OATAO is an open access repository that collects the work of Toulouse

researchers and makes it freely available over the web where possible

Any correspondence concerning this service should be sent

to the repository administrator:

tech-oatao@listes-diff.inp-toulouse.fr

This is an author’s version published in:

http://oatao.univ-toulouse.fr/25156

To cite this version:

Brunet, Magali and Malard, Benoît

and Ratel-Ramond, Nicolas and

Deshayes, Christophe and Joulié, Sébastien and Warot-Fonrose, Bénédicte and

Sciau, Philippe and Douin, Joël and De Geuser, Frédéric and Deschamps,

Alexis Precipitation in original Duralumin A-U4G versus modern 2017A

alloy. (2019) Materialia, 8. 100429. ISSN 2589-1529

Precipitation in original Duralumin A-U4G versus modern 2017 A alloy

Magali Brunet

a,

*

, Benoit Malard

b, Nicolas Ratel-Ramond

a, Christophe Deshayes

a,

Sébastien Jouli

e

, Bénédicte Warot-Fonrose

a, Philippe Sciau

a, Joël Douin

a, Frédéric De Geuser

c,

Alexis Descham ps

c• CEMES, CNRS, UniYemti de Toulouse, 29 rue Jeanne MIJJ'Vi& BP 94347 31055 Toulouse Cedex 4, Fronce • CIRIMA T, TNP Toulouse, CNRS, 4 aHé.e Emile Manso, 31030 Toulouse, France

• UniYemté Grenoble Alpes, CNRS, Grenoble TNP, SJMoP, F-38000 Grenoble, France

ARTICLE INFO ABSTRACT

Keyword.s: Duralumin Al-Co-Mg-Si alloy Predpitation SAXS STEM-HMDF

Precipitation in Duralumin, a historie quatemary alloy of the type: Al-Cu-Mg-Si, was never fully studied nor observed bycurrentelectron microscopytechniques. This article presents the full characterization and comparison of two alloys: a Duralumin (A-U4G) from the 19SOs collected on a vintage aircraft and its modern equivalent: a 2017 A alloy. The as-received and peak-aging states were analysed with DSC, SAXS and TEM advanced techniques. It is shown that old Duralumin and modern 2017A present a similar nanoprecipitation in the as-received state and behave similarly upon artificial aging. As opposed to what has been reported in the past, three types of precipitates participating in hardening were found upon aging: 8'-Al2Cu, Q'(Q)-AICuMgSi and Q-Al2Cu.

1. Introduction

Duralumin, with a composition close to 4 Cu 0.7 Mg 0.6 Mn 0.6 Si wt°/4, is the oldest age hardening aluminium alloy. Discovered in 1906 by Alfred Wilm, a German metallurgist [1], it triggered the develop ment of aeronautics at the beginning of the XXth century. At the sci entific and technical research centre in Neubabelsberg, Wilm experi mented many treatments on Al Cu Mn alloys with small amounts of magnesium (0.5 wt%). He found out that by quenching from tempera tures below its melting point (about 450'C) and by letting it age natu rally for a few days, the new alloy exhibited enhanced mechanical prop erties (strength and hardness). Thanks to its low density and strength, Duralumin soon became the prime choice for airplanes construction, well illustrated by the airplane Breguet 14 whose production reached 12,000 during World War I [2]. From then on, aircraft production, pre viously a craftsmen business, transformed into a real industry. Following on this discovery and for reaching even higher performance, metallur gists in the 1920s tuned aluminium alloys via the addition of microal loying elements. This was done empirically, as no explanation could yet be provided for the age hardening phenomenon. Merica et al [3] were the first team in 1929 to explain that the hardening during aging of du ralumin was due to fine and highly dispersed Al2Cu precipitates. But the concept of dislocation, essential to a complete understanding of the structural hardening mechanism, was introduced by Orowan in 1934 [4]. The discovery of coherent copper rich zones in the Al Cu 4% al loy was achieved independently by Guinier [5] and Preston [6] with X ray experiments in 1938. lt took even longer to be able to observe

• Corresponding author.

E-mail address: magali.brunet@cemes.fr (M. Brunet).

directly the nanoprecipitates responsible for the hardening: first obser vations were made on oxide replicas in France in 1952 by Saulnier and

Syre [7].

Original Duralumin was thus improved experimentally by increas ing the magnesium content (up to 1.5wt%), leading to a new alloy, called Duralumin FR in France in the early 1930s [8]. Duralumin and Duralumin FR became A U4G and A U4Gl respectively in 1943, to fol low a new designation defined by AFNOR1 [9]. From the 1930s to the 1950s, because of its lack of strength and ductility, A U 4G was replaced gradually in aeronautics construction by A U4Gl. ln 1954, international standardization of aluminium alloys took place [10]: the numerical des ignation with 4 numbers was adopted. A U4G was designated as 2017 A and A U4Gl as the well known 2024.

Original Duralumin has not received a major focus in the scientific literature related to the precipitation at nanoscale. ln fact, published works on the precipitation occurring in Duralumin and even on the modern 2017 A alloys are scarce. Original studies on the precipitation of industrial Duralumin were published in the 1950s. ln 1950, Lambot studied the precipitation of an industrial Duralumin by X ray abnor mal scattering [11]. ln accordance with results found by Guinier and Preston in Al Cu alloys, after quenching and room temperature aging, he detected scattering due to copper clusters or Guinier Preston Zones (GPZ). Then, upon aging at moderate temperatures, a first form of pre cipitates was evidenced, with a structure of three aluminium rich planes

1 Created in 1926, AFNOR is the French association for standardization.

Table 1

Elementalcompositionofalloys(inwt%)obtainedbyICP-OES.

Al Cu Mg Mn Si Fe Ti Zn Cr

2017A Base 4.32 ± 0.08 0.68 ± 0.01 0.611 ± 0.002 0.618 ± 0.006 0.34 ± 0.01 0.043 ± 0.001 0.20 ± 0.04 0.029 ± 0.003

A-U4G Base 4.18 ± 0.04 0.710 ± 0.005 0.67 ± 0.01 0.61 ± 0.01 0.285 ± 0.008 0.010 ± 0.001 0.082 ± 0.008 0.007 ± 0.0001

in between two copper richplanes. This phase evolved tothe well

distinguished𝜃’ Al2Cuphasewhenagingathighertemperatures.Other scatteringpatterns,superimposedtotheonesoriginatingfromAl2Cu precipitates,weredetected.TheywereattributedtotheAl4CuMg5Si4 phase.Thisphaseisexpectedatequilibriumstate,inalloysofMg/Si ratioslowerthan1.73[12].Twoyearslater,SaulnierandSyre[7]iden tifiedinasimilarindustrialDuralumin,thankstoelectronmicroscopy (usingoxidereplicas),thepresenceoftheso calledphaseX(renamed 𝜃’’later)afteragingat260°Cevolvingintothe𝜃’ Al2Cuphaseat290°C,

confirmingthefindingsofLambot.Anotherphasewasevidencedwith

thermaldilatometry.However,itwasattributedtoMg2Sineedles.In thiswork,theQ Al4CuMg5Si4phasecouldnotbeevidenced.Similarly,

YanoandKodain 1968[13], observedby transmissionelectronmi

croscopy(TEM),thepresenceofthe𝜃’ Al2CuandMg2SiphasesinDu ralumin.Morerecently,Härteletal.[14]studiedthe2017Aalloyand observedthe𝜃’phaseandanotherphase,ΩAlCu.However,theydidnot mentionthepresenceofQ AlCuMgSi,neitherMg2Si.Itistobenoted thoughthatthesiliconcontentwas,intheircase,verylow(0.08wt%).

