Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Institute for Research in

Construction), 1987

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=d27878fd-65cb-46b3-ae91-8eef290a2420 https://publications-cnrc.canada.ca/fra/voir/objet/?id=d27878fd-65cb-46b3-ae91-8eef290a2420

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001393

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The normalized heat load concept and its use

Harmathy, T. Z.; Mehaffey, J. R.

Ser THl

N21d

National Research

Conseil national

LO.1474

$1

c

ouncil Canada

de recherches Canada

c. 2

B L E

Institute for

lnstitut de

- - -.Research in

recherche en

Construction

construction

,.

The Normalized Heat Load

Concept and its

Use

by

T.Z. Harmathy and J.R. Mehaffey

Reprinted from

Fire Safety Journal

Vol. 12, No. 1, 1987

p. 75

-

81

(IRC Paper No. 1474)

Price $3.00

NRCC 28005

Les auteurs Etudient l'utilit6 du concept de la charge

thermique normalisEe pour comparer la performance d'une

construction donnEe lors d'un incendie rEel et d'un feu

provoqu6. 11s montrent que ce concept est valable quelles que

soient les dimensions et la gEom6trie de la construction, et

soutiennent que les erreurs provenant du comportement non id6al

des mat&riaux de construction

3des tempgratures 6levEes ont de

bonnes chances de s'gliminer lors de la comparaison.

Fire Safety Journal, 12 ( 1 9 8 7 ) 75

-

81The Normalized Heat Load Concept and its Use

T . Z. HARMATHY and J. R. MEHAFFEY

National Research Council of Canada, Institute for Research in Construction, Ottawa, Ontario K I A O R 6 (Canada)

(Received October 29, 1986 ; in revised form February 1 9 , 1987)

SUMMARY

The utility of the normalized heat load in comparing the performance o f a given con- struction in real-world and test fires is exam- ined. It is shown that the concept is valid regardless of the dimensions and geometry of the construction, and argued that the errors arising from the non-ideal behaviour

of building materials at elevated tempera- tures are likely to cancel out in a compar- ison.

INTRODUCTION

Although the normalized heat load concept has been known for several years [ I , 21, its application t o the assessment of fire resis- tance requirements has not yet been fully explored. The purpose of this paper is t o elaborate, based on newer studies, on the utility of the concept.

THE NORMALIZED HEAT LOAD CONCEPT

The normalized heat load is the total heat absorbed by a unit area of the bound- aries of an enclosure during any fire (real- world fire or test fire), divided by the ther- mal absorptivity (or thermal inertia) of the boundaries. In mathematical formulation,

where H (s1I2 K) is the normalized heat load;

6

(J mP2 sP1I2 KP1) is the thermal ab-sorptivity (thermal inertia) of the boundaries ( k is thermal conductivity, p is density, and

c is specific heat); q (W mP2) is the heat flux

that penetrates the boundaries, t (s) is time,

and T (s) is the duration of fire exposure

(more exactly, the duration of heat penetra- tion).

The normalized heat load has three impor- tant characteristics:

(a) H is a measure of the maximum tem- perature rise at a certain depth from the surface of the enclosure boundary, and that depth is roughly where in conventional compartment boundaries the important load- bearing components are located [ I , 31.

(b) It follows from (a) and the definition

of H that the maximum temperature does

not depend on the temporal variation of

the heat flux that penetrates the enclosure

boundary [3]. Consequently, as long as two

fires are characterized by the same value of H, it does not depend on the temperature history of the two fires.

(c) If the boundaries of the enclosure are

made from different materials, H is (approx-

imately) the same for all boundaries, and in addition, for the enclosure as a whole. (This statement is usually referred t o as the theo- rem of uniformity of normalized heat load

[21.)

To save the reader the task of looking up references, the mathematical formulations of characteristics (a) and (c) are presented below.

