HAL Id: hal-00857498

https://hal.archives-ouvertes.fr/hal-00857498

Submitted on 3 Sep 2013

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Texture development in Fe-doped alumina ceramics via

templated grain growth and their application to carbon

nanotube growth

Yasemin Çelik, Ender Suvacı, Alicia Weibel, Alain Peigney, Emmanuel

Flahaut

To cite this version:

Yasemin Çelik, Ender Suvacı, Alicia Weibel, Alain Peigney, Emmanuel Flahaut. Texture

develop-ment in Fe-doped alumina ceramics via templated grain growth and their application to carbon

nan-otube growth. Journal of the European Ceramic Society, Elsevier, 2013, vol. 33, pp. 1093-1100.

�10.1016/j.jeurceramsoc.2012.11.013�. �hal-00857498�

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID: 8788

To link to this article: DOI: 10.1016/j.jeurceramsoc.2012.11.013

URL:

http://dx.doi.org/10.1016/j.jeurceramsoc.2012.11.013

To cite this version: Çelik, Yasemin and Suvacı, Ender and Weibel, Alicia

and Peigney, Alain and Flahaut, Emmanuel Texture development in

Fe-doped alumina ceramics via templated grain growth and their application

to carbon nanotube growth. (2013) Journal of the European Ceramic

Society, vol. 33 (n° 6). pp. 1093-1100. ISSN 0955-2219

!O

pen

A

rchive

T

oulouse

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

Any correspondence concerning this service should be sent to the repository

administrator:

staff-oatao@listes-diff.inp-toulouse.fr

!Texture

development

in

Fe-doped

alumina

ceramics

via

templated

grain

growth

and

their

application

to

carbon

nanotube

growth

Yasemin

C

¸

elik

a,

Ender

Suvacı

a,∗,

Alicia

Weibel

b,

Alain

Peigney

b,

Emmanuel

Flahaut

b,caDepartmentofMaterialsScienceandEngineering,AnadoluUniversity,26480Eskisehir,Turkey

bUniversitédeToulouse,UPS,INP,InstitutCarnotCirimat,118RoutedeNarbonne,F-31062Toulousecedex9France cCNRS,InstitutCarnotCirimat,F-31062Toulouse,France

Abstract

Fe-dopedalumina(Fe-Al2O3)materialswithacontrolledmicrostructurecouldbedesignedforsomespecialusessuchasasubstrateforcarbon

nanotubegrowth.Inthisstudy,Fe-dopedAl2O3ceramicswithvaryingdegreesoftexturewerepreparedviaTemplatedGrainGrowthmethodand

utilizedforcarbonnanotubesynthesisbyCatalyticChemicalVaporDepositioninordertoinvestigatehowa-Al2O3crystalorientationaffectscarbon

nanotubegrowthinpolycrystallineceramics.ThedegreeoftextureincreasedwiththeFecontentinthepresenceofliquidphase.Threekindsof carbonfilaments(few-wallcarbonnanotubesbundles,individualmulti-wallnanotubesandcarbonnanofibres)wereobservedoverFe-dopedAl2O3

ceramicswithvaryingdegreesoftexturedependingonthesurfaceroughness,crystallographicorientationandthesizeofthecatalystnanoparticles. Whilewell-texturedsubstrateswitharoughsurfaceledtoasmallamountofrandomlyorientedcarbonnanotubebundles,perpendicularlyoriented individualmulti-wallnanotubeswereobtainedoverrelativelysmoothsinglecrystala-Al2O3plateletsurfaces(basalplanes)whichremainedin

thematrixwithoutgrowing.

Keywords:Fe-dopedAl2O3;Tapecasting;Templatedgraingrowth;Carbonnanotubes

1. Introduction

Fe-dopedalumina(Fe-Al2O3)ceramicsexhibitpotentialas

readily available and relativelylow cost catalysts for carbon nanotubes(CNTs)synthesis.Peigneyetal.1havedevelopeda catalytic routefor the in situ formationof CNTs over a Fe-Al2O3 powderby selectivereductionof analumina–hematite

solid solution powder in H2–CH4 atmosphere. This simple

andscalabletechniqueprovidesaveryhomogeneous distribu-tion of CNTsintheCNTs-Fe-Al2O3 nanocomposite powder,

while avoiding the potentially hazardous effect of handling free CNTsin caseof simplemixing with the matrix.Suvaci etal.2,3 reportedsuccessfulsynthesisofCNTsover polycrys-talline Fe-doped Al2O3 ceramicsbycatalyticchemical vapor

deposition(CCVD).Theauthorsreportedthatthesizeand den-sityofthecatalyticnanoparticlesshowedvariationsdepending

∗Correspondingauthor.Tel.:+902223213550/6359;fax:+902223239501.