Asshownhere,literaturedoesnotprovideaclearandcomprehensive

reportonprecipitationoccurringinDuralumin.

This article focuses on the observation and identification of the

metastablephasesandprecipitationsequencesoccurringinaDuralu

min(A U4G)of1958collectedonanoldaircraftandagedatambient

temperatureformorethan60years.Itwillbecomparedtoamodern

equivalent,the2017Aalloy.Whenlookingattheinternationalstan

dards[10],itisinterestingtonotethat,asopposedtotheA U4G1which

compositionissignificantlydifferentfromthemodernequivalent2024,

thecompositionofA U4G/2017Ahasbarelyevolvedovertime.Asthe

collectedDuraluminismorethan60yearsold,bycomparingits be

haviourandmicrostructuretothemodernequivalent,itisalsotheoc casiontostudylong termagingonthistypeofalloy.Thisconstitutesa firstmotivationforstudyingthisalloy.Thesecondmotivationisrelated toCulturalHeritage.Duraluminconstitutesmostoftheairplanes’fuse

lageandstructurebeforeandduringWorldWarII.Preciousspecimens

conservedinMuseumshouldbepreserved.Byunderstandinganddoc

umentingtheintrinsicconstitutionofthealloyanditsbehaviourover time,itwillbeeasiertoanticipateproblemssuchaslackofmechanical resistanceand/orcorrosion.

ThemicrostructureoftheA U4Gand2017Aindifferentstates,as

receivedandafterartificialaging,willbereportedhereafterbycom biningdifferenttechniques:conventionalbrightanddarkfieldTEM,se lectedareadiffractionpatterns(SADP),scanningtransmissionelectron

microscopycoupledwithenergydispersiveX rayspectroscopy(STEM

EDS),withhighangleannulardarkfield(HAADF)imagingorwithelec

tronenergylossspectroscopy(EELS),differentialscanningcalorimetry (DSC)andsmallangleX rayscattering(SAXS)experiments.Itisshown that,comparedtowhatcouldbeexpectedfromtheliteratureonquater

naryAl Cu Mg Sialloys[15,16]witharangeof2.5 4.5wt%ofcop

per,andaratioofMg:Sicloseto1orwhatwasobservedinthe1950s

and1960sonDuralumin[7,13],acomplexandspecificprecipitation

sequenceoccursinthesealloys.

2. Materialsandcharacterizationtechniques

2.1. Materials

ThestudiedalloyisaDuralumin,identifiedasA U4Gintheshapeof plate(about1mmthick)collectedonanaircraftfrom1958,aBreguet

Sahara765:thesamplewasextractedfromaflapofthelandinggear,

a partnotsubjectedtohottemperaturesrelatedtoengine proximity

(seeFig.S1ofsupplementaryinformation).Theequivalentmodernal

loy,ENAW 2017A(labelledhereafter2017A)wasboughtfromBikar

MetalleGmbH.ItwasreceivedinT4state.Ingeneral,for2017Aand

2024alloys,thestatesT3andT4arecommonforpartsoflowthickness (<12mm).Inthesestates,thealloyexhibitsagoodcorrosionresistance, ahightoughnessandagoodfatigueresistance[17].Theplatecollected ontheplanereceivedalsoaT4treatmentuponfabrication:itwasclearly mentionedintheBreguetstandards[18].However,forthisalloy,theas receivedstatecorrespondsinfact,toaT4stateplus10yearsofservice and50yearsinoutdoorsconditions.

For each alloy, the inductively coupled plasma optical emission

spectrometry (ICP OES) measurements, performed byEvans Analyti

cal GroupSAS,is reportedin Table1.It isconfirmedthatthecom

positionsaresimilar.Currently,2017Acontainssomezincwhereasold

versionof thisalloydoesnot.TheratiosMg:Siare1.1and1.16for

2017AandA U4G,respectively,whichcorrespondtoreportedvaluesfor Duralumin[7].

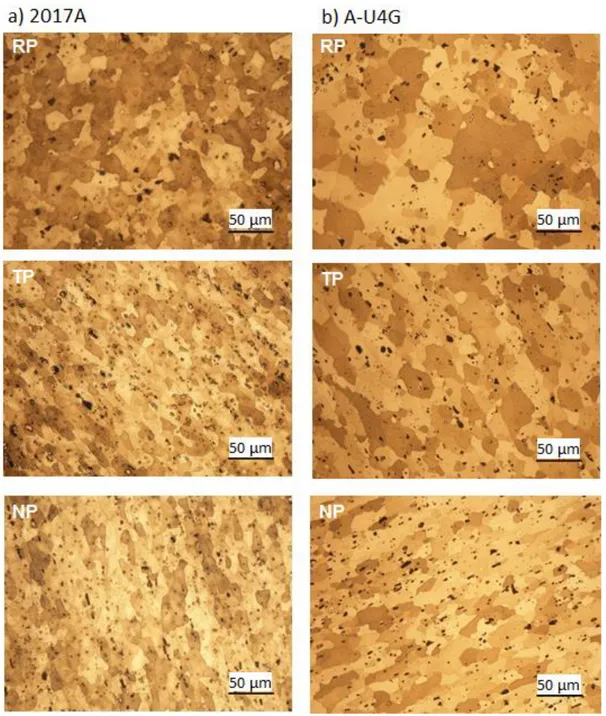

Forthestudyofhardeningprecipitation,twostateswerecompared:

as received andpeak agingconditions. Tofindpeak agingcondition,

received sampleswereheat treated at 180°C during different times.

Thesampleswerethencutalongthreeperpendiculardirectionsrela

tivetotherollingdirectionandmeasurementsofmicro hardness(Vick ers)werecarriedoutinthecorrespondingplanes(RP:rollingplane;NP: normalplane;TP:transverseplane).

2.2. Characterizationtechniques

Thealloyswereanalysedbydifferent techniques,which required

adapted preparations.Forhardnessmeasurements aswell asfor the

observation of the microstructure by optical microscope (OM) and

scanningelectronmicroscope(SEM),eachspecimen(inthe3planes)

wasembeddedinanepoxyresinandmechanicallypolishedonwater

lubricatedabrasivepapers(siliconcarbide):P600thenP1200andeven

tually on polishing cloths with diamond paste (from 3μmdown to

1μm).

