HAL Id: cea-02339616

https://hal-cea.archives-ouvertes.fr/cea-02339616

Submitted on 4 Nov 2019

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Damage characterization of (U,Pu)O_2 under

irradiation by molecular dynamics simulations

H. Balboa, L. van Brutzel, A. Chartier, Yann Le Bouar

To cite this version:

H. Balboa, L. van Brutzel, A. Chartier, Yann Le Bouar. Damage characterization of (U,Pu)O_2

under irradiation by molecular dynamics simulations. Journal of Nuclear Materials, Elsevier, 2018,

512, pp.440-449. �10.1016/j.jnucmat.2018.07.056�. �cea-02339616�

Mechanical properties of (U,Pu)O

2under irradiation studied by Molecular Dynamics

simulations

Laurent Van Brutzela,∗, Hector Balboaa, Alain Chartiera

aDen-Service de la Corrosion et du Comportement des Mat´eriaux dans leur Environnement (SCCME), CEA, Universit´e Paris-Saclay, F-91191, Gif-sur-Yvette, France

Abstract

Molecular dynamics simulations using two empirical potentials: Cooper and MOX-07 are carried out to assess the mechanical properties of UxPu1−xO2solid solution as a function of irradiation dose. The structural damage evolution with dose is modelled with

the accumulation of Frenkel pairs method. The structural change follows classical steps with increasing dose: first accumulation of point defects that cluster and form dislocation loops which transform in turn to dislocation lines. Elastic properties such as the bulk modulus and the anisotropic factor via the Zener’s ratio are evaluated for each steps. Overall, bulk moduli decrease with increasing dose while anisotropic factor behaviour depends on the potential used. It is also found that point defects play a major role in these evolution. Traction-separation curves used in cohesive zone models are also calculated for different irradiation doses. From these curves we extract the tensile strengths and the energy release rates as well as the fracture toughness. Fracture toughness is found to increase steadily with dose whereas tensile strengths displays v-shape curves which decreases for low doses and raises for high doses. For all these mechanical properties, point defects seem to play a major role while the impact of the dislocations is rather minor.

Keywords: Molecular dynamics, MOX fuel, irradiation, mechanical properties

1. Introduction

New generation of nuclear reactors is functioning with higher fuel burn-up and uses more systematically uranium-plutonium mixed oxide fuels (MOX). Such conditions increase radiation-induced damage, which in turn affects the structure and the thermo-mechanical properties of all the nuclear core compo-nents. In particular, pellet-cladding interaction can suffer due to the stresses induced by the fuel swelling onto the cladding [1, 2]. Therefore, to ensure the stability and durability of the nu-clear reactor core in these operating conditions, a solid knowl-edge of the thermo-mechanical properties under irradiation of the fuel is needed.

It is well known that UO2 and MOX mechanical properties

depend on porosity and oxygen-to-metal ratio [3]. Concerning the influence of the plutonium (Pu) content, it is admitted that Young’s modulus increases slightly (3 to 10%) with addition of PuO2 as demonstrated by experiments carried out in the

sev-enties on MOX fuel up to 20% PuO2 [4–7]. A recent study

performed by Hirooka et al. [8] on MOX fuel containing the full range of Pu content (i.e., from 0 to 100%) confirms a 10% increase of the Young’s modulus.

On the other hand, few studies are available regarding the changes in mechanical property under irradiation of UO2 and,

even less, of MOX. This is due mainly to the complexity of handling irradiated fuels. Moreover, the sparse results under ir-radiation are contradictory and still under debate. Some authors

∗

Corresponding author. Tel.:+33-169087915; Fax: +33-169089221 Email address: laurent.vanbrutzel@cea.fr (Laurent Van Brutzel)

using acoustic microscopy [9] or Vickers microindentation tests [10–12] found an increase of the elastic modulus with an in-crease of the burn-up. Conversely, other authors using the same techniques [13–15] concluded that elastic modulus decreases as the burn-up increases. These contradictions, can be attributed to the multiplicity of fuel microstructures used and differences on flux and temperature conditions. Indeed, some experiments have been carried out using simulated fuel, which mimics the chemical properties of the irradiated nuclear fuel whilst other studies used UO2fuel pellets containing different grain

dimen-sions and porosity. Therefore, comparison and conclusion are difficult to draw. Atomistic modelling such as molecular dy-namics simulations (MD) can then bring some insight into this issue because in such method the microstructure is well con-trolled.

Mechanical properties such as crack initiation and propaga-tion on unirradiated UO2have already been assess via MD

sim-ulations using empirical potentials [16–18]. These simsim-ulations examined the strain-stress curves during crack propagation and reported the existence of phase transitions ahead from the crack tip from fluorite to scrutinyite-type or rutile-type structure. We also obtained, in our previous assessment [19], the same be-haviour in UxPu1−xO2 solid solution with more or less

em-phases according the loading direction and the empirical poten-tial used. However, to the best of our knowledge, the influence of radiation damage on the cracking processes has not been yet investigated.

For the elasticity behaviour, elastic stiffness matrix is often used to fit the parameters of the interatomic potentials in MD

simulations. Nonetheless, the elastic modulus evolution with temperature or in case of MOX with Pu content is not usually included into the fitting process. However, they are rather used as justification for the reliability of the potentials [19–22]. But yet, evolution with radiation damage is not reported.

This work is an attempt to fill this gap. In our previous stud-ies [19], we have assessed 5 empirical potentials on some ther-modynamics and mechanical properties (e.g. thermal expan-sion, specific heat capacity, elastic constants, and ultimate ten-sile strength) for U1−xPuxO2 solid solution. Best results were

obtained with Cooper’s [22, 23] and MOX-07 [21] potentials. Recently, we continued the assessment with these two poten-tials by investigating the structural evolution as a function of the irradiation dose [24]. The calculated atomic configurations from [24] are used in the present work to determine the change in the mechanical properties including: elastic moduli, tensile strength, and toughness as a function of irradiation dose. Both, MOX-07 and Cooper’s potentials are used for this assessment.