E-mailaddress:esuvaci@anadolu.edu.tr(E.Suvacı).

onthesurfacecharacteristics2,3;however,theydidnotgive infor-mationaboutthesurfacedensityofthesenanoparticlesonthe polycrystalline surface and did not evaluate whether there is anyrelationshipbetweencrystallographicorientationofgrains andCNTsgrowth.Hongoetal.4reportedthat thesingle-wall CNTs(SWNTs)yielddependsonthecrystallographic orienta-tion ofsapphiresubstratecoatedwithFe-filmandonthefilm thickness. Itisobvious fromthesestudiesthatthereisa cor-relationbetweenthecrystallographic orientationof thesingle crystal substrate and CNTs growth. Although several single crystalssuch asquartz andsapphirewithaspecific crystallo-graphic orientation havebeen investigated as a substrate for CNTs synthesis,4–7 polycrystalline ceramics with a textured microstructure havenotbeenused inCNTsgrowthstudiesto thebestofourknowledge.BytexturingFe-dopedAl2O3

ceram-ics,onecanevaluateeffectoforientationonCNTsgrowthand hence benefitfrom the orientationof certain crystallographic planesonthesubstratesurfaceforCNTsgrowth.Thecrystals ofapolycrystallinematerialcanbeorientedatcertainplanesby avarietyoftechniquessuchashotpressingandsinterforgingof

systemscontainingorientedwhisker-,fibre-,orplatelet-shaped particles.8–10TemplatedGrainGrowth(TGG)isanotherwidely utilized methodfor the productionof texturedceramics.11 In TGG, asmall numberof largeanisometrictemplate particles are aligned in afine powder matrix during tapecasting, slip casting,extrusionoruniaxialpressing.Afterdensification,these largeranisometricgrainsgrowandconsumethematrixgrainsto yieldceramicswithtexturedgrainsandhighdegreesof crystal-lographicorientation.Consequently,theobjectiveofthisstudy was to investigate how to tailor microstructure in Fe-doped Al2O3 ceramics via TGGmethod inorder toachieve a

con-trolleddegreeoftexturebycontrollingtheamountofFeand/or sinteringconditions,andthentoinvestigatethepossibleuseof theseceramicsassubstratesforthecatalyticgrowthofCNTs.It wasalsoaimedtoevaluateroleofcrystallographicorientation ofFe-dopeda-Al2O3crystalsonCNTsgrowth.

2. Experimentalprocedure

2.1. Textureformation

1%, 2%, 5% and 10cat.% Fe-doped Al2O3 powders

(Al2(1−x)Fe2xO3 (x≤0.1)), later used as matrix material for

texturedsubstratefabrication,weresynthesizedbycombustion synthesismethodasdescribed byCordieretal.12 Inthis pro-cess,therequiredproportionofaluminumnitratenonahydrate (Al(NO3)3·9H2O,Merck,extrapure)andironnitrate

nonahy-drate(Fe(NO3)3·9H2O,Merck,GRforanalysis)weredissolved

indistilledwaterinaPyrex® beaker.Amixtureofcitricacid andurea(75%citricacidand25%urea)wasusedasfuel,ina quantityequaltotwicethestoichiometricratio.12Therequired amountofcitricacidandureaweredissolvedindistilledwater andthenaddedintothenitratesolution.Thesolutionwasstirred at600rpmandca.120◦Cfor1h.ThePyrex®beakerwasthen placedinapreheatedfurnace,at550◦C,andkeptthereforat least 20min.Theas-synthesizedamorphous powderwas sub-jected totwo-stage calcinationprocess: it was first heated at 5◦C/minupto600◦C,1.5hof dwelltimeinordertoremove theresidualcarbonandthenat15◦C/minupto1100◦C,20min ofdwelltimetoobtainthea-phase.Aftercalcination,the pow-derswereattritionmilledat250rpmfor4hindistilledwaterby usingyttria-stabilizedZrO2balls,3mmindiameter.

Fe-doped Al2O3 ceramic substrates were prepared by

tape casting. The matrix consisted of the a-Al2(1−x)Fe2xO3

powder witha specific surface area of ∼33m2/g. 5vol% a-Al2O3platelets(PyrofinePlatelets,Elf-Atochem,Pierre-Benite,

France)of 20±5mmindiameter and2.0mmthicknesswere addedtothematrixastemplates.CaOandSiO2wereusedas

hightemperatureglassformersataratioof1.3:1inanamountof 0,1or5vol%ofthematrixpowder.Tapecastingslurryconsisted ofanazeotropicmixtureofmethylethylketone(MEK,66vol%) and ethanol (EtOH, 34vol%) as solvent, sodiumtripolyphos-phate(STPP)asdispersant,polyvinylbutyral(PVBButvar76) asbinder,andpolyethyleneglycol(PEG3000,Fluka,Steinheim, Switzerland)anddibutylphthalate(DBP)asplasticizers.

A suspension with 39vol% solids loading was prepared by dispersing a-Al2(1−x)Fe2xO3 powder in the azeotropic

mixtureofMEKandEtOHwith8vol%STPPbyballmillingfor 4husingyittria-stabilizedZrO2balls,3mmindiameter.PEG

(11vol%)andDBP(4vol%)wereaddedtothesuspensionand againballmilledfor2h.Then,PVB(23vol%)wasaddedandthe suspensionwasagainballmilledforadditional15h.Afterball milling,a-Al2O3plateletswereaddedtotheslurryandmixed

withamagneticstirrer for 2h. Theprepared slurry wastape castedonaglassplateatabladeheightof400mmata30cm/s castingspeed.Afterdryingatambientconditionsfor30min,the tapewascutandlaminatedat45MPaand70◦Cfor10min. Lam-inatedtapeswereheattreatedforremovingorganicsbyheating thesamplesto450◦Catarateof 1◦C/minandholdingthem atthistemperaturefor2h.Unlessotherwisenoted,thesamples weresinteredat1600◦Cfor2hinairwithheatingandcooling

ratesof10◦C/min.ThenotationforsamplesisxFeyLP,where

xis the cationicpercent of Fe inthe a-Al2(1−x)Fe2xO3

pow-derandy isthevolumefractionofliquidphaseformers(LP), CaO+SiO2,intheinitialpowdermixture.Thevolumefraction

ofa-Al2O3platelets(i.e.,PL)was5vol%forallsamplesunless

otherwiseindicated.

