Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building

Research), 1964-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=8287da11-b50f-4d4f-bdbe-6a7a9dd6a057 https://publications-cnrc.canada.ca/fra/voir/objet/?id=8287da11-b50f-4d4f-bdbe-6a7a9dd6a057

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20338298

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Investigation of plaster adhesion test method

Hutcheon, N. B.

NATIONAL RESEARCH COUNCIL CANADA

DIVISION OF BUILDING RESEARCH

INVESTIGATION O F P L A S T E R ADHESION TEST METHOD b y N. B . Hutcheon Internal R e p o r t No.

285

of t h e D i v i s i o n of Building R e s e a r c h OTTAWA January1 9 6 4

P R E F A C E

A s m a l l p a t c h m e t h o d of d e t e r m i n i n g adhesion h a s b e e n adapted by t h e Division f o r s o m e of i t s w o r k on p l a s t e r . S o m e f u r t h e r e x p l o r a t i o n of the method w a s d e s i r a b l e t o a s s i s t i n the i n t e r p r e t a t i o n of r e s u l t s obtained. P l a s t e r itself w a s employed a s a b r i t t l e m a t e r i a l i n a n investigation of t h e effect of c u t t e r p r o f i l e s a n d depth of c u t u s e d i n i s o l a t i n g t e s t p a t c h e s . T h e s e r e s u l t s a r e now r e p o r t e d . T h e w o r k w a s c a r r i e d out u n d e r t h e g e n e r a l d i r e c t i o n of t h e a u t h o r , who is A s s i s t a n t D i r e c t o r of t h e Division. Ottawa J a n u a r y 1964 R o b e r t

F.

Legget D i r e c t o rINVESTIGATION O F P LASTER ADHESION TEST METHOD

by

N. B. Hutcheon

P r o b l e m s involving bond of p l a s t e r which have been brought t o t h e DiGision h a v e l e d at v a r i o u s t i m e s t o a number of l a b o r a t o r y i n - vestigations in which a t t e m p t s have been m a d e t o m e a s u r e bond strength. R e l a t i v e l y l a r g e s a m p l e s about

9

in. s q u a r e w e r e employed in e a r l i e r work, but t h e s e c a m e t o b e r e g a r d e d a s of doubtful m e r i t . Attention w a s then directed t o a f o r m of t e s t used by Ryder ( 1 ) i n which a s m a l l patchof p l a s t e r about 2 in. in d i a m e t e r i s i s o l a t e d by cutting, and then pulled f r o m t h e b a s e , t h e r e q u i r e d f o r c e being m e a s u r e d . Subsequently, a number of l a b o r a t o r y t e s t s w e r e c a r r i e d out on v a r i o u s p l a s t e r s y s t e m s on a v a r i e t y of b a s e s .

A s it w a s anticipated that adhesion m e a s u r e m e n t s would

eventually b e m a d e in t h e field a s well as in t h e l a b o r a t o r y , c o n s i d e r a b l e attention w a s given t o t h e development of a p p a r a t u s and techniques which would b e e a s y t o u s e on w a l l s and ceilings as well a s on l a b o r a t o r y t e s t panels. Ryder u s e d a hand-grip s p r i n g device for pulling and m e a s u r i n g adhesion f o r c e s . An a l t e r n a t i v e design employing loading b y c o m p r e s s e d a i r through d i a p h r a g m s w a s designed and c o n s t r u c t e d ( ( F i g u r e 1) ( 2 ) ) . An e l e c t r i c a l l y powered cutter w a s a l s o developed for isolating t h e t e s t patches.