The correlation between the maximum

temperature rise at a point a in the bound-

ary element and the normalized heat load is [I]:

provided that

where a (m) is the depth of the point from the boundary surface, K (m2 s-') is the ther-

mal diffusivity of the boundary,

T,,,

(K) is the maximum temperature reached at the distance a, andTo

(K) is the initial tem- perature of the enclosure boundary. Equa- tion (2) makes it possible to evaluate the normalized heat load from experimentally determined values of temperature rise.The theorem of uniformity of normalized heat load is as follows:

where 1

JhTpc=

- E A i = i A iand

The subscripts refer t o information pertaining to the i-th boundary element, and A (m2) stands for the boundary surface area (for the total enclosure or, with subscript i, for the i-th boundary element).

THE UTILITY OF THE NORMALIZED HEAT LOAD CONCEPT

The term "equivalent fire exposure" has been adopted to quantify the destructive potential of real-world fires in terms of fire resistance, in other words, in terms of time to failure in standard fire tests. Law [4], Petterson [ 5 , 6 ] , and a German group [7] have developed empirical techniques for the calculation of that quantifier. The prin- cipal value of the normalized heat load concept is that, based on theoretical insight and experimental support, it now offers a reasonably accurate and comprehensive tech- nique for the calculation of equivalent fire exposure.

Since (according t o characteristic (b)), the normalized heat load does not depend directly on the temperature history of the fire, the important load-bearing components (e.g., reinforcing steel bars) in a building element will (according t o characteristic (a)) experience the same maximum temperatures in any two fires that are quantified by the

same normalized heat load. One of these fires may be a real-world compartment fire, the other a standard test fire*.

For real-world compartment fires (of mainly cellulosic fire load), the normalized heat load, H ' (and other process variables of the fire), can be determined by an iterative procedure [B] based on first principles. It can also be approximated by the following semi-empirical equation [ 9 ]

**

:where

6 = \ 0.79

Jm

whichever is less1 (8)

and Q (kg s-') is the ventilation parameter defined as

In eqns. (7)

-

(9), AF (m2) is the floor area of the compartment, L (kg m-2) is the fire load,A v

(mZ) is the area of ventilation opening (window, door),h,

(m) is the height of the compartment,hv

(m) is the height of the ventilation opening, pa (kg m-3) is the den- sity of air entering the compartment, and g (m sK2) is the gravitational constant.For standard test fires, because of the uniqueness of the test conditions, the nor- malized heat load, H", depends (as a first approximation) on a single variable: the duration of the test fire, T" (h). For the Na-

tional Research Council Canada (NRCC) floor test furnace, the following equation is applicable :

T" = 0.11

+

0.16 X ~ o - ~ H "+

0.13 X I O - ~ ( H " ) ~ (10)*The normalized heat load concept cannot be applied to building elements containing important load-bearing components in, or in the immediate vicinity of, the fire-exposed surface. For example, it cannot be applied t o unprotected steel. On the other hand, the validity of the concept in comparing the detrimental effects of real-world fires and test fires on load-bearing components can usually be extended well beyond the o = 1.2

.\/;;;

limit (see eqn. ( 3 ) ) for reasons t o be discussed in the last Section.**It has been found from a series of full-scale experi- ments [lo] that the values of H' calculated from eqns. ( 7 ) - ( 9 ) are, on average, 5.8% lower than the experimental values, and the coefficient of variation for the error is 10.1%.

(This equation, for practical reasons, de- scribes T" as a function of H", rather than

H" as a function of T".) For other test fur- naces the constants in this equation may be slightly different, depending on the efficiency of the furnace [ I

11.

If a specimen of a building element success-

-

fully withstands the standard test fire for atime T", then T" is regarded as the fire resis-

-

tance of that building element. Clearly, the equivalent fire exposure or (what means essentially the same) the fire resistance requirement is obtained by substituting in eqn. (10) H ' (calculated by employing eqn.

(7)) for H".

Since the normalized heat load concept has been based on studies of one-dimensional heat flow into semi-infinite solids with con- stant thermal properties, some researchers have questioned its general applicability. The rest of this paper will deal with that question.

