Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Cement and Concrete Research, 16, July 4, pp. 554-560, 1986-07-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=3662cd60-6354-468f-97b8-8b36ede41335

https://publications-cnrc.canada.ca/fra/voir/objet/?id=3662cd60-6354-468f-97b8-8b36ede41335

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1016/0008-8846(86)90093-1

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Effect of mica addition on the microstructure of Portland cement paste

Ser

TH1

N21d

Natronal Research

Conseil

national

no.

1407

IS

CouncllCanada

denchrehrCan&h

I

c . 2BLDG

Institute for

lnstitut de

Research in

recherche en

--

Construction

construction

Effect of Mica Addition on

the

Microstructure of Portland

Cement Paste

by J.J. Beaudoin

Reprinted from

Cement and Concrete Research

Vol. 16, No. 4, 1986

p. 554

-

560

(IRC

Paper No. 1407)

Price $2.00

NRCC 26401

N R C

-

CiSTlPour dgterminer l'effet de l'addition de mica sur la microstructure de la p&e de ciment,

on

a observ6 les modifications survenues dans des Bprouvettes hydrathe pendant des psriodes atteignant cinq ans au niveau de la rbpartition des pores par tailles, de la porositb, de la teneur en eau captive et de la rbpartition des particulesCH

selon la dimension. Les changemente microstructurels dgpendaient du rapport eau-ciment et de la quantit6 de mica ajoutge.CEMENT and CONCRETE RESEARCH. Vol. 1 6 , pp. 554-560, 1986. P r i n t e d i n t h e USA. 0008-8846186 $3.00+00. Copyright ( c ) 1986 Pergamon J o u r n a l s , L t d .

BPPECT OF MICA ADDITION ON THE MICKOSTKUCTUKE OF PORTLAND CEMENT

PASTE

1.1. Beaudoin

I n s t i t u t e f o r Uesearch i n C o n a t n ~ c t i o n , N a t i o n a l Research C o u n c i l of Canada, Ottawa, Canada, KIA OR6

(Communicated by F.H. Wittmann) (Received A p r i l 24, 1986) ABSTRACT

I n a s s e s s i n g t h e e f f e c t of mica r e i n f o r c e m e n t on cement p a s t e m i c r o s t r u c t u r e , m o d i f i c a t i o n s t o p o r e - s i z e d i s t r i b u t i o n , p o r o s i t y , non-evaporable w a t e r c o n t e n t , and CH p a r t i c l e s i z e d i s t r i b u t i o n were o b s e r v e d f o r samples h y d r a t e d f o r up t o f i v e y e a r s . M i c r o s t r u c t u r a l changes were dependent on water-cement r a t i o and amount of mica added.

I n t r o d u c t i o n

There h a s been i n t h e p a s t decade a p r o l i f e r a t i o n of new p r o d u c t s marketed f o r c o n c r e t e r e p a i r ( I ) . I n r e c o g n i t i o n of t h e s e r i o u s s t a t e of d e t e r i o r a t i o n of c o n c r e t e s t r u c t u r e s s u c h a s p a r k i n g g a r a g e s and b r i d g e d e c k s , many o f t h e s e p r o d u c t s i n c l u d e f i b r e - r e i n f o r c e d cement syntems. The a d d i t i o n of a r e i n f o r c e m e n t ( f i b r e o r f l a k e ) t o a p o r t l a n d cement-based m a t r i x

g e n e r a l l y r e s u l t s i n a n i n c r e a s e of e i t h e r o r b o t h f l e x u r a l s t r e n g t h and toughnesq, p r o p e r t i e s h i g h l y d e s i r a b l e i n a r e p a i r . Composite t h e o r y , u s u a l l y some form o f m i x t u r e r u l e , i s g e n e r a l l y a p p l i e d t o p r e d i c t t h e b e h a v i o u r of t h e m a t e r i a l s ( 2 ) .

