loads ayrd perforrn intended function); (2) adequate therrnal insulation (average ternperature rise of l40C deg

( Z 5 Z F d e g ) o r l 8 0 C d e g ( 3 2 4 F d e g a t o n e p o i n t ) ; ( g ) r e s i s t a n c e t o t J r e P a s s a g c of flarnes, (4) no ernission of flarnrnable gases on the unexposed side.

T h e c l a s s i f i c a t i o n s a d o p t e d a r e : ( a ) t ' S t a b l e s a u f e u r r : t h i s d e s c r i b e s p e r f o r r n a n c e o f e l e r n e n t s f o r w h i c h o n l y c r i t e r i o n N o . ( I ) i s r e q u i r e d -( b ) r r P a r e - f l a r n e s t t : t h i s d e s c r i b e s t h e p e r f o r r n a n c e o f c l e r n e n t s f o r w h i c h t h e c r i t e r i a o f s t r u c t u r a l s t a b i l i t y r r € s i s t a n c e t o t h e p a s s a g e o f f l a r n e s a n d f l a r n r n a b l e g a s e s ( l ) , ( 3 ) a n d ( ) a b o v e a r e r e q u i r e d . ( c ) r r C o u p e - f e u r t : t h i s c i e s c r i b e s t h e p e r f o r r n a n c e o f e l e r n e n t s f o r w h i c h a l l o f t h e c r i t e r i a ( l ) , ( 2 1 , ( 3 ) a n d ( 4 ) a b o v e a r e r e q u i r e d .

The Danish test Iollows the sarne general lines as the French and R r i t i s h t e s t s . l n t h o s e r e p o r t e d i n t h i s d o c u m e n t ( S e c t i o n 2 . 7 1 n o e n d p o i n t

is specified, but behaviour during tJre S o r n e e a r l i e r U . S . t e s t s w e r e E l 5 Z w a s d e v e l o p e d . F o r t h e s e a l s o

period. A nurnber of significant end

3

-t e s -t i s d e s c r i b e d .

conducted before the ASTM Standard there was no specific fire endurance p o i n t s w e r e , h o w e v e r , r e c o r d e d . SECTION I

Propietarv Materials

S e c t i o n s 2 . 3 , 2 . 5 a n d 2 . 6 t o 2 . 8 i n c l u d e d e s c r i p t i o n s o f f i r e t e s t s

of assernblies that contained proprietary rnaterials and, in particular,

fire retardant paints. Following the policy adopted for this series these

tests are not reproduced in this docurnent because the inforrnation cannot b e a p p l i e d d i r e c t l y t o o t J r e r a s s e r n b l i e s . W h e r e a f i r e r e t a r d a n t p a i n t o r

treatment is described, giving the nature of the rnaterial and the rate of

application, the tests are included in this report.

T h e B r i t i s h t e s t s ( S e c t i o n 2 . 4 ) i n c l u d e a c o m p a r a t i v e f i r e e x p o s u r e t e s t o f d i f f e r e n t s p e c i e s o f w o o d , i n c l u d i n g a f i r e r e t a r d a n t i r n p r e g n a t e d

soft wood. The results show no increase in fire endurance attributable to

this treatrnent. Fire retardant treatrnent of the rneeting edges of door

a n d f r a r n e d o e s , h o w e v e r , a p p e a r t o l i m i t t h e p a s s a g e o f f l a m e s . I n a d d i t i o n , t h e D a n i s h t e s t s ( S e c t i o n 2 . 7 ) i n c l u d e a n u r n b e r o f t e s t s o f doors with an inturnescent paste (not described) that was forced into a groove in

the door. This paste swelled when exposed to fire, filling the gap between

door and frame,effectively stopping tJ e passage of flame and srnoke for an

the pubtished test inforrnation available to the Division of Building Research. T h e r e a r e , i n a d d i t i o n , r n a n y f i r e t e s t s o f p r o p r i e t a r y d o o r s , f r a r n e s a n d h a r d w a r e t h a t h a v e b e e n t e s t e d b y U n d e r w r i t e r s r L a b o r a t o r i e s I n c . T h e s e

rnay be identified through the U.L. listing and labelling service.

T h e d o o r s d e s c r i b e d i n t h i s p a p e r a r e w o o d d o o r s i n w o o d o r m e t a l frames and have a fire endurance between a few rninutes and a little rnore than one hour.

SECTION Z. I R e f e r e n c e F i r e E > c p o s u r e T e s t s o f O I d F i r e p r o o f e d W o o d D o o r s , B u l l e t i n o f R e s e a r c h N o . 5 , u n d e r w r i t e r s t L a b o r a t o r i e s I n c . , c h i c a g o , N o v . 1 9 3 8 . G e n e r a l D o o r s t a k e n f r o r n a N e w Y o r k h o t e l d e r n o l i s h e d i n 1 9 3 0 - 3 I w e r e

tlre subject of this series of tests. Thus they were at least ?5 to 30 years

old when tested. Chernical analysis showed that the wood had been treated

witJr large arnounts of arnmoniurn sulphate and arnrnoniurn phosphate.

Construction

T h e d o o r s w e r e a p p r o x i r n a t e l y 3 - b y 6 - f t 8 - i n . a n d Z - f t 6 - i n . b y 7 - 1 t 6 - i n f o u r - p a n e l l e d d o o r s . P a n e l s , s t y l e s , a n d r a i l s w e r e o f w h i t e

pine with birch veneer on exposed faces. Panel rnoulding-s were of birch.

The doors were rnounted in steel frarnes with two steel +l-in. rnortised

hinges; the upper hinge was 8 in. below tJre top of the door and the lower

,hinge was l2 in. above the sill. Each door was equipped with a rnortised

s i n g l e - p o i n t l r > c k w i t h a l a t c h b o l t p r o j e c t i n g 3 / 4 i n . f r o r n i t s c a s e . T h e r e w a s a c l e a r a n c e o f . 3 / 1 6 i n . a t t h e s i l l a n d 3 1 3 2 i n . a l o n g t h e o t h e r e d g e s o f e a c h d o o r .

F i r e T e s t

exposed to a furnace following the The furnace aperated with a minus T h e d o o r a s s e r n b l i e s w e r e

)

-p r e s s u r c o f l o w o r d e r i n t h e c o r n b u s t i o n c h a m b e r . H e n c e , f l a r n e s d i d n o t

cxtend through openings in and around tJle test subject. The hose strearn

test was not applied to the door assernblies following fire exposure. D o o r T e s t N o . I

At l7i rnin the top panel fell into the furnace.

At ISzL rnin the panel second frorn the top fell into the furnace. At Z0 min the test was terminated.

D o o r T e s t N o . 2

l5 rnin the top panel fell into the furnace. l? j rnin the test was terrninated.

D o o r T e s t N o . 3

At 16 rnin the top panel fell into the furnace. At 17t rnin the test was terrninated.

At At

F i r e E x p o s u r e T e s t s o f O r d i n a r y W o o d D o o r s , B u l l e t i n o f R e s e a r c h N o . 5 , U n d e r w r i t e r s t L a b o r a t o r i e s I n c , , C h i c a g o , D e c . 1 9 3 8 . Gene raI T h i s r e p o r t d e s c r i b e s f i r e t e s t s o n t h r e e s t a n d a r d w o o d d o o r s i n w o o d f r a r n e s . C o n s t r u c t i o n

Door No. I was a flush door 3 ft wide by7 tt high by I 314 ir.. thick. It consisted of a core of vertical strips of softwood (white pine) g l u e d t o g e t h e r a n d c o v e r e d o n e a c h f a c e b y a c r o s s - b a n d i n g o f v e n e e r a n d a f i n i s h v e n e e r ( o a k ) . O n e a c h e d g e o f t h e d o o r t h e r e w a s a 3 / 4 - i n . thick tongue and groove hardwood strip (oak). The door was rrrounted in a standard wood frarne (birch).

