Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB. Building Research Note, 1971-08-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=0120530c-edcd-49f6-b014-1dfbe155ea1a https://publications-cnrc.canada.ca/fra/voir/objet/?id=0120530c-edcd-49f6-b014-1dfbe155ea1a

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40000631

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Wetting and drying of small wood panels

, , CANADA

i

SerI !

TIEL I 392 I no. 78 I c . 2 IWETTZNG

AND

DRYING OFSMALL WOOD PANELSby

D,

C . Tibbetts andD.

R.

RobsanO E V I S I O N O F D U I L D I H O R E S E A R C H M A T I O N A L R E S E A R C H C O U N C I L * O T T A W A C A N A D A

WETTING AND DRYING

OF

SMALL WOOD PANELS byD.

C.

Tibbetts and D.R. RobsonObservations of painted wood sidings on houses, and subsequent study of instrumented panels e x p o s e d to the elements suggest that much of the water associated with paint f a i l u r e

is

due to

rain. F r o m auto- matic recordings of wood m o i s t u r e content in the exposed panels (at onedepth only), rapid increases were observed during a rain followed b y

what appeared to b e similar r a t e s of decreases when the r a i n ceased (1)

Both wetting and d r y i n g of the wood w e r e a s s u m e d to occur through t h e

paint films

.

In

order t o investigate if apparent d r y i n g rates of the exposedpanels w e r e due to moisture redistribution, a labor ator y p r o g r a m using small panels was initiated whereby artificial but controlled methods of

wetting could be observed.

The

program a l s o studied t h e relative p e r - f o r m a n c e s of coated and uncoated panels, the effects of prolonged p e r i o d sof wetting, cycling influences, w a t e r temperature and rates of unintex- rupted d r y i n g under controlled conditions.

The laboratory experiments i n i t i a l l y involved t h e use of a rain leakage apparatus which provided a continuous film of water over the ex-

p o s e d f a c e of the p a n e l and an air pressure approximating a 50 rnph (22.37111/

s e c ) wind (2). During this period, when some modkfications to existing apparatus w e r e being made, it was observed that variation of the waterrs

temperature, between 5 0 ° F and 7 0 ° F (10' to 21.1"C) appeared t o have

no significant influence on the wood moisture contents recorded.

APPARATUS

In an attempt to simulate wind-driven rain a "spray boxtm was

developed to accommodate two panels simultaneously, but in separate chasnbers (Figure 1). Each chamber w a s equipped with f o u r downward- oriented water n o z z l e s which together supplied

4

gallons of w a t e r per hour (300 m l /rnin), and f o u r horizontally arranged air nozzles under a pressure of 1 p s i (7 k g / m m 2 ) which broke up the water into d r o p l e t s and d i r e c t e d it atthe, panel (Figure 2 ) . This a r r a n g e m e n t supplied water to the exposed face of t h e panel at the rate of 1 3 g a l / f p J h r ( 6 3 6 d /rn2/hr). P r e s s u r e in the

c h a m b e r w a s maintained at 2 in. of w a t e r column ( 5 newtons/meter2].

U n t i l the laboratory was relocated in April

1968,

an accuratewater temperature control w a s maintained by u s e of a thermally controlled

heater in t h e reservoir providing the required water head. After this time the water (filtered) was kept in t h e range of 5 6 ° F t o 70°F ( 1 3 . 3 O C t o 21. 1 " C ) by

PANELS

T e s t panels of a s i z e

6;

x 7 1 J 8 x 2 5 / 3 2 in. (15.9 x 18.1 x 1 . 9 8 cm) were c a t from an Eastern white pine board that had been stored in a r o o m conditioned to 5 0 per centR H

and 70°F (21. l o C) f o r an extended period prior t o being installed in the "spray box. I ' Panels were exposed uncoatedand with. various surface t r e a t m e n t s ; in all c a s e s the wood grain was

vertical.