Microstructuredevelopmentofsinteredsampleswas exam-inedusingscanningelectronmicroscope(SEM,ZeissEVO50). TheSEManalyseswereperformedonpolishedandthermally etchedcross-sectionsurfaces.Thedimensionsandaspectratios ofanisotropicgrainsweredirectlymeasuredfrommicrographs (at least 24 measurements) and averaged. Crystallographic texture development in the samples was characterized by an X-raydiffractometer(XRD,RigakuRint2200,Tokyo,Japan) with CuKa1 radiation. Texture fraction of the samples was

determinedbyLotgeringFactor,whichisanX-raybased semi-quantitativecharacterizationmethod.13

2.2. Carbonnanotubegrowth

Thesinteredsampleswerethenplacedinaluminaboatsinthe middleofaCCVDchamberandreducedinH2–CH4gas

mix-ture(82mol%H2asreducinggasand18mol%CH4ascarbon

source)at1000◦Cwithaheatingandcoolingrate of5◦/min. Nodwelltimewasapplied.1,14AfterCCVD,thesampleswere characterizedby field-emission-gun scanning electron micro-scope(FEG-SEM,JeolJSM6700FatTEMSCAN,Universite Paul-Sabatier).

3. Resultsanddiscussion

3.1. Texturedevelopment

Texture developmentwas investigated as a functionof Fe contentandliquidphaseformeramountbykeeping a-Al2O3

templateamount,sinteringtemperatureandtimeconstant.The SEMmicrographsinFig.1 showthe effectof Fe-contenton themicrostructuredevelopmentof5vol%template(a-Al2O3

)-containingaluminasamplessolid-statesinteredat1600◦Cfor 2h. No texture could beachieved for the solid-state sintered Fe-dopedAl2O3samplesatthattemperature,whatevertheirFe

content.Neithermatrixnorplateletgrainsexhibitedsignificant graingrowthinthesampleswithlowFecontent(i.e.,1Fe0LP

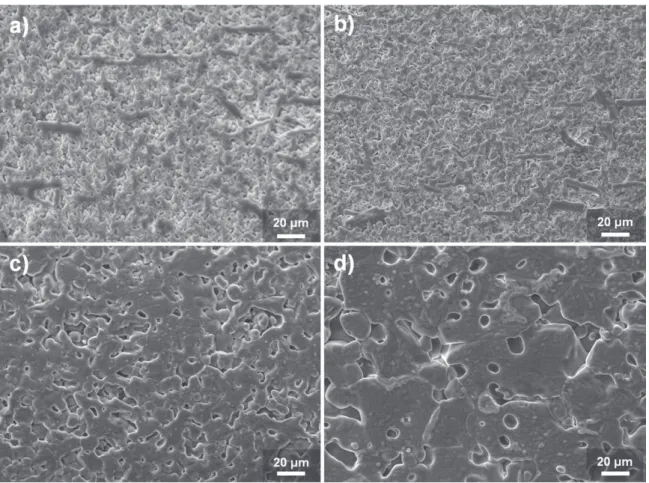

Fig.1.SEMmicrographsof(a)1Fe0LP,(b)2Fe0LP,(c)5Fe0LPand(d)10Fe0LPsamplessinteredat1600◦Cfor2h.

and2Fe0LP)duetolimiteddegreeofdensification,althoughthe samplesweresinteredatarelativelyhightemperature(Fig.1(a) and(b)). Thisretardation indensification could be attributed tothenegativeeffectofplateletsonthepackingofthematrix particles.Özeretal.15andBelmonteetal.16investigatedthe sin-teringbehaviorofaluminapowdercompactscontainingalumina plateletparticlesandshowedthata-Al2O3plateletparticles

hin-dereddensification.Cariseyetal.17alsosuggestedthatplatelets

constraineddensificationinsolid-statesinteredAl2O3.While1

and2cat.%Fe-doping could not suppress the negativeeffect of platelets on densification, it was observed that increasing the Fecontent to5 andespecially to10cat.%influenced the microstructuredevelopmentofplatelet-containingalumina sig-nificantly(Fig.1(c)and(d)).In5Fe0LPsample,matrixgrains alsogrewtosomeextentbesidestheplatelets,leadingtolarge poresinthemicrostructure(Fig.1(c)).IncreasingtheFe con-tentfurtherto10cat.%(10Fe0LP)resultedinexaggeratedgrain growth,whereitisnoteasytodistinguishwhetherthese abnor-mallyandisotropicallygrowngrainsformed fromthematrix orfromtheplatelets(Fig.1(d)).Bothinsideandbetweenthese grains,ahighamountof largeporeswere formed.Itis obvi-ousfromthemicrographsthatcertainamountofFe-doping(i.e., ≥5cat.%)improvesthesinteringbehaviorofplatelet-containing Al2O3.Calculationsbasedonsinteringequationsshowedthat

thediffusioncoefficientsincreasewithincreasingFecontent; consequently,the sintering rate of Fe-doped Al2O3 increases