Door No. 2 was a two-panelled door 3 ft wide by 7 ft high. Styles a n d r a i l s w e r e | 3 1 4 i n . t h i c k . P a n e l s w e r e 5 l 1 6 i n . t h i c k . T h e s f , y l e s and rails were built up of a glued softwood core (white pine) faced with

1 / 8 - i n . o a k v e n e e r , 3 1 4 - i n e d g e s t r i p s a n d 3 l + - i r , . r n o u l d i n g s . T h e p a n e l s w e r e o f 3 - p l y s o f t w o o d ( g u r n ) w i t h l / 1 6 - i n . f a c e v e n e e r s o f o a k . T h e

d o o r s w e r e i n s t a l l e d i n a s t a n d a r d w o o d f r a r n e ( b i r c h ) .

Door No. 3 was a single-panelled door 3 ft wide by 7 f.t high. Styles a n c l r a i l s w e r e I 3 / 4 i n . t h i c k . C o n s t r u c t i o n w a s s i r n i l a r t o t h a t o f d o o r N o . ? . T h e d o o r w a s i n s t a l l e d i n a s t a n d a r d w o o d f r a r n e ( b i r c h ) .

T c s t M e t h o d

The door assernblies were e)<posed in a furnace following the standard timc/tcrnperaturc pattern. It rnay be assurned that the furnace was tJ.e salrle a s t h a t u s e r l i n t h e t e s t s r e f e r r e d t o i n S e c t i o n 2 . I . T h e d o o r a s s e r n b l i e s w e r ( l n o t c x p o s e c l t o t h e h o s e s t r e a r n t e s t . F i r e T e s t s D o o r N o . I

At 8i

At ?4rnirqpassage of flarne occurred along the top of door. rnin, the door fell into the furnace.

7

-D o o r N o . 2

A t 4 3 / 4 r n i n , f l a r n e s i s s u e d f r o r n c e n t r e o f l o w e r p a n e l . At 4 3/+ rnin, l0 sec there was similar penetration of the tJre upper panel.

D o o r N o . 3

At7: min flarnes 6 to 24 ir, . long issued frorn cracks at edge o f p a n e l .

At 9+ rnin portions of panel fell away. At l0 rnin the test was terrninated.

R e f e r e n c e F i r e T e s t s o n W o o d D o o r s , b y G . C . M a c N a u g h t o n a n d T . J . M a r t i n , U . S . D e p t . o f A g r i c u l t u r e F o r e s t S e r v i c e , F o r e s t P r o d u c t s L a b o r a t o r y , M a d i s o n , W i s c o n s i n , I 9 4 0 . G e n e r a l T h i s r e p o r t i n c l u d e s n i n e t e s t s o f 3 - b y 7 - f t w o o d f l u s h d o o r s i n w o o d o r s t e e l f r a r n e s . S o r n e t e s t s r o f d o o r s i n f i r e r e t a r d a n t t r e a t e d w o o d f r a r n e s a r e n o t r e p r o d u c e d i n t h i s

docurnent because the rnethod of treatrnent of the frames is not a c c u r a t e l y d e s c r i b e d a n d a d e q u a t e i d e n t i f i c a t i o n i s n o t p o s s i b l e . C o n s t r u c t i o n T h e d o o r s u s e d i n t h e s e e x p e r i r n e n t s w e r e o f u n t r e a t e d , , u n f i n i s h e d w o o d , 3 b y ? f t i n s i z e b y l - 3 / 4 i r . , . t h i c k , a n d w e r e o f f o u r d i f f e r e n t t y p e s . T h e y a r e i l l u s t r a t e d i n F i g u r e 2 . 3 . 4 a n d d e s c r i b e d b e l o w . T l r p e I : s o l i d c o r e , r n a d e o f p o n d e r o s a p i n e c o r e b l o c k s t / 8 t o l - t / 2 i n . w i d e a r r a n g e d p a r a l l e l t o t h e v e r t i c a l e d g e s o f t h e d o o r , a n d g l u e d t o g e t h e r w i t h c a s e i n g l u e , u s i n g b u t t j o i n t s a t s i d e s a n d e n d s . O n e a c h s i d e o f t h e c o r e , t / t 6 - i n . b i r c h c r o s s b a n d a n d f a c e p l i e s w e r e g l u e d w i t h h o t P r e s s p h e n o l i c -r e s i n g l u e .

- 9

. T v p e I I : s o l i d c o r e , m a d e o f p o n d e r o s a p i n e c o r e b l o c k s I - l / 4 i n . w i d e g l u e d ( w i t h b u t t j o i n t s ) i n t o s t i l e s a n d r a i l s 5 - t / Z i n . w i d e a n d a s s e r n b l e d w i t h d o w e l s a t e a c h i n t e r s e c t i o n . O n e a c h s i d e o f t h e c o r e , t / t 6 - i r . . s a p g u r r r c r o s s - b a n d s a n d b i r c h f a c e s w e r e glued. Casein glue was used throughout the door.

T ) r p e I I I : t h e c o r e c o n t a i n e d h o l l o w , h o r i z o n t a l c o r n -p a r t r n e n t s 2 i n . w i d e , s e -p a r a t e d b y -p o n d e r o s a -p i n e s t r i -p s l/8 in. t h i c k . T h e s t i l e s w e r e o f s o l i d p o n d e r o s a p i n e Z - l / Z i n . w i d e a n d t h e r a i l s w e r e 3 - l / Z i n . w i d e , o f t h e s a r n e w o o d . T h e e n d s of the cornpartrnent strips were rnortised into the stiles.

A p l y w o o d p a n e l o f t h r e e p l i e s o t t / L 6 - i n . b i r c h v e n e e r w a s a p p l i e d t o e a c h s i d e o f t h e c o r e . C a s e i n g l u e w a s u s e d throughout.

T v p e I V : t h e c o r e c o n t a i n e d s q u a r e c e l l s s e p a r a t e d o p 2 - i n . c e n t r e s b y t / e - i n . t h i c k p o n d e r o s a p i n e s t r i p s ; e a c h c e l l was filled with a granulated type of rnineral wood averagiqrg : approxirnately I Ib per square foot of cell area. A plywood p a n e l c o n s i g t i n g o f o n e p l y o f t / t 6 - i n . b a s s w o o d b e t w e e n t w o p l i e s o t I /16 -in. birch was applied to each side of the c o r e . C a s e i n g l u e w a s u s e d t h r o u g h o u t .

D o o r A s s e r n b l v

The doors were rnounted in wood or rnetal frarnes u s i n g 5 - b y 5 - i n . f u l l r n o r t i s e b u t t h i n g e s a n d a l i g h t - w e i g h t

m o r t i s e c a s e l o c k w i t h k n o b s a n d p l a t e s . T h e r e w a s a c l e a r a n c e of. t/8 in. between head of door and frarne, l/32 in. on both styles and 3/16 in. at the foot.

standar d tirne/temperature pattern of ASTM E -t 19. The t h e r r n o c o u p l e s c o n t r o l l i n g f u r n a c e t e r n p e r a t u r e s w e r e b a r e a n d n o t e n c l o s e d i n t u b e s a s p r e s c r i b e d i n t h e A S T M S t a n d a r d M e t h o d s o f T e s t . T h e f u r n a c e e x p o s u r e w a s t h e r e f o r e a l i t t l e l e s s s e v e r e t h a n t h a t o f t h e s t a n d a r d t e s t . T h e f i r e e n d u r a n c e m a y b e a s s u r n e d t o b e 2 t o 4 r n i n l e s s t h a n r e p o r t e d . T w o o f t h e t e s t s , N o . P 3 2 a n d P 3 3 , w e r e r e s t u d i e d l a t e r b y M i n i u t t i ( s e e S e c t i o n 2 . 5 ) , w h o a p p l i e d a c o r r e c t i o n f a c t o r t o t h e r e s u l t s f o l l o w i n g t h e r n e t h o d p r e s c r i b e d i n A S T M E - l l 9 f o r e v s l ' - o r u n d e r - e x p o s u r e . T h e r e s u l t s a r e r e p o r t e d i n S e c t i o n 2 . 5 . F i r e T e s t s T h e r e s u l t s o f t h e f i r e t e s t s a r e s u r n r r r a r i z e d i n T a b l e 2 . 3 . I .