ForTEMobservations,thepreparationwasthefollowing:tobring

thesamplethicknessdownto25μm,amechanicalpolishingwithpaper

gradeupto2400SiC,wasperformed.Thespecimenswerethenelec

trochemicallythinnedusingaTenupol 5Struersapparatusoperatingat 60Vinasolutionofmethanolandnitricacid(3:1)at−15°C.Observa tionsofthenanostructurewerecarriedoutonaJEOL2010operatingat

200kV.Brightfieldimagesweretakenwithanorientationslightlyoff

the[100]Alzoneaxis.ChemicalelementswereidentifiedwithaCM20

FEGTEM/STEMmicroscope,operatingat200kVandequippedwithan

energydispersiveX rayspectroscopy(QuantaxEDSsystemwithsilicon

driftdetectorfromBruker).ForEDSmapping,anareaof235×88pix

elswas scannedwithaprobesizeofabout5nmandahighstatistic

(20000cps).

HAADFscanningTEMmicrographsofas receivedandheat treated

sampleswereacquiredusing aJEOLcold FEGJEM ARM200Finstru

mentoperatedat200kV(energyresolution,0.3eV)andequippedwith

aprobeCscorrectorwithaspatialresolutionof0.078nm.Toidentify thephasesandchemistry,energyelectronlossspectroscopy(EELS)spec

trawereacquiredusingaGIFQuantumERimagingfilter,between850

and1850eVinorder toincludetheCu L2,3 (931 951eV),theMg K

(1305eV),theSi K(1839eV)andtheAl K(1560eV)edges.EELSwas

performed onlinescansacrossprecipitatesaswellason somefixed

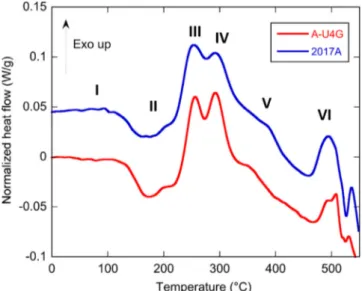

Fig. 1. DSCcurvesofA-U4Gand2017A,as-receivedstate.Theheatingrateis 20°C/min.2017Acurveisshiftedupwardforabettervisualisation.

DSCexperiments were alsocarried out.For this,sampleswith a

thicknessof1mmandaweightofabout20mgwereprepared.They

weresubjectedtorampheatingbetween−10°Cand550°Cat20°C/min inaMettler ToledoDSC3+.Resultswerecorrectedforbaselineandnor malizedforthesampleweight.

SAXSmeasurementswereperformedonanXeussequipmentpro

posedbyXenocs.TheX raysourceisequippedwithaCu anodeand

theSAXSsetupisequippedwithanti scatteringslitsand6MPilatusde

tector.Thebeamsizeis1mm2.ForSAXSexperiments,sampleswere

thinneddownto100μm.Inordertoinvestigatethelargeq rangeavail able,3sample to detectordistanceswereconsidered(40cm,1.2mand 2.5m).Inaddition,afixeddetectorcollectedtheintensityscatteredat wideangles,andallowedtoobtainthefirstdiffractionpeaksofthema

terial.Transmissionandbackgroundcorrectionsweremadeusingstan

dardprotocols.Thequantitativeanalysiswascarriedoutaccordingto theapproachdescribedinapreviousarticle[19].

3. Results

3.1. Asreceivedstate

DSCresultsforA U4Gand2017Ainas receivedstatearepresented

inFig.1.Sixdifferentregionscanbeidentified.Peaksaredirectlyre latedtoprecipitatesnucleationandgrowthinthealloy.Thefirstregion (I),fromroomtemperatureupto150°Cisflat.Itisgenerallyassumed

thatinthistemperaturerange,Guinier Prestonzonesshouldappear.

Here,intheas receivedalloys,GPZaresupposedlyalreadyformed.A

secondregion(II)containsanendothermicpeakbetween150°Cand

180°Candasmallexothermicpeakaround200°C,ascribedtothedis solutionofGPZandtheformationof𝜃’’phase,respectively.Thethird andfourthregions(IIIandIV)exhibittwolargeexothermicpeaks:one

between 220°C and280°C (III)and onebetween 280°C and320°C

(IV).InliteratureonAl Cu Mg Sialloys,thesepeakswereattributed todifferentphases.ItwasfirstobservedbySaulnierandSyre[7]that

anexothermic peakat290°Ccoincidedwith thepresenceof the𝜃’

Al2Cuphasewhereasthepeakat350°Cwasmarkedbytheapparition

ofaneedleshapeprecipitation,supposedlyMg2Si.Morerecentworks [20 22]reportapeakaround250°Casthegrowthofthequaternary(Q’ or𝜆’) AlCuMgSiphaseandapeakaround280°Castheapparitionofthe 𝜃’ Al2Cuphase.Thefifthregion(V)isasmallexothermicpeakbetween 350°Cand400°C,associatedbysomeauthorstotheincoherent𝜃 Al2Cu phaseprecipitation[22].However,insteadofaprecipitationpeak,this

shouldercouldcorrespondtothestartofthedissolutionofprecipitates presentinthealloy,whichoccursherebetween450°Cand520°C(re gion VI)andthenproceedstofullsolidsolutionatthesolutionizing temperature.

ThemainobservationfromFig.1isthesimilarityinbetween the

A U4Gand2017Abehaviour.Inthemeasurements,theobservedpeaks

areclosetowhatisreportedfortheDuraluminin1952bySaulnierand Syre[7]andforthe2017AalloybyHärteletal.[14].Similarprecip

itationshouldthusbeexpected.PeakVishoweverslightlyshiftedto

highertemperatures(around400°C)for2017AcomparedwithA U4G

(around350°C).Thiscouldbethesignofanearlierstartforprecipitate dissolutionintheA U4Galloy.

Representativebright fieldTEMimagesinconventionalmodeforthe

as receivedsamplesorientedin[001]AlzoneaxisareshowninFig.2(a)

and(b).Intheas receivedsamples,onlydispersoids(AlMnSi)canbe

observedinbrightfieldmode:theyarelargerinsize(125nm±51nmin

average)in2017AthanintheA U4G(57nm±25nminaverage),both

presentingalargestandarddeviation.Diffractionpatterns(notshownin Fig.2)donotpresentanyvisiblespotthatcanbeattributedtocoherent precipitation.