The

treafments involved (1) clear sealers of the alkyd type f r o m three manufacturers, ( 2 ) sealers plus one coat of primer followed by onec o a t of exterior g l o s s paint, ( 3 ) sealers plus one coat of primer followed by two c o a t s of exterior g l o s s paint, (43 a c o a t of primer plus one coat of

exterior g l o s s paint, and (5) a c o a t of primer plus two c o a t s of exterior gloss paint.

INS

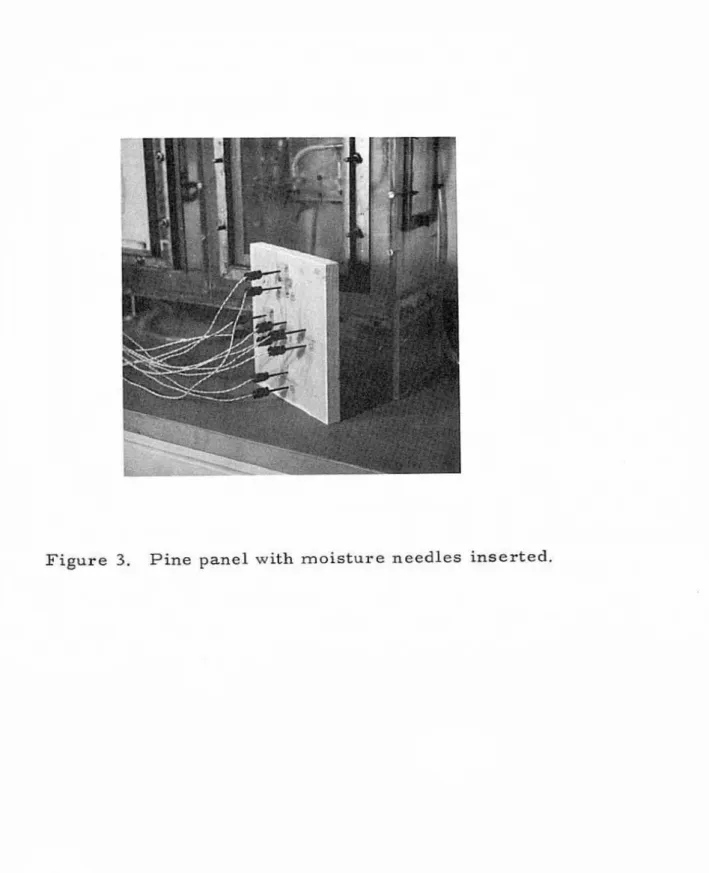

TRUMEN TATIONIn

o r d e r t o observe the distribution of the moisture content in the panels, electrodes, connected to a r e s i s t a n c e type moisture meter, w e r e inserted at three different depths from the exposed surface:(1) 1 i n (1. 6 ; ( 2 ) 1 3 / 3 2 in. (10. 3 mm); and ( 3 )

9

116 in. (14.3mm), ( F i g u r e 3 ) .

T h e

2 in, long electrodes w e r e installed in pairs in thedirection of the wood grain. Electrodes had insulated shanks with exposed tips at the sensing end and wit% the opposite ends uninsulated for connection

t o the meter. F o r the needle diameter of 0.087 in. ( 2 - 2 1 rnm) pilot holes

of 0.030 in. ( 1 - 7 8 mm) w e r e drilled to protect the electrode insulation and

to prevent splitting of the wood.

MOISTURE CONTENT READINGS

Readings of wood m o i s t u r e content w e r e taken daily at 0830 and

1700 hours except for weekends, holidays, and a f e w other noted times. No corrections of meter readings were made f o r temperature, wood

species, or for 2-pin v e r s u s 4-pin electrodes. Readings w e r e continued in a l l c a s e s f o r 1000 h o u r s or until t h e wood attained a moisture content

of

3 0 per cent, whichever occurred first. At completioll of the exposure period the panels w e r e removed, weighed, and stored in a room conditioned to 5 0 per cent RH and 70°F (2 1. 1'C)

w h e r e periodic (daily at 083 0) weigh- ings and m o i s t u r e content readings w e r e m a d e to determine the rate of drying.OBSERVATIONS Series

I

For

this

s e r i e s several panels were c u t f r o m one board; typicalof their behavisur was "Panel 4. r 2

The

graph in F i g u r e 4 shows the b e -havioar of the panel uncoated, w h e n i t is wetted and dried. During the f i r s t 70 hours, the electrode near t h e surface of the wood (at a depth of

8 t o 32 per cent; the electrodes at the 1 3 / 3 2 i n . ( 1 0 . 3 mm) and 9 / 1 6 in.