The goal of the present work has twofold. First, it is to obtain a data base for the mechanical properties under irradiation for stoichiometric single crystal (U,Pu)O2mixed oxide. Second, it

is to correlate, if possible, the microstructure with the mechan-ical properties. These two points could be later implemented into fuel performance codes such as PLEIADES [25].

This present paper is organized as followed. Section 2 recalls the methodology used herein. Section 3.1 details the calculation of the elastic constants as a function of temperature and Pu con-tent for non-irradiated (U,Pu)O2mixed oxide and subsequently

as a function of irradiation dose calculated at 1600 K. In sec-tion 3.2, we discuss the tracsec-tion-separasec-tion curves obtained for different doses and the correlation found between the mechani-cal properties and the structural damage.

2. Computational method

2.1. Interatomic potentials and system size

All the simulations presented herein have been performed with the LAMMPS code [26] and the atomic structures were analysed with the OVITO software [27]. This mechanical study is carried out using two different potentials: Cooper’s potentials [22, 23] and MOX-07 potentials [21]. These two rigid ions po-tentials were selected among five from a previous assessment based on structural and mechanical properties for a full range of Pu content (0 to 100%) and temperatures up to the melting point [19]. Both give good results for structural and thermodynam-ics properties. Elastic stiffness constants are best reproduced with Cooper’s potential, which has been fitted on experimen-tal data for single crysexperimen-tal elastic constants [28] and provides the closest results to the Fink’s recommendation [29]. How-ever, Cooper’s potential renders a strong plastic-like behaviour during crack propagation while MOX-07 potential presenting a brittle-like behaviour. Concerning the behaviour under irra-diation, previous studies [24] show that Cooper’s potential is more sensitive to Pu content changes than MOX-07 potential. Yet, due to a long kinetics of defect recovery, undesirable de-fect configurations are observed for high energy displacement

cascades. Therefore, both potentials have their advantages and disadvantages, which provide a broader assessment for the me-chanical properties under irradiation.

Because our goal is to calculate the evolution of the mechan-ical properties as a function of irradiation dose, we use some of the defected systems calculated previously with the Frenkel pair accumulation method [24]. In this method, random Frenkel pairs are generated periodically to model the accumulation of damage arising from displacement cascades. Between each Frenkel pair introduction, the system is allowed to relax un-der constant temperature and pressure. With this method, we are able to link structural changes such as small point defect cluster and dislocation loop formation with the evolution of ir-radiation dose. In our previous study, we showed that the oxy-gen sublattice seems to follow the cation disorder, consequently in order to gain computational time only cation-Frenkel pairs are introduced. Therefore, we express the dose in displacement per cation (dpc) because this metric unit corresponds exactly to what is simulated with this method.

The size of these systems includes 40 × 40 × 40 fluorite unit cells (i.e., 22.5 × 22.5 × 22.5 nm), involving 768 000 atoms.

Before calculating all the mechanical properties, each sys-tem (i.e., at a given dose) is relaxed during 10 ps under zero pressure. The constant pressure equilibration is achieved by us-ing the Parrinello-Rahman algorithm available in the LAMMPS package. This ensures that for the whole system no residual stress due to the defects is present. Indeed, fluctuation of local stress can reach up to 10 GPa. This relaxation also provides extra annealing time for defects to recombine or cluster.

The heavy computational cost of the irradiated systems im-poses a limit on the number of cases that we can investi-gate for the dose effect. Therefore, for irradiated MOX, only three Pu contents are studied: 0% (pure urania, UO2), 50%

(U0.5Pu0.5O2), and 100% (pure plutonia, PuO2). Moreover, the

mechanical properties with irradiated MOX are calculated at 1600 K. Results from our previous assessment under irradia-tion carried out with the Frenkel pair accumulairradia-tion method [24] show that we obtain formation of dislocation with Cooper’s po-tential only at this temperature. At 300 K only point defects are created within the time frame of the MD simulation.

2.2. Elastic constants

The elastic properties are evaluated by computing the sti ff-ness matrix at finite temperature for different doses in a step-wise method. First, small deformation (< 0.1%) is imposed on the relaxed system for all the six Voigt components of the strain tensor. This step is followed by a relaxation at constant temper-ature and constant volume during 2 ps. Elastic moduli are then calculated from the slopes of the resulting stress-strain curves obtained using appropriate components of stress and strain ten-sors.

Subsequently, the Poisson’s ratio and the elastic anisotropy can be directly extracted from this stiffness matrix. The best known measure of the elastic anisotropy is perhaps the Zener’s ratio, denoted A, introduced for the first time by Zener in a study of β-brass [30]. This ratio is simply defined for a cubic

symme-try system as the ratio between the two extreme shear coe ffi-cients: µtrigonal= c44, and µtetragonal = (c11− c12)/2:

A= 2c44 (c11− c12)

(1)

We note that the numerator consists of the shear elastic con-stant c44, which signifies resistance to shear on the {1 0 0} planes

when a pair of opposing shear forces are acting in the h0 k li di-rections. Similarly, the denominator (c11 − c12)/2 represents

resistance to shear on the {1 1 0} planes with forces acting along the h1 1 0i directions. As such, the Zener’s ratio equals to unity (i.e., A= 1) for a truly isotropic material.