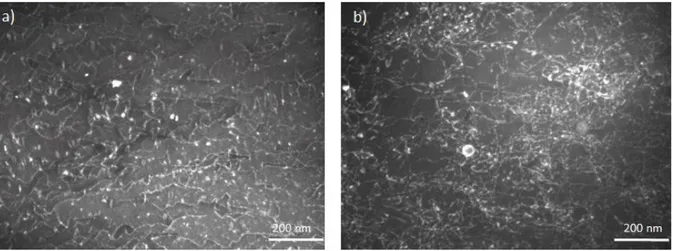

AtomicresolvedSTEM HAADFexperimentswereperformedonthe

as receivedalloys,seeFig.3fortheimagesofA U4Gin[001]Alzone axis.Precipitationinthematrixwashardlydetectable.InHAADF mode, seeFig.3(b)and(d),theintensityisproportionaltoZ1.5–1.8,Zbeing

theatomicnumber[23].Brightdots/areascorrespondtotheheavier

elementandarethusrepresentativeofcopperatoms.TheEDSanalysis

confirmedthepresenceofcopperinhigherconcentrationinthesezones

comparedwiththematrix.Thus,Cu richzones,notverywelldefined

andhavingasizeofafewnanometres,weredetectedhereandtherein thematrix(seeFig.3(a)and(b)).Someclusterswerealsolocatedatthe matrix/dispersoidinterfaces(seeFig.3(c)and(d)).

SAXSmeasurements,performedonA U4Gand2017Aalloysinthe

as receivedstate,areshowninFig.4.TheSAXSdataobservedonboth

specimensshowaverysimilarbehaviourthatcanbedescribedbytwo

maincontributions.Inthelowqrange(0.01<q<0.1Å−1),aclear q−4contributionisobserved,whichcanbeattributedtolargeprecip itatessuchasthedispersoids.Intherange0.1<q<1Å−1,aplateau isobserved,followedbyanintensitydecreaseasqincreases.Wehave modelledthiscontributionbyadistributionofsphericalprecipitatesof uniformelectrondensity(i.e.,composition)withapolydispersitygiven bytheSchultzdistribution(see[24]forthedetailedexpressionofthis

contribution). Aleast square fitof thedatagives meandiametersof

about8Å,whichisconsistentwiththeexistenceofGPZorsmallclus tersinthealloymatrix.Theexactnatureoftheclustersisatthisstage

notdetermined.

3.2. Artificialagingtreatmentat180°Candidentificationofprecipitates Fig.5presentstheVickershardnessasafunctionofagingtimeforthe

twostudiedalloys:A U4Gand2017A.OnlyRPhardnesswasplottedas

measurementsonotherplanesgavesimilarresults.TheA U4Gisharder

thanthemodernalloy2017Abyabout10 HVthroughouttheaging

curveexceptforlongover agingtimeswheretheA U4Ghardnessdrops

faster.Inbothcases,theconditionscorrespondingtothemaximumpeak hardnesswerereachedafter8hat180°C.Thesepeakageingconditions wereselectedfortheinvestigationofthemicrostructure.

Fig.6showstheSAXSmeasurementsafteragingfor8hat180°C.

Onceagain,bothalloysbehavesimilarly.Fromthesemeasurements,it

isseenthatthesignal,intherangeof0.1<q<1Å−1,disappearedin favourofasignalintherange0.04<q<0.2Å−1,whichtranslatesinto thedisappearanceofsmallclustersandtheformationoflargerparticles. Thiscontributiontothescatteredintensitycanbereproducedbyusing

aflatcylindermodel.Dimensionsofprecipitatesare:4nmthick and

70nmlongforA U4Gand3nmthickand40nmlongfor2017A.

Themicrostructurescorresponding tothispeak agedcondition in

Fig. 2. TEM bright field images of as-received al-loys(a)2017A;(b)A-U4Gshowingmainly AlMnSi-dispersoidsinthematrix.

Fig. 3. STEMimagesofas-receivedA-U4Galloyin[001]Al

zoneaxis;(a)and(c)Annularbrightfield;(b)and(d)high angleannulardarkfield.Images(a)and(b)ononesideand(c) and(d)ontheothersidecorrespondtotheexactsamearea. Aclusterisindicatedwiththewhitearrowattheinterface dispersoid/matrix.

Fig. 7: bright field images and corresponding selected area electron

diffractionpatternsarepresented.Fig.8showstheSTEM EDSmapping

fortheA U4Galloy.

After8hat180°C,averydenseprecipitationisobservedinsidethe matrix(Fig.7)andatgrainboundaries(Fig.8).Inbothalloys(Fig.7(a)

and(c)), precipitateslyingin {100}Al planes areobserved:some as

plateletsandothersasrods,withprecipitationondislocations.Asthe

observedprecipitationissimilarinbothA U4Gand2017Aalloys,ad

vancedanalysesresultsarethenonlyshownforA U4Galloy.

InFig.8,precipitatesatgrainboundaries wereidentifiedbyEDS:

theyare(Mg,Si) precipitatesandcopper precipitates.OntheseEDS

maps,dispersoidsofAlMnSinaturearepresent.Aprecipitationinthe matrixisalsovisiblebuthardlyidentifiable.

Asamatter of fact,different precipitatespopulationsco exist in

sidethegrainsandtheiridentificationwasmadepossiblebycombin

ingdifferentelectronmicroscopytechniques.FromSADPtakenalong

[001]Alzoneaxis,showninFig.7(b)and(d),thepresenceof𝜃’ Al2Cu phasewasevidencedthankstothestrikesalong<001>Aldirectionsand faintspots(110)𝜃’at 12 of(220)Al[25].Theycorrespondtothreevari

antsofplate shapesemi coherentprecipitatesgrowinginthe{100}Al planes:oneface onandtwoedge on.The𝜃’ Al2Cuprecipitatenature

wasconfirmedthankstoSTEM HAADFasshowninFig.9(b).Similarly

toHAADFimagestakenonas receivedstates,brightdotscorrespondto

copper richatomiccolumns.Seenedge on,thecrystalstructureofthis

plateletisbody centredtetragonalaspreviouslyshownbyBourgeois

etal.[26]andShenetal.[27].Thepresenceofpre𝜃’−1(Al2Cu)pre cipitatescoherentonthe{100}Alplanes,wasalsorevealedwithSTEM HAADF,asshowninFig.9(c)):thesetypesofprecipitateswererecently identifiedbyLiuetal.[28].Theyconsistofthreeparallelcopperplanes,

eachseparatedbytwoaluminiumplanes.OnSADP,diffractionpatterns

ofthepre𝜃’−1coincidewithdiffractionpatternsof𝜃’ Al2Cu.Bothtypes arethus,difficulttodifferentiate.Atpeak agedconditions,thisphase, whichcorrespondstothefirststageof𝜃’ Al2Cuformation,isnotpre dominant:mostofthepopulationhasevolvedtothe𝜃’ Al2Cuphase.