Composite t h e o r y , however, h a s normally been a p p l i e d w i t h o u t

c o n s i d e r a t i o n f u r changes t o t h e m a t r i x , i n c l u d i n g m i c r o s t r u c t u r a l change9 brought a b o u t by t h e r e i n f o r c e m e n t . Such changes may d e t e r m i n e d u r a b i l i t y a s w e l l a s s t r e n g t h and toughness. A s mica f l a k e s have heen found t o be a u s e f u l

rrinforcemnent f o r p o r t l a n d cement m a t r i c e s ( 3 1 , i t was t h e o b j e c t i v e of t h e p r e s e n t work t o d e f i n e t h e i r e f f e c t on t h e m a t r i x ~ n i c r o s t r u c t u r e of cement composites moist cured f o r p e r i o d s o f up t o f i v e y e a r s .

E x p e r i m e n t a l M a t e r i a l s

Cement: P o r t l a n d cement comnposition: C3S = 51.4%; C2S = 20.3%; C3A = 12.7%; C,,AF

-

6.7% and CaSO,, = 5.4% a s c a l c u l a t e d by t h e Bogue method.Mica: A p h l o g o p i t e t y p e m i n e r a l w i t h high-aspect r a t i o ; p h y s i c a l and chemical p r o p e r t i e s of t h e f l a k e s have been p u b l i s h e d (3).

Vol. 1 6 , No.

4

555 MICA, REINFORCEMENT, MICROSTRUCTURE, CEMENT PASTE, PORE STRUCTUREMixes: Cement p a s t e mixes w i t h water-cement r a t i o s of 0.25-0.70 and mica c o n t e n t of 0-7% by volume were h y d r a t e d i n l i m e - s a t u r a t e d w a t e r f o r up t o f i v e yearn. Mix d e t a i l s a r e provided e l s e w h e r e ( 3 ) .

Technique

P o r o s i t y and p o r e - s i z e d i s t r i b u t i o n s were determined by mercury i n t r u s i o n cunder p r e s s u r e s up t o 408 MPa, u s i n g an American Instrument CO. p o r o s i m e t e r .

Non-evaporable w a t e r c o n t e n t was determined by TGA, employing a 1090 Dupont Thermal Analyzer c o n t a i n i n g a 951 TGA a c c e s s o r y .

Leaching of CH from mica-cement specimens ( s l i c e d 0.030 pm t h i c k ) was accomplished w i t h p a r t i a l l y - s a t u r a t e d lime s o l u t i o n s a c c o r d i n g t o t h e method developed by Ramacliandra8l and Polomark ( 4 ) . Leaching time was a t l e a s t 30 days; i t s e f f i c i e n c y was checked by TGA.

E s t i m a t i o n s of CH c o n t e n t were v e r i f i e d by DSC. A Oupont 1090 t h e r m a l a n a l y s i s system was used.

R e s u l t s and D i s c u s s i o n P o r e - s i z e d i s t r i b u t i o n P o r e - s i z e d i s t r i b u t i o n f o r m i c a - r e i n f o r c e d cement p a s t e specimens h y d r a t e d f o r Eive y e a r s 25 i s p r e s e n t e d i n F i g u r e 1. Mica a d d i t i o n g e n e r a l l y r e s u l t s i n 1 5

g r e a t e r pore volume above a p o r e ... d i a m e t e r g r e a t e r t h a n 0.10 pa. T l ~ e

t h r e s h o l d v a l u e of t h e c o n t r o l samples ( p o r e s i z e a t which the,

i n i t i a l mercury i n t r u s i o n r a t e 3 0 changes s i g n i f i c a n t l y ) a l s o 25 i n c r e a s e s w i t h w/c r a t i o from

-

.