2.3. Traction-separation curves

Beside the elastic behaviour another important set of me-chanical properties is the resistance to crack initiation and prop-agation. Since we study fuel under irradiation, small radia-tion induced-damage could affect locally the crack behaviour. Hence, an interesting approach to characterize such mechanical properties is to use a cohesive zone model (CZM). Such model describes a discrete crack initiation and propagation within the process zone, in vicinity of the crack tip, where plastic defor-mation and complex damage behaviour take place. CZM is based on the original works of Dugdale [31] and Barenblatt [32] where they represent non-linear processes in the so called dam-age zone. In this model, the fracture process is concentrated into the cohesive crack and is characterized by a cohesive law that relates traction (normal stress in mode-I fracture), σ, to separation (displacement jump across cohesive surface), λ, see Fig. 1.

The cohesive law is called traction-separation curve. The ad-vantage of this approach is that CZM eliminates singularity of stress at the crack tip. This approach has been used for nuclear fuels and implemented into fuel performance codes [33, 34]. The pick stress on the cohesive law is the cohesive strength of the material, σc, and corresponds to the point at which the crack

initiates for a critical separation, λf. The opening displacement

of the cohesive surfaces at which the cohesive traction is re-duced to zero is denoted λ0. The area under the curve is the

co-hesive fracture energy, Gc= R λ0

0 σ(λ)dλ, is the external energy

required to create and completely break a unit surface area of the cohesive crack. It is related to the energy release rate of the Griffith’s criteria. Consequently, the fracture toughness (KIc)

can be calculated under plane stress condition as KIc=

√ Gc.E,

where E is the Young’s modulus.

To evaluate the traction-separation curves in MD, we use the methodology developed by Yamakov et al. [35, 36] for inter-granular fracture in Al. All the steps of this method are sum-marized in Fig. 2. First, the zero pressure relaxed systems are loaded hydrostatically in tension (i.e., σxx= σyy = σzz = σH).

The value of σHdepends on the interatomic potentials. Based

on our previous assessment of the strain-strain curves during crack propagation [19], σHis chosen equal to 6 GPa and 8 GPa

for MOX-07 and Cooper’s potentials respectively. These val-ues correspond to the maximal stress found before crack prop-agates. When the system is equilibrated, the simulation then

Figure 1: The Cohesive Zone Modelling (CZM) of fracture. (a)Schematic of the cohesive zone in the process zone. (b)Idealized traction-separation curve.

proceeds under isovolume-isothermal ensemble (NVT) main-taining the strain associated with the prestress condition. It has been demonstrated that applying this triaxial hydrostatic stress eliminates undesirable plasticity effects [37].

Subsequently, a sharp pre-crack of length Lcrack = 7 nm is

initiated in the center of the simulation box by screening the atomic interactions between atoms embedded in a region of length Lcrack over a distance corresponding to twice the

empir-ical potential cut-off (i.e., 2 nm). The distance Lcrack is chosen

such that with the prestress applied crack can propagate. The screening remains active throughout the entire simulation.

The crack starts growing in a steady-state condition and evolves until it stops after propagating in both directions for ap-proximatively 3-4 nm. During crack propagation, we extract the traction-separation curves by averaging atomic tensile stresses in each cohesive zone volume element (CZVE) ahead of the initial crack tip (see Fig. 2) as a function of the crack open-ing displacement, λ. This last one is calculated by trackopen-ing the change in the y-position of the center of mass of two vertically neighbouring CZVEs. The size of each CZVE is set to 0.9 nm according to the careful analysis of Barrows et al. [39]. Detail of this CZVE procedure analysis can also be found in the same reference. With this method, the maximum cohesive strength corresponds to the the maximum tensile strength.

Figure 2: Schematic of the different MD steps to compute the traction-separation curves.

3. Results and discussion 3.1. Elastic behaviour

3.1.1. Elastic behaviour on non-irradiated (U,Pu)O2

Prior to study the influence of the dose effect for which only three Pu contents and one temperature are investigated, we re-call the evolution of the elastic behaviour in pristine MOX as a function of a full range of the temperature (300 K to melting point) and Pu content (0% to 100%).

Evolutions as a function of the temperature of the bulk modu-lus and the Zener’s ratio for both potentials used herein are dis-played in the Fig. 3 and compared with Hutchings’ experimen-tal data obtained on single crysexperimen-tal [28]. For both potentials bulk modulus decreases quasi-linearly with increasing temperature. It also shows that Cooper’s potential reproduces relatively well the available experimental data for UO2while MOX-07

under-estimates the values of the bulk modulus by approximatively 40%. However, the absolute values of the Young’s modulus for MOX-07 are in the order of the Young’s modulus recommen-dation of Fink [29] for polycrystalline UO2.

Another difference between these two potentials is the anisotropy factor evaluated by the Zener’s ratio, A. For MOX-07 potential A is roughly equal to 1 (i.e., isotropic) until 2400 K whereas for Cooper’s potential it is equal to 0.47 until the same temperature. As already mentioned in our previous assessment [19], the change in Zener’s ratio after this temperature is due probably to the Bredig’s transition which is often associated with premelting of the oxygen sublattice. The A value cal-culated from the experimental elastic constants [28] increases from 0.52 to 0.65 in the same range of temperature. It is also worth noting that other experimental values calculated at 300 K are closer to Cooper’s value and range between 0.44 to 0.47 [38, 40]. Thus, A < 1 indicates that the UO2

sys-tem is anisotropic and that the Young’s modulus values will be maximum along the h1 0 0i direction and minimum along the h1 1 1i direction. Therefore, it is interesting to compare fur-ther mechanical behaviour with both potentials knowing this difference in the anisotropy. Furthermore, for both potentials the anisotropic factor at 1600 K (temperature studied for the irradiated case) is still in the order of the one at 300 K.