with increasing total Fe amount.18 It was also reported that

additionofFe2O3intoAl2O3overacertainamountcanpromote

anisotropicandexaggeratedgraingrowthathightemperatures suchas1650◦C.19ThisarisesfromreductionofsomeoftheFe3+ toFe2+ leadingtocreationof oxygenvacanciesoraluminum interstitials whichincreasegrainboundarydiffusionandfrom segregationofasignificantamountofFe2+tograinboundaries resulting inanexaggerated graingrowth.19 At1450–1500◦C in air,ironis primarilyinthe trivalentstate, andonly2% of the totalFe3+ is reduced.20 The solubility of Fe2+ inAl2O3

is 0.7–1.9% at 1450◦C.19,21 The reduction of Fe3+ to Fe2+

overthesolubilitylimitresultsinsegregationoffreeironoxide at grainboundariesforming FeAl2O4 phaseandcausesrapid

growth anduncontrolledmicrostructuraldevelopment.19,22 In the presentstudy,theincreasinggraingrowthwithincreasing Fe3+dopingcouldbeattributedtoformationofhigheramount ofFe2+duetoreductionofFe3+cations.Forthesampleswith lowerironcontent(e.g.,1and2cat.%),theamountofreduced Fe3+ maynotbesufficienttopromoteenhancedgraingrowth. Forthe5Fe0LPsample,theamountofFe2+formedbythe reduc-tion of Fe3+ is higher than that of the 1Fe0LP and2Fe0LP; however theamountofFe2+ isstill belowthesolubility limit; therefore,theenhancedgraingrowthcouldbeexplainedbythe mechanismbasedonthecreationofoxygenvacanciesas sug-gestedbyTartajandMessing.19Astheironcontentincreasesto 10cat.%,higheramountofFe3+isreduced(overthesolubility limit) andthismaycausethe segregationatgrainboundaries resultingtoanexaggeratedgraingrowth.However,atextured

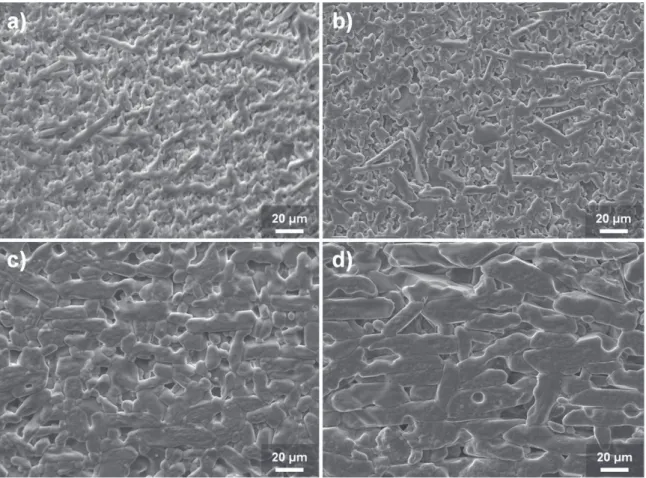

Fig.2.SEMmicrographsof(a)1Fe1LP,(b)2Fe1LP,(c)5Fe1LPand(d)10Fe1LPsamplessinteredat1600◦Cfor2h.

microstructurecouldnotbeachievedforthesolidstatesintered Fe-doped Al2O3 samples due to uncontrolled microstructure

development, althoughthenegativeeffectofplateletparticles ondensificationofAl2O3wassuppressedbycertainamountof

Fe-doping.

Therefore, the samples were also liquid-phase sintered withdifferent liquid phaseamounts tobe ableto control the microstructure, based on the information from the previous studieswhereitwasshownthatliquidphasesinteringreduces constraineddensificationcausedbythetemplate particlesand acceleratesgraingrowth23–25andwhereitwasreportedthatthe additionofCaOandSiO2createsfavorablekineticconditions

foranisotropicgraingrowthduringsintering.24,26

Fig.2(a)–(d)show theSEMmicrographsof liquidphased sintered 1Fe1LP, 2Fe1LP, 5Fe1LP and 10Fe1LP samples, respectively.Theliquidphaseregulatedthemicrostructureand promoted anisotropic growthof the plateletsin theFe-doped Al2O3 samples, prominentlyas from 5cat.%Fe doping. The

degreeof textureincreased withincreasing Fecontent at the presence ofliquidphase,duetoexistenceof thestrong influ-enceofcertainamountofFe-dopingonthesinteringkineticsof aluminaandtheeffectofliquidphaseonanisotropicgrowthof thetemplateparticlestogetherinthesystem.Thetexture forma-tionbecomes apparentwiththe 5%Fedoping(Fig.2(c))and the 10Fe1LPsystemshowsthehighestmorphological texture amongtheother1%LPformercontainingsamples(Fig.2(d)). Theaverageaspectratiooftheanisotropicgrainsinthis sam-pleis∼4.1withanaveragediameterof59mmandthicknessof

14mm.Besidesthewellorientedtemplategrainsalongthetape castingdirection,somemisorientedtemplatesarealsopresent leadingtotheformationoflargeporesinthemicrostructure.