2 0 0.05 pm a t w/c = 0.35 t o 0.30 pm 3 1 5 a t w/c = 0.70. Yores g r e a t e r t h a n $ 1 0 0.30 pm were d e t e c t e d o n l y i n mica-"

5 r e i n f o r c e d i n a t e r i a l (wlc = 0.70). " 2 0 0 Many p o r e s e x i ~ t i n t h e i n t e r f a c e a 1 5zone, between t h e bulk m a t r i x and

1 0 t h e mica s u r f a c e s where p r o p e r t i e s a r e dependent on w/c r a t i o and 5 0 c!rring c r > ~ i d i t i o n s - ( 5 ) . 1 5 r r f r t

,

,

, ,

.

t T o t a l p o r o s i t i e s e x p r e s s e d a s pore volune p e r u n i t volume of p a s t e5

"/A,,,

-., ,

,

( c o r r e c t i o n s a r e made f o r t h e,

,

volume of mica i n a g i v e n s a m p l e ) l o -

a r e g i v e n i n Table 1. The cement m a t r i x (w/c

.

. = 0.70) c o n t a i n i n e 5%-

mica has l e s s t o t a l pore volume 2 0 . 2 0. 0 2 0 . 0 0 2

( o v e r t h e e n t i r e pore s i z e r a n g e ) PORE D I A M ' E T E R , , ~ ~

than m a t r i c e s c o n t a i n i n g l e s s mica

(1-3%), i n d i c a t i n g t h a t mica does FTG. I. P ~ r e s i z e d i s t r i b u t i o n of not n e c e s s a r i l y i n c r e a s e t o t a l cement p a s t e s a m l ~ l e s ( w i t h and w i t h o u t p o r o s i t y a t h i g h e r w/c r a t i o s . The mica) h y d r a t e d f o r f i v e y e a r s w i t h t o t a l p a r e volume of specimens d i f f e r e n t amounts of mica.

556 Val. 1 6 , No. i J.J. Beaudoin 0 . 2 2 F I G . 2. Non-evaporable w a t e r v e r s u s mica c o n t e n t f o r cements h y d r a t e d f o r ( a ) f i v e y e a r s and ( b ) 35 d a y s + a WIC = 0.50

5

0.19 0 . 1 7 0. 19 mica c o n t e n t i s a l s o l e s s t h a n t h a t f o r t h e c o n t r o l sample c o n t a i n i n g no mica. Non-evaporable w a t e r c o n t e n t P l o t s of Wn (non-evaporable 4 w a t e r c o n t e n t ) v e r s u s mica c o n t e n t f o r samples h y d r a t e d f a r 35 d a y s and Q2

0 . 1 4 f i v e y e a r s a c e p r e s e n t e d i n F i g u r e 2. I n g e n e r a l , W n d e c r e a s e s5

0 . 1 3 Z\.

w i t h mica f l a k e a d d i t i o n , a l t h o u g h 0. 12 a t t h e l o w e s t w/c r a t i o (0.25) Wn.-

0.25 a p p e a r s t o be independent of i t . 0. 1 1 R e g r e s s i o n c u r v e s of W v e r s u s m a t r i x p o r o s i t y ( f o r 3? d h y d r a t i o n ) 0. 1 0 0 1 2 3 4 5 6 , 7 8 9 a r e g i v e n i n F i g u r e 3 f o r W / C = 0.25-0.50, f o r which F L A K E VOLUME, % c o r r e l a t i o n c o e f f i c i e n t s were g r e a t e r t h a n 90%. Values of W n o v e r most of t h e p o r o s i t y range wereg e n e r a l l y l e s s when mica was added t o t h e p a s t e . A t a g i v e n p o r o s i t y , Wn d e c r e a s e d w i t h p e r c e n t a g e o f mica. A s t m i l a r e f f e c t h a s been o b s e r v e d w i t h a d d i t i o n o f g l a s s f i b e r s ( 6 ) .

Some workers have p o s t u l a t e d t h a t CH p a r t i c l e s i n cement p a s t e a c t a s n u c l e a t i o n s i t e s f o r C-S-H growth ( 7 ) . Mica a f f e c t s t h e d l s t r t h v ~ t i . o n of CH

p a r t i c l e s i n cement p a s t e , e . g . , i n t e r f a c e r e g i o n s i n mica cements a r e CH-rich (2)., A m o d i f i c a t i o n of t h i s n u c l e a t i o n p r o c e s s i n t h e p r e s e n c e of mica r e l n f o e < : e t r ? r ~ t <nay be one e x p l a n a t i o n f o r lower r a t e s of h y d r a t i o n . It i s p o s s i b l e t h a t mica enhances t h e e a r l y c r y s t a l l i z a t i o n o f CH 8 0 t h a t t h e

n u c l e a t i o n e f f e c t of CH ( w i t h l a r g e s u r f a c e f a c e e n e r g y ) i s reduced.