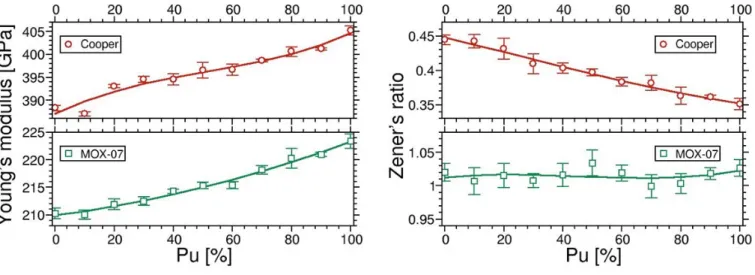

Since we are assessing the mechanical behaviour in (U1−xPux)O2solid solution, it is important to check the

influ-ence of the Pu content on the elastic properties. Fig. 4 shows the evolution for both potentials of the bulk modulus and the Zener’s ratio as a function of the Pu content. Both potentials are displayed in two different graphs because of their differ-ent scales. This helps to better appreciate their evolution. For the bulk modulus, apart the difference of scale, both potentials show an increase of about 5% with an increase of the Pu con-tent. Recent sound wave measurements carried out by Hirooka et al. [8] on polycrystal MOX show also an increase of the bulk modulus (about 12%) with the addition of plutonium content.

For the anisotropy factor, the behaviour is very different. For MOX-07, A = 1 through the entire range of Pu content, showing no change in the isotropic behaviour. Conversely, for Cooper’s potential the A factor decreases quasi linearly as the Pu content increases, yielding to an even more pronounce

anisotropy for PuO2(i.e., E111is 45% of E100for UO2and E111

decreases to 35% of E100 for PuO2). This behaviour is also

found with DFT+U calculations [41] but with A factor decreas-ing from 0.7 to 0.6 between UO2 to U75Pu25O2. In all cases

the elastic behaviour is quasi-linear with respect to the Pu con-tent. Therefore one intermediate point between pure urania and plutonia should be sufficient to follow the behaviour under irra-diation.

3.1.2. Elastic behaviour on irradiated (U,Pu)O2

Before presenting the results on the elastic properties as a function of the irradiation dose, it is important to summarize the structural evolution changes undergone by the accumula-tion of defects. Fig. 5 gathers for both potentials the evoluaccumula-tion of the point defects (vacancies and interstitials) and the disloca-tion density as a funcdisloca-tion of dose expressed in dpc for three Pu contents (0%, 50% and 100%) at 1600 K.

As previously detailed for UO2[42] and for U1−xPuxO2solid

solution [24], we show that nucleation and growth of disloca-tions in these materials follow a five stages process. (1) Point defects are first created by irradiation, this is demonstrated by a rapid increase of the number of vacancies and interstitials at low dose (< 0.2 dpc). (2) The interstitials aggregate into clus-ters. (3) For MOX-07 potential, these clusters nucleate mostly Frank loops that transform into perfect dislocations whereas for Cooper’s potential the interstitial clusters directly form perfect dislocations. This is shown in Fig. 5 by the decrease of the number of interstitials followed by the increase of dislocation density. (4) Subsequently, the perfect dislocations grow; and (5) finally reorganize into forest dislocations that results in the decrease of the dislocation density at higher doses. The main differences between both potentials are the quasi-absence of Frank loops generation and the influence of the Pu content for Cooper’s potential. Namely, as the Pu content increases the to-tal density of dislocation loops decreases and the peak in the dislocation density appears for higher dose.

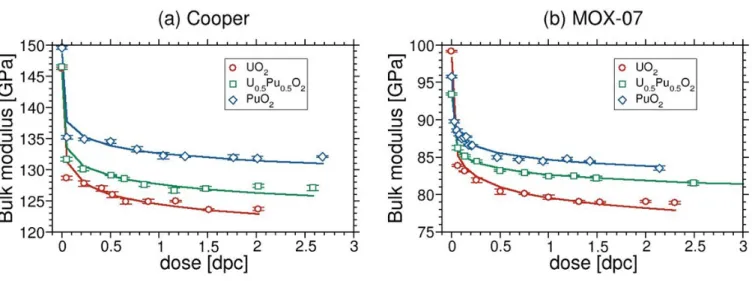

The elastic mechanical properties are now evaluated as a function of the irradiation dose. Fig. 6 and 7 compare respec-tively the evolution of the bulk modulus and the Zener’s ratio as a function of dose calculated at 1600 K for pure UO2and PuO2

and for a solid solution of 50% Pu.

For both potentials we observed the same behaviour for the bulk modulus. It decreases rapidly for doses less than 0.1-0.2 dpc, and becomes almost constant for the high dose levels. The decrease is sensibly the same for all Pu contents indicat-ing no real influence of the Pu content with the accumulation of damage on the elastic moduli, even with Cooper’s potential. This decrease at low dose is strongly correlated to the rapid increase of the point defects for the same doses. This indicates that point defects contribute for the most part in the reduction of the bulk modulus at low dose. This behaviour has already been reported by Gao et al. [43] for another ceramic material, SiC. Furthermore, analysis of simulated-XRD in UO2 [42] shows

that lattice expansion at low doses is mainly related to point de-fects accumulation, while the onset of lattice contraction starts when perfect dislocations nucleate. Bulk modulus being a

mea-Figure 3: Evolution of the bulk modulus (left) and the Zener’s ratio (right) as a function of the temperature for both MOX-07 and Cooper’s potentials in UO2. The black triangle symbols are points calculated from the measured elastic constants on single crystal reported by Hutchings et al. [28].

Figure 4: Evolution of the bulk modulus (left) and the Zener’s ratio (right) as a function of the Pu content for both MOX-07 and Cooper’s potentials at 300 K. For the bulk modulus the values are compared with experimental data from Hirooka et al. [8] carried out on polycrystal MOX at 300 K with sound wave measurements.

sure of the resistance to compressibility, hence it is not surpris-ing that a decrease of the bulk modulus promotes swellsurpris-ing.