( 1 4 . 3 mm) depths detected an increase to only 12 and 1 1 . 5 per c e n t respectively.

After the 70-hour wetting period, the panel was removed from

the s p r a y box and put i n a conditioned r o o m . The moisture content at

the 1 / 1 6 - i n .

( 1 . 6 - m m )

depth decxeased v e r y rapidly (130 hours) to 12 p e r cent, and after 4 0 0 hours reached a low of 9 p e r cent. Instead of a decrease, the electrode at 1 3 / 3 2 in. ( 1 0 . 3 mrn) d e p t h d e t e c t e d an in- c r e a s e in 26 hours from 12 t o 16.5 per cent and then a drop to 12 p e rcent a f t e r an additional72 h o u r s . The electrode a t 9 / 1 6 in. ( 1 4 . 3 mm) a l s o detected a small increase (about 2 p e r cent) after removal f r o m the spray box. Although the wood moisture content at the inner depths w e r e

observed to increase on removal f r o m the spray box, the overall weight of t h e panel. was decreasing due to the loss of moisture near the ex- posed face.

The panel w a s next dried t o 7 per c e n t MC and c o a t e d with a clear

alkyd-type sealer that was allowed to d r y 2 4 h o u r s before being exposed to the spray in the t e s t box. F i g u r e 5 shows that a l t h o u g h all three

electrodes showed a rapid increase i n the f i r s t 7 6 h o u r s , the amounts reached w e r e not exceeded during an exposure period of 1 0 7 0 hours. But when t h e panel w a s removed f r o m the box the moisture content i n c r e a s e d

sharply at all electrodes: at a depth of 1 / 1 6 in. (1. 6 rnm) it i n c r e a s e d f r o m 14.8 per c e n t to 16 per cent; at 1 3 / 3 2 in. ( 1 0 . 3 mm), from 40 per

cent to 1L.$ per cent; and at 9 / 1 6 in. ( 1 4 . 3 m), f r o m 8.2 p e r cent t o 10 per cent. The drying time was similar to that f o r the same panel

when it was uncoated.

Following a f u r t h e r d r y i n g to 7 per cent, Panel 4 was painted (over t h e sealer) with one primer c o a t and two topcoats of paint to a paint

film thickness of 3 mils (1 mil

=

1 thousandth of an inch). After the paint had dxied (48 hours, 2 4 hours, 24 hours) the panel w a s exposed in the spray box f o r 1050 h o u r s (Figure 6). It was observed that even the electrode nearest the exposed surface did not d e t e c t a m o i s t u r e content in excess of 7 i p e r cent, and the other electrode locations indicated l e s sthan 7 p e r c e n t throughout the period. Again an removal from t h e box all

points showed rapid increases. These increases suggest a moisture mi-

gration from the paint f i l m t o t h e w o o d o r from a paint wood interface layer of w a t e r . The delayed drying at the 9

/

1 6 in. ( 1 4 . 3 mm) depth s ug - g e s t s that drying was l a r g e l y through the non-exposed face of the panel,Series

II

The following observations relate t o a second s e r i e s of panels cut f r o m another board of the same species as was u s e d in the f i r s t s e r i e s .

to relate, with any degree of accuracy, the e f f e c t of wood d e n s i t y on the ingres s or internal distribution of moisture from whatever source.