_ l l _ ' I A l l L E 2 . 3 . I F I R E R E S I S T A N C E O F D O O R A S S E M B L I E S T c s t : N u m - : n u n - : b e r : b o r : o f : : d a o r :

Type of frame :lotal:Separation of top of :Failure of assemblT lu,:- to :ti.nd :Iatch stile and stop

!---: of : after given nlnutes : lrame 3Eardrzare: Door

: test : of e:eosllro : i : i n : - ' - - - : : : nln. *lZn I 3/ l+tt 3 ttt : 1-1/Zn : : : des;i.,1rr P-2{)z P-321 P - J l : PtJJz a a

: - - : - - :

- -

: I 9 . 9

t \ 9 : \ O : 4 2

:

-I 2 I

2

: U n t l e a t o d .

: P r e s s e d . s t e e l

w o o d . . 2 L . 1 : 2 0 : - - : - - : - -

t r $ , - 5 : 3 L z J 6 r - - :

- -

: 1 5 . 3 :

:

- - | 2 3 . 3 | 1 t 0 . 2

, ?f.Jg

a a I ' l i n u t e s : : : : : : 3 :trpe I Door -- So1ld. core -- Blocks ln vertical strips

Trrpo II Door -- So1itl coro -- Bloclls for4ninA stiles, r+iIs, and panels

:Untreated. wood, ,3O.7 :

--: P r e s s e d s t e e l : \ ! . 0 : 3 2

: J O . d

3 O . 7 : \ 3 , 7

P - J O : I

P - J 4 : 2

P - 3 7 t t

1 9 : 2 0 :

-2 j : -2 6 -2 -2 8

: !P - 4 5 : 2

p - M r ? - ' v r ) : :Untroatcd. : U n t r o a t e d :UntroatedType III Door -- iiollov corr:r unfillod wood :1O.4 : No separatlon ! --wood :10.1 : l{o separation : --wood. :10. J : 1[o separation !

--:

9 , 8

9 . 1 +

9 . 6

1 9 . 5

29.O

Type IV Door -- IIoIIow core, fllled with insurlation

: P r e s s e d . s t e o l : 2 2 . J

:Pressed. steel 45,5

l0

9teet dlscontlnued, at tlne lnd,icated. because

to deetructton of Ja.rnb or warplrrg of d.oor

flre reached rutoxposed. face due or both.

_r -.

tlllr

rYPE W

I rr?Cr?J t

f fPE I rYPT E

_ t 3

-S E C T I O N 2 . 4

R e f e r e n c e

I n v e s t i g a t i o n s o n B u i l d i n g F i r e s , T i r n b e r D o o r s , b y C . J . W e b s t e r Building Studies Technical Paper O f f i c e , L o n d o n 1 9 5 1 .

G e n e r a l

P a r t l V , F i r e R e s i s t a n c e o f and L. J. Ashton, National

N o . 6 , H . M . S t a t i o n e r y

This publication includes reports of ten fire tests on wood door a s s e r n b l i e s . T a b l e s a n d f i g u r e s a r e r e p r o d u c e d w i t h t h e p e r m i s s i o n o f

the Controller of Her Majestyrs Stationery Office. (Table and figure

nurnbers have been changed for purposes of tJ:is paper. ) A nurnber of

wood panels were also exposed to furnace ternperatures to compare the

f i r e p e r f o r m a n c e o f v a r i o u s s p e c i e s o f w o o d ( s e e T a b l e 2 . 4 . 2 1 . Construction

The construction of the doors and frarnes is shown in Table 2.4.1 .

T h e a r r a n g e r n e n t o f t h e d o o r s i n t h e t e s t w a l l i s s h o w n i n F i g u r e 2 . 4 . 4 ,

The installation for cornparing the fire perforrnance of the wood panels is

shown in Figure 2.4.8. A surnrnary of the behaviour of the panels when

exposed to the furnace is shown in Table 2.4.? and a graph comparing the f i r e r e s i s t a n c e o f t h e d i f f e r e n t w o o d s i n F i g u r e 2 . 4 . C .

T e s t M e t h o d

T h e d o o r a s s e r n b l i e s w e r e t e s t e d i n a c c o r d a n c e w i t h t h e p r i t i s h

Standard rnethod of fire test BS 475. The door assernblies were assurned

t o b e n o l o n g e r r r e f f e c t i v e a s a f i r e b a r r i e r r r w h e n a c r a c k 6 i n . l o n g eleveloped on an opening or an area of flarning 6 in. square was observed o n t h e s u r f a c e . T h i s c r i t e r i o n , h o w e v e r , i s n o t p a r t o f B S 4 7 6 . F i r e c n d u r a n c c s b y t h e c r i t e r i a o f B S 4 ? 6 a n d b y t h i s a r b i t r a r y p r o v i s i o n a r e l i s t e d i n T a b l e 2 . 4 . 1 . I t s h o u l d b e n o t e d t h a t t h e t h e r r n o c o u p l e s r n e a s u r i n g f u r n a c c t e r n p e r a t u r e s i n t h e B r i t i s h t e s t a r e b a r e , a s i n t J r e t e s t s d e s c r i b e d i n S e c t i o n 2 . 3 . T h e f i r e e x p o s u r e r r a y t h e r e f o r e b e a t i t t l e l e s s s e v e r e tlran t]-at in the ASTM E-I5? rnethod of test.

' a o' .: ! (] C)

_-t

I I @ 14 Jn '

t'l U) U)i8

\ t O

, { A

frt 14f,o

tr t'l F { Z H o H a f'l&

t']

g

Ir T g F . : \., tr c c . " N F E € o o t . : + a = , a ( ' E o o o 6l"

1 5 -c E a a ; a 6, 6 B o c c b o c o L) & G a

?.E

( J o 6s

N GI6'

t"

z

o

g

d

Nrd

rlm

tsr

a F fll !i9l'r

?i:,9

Es. :l I I r.lF

iF90i.e

F€s€

I g

o o o U o-t o

=t

\ J C t = c .(a'= L J t r &o

F{z

o

I

$"i

H ,1n

4

t{

o\ t I 2 ? 4 6 i L . C o q . c 0 c -t ? o 8 ; ; i j s . E i i H 6 . G J t r 9 ' E 9 : h i -.;i.! 6 s 6 ' 4 " - t 2 * l - . = 6 9 . 'i E l

e u = o h' r C , F ] . F 6 q ,Z Z "

{E!

a 6 o c0 o Fif;s e

i zE"la

EEEE

t eEr*E .

Et"r.6

I C r € l i i f 8.?8 g:ElE

o o u1 ?