Contrarily, the evolution of the anisotropy factor is really dif-ferent for both potentials. For Cooper’s potential, the Zener’s ratio first follows a rapid increase and saturates for higher doses, corresponding to a decrease of the anisotropy. Different Pu con-tents also show difference; the richest Pu content shows higher anisotropy. This behaviour is similar to the one found for bulk modulus and indicates that point defects play a major role in this evolution.

Conversely, for MOX-07 potential, which renders isotropic feature, the Zener’s ratio drops rapidly to a minimum of A = 0.87 before increasing around 0.2-0.3 dpc and returns to almost perfect isotropic behaviour at high doses. This short anisotropy increase is related to point defects creation, but also to the cre-ation of Frank loops, which almost reaches its peak density at

that dose. After 0.5-0.6 dpc, Frank loops transform into perfect dislocations and at that point Zener’s ratio is almost back to its non-irradiated value.

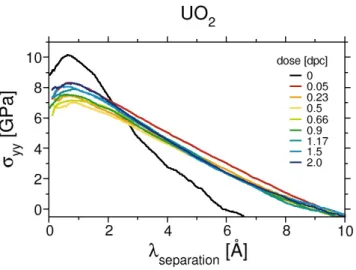

3.2. Traction-separation curves evolution

Traction-separation curves, which are essential in cohesive zone models, describe the non-linear local fracture processes next to the crack tip. Furthermore, tensile strength, energy re-lease rate as well as fracture toughness can be extracted from them. Therefore, traction-separation curves are calculated at different doses for the three Pu contents at 1600 K for both po-tentials as described in the section 2.3. The traction-separation curves are really similar for all the cases, hence in order to al-leviate this paper with figures, we present only in Fig. 8 the traction-separation curves calculated with Cooper’s potential in UO2for different irradiation doses.

Figure 5: Evolution of the number of point defects (vacancy and interstitial) expressed in % of defect and the dislocation density (Frank loops with Burgers vector 1/3h1 1 1i and perfect dislocations with Burgers vector1/2h1 1 0i) as a function of dose for both (a) Cooper’s and (b) MOX-07 potentials at 1600 K.

Figure 8: Traction-separation curves calculated with Cooper’s potential in UO2 at 1600 K for different irradiation doses.

The shape of the traction-separation curves is almost identi-cal for all doses and can be approximated with the Tvergaard’s constitutive model [44]. This model is a trapezoidal CZM de-composed into three linear regions. For separation less than 0.5 Å the crystal is stretched elastically. This region corre-sponds to the elastic stiffness far from the crack tip. It is fol-lowed by a very short region, up to 1 Å, where the traction is almost constant with the separation. This region is referred as the plastic-like region. Finally, the third region corresponds to a linear drop of the traction until complete failure by fracture occurs at separation distance , λ0, close to 10 Å for irradiated

material and 6 Å for pristine material. Tvergaard et al. demon-strated that the details of the shape of the separation law are

relatively unimportant, and only the work of separation per unit area (i.e., energy release rate corresponding to the area under the curve), Gc, and the peak traction (i.e., tensile strength), σc,

are the most relevant parameters. Therefore, only these two parameters will be discussed in the following. It is worth not-ing that such traction-separation behaviour fitted with the same Tvergaard’s model has already been observed in pure UO2for

the decohesion ofΣ5 grain boundary interfaces with MD simu-lation by Zhang et al. [17].

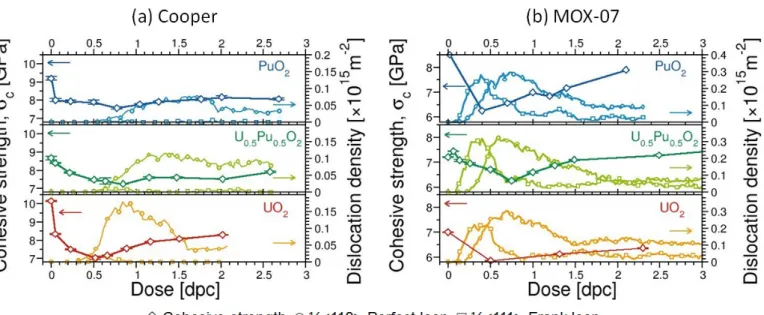

The evolution of the tensile strengths as a function of doses is plotted in Fig. 9 for the three different Pu contents and both potentials. They are compared with the evolution of the dis-location densities, which are plotted respectively on the same graph. The general feature of the σcevolution with dose is

sim-ilar for both potentials, even if, as for the elastic properties the Pu content influence is more pronounced with Cooper’s poten-tial. For low doses, σcdecreases to reach a minimum between

0.5 to 0.8 dpc. Subsequently, as dose increases, σc increases

and seems to saturate. However the values at high doses are systematically lower than the non-irradiated values. This in-dicates that low irradiated U1−xPuxO2withstands lower tensile

load than high irradiated one before cracking.

The minima of σccorresponds approximatively to the point

at which perfect dislocation density begins to increase signif-icantly. Consequently, interstitials and Frank loops degrade more the material resistance to crack initiation than perfect dis-locations. As already stated in the previous section, this is linked to the contribution of each defect to the lattice deforma-tion; where point defects contribute mainly to lattice expansion whereas perfect dislocations are related to lattice contraction [42].

The second important parameter, which defines the traction-separation curves is the energy release rate, Gc. From it, one can

Figure 6: Evolution of the bulk modulus as a function of irradiated dose expressed in displacement per cation (dpc) for (a) Cooper and (b) MOX-07 potentials at 1600 K.