THE EFFECT OF FINITE THICKNESS

In the case of slab-like building elements (walls, floors, etc.), one would expect that the thinner the slab and the higher its ther- mal absorptivity, the larger the error com- mitted by picturing it as a semi-infinite solid. From numerical studies of heat flow through slabs of various thicknesses and thermal absorptivities (performed in the authors' laboratory), it appears, however, that under practical conditions the error is hardly notice- able. For example, the studies have shown that for a concrete slab as thin as 40 mm (an unlikely dimension for a building element) at .a 20-min standard fire exposure (the approximate fire resistance of the slab), the error is about 1%. Clearly, for thicker slabs the error is even less.

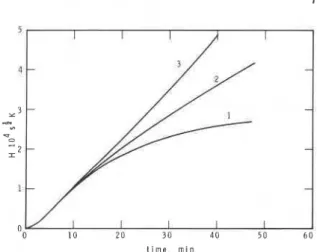

If a building element consists of layers of various materials, the layer exposed to fire is

of principal importance [12]. Figure 1 shows

the calculated history of normalized heat load in test fires for three walls lined with a 13-mm plaster board. The following cases are illus-

trated: curve 1 - the wall is a perfect insula-

tor; curve 3 - the wall is a perfect conductor;

curve 2 - the wall is made from the same

material as the lining (plaster). (To facilitate the calculations, the thermal properties of

l i m e , m i n

Fig. 1 . Normalized heat load in a standard test fire for a wall lined with a 13-mm plaster board. Curve 1

- wall is a perfect insulator; curve 2 - wall is plaster; curve 3 - wall is a perfect conductor.

plaster were regarded as constant; the heat of dehydration of plaster was added t o its spe- cific heat.)

The Figure shows that for a period of about 1 8 min the nature of the wall behind the surface plaster layer has hardly any effect on the normalized heat load. Consequently, for short fires (fuel-surface-controlled fires, in general, for which the duration is about 20 min [13]), only the lining material needs t o be considered in selecting the thermal absorptivity for the compartment bound- ary. For ventilation-controlled fires, the designer may use judgment in choosing the effective value of the thermal absorptivity, slightly below or above the thermal absorp- tivity of the surface layer, depending on the nature of the substratum.

THE EFFECT OF NON-CONSTANCY OF MATE- RIAL PROPERTIES

The normalized heat load concept was developed from studies of idealized solids with constant thermal properties (thermal absorptivity, thermal conductivity, density and specific heat). The question is whether it is permissible t o regard these properties as constants when dealing with real-world building materials, the properties of which are dependent on the temperature and per- haps on some other factors.

Among the material properties that may affect the accuracy of the calculation results, the "apparent" specific heat [14] is the most

troublesome. It includes the heats associated with possible physicochemical changes that occur in the material on heating, such as chemical reactions, thermal decomposition, and changes in the crystalline structure.

If the material is porous (and most non- metallic building materials indeed are), it contains some moisture either adsorbed t o the pore surfaces or in the form of capillary water. In simpler heat flow models [15] only the heat of desorption of moisture is considered, by adding it t o the apparent specific heat. Yet, moisture is a mobile com- ponent of the material, and the convective heat transmission effected by its movement in the pores (both in adsorbed and gaseous phases) is a very complex phenomenon

[161.

To take account of the nonconstancy of the thermal properties and moisture migra- tion, the calculation of the normalized heat load would require the use of some numer- ical follow-up techniques. One should re- member, however, that the practical utility of the normalized heat load concept is re- lating the performance of a given construction in a real-world fire t o its performance in a standard test fire. In doing so, it is a fair assumption that some factors (e.g. the pres- ence of moisture, the nonconstancy of thermal properties) not taken into account in calculating the normalized heat loads for the two fires, H ' and H", will lead t o errors of similar magnitude and thus cancel out when H' = H".

The reader is reminded that the H ' = H"

condition implies, according t o characteristic (a), the approximate equality of temperature ranges reached inside the building element during the real-world fire and the test fire.