Ryder used t h e s m a l l "patch" method t o study t h e adhesion of p l a s t e r t o c o n c r e t e s o t h a t , p r e s u m a b l y , t h e b a s e m a t e r i a l w a s always v e r y rigid, and t h e p l a s t e r t e s t patch w a s always undercut a s f a r a s t h e concrete. In t h e study of other p l a s t e r s y s t e m s , . the b a s e coat and t h e p l a s t e r b a s e w e r e often weaker than t h e putty coat, and t h e r e w e r e a l s o

questions t o b e r a i s e d about t h e m o s t a p p r o p r i a t e depth and shape of cut. A s p l a s t e r i s a r e l a t i v e l y b r i t t l e m a t e r i a l i t w a s s u s p e c t e d t h a t it would r e s p o n d t o s t r e s s c o n c e n t r a t i o n s a t t h e a b r u p t change i n section f o r m e d by t h e cut, and t h a t t h e a p p a r e n t adhesion s t r e n g t h might be affected by varying t h e depth and p r o f i l e of t h e cut. A number of e x p e r i m e n t s , now t o b e r e p o r t e d , w e r e undertaken t o provide information on t h e s e questions

as a n aid in i n t e r p r e t i n g t h e r e s u l t s of t h e t e s t s and in evaluating t h e t e s t method.

THE PROBLEM

An i s o l a t e d p l a s t e r p a t c h m a y b e r e g a r d e d a s a v e r y s h o r t t e n - s i l e s p e c i m e n with a n a b r u p t change of section a t its b a s e . It is known t h a t abrupt changes in section produce s t r e s s c o n c e n t r a t i o n s i n t e n s i l e s p e c i m e n s i n p r o p o r t i o n t o the s h a r p n e s s o r a b r u p t n e s s of t h e change.

Such localized s t r e s s e s can be m a n y t i m e s higher than t h e a v e r a g e s t r e s s over t h e m i n i m u m section. T h e u s e of f i l l e t s r a t h e r than s h a r p c o r n e r s c a n m a r k e d l y r e d u c e the s t r e s s concentration.

T h e effect of s t r e s s concentrations in ductile m a t e r i a l s being subjected t o a n i n c r e a s i n g load t o f a i l u r e m a y not be s e r i o u s s i n c e t h e m a t e r i a l i s able by i t s ductility t o flow locally, t h u s r e l i e v i n g t h e high l o c a l s t r e s s e s and t h e i r potential effects. Such s t r e s s concentrations, however, a r e of i m p o r t a n c e in ductile m a t e r i a l s under r e p e a t e d loading

s i n c e the); m a y l e a d t o t h e f o r m a t i o n of a c r a c k which i s itself a s t r e s s - r a i s e r , and i s capable of propagating until f a i l u r e o c c u r s . When a m a t e r i a l i s b r i t t l e , i t cannot flow p l a s t i c a l l y t o r e l i e v e t h e l o c a l high s t r e s s e s , and s o m a y f r a c t u r e whenever t h e localized s t r e s s r e a c h e s a limiting value r e p r e s e n t a t i v e of the t e n s i l e s t r e n g t h of t h e m a t e r i a l . S t r e s s concentrations in a b r i t t l e m a t e r i a l m a y t h e r e f o r e induce f a i l u r e a t l o a d s considerably lower than t h o s e which could be c a r r i e d i f the s t r e s s concentrations w e r e not p r e s e n t .

It i s known a l s o t h a t r e a l m a t e r i a l s do not r e s p o n d ideally t o t h e effects of s t r e s s c o n c e ~ l t r a t i o n s , s o that t h e r e d u c t i o n s in b r e a k i n g l o a d s t h a t r e s u l t in t h e c a s e of p r a c t i c a l b r i t t l e m a t e r i a l s a r e usually l e s s than those p r e d i c t e d f r o m theory. P l a s t e r of p a r i s h a s been u s e d a s a m o d e l m a t e r i a l for t h e e x p e r i m e n t a l evaluation of s t r e s s concentrations. T h e b r e a k i n g l o a d s of two s p e c i m e n s m a d e of p l a s t e r , one with a s t r e s s

concentration and one without, can be c o m p a r e d , and t h e s t r e s s concen- t r a t i o n f a c t o r obtained f r o m the i n v e r s e r a t i o of the loads.