Figure 7: Evolution of the Zener’s ratio as a function of irradiated dose expressed in displacement per cation (dpc) for (a) Cooper and (b) MOX-07 potentials at 1600 K.

calculate easily the fracture toughness as: KIc=

√

Gc.E where

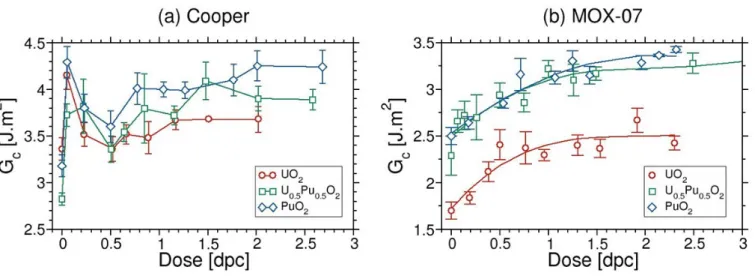

Eis the Young’s modulus along the tensile direction. The evo-lution of the Gc as a function of dose is reported in Fig. 10.

As shown in this figure, differences appear between both po-tentials for low doses. With MOX-07 potential, Gcincreases

strongly up to 1 dpc and subsequently increases slightly to reach for all the Pu contents a value approximately 30% higher than the value of the non-irradiated material. The values at the high-est doses invhigh-estigated herein are 2.4, 3.2, and 3.4 J/m2 corre-sponding to KIcequals to 0.61, 0.68 and 0.72 MPa

√

m for UO2,

U0.5Pu0.5O2 and PuO2 respectively. Conversely, for Cooper’s

potential a peak appears at low dose, around 0.2 dpc, which is correlated to the maximum of the number of point defects (see Fig. 5). Afterwards, as dose increases the value of Gcincreases

slightly to reach 3.7, 3.9, and 4.3 J/m2 for UO

2, U0.5Pu0.5O2

and PuO2 respectively. The corresponding values of the

frac-ture toughness for the same order of the Pu content are 0.94,

0.97, and 1.2 MPa√m.

No experimental measurement in the same conditions are di-rectly available to compare with our results. However, exper-iments on non-irradiated polycristal UO2 over large range of

porosity, stoichiometry and temperature using different tech-niques [45–48] report values of KIc ranging from 0.88 to

1.20 MPa√m. For the energy release rate, Solomon measured it for UO2including impurities and found values ranging from

1.6 to 5 J/m2[49]. MD calculations carried out by Zhang et al. [17] on decohesion ofΣ5 in UO2 gives value for Gcequals to

3.6 J/m2 for 1500 K. All these values are in the range of our

calculations.

Overall, for both potentials, we observe an increase of the fracture toughness and the energy release rate with an increase of the irradiation dose. This is explained by the presence of increasing damage that scatters the stresses and renders more difficult the initiation and propagation of a single crack. How-7

Figure 9: Evolution of the tensile strength, σc, and the dislocation density (Frank loops with Burgers vector1/3h1 1 1i and perfect dislocations with Burgers vector 1/2h1 1 0i) as a function of dose for both (a) Cooper’s and (b) MOX-07 potentials at 1600 K.

ever, with Cooper’s potential point defects seem to play a major role in this dissipation while with MOX-07 potential all types of defects are affecting equally the mechanical resistance to frac-ture.

4. Conclusions

Molecular dynamics simulations have been carried out to as-sess the evolution on the mechanical properties of U1−xPuxO2

solid solution as a function of the irradiation dose. Two empir-ical potentials are used for this assessment: Cooper and MOX-07. Previous studies show that both provide good structural and thermodynamics properties and rather similar behaviour under irradiation such as displacement cascades and dose ef-fect. However, mechanical properties are comparatively dif-ferent. The main difference is that Cooper’s potential shows anisotropic behaviour for the elastic stiffness (i.e., E100, E111)

whereas MOX-07 yield to pure isotropic behaviour.

Evolution of the structural damage as a function of irra-diation dose is modelled via the Frenkel pairs accumulation method. Snapshot configurations at different doses expressed in displacement per cation are taken from our previous study and submitted to small deformation procedure to calculate the components of the stiffness matrix. These irradiated configu-rations are obtained at 1600 K because for Cooper’s potential dislocation formation mechanism from point defects can only be obtained at high temperature. However, for this temperature the anisotropic factor is almost identical to the one at 300 K. Furthermore, moduli evolve linearly with temperature thus the general behaviour should be similar and only changes on the absolute values are expected.

Overall, for both potentials the elastic moduli decrease by 10 to 20% as the irradiation dose increases. This decay is more

abrupt for low doses, less than 0.2 dpc, where point defects are still the most relevant defect. This behaviour is related to the material swelling for which point defects has revealed to be the largest contributor.

For the elastic anisotropy both potentials show different features. For Cooper’s potential, the Zener’s ratio increases strongly for low doses and more steadily after 0.2 dpc. Like for the elastic moduli, point defects seem to play an important role while perfect dislocations effect is minor. Conversely, for MOX-07 potential point defects as well as Frank loops alter slightly the perfect isotropy whereas perfect dislocations show same isotropic behaviour than pristine material.

Fracture processes next to the crack tip are investigated via traction-separation curves used in cohesive zone model. From these curves the tensile strengths, energy release rates, and frac-ture toughness are extracted. This method avoids undesirable phase transition appearing due to the high strain-rate usually imposed in molecular dynamics simulations. For both poten-tials, the overall evolution on these properties are analogous, even if the type of defects affecting it can be different. The tensile strengths present a v-shape curve with minimum corre-sponding to the maximum of point defects and Frank loops. The energy release rates related to the fracture toughness increase with dose but with a stronger increase when point defects and Frank loops dominate damage.

Overall, the same mechanical behaviour is found for the three Pu contents studied. Although elastic properties are different for both potentials studied herein, point defects or Frank loops affect strongly the mechanical properties while perfect disloca-tions seem to play a minor role.