From this second series, F i g u r e s 7, 8 and 9 w e r e prepared to illustrate the relative wetting and d r y i n g b ehaviour of m c oa ted, s ealed,

and sealed and painted panels. M o i s t u r e contents attained b y t h e panels

in this series were not as high as t h o s e attained by Lhe panels in the

fir st series. There i s very little difference, however, between the

sealed and painted panels in each series (Figures 6 and 9 ) although the panel in Figure

9

had a 4 mil paint thickness (one topcoat) and the panel in Figure 6 had a 3 mil thickness (two topcoats). Although theresults in Figure 9 show a slightly lower wood moisture content and a higher increase following removal f r o m the spray box than those p r e -

sented in Figure 8, the paint system in both instances appears to nullif y

any effect of wood deneity differences. In both s e r i e s the beneficial

effects of coatings as they relate to wood moisture gain are clearly d e m -

ons trated.

F o r comparison, three alkyd- type sealers from different

manufacturers, b u t all conforming to Canadian Government Specification Board Specification l -GP -1 02, w e r e applied.

T h e

mais ture contentsfrom electrodes nearest the exposed surfaces only were plotted { F i g u r e 10). Although one sealer ( T e s t c, F i g u r e 10) appears superior to the oihers

with regard to rate

of

increase and maximum moisture content attainedduring the t e s t period,

the

differences are small and m a y reflect that t h et e s t s w e r e not made simultaneously.

T e s t s w e r e a l s o made on panels c o a t e d with a primer and two top

c o a t s (to a depth of 5 mils). This protection resisted water penetration well; the results were not unlike those obtained f r o m a panel coated with a sealer and a 4-mil paint system ( F i g u r e

91,

and its resistance w a s slightly better than for a panel with a sealer and a 3 -mil paint s y s tern ( F i g u r e 6 ) .Additional t e s t s were made to c o m p a r e this system of a primer

a n d two topcoais (locally referred to as a conventional paint system)

with a primer and one topcoat system. In both, the wood moisture con- tents attained w e r e similar, suggesting that the systems a r e e q u a l y satisfactory even though the two-topcoat s y s t e m w a s 5 mils thick and

the one-topcoat system w a s 4 mils thick. Paintfilm thicknesses typically recommended in the Canadian Maritirnes area a r e in the 4 to 5 mil range. Preliminary t o s o m e proposed future t e s t s involving cycling (spray alternately

on

and off) by a variety of on-off periods, two 3 18-in. (9.5-mm) thick panels were exposed simultaneously (Figure 111, O n e panel was e x - posed to continuaus spray (Test d, Figure 11) and the other ta cyclingconditions for

the

same total t e s t period ( T e s t el. The wood moisture c o n -t e n t occasioned by continuous wetting was much Lower than f o r that by

cycling the spray. Although these panels w e r e relatively thin and w e r e w c oateds approximate minimum rnoi s tux e contents wer e obtained in ah acit

the same t i m e period f o r both panels following their removal f r o m the t e s t box. Unlike Test d and previous t e s t s with thicker panels, T e s t e indicated

that

after art initial l a g during the f i r s t 1 0 0 hours the m o i s t u r e content at the electrode farthest from the exposed face exceeded that measured by the electrode nearer to the surface.CONCLUSIONS

1.

In

neither coated n o r uncoated panels does water penetrate more than a fraction of an i n c h beyond the exposed face while the panels are be- ing sprayed.2. Ragidincreases i n m o i s t u r e c o n t e n t a t t h e electrodes occur following removal of the panel f rorn the spray chamber followed by a fairly

rapid drying down to the original moisture content of the wood (under

5 0 p e r cent and 70°F (21. 1°C)).

3 . Noticeable increases i n moisture content occur at the inner electrodes after t h e panels are removed, suggesting inward movement of moisture from t h e previously exposed face.

4. Allpaint systems usedproduced similar r e s u l t s i n r e g a r d t o r e d u c e d moistur e penetration, compared with uncoated panels, when applied in

thicknesses of from 3 to 5 mils.