F o r t h e s e r e a s o n s i t w a s thought that t h e p l a s t e r adhesion l o a d s found f r o m the s m a l l patch t e s t would v a r y with t h e depth and p r o - file of the cut and that t h e influence of t h e s e f a c t o r s should b e investigated. T h e s t r e s s distributions in t h e isolated p l a s t e r patch a r e undoubtedly

complicated by ( a ) t h e p r o x i m i t y of t h e aluminum d i s c having different

e l a s t i c p r o p e r t i e s than the p l a s t e r , ( b ) t h e e f f e c t of t h e adhesive u s e d which m a y introduce shrinkage s t r e s s e s into t h e p l a s t e r a s it h a r d e n s , and ( c ) t h e v a r i a b l e and complex e l a s t i c - p l a s t i c situation posed by the multiple l a y e r s of t h e r e a l p l a s t e r s y s t e m .

TEST METHOD AND RESULTS

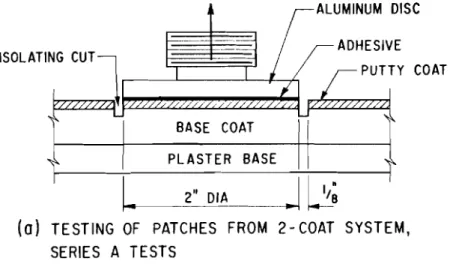

Some p r e l i m i n a r y t e s t s ( S e r i e s A) w e r e m a d e using existing l a r g e panels of a conventional putty coat over a b a s e coat s y s t e m which had been m a d e by a p l a s t e r e r for adhesion t e s t s in t h e l a b o r a t o r y . Two c u t t e r s w e r e u s e d t o i s o l a t e t h e t e s t patches. One w a s square-edged, 1/8 in. wide, a s had been u s e d in a l l p r e v i o u s work. T h e other w a s a l s o 1/8 in. wide but w a s rounded a t i t s end s o t h a t i t f o r m e d a full fillet of 1/16-in. r a d i u s at t h e bottom of t h e cut. Twenty-four p a t c h e s w e r e cut with e a c h c u t t e r , twelve being taken t o t h e depth of the putty coat and twelve being a t varying depths f r o m about 0. 2 t o 0. 4 in. T h e r e s u l t s a r e

shown in T a b l e I, t h o s e for t h e depths t o b a s e coat being a r r a n g e d in o r d e r of load c a r r i e d .

T h e r e was evidence of quite a m a r k e d influence of depth of cut, the l o a d s c a r r i e d being only about h a l f a s g r e a t at depths over 0. 3 in. a s at 0. 2 in. T h e c u t s m a d e t o the b a s e coat w e r e not checked for depth but w e r e about 1/8 i n ; a l l other c u t s w e r e well into t h e b a s e coat. No p a r t i c u l a r benefit f r o m the rounded c u t t e r w a s shown.

F a i l u r e s o c c u r r e d in t h e b a s e coat and not a t the i n t e r f a c e with t h e putty coat.

F i v e homogeneous p l a s t e r of p a r i s s l a b s 12 by 16 by 1 in. thick w e r e c a s t for S e r i e s B t e s t s , and a f t e r 1 day in a damp r o o m w e r e allowed t o d r y t o constant weight in a r o o m a t m o s p h e r e of 50 p e r cent R. H. ; t h i s r e q u i r e d about 2 months. A s e r i e s of p a t c h e s w e r e then cut

for adhesion testing. T h e shapes of t h e c u t t e r s u s e d and t y p i c a l s p e c - i m e n s a r e shown in F i g u r e 2. Depths of cut w e r e m e a s u r e d in t e r m s of the depth of p a r a l l e l portion, which w a s adjusted t o 1/16, 1/8, and 1/4 in. for each shape of cutter. One s p e c i m e n for each cutter shape and each depth w a s p r e p a r e d on each of the five s l a b s using the e l e c t r i c a l l y

o p e r a t e d cutting machine in each c a s e . One s h o r t cyclinder

$

in. long and one 1 in. long w e r e a l s o cut f r o m e a c h slab, and w e r e glued between two d i s c s t o f o r m a t t a c h m e n t s for s p h e r i c a l l y seating tackle in a t e n s i l e t e s t i n g machine. All p a t c h e s w e r e loaded by m e a n s of the a i r - o p e r a t e d m e m b r a n e device, which w a s c a l i b r a t e d in the t e n s i l e t e s t i n g machine (Appendix A).T h e r e s u l t s of t h e S e r i e s B t e s t s a r e given in T a b l e