-A 4 o o 6 G's

F I g @ "i rt z q o ?'5

g c 6 o c I E tv

o o U ! . 9 o I ' = * a/: Ea

f"

z

o

g

\il "; 14 rln

l{;F;i.!

t o g 6 a o e I: i € L S 5 a - l - o ^ a / . o 9 a {,: c t F 6' o 'g .) 7 o (j d f o _ . 4 ' i ( J C :a

o

i.

z

o

u

,s

"i

f'l J E F{ = i 6 c = ac \ - e o 9 .9'', 1 - ox 8

; 2d ' a

- / 5 3/.fr

{.E

o a : ate

€ € ! a1 ,t :1 :4 ' o o ' " =T i . . :

F ' A L I ' a r - a t o -o o o a € 6 ; : l ii a 4

a- .'. ^ . 1 . i ! 7 ! ; E - : ' ! '* ,1. t u i ' i o 7 e t l , o , " : i;'-/ t_ 1 9 _

T A B L E 2 . 4 . 2

FINE RESISTANCE OF WOOD PAT{ELS

TtlytE tN trttN, tnort sT^llif oT TEST

CIIANCESI IN CONDTTION OF PANEA

Gtrrjun Trl{k Spruce

ilmplc1mr llaltic I l}rltic

lgnition of exposcd facc of ponels . . I ia. Tlicbres

Uncxpoced .utf*,..t.r1;:3: : : r40cc. t55"c. Charring of uncxporcd rurl'uce Penctratiorr by flome

t ia, Thkhncr (mcon of z epccimcnr) Unexporcd .utt"". t"-p.r??13.

: : r4;oc. charring of uncxpoar'd r"il"'*"' :: Penetration by flamc

Rc'ds'oodi llcdsood

U

3 l i 3 2 1 tL in. Thhhacr;s (megn of z spccimcntl

Uncxposcd rurfacc ttmp. 8ooC.

NOfff :--Owing to th€ natulc of the surfoccr,- anil, with the impregtrated wood, the pt i.i.c ot.uhJ, thc cotour chsngo oi the icrnpcrature indicating peintg could not.alwryr bc dctermincd.

Whcrc s rDecimsn beforc tedting rhorvcd dcfccts cuch as knotc and rhokcc which ellowcrt trbid flutr. pcnctration to toke placc in the furnscc, lr fir s poesiblc it nt . not cdvcrcd till isilurc occurrcd thrdqh thc full thic*ncs.

did not flarnc + : I ( r ! z ! s l r.l

I

r E 2 l 9 r 3ir

f ' t 3 {. , 1 - t l l tr, i s l - t 5 3 0 1 39,.rl

45 soI

65 69 I I I I 3 t : I ' J J 3j 3 6 ! 39 :-6sl 3e _5O sol s z .i3 | 60 8 5T

92y_r

7o2 ' f t A x . o @ R . (unprolechd)

lh' torr tooo Dooa. (unprolccld)

4 ' t 2 ' u

E t E v a r t o N

,ef,al"

OF ANFXNSED FACE

fxPosaD FACE i" a'planlecl slcp

t'brick *ah

Details of Door Assernblies

ffif,4J\ti'

? L

-ttEvlrtoN oF uNExPostD ttoc

4.lnsuhfion for posk

Secnop I A.

F i g u r e 2 . 4 , 8 A r r a n g e r n e n t o f P a n e l s F o r F i r e - R e s i s t a n c e T e s t g

I

I I

Comparieon of the Fire-Reeistance of Various Thicknesses to lo foilur2 -1 0

I

I

I

-*F i g u r e 2 . 4 . C of Hard and Soft Woods

2 3 -S E C T I O N 2 . 5 R e f e r e n c e F i r e R e s i s t a n c e T e s t s o f S o l i d W o o d F l u s h D o o r s , b Y V . P . M i n i u t t i , F o r e s t P r o d u c t s J o u r n a l , A p r i l 1 9 5 8 , ( V o l . X I I , N o . 4 ) , F o r e s t P r o d u c t s R e s e a r c h S o c i e t y , M a d i s o n 5 , W i s c o n s i n . G e n e r a l T h e r e p o r t d e s c r i b e s f i v e t e s t s o n s o l i d - c o r e w o o d d o o r a s s e r n b l i e s . T w c r < r f t h e s e , P 3 ? a n d P 3 3 , a r e a r e a s s e s s r n e n t o f t h e i n f o r r n a t i o n o n t e s t s o r i g i n a l l y r e p o r t e d i n a n e a r l i e r p u b l i c a t i o n ( s e e S e c t i o n 2 . 3 1 . T h e r e p o r t

also includes two tests of doors in fire retardant wood frarnes that are not

included in this srurunary because of lack of identification of the fire retardar,t.

C o n s t r u c t i o n

E a c h d o o r a s s e r n b l y c o n s i s t e d o f a s o l i d w o o d f l u s h d o o r , a d o o r frarne, tJrree hinges, and a lock.

D o o r s : A l l d o o r s w e r e r n a d e c o r r u r l e r c i a l l y , w e r e L - 3 1 4 i n . t h i c k b y

3 ft wide, and were of qolid wood, flush 5-pty construction with a face and

c r o s s - b a n d v e n e e r p l y g l u e d t o e a c h s i d e o f a l u r n b e r c o r e . T h e c o r e s

werc butt-jointed ponderosa pine blocks bonded together with casein glue.

F a c e s w e r e b i r c h v e n e e r . T h e d o o r s v a r i e d i n h e i g h t , f a c e v e n e e r t h i c k

-n e s s , s p e c i e s a -n d t h i c k -n e s s o f c r o s s - b a -n d v e -n e e r s , s p e c i e s o f e d g e s t r i p s , ancl types of glue used in bonding the veneers to each other and to the core.

Two arrangements of core blocks were ernployed. Construction details

a r e g i v e n i n T a b l e 2 . 5 . L . D o o r P - 3 2 , ( S e r i e s A ) - - T h i s d o o r w a s 7 f t h i g h a n d h a d w o o d c o r e b l o c k s L - L / 4 i n . w i d e g l u e d i n t o s t i l e s , r a i l s a n d p a n e l s . T h e s t i l e s a n d r a i l s w e r c S - j - i n . w i d e a n d w e r e a s s e r n b l e d w i t h d o w e l s a t e a c h i n t e r s e c t i o n . E d g e s t r i p s w e r e 3 / 4 i n . w i d e b i r c h , b u t n o e n d s t r i p s w e r e u s e d . C a s e i n g l u e w a s u s e d t o b o n d L l L 6 - i n . g u r n c r o s s b a n d a n d b i r c h f a c e v e n e e r s t o e a c h s i d e o f t h e c o r e . D o o r P - L 3 4 a n d P - 1 3 5 ( S e r i e s B ) - - D o o r P - 1 3 4 h a d p o n d e r o s a p i n e e d g e s t r i p s , a n d P - 1 3 5 b i r c h e d g e s t r i p s , b u t t h e d o o r s w e r e a l i k e i n a l l

core blocks, with the wood grain parallel to tJ:e vertical edge of the door. T h e e n d s t r i p s w e r e p o n d e r o s a p i n e . B o t h e d g e a n d e n d s t r i p s w e r e g l u e d to ttre core with potyvinyl resin. Urea-forrnaldehyde resin was used to g l u e a L I I ? - i n . b a s s w o o d c r o s s - b a n d a n d a I / 2 0 - i n . b i r c h f a c e t o e a c h side of lfie core.