5. Three clear alkyd- type sealers from different sources produced f a i r l y 'similar results, and a l t h o u g h they w e r e a marked improvement over

uncoated panels they c a m e far from providing the same resistance to moisture gain as did the paint s y s terns.

6

Intermittent spraying produced moisture contents in uncoated panels that w e r e about t w i c e as h i g h as those resulting from continuousspraying; the results f r o m the intermittent spraying relate m o r e closely to f i e l d exposed panel performances.

7. W i t h paint-coated panels it appears, from conditions observed follow-

i n g wetting, that during the wetting p e r i o d most of the water is s t o r e d in the paint, or at the paint wood interface, or both.

REFERENCES

1. Tibbetts,

a.

C.

and D.R.

Robson. Moisture content of exposed paintedwood panels. DBRJNRC

BR

Note No. 79.2 . Ritchie,

T. A

small-panel method for investigating moisture pene- tration and bond strength of brick masonry. Materials Research and Standards, l(5): 3 6 0 - 3 6 7 .TUBING CONNECTION FOR

li

W4TER ONLY SHOWN-

U

T I P l C l L F O R A I R-

BACKPLATE C NOZZLE HOLDERS * 318" LUCITENOZZLES - GLASS SCREWS

-

BRASSFIGURE

2

DETAIL OF SPRAY ASSEMBLY FOR WOOD PANEL TESTS

28 ae

-

M C

a t First ' E l e c t r o d e I-.-----

5 305

24-.

-

M C

a t S e c o n d E l e c t r o d e 2-

M C

a t T h i r d E l e c t r o d e 5 20 I- Z 0 W e i g h t o f P a n e l 5 10 20 W a t e r T e m p-

67°F t o 6 2 ° F 560, W E R o o m T e m p - 76°F 3 ZE R o o m R H-

54% 490 4+

Cr: V"-

16 480 0 S 470z

1 2 0 460 3 450 8 200 400 600 800 1000 1201) 1400 1600 1800 H O U R S F I G U R E 4 M O I S T U R E C O N T E N T OF AN U N C O A T E D P A M E L ( S E R I E S 11 WHILE B E I N G W E T T E D A N D D R I E D MC a t F i r s t E l e c t r o d e MC a t S e c o n d E l e c t r o d e MC a t T h i r d Electrode W e i g h t of P a n e l 5 20 W a t e r T e m p - 70°F t o 62°F 5 10 R Q O ~ T e m p-

77°F RoornR1-l - 6 2 % t o 3 8 500 490%

4 480 470 460 450 200 400 600 800 1000 120.0 1400 1600 1800 H O U R S F I G U R E 5 M O l S T U R E C O N T E N T OF A S E A L E D P A N E L ( S E R I E S 11 W H I L E B E I N G W E T T E D A N D D R I E D-

MC a t F i r s t E l e c t r o d e-

-

--

M C

a t Second E l e c t r o d e-.-.

-

- MC a t T h i r d E l e c t r o d e W e i g h t o f P a n e l W a t e r T e m p-

5 9 ° F R o o m f e m p - 7 5 " ~ R o o r n R H - 4 0 % t o 15%-

H O U R S M O I S T U R E C O N T E N T OF A S E A L E D A N D P A I N T E D P A N E L(SERIES

11 W H I L E B E I N G W E T T E D A N D D R I E D . ( T H I C K N E S S O F P A I N T FILM 15 3 MILS. 1 W a t e r T e m p - 6 6 ° F l a 5 9 ° F R o o m T e m p-

7 6 " ~ R o o m R H - 44-38-53-40% 28 ba 2 4 - w H O U R S 1 1 1 1 1 1 1 1 1 1 I I 1 1 1 1 ' --

MC a t F i r s t E l e c t r o d e -----

MC a t S e c o n d E l e c t r o d e - -.-.

-

MC a t T h i r d E l e c t r o d e --

W e i g h t o f P a n e l - F I G U R E 7M O I S T U R E CONTENT OF AN U N C O A T E D PANEL 15ERIES 111