OtherprecipitatesintheshapeofrodswereobservedintheA U4G

alloyafter8hat180°C,asshowninthebrightfieldimagesofFig.7(a) andintheHAADFimageofFig.9(a).Therods,seenend on,areoriented along<001>Aldirections.Noclearidentificationbeingpossiblewith

Fig. 4. SAXScurvesfor2017AandA-U4Gintheas-receivedstate.Themodel wassuperimposedtotheexperimentalcurves.

Fig. 5. Hardnessmeasurementonrollingplaneforold(A-U4G)andmodern (2017A)alloysheattreatedat180°C.

SADP,thisphasewasidentifiedthankstoSTEM EELS.Rodsappeared

tobetheQ AlCuMgSiphaseoroneofitsprecursors(Q’).Thecomposi tionfoundforthisphasebySTEM EELSwasinaverage73±10Al 10±4 Cu 12±6Mg 5±5Siat%.Aluminiumcontentforthisphaseisoveresti

matedaspartofthematrixisalsoprobed.Moreover,asobservedon

theSTEM HAADFimage(Fig.10(b))andconfirmedbySTEM EELS,the

precipitateshaveacore shellstructurewithacorerichinsiliconand

magnesiumandacopper richshell.Thiscore shellstructureobserved

herecoincideswithresultsreportedbyMatsudaetal.in2007[29]and Biswasetal.in2014[21].

InFig.9(b),oneofthequaternaryprecipitateisseenedge on,co precipitatedwitha𝜃’ Al2Cuprecipitate.Inthisorientation,bySTEM

HAADF,theQ’(Q) AlCuMgsiphase canbe recognizedbytheCu rich

columns (highintensity due tohighatomic number) surrounded by

lowerintensitycolumns(Si,AlandMg)similartothecross sectionstruc tureviewedalong<100>AlzoneaxisshowninDingetal.[30].

Eventually,athirdphase is present,detectedthankstothespots

at1/3and2/3ofthe[022]AlorientationinSADP(Fig.7(b)and(d)). STEM HAADFintwoorientations[110]Aland[112]Al(seeFig.11)was necessarytoidentifythisphaseastheΩAl2Cu.Thisphaseisknownto

haveanorthorhombicstructure,spacegroupFmmmwitha=0.496nm;

b=0.859nmandc=0.848nmandtoprecipitateinthe{111}Alplanes

[31].MeasurementsofCu CudistancesonSTEM HAADFimagesalong

Fig. 6. SAXScurvesfor2017AandA-U4Gatpeak-agingstate:after8hat 180°C.Themodelwassuperimposedtotheexperimentalcurves.

[001]Ω,[100]Ωand[010]Ωcorrelatewiththeexpectedlatticeparame ters.Theseprecipitatesgrowpreferentiallyondispersoids(AlMnSi).

Alltheobservationsprovidedaclearevidenceonthephasespresent

uponartificialaging: atgrain boundaries,copperandMg Si precipi

tateswereformedwhileinthematrix,𝜃’ Al2Cu,Q’(Q) AlCuMgSiand

ΩAl2Cuwereclearlyidentified.

4. Discussion 4.1. Hardnessevolution

ThehigherhardnessofA U4Gcomparedto2017Aintheas received

state(about10HVdifference)couldbeexplainedbydifferentfactors.

Whenconsidering precipitationat nanoscale,SAXS experiments pro

videdevidenceofthepresenceofclustersinas receivedstatewhether

inA U4Gorin2017A.DSCconfirmedthepresenceofthispopulation

intheas receivedstate,asadissolutioneventoccurredaround180°C. These clusters,withadiameterin therangeof8Å,aretheprincipal

causeofhardnessinDuralumin.However,itwasshownthatthenano

precipitationisidenticalinbothalloys,whichrulesoutthisfactoras theprimarycauseinthehardnessdifference.Secondly,dispersoidscon tributepartlytohardnessbycontrollingthegrain size.Itwasshown

thattheyaresmallerandmorenumerousinA U4Gthanin2017A.This

couldbeanexplanationforthedifferenceinhardness.However,since

thegrainsizeiscloseinbothalloys(seeFig.S2inSupplementaryin

formation), thecontributionofdispersoidsshould notbe significant.

Thethirdexplanationcomesfromtheplates’conditions.Theoldplate

wasbentwhencollected.Thisactiongeneratedstrainhardening,with

ahigherdensityofdislocations(seeFig.S3inSupplementaryinforma tion).Thepresenceofthesedislocationsisbelievedtobethemainfactor inthehigherhardnessoftheA U4Galloyintheas receivedstate.

Forover ageingconditions,thehardnessoftheA U4Galloydrops

fasteruntilreachingthehardnessofthemodernalloy.Itcanbehypoth esized thatafterartificialageing,thehistoricalalloylosespartofits additionaldislocationdensitythroughfasterrecovery.Thefinalpartof thehardnesscurvecouldalsobeexplainedbethefactthatalloysage fasterwhenadditionaldislocationsareintroduced,becausethedisloca

tionnetworktransportssoluteatomsthroughpipediffusion[32]and

thusacceleratesgrowthandcoarseningof𝜃’precipitates,knowntonu cleateondislocations[33].Thisgrowthandcoarseningwillinducea decreaseinhardness.

Fig. 7. TEM bright-field images andcorresponding SADPin[001]Al zoneaxisaftertreatmentat180°C–

8hfor2017A:(a)and(b) andforA-U4G:(c) and (d).(110)𝜃’spotsandstrikesalong[001]Aldirections

forthe𝜃’phaseareindicatedwitharrows.Spotsat 1/3and2/3of(022)AlcorrespondingtoΩphaseare

surrounded.

Fig. 8. STEM-EDSmappingaftertreatmentat180°C–8hinA-U4Gshowingprecipitationatgrainboundaries:MgSiandCuaswellasinthematrix.

4.2. Nano structureintheas receivedstate

About thenano clusters presentin theas received states, several

pointscanbemade.Thecopper richclustersobservedbyatomically

resolvedTEMimagesinHAADFmodewerenotsufficientlynumerous

tocorrelatewiththemeasuredSAXSsignal.Electronmicroscopyisthus

notfullysucceedinginobserving andanalysingnanoclusters.Onan

otherhand,atthisstage,ourexperimentscannotdifferentiatebetween GPZ(flatclustersgrowingintheplanesparalleltothe<100>Alaxes)

anddisorderedclusters.GPZareusuallyfoundinthemodelAl 4%Cu

alloyagedatroom temperature,asitwasfirstlyprovedbyGuinierand

PrestonbyXRDin1938.Lambot[11],whostudiedbothAl 4%Cuand

DuraluminbyX rayscattering,provedthatthescatteringsignalwasper fectlyidenticalinbothalloys,concludingthusthatGPzonesarepresent inDuraluminagedatroomtemperature.Itistobenotedthattheirstud ieswerecarriedoutonsinglecrystals.Inthepresentcase,SAXSsignal

isanaverageofthemeasurementsmadeonseveralgrains:theinfor

Fig. 9. (a)STEMBright-fieldimageofA-U4G alloy in [001]Al zone axisshowing𝜃’-Al2Cu

(blackarrows)andQ-AlCuMgSirods(white ar-rows),(b)HAADFimagesof𝜃’-Al2Cuplatelets

seenedge-onwithco-precipitation of Q’(Q)-AlCuMgSiand(c)pre-𝜃’−1Al2Cudisksseen

edge-on.