T a b l e 1. P o r o s i t y

(XI

of Mica Cements Hydrated f o r F i v e Years-

-

-

--

- - - -

- - -

-

Mica 0.50 % 0.70 0.60 W/ c 0.40 0.35-- - -

-

--

- -

-

-

-

--

-

- --

0 32.0 26.0 17.0 11.5 8.0 1 35.9 25.8 18.7 12.8 8.6-

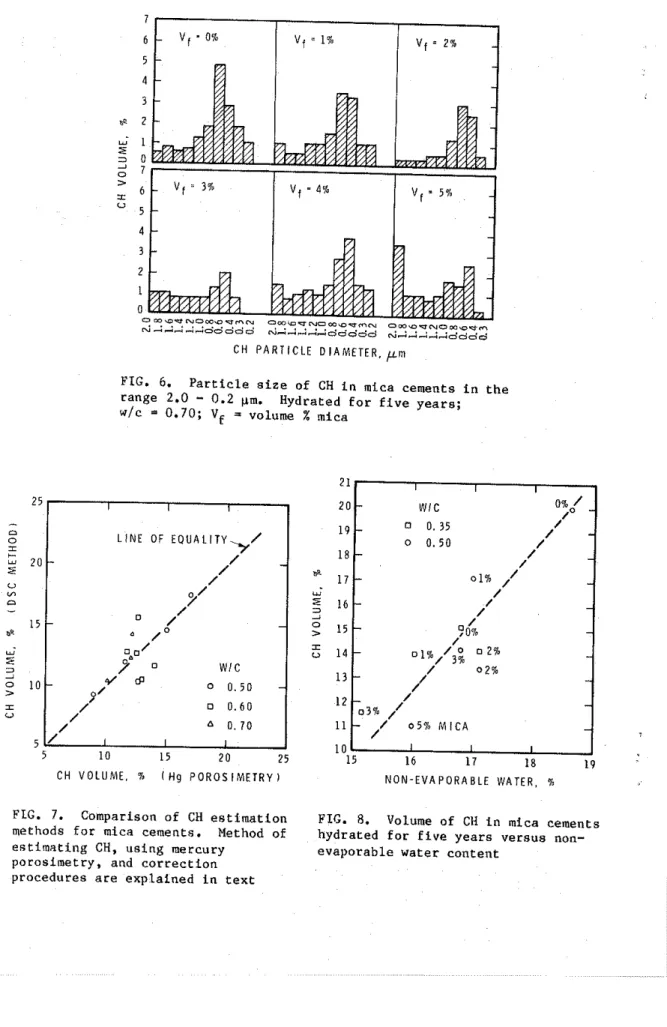

( o v e r t h e s i z e r a n g e 2-0.2 pm) f o r W / C = 0.79 a r e p r e s e n t e d i n F i g u r e 6. The l a r g e s t volume of CH p a r t i c l e s o c c u r s i n t h e s i z e r a n g e 0.8-0.6 pm f o r mica a d d i t i o n s up t o 2% andi s

g r e a t e s t f o r t h e c o n t r o l samples. The range f o r maximum CH volume s h i f t s t o 0.6-0.4 pm f o r 3 andG%

mica. The p a r t i c l e s i z e r a n g e s f o r maximum CH volume f o r wlc = 0.60, 0.50 and 0.40 ( h i s t o g r a m s a r e not p l o t t e d ) a r e 0.6-0.4, 0.4-0.3, and 0.3-0.2 pm, r e s p e c t i v e l y . C o n t r o l samples f o r t h e s e w/c I1