D o o r P - I 3 6 ( S e r i e s B ) - - T h i s d o o r w a s 6 f t 8 i n . h i g h a n d h a d l - 3 / 8 - i n . w i d e c o r e b l o c k s , w i t h t h e w o o d g r a i n p a r a l l e l t o t h e v e r t i c a l edge <rf the door. Edge strips of.3l4-in wide birch were glued to t.Le corc wilfi polyvinyl resin glue. The end strips were soft rnaple glued w i t h u r e a r e s i n t o I 5 l 8 - i n . w i d e p o n d e r o s a p i n e , w h i c h w a s n o t g l u e d t o t h e c o r e . M e l a m i n e - u r e a r e s i n g l u e w a s u s e d t o b o n d a L / l ? - i n . s o f t n r a p l e c r o s s - b a n d a n d a I l 2 0 - i n b i r c h f a c e t o e a c h s i d e o f t h e c o r e . I ) o o r F r a r n e s : F o r t h e S e r i e s A t e s t s ( P 3 2 , P 3 3 ) , f r a m e s o f l 6 -g a u -g c p r e s s e d s t e e l w e r e u s e d . T w o t e s t s w e r e r n a d e w i t h e a c h t y p e o f f r a n r e . F o r t h e S e r i e s B t e s t s , ( P - I 3 4 , P - 1 3 5 , P - 1 3 6 ) l 6 - g a u g e p r e s s e d steel frames beari:rg the Underwritersr Laboratories label for fire-door f r a r n e s w e r e u s e d .

Hinge s: Three full-rnortise , loose -pin hinge s used with each door. In Series A the hinges were 5 S e r i e s B t h e y w e r e 4 - I l 2 b y 4 - L / 7 i n .

of wrought steel weie b y 5 i n . , a n d i n

L o c k s : T h e l o c k s u s e d i n S e r i e s A t e s t s w e r e l i g h t w e i g h t r n o r t i s € - c a s € I o c k s w i t h 3 - - j - b V Z I - b y 3 / 4 - i n c a s e , j - i . r . l a t c h b o l t t h r o w , ? 3 / 4 - i n . b a c k s c t , a n r l ? 5 - b V 7 - i n . e s c u t c h e o n s . T h e l o c k s w e r e i n s t a l l e d w i t h t h e <:cntrc of thc iatch bolt 39-j- in. above the floor line. The locks used in Scrics IJ tcsts we re heavy-duty, cylindrical case locks bearing tl.e U n d c r w r i t c r t L a b o r a t o r y R e - e x a r n i n a t i o n S e r v i c e L a b e l . T h e l o c k s h a d a I / Z - i n . l a t c h b o l t t h r o w , o 2 - 3 1 4 - i n b a c k s e t , ? - l / 1 6 - i n . d i a r n e t e r c a s e , a n c l ? - 9 / I ( t - i n . c l i a m o t e t e s c u t c h e o n s . T h e l o c k s w e r e i n s t a l l e d w i t h t h e c e n t r e o f t h c l a t c h b o l t 3 8 i n . a b o v e t h e f l o o r l i n e . C l c a r _ a n c e b e t w e e n D o o r a n d F r a r n e : I n S e r i e s A t e s t s t h e d o o r s w e r e r n o u n t c d w i t h c l e a r a n c e b e t w e e n d o o r a n d f r a m e a d j u s t e d t o l / 1 6 i n . a t t h e t . p , 3 / 3 2 i n . a t t h e s i d e s , a n d 3 / L 6 i n . a t t h e b o t t o r n . I n S e r i e s B t e s t s the clearance was I lL6 in. at tJre top and sides and 3l16 in. at the bottorn.

2 5

-F i r c T c s t s

The rloor assernblies were exposed to a furnace following tJre standard tirne ltnrnperature curve (see Table 2.5.21. In two exarnples, P - 3 2 a n d P - 3 3 ( a l e o r e p o r t e d i n S e c t i o n 2 . 3 1 , b a r e t h e r r n o c o u p l e s w e r e u s e d , r e e u l t i n g i n a l e s a s e v e r e t e s t . T h e r e e u l t s s h o w n i n T a b l e 2 . 5 . 2 rcpresent a correction of the fire endurance uping the correction factor in ASTM E-119. In this series of tests the inforrnation relating to end criteria is presented without interpretation of tirne of failure. The end points are shown graphically in Figure 2.5.4. Collapse of tJrp door and flarning ignition of the unexposed face would probably be considered a failure, but intermittent flarnes, srnall holes, warping of the door and considerably elevated ternperatures on the nnetq)osed side may not be c o n s i d e r e d o f c o n s e q u e n c e .

Itoot l\tt l,ilil

TESTED AT U. S. FOREST PRODUCTS I.ABORATORY

Erlge drlpr Blrth X lu vlde Btrcb. % la, ddc on dde only Pondorue pinr Blrcb on ridcr; Doodcu pino oo eodr Blrcb. X In. wldr. or ddci roft nnrplc. N is. wide. ob otrdr

lAll corc r.ru bstt jolnt d pordorm ptlc bbcf. boodcd wltb crrdo y'uo

T A B L E 2 . 5 . 2

SUMMARY OF. OBSERVATIONS ON FIRE-RESISTANCE TESTS

OF SOLID-WOOD FLUSH DOOR ASSEMBLIES

St*l frumcr

ttlrr, tslcor rnd crwbrndr Voncer rdbedvr

'?''r'i.s, ,t' l/10-tn. btrch Phanollo rda

Ut7'tltl{t' l/l0 In. bitoh tta.r. Cscln

l/lli-ln. gsm cro|rlreodl

3l'r0'tt"ttfr" l/90-ln,birchfrc.c. ' Uredlatl

l/12-ln, bosrood crcbrndr

ll'lri'r*"rlr-" ' l/20-ln, birch frcrr, Urc reln lll:J ln. burwood ctqrb.adt

il'rti'tt"rlja" l/!0-tn. blrch hce+ Mslrmlorn|rcl

lltz-in, oL mrplo crcIboodr ttln

Corl

Blo{}t Vl la. to ll.6 In. sld.

nrcrr rx ii, *ri" rn rtiln+

ratlr, prn6b: doilolLd rl lntoEdtloaa yffr.i %ii..'iiki;.-BlocL. X In and lX lL rld. Bloclrr t% ll. rillr Fnral SrcGl ff.|na Str.cl fr.no Stccl-frran std"l lr.rr|. Etd fraras I'lc,l Ptt6 Pll0 Condltlon I rl,.rrlit t.'lt ll,rrrrr lr,l wrt,l d.rtr lnd tramt.... - - - -. l , l i l f f r i f r r l i t J f f f t i f t r f r r J u l r . ' t p r n ' d l t e c . . . . -f -f r ' -f | r ' , . , , , , , ' r t r f , r r r In h r r k r r . t i _ _ _ _ _ _ - - . _ _ lL82 Min. 25.7 2 0 . 5 3 6 . 7 2 5 . 5 8 3 . 8 3 r . 8 l L l i t i M l n . I lt .:l :1.'. . i ?:l. n 3ti'.:l : , L 3 g $ . 3

ii:l

::o. ? : 1 6 . 3 ito. ri . $ ? . 3 8 7 . 8 lr+13 l'-l:t4 Mln, Min, s 6 . I : l . 3 4 , 1 . 8 8 r ; . f l g.7.1 80.(l - t 0 , 2 3 r i . ( , z r . 9 1 8 . { ; tt,? 2.i.0 4 B . U 3 t . 6 , r { . 6 2 8 . 9 1 3 . 8 l i l i . { i l ? . 9 89,2 l!ir.0 rg.i,,1 { 5 , S 3 6 . { lL l:lti !1in. l n . : l 3.t . r, Z i : t i '.:(). I J i . l t :13 . r, ilr,.2 29.7 ' . , 5 . 0 3 l , 4 3 7 . 9 i i , tI Ltrrt iltx{!{l it,lrr lurnlo!. _ _ -t l l r o r v n -t i r r -t r r r l s l r r l " . . . .