Fig. 10. (a)STEMBright-fieldimageofA-U4G alloyin[001]Alzoneaxis(b)STEM-HAADF

im-ageofQ-AlCuMgSirodsseentop-on.

Furtherinvestigationisrequiredtoconfirmthestructuralnatureofthese clusters.

4.3. Uponartificialaging identificationofprecipitation

Uponartificialaging(at180°C for8h),itwasdemonstratedthat

threepopulationsofprecipitatescoexistinthematrix:𝜃’ Al2Cu,Q’(Q)

AlCuMgSiandΩAl2Cu.LinkingbacktheTEMobservationswithDSC

resultsandthankstoresultsreportedintheliteratureforAl Cu Mg

Sialloys,itcanbe hypothesizedthatregionIII(between220°Cand

280°C)isrelatedtothegrowthofQ’(Q) AlCuMgSiphaseandregionIV (between280°Cand320°C)tothegrowthofthe𝜃’ Al2Cuphase.Asfor theΩAl2Cuphase,havingthesamestoichiometryasthe𝜃’ Al2Cuphase andifitsgrowthiscontrolledbydiffusion,therecouldbesuperimposi tionofpeaksintheDSCcurve.

The𝜃’ Al2Cuphase,foundinlargequantity,isnotsurprising.Itcon

stitutesthemainhardeningphasein the2xxxfamilyalloysandwas

reportedinallstudiesonDuraluminor2017Aalloy[7,11,13].

The presence of the Q AlCuMgSi phase or one of his precursors

(Q’)wasevidenced,inbotholdandmodernalloys.Althoughnotsys

tematicallyrevealedinprevious studiesof Duralumin,thesefindings

confirmtheequilibriumdiagramsdatareportedbyMondolfoin1943

[12]whichpredictsthatwithMg:Siratio<1.73,hardeningconstituents shouldleadtotheAl2CuandAl4CuMg5Si4equilibriumphases.Thesil

icon contentisindeedhigherthanthatrequiredfortheformationof

Mg2Si(Mg:Si=1.08):theexcessof silicon willcombinewithcopper

andmagnesiumtoformthequaternaryphase.Theglobalstoichiomet

riccompositionfortheQphasehasbeen,however,acontroversialmat ter.Mondolfopredictstwopossiblequaternaryphases:Al4CuMg5Si4or Al4CuMg4Si4.Inmorerecentliterature,mainlyforalloysofthe6xxx family(Al Mg Siwithadditionsofcopper)[15],butalsofor2014al loys[20],thestoichiometryreportedinbulkalloyswereAl5Cu2Mg8Si6, Al4Cu2Mg8Si7, Al3Cu2Mg9Si7 etc.However, the nanometre scale of theseprecipitatesmakesthequantitativeanalyseschallenging.Biswas

et al.[21]usedatomprobe analysisandprovedthat theQprecipi

tatesevolved,uponaging,fromacopper richcomposition(44Al 22Cu

16Mg 16,5Siat%)toamagnesiumandsilicon richcomposition(28Al

9Cu 37Mg 26Siat%.)after4hat260°C.Inaveryrecentpaper,Ding

etal.[30]wereabletoprovide,bycombiningatomprobetomography

andatomiccolumnintensityquantificationinSTEM HAADFimages,the

reasonwhyvaryingcompositionwerereportedinpastwork:itwasin

deedprovedtobeduetotheoccupancychangeoftheatomiccolumns.

ThestoichiometryoftheQphaseanditsprecursor,theQ’phasewere

Fig. 11. STEMBright-fieldimagesandHAADF imagesofA-U4Galloyin(a)and(b):[110]Al

zoneaxis;(c)and(d):[1̄12]Alzoneaxis

show-ingΩ-Al2Cuplatelets(whitearrows)growing

ondispersoids.

matrixeffectscannotbeexcludedwithEELS,theelementalcomposi

tionfoundherebyEELSinDuralumin(73±10Al 10±4Cu 12±6Mg

5±5Siat%)isinallcasesmuchleanerinmagnesiumandsiliconthan whatisusuallyreported.Thisresultsshouldbecorroboratedwithother

techniquestoconfirmthetendency.Theheterogeneousnucleationof

𝜃’ Al2CuphaseandtheQ’(Q) AlCuMgSiphase,observed inFig.9(b), wasalsoreportedbyotherauthors[21,34].Itcouldbecausedbythe strainfieldofQ phaseprecipitatesonwhichthe𝜃’ Al2Cunucleate.

Anotherphase,ΩAl2Cu,ishereobserved.TheΩphaseisusually

foundinhighdensityinAl Cu Mg Agquaternaryalloyswithahigh

Cu:Mgratio[25,31].Itpresents oneofthehigheststrengtheningpo

tentialin aluminiumalloys. Inparticular, Al Cu Mg Agalloys have

beendevelopedforelevated temperatureaerospaceindustryapplica

tions[35]duetotheenhancedthermalstabilityoftheΩphase.Some

authorsprovedthatsilverwasnotrequiredfortheformationofΩpre cipitatesalthoughitspresenceincreasestheirdensity[36].TheΩphase

wasindeedobservedin2024and2124alloysbyWangetal.[37]and

wasactuallyfoundin2017Aalloyaswell[14].In2024and2014al

loys,theΩphasewasfoundtoformpreferentiallyonmanganese based

dispersoids.Thisheterogeneousgrowthisclearlyevidencedinourre

portedresults.TounderstandwhysuchaphaseappearedinDuralumin,

itisinterestingtodiscussitsnucleationprocess.InAl Cu Mg Agalloys,

theprocesshasbeenwidelyinvestigated:uponaging,magnesiumand

silverco cluster,thencopperatomsaggregatetothe{111}Al planes. Duringcoarsening,whencopperconcentrationbecomesclosetoAl2Cu, silverandmagnesiumstarttomigratefromtheinteriortotheinterface oftheprecipitate.Theinterfacialstructurewasprovedtobeadouble

layercomposedofAginhexagonalstructureandMgandCubelowthe

centreofthehexagon[38].Magnesiumisconsiderednecessaryforthe

nucleationoftheΩphase.Asforsilver,itsroleistoacceleratetheaggre gationofmagnesiumatomsbyretainingvacanciesandtoassistinthis waythemagnesiumdiffusion[39].Siliconisalsoanelementthatinflu encesthepresenceofΩphase.FromPolmearetal.[35],silicon(and iron)shouldremainlow(lessthan0.10wt%)tominimisetheformation

oflowmeltingpointeutecticsatgrainboundariesandtomaximiseΩ

precipitation.Infact,highlevelsofsiliconinterferewithprecipitationof Ωbecausesiliconinteractswithmagnesiumandthusreducestheforma tionMg Agco clusters,whichgenerallyfacilitatenucleationofΩ.This wasalsoobservedintheworkbyÜnluetal.[40].However,theauthors showedthatitisrathertheMg:Siratiothathadtobeconsidered:some

Ωprecipitationwasfoundinalloyswithsiliconlevelsashighas0.5

and0.65wt%withcorrespondingMg:Siratiosof3.0and2.23.Inthe

presentalloys,theobservationthatΩformsprincipallyondispersoids

intheDuraluminand2017Acanbeexplainedbythepresenceofcop

perclustersatthematrix/dispersoidinterfaceintheas receivedstate.