I1

andF i g u r e 3. R e s u l t s on any one horizontal line in T a b l e I1 apply t o s p e c i m e n s f r o m t h e s a m e slab, t h e s e being p r e s e n t e d in t h e s a m e o r d e r in each group of five r e s u l t s s o t h a t any p o s s i b l e differences between t e s t s l a b s m a y be noted. T h e r e s u l t s a r e not v e r y r e l i a b l e in view of t h e l i m i t e d number of s a m p l e s ( 5 i n each c a s e ) and t h e s u b s t a n t i a l variation shown. T h e

difference between t h e square-ended c u t t e r and t h a t with the l a r g e s t fillet i s not g r e a t , being about 15 p e r cent for 1/8-in. depth of cut. A t r e n d t o w a r d s lower s t r e n g t h s with i n c r e a s i n g depth of cut i s shown. T h e s t r e s s

concentrations shown by the s q u a r e c u t t e r by c o m p a r i s o n with cylinder s p e c i m e n s t r e n g t h s a r e about 1. 5 for 1/8 -in. depth and about 1.75 for 1/4-in. depth of cut.

In view of t h e v a r i a b i l i t y of the r e s u l t s , f u r t h e r t e s t s w e r e m a d e ( S e r i e s C). T h i s t i m e only t h e square-edged c u t t e r t o a depth of

1/4 in. w a s used for c o m p a r i s o n with $-in. and 1 -in. c y l i n d e r s cut f r o m two t e s t s l a b s m a d e and conditioned a s b e f o r e . Both p a t c h e s and

c y l i n d e r s w e r e pulled in the t e n s i l e t e s t i n g machine using suitable s p h e r i c a l l y seating tackle. T h e r e s u l t s f r o m the 1 -in. c y l i n d e r s w e r e spoiled by p r e m a t u r e glue f a i l u r e s and had t o be discarded. A c o m p a r i s o n of patch and cylinder l o a d s for t h e r e m a i n i n g s p e c i m e n s given in T a b l e 111 shows a s t r e s s concentration for the square-end c u t t e r a t 1/4-in. depth of about 2. 2 c o m p a r e d to 1. 75 f r o m S e r i e s B, t h e patch s t r e n g t h s being lower and the cylinder s t r e n g t h s higher than before.

CONCLUSIONS

Although not a c c u r a t e l y e s t a b l i s h e d by t h e s e r e s u l t s , t h e r e does a p p e a r t o b e a s t r e s s c o n c e n t r a t i o n effect v a r y i n g f r o m about 1. 5 t o 2, i n homogeneous m a t e r i a l r e s u l t i n g f r o m t h e u s e of a s q u a r e - edged c u t t e r t o i s o l a t e t e s t p a t c h e s . Modifications t o t h e c u t t e r p r o - file within the l i m i t s s e t by a 1/8 -in. width do not i n d i c a t e sufficient i m p r o v e m e n t t o justify t h e c o m p l i c a t i o n s introduced. T h e effect of t h e s t r e s s c,oncentrations will p r o b a b l y be t o r e d u c e t h e a p p a r e n t bond s t r e n g t h s obtained f o r t h e m o r e b r i t t l e p l a s t e r s m o r e t h a n f o r t h e l e s s b r i t t l e m a t e r i a l .

T h e r e s u l t s obtained a r e f o r a homogeneous m a t e r i a l with n o defined adhesion plane having s t r e n g t h s up t o 10 t i m e s t h o s e expected in a r e a l p l a s t e r s y s t e m . T h a t t h e s t r e s s c o n c e n t r a t i o n s shown will b e found in t h e c a s e of a thin putty coat r e l a t i v e l y weakly bonded t o a b a s e coat of d i f f e r e n t m a t e r i a l m a y b e questioned. T h e r e is r e a s o n , however, t o u s e a l l s u c h r e s u l t s with r e s e r v a t i o n , r e g a r d i n g t h e m not a s a c t u a l s t r e n g t h s but a s v a l u e s which a r e exceeded by the r e a l s y s t e m , b y s o m e i n d e t e r m i n a t e amount. T h e s e r e s u l t s i n d i c a t e t h a t p l a s t e r is

a t b e s t l i k e l y t o be quite v a r i a b l e in s t r e n g t h , s o t h a t a l a r g e n u m b e r of t e s t s a m p l e s should a l w a y s b e used.