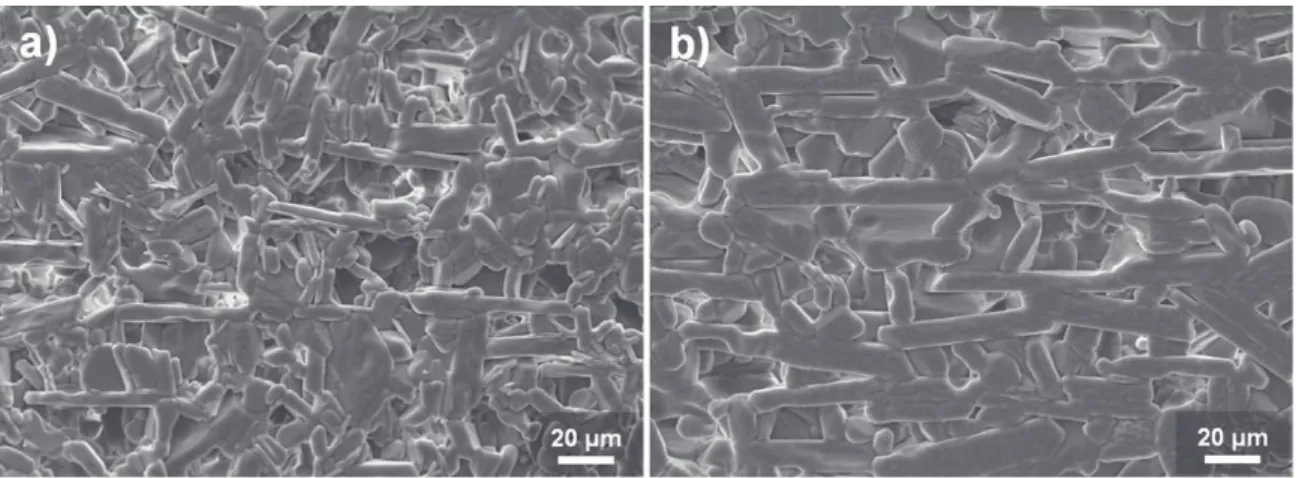

Fig.3 shows the effect of 5% LP former addition on the texture developmentof 5 and10% Fe-doped samples, which werealsosinteredat1600◦Cfor2h.Theincreasedliquidphase amountledtomorefacetedtemplategrainswithahigheraverage aspectratiointhesesamples.26Theaspectratioof10Fe5LP sam-plewas∼6.1.Theaveragediameterofanisotropicgrainsinthis samplewas57mmandtheaveragethicknesswas9mm.Besides the aligned grainsin the tape casting direction, somecoarse matrixgrainsandmisalignedanisotropicgrainsalsoremained. Thesegrainshindereddensificationandsubsequentlytheradial growthofalignedtemplates.Consequently,largeporesbetween thetemplategrainswereformed,preventingtoachieveahigher degreeoftexture.Seabaughetal.26 reportedthat liquidphase dramaticallyaffectsdensificationandthefacetingofgrainsand degreeofgrainfacetingincreasesastheamountofliquidphase increases.

TheXRDanalysesofthetopsurfacesof10Fe0LP,10Fe1LP and10Fe5LPsamplesareshowninFig.4.TheXRDpatterns revealedcrystallographictextureintheliquidphasecontaining Fe-dopedAl2O3samplesinagreementwiththemorphological

texture,observedinSEMimages.An increaseintheratio of basalplanepeak intensities(0006) and(00012) relative to thepeakwiththehighestintensityinthenon-template contain-ingsample (11 ¯2 3) wasobserved. The intensity ratiosof the (0006)to(11 ¯2 3)peakswere0.05,0.31,1.59and0.81forthe

Fig.3.SEMmicrographsof(a)5Fe5LPand(b)10Fe5LPsamplessinteredat1600◦Cfor2h.

10%Fe-dopedsamplewithoutanytemplateandliquidphase for-mers,10Fe0LP,10Fe1LPand10Fe5LPsamples,respectively. ThehighesttexturefractionrevealedbyLotgeringfactor calcu-lationswasca.0.33for10Fe1LPsystem.Thetexturedegreeof theseFe-dopedAl2O3ceramicscouldbeimprovedby

control-lingthe orientationofplatelet particlesinthe matrixpowder, liquidphase content,plateletsamount,rheologyof tape cast-ingslurry,sinteringtemperatureandtime.However,thetexture levelobtainedinthisstudywassufficienttoinvestigatehowa texturedceramicsubstratecouldaffectCNTsgrowthbyCCVD.

3.2. CarbonnanotubesgrowthovertexturedFe-doped

Al2O3

Fig.5showstheschematicrepresentationoftexture develop-mentinFe-dopedAl2O3byTGGandtheproposedCNTsgrowth

overthistexturedceramicsubstratebyCCVD.5vol%a-Al2O3

plateletshapedtemplateswereorientedinfineFe-dopedAl2O3

matrixbytapecastingwiththeirbasalplanesparalleltothe sub-stratesurface.Byasubsequentheattreatment,thesetemplates grewattheexpenseofthematrix.Sincetheymaintainedtheir

40 60 80 100 (a) (b) (c) (00012) (11 • 23) (0006) • • •• • • • • • • • • • • • • • • • •

οcorundum•calcium silicate♦ZrO2

2θ (°)

Intensity (arbitrary units)

(d)

♦

Fig.4.XRDpatternsofthe(a)10cat.%FewithoutanyplateletsandLP(b) 10Fe0LP,(c)10Fe1LPand(d)10Fe5LPsamplessinteredat1600◦Cfor2h. (0006)and(00012)indicatetheMillerindicesforbasalplanesofa-Al2O3

platelets.

originalpositionduringgraingrowth,thesubstratesurfacewas coveredbythebasalplanesofthetemplatesattheendofTGG process.TheCNTsgrowthbyCCVDwasperformedonthistop basalplaneorientedsurfaceofthesubstrate.Accordingtoour hypothesis,whenthetexturedsubstrateissubjectedtoCCVD, homogeneouslydistributedsubstitutionalFe3+cationsarefirst reduced to metallic Fe atomsandthen coalesceinto clusters andlatercatalyticnanoparticlesbyselectivereduction.Wenow investigatetheCNTsgrowthbyCCVDoverthesesubstrates.