Figure 10: Evolution of the energy release rate, Gc, as a function of dose expressed in dpc at 1600 K for 3 Pu contents calculated with (a) Cooper’s and (b) MOX-07 potentials.

Acknowledgements

This research is part of the INSPYRE project, which has received funding from the Euratom research and training pro-gramme 2014-2018 under Grant Agreement No 754329. This research contributes to the joint programme on nuclear materi-als (JPNM) of the European energy research alliance (EERA). This work was granted access to the HPC resources of [TGCC] under the allocation 2016-mtt7073 made by GENCI.

[1] B. Michel, J. Sercombe, C. Nonon, O. Fandeur, 3.22-Modeling of pellet cladding interaction, in: R.J.M. Konings (Ed.), Comprehensive Nuclear Materials, Elsevier, 2012.

[2] B. Baurens, J. Sercombe, C. Riglet-Martial, L. Desgranges, L. Trotignon, P. Maugis, ”3D thermo-chemical-mechanical simulation of power ramps with ALCYONE fuel code”, J. Nucl. Mater. 452 (2014) 578-594. [3] ESNII+ European commission. Deliverable D7.11 state of the art with a

literature review of MOX properties. (2015)

[4] C.H. de Novion, B. Amice, A. Groff, Y. Guerin, A. Padel, Mechani-cal Properties of Uranium Plutonium Based Ceramics, Nucl. Metall. 17 (1970) 509-517.

[5] A.W. Nutt Jr., A.W. Allen, J.H. Handwerk, ”Elastic and anelastic response of polycrystalline UO2PuO2”, J. Am. Ceram. Soc. 53 (1970) 205-209. [6] J. Boocock, A.S. Furzer, J.R. Matthews, ”The Effect of Porosity on the

Elastic Moduli of UO2 as Measured by an Ultrasonic Technique”, AERE-M 2565, September 1972.

[7] J.R. Matthews, ”Mechanical Properties and Diffusion Data for Carbide and Oxide Fuels, Ceramics Data Manual Contribution”, AERE-M2643, 1974.

[8] S. Hirooka and M. Kato, ”Sound speeds in and mechanical properties of (U,Pu)O2x”, J. Nucl. Sci. and Technology, 55 (2018) 356-362. [9] V. Roque, D. Baron, J. Bourgoin, and J.M. Saurel, ”Study by acoustic

microscopy of irradiated and non-irradiated uranium dioxide”, J. Nucl. Mater. 275 (1999) 305-311.

[10] J. Spino, J. Cobos-Sabate, F. Rousseau, ”Room-temperature microinden-tation behaviour of LWR-fuels, part 1: fuel microhardness”, J. Nucl. Mater. 322 (2003) 204-216.

[11] M.C. Pujol, M. Idiri, L. Havela, S. Heathman, and J. Spino, ”Bulk and Youngs modulus of doped UO2 by synchrotron diffraction under high pressure and Knoop indentation”, J. Nucl. Mater. 324 (2004) 189197. [12] M.S. Elbakhshwan, Y. Miao, J.F. Stubbins, and B.J. Heuser, ”Mechanical

properties of UO2 thin films under heavy ion irradiation using nanoinden-tation and finite element modeling”, J. Nucl. Mater. 479 (2016) 548-558. [13] D. Laux, D. Baron, G. Despaux, A.I. Kellerbauer, and M. Kinoshita,

”De-termination of high burn-up nuclear fuel elastic properties with acoustic microscopy”, J. Nucl. Mater. 420 (2012) 94100.

[14] M. Marchetti, D. Laux, L. Fongaro, T. Wiss, P. Van Uffelen, G. Despaux, and V.V. Rondinella, ”Physical and mechanical characterization of irra-diated uranium dioxide with a broad burnup range and different dopants using acoustic microscopy”, J. Nucl. Mater. 494 (217) 322-329. [15] F. Cappia, D. Pizzocri, M. Marchetti, A. Schubert, P. Van Uffelen, L.

Luzzi, D. Papaioannou, R. Maci`an-Juan, V.V. Rondinella, ”Microhard-ness and Young’s modulus of high burn-up UO2 fuel”, J. Nucl. Mater. 479 (2016) 447-454.

[16] Y. Zhang, Xiang-Yang Liu, P.C. Millett, M. Tonks, D.A. Andersson, and S. Bulent-Biner, ”Crack tip plasticity in single crystal UO2: Atomistic simulations”, J. Nucl. Mater. 430 (2012) 96105.

[17] Y. Zhang, P.C. Millett, M.R. Tonks, X. Bai, and S. Bulent-Biner, ”In-tergranular fracture in UO2: derivation of traction-separation law from atomistic simulations”, GLOBAL 2013

[18] P. Fossati, L. Van Brutzel, A. Chartier, and J-P. Crocombette, ”Simulation of uranium dioxide polymorphs and their phase transitions”, Phys. Rev. B 88 (2013) 214112.

[19] H. Balboa, L. Van Brutzel, A. Chartier, and Y. Le Bouar, ”Assessment of empirical potential for MOX nuclear fuels and thermomechanical proper-ties”, J. Nucl. Mater. 495 (2017) 66-77.

[20] T. Arima, S. Yamasaki, Y. Inagaki, and K. Idemitsu, ”Evaluation of ther-mal properties of UO2 and PuO2 by equilibrium molecular dynamics sim-ulations from 300 to 2000 K”, J. Alloys Compd. 400 (2005) 43-50. [21] S.I. Potashnikov, A.S. Boyarchenkov, K.A. Nekrasov, A.Ya.

Kupryazhkin, ”High-precision molecular dynamics simulation of UO2PuO2: Pair potentials comparison in UO2”, J. Nucl. Mater. 419 (2011) 217-225.