THE EFFECT O F NON-ONE-DIMENSIONAL HEAT FLOW

It may be useful t o recall at this point the general conclusions reached in the original study [3] that led t o the normalized heat load concept. That study was related t o a semi-infinite solid penetrated by a heat flux

Q (W m-2) for a period T (s). After that period

the solid was allowed t o cool. Using dimen- sional analysis, a large number of computer- generated results were correlated by an equa-

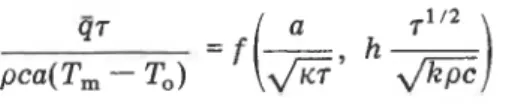

tion of the following form :

where h (W mP2 K-l) is the heat transfer

coefficient of cooling after the heat penetra-

tion has ceased. (a@, the inverse square

-

root of the Fourier number, is used instead of the Fourier number, because it offers

some advantages in plotting the correlation.)

..

Based on a series of numerical heat flow

studies, a plot of Q~/pca(T, - To) against

was prepared, with h ~ " ~ / @ as parameter. The plot (see Fig. 2 in ref. 3)

showed that within the range of a / given

in eqn. (3), ij~/pca(T,

-

To) was approxi-mately constant, equal t o 2.3, and thus independent of the rate of cooling after the cessation of heat penetration (i.e., inde- pendent of the group h?'12/ m e ) .

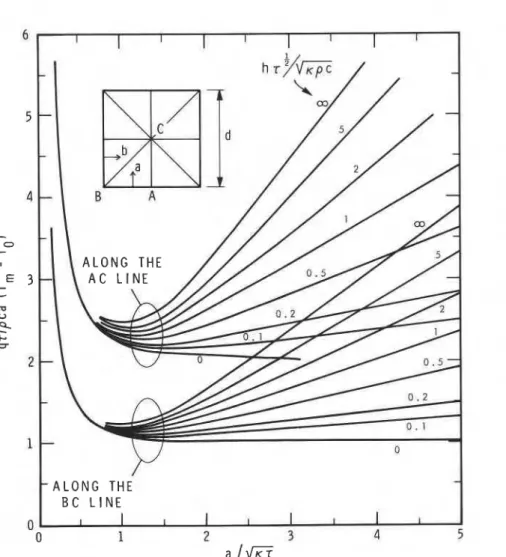

To demonstrate that an equation of the form of eqn. (11) is applicable t o geomet- rical configurations in which the heat flow is markedly non-one-dimensional, a new series of numerical studies has been con- ducted on square columns, using a finite

difference scheme [17]. The number of

geometric variables needed t o define the heat flow problem is now three: a and b (m), the coordinates of the point at which the temperature rise is monitored, and d (m), the side dimension of the column (see insert in Fig. 2). Hence two other dimensionless groups will appear in eqn. ( l l ) , which may be conveniently chosen as a/d and bld.

In all studies d was chosen as 0.305 m,

while the group Q ~ / p c was selected t o vary

withih the range 4.72 and 36.4 mK, and the

group h?l12/

@

between 0 and infinity.The calculation results have been correlated

in the usual fashion, Q~/pca(T,

-

To) againsta /

@,

with h ~ l ' ~ / as parameter.Figure 2 is a sample plot. It shows two farn-

ilies of curves: one (the upper) for a varying

along the line AC (at which b = d/2, see the

Figure), and another (the lower) for a varying

along the diagonal, line BC (at which a = b).

It is interesting t o note that for the range

of a/

fl

given in eqn. (3), Q~/pca(T,-

To)can be again regarded as approximately constant.

- A L O N G THE

-

B C L I N E0 I I I

I

I I II

I0 1 2 3 4 5

a

Fig. 2. Dimensionless presentation of the maximum temperatures attained in a square column at points located on lines AC and BC (d = 0.305 m, i j r l p c = 7.16 mK).

For a varying along the diagonal, line BC,

Equation (12) can now be rearranged into

the form of eqn. (2), and eqn. (13) into the

following form :

As in previous studies, the nonconstancy of the heat flux penetrating the solid has also been examined. It has been confirmed that,

within reasonable limits (see ref. 3), the

variation of q does not affect the validity of eqns. (2) and (14). This finding, in turn, confirms that the normalized heat load does not depend on the temporal variation of the heat flux or, what means the same thing, on the nature of the variation of the fire tem- perature; thus the normalized heat load con-

cept can be applied t o real-world fires as well

as test fires.