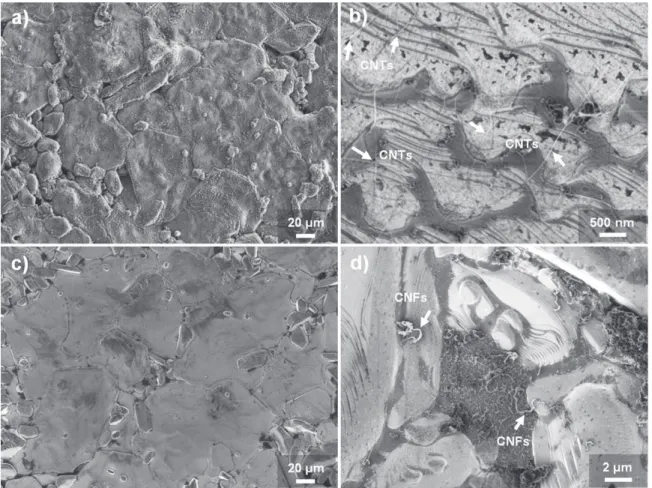

Fig. 6 shows the SEM micrographs of the top surface of CCVD-subjected10Fe1LPand10Fe5LPsamples,whichshow

Fig.5.SchematicrepresentationoftexturedFe-dopedAl2O3 productionby

TGGmethodandCNTsgrowthovertheseceramicsbyCCVD(I.Tapecasting, II.Sintering,andIII.CCVDsteps).

Fig.6.SEMmicrographsof10Fe1LP(a,b)and10Fe5LP(c,d)afterCCVDprocess.(b)and(d)arehighermagnificationimagesofthecorrespondingsamples. Whitearrowsindicatecarbonnanotubes(CNTs)andcarbonnanofibers(CNFs)in(b)and(d),respectively.

a relatively higher degreeof texture compared toothers. On the contrary of our hypothesis, these substrates led to small amountsof randomly oriented CNTs. Fig.6(a) and(b) show ageneralviewofthesurfacemorphologyof10Fe1LPsample after CCVD and a higher magnification image of this sam-ple, showingboth longandflexibleinterconnectedfilaments, characteristicofbundlesoffew-wallCNTs(indicatedbywhite arrows)andtheabsenceofanycarbonnanofibre,respectively. Thissamplepresentedabimodalmicrostructurewithrelatively small matrix grains and much larger template grains which were grownby consumingthe matrix grainsforming aquite rough surfacetopography (Fig.6(a)).This surfaceroughness could be responsible for the small amount of randomly ori-entedCNTsgrowthsinceitmayhaveaffectedthedensityand size of the catalyticnanoparticles(Fig.6(b)).Suvaci etal.2,3 observedrandomlyorientedCNTsbundlesoverpolycrystalline Fe-dopedAl2O3ceramics.TheauthorsreportedthattheCNTs

yield was relatively low with respect to the totalnumber of catalytic nanoparticles and they suggested that the variation incatalyticnanoparticlesizeonpolycrystallinesubstratesmay arisefromthevariationofclusterformationkineticsdepending onthesurfacemorphologyandcrystallographicorientationof the grains.2,3 Cao etal.27 reported dense, randomly oriented bamboo-like multi walled CNTs with different outer diam-eters over metallic film-coated rough polycrystalline Al2O3,

where catalytic nanoparticles with varying sizes and shapes wereformedsinceeachnanoparticlewasformedonitsunique position.Thesurfaceof10Fe5LPlookedmuchsmootherthan that of 10Fe1LP, although it could be still defined as rough (Fig.6(c)). Thisis most probably duetoan increased liquid phaseamountwhichpromotedthegrowthofmorefaceted tem-plategrains.VeryfewCNTswereformedonthissubstrate,while arelativelyhigheramountofcarbonnanofibersandother non-tubularcarbonaceousspecieswereobserved,especiallyonthe phasewhichcomesfromtheliquidphaseandlocatedatgrain boundaries(Fig.6(d)).Itshouldbenotedherethatsome non-tubularcarbonformslikecarbonnanofiberswerealsoobserved eveninthesampleswithoutanyliquidphaseformeraddition. Thismay have arised from the impurities (like SiO2) in the

plateletswhichcouldhaveformedaliquidphaseduring sinter-ing.Anotherreasoncould bethe secondaryphasesegregated atgrainboundaries.Probably,ahighamountof Fespeciesin thegrainboundaryphasecouldhavecausedlargerFe nanopar-ticles upon reduction and thus carbon nanofibers instead of CNTs.