Vol. 1 6 , No.4

557MICA, REINFORCEMENT, MICROSTRUCTURE, CEMENT PASTE, PORE STRUCTURE

i

CH P a r t i c l e S i z e D i s t r i b u t i o n

The s i z e d i s t r i b u t i o n of CH p a r t i c l e s i n p a s t e was determined i n t h e f o l l o w i n g manner. A p o r e - s i z e d i s t r i b u t i o n c u r v e was o b t a i n e d u s i n g a sample from which CH had been removed by l e a c h i n g w i t h a p a r t i a l l y - s a t u r a t e d l i m e

s o l u t i o n ( 4 ) . It i s assumed t h a t mercury e n t e r s a l l t h e s p a c e s formed when CH

'

in removed, and t h a t CH p a r t i c l e s i z e is e q u i v a l e n t t o t h e s i z e of t h e v a c a t e d space. A c o r r e s p o n d i n g p o r e - s i z e d i s t r i b u t i o n c u r v e f o r an unleached

companion sample was a l s o o b t a i n e d . A CH p a r t i c l e s i z e d i s t r i b t ~ t i o n c u r v e was t h e n c o n s t r u c t e d by p l o t t i n g t h e d i f f e r e n c e i n c u m u l a t i v e pore volume from t h e p o r e - s i z e d i s t r i b u t i o n c u r v e s s o o b t a i n e d v e r s u s t h e p a r t i c l e s i z e . T y p i c a l p o r e - s i z e d i s t r i b u t i o n s f o r l e a c h e d and unleached cement p a s t e s c o n t a i n i n g 4% mica a r e g i v e n i n F i g u r e 4; t h e c o n s t r u c t e d CH p a r t i c l e s i z e d i s t r i b u t i o n i s

a l s o given. I n g e n e r a l , t h e curve h a s t h r e e r e g i o n s : one of i n c r e a s i n g pore volume, 0-1; one w i t h e s s e n t i a l l y no i n c r e a s e i n p o r e volume, 1-2; and a f i n e

i

pore r e g i o n w i t h i n c r e a s i n g p o r e volume, 2-3. I I CH p a r t i c l e s i z e d i s t r i b u t i o n !PI(;.

4. T y p i c a l p o r e s i z e and CH p a r t i c l e s i z e d i s t r i b u t i o n f o r m i c a - r e i n f o r c e d cement p a s t e , W / C = 0.60, 4% mica, h y d r a t e d f o r f i v e y e a r s . V f-

volume % micai

c u r v e s f o r f i v e - y e a r mica- 0 . 2 0 I r e i n f o r c e d p a s t e s a r e g i v e n i n + z w 0 . 1 9 - F i g u r e 5. The volume of CH i n c o n t r o l and m i c a - r e i n f o r c e d5

u 0. 1 8 samples g e n e r a l l y i n c r e a s e s w i t h=

w l c g r e a t e r r a t i o t h a n f o r 0.20 p a r t i c l e pm. s i z e s S e v e r a lE

0 0 . 1 6 - c u r v e s e x h i b i t a low s l o p e between-

4 0.2 and 0.02 pm a n d an i n c r e a s i n g 5 0. 15 s l o p e between 0.02 and 0.004 pm. L,, Many s a m p l e s , t h e r e f o r e , c o n t a i n 0. 1 4 4 s m a l l amounts o f CH i n t h e Eormer 0 . 1 3 - s i z e r a n g e and, a p p a r e n t l y , l a r g e r a amounts i n t h e l a t t e r . 4 0 . 1 2 -2

CH p a r t i c l e s i z e h i s t o g r a m s&

0 . 1 1 - 0. 10-1 5 2 0 25 3 0 3 5 P O R O S I T Y , 4. I I I V t = 0% I / / :-

-

-

-

-

-

-

-

FIG. 3. Non-evaporable w a t e r v e r s u s m a t r i x p o r o s i t y f o r mica cements h y d r a t e d t o r 35 days. Vf = volume % micaI " " ' ' STE WIC

-

0.60; V, ; 4% 8 - CH PRESENT DISTRIBUTION-

A-B 15---

0,

' " 2 0. 2 0. 0 2 P O R E [ P A R T I C L E S I Z E 1 D I A M E T E R , pm558 Vol. 1 6 , No. 4

I

.]..I. Deaudoin r a t i o s g e n e r a l l y have t h e l a r g e s t CH volume i n t h e s e ranges. Volumes of CH d e t e r m i n e d by 0% M I C A mercury p o r o s i m e t r y were n e a r l y...

always h i g h e r t h a n t h o s e-

. - .-.