Moreover,itdoesnotformasaphasedispersedinthematrixbecause

oftheabsenceortheverylowdensityofmagnesiumclustersinthema trix.Themagnesiumclustersareinthiscaseimpededbysilicon,which ratherfacilitatestheformationoftheQ AlCuMgSiphase.

Conclusion

AnoldDuralumin(A U4G)anditsmodernequivalent(2017A)were

studiedwithdifferentcharacterizationtechniquestoclarifytheprecip itationprocesses.Themainfindingsare:

TheprecipitationsequenceinDuraluminandmodern2017Aupon

artificialaging issimilar. Itconsistsin 𝜃’ Al2Cu,Q’(Q) AlCuMgSi andΩAl2Cuinthematrix.Atgrainboundaries,variousprecipitates

arefound:copper basedand(Mg,Si)precipitateswithunknownsto ichiometry.

TheQ AlCuMgSiphaseoroneofitsprecursors(Q’)isobservedin

thematrixbutthe𝛽 Mg2Siphase,previouslyreportedinDuralumin, isnotpresent.Thisphasefacilitatesthenucleationofthe𝜃’ Al2Cu phasethroughstrainfield.

TheΩphaseisobservedanditgrowspreferentiallyondispersoids.

Itpresumablynucleatesdue tothepresenceof copperclustersat

thematrix/dispersoidinterface.Thisphaseisaminorphasedueto theabsenceorrareoccurrenceofmagnesiumclustersinthematrix.

ThenucleationmechanismsfortheΩphaseondispersoidsinthese

Al Cu Mg Sialloysremainstobeevidenced.

Intheas receivedstate(naturallyaged),thepresenceofclustersis evidenced,withcopperasthemainelementbutthestructuralnature oftheseclustersisyettobedetermined.

Despitesomedifferencesinthemicrostructure,suchasthedisper

soids’sizeanddensity,Duraluminexhibitsasimilarnanoprecipita tionasitsmodernequivalentinthenaturallyagedconditions,andit behavesalsosimilarlyuponartificialaging.Theseobservationslead

totheconclusionthattheconditionsexperiencedbythecollected

plate(10yearsofserviceplus50yearsatambienttemperature)had

nosignificantimpactonthenanostructure.

Overall,theseresultsconstituteabaseforassessingtheverylong termagingofaluminiumalloysinaeronautics.

DeclarationofCompetingInterest

None

Acknowledgments

TheauthorswhichtothankPierreRoblinfromFRFERMAT,Uni

versité deToulouse,CNRS,Toulouse,France,forSAXSmeasurements,

TeresaHungria Hernandez,fromRaimondCastaingMicroanalysisCen

tre,ToulouseforSTEM(HAADF,EDSandEELS)experimentsandthe

volunteersofLesAilesAnciennesToulouseforprovidinguswiththeplate collectedontheBreguetSahara765aircraft.

ThisstudyhasbeenpartiallysupportedthroughthegrantNanoXn°

ANR 17 EURE 0009intheframeworkofthe“ProgrammedesInvestisse

mentsd’Avenir”.

Supplementarymaterial

Supplementarymaterialassociatedwiththisarticlecanbefound,in theonlineversion,atdoi:10.1016/j.mtla.2019.100429.

References

[1] O. Hardouin Duparc , Alfred Wilm et les débuts de Duralumin, Cah. d’hist. de l’alum. Inst. Pour l’Hist. de l’Alum. Paris (2005) 63–77 .

[2] M. Victor , Comment a été construit le premier avion en Duralumin, Rev. Alum. (1951) 339–340 .

[3] P.D. Merica , R.G. Waltenberg , H. Scott , Heat treatment of Duralumin, Sci. Pap. Bur. Stand. 15 (1919) 271–316 Scientific Paper 347 (S347) .

[4] E. Orowan , Zur kristallplastizität. III, Z. Phys. 89 (9) (1934) 634–659 .

[5] A. Guinier , Structure of age-hardened aluminium-copper alloys, Nature 142 (1938) 569 .

[6] G.D. Preston , LXXIV. The diffraction of X-rays by an age-hardening alloy of alu- minium and copper. The structure of an intermediate phase. The London, Edinburgh, and Dublin, Philos. Mag. J. Sci. 26 (178) (1938) 855–871 .

[7] A. Saulnier , R. Syre , Maturation, revenu et réversion des alliages Al–Cu 4%, Al–Cu–Mg et Al–Cu–Mg–Si de haute pureté, Rev. Met. Paris 49 (1) (1952) 1–21 .

[8] Duralumin, notice générale, Société du Duralumin, Paris, 1938.

[9]H. Lebouteux , La symbolisation de l’aluminium et de ses alliages en France et dans quelques pays étrangers, Encycl. Trav. Alum. Extrait Rev. Alum. Paris (1956) 1–3 .

[10] The-Aluminum-Association, International alloy designations and chemical com- position limits for wrought aluminum and wrought aluminum alloys, 2015

http://www.aluminum.org/resources/industry-standards/aluminum-alloys-101 .

[11]H. Lambot , Etude cristallographique de la précipitation structurale dans les duralu- mins, Rev. Met. Paris 47 (10) (1950) 709–726 .

[12]L.F. Mondolfo , Metallography of Aluminum Alloys, John Wiley & Sons, Inc., New York, USA, 1943 .

[13]S. Yano , S. Koda , Electron microscope observation of duralumin, J. Jpn. Inst. Light Metals 18 (7) (1968) 371–376 .

[14] M. Härtel , S. Wagner , P. Frint , M.F.-X. Wagner , Effects of particle reinforcement and ecap on the precipitation kinetics of an Al–Cu alloy, IOP Conf. Ser.: Mater. Sci. Eng. 63 (1) (2014) 012080 .

[15]D.G. Eskin , Decomposition of supersaturated solid solutions in Al–Cu–Mg–Si alloys, J. Mater. Sci. 38 (2) (2003) 279–290 .