From a comparison of eqns. (2) and (14) it is clear that the normalized heat load is indeed a measure of the maximum tempera- ture rise at some critical depth in the con- struction, regardless of the surface geometry of the building element. The actual value of the maximum temperature rise is, of course, dependent on the surface geometry. It is (at identical values of H) higher at a location below a rectangular comer than at a location below a plane surface. The reader is reminded, however, that the utility of the normalized heat load is in allowing the comparison of the performance of a given building element in two different fires (one real-world fire and the other test fire); the normalized heat

load is not a failure criterion.

With square columns, under certain con- ditions, namely at high values of the group

i j ~ / p c and small values of d, eqns. (12) and (13), and hence eqns. (2) and (14), may not be valid. This may be the case if the heat flow that feeds the temperature rise arrives not only from the sides closest t o the point but also, t o a not-negligible extent, from the opposite sides of the column. (A slight decline of the curve for the points on the AC line for h?'12/ @c = 0 (Fig. 2) beginning at a l f i

--

2 reflects this effect.) It is, how- ever, only with very slim columns and very high values of q ~ / p c that the presence of heating from the opposite surfaces of the column may be noticeable within the range of validity of eqns. (2) and (14), i.e. within the 0.8 t o 1.2 range of a /fi.

SOME FURTHER REMARKS

As Fig. 2 shows, the Sj~/pca(T, -To) versus curves start fanning out at a / @ ~

=

1.2, on account of the h r 1 1 2 / m group. The magnitude of this group for a given type of building element depends primarily on h, the heat transfer coefficient of cooling after the cessation of fire expo- sure (i.e., heat penetration). One can expect, however, that h will be of the same order of magnitude for real-world fires and test fires, and therefore the value of the group h7ll2/@

will differ by no more than a factor of 3. Figure 2 shows that up t o a l f i=

2 the fanning out of the curves is not too significant, and therefore, Q~/pca(T, --To) can be taken as roughly the same for two fires characterized by moderate differences in the hr112/@c group. For example, at a/t/K7"--

2 for the range 0.2<

hr112/<

1.0 (along the AC line),After rearrangement, this equation gives

Thus, even though a / @ is larger than the upper limit in eqn. (3), the practice of using the normalized heat load for comparing the detrimental effect of two fires (such as a real-world fire and a test fire) will lead (in the case discussed) to an error not larger

than (0.18/2.45) X 100 = 7%. (Naturally, if a / f i

>

1.2, eqn. (2) is not suitable for the evaluation of the normalized heat load from experimentally determined values of the temperature rise.)CONCLUSIONS

The utility of the normalized heat load concept has been reviewed. I t has been shown that the concept provides a convenient way of comparing the performance of given building elements in real-world fires and in test fires, irrespective of the geometry and dimensions of the construction and the non-ideal behaviour of the materials on heating. In the case of layered constructions, the properties of the layer exposed t o fire are of dominating influence.

LIST O F SYMBOLS

a depth of a point from the surface of the solid or one of the coordinates (m)

b second coordinate (m)

A surface area; without subscript: sur- face area of compartment (m2) &? gravitational constant (m s - ~ ) h height (m)

H normalized heat load (s'12 K)

H' normalized heat load in a real-world fire (s'12 K)

H"

normalized heat load in a test fire (s l2 K)k

thermal conductivity (W m-' K-')fit

thermal absorptivity (thermal inertia)( J m-2 K-l )

L fire load (cellulosic) (kg mP2)

4 heat flux penetrating the building element (W mP2)

G'

time- and surface-averaged heat flux penetrating the building element (W mP2)t time (s)

T temperature (K) Greek symbols

6 factor, defined by eqn. (8)

K thermal diffusivity (m2 s-l) P density (kg m-3)

duration of fire exposure in standard test (h)

ventilation parameter (kg s-') Subscripts

a of air entering the compartment

r

c of compartment enclosure

F of floor

i

pertaining t o the i-th surfacem maximum

o initial

V of ventilation opening

R E F E R E N C E S

1 T. Z. Harmathy, Fire Mater., 5 (1981) 112. 2 T. Z. Harmathy and J. R . M e h a f f e y , Fire Mater.,

6 (1982) 27.