[22] M.W.D. Cooper, S.T. Murphy, M.J.D. Rushton, R.W. Grimes, J. Nucl. Mater. 461 (2015) 206-214.

[23] M.W.D. Cooper, M.J.D. Rushton, and R.W. Grimes, J. Phys. Condens. Matter. 26 (2014) 105401.

[24] H. Balboa, L. Van Brutzel, A. Chartier, and Y. Le Bouar, ”Damage char-acterization of (U,Pu)O2 under irradiation by Molecular Dynamics simu-lations”, submitted to JNM.

[25] B. Michel, C. Nonon, J. Sercombe, F. Michel, and V. Marelle, ”Simula-tion of Pellet-Cladding Interac”Simula-tion with the PLEIADES Fuel Performance Software Environment”, Nuclear Technology, 182 (2013) 124-137. [26] http://lammps.sandia.gov/

[27] A. Stukowski , K. Albe, ”Visualization and analysis of atomistic simula-tion data with OVITO - the Open Visualizasimula-tion Tool”, Modelling Simul. Mater. Sci. Eng. 18 (2010) 015012 http://ovito.org/

[28] M.T. Hutchings, ”High-temperature Studies of UO2, and ThO2, using Neutron Scattering Techniques”, J. Chem. Soc., Faraday Trans. 2, 1987, 83, 1083.

[29] J. Fink, J. Nucl. Mater. 279 (200) 1-18; IAEA-TECDOC-1496 , Ther-mophysical properties database of (materials for light water reactors and heavy water reactors

[30] C. Zener, Phys. Rev.,”Contributions to the Theory of Beta-Phase Alloys”, 71 (1947) 846.

[31] D.S. Dugdale,”Yielding of steel sheets containing slits”, J. Mech. Phys. Solids, 8 (1960) 100-104.

[32] G.I. Barrenblatt,”The Mathematical Theory of Equilibrium Cracks in Brittle Fracture”, Adv. Appl. Mech., 7 (1962) 55-129.

[33] R.L. Williamson, and D.A. Knoll, ”Simulating Dynamic Fracture in Ox-ide Fuel Pellets Using Cohesive Zone Models”, 20th International Confer-ence on Structural Mechanics in Reactor Technology (SMiRT 20) Espoo, Finland, August 9-14, 2009, SMiRT 20-Division III, Paper 1775 [34] J.-M. Gatt, J. Sercombe, I. Aubrun, J.-C. M´enard, ”Experimental and

nu-merical study of fracture mechanisms in UO2 nuclear fuel”, Engineering Failure Analysis, 47 (2015) 299-311.

[35] V. Yamakov, E. Saether, D.R. Philipps, and E.H. Glaessgen,”Molecular-dynamics simulation-based cohesive zone representation of integranular fracture processes in aluminum”, J. Mech. Phys. Solids, 54 (2006) 1899-1928.

[36] V. Yamakov, E. Saether, E.H. Glaessgen, ”Multiscale modeling of inter-granular fracture in aluminum: Constitutive relation for interface debond-ing”, J. Mater. Sci. 43 (2008) 74887494.

[37] V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, H. Gleiter, ”Dislo-cation processes in the deformation of nanocrystalline Al by molecular-dynamics simulation”, Nature Mater., 1 (2002) 45-48.

[38] J.B. Wachtman, M.L. Wheat, H.J. Anderson, and J.L. Bates, ”Elastic con-stants of single crystal UO2 at 25C”, J. Nucl. Mater. 16 (1965) 39-41. [39] W. Barrows, R. Dingreville, and D. Spearot, ”Traction-separation

rela-tionships for hydrogen induced grain boundary embritllement in nickel via molecular dynamics simulations”, Mater. Sci. & Eng. A, 650 (2016) 354-364.

[40] R. Berman, T.S. Tully, J. Belle, and I. Goldberg, ”Assessment of thermal conductivity of high-density thoria-urania compositions (LWBR develop-ment program)”, Transactions of the American Nuclear Society 14 (1971) 147.

[41] B. Dorado and Ph. Garcia, ”First-principles DFT+U modeling of actinide-based alloys: Application to paramagnetic phases of UO2 and (U,Pu) mixed oxides”, Phys. Rv. B, 87 (2013) 195139.

[42] A. Chartier, C. Onofri, L. Van Brutzel, C. Sabathier, O. Dorosh, and J. Jagielski, ”Early stages of irradiation induced dislocations in urania”, Appl. Phys. Lett. 109 (2016) 181902.

[43] F. Gao, W.J. Weber, ”Mechanical Properties and Elastic Constants Due to Damage Accumulation and Amorphization in SiC”, Phys. Rev. B 69 (2004) 224108.

[44] V. Tvergaard and J. W. Hutchinson, ”The relation between crack growth resistance and fracture process parameters in elastic-plastic solids”, J Mech. Phys. Solids 40 (1992) 1377-1397.

[45] A. Evans and R. Davidge, J. Nucl. Mater. 33 (1969) 249.

[46] H. J. Matzke, T. Inoue and R. Warren, ”The surface energy of UO2 as determined by Hertzian indentation,” Journal of Nuclear Materials, 91 (1980) 205-220.

[47] T. Kutty, ”Fracture toughness and fracture strength energy of sintered ura-nium dioxide fuel pellets,” Journal of Materials Science Letters, 6 (1987) 260-262.

[48] R. McDonald PhD thesis ”An Evaluation of the Mechanical Properties and Microstructure in Uranium Dioxide Doped with Oxide Additives” 2014.

[49] A.A. Solomon, ”Influence of Impurity Particles on the Fracture of UO2”, J. of the Am. Ceram. Soc., 55 (1972) 622-627.