-

.

-

.-

d e t e r m i n e d by USC methods. The ... two were a p p r o x i m a t e l y e q u a l ,however, i f t h e " f i n e pore" volume

20 ( r e g i o n 2-3 of t h e C o n a t r u c t e d c u r v e , F i g u r e

4)

was s u b t r a c t e d 15 1 0 from t h e t o t a l volume d e t e r m i n e d by p o r o s i m e t r y . DSC v a l u e s of CH volume a r e p l o t t e d a g a i n s t volumes d e t e r m i n e d by t h e c o r r e c t e d mercury p o r o s i m e t r y method i n 1 0 F i g u r e 7. It a p p e a r s t h a tl e a c h i n g of CH from cement compos- i t e s "opens up" f i n e p o r e s p r e v i - o u s l y i n a c c e s s i b l e t o mercury.

Volumes of CH d e t e r m i n e d by t h e mercury i n t r u s i o n method a r e g i v e n i n T a b l e 2. Nearly a l l t h e f r e e lime was removed from most samples by t h e l e a c h i n g p r o c e s s , a s v e r i f i e d by t h e r m a l methods, but i n a few samples some remained, e.g., w/c

-

0 . 4 0 .The volume of CH g e n e r a l l y d e c r e a s e s w i t h mica a d d i t i o n f o r W / C 2 0 . 5 0 . The e x c e p t i o n is a t 4% mica c o n t e n t , a t which t h e p a r t i c l e s i z e c u r v e d o e s n o t f l a t t e n ( F i g u r e 5) and t h e amount of CH may be o v e r e u t i m a t e d . A lower amount of lime w i t h mica a d d i t i o n can be e x p l a i n e d , i n p a r t , by t h e lower v a l u e s of

non-evaporahle w a t e r f o r t h e s e 2 0.2 0.02 0.002 samples ( F i g u r e 8). Higher CH C H P A R T I C L E S I Z E ,

pm

c o n t e n t s wLth 4% mica may be due

t o p o r o s i t y n o t accounted f o r i n

a p p l y i n g c o r r e c t i o n s t o c o n s t r u c - FIG. 5. P a r t i c l e s i z e distribution

t e d p a r t i c l e s i z e d i s t r i b u t i o n of CH i n mica cements. Hydrated f o r curves. A d i f f e r e n c e i n CIS r a t i o f i v e y e a r s of t h e C-S-H formed i n t h e p r e s e n c e of mica would a l s o a f f e c t t h e CH c o n t e n t and non-evaporable c o n t e n t . Conclusion

I , Mica f l a k e s modify t h e p o r e - s i z e d i n t r i b t i t i o n and t u e a l purosity of t h e m a t r i x i n cement c o m p o s i t e s h y d r a t e d f o r f i v e y e a r s . Pores of d i a m e t e r g r e a t e r t h a n 0.30 pm a r e dependent on water-cement r a t i o and mica

c o n t e n t .

2. Addicion of mica f l a k e g c n c r n l l y r e t a r d s h y d r a t i o n of cements. The d e c r e a s e i s dependent on water-cement r a t i o and mica a d d i t i o n .

Val. 1 6 , No.