3 T. Z. Harmathy, Fire Mater., 4 (1980) 71. 4 M. L a w , A Relationship B e t w e e n Fire Grading

and Building Design and Contents, Fire Res. N o t e N o . 8 7 7 , J F R O , 1971.

5 0. Pettersson, T h e Connection B e t w e e n a Real Fire Exposure and t h e Heating Conditions A c - cording t o Standards Fire Resistance Tests -

W i t h Special Application t o Steel Structures, CECM-III-74-2E, European Convention f o r C o n - structional Steelwork, 1974, Chap. 11.

6 Design Guide Structural Fire S a f e t y , W o r k s h o p C I B W14, Chapter 4, Fire S a f e t y J., 1 0 (1986) 89.

7 DIN 18230, Structural Fire Protection i n Indus- trial Building Construction; Part 1 : Required Fire

Resistance Period; Part 2: Determination o f t h e Burning Factor m ; A p p e n d i x 1 t o Part 1: Calo- rific Values and m-factors. Draft i n manuscript f o r m , March 1978.

8 T . Z . Harmathy, Fire severity: basis o f fire s a f e t y design, i n M. S. Abrams ( e d . ) , Fire S a f e t y o f Concrete Structures, Publication SP-80, American Concrete Institute, Detroit, 1983, p. 115. 9 J . R . M e h a f f e y and T . Z . Harmathy, Fire Tech-

nol., 1 7 (1981) 221.

10 J. R . M e h a f f e y and T . Z . Harmathy, Thermal Response o f C o m p a r t m e n t Boundaries to Fire, i n C. E. Grant and P. J . Pagni (eds.), Proc. First International S y m p o s i u m o n Fire S a f e t y Science, Hemisphere Publ. Co., Washington, DC, 1986,

p . 111.

11 M. A. Sultan, T . Z . Harmathy and J. R . M e h a f f e y , Fire Mater., 1 0 (1986) 47.

12 M. V . G r i f f i t h and G . K . Horton, Proc. Phys. Soc., 5 8 (1946) 481.

13 T. Z. Harmathy, Fire Technol., 8 (1972) 196, 326.

14 T. Z. Harmathy, Properties o f building materials: bases f o r fire s a f e t y design, i n R. D. Anchor, H. L. Malhotra and J. A. Purkiss (eds.), Design o f Structures Against Fire, Elsevier Appl. Sci. Publ., Barking, 1986, p. 87.

15 T. Z. Harmathy, A treatise o n theoretical fire endurance rating, Fire T e s t Methods, A S T M S T P 3 0 1 , American Society f o r Testing and Materials, Barking, 1986, p. 87.

16 T. Z. Harmathy, I&EC Fundamentals, 8 (1969) 92.

17 T. T . Lie and T . Z . Harmathy, A Numerical Pro- cedure t o Calculate t h e Temperature o f Protected Steel Columns Exposed t o Fire, Fire S t u d y N o . 28, N R C C 12535, Division o f Building Research, National Research Council o f Canada, 1972.

T h i s paper i s being d i s t r i b u t e d i n r e p r i n t form by t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n . A l i s t of b u i l d i n g p r a c t i c e and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r Research i n C o n s t r u c t i o n , N a t i o n a l Research C o u n c i l o f C a n a d a , O t t a w a , O n t a r i o , KIA OR6.

C e document e s t d i s t r i b u g sous forme de t i r 6 - 3 - p a r t p a r 1 ' I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n . On p e u t o b t e n i r une l i s t e d e s p u b l i c a t i o n s de 1 ' I n s t i t u t p o r t a n t s u r l e s t e c h n i q u e s ou l e s r e c h e r c h e s e n m a t i e r e d e bdtiment e n S c r i v a n t