-r lll-r-r-rk -r-r'N'-r l-r-rli.at. thot eonditlon-r liated did not occu-r du-rlng tdt., it't,n to.t i,ulhd from tbe door, rod thc door op*d. i -'

2 7

-LE6EIIO:

@ 2&'F fEItP€PAfuP€ RtsE oiv ul,;ExPos€o FAc€

f-1FLAAW6 tiMftoit 6 uitExposEo FAaE d /t6"4fFafcTrorv 6 NoP coPttER Etrao@n QPENEO ttt70 FunuacE

. TEST Otsc@lnMuto E€FaRE CoilOtrrorr occuRREO

i wt HELD CLOS€O AFn€R fHtS ttw

= r

I

i . = l

F i g u r e 2 . 5 . A Re gulte of I'ire -Re gistance ltlood Doorg

E e s a i e d e R 6 e i s t a n c e a u f e u , d e P o r t e s e n B o i s o u i B a s e de lloie, by J.P. Fackler, Cahiers du Centre Scientifique et Technique du Bitirnent, No 38, Cahier 306, Paris, J u n e I 9 5 9 .

G e n e r a l

The report describes tests of wood door assernblies in accordance witJ. the French standard for fire testing.

Construction

The construction of each door is described w'ith the fire perforrnance in the following pages. There are two points of diJficulty in interpreting the description of tfie assernblies in these test reports. Although the size of the furnace is given, there is no meaaure of the depth of stop, that is, the

arnount the door overlape the frarne on each side. In British and North American practice thie is l12to 518 in. and in sorne of the Danish tests,

I in. If the depth of etop is too great, there is difficulty in fitting the door knob on the face side of the door. If the details are to scale, the stop in the French tests is frorn about 1| to f 5/8 in. AIeo, the drawings and the photograph do not show a rnortise latch and knobs; they illustrate what appear6 to be a forrn of surface catch on the fire-exposed side.

_ 2 9 _

T E S T N O . 5 7 . 5 0 6 4 .

Description: three-panelled door. The aseernbly was rnade up a6 follows:

- a f r a r n e o f f i r 0 . 0 6 r A ( 2 3 / 8 i n . ) by 0.05 rn (L 718 in.) by 0.025 m ( 0 . 6 5 i n . ) .

- a d o o r I . 8 5 r n ( 7 3 i n . ) b y 0 . 8 r n ( 3 2 i n . ) i n t h r e e p a n e l s , 0 . 6 6 m (26 in. ) by 0. 5 rn (2O in. ) of plywood, 0.005 rn thick rnounted in a frame of fir with charnfered edge (see Figure 2.6. Al.

Obeervatione during teet

Initial temperature: 14oC (5? "tr.).

- at I rnin 30 eec, charring of the rebate in the upper part of the non fire-e:cposed face.

- at 2 rnin 30 sec, charring in tJle centre of the panel on the non fire-e:qposed face.

- at 2 rnin 45 sec, perforation of the plywood and flaming. ClagsiJication

Cause of failure: General flaming following perforation. Duration of fire endurance: 2 rnin 45 sec.

Descripti-o+: 32 mrn (I Ll4 in.) hollow flush door. The assernbly was rnade up as follows:

- A f r a r n e o f f i r 0 . 0 6 r n ( Z 3 l 8 i n . ) by 0.05 rn (L 7 18 in. ) by 0 . 0 1 8 m ( 1 1 / 1 6 i n . ) .

- A d o o r w i t ] l a f r a r n e w o r k o f f i r I . 8 5 r n ( 7 3 i n . ) 0 . 8 r n ( 3 2 i n . ) by 0. 032 rn (l ll4 in. ) including a central wood honeycomb

(beech) of. L5 / l0 mrn (L I L6 in. ) faced with plywood. 28/ 10 mrn

( 7 1 6 4 i n . ) t h i c k ( s e e F i g u r e 2 . 6 . B ) . O_b s e rvation s du{in& te. qt

Initial ternperature: lgoC ( 660E.).

- at 22 sec, charring of plywood on fire-exposgd face.

- at I rnin 30 sec, interrnittent flarning at edge of frame on non-exposed

f a c e .

- at 3 min, developrnent of opening between door and frarne.

- at 4 rnirt 15 secr passage of flarnes at opening between door and frame. - at 5 rnin, end of test.

Cla s sification

Cause of failure: general flarning of surface.

3 I

-T E S -T N O . s 7 . 5 0 6 C

D_e sc riptio+ of te st gleJngg!: 3? rnrn (L I I 4 in. ) flush door .

The assernbly was rnade up as follows:

a f r a r n e o f f i r : 0 . 0 6 r n ( 2 3 1 8 i n " ) b y 0 . 0 5 m ( l 7 1 8 i n . ) b y 0 . 0 1 8 r n ( I l / 1 5 i n . ) .

a d o o r w i t J : a f r a r n e w o r k o f f i r : 1 . 8 5 m ( 7 3 i n . ) b y 0 . 8 r n ( 3 2 i n . ) b y 0 . 0 3 2 r n ( 1 I l 4 i n . ) e n c l o s i n g a p a n e l o f c h i p b o a r d 0 . 0 2 8 m ( 1 3 1 3 ? i n . ) t h i c k w i t h t u b u l a r c o r e s 0 . 0 1 5 m ( l 9 l 3 2 i n . ) o n h o r i z o n t a l a x e s a n d o n each face two veneers with cross-Brain having a total thickness of

Z Z l l 0 r n r n ( 3 1 3 2 i n . ) , t h e e x t e r i o r v e n e e r b e i n g o k o u r n e ( s e e F i g u r e 2 . 6 . C ) . Qbse rvation-s dur ing. te st

Tirne Fire-e_xposed- Face

Flaming of first panel.

Nog-e-xp_os_ed _{lc-e 0 I m i n 4 5 s e c r n i n l 0 s e c rnin 5 sec r n i n l 0 s e c 7 r n i n 3 0 s e c l0 rnin 19 rnin 4 5

Total destruction of first p a n e l . D i s c h a r g e o f g a s a t t o p o f d o o r . L i g h t p a s s a g e o f s m o k e . Flarning of cotton a p p l i e d t o d o o r .

Light flaming of door at top next to frarne.

Light flarning of the rlrror at lower right near ther f r a r n e .

Total flanring t:f the w h o l e n o n - e x p o s e d f a c e . 24 rnin 26 rnin Cla s sification E n d o f t e s t . C a u s e o f f a i l u r e : g e n e r a l f l a r n i n g . Duration <lf fire endurance: 24 rnin.

The'door had been rernoved frorn a tnrilding in an undesirable district to perrnit a cornparative test of the standard of fire resistance on an element as close as possible to that which had been tJle subject for a test during an experirnental fire in a real building.

T h e e s s e n t i a l c h a r a c t e r i s t i c s a r e a s f o l l o w s :

- Panelled door entirely of fir with old paint, height 1.85 rn (73 in.) w i t h 0 . 6 5 m ( 2 6 i n . ) b y . 0 3 4 r n ( I 3 / 8 i n . ) .

- The frarne, also of fir, had been rnade at the experirnental station o f C S T B ( s e e F i g u r e 2 . 5 . D ) .

Note that the door had light cracks in several places probably resulting frorn aging in its original location.

Obtq rvatjons {r}r iJtg- te st Tirne 0 rnin 30 sec I m i n 0 0 5 s e c I m i n 4 0 s e c 7 r n i n 3 0 s e c 8 min 1 3 m i n 1 6 r n i n

EIpqse.4 4ace

Blistering of paint over

surface of door.

Beginning of charring of door

and of frarne.

Charring of whole door and

f r a m e .

Non-expo_sgd Face

Discharge of srnoke at top between frame and d o o r .

Light passage of srnall flarnes between door and frarne on left side of door in the rniddle. L i g h t p a s s a g e o f s m a l l flarnes at top between door and frarne.

Little flames appear on centre panel.