4

559

MICA, REINFORCEMENT, MICROSTRUCTURE, CEMENT PASTE, PORE STRUCTURE

C H P A R T I C L E D I A M E T E R . p m

FIG. 6. P a r t i c l e s i z e of CH i n mica cements i n t h e range 2.0

-

0.2 pm. Hydrated f o r f i v e y e a r s ;W / C = 0.70; Vf = volume X mica

CH V O L U M E , % I H g P O R O S I M E T R Y I

FIG. 7. Comparison of CH e s t i m a t i o n methods f o r mica cements. Method of e s t i m a t i n g CH, u s i n g mercury

p o r o s i m e t r y , and c o r r e c t i o n p r o c e d u r e s a c e e x p l a i n e d i n t e x t

FIG. 8. Volume of CH i n mica cements h y d r a t e d f o r f i v e y e a r s v e r s u s noo- e v a p o r a b l e w a t e r c o n t e n t 2 1 2 0 19 1 8 az 1 7

$

1 6 - L 15 r o 1 4 13 I 2 11 1 0 15 I I I-

W I C 0% /"-

-

0 0. 35 0 0.50 / //-

-

/ / --

01% //-

/ / - /-

/ 70%-

/ - 0 1 % / / 3% 0 2 % 0 2 +-

-

-

-

///

0 3 % /'-

-

/ 0 5 % M I C A / - I I I-

16 1 7 1 8 19 N O N - E V A P O R A B L E W A T E R , %560 Vol. 1 6 , No. 4

J . J . Beaudoin

Table 2. T o t a l Volume ( % ) of CH Determined by Mercury Porosimetry f o r Mica Cements Hydrated f o r F i v e Years

- - --- -

- - -

- - - -

- - -

- -

-

*-- - - --

- - - -

-

- --

-

-

-

-

-- -

- --

-

-

- - -

- -

--

-

Mica ( % ) 0.40 12.5**(12.5)-

12.5**(12.5) 17.0(17.0) 16.0(16.0)-

---

---

" E s t i m a t e s i n h r a c k e t s o b t a i n e d by c o r r e c t i n g p a r t i c l e s i z e d i 3 t r i b o t i o n c u r v e s ( s e e t e x t ) . **Not a l l lime l e a c h e d o u r . 3. Mica f l a k e s modlfy t h e s i z e d i s t c i h u t i o n of CH p a r t i c l e s i t ? t h e m a t r i x ofcement composites h y d r a t e d f o r f l v e y e a r s . Maximum p a r t i c l e e i z e i n c r e a s e s w i t h water-cement r a t i o .

4.

The volume p e r c e n t a g e of l a r g e CH p a r t i c l e s i n c r e a s e s a t mica c o n t e n t s g r e a t e r t h a n 2%.5. CH i n cements p r e v e n t s mercury from e n t e r i n g some of t h e micropores. When t h e CH i a removed, t h e p o r e s a r e a c c e s s i b l e t o mercury.

6. C o n s i d e r a t i o n s h o u l d be g i v e n t o t h e e f f e c t of f i b e r o r f l a k e

r e i n f o r c e m e n t on t h e cement m a t r i x when making long-term p r e d i c t i o n s o f s t r e n g t h and d o r a b i l i t y .

Acknowledgement

The a u t h o r wishes t o thank R. Myers and

F.

G o e r t i n f o r a s s i s t a n c e w i t h t h e e x p e r i m e n t a l work. This paper i s a c o n t r i b u t i o n from t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n , N a t i o n a l Keaearch Council of Canada.ReferenCes

I. P. H e w l e t t , C o n s t r u c t i o n R e p a i r s and Maintenance,

I

,

3 (1985). 2. V.S. Kamacharldran, K.P. Feldrnan and .J.J.

Reaudoin, Concrete S c i e n c e ,Heyden h Son, 427 p. (1981).

3. ..I.J. Reaudoin, Cem. Concr. R e g .

3,

153 (1983).4. V.S. Ramachandran and G.M. Polomark, J. Chem. Tech. and B i o t e c h . ,

2,

946 (1982).5. A. R e n t u r , S. Uiamorld and S. MindBss, 3. Mats. S c i .

c,

3360 (1985).6. R. Sh. M i k h a i l , M. Abd-El-Khalik and A . H a s s a n e i n , Cem. Concr. R e s .

-

8, 765 (1978).7. J. Skalny and .J.F. Young, Proc. 7 t h I n t . Congr. Chem. Cem., P a r i s , Paper 11-1, 3 (1980).