[16]J.-F. Nie , 20 – Physical metallurgy of light alloys, in: D.E. Laughlin, K. Hono (Eds.), Physical Metallurgy, 5th Edition, Elsevier, Oxford, 2014, pp. 2009–2156 .

[17]R. Develay , Propriétés de l’aluminium et des alliages d’aluminium corroyés, Tech. de l’Ing. M440 – V2 (1992) .

[18] Breguet, Standard forms, Vélizy factory, Archives Les Ailes Anciennes Toulouse, 1946-1954.

[19]A. Deschamps , F. de Geuser , Quantitative characterization of precipitate microstruc- tures in metallic alloys using small-angle scattering, Metall. Mater. Trans. A 44 (1) (2013) 77–86 .

[20]I. Dutta , C.P. Harper , G. Dutta , Role of Al 2O 3particulate reinforcements on precipita- tion in 2014 Al-matrix composites, Metall. Mater. Trans. A 25 (8) (1994) 1591–1602 .

[21]A. Biswas , D.J. Siegel , D.N. Seidman , Compositional evolution of Q-phase precipi- tates in an aluminum alloy, Acta Mater. 75 (Suppl. C) (2014) S322–S336 .

[22]P. Bassani , E. Gariboldi , D. Ripamonti , Thermal analysis of Al–Cu–Mg–Si alloy with Ag/Zr additions, J. Therm. Anal. Calorim. 91 (1) (2008) 29–35 .

[23]S.J. Pennycook , Z-contrast stem for materials science, Ultramicroscopy 30 (1) (1989) 58–69 .

[24]M. Kotlarchyk , S.H. Chen , Analysis of small angle neutron scattering spectra from polydisperse interacting colloids, J. Chem. Phys. 79 (5) (1983) 2461–2469 .

[25]S.C. Wang , M.J. Starink , Precipitates and intermetallic phases in precipitation hard- ening Al–Cu–Mg–(Li) based alloys, Int. Mater. Rev. 50 (4) (2005) 193–215 .

[26] L. Bourgeois , C. Dwyer , M. Weyland , J.-F. Nie , B.C. Muddle , Structure and energetics of the coherent interface between the 𝜃′ precipitate phase and aluminium in Al–Cu, Acta Mater. 59 (18) (2011) 7043–7050 .

[27]Z. Shen , Q. Ding , C. Liu , J. Wang , H. Tian , J. Li , Z. Zhang , Atomic-scale mechanism of the 𝜃″ →𝜃′ phase transformation in Al–Cu alloys, J. Mater. Sci. Technol. 33 (10) (2017) 1159–1164 .

[28]C. Liu , Z. Ma , P. Ma , L. Zhan , M. Huang , Multiple precipitation reactions and for- mation of 𝜃’-phase in a pre-deformed Al–Cu alloy, Mater. Sci. Eng.: A 733 (2018) 28–38 .

[29]K. Matsuda , D. Teguri , T. Sato , Y. Uetani , S. Ikeno , Cu segregation around metastable phase in Al–Mg–Si alloy with Cu, Mater. Trans. 48 (5) (2007) 967–974 .

[30]L. Ding , A. Orekhov , Y. Weng , Z. Jia , H. Idrissi , D. Schryvers , S. Muraishi , L. Hao , Q. Liu , Study of the Q ′ (Q)-phase precipitation in Al–Mg–Si–Cu alloys by quantifica- tion of atomic-resolution transmission electron microscopy images and atom probe tomography, J. Mater. Sci. 54 (10) (2019) 7943–7952 .

[31]K.M. Knowles , W.M. Stobbs , The structure of {111} age-hardening precipitates in Al–Cu–Mg–Ag alloys, Acta Crystallogr. Sect. B 44 (3) (1988) 207–227 .

[32]M. Legros , G. Dehm , E. Arzt , T.J. Balk , Observation of giant diffusivity along dislo- cation cores, Science 319 (5870) (2008) 1646 .

[33] C. Liu , S.K. Malladi , Q. Xu , J. Chen , F.D. Tichelaar , X. Zhuge , H.W. Zandbergen , In-situ stem imaging of growth and phase change of individual CuAlX precipitates in Al alloy, Sci Rep 7 (1) (2017) 2184 .

[34]S. Wenner , C.D. Marioara , S.J. Andersen , M. Ervik , R. Holmestad , A hybrid alu- minium alloy and its zoo of interacting nano-precipitates, Mater. Charact. 106 (2015) 226–231 .

[35]I.J. Polmear , G. Pons , Y. Barbaux , H. Octor , C. Sanchez , A.J. Morton , W.E. Borbidge , S. Rogers , After concorde: evaluation of creep resistant Al–Cu–Mg–Ag alloys, Mater. Sci. Technol. 15 (8) (1999) 861–868 .

[36]A. Garg , Y.C. Chang , J.M. Howe , Precipitation of the Ω phase in an Al–4.0Cu–0.5Mg alloy, Scr. Metall. Mater. 24 (4) (1990) 677–680 .

[37]L.M. Wang , H.M. Flower , T.C. Lindley , Precipitation of the Ω Phase in 2024 and 2124 Aluminum Alloys, 1999 .

[38]S.J. Kang , J.-M. Zuo , H.N. Han , M. Kim , Ab initio study of growth mechanism of omega precipitates in Al–Cu–Mg–Ag alloy and similar systems, J. Alloys Compd. 737 (2018) 207–212 .

[39]G.B. Winkelman , K. Raviprasad , B.C. Muddle , Stimulation of the Ω phase in an Al–1.1 at% Cu–0.5 at% Mg alloy by a duplex ageing treatment involving initial nat- ural ageing, Philos. Mag. Lett. 85 (4) (2005) 193–201 .

[40]N. Ünlü, B.M. Gable , G.J. Shiflet , E.A. Starke , The effect of cold work on the pre- cipitation of Ω and 𝜃′ in a ternary Al–Cu–Mg alloy, Metall. Mater. Trans. A 34 (12) (2003) 2757–2769 .

![Fig. 7. TEM bright-field images and corresponding SADP in [001] Al zone axis after treatment at 180 °C–](https://thumb-eu.123doks.com/thumbv2/123doknet/2965823.82010/7.892.57.769.88.911/fig-tem-bright-field-images-corresponding-sadp-treatment.webp)

![Fig. 9. (a) STEM Bright-field image of A-U4G alloy in [001] Al zone axis showing](https://thumb-eu.123doks.com/thumbv2/123doknet/2965823.82010/8.892.57.602.81.731/fig-stem-bright-field-image-alloy-zone-showing.webp)

![Fig. 11. STEM Bright-field images and HAADF images of A-U4G alloy in (a) and (b): [110] Al](https://thumb-eu.123doks.com/thumbv2/123doknet/2965823.82010/9.892.58.600.84.623/fig-stem-bright-field-images-haadf-images-alloy.webp)