Tirng 20 min 24 rnin 27 rnin C l a s s i f i c a t i o n End of test.

Cause of failure: continuous flarning of tJre door. D u r a t i o n o f f i r e e n d u r a n c e : l 5 r n i n 3 0 s e c .

It was judged tJrat the length of interrnittent flarning before the corrurrencernent of rnore perrnanent flarning should be ignored. The behaviour coffrpared well with observed fire behaviour in a building f i r e d e s c r i b e d i n C a h i e r C S T B N o . 2 9 2 .

No_r]-e-xp_osed {ace Flaming of the door rrrany place s.

Photograph taken of u n e x p o s e d f a c e ( n o t r e p r o d u c e d ) .

The assernbly is rnade up as follows:

- a n o a k f r a r n e 0 . 0 6 r n ( z 3 1 8 i n . ) b y 0 . 0 5 r n ( I 7 1 8 i n . ) b y 0 . 0 2 5 r n ( I i n . ) a c l o o r 1 . 8 5 m ( ? 3 i n . ) b y 0 . 8 m ( 3 ? i n . ) b y 0 . 0 3 5 r n ( l 3 / 8 i n . ) o f t o n g u e

-and-groove oakvertical battens framed in oak with styles and top and bottorn r a i l s ( s e e F i g u r e 2 . 5 . E ) .

Obse_rvjr tio ns jur ing te *

Initial ternperature LZoC (54oF).

Z rnin I7 rnin Tirne ? 5 s e c ?4 rnin 3 0 r n i n 3 0 s e c ITIlN min 4 5 r n i n Fire:.expgsed 9i{e Beginning of charring.

Charring of whole surface accorrrpanied by falling of l i g h t p i e c e s o f c h a r c o a l .

Non-eTpos_ed Side D i s c h a r g e o f s r n o k e .

Swelling of all tJle battens.

Flarning of cof;on applied to crack.

L i g h t p a s s a g e o f f l a m e s at top left.

Flarning of battens at toP. Perforation of battens at front of door and on t.he right side.

FaII of battens at top.

3 3 3 4

Tirne

Non:e_xpqqsd

EIlg

Fall of battens. 47 rnin 48 rnin CIa s sification End of test.Cause of failure: flarning of door.

F i g u r c Z . 6 . I . l .

Obsq rvatior-rs rluring_ te_st

t n i t i a l t c r n p e r a t u r e : ? O o C ( 4 5 o F ) .

Tinre Fire -expose-d_Side

I rnin l0 3 rnin 50 7 m i n 25 rnin 42 rnin 50 rnin 54 rnin ( r 0 r r r i n s e c

s e c Flarning of gas corning frorn

behind the sheet steel. Beginning of charring of frarne.

Furnace therrnoc ouple s I and 2 holding the door in p o s i t i o n . E n d o f t e s t . Ngn-exposed Side C o p i o u s d i s c h a r g e o f srnoke. Distillation of tar. Spontaneous iguition of gas at the top.

Flarning of frarne on r i g h t s i d e .

Separation of the door frorn the frame at the top (rnovernent of about 2 crn) ( 7 5 l 3 2 L n . l F l a m e s a p p e a r o n r i g h t side of frarne. 64 rnin C I a s s i f i c a t i o n C a u s c o f f a i l u r e : f l a r n i n g o f d o o r . l ) u r a t i o n o f f i r e c n d u r a n c e : 2 5 r n i n .

3 7

-T E S -T N O 5 7 . 5 0 6 F

D e s c r i p t i g . l n o f t e s t a s s e r p b l l : d o o r o f o a k 3 5 r n r n t h i c k ( l 3 / 8 i n . ) c o v e r e d on non fire-exposed face with sheet steel. This door was identical with t h a t t e s t e d u n d e r N o . 5 7 . 5 0 6 D , e x c e p t t h a t t h e r e w a s s h e e t s t e e l 5 / 1 0 r n r n ( L 1 6 4 i n . ) t h i c k o n t h e n o n f i r e - e x p o s e d f a c e ( s e e F i g u r e 2 . 6 . E ) ,

Obse Tyations_duri.ng te st

I n i t i a l t e r n p e r a t u r e : 7 o C ( 4 5 o F . ) .

Tirne Fire -expos_ed Side 0 rnin I rnin 3 rnin 23 rnin 23 min 29 rnin 40 rnin 4 6 m i n 4lJ rnin 50 rnin 2 5 s c c 3 0 s e c 0 s e c l 0 s e c O l a s s i L i c a r t i o n ( l a r , r s c <lf [ailure: r y l o v e r n e n t l ) u r a t i o n o f f i r e e n d u r a n c e : Beginning of charring T h e r m o c o u p l e s N o . I a n d 2 holding the door in position. E n d o f t e s t .

and flarning of doors. 29 rnin.

{on -fir e -e-xpo s e { Side T h i c k d i s c h a r g e o f s m o k e -Distillation of tar at top. Light passage of flarnes a t t o p . Ignition of cotton. S e p a r a t i o n o f d o o r f r o m frarne at top. Ignition of frarne at r i g h t s i d e .

Ignition of frame at left s i d e .

tested under No. 57.506 D except that tJrere v,ras a sheet steel 5/I0 rnm ( 1 1 6 4 i n . ) t h i c k o n t h e f i r e - e > c p o s e d f a c e ( s e e F i g u t e 2 . 6 . E ) .

Tirne Fire-exposel! $ide_

Beginning of test. Beginning of charring of f r a m e . N o n - e x p o s e d Sidg C o n s i d e r a b l e d i s c h a r g e of srnoke. Swelling of oak" D i s c h a r g e o f s m o k e p e r s i s t s a b u n d a n t l y . Separation of therrno-c o u p l e s .

The deflection of the oak battens reached I crn ( z 3 / 4 i n . ) .

Glowing point iir rebate a t t o p .

On tle application of flarne, g?s at tJ.e bottom ignited.

Flarne extinguished. Glowing along all the rebate at the top. Flickering flarnes at tJ:e bottorn.

Light flarning at tJle bottorn left. Displacernent of oak b a t t e n s , 8 . 5 c m ( 3 l I l 3 z i n . ) . 0 2 min min rnin rnin s e c s e c 3 0

z 5

5 6 l0 rnin l Z m i n 4 5 s e c 19 rnin 1 9 r n i n 1 5 s e c 2Z rnin m i n 4 5 s e c min 27 ntin 15 sec 2tJ rnin 30 rnin? 2

2 7

Tirne 33 rnin 33 rnin 30 sec 37 rnin Clas s ification End of test.

Cause of failure: flaming.

Period of fire endurance: 28 rnin.

\on-exqgsqd Si€

Appearance of flames ( a b o u t I 0 c r n ( a i n . ) long) at the top of the d o o r .

etation of csTB for testing. The elernents are as follows:

- a f r a m e o f o a k 0 . 0 ? r n ( z 3 1 4 i n . ) b y 0 . 0 6 ? r n ( 2 5 / 8 i n . ) b y 0 . 0 3 r n ( 1 3 / I 6 i n . ) .

- a door with frarning in oak I.85 m (73 in.) by 0.8 rn (32 in.) by 0.03? m ( I 1 3 1 3 2 ir r . ) v / i t h a g r o o v e 0 . 0 2 5 r n ( I i n . ) b y 0 . 0 1 5 r n ( 1 9 l3 Z n . )

containing on each side a panel of plaster board I crn thick (3/8 in.) a n d a p a n e l o f p l y w o o d 5 m r n ( 3 1 L 6 i n . ) t h i c k ( s e e F i g u r e ? , 6 . F ) .

O] s e rvations dur ing- te. s_t

fi*.