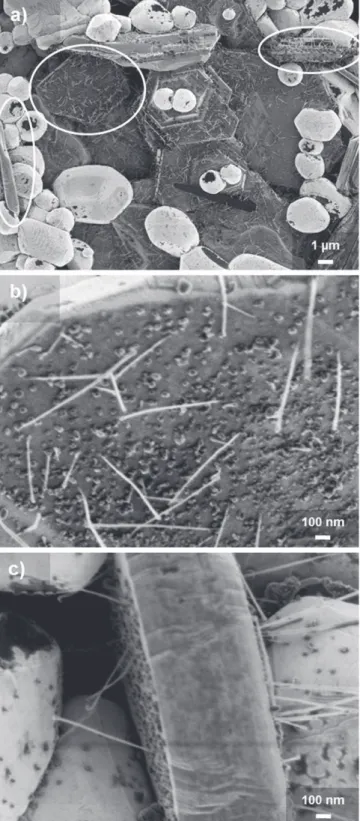

AlthoughorientedCNTscouldnotbegrownoverwell tex-turedsubstrates,someinterestingresultswereobservedduring thisstudy.Fig.7showstheFEG-SEMmicrographsofa5cat.% Fe-doped Al2O3 sample, containing 5vol% liquidphase

Fig.7.(a)FEG-SEMmicrographoftheverticallyalignedCNTgrowthover basalplanesofa-Al2O3 plateletsin 5cat.%Fe-doped Al2O3 samplewith

5vol%liquidphaseformercontentsinteredat1400◦Cfor2h.(b,c)Higher

magnificationimagesofCNTsovera-Al2O3platelets.

afterCCVD. Thesamplewas sinteredatalowertemperature (1400◦C) for 2h. The SEM micrograph in Fig. 7(a) reveals thata-Al2O3plateletsweredistributedrandomlyand

inhomo-geneouslyinthematrixandtheycouldnotgrowduringsintering, whilematrixgrainsgrewtosomeextent.However,interestingly,

shortandveryrigidCNTsweregrownperpendicularlytothe basalplanesofthesea-Al2O3platelets,asshowninFig.7(b)

and (c). Theseare probably large diameter individual multi-wallCNTs(MWNTs)ratherthanbundlesof few-wallCNTs. It was alsoobserved thata highamountof Fe nanoparticles, onlyasmallpartofwhichcatalyzedCNTsgrowth,wereformed overthebasalplanesoftheplatelets.Itisproposedthatsome Fe3+cationsdiffusedintotheplateletsduringsinteringandwere reduced intotheFe0 duringCCVDpreferentiallyatthebasal planesoftheplatelets.Hongoetal.4reportedthatSWNTsyield depended onthecrystallographic orientationofsapphire sub-stratecoatedwithFe-filmandonthefilmthickness.Theauthors explainedthisresultwithdifferentdiffusionconstantsofFeon the sapphiresurfacesor affinitybetweenFeandthe substrate surface.4 In contrast tothetexturedsubstrates,the surface of thea-Al2O3plateletsisquitesmooth.Thisobviouslysupports

thefactthatthesurfaceroughnessofthesubstrateand crystal-lographic orientationof grainsplayacritical roleonthesize, location andorientation of catalyticnanoparticles and subse-quentlyonorientationofCNTs.

Theseresultsindicatedthatthreekindsofcarbonfilaments (few-wallCNTsbundles,individualMWNTsandCNFs)were grown over Fe-doped Al2O3 substrates withvarying degrees

of texture. Whileroughtexturedsubstrate surface resultedin randomlyorientedlongandflexibleCNTsbundles, perpendicu-larlyorientedindividualMWNTswereobservedoverrelatively smoothsinglecrystala-Al2O3plateletsurfaces(basalplanes)

in a non-textured Fe-doped Al2O3 sample. CNFs and other

forms of non-tubular carbonaceous forms were observed at grain boundaries where segregated secondary phase and the liquidphaselocatedandaffectedthecatalyticFenanoparticle size.

4. Conclusions

Fe-doped Al2O3 ceramics with a textured microstructure

wereproducedbytemplatedgraingrowthmethod.Fe-doping intoAl2O3helpedsintering;however,exaggeratedgraingrowth

occurred at high amount of Fe addition (i.e., ∼10cat.%) at 1600◦C.IntroducingCaO-SiO2asliquidphaseformersintothe

systemenhanceddensification andliquid-phasesintering pro-moted anisotropic graingrowthinthosesamples.Thedegree of texture increased with the Fe content in the presence of liquid phase. 1vol% liquid phase former-added 10cat.% Fe-doped Al2O3 sample showed the highest degree of texture,

whileaverylimitedtemplategrowthoccurredin1and2cat.% Fe-doped samples. The Fe-doped Al2O3 ceramics with

vary-ing degrees of texture were subjected to CCVD and three kinds of carbon filaments (few-wall CNTs bundles, individ-ual MWNTs and CNFs) were grown over these substrates depending on the surface roughness, the size of the catalyst nanoparticles and the grain boundary phase. Well textured substrates led to randomly oriented few amount of CNTs bundles. However, on a substrate where no template growth occurred due to random and inhomogeneous distribution of a-Al2O3 plateletsin the Fe-doped Al2O3 matrix and

perpendicular to the basal planes of single crystal a-Al2O3

platelets.

Acknowledgements

The financial support for thisstudy by The Scientific and Technological Research Council of Turkey (TUBITAK) and Centre National de la Recherche Scientifique (CNRS) under thecontractnumber106M543isgratefullyacknowledged.One of theauthors,E.Suvaci,thankstoTurkishAcademyof Sci-ences(TUBA)forfinancialsupportthroughOutstandingYoung Investigator Award(GEBIP) Programme. AnadoluUniversity Scientific Research Projects Commission (under the project number of 050262)is also gratefully acknowledgedfor their supporttothisstudy.