T h e a s s i s t a n c e given b y G. Quenneville who m a d e a l l s a m p l e s a n d c a r r i e d out t h e t e s t s is g r a t e f u l l y acknowledged.

R E F E R E N C E S

1 R y d e r ,

J. F.

Methods f o r t e s t i n g t h e adhesion of p l a s t e r t o con- c r e t e . C h e m i s t r y and Industry, August 10, 1957, p. 1090-2. 2 O'Kelly, B. M. P o r t a b l e adhesion t e s t i n g device. M a t e r i a l sBulletin No. 250, A m e r i c a n S o c i e t y f o r T e s t i n g and M a t e r i a l s , D e c e m b e r

1960,

p. 3 2 - 3 .TABLE

I

SERLES A TESTS

- E F F E C T O F DEPTH AND CUTTER SHAJ?E

ON ADHESION TEST STRENGTHT e s t P a n e l s 1/2-in. B a s e Coat over P l a s t e r B a s e , 1/8-in. P u t t y Coat. C u t t e r s 1/8 in. Wide,

One S q u a r e End, One Rounded End.

Cutter Cut t o b a s e coat, lb 55 61 6 7 67 68 71 7 1 7 3 76 8 6 8 6 9 1 72. 7 Rounded Depth, in. 0 . 1 8 5 0. 19 0. 19 0. 20 0 . 2 1 0 . 2 1 0 . 2 2 5 0. 24 0. 26 0. 28 0. 29 0. 36 Depth, in. 0 . 2 1 0 . 2 2 0. 265 0. 31 0. 31 0 . 3 3 5 0 . 3 4 5 0 . 3 5 0. 35 0. 37 0. 38 0. 38 Avg S q u a r e End Load, lb 6 4 4 9 4 9 5 3 3 9 32 43 3 7 39 3 6 4 5 43 44. 1 End Cutter Load, Ib 7 6 67 53 55 6 4 5 8 5 7 52 5 1 43 43 27 53. 8 (1/16 in. r a d i u s ) Cut to b a s e coat, lb 55 57 62 6 4 66 67 68 7 3 74 76 82 8 2

-

68. 8TABLE I1

SERIES B TESTS

- LOADS AT FAILURE WITH VARIOUS

DEPTHS AND C U T T E R P R O F I L E S S h o r t C y l i n d e r s 1/2 in. 1 in. 7 60 8 0 4 8 40 8 36 7 28 9 6 7 7 0 6 6 5 6 7 38 4 4 4 7 5 4 7 4 1 C u t t e r A A% B Avg C Avg D Avg A2-in. Dia. P a t c h e s , Undercut

1/16 in. 48 8 599 512 422 69 1 5 46 49 2 560 5 18 440 563 515 46 4 5 8 2 600 5 30 7 8 6 59 2 47 9 6 0 1 576 570 706 586 Load, lb 1/8 in.

-680 399 48 0 37 1 562 498 46 0 442 376 47 1 40 1 430 560 55 1 49 9 447 49 1 510 56 2 507 56 1 57 3 646 57 0 1/4 in. 460 43 3 37 3 39 2 45 2 42 2 5 4 1 440 4 1 4 398 5 3 5 46 6 6 5 2 316 367 47 1 43 6 448 4 5 0 50 5 509 47 1 529 49 3TABLE 111