0 min 25 sec 0 m i n 5 5 s e c I rnin 35 aec 4 rnin 30 sec 5 m i n 5 0 e e c I I rnin 30 sec 15 rnin l 8 m i n 19 min 29 rninFir e.- e xp o s e_d_,F iJLe

Separation of plywood panel. Fall of plywood panel.

Beginning of destruction of plywood.

Separation of plasterboard p a n e l . T h e p l a s t e r b o a r d i s held in position by therrno-couple No. I on the interior of the furnace.

Beginning of charring of oak frarning. F a l l o f p l a s t e r b o a r d p a n e l . No_n-e_xposed Eidg D i s c h a r g e o f s m o k e . L i g h t p a s s a g e o f f l a m e s a t t o p .

Flaming of cotton at toP. Light penetration at right of therrnocouple No. 5 at top of d o o r .

4 I

-Clas sification

Cause of fail'ure: flarning following penetration. Duration of fire endurance: 30 min.

the test.

The test aseernbly was constructed as follows:

- a f r a r n e o f o a k 0 . 0 ? 8 m ( 3 I / 1 6 i n . ) b y 0 . 0 ? ? r n ( 3 L l I 6 i n . ) b y 0 . 0 3 0 m ( r 3 l 1 6 i n . ) .

- a d<;or with frarning of oak 1.85 rn (?3 in.) by 0.8rn (32 in.) by 0.04? rn ( Z 2 7 1 3 2 i n . ) w i t h a r e b a t e O . O Z 5 rn ( l i n . ) b y 0 . 0 1 5 r n ( 1 9 l 3 2 i n . ) c a r r y i n g o n e a c h s i d e a p a n e l o f p l a s t e r b o a r d 0 . 0 1 r n ( 3 / 8 i n . ) t h i c k a n d a s h e e t o f a s b e s t o s c e r n e n t 0 . 0 0 5 r n ( 3 l L 6 L n . ) t h i c k . O n e a c h f a c e t h e r e w a s a p a n e l o f p l y w o o d 0 . O O 5 rn ( 3 l1 6 i r ' . ) thick. (See Fig . 2.6 .Gl.

Ob se rvatlotls agllg.-!g_g!

Tirne Sre-expoged SiSe

Flarning of plywood.

Partial fal} of plywood panel.

Total faII of plywood. Beginning of charring of frarne.

\orl-exp-o-s_e_4

Sllg

Discharge of srnoke at top. 0 m i n 1 5 s e c 0 m i n 3 0 s e c I r n i n l 0 s e c 2 rnin 26 rnin 48 min I h r 2 m i n I h r l 7 m i n 4 5 s c c I h r 1 9 r r r i n End of test. Clas sification

Cause of failure: flarning.

Duration of fire exposure: strictly cxtcncled to I hr 19 rnin.

Beginning of flarning of frame at top right.

Light charring of plywood at toP right due to flarnes frorn frarne. FaIl of tiherrnocouple No. 7 at toP o f d o o r .

Flarning of plywood at top of door.

4 3

-ESSAI No 52.506 A

C O U P E A . A

-Porte rnenuis6e b panneaux. e t c o u p e s .

Sch6rnas de montage F i g u r e 2 . 6 . A

ESSATS N.' 52.506 B.

j-l-I - - !0

L @ i 1'-I A I .-l--CAONE 2 IAIITJ ACCOITE5

- coillRtfl-aQut-z{tq F i g u r e Z . 6 . R P o r t e R e c o r d d e 3 2 I T I r r l . e t c o u p e s . Sch6rnas de rnontage C O U P E A . A .

F i g u r e 2 . 6 . C

4 5

-ESStrI no 52.506C

o 0 0

1 - - - - ' l

Porte Fontexa de 32 ffrlrl. Sch6mas de morttage e t c o u p e s .

F i g u r e 2 . 6 . D

E S S A I N , , 9 9 1 . R . 0 0 4

Porte rnenuis6e ) panneaux en sapin. Sch6rnas de rnontage et couPes.

F i g u r e 2 . 6 . 8

4 7

-ESSAI No 5U.506,D

Porte en ch6ne de 35 mrrr nue. Schdrnas de m o n t a g e e t c o u p e s .

s_oueg__a

A_

Porte cornposite rnise au Point Uni (2 plaques de placoplltre). rnontage et coupes. dans le Royaurne -Sch6rnas de t 0 0 . . L t , i ) . . \ ' n I F i g u r e 2 . 6 . F

_ 4 9 _

ESSAr No 5?.506 H

C O U P E B . B

B r a n d t c k n i s k e F o r s o g r n e d E n t r e d o r e ( T e s t i n g o f F i r e R e s i s t i n g F r o n t D o o r s ) , b y G e r h a r d H a n s e n a n d H . W i n c k e l r n a n n , S t a t e n s Byggeforskningsinstitot sBI. Rapport 31, I Kornrnission Hos Teknisk Forlag, Kobenhavn, L959,

G e n e r a l

F i r e t e s t s o f 1 5 w o o d d o o r a s s e r n b l i e s a r e d e s c r i b e d . T h e t e r r n rrfront doorstr used in the English stunlnary rnay be intended to include the cloor between an apartrnent and a corrrrrron corridor, because the doors wcre tcsterl opening both in and out of the furnace.

C o n s t r u c t i o n

D e t a i l s o f c o n s t r u c t i o n o f e a c h d o o r a r e i n c l u d e d i n t h e d e s c r i p t i o n s of the fire tests in the following pages.

T c s t M e t h o d

Thc Danish test rnethod follows generally the sarnc tirne/temperaturc r c l a t i o n a s t h e N o r t h A r n e r i c a n a n d B r i t i s h t e s t s ( s e e T a b l e 3 . 1 ) ' E x p e r i -rncnts wcre rnade to study the effect of varying tlre air pressure in the

furnace frorn 0 to 4 mrn water gauge above the air pressure in the roorn during thr: firc test.

t - i r c T c s t s

T h c f i r e t e s t s a r e d e s c r i b e d o n t h e f o l l o w i n g p a g e s . A s o l i d w o o c l rlrrr>r 35 tq 45 mnr ( I 3lS to I 3 /4 in.) thick wiII burn through in about 30 rnin, lrtrt p<:n<:tration of flarnc between door and frarne can occur within a very few rrrinut<:s. Incrcasing thc depttr of Nhe stop or providing rnetal weatherstrips rlirl not arlcl to the fire e-rndurance. A positive air Pressure of I to 2 rnrn water garrg() was founcl to be rnost satisfactory for testing doors as this contributed to

str:a<ly conrbustion. Pressures at or near 0 rnrn had the effect of lirniting thc l ) a s s a g ( , o f f l a r n c o r s m o k e w h e r e a s a t p r e s s u r e s o f ' Z t o 4 r n m w a t e r g a u g e thcr<: was intcnse burning and projection of flarnes.

5 I

-T E S -T N O . 8 O O

Standard door frarne - door opening o'ut frorn furnace; clearance a r o u n d e d g e s o f d o o r Z t o 3 r n r n ( 5 1 6 4 t o l / 8 i t t . ). Obse rvations dq119g-lgg! 2 rnin 2 r n i n 3 0 s e c 3 min 5 min 9 rnin 3 0 m i n

Appe atance gfter fire__exposure

Whole inner surface of door charred.

Lower corner of door burned through at latch side. Alrnost all of wood door frarne burned through.

Thickness <lf unburned wood at centre of door I l . 5 r n m ( 2 9 | 6 4 i n . ).

I g n i t i o n o f f i r e - e x p o s e d s i d e o f d o o r .

Burning between door and frarne at bottorn

Burning of wood face of door at lower edge on latch side.

Burning of wood edge above top hinge. Burning along upper edge of dqor. Test terrninated.