References

1.PeigneyA,LaurentCh,DobigeonF,RoussetA.Carbonnanotubesgrown in-situbyanovelcatalyticmethod.JMaterRes1997;12:613–5. 2.SuvacıE,C¸elikY,WeibelA,PeigneyA,FlahautE.Organizedgrowth

ofcarbon nanotubes on Fe-dopedalumina ceramicsubstrates. Carbon

2012;50:3092–5.

3.BozkayaY. KarbonNanotüp Sentezinde KullanılmakÜzereFe-Katkılı Al2O3 SeramikTozlarınınveAltlıklarınÜretimi.M.Sc.Thesis.Turkey:

AnadoluUniversity;2008.

4.HongoH,YudasakaM,IchihashiT,NiheyF,IijimaS.Chemicalvapor depositionofsingle-wallcarbonnanotubesoniron-film-coatedsapphire substrates.ChemPhysLett2002;361:349–54.

5. AgoH,NakamuraK,IkedaK,UeharaN,IshigamiN,TsujiM.Aligned growthofisolatedsingle-walledcarbonnanotubesprogrammedbyatomic arrangementofsubstratesurface.ChemPhysLett2005;408:433–8. 6.Han S, Liu X, Zhou CJ. Template-free directional growth of

single-walled carbon nanotubes on a- and r-plane sapphire. Am Chem Soc

2005;127(15):5294–5.

7.IsmachA,SegevL,WachtelE,JoselevichE.Atomic-step-templated for-mation of single wall carbon nanotube patterns. Angew Chem Int Ed

2004;43(45):6140–3.

8.KimuraT, YahimotoT, IidaN,Fujita Y,YamaguchiT. Mechanismof grainorientationduringhot-pressingofbismuthtitanate.JAmCeramSoc

1989;72:85–9.

9.MaY,BowmanKJ.Textureinhot-pressedorforgedalumina.JAmCeram Soc1991;74:2941–4.

10.Watanabe H, KimuraT, Yamaguchi T. Sintering of platelike bismuth titanatepowder compactswith preferred orientation.J Am Ceram Soc

1991;74:139–47.

11.SeabaughMM,HongSH,MessingGL.Processingoftexturedceramics bytemplatedgraingrowth.In:TomsiaAP,GlaeserA,editors.Ceramic microstructure:controlattheatomiclevel.NewYork:Plenum;1998.p. 303–10.

12.CordierA,PeigneyA,DeGraveE,FlahautE,LaurentC.Synthesisof themetastablea-Al1.8Fe0.2O3solidsolutionfromprecursorspreparedby

combustion.JEurCeramSoc2006;26:3099–111.

13.Lotgering FK. Topotactical reactions with ferrimagnetic oxides hav-ing hexagonal crystal structures-I. J Inorg Nucl Chem 1959;9: 113–23.

14. Flahaut E, BacsaR, Peigney A, Laurent Ch. Gram-scale CCVD syn-thesis of double walled carbon nanotubes. Chem Commun 2003;12: 1442–3.

15.OzerIO,KarademirB,DoganA,Suvaci E,MissiaenJM, BouvardD, etal.Anisotropicshrinkageinsolidstatesinteringofaluminaceramics withorientedplatelets.JAmCeramSoc2006;89:1972–6.

16.Belmonte M, Moreno R, Moya JS, Miranzo P. Obtention of highly dispersed platelet reinforced Al2O3 composites. J Mater Sci 1994;29:

179–83.

17.CariseyT,Laugier-WerthA,BrandonDG.ControloftextureinAl2O3by

gel-casting.JEurCeramSoc1995;15:1–8.

18.RaoWR,CutlerIB.EffectofironoxideonthesinteringkineticsofAl2O3.

JAmCeramSoc1973;56:588–93.

19.TartajJ,MessingGL.Anisotropicgraingrowthina-Fe2O3-dopedalumina.

JEurCeramSoc1997;17:719–25.

20. IkumaY,GordonRS.Effectofdopingsimultaneouslywithironand tita-niumonthediffusionalcreepofpolycrystallinealumina.JAmCeramSoc

1983;66:139–47.

21.Muan A. On the stability of the phase Fe2O3-Al2O3. Am J Sci

1958;256:413–22.

22.Tartaj P, Tartaj J. Microstructural evolution of iron-oxide-doped alu-mina nanoparticles synthesized from microemulsions. Chem Mater

2002;14:536–41.

23.SeabaughMM.Texturedevelopmentinliquidphasesinteredalphaalumina viaanisotropictemplategrowth.Ph.D.Dissertation.UniversityPark:The PennsylvaniaStateUniversity;1998.

24.SeabaughMM,MessingGL,BrahmaroutuB.Anisotropictemplategrowth intexturedalumina.In:YouHI,JoongS,editors.Interfaces‘98.London: InstituteofMaterials;2000.

25.Suvaci E, Seabaugh MM, Messing GL. Reaction-based processing of textured alumina by templated grain growth. J Eur Ceram Soc

1999;19:2465–74.

26.SeabaughMM,KerschtI,MessingGL.Texturedevelopmentbytemplated graingrowthin liquid-phase sintered alpha-alumina. JAm Ceram Soc

1997;80:1181–8.

27.CaoPJ,ZhuDL,LiuWJ,MaXC.Theeffectofsubstratemorphologyon thediameterdistributionofcarbonnanotubesgrownonsilicaandceramic substrates.MaterLett2007;61(8–9):1899–903.