SERIES C

- TESTS WITH SQUARE -CUT PATCHES

AND 1 / 2 -IN. CYLINDERSNote: Cylinders f r o m Slab 2 failed p r e m a t u r e l y a t glue joints. Slab 1 1/2 -in. Cylinder s B r e a k i n g Load, lb 7 6 2 7 7 0 9 0 0 708 8 6 4 9 0 0 9 18 7 9 0 7 0 7 79 2 8 11 Slab 1 P a t c h e s Breaking Load, Ib 29 6 337 3 2 4 298 3 14 4 58 46

o

42 0 49 0-

Avg 377 Slab 2 P a t c h e s Breaking Load, l b 2 3o

2 6 0 2 6 6 422 460 3 50 49 6 236 370-

343N E T UPWARD

FORCE

-7

AIR

=I

INLET

Rl NG

I S O L A T E D P L A S T E R

S A M P L E

SECTION THROUGH ADHESION TESTING DEVICE

t

r

ALUMINUM DISC ADHESIVE ISOLATING CUT1

7 PUTTY COAT( 0 ) TESTING OF PATCHES FROM 2-COAT SYSTEM, SERIES A TESTS

r

DEPTH OF CUT BASED ON IPARALLEL PORTION, X = I/;, I/;,

'1; OR I" PLASTER CYLINDER GLUED

BETWEEN 2 DISCS

(c)

SHORT CYLINDER SPECIMENS EMPLOYED IN SERIES8 8 C TESTS

FIGURE 2

DETAILS OF TEST SPECIMENS

I

I

I

4

CYLINDERS SERIES C, SLAB

L

-

I"

CYLINDERS SERIES B

I"

-

-

-

-

-

-

SERIES B

-

PATCHES

B

FOR VARIOUS

C

CUTTER PROFILES

A

SEE FIG 2 ( b )

1

1

-

I-

SERIES C

-

PATCHES

,SLAB

2 x

'/;WIDE CUTTER

I/:DEEP, PROFILE A

-

-

-

-

-

-

I

.

DEPTH OF PARALLEL CUT, IN

FIGURE

3

RESULTS OF SERIES B AND C TESTS ON PATCHES AND CYLINDERS

Appendix A

CALIBRATION O F P O R T A B L E ADHESION TESTING DEVICE

T h e p o r t a b l e a d h e s i o n t e s t i n g d e v i c e w a s c a l i b r a t e d o r i g i n a l l y in a 1 2 , 0 0 0 - l b u n i v e r s a l t e s t i n g m a c h i n e with low r a n g e s of 120 and 600 Ib, known t o b e ' r e a s o n a b l y a c c u r a t e . T h e p r e s s u r e gauge u s e d t o

m e a s u r e a i r p r e s s u r e w a s u n c a l i b r a t e d s o t h a t t h e c a l i b r a t i o n c u r v e obtained f o r t h e d e v i c e w a s given in t e r m s of t h e gauge p e r f o r m a n c e a t t h e t i m e of c a l i b r a t i o n . It cannot b e j u s t i f i e d t h e r e f o r e t o d r a w c o n - c l u s i o n s f r o m t h e o r i g i n a l c a l i b r a t i o n c u r v e about t h e l i n e a r i t y of r e s p o n s e o r t h e c o r r e s p o n d e n c e with c a l c u l a t e d v a l u e s b a s e d on known m e m b r a n e a r e a s . Subsequent u s e of t h e m e m b r a n e d e v i c e on t w o - c o a t p l a s t e r s y s t e m s e m p l o y e d t h e s a m e p r e s s u r e gauge ( 1 5 p s i r a n g e ) a n d r e s u l t s w e r e c o n v e r t e d t o pounds p e r p a t c h o r t o p s i b a s e d on p a t c h a r e a u s i n g t h e o r i g i n a l c a l i b r a t i o n . S t r e n g t h s obtainc:d did not r e q u i r e t h a t t h e

gauge l i m i t of 15 p s i b e exceeded. In t h e w o r k c o v e r e d in t h i s r e p o r t , h o w e v e r , c o n s i d e r a b l y h i g h e r s t r e n g t h s w e r e e n c o u n t e r e d , r e q u i r i n g a i r p r e s s u r e s up t o 60 p s i t o p r o d u c e f a i l u r e . Unfortunately, o t h e r a i r

-

p r e s s u r e g a u g e s of a h i g h e r r a n g e w e r e s u b s t i t u t e d i n i t i a l l y , without r e c a l i b r a t i o n . F u r t h e r , i t had not b e e n e s t a b l i s h e d t h a t t h e m e m b r a n e s in t h e a d h e s i o n device w o i l d s u c c e s s f u l l y w i t h s t a n d t h e s e h i g h e r p r e s s u r e s without slipping o r s t r e t c h i n g t h a t m i g h t i n t r o d u c e v a r i a t i o n s in t h e m e a s u r e d loads. S e v e r a l s t e p s h a d t o b e t a k e n t h e r e f o r e t o r e - e s t a b l i s h valid c a l i b r a t i o n c u r v e s f o r s o m e w o r k t h a t had a l r e a d y b e e n c o m p l e t e d , a s well a s f o r t h e w o r k in hand. A f u r t h e r r e f i n e m e n t had a l s o t o b e i n t r o d u c e d . It w a s s u s - p e c t e d t h a t t h e position of t h e floating p l a t e s c l a m p e d t o t h e m e m b r a n e s r e l a t i v e t o t h e body of t h e a d h e s i o n d e v i c e m i g h t a f f e c t t h e c a l i b r a t i o n , i. e. v a r i a t i o n s in i n i t i a l d i a p h r a g m d i s t o r t i o n m i g h t influence r e s u l t s . T h i s p o s i t i o n i s defined and r e p r o d u c e d b y t h e d e v i c e i t s e l f when it i s u s e d on a flat p l a s t e r s u r f a c e , but not when i t i s r i g g e d f o r c a l i b r a t i o n , u n l e s s t h i s is s p e c i f i c a l l y a r r a n g e d . A jig t o which t h e floating plate position in n o r m a l u s e could b e r e f e r e n c e d w a s t h e r e f o r e c o n s t r u c t e d and r e p r o d u c e d a c c u r a t e l y when t h e d e v i c e w a s p l a c e d in t h e t e s t i n g m a c h i n e f o r c a l i b r a t i o n . It w a s not thought t h a t a n y d i s p l a c e m e n t f r o m t h i s i n i t i a l p o s i t i o n r e s u l t i n g f r o m t h e e l a s t i c i t y of t h e t e s t i n g m a c h i n e weighing s y s t e m a s a i r p r e s s u r e w a s a p p l i e d t o t h e m e m b r a n e s , t h u s i m p o s i n g l o a d on t h e t e s t i n g m a c h i n e d u r i n g c a l i b r a t i o n , would i n t r o d u c e a n y significant e r r o r . T h e a d h e s i o n device u s i n g t h e 60-lb gauge w a s t h e n c a l i b r a t e d in t h e t e s t i n g m a c h i n e without a n y change in t h e m e m b r a n e s . T h i sc a l i b r a t i o n could not b e c o m p a r e d e x a c t l y with t h e p r e v i o u s one u s i n g t h e 15-lb gauge a s t h e s e g a u g e s t h e m s e l v e s w e r e not c a l i b r a t e d , but gave

approximately the s a m e slope. T h e adhesion device showed a s a t i s - f a c t o r i l y l i n e a r and reproducible c a l i b r a t i o n c u r v e t o provide a s s u r a n c e t h a t the new calibration could be used s a t i s f a c t o r i l y to convert r e s u l t s obtained with the 6 0 -1b gauge.

After t h e work in hand using the 6 0 -1b gauge had been c o m -

pleted, the adhesion device was r e c a l i b r a t e d , using the 15-lb gauge. T h e original calibration c u r v e w a s not reproduced, t h e l o a d s obtained being about 8 p e r cent higher for t h e s a m e gauge p r e s s u r e s a s before. It i s now believed that t h i s c a l i b r a t i o n was faulty. Upon c a r e f u l r e - calibration following r e p l a c e m e n t of the diaphragm, using the original 15 -1b gauge, t h e original calibration c u r v e w a s r e p r o d u c e d t o within 1 p e r cent.

It h a s not yet been established t h a t the m e m b r a n e s can always be used r e l i a b l y a t a i r p r e s s u r e s up t o 6 0 psi.